lock FIAT DUCATO 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO, Model: FIAT DUCATO 2014Pages: 367, PDF Size: 20.39 MB

Page 197 of 367

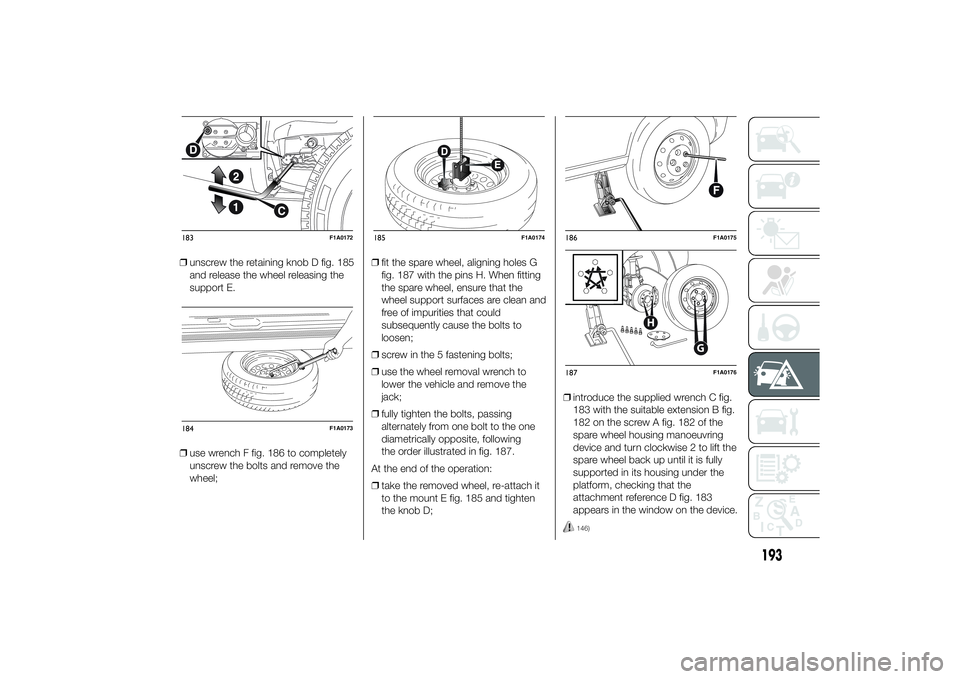

❒unscrew the retaining knob D fig. 185

and release the wheel releasing the

support E.

❒use wrench F fig. 186 to completely

unscrew the bolts and remove the

wheel;❒fit the spare wheel, aligning holes G

fig. 187 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

❒fully tighten the bolts, passing

alternately from one bolt to the one

diametrically opposite, following

the order illustrated in fig. 187.

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 185 and tighten

the knob D;❒introduce the supplied wrench C fig.

183 with the suitable extension B fig.

182 on the screw A fig. 182 of the

spare wheel housing manoeuvring

device and turn clockwise 2 to lift the

spare wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 183

appears in the window on the device.

146)

183

F1A0172

184

F1A0173

185

F1A0174

186

F1A0175

G

H

187

F1A0176

193

Page 198 of 367

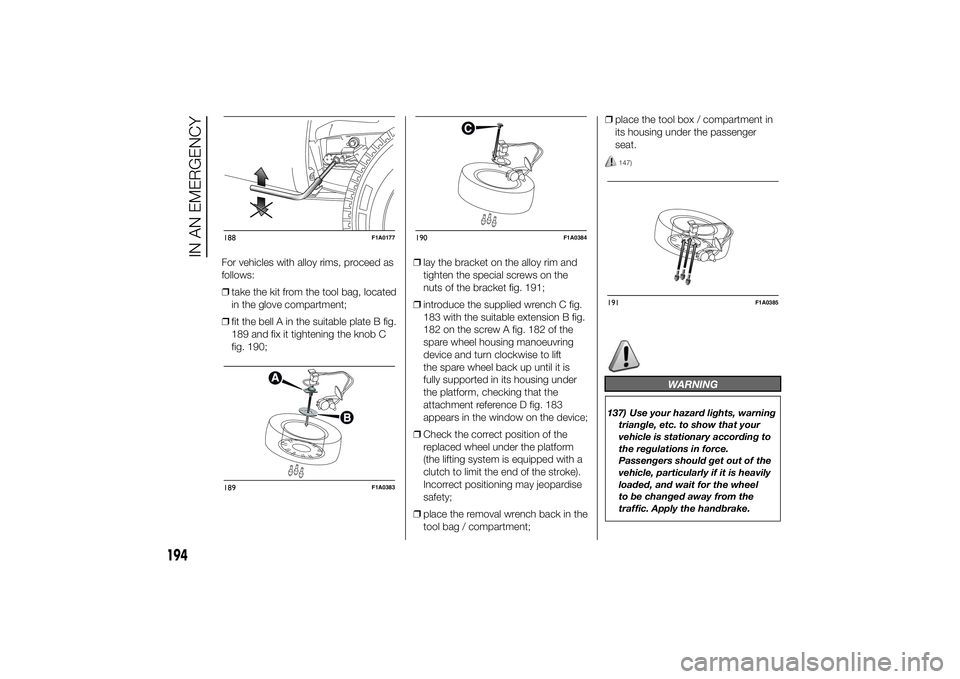

For vehicles with alloy rims, proceed as

follows:

❒take the kit from the tool bag, located

in the glove compartment;

❒fit the bell A in the suitable plate B fig.

189 and fix it tightening the knob C

fig. 190;❒lay the bracket on the alloy rim and

tighten the special screws on the

nuts of the bracket fig. 191;

❒introduce the supplied wrench C fig.

183 with the suitable extension B fig.

182 on the screw A fig. 182 of the

spare wheel housing manoeuvring

device and turn clockwise to lift

the spare wheel back up until it is

fully supported in its housing under

the platform, checking that the

attachment reference D fig. 183

appears in the window on the device;

❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal wrench back in the

tool bag / compartment;❒place the tool box / compartment in

its housing under the passenger

seat.

147)

WARNING

137) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake.

188

F1A0177

189

F1A0383

190

F1A0384

191

F1A0385

194

IN AN EMERGENCY

Page 199 of 367

138) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

139) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

140) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

141) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.142) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.

143) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

144) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

145) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.146) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (white notch inside the

window on the device), the key

must be extracted, taking care not

to turn it in the wrong direction

to facilitate the extraction of the

key itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained fig.

188.

147) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

195

Page 200 of 367

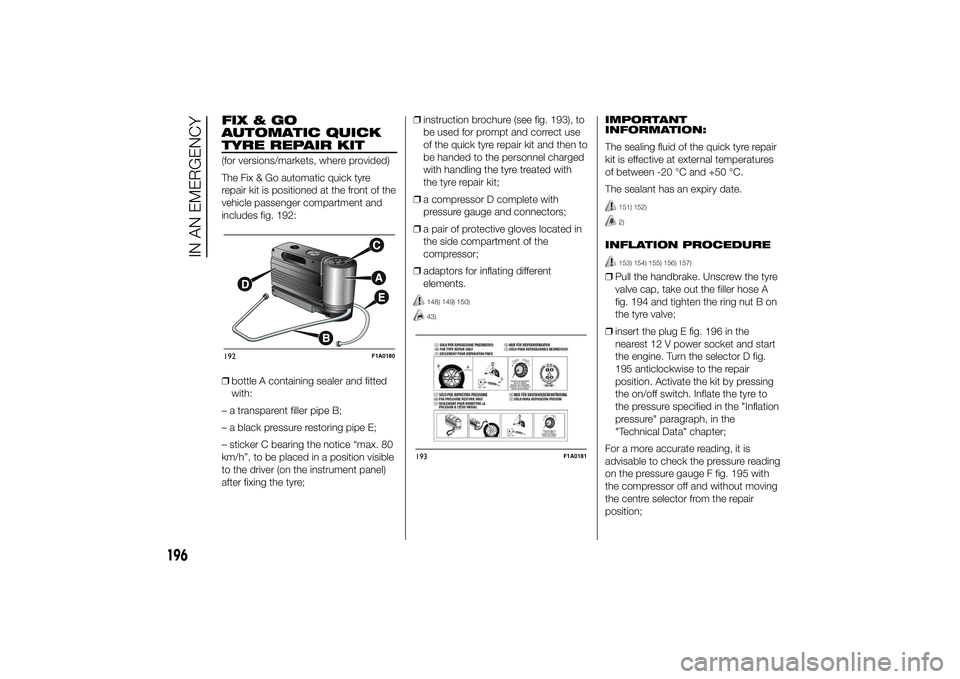

FIX&GO

AUTOMATIC QUICK

TYRE REPAIR KIT(for versions/markets, where provided)

The Fix & Go automatic quick tyre

repair kit is positioned at the front of the

vehicle passenger compartment and

includes fig. 192:

❒bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;❒instruction brochure (see fig. 193), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit;

❒a compressor D complete with

pressure gauge and connectors;

❒a pair of protective gloves located in

the side compartment of the

compressor;

❒adaptors for inflating different

elements.

148) 149) 150)43)

IMPORTANT

INFORMATION:

The sealing fluid of the quick tyre repair

kit is effective at external temperatures

of between -20 °C and +50 °C.

The sealant has an expiry date.

151) 152)2)

INFLATION PROCEDURE

153) 154) 155) 156) 157)

❒Pull the handbrake. Unscrew the tyre

valve cap, take out the filler hose A

fig. 194 and tighten the ring nut B on

the tyre valve;

❒insert the plug E fig. 196 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig.

195 anticlockwise to the repair

position. Activate the kit by pressing

the on/off switch. Inflate the tyre to

the pressure specified in the "Inflation

pressure" paragraph, in the

"Technical Data" chapter;

For a more accurate reading, it is

advisable to check the pressure reading

on the pressure gauge F fig. 195 with

the compressor off and without moving

the centre selector from the repair

position;

192

F1A0180

193

F1A0181

196

IN AN EMERGENCY

Page 202 of 367

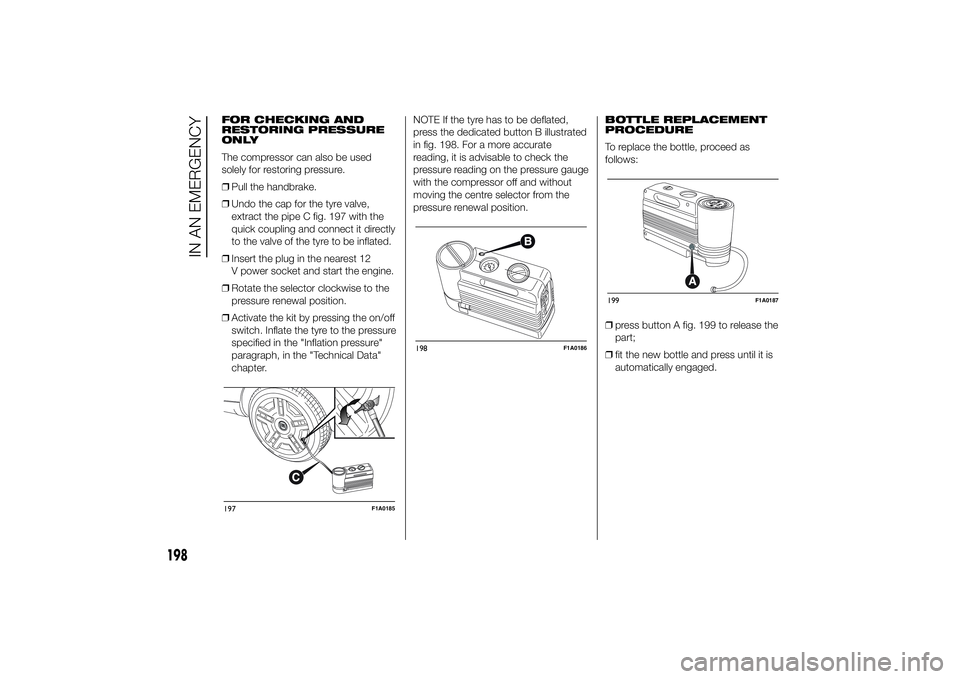

FOR CHECKING AND

RESTORING PRESSURE

ONLY

The compressor can also be used

solely for restoring pressure.

❒Pull the handbrake.

❒Undo the cap for the tyre valve,

extract the pipe C fig. 197 with the

quick coupling and connect it directly

to the valve of the tyre to be inflated.

❒Insert the plug in the nearest 12

V power socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter.NOTE If the tyre has to be deflated,

press the dedicated button B illustrated

in fig. 198. For a more accurate

reading, it is advisable to check the

pressure reading on the pressure gauge

with the compressor off and without

moving the centre selector from the

pressure renewal position.BOTTLE REPLACEMENT

PROCEDURE

To replace the bottle, proceed as

follows:

❒press button A fig. 199 to release the

part;

❒fit the new bottle and press until it is

automatically engaged.197

F1A0185

198

F1A0186

199

F1A0187

198

IN AN EMERGENCY

Page 206 of 367

TYPES OF BULBSVarious types of bulbs are fitted to your car:All-glass bulbs:(type A) press-fitted. Pull to remove.Bayonet type bulbs:(type B) to remove them press the bulb

and turn it anticlockwise.

Tubular bulbs:(type C) release them from their contacts to

remove.

Halogen bulbs:(type D) to remove the bulb, release it and

extract it from its housing.

Halogen bulbs:(type E) to remove the bulb, release it and

extract it from its housing.

202

IN AN EMERGENCY

Page 210 of 367

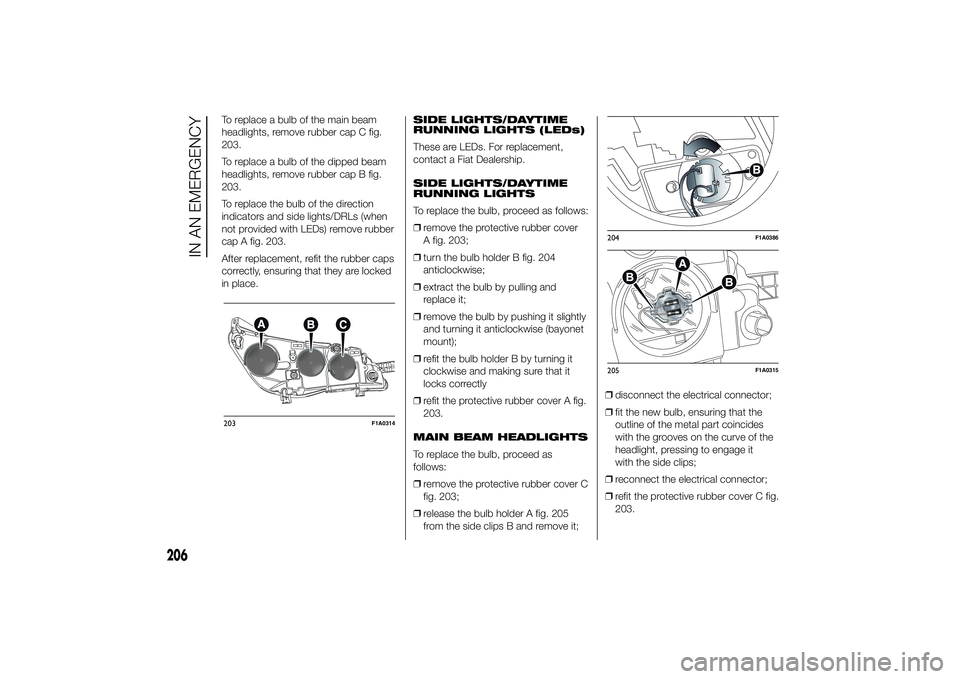

To replace a bulb of the main beam

headlights, remove rubber cap C fig.

203.

To replace a bulb of the dipped beam

headlights, remove rubber cap B fig.

203.

To replace the bulb of the direction

indicators and side lights/DRLs (when

not provided with LEDs) remove rubber

cap A fig. 203.

After replacement, refit the rubber caps

correctly, ensuring that they are locked

in place.SIDE LIGHTS/DAYTIME

RUNNING LIGHTS (LEDs)

These are LEDs. For replacement,

contact a Fiat Dealership.

SIDE LIGHTS/DAYTIME

RUNNING LIGHTS

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

A fig. 203;

❒turn the bulb holder B fig. 204

anticlockwise;

❒extract the bulb by pulling and

replace it;

❒remove the bulb by pushing it slightly

and turning it anticlockwise (bayonet

mount);

❒refit the bulb holder B by turning it

clockwise and making sure that it

locks correctly

❒refit the protective rubber cover A fig.

203.

MAIN BEAM HEADLIGHTS

To replace the bulb, proceed as

follows:

❒remove the protective rubber cover C

fig. 203;

❒release the bulb holder A fig. 205

from the side clips B and remove it;❒disconnect the electrical connector;

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips;

❒reconnect the electrical connector;

❒refit the protective rubber cover C fig.

203.203

F1A0314

204

F1A0386

205

F1A0315

206

IN AN EMERGENCY

Page 211 of 367

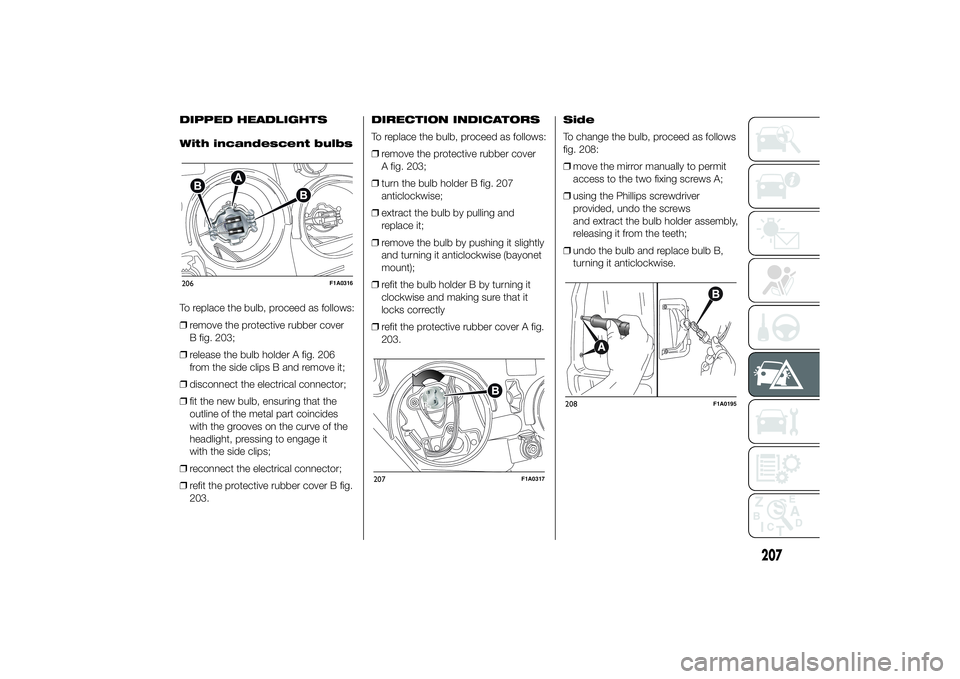

DIPPED HEADLIGHTS

With incandescent bulbs

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

B fig. 203;

❒release the bulb holder A fig. 206

from the side clips B and remove it;

❒disconnect the electrical connector;

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips;

❒reconnect the electrical connector;

❒refit the protective rubber cover B fig.

203.DIRECTION INDICATORS

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

A fig. 203;

❒turn the bulb holder B fig. 207

anticlockwise;

❒extract the bulb by pulling and

replace it;

❒remove the bulb by pushing it slightly

and turning it anticlockwise (bayonet

mount);

❒refit the bulb holder B by turning it

clockwise and making sure that it

locks correctly

❒refit the protective rubber cover A fig.

203.Side

To change the bulb, proceed as follows

fig. 208:

❒move the mirror manually to permit

access to the two fixing screws A;

❒using the Phillips screwdriver

provided, undo the screws

and extract the bulb holder assembly,

releasing it from the teeth;

❒undo the bulb and replace bulb B,

turning it anticlockwise.206

F1A0316

207

F1A0317

208

F1A0195

207

Page 213 of 367

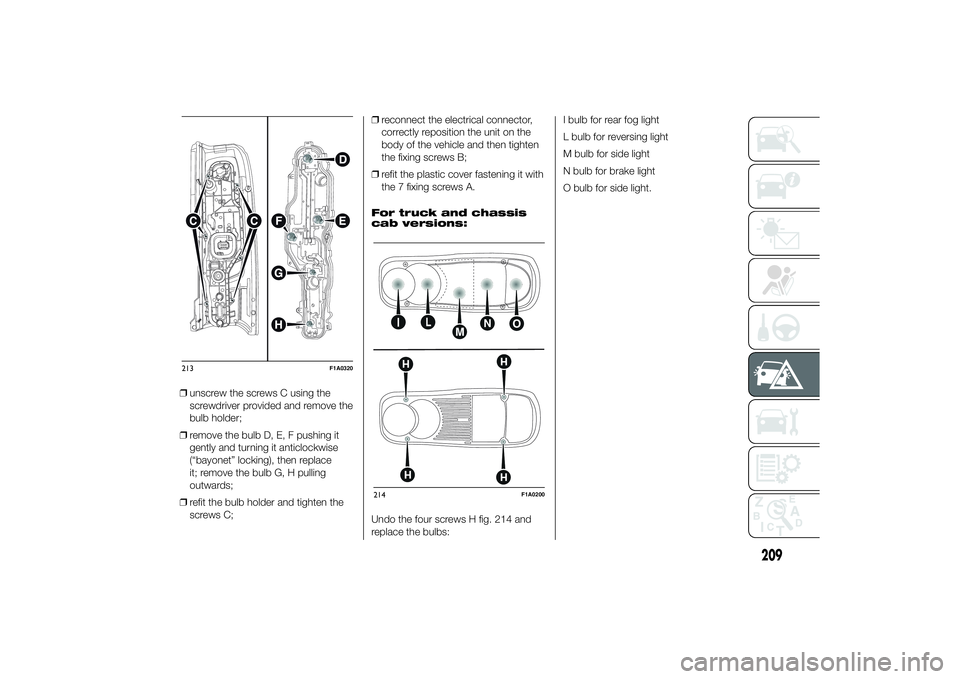

❒unscrew the screws C using the

screwdriver provided and remove the

bulb holder;

❒remove the bulb D, E, F pushing it

gently and turning it anticlockwise

(“bayonet” locking), then replace

it; remove the bulb G, H pulling

outwards;

❒refit the bulb holder and tighten the

screws C;❒reconnect the electrical connector,

correctly reposition the unit on the

body of the vehicle and then tighten

the fixing screws B;

❒refit the plastic cover fastening it with

the 7 fixing screws A.

For truck and chassis

cab versions:

Undo the four screws H fig. 214 and

replace the bulbs:I bulb for rear fog light

L bulb for reversing light

M bulb for side light

N bulb for brake light

O bulb for side light.213

F1A0320

214

F1A0200

209

Page 215 of 367

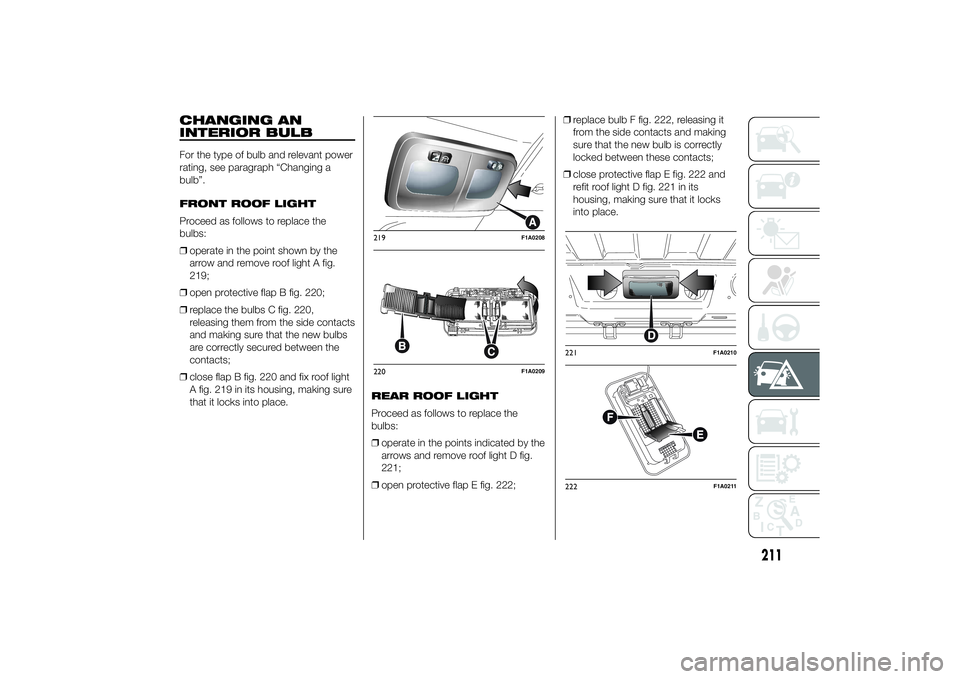

CHANGING AN

INTERIOR BULBFor the type of bulb and relevant power

rating, see paragraph “Changing a

bulb”.

FRONT ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the point shown by the

arrow and remove roof light A fig.

219;

❒open protective flap B fig. 220;

❒replace the bulbs C fig. 220,

releasing them from the side contacts

and making sure that the new bulbs

are correctly secured between the

contacts;

❒close flap B fig. 220 and fix roof light

A fig. 219 in its housing, making sure

that it locks into place.REAR ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the points indicated by the

arrows and remove roof light D fig.

221;

❒open protective flap E fig. 222;❒replace bulb F fig. 222, releasing it

from the side contacts and making

sure that the new bulb is correctly

locked between these contacts;

❒close protective flap E fig. 222 and

refit roof light D fig. 221 in its

housing, making sure that it locks

into place.

219

F1A0208

220

F1A0209

221

F1A0210

222

F1A0211

211