Power FIAT DUCATO 244 2005 3.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2005, Model line: DUCATO 244, Model: FIAT DUCATO 244 2005 3.GPages: 258, PDF Size: 4.05 MB

Page 138 of 258

137IN AN EMERGENCY

BUMP STARTING IF A TYRE IS

PUNCTURED

General instructions

Observe the instruc-

tions on this and the fol-

lowing pages to use the

jack and spare wheel correctly.Catalysed vehicles must

not be bump started

(pushed, towed or

coasted downhill) as this could

cause fuel to flow into the cat-

alytic exhaust system and dam-

age it beyond repair.

Never start the engine

when the vehicle is jacked

up.

WARNING

Remember that until the

engine has started the

brake booster and power steering

systems will not work and a greater

effort will therefore be required to

depress the brake pedal or turn the

steering wheel.

WARNING

If you are towing a trailer,

remove the trailer before

jacking up the vehicle.

WARNING

The jack should only be

used to changed a wheel on

the vehicle for which it was de-

signed. It should not be put to oth-

er uses or employed to raise other

models. Under no circumstances

should it be used when carrying out

repairs under the vehicle. An incor-

rectly positioned jack may cause

the vehicle to fall. Do not use the

jack to lift loads exceeding that in-

dicated on the label attached to the

to the jack itself.

WARNING

Page 142 of 258

141IN AN EMERGENCY

GENERAL INSTRUCTIONS

When a light is not working, check

that it has not fused before changing

the bulb.

For the location of the fuses, refer to

“If a fuse blows” in this section.

Before replacing a bulb that does not

work, check that the contacts are not

oxidised.

Burnt-out bulbs must be replaced

with ones of the same type. Light from

bulbs with insufficient power is dim

while those which are too powerful

use too much electricity. Always check

the height of the headlight beam after

changing a bulb. Only touch the metal

part when handling halo-

gen bulbs. If the transpar-

ent bulb is touched it reduces the

intensity of the light emitted and

can also reduce the life of the

bulb. If you touch the bulb acci-

dentally, rub it with a cloth

moistened with alcohol and leave

it to dry.IF A BULB

BURNS OUT

Modifications or repairs to

the electrical system car-

ried out incorrectly and without

bearing the features of the system

in mind can cause malfunctions

with the risk of fire.

WARNING

You should have the bulbs

replaced at a Fiat Dealer-

ship, if possible. Correct operation

and proper beam height are essen-

tial for safe driving and compliance

with law requirements.

WARNING

Halogen bulbs contain

pressurised gas which, if

broken, may cause small fragments

of glass to be projected outwards.

WARNING

IMPORTANTOn the inside sur-

face of the headlight there could ap-

pear a slight coat of fogging; this does

not show a defect, since it is a natur-

al occurrence due to low temperature

and to the degree of humidity in the

air; it will disappear as soon as the

lights are turned on. The presence of

drops inside the headlight shows wa-

ter seepage, contact Fiat Dealership.

Page 144 of 258

143IN AN EMERGENCY

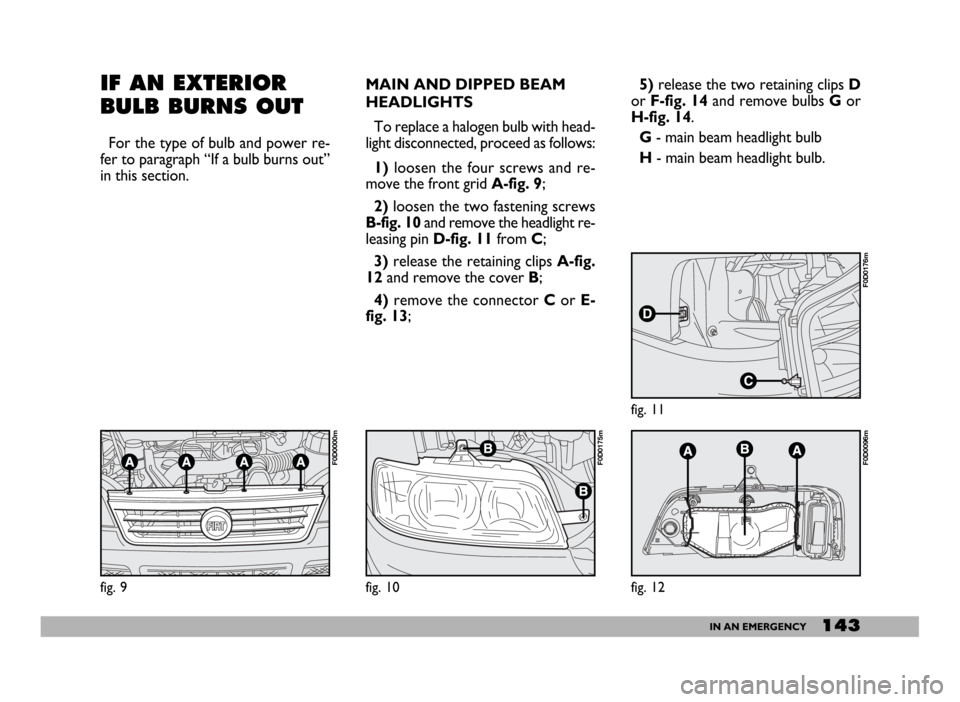

MAIN AND DIPPED BEAM

HEADLIGHTS

To replace a halogen bulb with head-

light disconnected, proceed as follows:

1)loosen the four screws and re-

move the front grid A-fig. 9;

2)loosen the two fastening screws

B-fig. 10and remove the headlight re-

leasing pin D-fig. 11from C;

3)release the retaining clips A-fig.

12and remove the cover B;

4)remove the connector Cor E-

fig. 13;5)release the two retaining clips D

or F-fig. 14and remove bulbs Gor

H-fig. 14.

G- main beam headlight bulb

H- main beam headlight bulb.

fig. 12

F0D0096m

fig. 11

F0D0176m

fig. 10

F0D0175m

IF AN EXTERIOR

BULB BURNS OUT

For the type of bulb and power re-

fer to paragraph “If a bulb burns out”

in this section.

fig. 9

F0D0000m

Page 149 of 258

148IN AN EMERGENCY

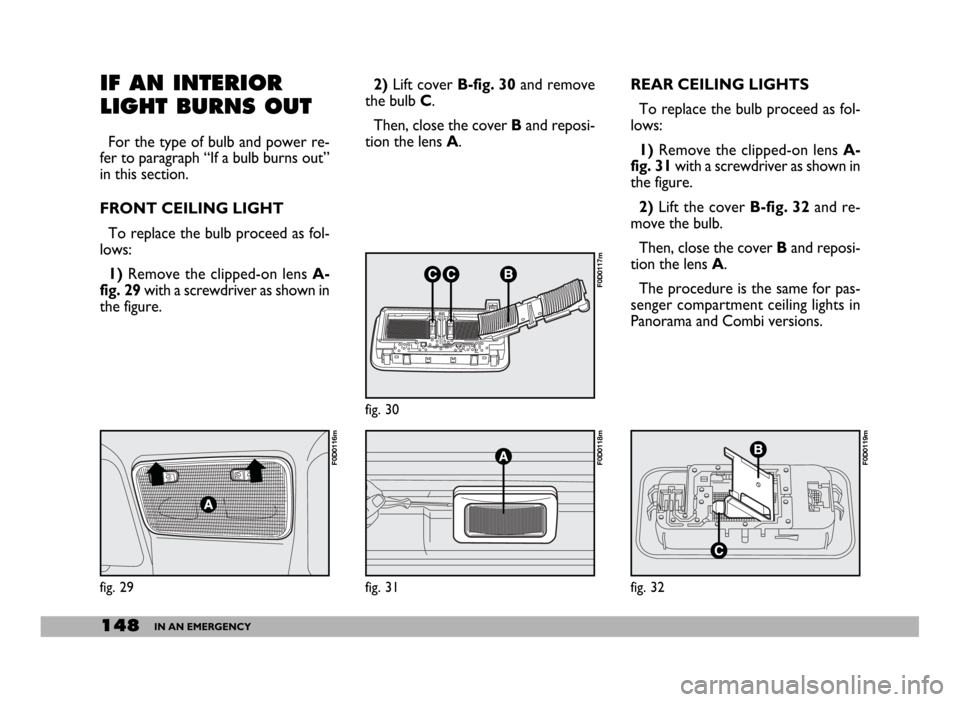

REAR CEILING LIGHTS

To replace the bulb proceed as fol-

lows:

1) Remove the clipped-on lens A-

fig. 31with a screwdriver as shown in

the figure.

2)Lift the cover B-fig. 32 and re-

move the bulb.

Then, close the cover Band reposi-

tion the lens A.

The procedure is the same for pas-

senger compartment ceiling lights in

Panorama and Combi versions.IF AN INTERIOR

LIGHT BURNS OUT

For the type of bulb and power re-

fer to paragraph “If a bulb burns out”

in this section.

FRONT CEILING LIGHT

To replace the bulb proceed as fol-

lows:

1) Remove the clipped-on lens A-

fig. 29with a screwdriver as shown in

the figure.2)Lift cover B-fig. 30and remove

the bulb C.

Then, close the cover Band reposi-

tion the lens A.

fig. 29

F0D0116m

fig. 30

F0D0117m

fig. 31

F0D0118m

fig. 32

F0D0119m

Page 154 of 258

153IN AN EMERGENCY

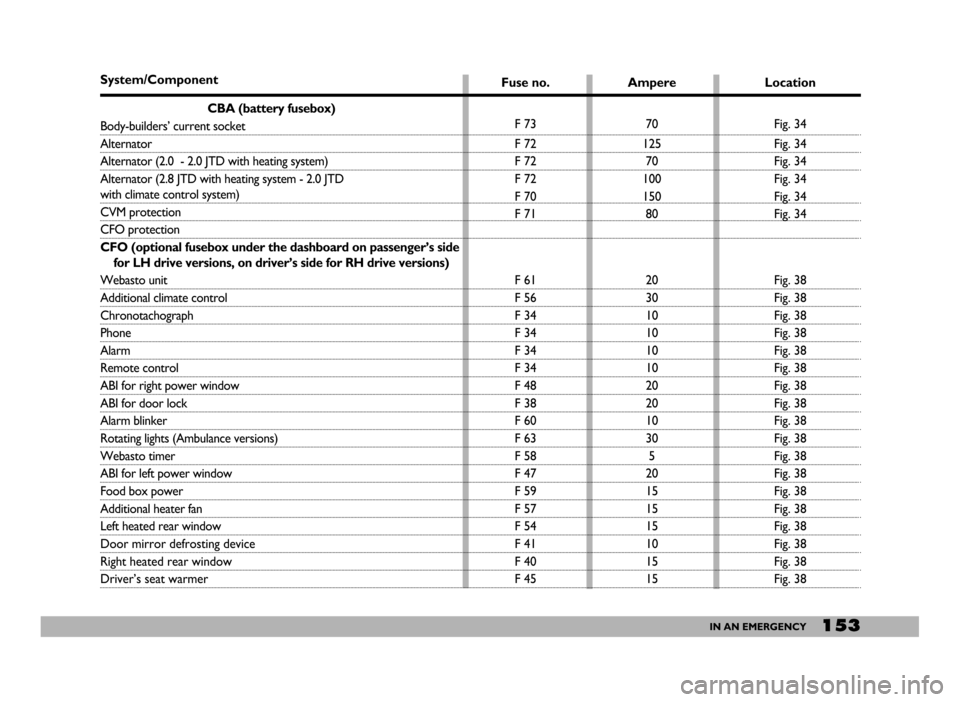

System/Component

CBA (battery fusebox)

Body-builders’ current socket

Alternator

Alternator (2.0 - 2.0 JTD with heating system)

Alternator (2.8 JTD with heating system - 2.0 JTD

with climate control system)

CVM protection

CFO protection

CFO (optional fusebox under the dashboard on passenger’s side

for LH drive versions, on driver’s side for RH drive versions)

Webasto unit

Additional climate control

Chronotachograph

Phone

Alarm

Remote control

ABI for right power window

ABI for door lock

Alarm blinker

Rotating lights (Ambulance versions)

Webasto timer

ABI for left power window

Food box power

Additional heater fan

Left heated rear window

Door mirror defrosting device

Right heated rear window

Driver’s seat warmerFuse no.

F 73

F 72

F 72

F 72

F 70

F 71

F 61

F 56

F 34

F 34

F 34

F 34

F 48

F 38

F 60

F 63

F 58

F 47

F 59

F 57

F 54

F 41

F 40

F 45Ampere

70

125

70

100

150

80

20

30

10

10

10

10

20

20

10

30

5

20

15

15

15

10

15

15Location

Fig. 34

Fig. 34

Fig. 34

Fig. 34

Fig. 34

Fig. 34

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Page 155 of 258

154IN AN EMERGENCY

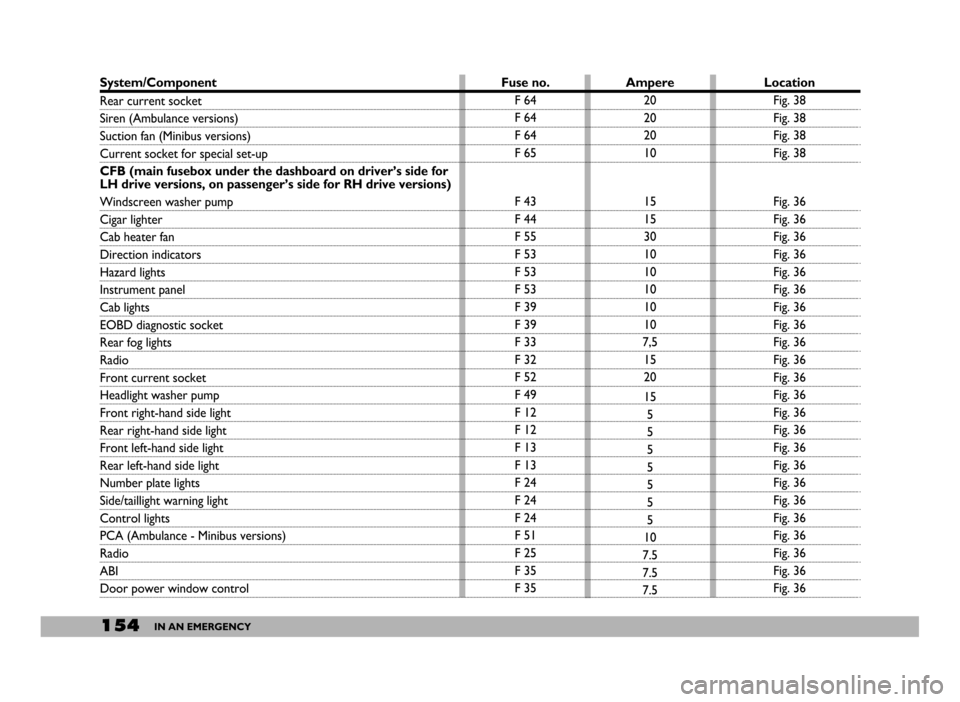

System/Component

Rear current socket

Siren (Ambulance versions)

Suction fan (Minibus versions)

Current socket for special set-up

CFB (main fusebox under the dashboard on driver’s side for

LH drive versions, on passenger’s side for RH drive versions)

Windscreen washer pump

Cigar lighter

Cab heater fan

Direction indicators

Hazard lights

Instrument panel

Cab lights

EOBD diagnostic socket

Rear fog lights

Radio

Front current socket

Headlight washer pump

Front right-hand side light

Rear right-hand side light

Front left-hand side light

Rear left-hand side light

Number plate lights

Side/taillight warning light

Control lights

PCA (Ambulance - Minibus versions)

Radio

ABI

Door power window controlLocation

Fig. 38

Fig. 38

Fig. 38

Fig. 38

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36 Ampere

20

20

20

10

15

15

30

10

10

10

10

10

7,5

15

20

15

5

5

5

5

5

5

5

10

7.5

7.5

7.5 Fuse no.

F 64

F 64

F 64

F 65

F 43

F 44

F 55

F 53

F 53

F 53

F 39

F 39

F 33

F 32

F 52

F 49

F 12

F 12

F 13

F 13

F 24

F 24

F 24

F 51

F 25

F 35

F 35

Page 156 of 258

155IN AN EMERGENCY

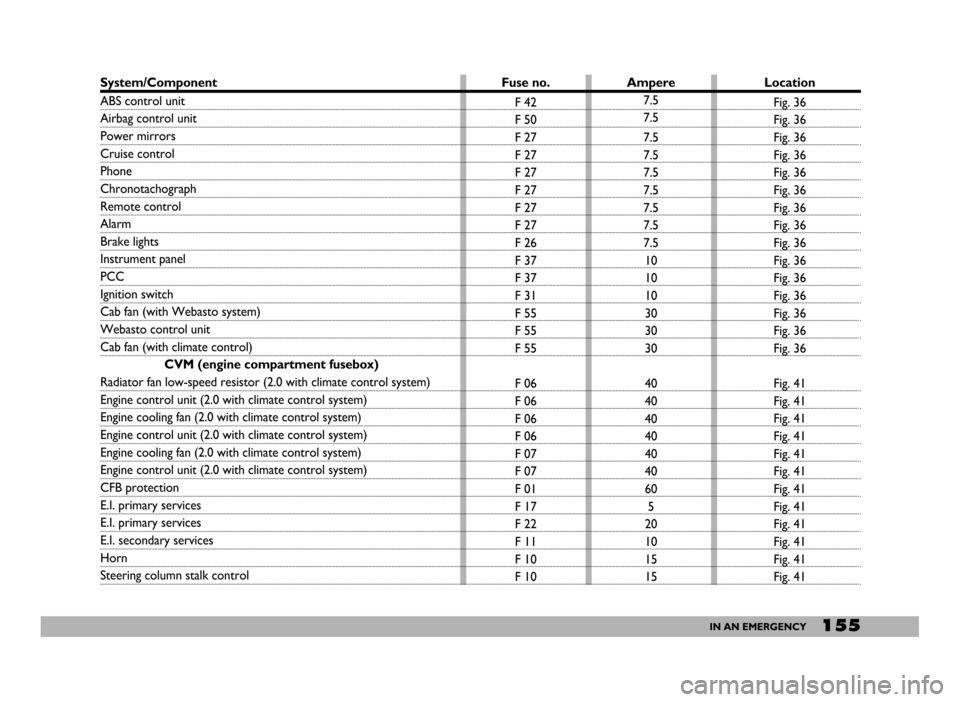

System/Component

ABS control unit

Airbag control unit

Power mirrors

Cruise control

Phone

Chronotachograph

Remote control

Alarm

Brake lights

Instrument panel

PCC

Ignition switch

Cab fan (with Webasto system)

Webasto control unit

Cab fan (with climate control)

CVM (engine compartment fusebox)

Radiator fan low-speed resistor (2.0 with climate control system)

Engine control unit (2.0 with climate control system)

Engine cooling fan (2.0 with climate control system)

Engine control unit (2.0 with climate control system)

Engine cooling fan (2.0 with climate control system)

Engine control unit (2.0 with climate control system)

CFB protection

E.I. primary services

E.I. primary services

E.I. secondary services

Horn

Steering column stalk controlFuse no.

F 42

F 50

F 27

F 27

F 27

F 27

F 27

F 27

F 26

F 37

F 37

F 31

F 55

F 55

F 55

F 06

F 06

F 06

F 06

F 07

F 07

F 01

F 17

F 22

F 11

F 10

F 10Ampere

7.5

7.5

7.5

7.5

7.5

7.5

7.5

7.5

7.5

10

10

10

30

30

30

40

40

40

40

40

40

60

5

20

10

15

15Location

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 36

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Fig. 41

Page 160 of 258

159IN AN EMERGENCY

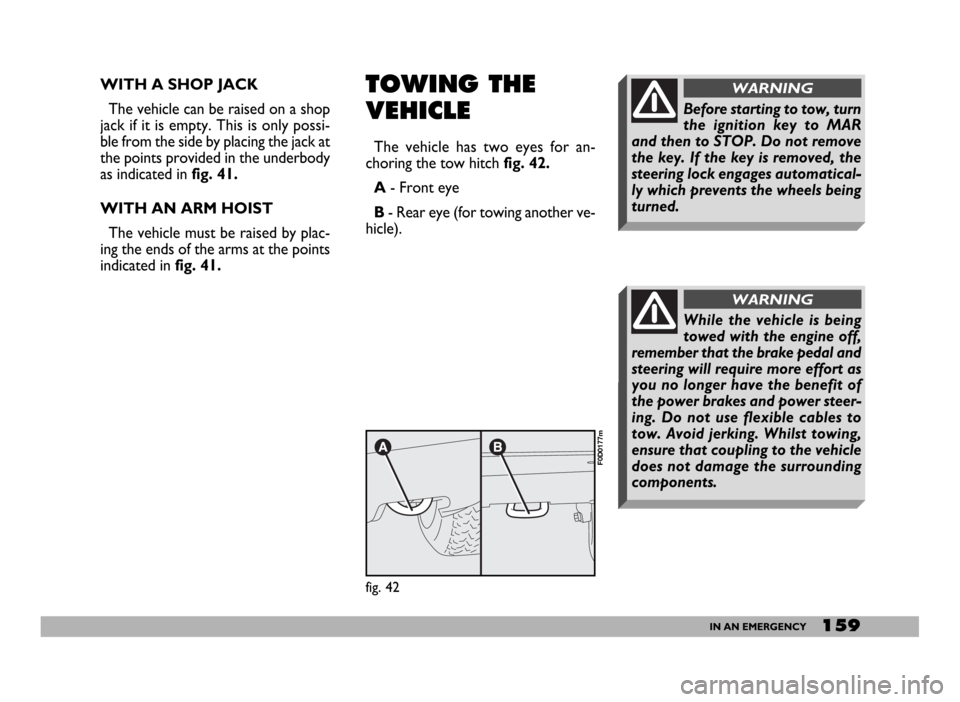

WITH A SHOP JACK

The vehicle can be raised on a shop

jack if it is empty. This is only possi-

ble from the side by placing the jack at

the points provided in the underbody

as indicated infig. 41.

WITH AN ARM HOIST

The vehicle must be raised by plac-

ing the ends of the arms at the points

indicated in fig. 41.TOWING THE

VEHICLE

The vehicle has two eyes for an-

choring the tow hitch fig. 42.

A- Front eye

B- Rear eye (for towing another ve-

hicle).

fig. 42

F0D0177m

Before starting to tow, turn

the ignition key to MAR

and then to STOP. Do not remove

the key. If the key is removed, the

steering lock engages automatical-

ly which prevents the wheels being

turned.

WARNING

While the vehicle is being

towed with the engine off,

remember that the brake pedal and

steering will require more effort as

you no longer have the benefit of

the power brakes and power steer-

ing. Do not use flexible cables to

tow. Avoid jerking. Whilst towing,

ensure that coupling to the vehicle

does not damage the surrounding

components.

WARNING

Page 165 of 258

164VEHICLE MAINTENANCE

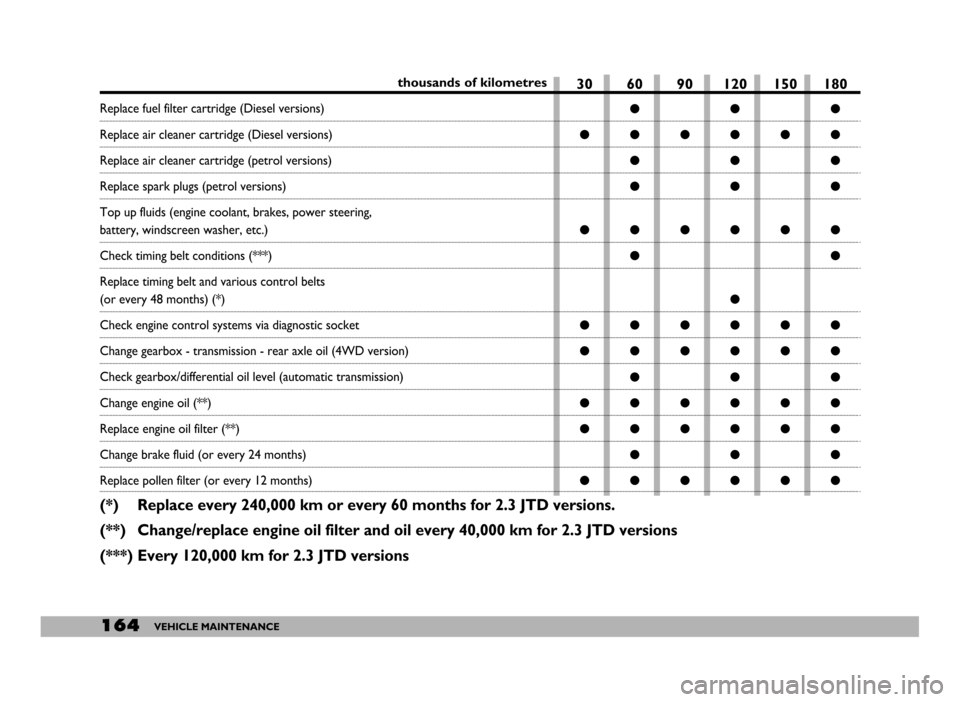

thousands of kilometres

Replace fuel filter cartridge (Diesel versions)

Replace air cleaner cartridge (Diesel versions)

Replace air cleaner cartridge (petrol versions)

Replace spark plugs (petrol versions)

Top up fluids (engine coolant, brakes, power steering,

battery, windscreen washer, etc.)

Check timing belt conditions (***)

Replace timing belt and various control belts

(or every 48 months) (*)

Check engine control systems via diagnostic socket

Change gearbox - transmission - rear axle oil (4WD version)

Check gearbox/differential oil level (automatic transmission)

Change engine oil (**)

Replace engine oil filter (**)

Change brake fluid (or every 24 months)

Replace pollen filter (or every 12 months)

(*) Replace every 240,000 km or every 60 months for 2.3 JTD versions.

(**) Change/replace engine oil filter and oil every 40,000 km for 2.3 JTD versions

(***) Every 120,000 km for 2.3 JTD versions

30 60 90 120 150 180

●●●

●●●●●●

●●●

●●●

●●●●●●

●●

●

●●●●●●

●●●●●●

●●●

●●●●●●

●●●●●●

●●●

●●●●●●

Page 166 of 258

165VEHICLE MAINTENANCE

ANNUAL

INSPECTION

SCHEDULE

The following annual inspection

schedule is required for vehicles trav-

elling 15,000 Kmapprox. a year. The

schedule includes the following oper-

ations:

– check tyre condition and wear and

adjust pressure, if required (including

spare wheel);

– check operation of lights (head-

lights, direction indicators, hazard

lights, boot light, passenger compart-

ment light, instrument panel lights,

etc.);

– check windscreen wiper/washer

and adjust nozzles;

– check position and wear of wind-

screen/rear window wiper blades;

– check front pad conditions and

wear;

– check for bonnet and boot lock

cleanness, lever cleanness and lubri-

cation;– inspect conditions of: engine, gear-

box, transmission, piping (exhaust, fu-

el feed, brakes), rubber parts (boots,

sleeves, bushings, etc.), brake and fu-

el line hoses;

– check battery charge status;

– check conditions of various control

belts;

– check and top up fluid levels (en-

gine coolant, brakes, windscreen

washer, battery, etc.);

– check and top up engine oil;

– replace pollen filter.

ADDITIONAL

CHECKS

Every 1,000 km or before long

trips, check and top up as necessary:

– engine coolant level

– brake fluid level

– power steering fluid level

– battery electrolyte level

– windscreen washer fluid

– tyre pressure and conditions.

Every 3,000 km or before long

trips, check and top up as necessary:

engine oil

Every 10,000 kmor at cwarning

light coming on (diesel engines only):

bleed water from fuel filter.

You are recommended to use FL

Seleniaproducts designed and pro-

duced for Fiat vehicles (see the “Ca-

pacities” table in the “Technical Spec-

ifications” section).