spare wheel FIAT DUCATO BASE CAMPER 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2014Pages: 367, PDF Size: 20.39 MB

Page 86 of 367

❒interference caused by electronic

devices or radio frequency emissions

similar to those of the TPM sensors.

❒Application of tinted films which

interfere with the signals of the radio

waves.

❒Presence of snow or ice on the

wheels or the wheel arches.

❒Use of snow chains.

❒Use of wheels/tyres not equipped

with TPM sensors.

❒The space-saver wheel is not

equipped with the tyre pressure

control sensor. Therefore, the tyre

pressure is not controlled by the

system.

❒If the space-saver wheel replaces a

tyre with a pressure lower than the

insufficient pressure limit, an acoustic

signal will be emitted and the warning

light

will switch on at the next

ignition cycle.❒When the original tyre is repaired or

replaced and it is mounted back on

the vehicle to replace the space-

saver wheel, the TPMS will update

automatically and the warning light

will switch off, provided that the

pressure of none of the four tyres is

below the insufficient pressure limit.

You may need to drive the vehicle for

about 20 minutes at a speed higher

than 20 km/h to allow the TPMS

to receive this information.IMPORTANT

INFORMATION

WARNING

65) The TPMS is optimised for the

original tyres and wheels

provided. TPMS pressures and

alerts have been defined

according to the size of the tyres

mounted on the vehicle. Using

equipment with different size,

type or kind may cause irregular

system operation or sensor

damage. Non-original spare

wheels can damage the sensor.

Do not use tyre sealant or

balancing weights if the vehicle is

equipped with TPMS as these

may damage the sensors.

66) If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the

pressure on all four tyres.

67) TPMS does not relieve the driver

from the obligation to check the

tyre pressure every month; it is

not even to be considered a

replacing system for maintenance

or a safety system.

82

KNOW YOUR VEHICLE

Page 195 of 367

BUMP STARTING

Never bump start the engine by

pushing, towing or driving downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.

WARNING

136) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

REPLACING A

WHEELGENERAL

INSTRUCTIONS

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

137) 138) 139) 140) 141)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

142)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒take the extension arm and the

wrench from the tool box/bag under

the passenger seat (see

“Compartment under front passenger

seat” in the “Know your vehicle”

section);

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒loosen the bolts on the wheel to be

replaced by one turn;

❒turn the ring nut to partly extend the

jack;

179

F1A0168

191

Page 196 of 367

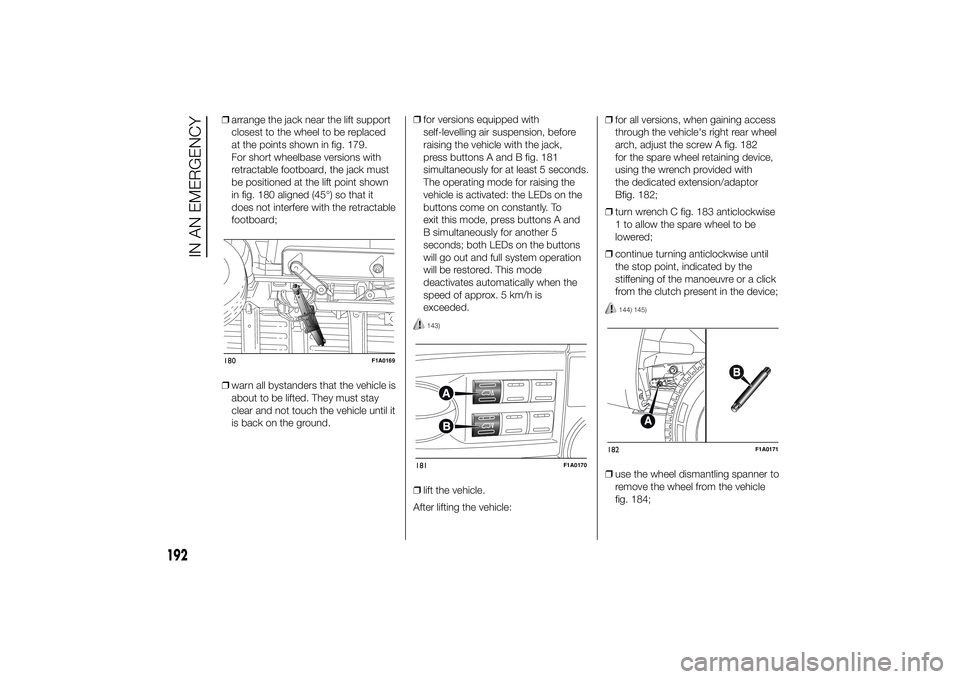

❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 179.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 180 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 181

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

143)

❒lift the vehicle.

After lifting the vehicle:❒for all versions, when gaining access

through the vehicle's right rear wheel

arch, adjust the screw A fig. 182

for the spare wheel retaining device,

using the wrench provided with

the dedicated extension/adaptor

Bfig. 182;

❒turn wrench C fig. 183 anticlockwise

1 to allow the spare wheel to be

lowered;

❒continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

144) 145)

❒use the wheel dismantling spanner to

remove the wheel from the vehicle

fig. 184;

180

F1A0169

181

F1A0170

182

F1A0171

192

IN AN EMERGENCY

Page 197 of 367

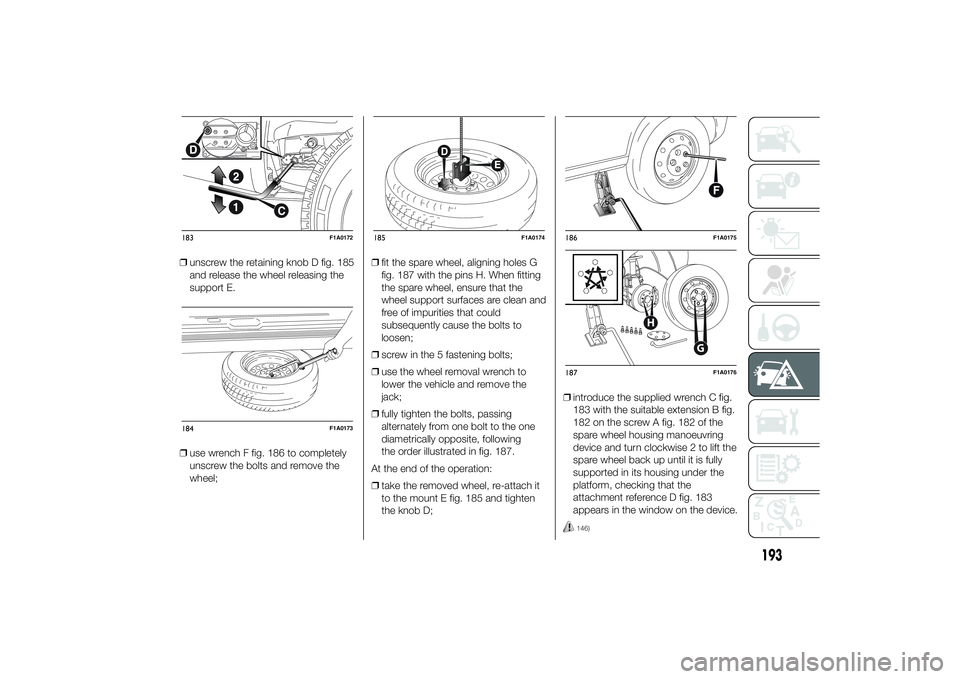

❒unscrew the retaining knob D fig. 185

and release the wheel releasing the

support E.

❒use wrench F fig. 186 to completely

unscrew the bolts and remove the

wheel;❒fit the spare wheel, aligning holes G

fig. 187 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

❒fully tighten the bolts, passing

alternately from one bolt to the one

diametrically opposite, following

the order illustrated in fig. 187.

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 185 and tighten

the knob D;❒introduce the supplied wrench C fig.

183 with the suitable extension B fig.

182 on the screw A fig. 182 of the

spare wheel housing manoeuvring

device and turn clockwise 2 to lift the

spare wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 183

appears in the window on the device.

146)

183

F1A0172

184

F1A0173

185

F1A0174

186

F1A0175

G

H

187

F1A0176

193

Page 198 of 367

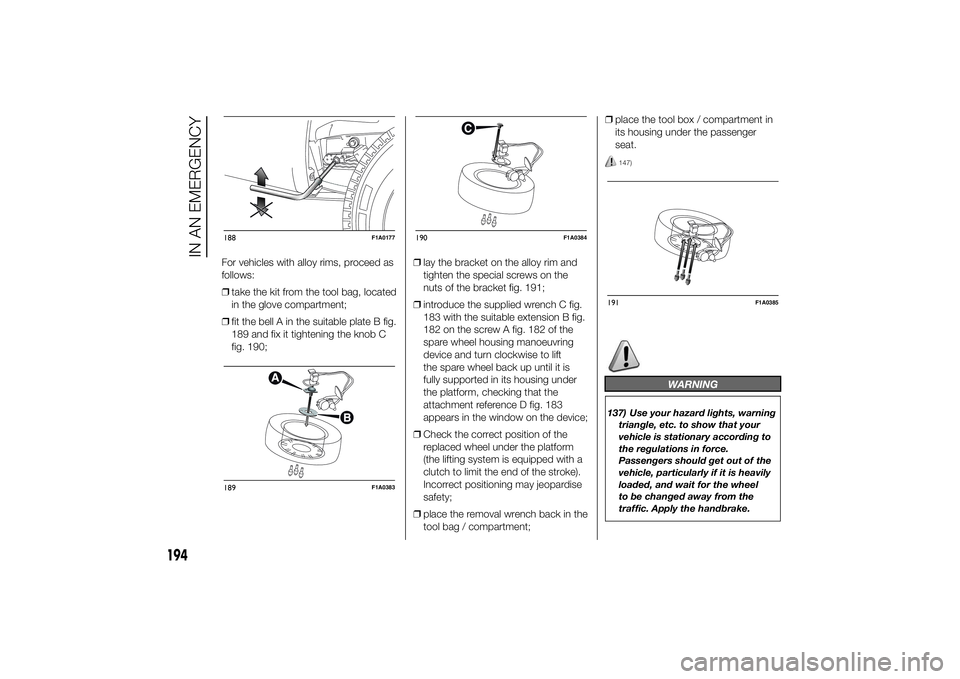

For vehicles with alloy rims, proceed as

follows:

❒take the kit from the tool bag, located

in the glove compartment;

❒fit the bell A in the suitable plate B fig.

189 and fix it tightening the knob C

fig. 190;❒lay the bracket on the alloy rim and

tighten the special screws on the

nuts of the bracket fig. 191;

❒introduce the supplied wrench C fig.

183 with the suitable extension B fig.

182 on the screw A fig. 182 of the

spare wheel housing manoeuvring

device and turn clockwise to lift

the spare wheel back up until it is

fully supported in its housing under

the platform, checking that the

attachment reference D fig. 183

appears in the window on the device;

❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal wrench back in the

tool bag / compartment;❒place the tool box / compartment in

its housing under the passenger

seat.

147)

WARNING

137) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake.

188

F1A0177

189

F1A0383

190

F1A0384

191

F1A0385

194

IN AN EMERGENCY

Page 199 of 367

138) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

139) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

140) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

141) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.142) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.

143) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

144) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

145) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.146) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (white notch inside the

window on the device), the key

must be extracted, taking care not

to turn it in the wrong direction

to facilitate the extraction of the

key itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained fig.

188.

147) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

195

Page 225 of 367

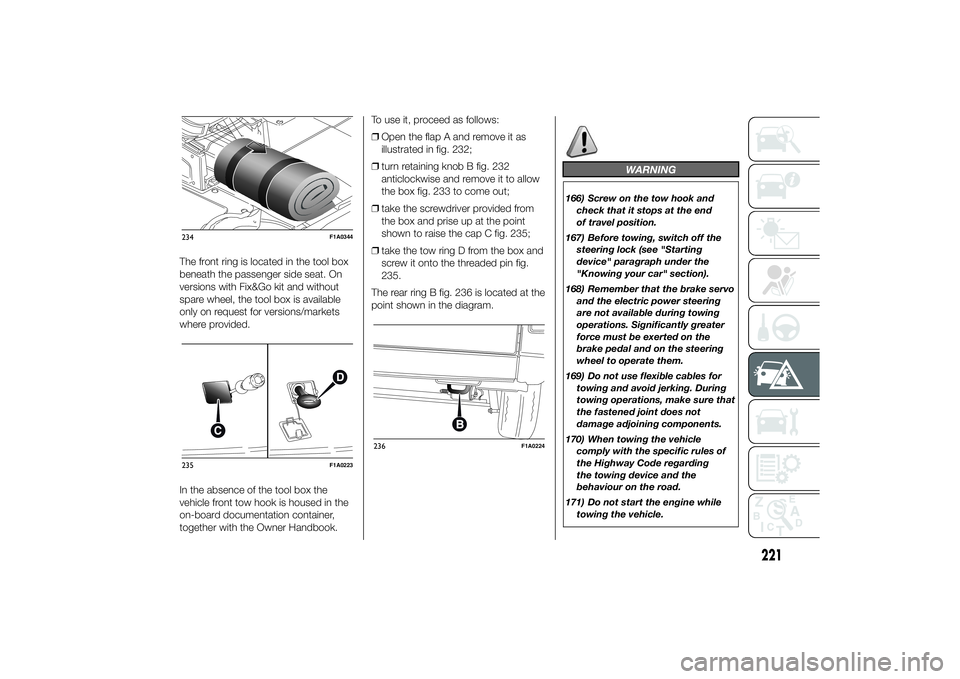

The front ring is located in the tool box

beneath the passenger side seat. On

versions with Fix&Go kit and without

spare wheel, the tool box is available

only on request for versions/markets

where provided.

In the absence of the tool box the

vehicle front tow hook is housed in the

on-board documentation container,

together with the Owner Handbook.To use it, proceed as follows:

❒Open the flap A and remove it as

illustrated in fig. 232;

❒turn retaining knob B fig. 232

anticlockwise and remove it to allow

the box fig. 233 to come out;

❒take the screwdriver provided from

the box and prise up at the point

shown to raise the cap C fig. 235;

❒take the tow ring D from the box and

screw it onto the threaded pin fig.

235.

The rear ring B fig. 236 is located at the

point shown in the diagram.

WARNING

166) Screw on the tow hook and

check that it stops at the end

of travel position.

167) Before towing, switch off the

steering lock (see "Starting

device" paragraph under the

"Knowing your car" section).

168) Remember that the brake servo

and the electric power steering

are not available during towing

operations. Significantly greater

force must be exerted on the

brake pedal and on the steering

wheel to operate them.

169) Do not use flexible cables for

towing and avoid jerking. During

towing operations, make sure that

the fastened joint does not

damage adjoining components.

170) When towing the vehicle

comply with the specific rules of

the Highway Code regarding

the towing device and the

behaviour on the road.

171) Do not start the engine while

towing the vehicle.

234

F1A0344

235

F1A0223

236

F1A0224

221

Page 244 of 367

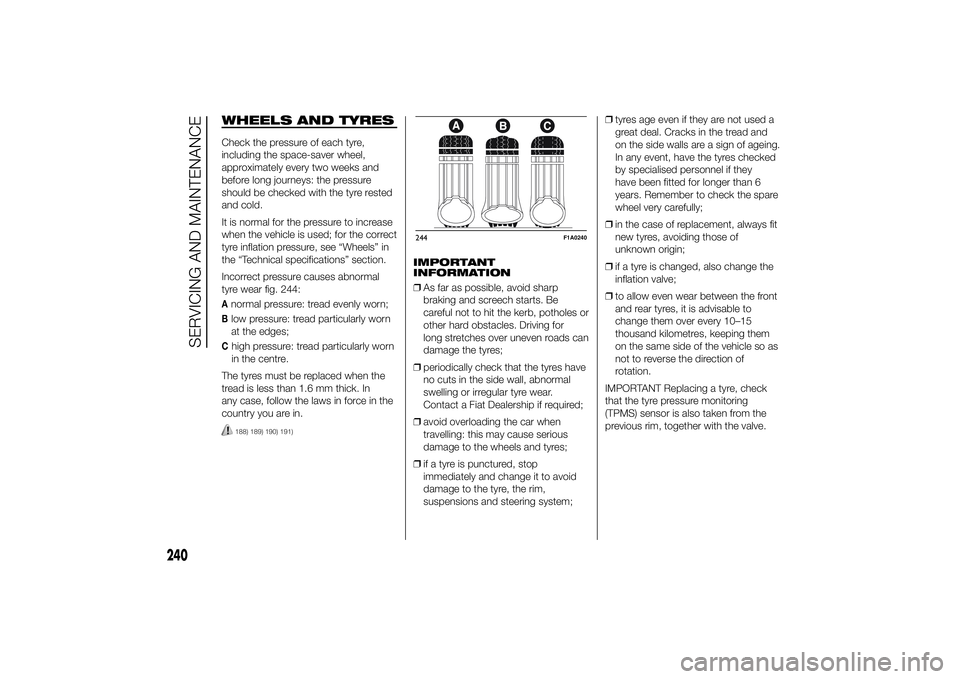

WHEELS AND TYRESCheck the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

Incorrect pressure causes abnormal

tyre wear fig. 244:Anormal pressure: tread evenly worn;Blow pressure: tread particularly worn

at the edges;Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.188) 189) 190) 191)

IMPORTANT

INFORMATION

❒As far as possible, avoid sharp

braking and screech starts. Be

careful not to hit the kerb, potholes or

other hard obstacles. Driving for

long stretches over uneven roads can

damage the tyres;

❒periodically check that the tyres have

no cuts in the side wall, abnormal

swelling or irregular tyre wear.

Contact a Fiat Dealership if required;

❒avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

❒if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;❒tyres age even if they are not used a

great deal. Cracks in the tread and

on the side walls are a sign of ageing.

In any event, have the tyres checked

by specialised personnel if they

have been fitted for longer than 6

years. Remember to check the spare

wheel very carefully;

❒in the case of replacement, always fit

new tyres, avoiding those of

unknown origin;

❒if a tyre is changed, also change the

inflation valve;

❒to allow even wear between the front

and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them

on the same side of the vehicle so as

not to reverse the direction of

rotation.

IMPORTANT Replacing a tyre, check

that the tyre pressure monitoring

(TPMS) sensor is also taken from the

previous rim, together with the valve.244

F1A0240

240

SERVICING AND MAINTENANCE

Page 254 of 367

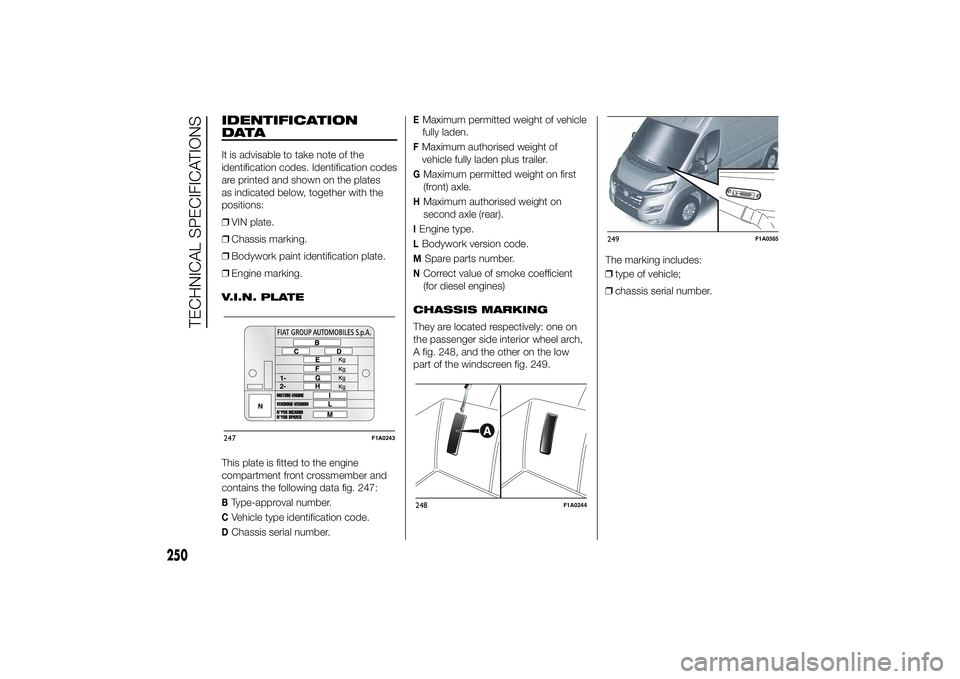

IDENTIFICATION

DATAIt is advisable to take note of the

identification codes. Identification codes

are printed and shown on the plates

as indicated below, together with the

positions:

❒VIN plate.

❒Chassis marking.

❒Bodywork paint identification plate.

❒Engine marking.

V.I.N. PLATE

This plate is fitted to the engine

compartment front crossmember and

contains the following data fig. 247:BType-approval number.CVehicle type identification code.DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.FMaximum authorised weight of

vehicle fully laden plus trailer.GMaximum permitted weight on first

(front) axle.HMaximum authorised weight on

second axle (rear).IEngine type.LBodywork version code.M

Spare parts number.

NCorrect value of smoke coefficient

(for diesel engines)

CHASSIS MARKING

They are located respectively: one on

the passenger side interior wheel arch,

A fig. 248, and the other on the low

part of the windscreen fig. 249.The marking includes:

❒type of vehicle;

❒chassis serial number.

247

F1A0243

248

F1A0244

249

F1A0365

250

TECHNICAL SPECIFICATIONS

Page 264 of 367

WHEELSRIMS AND TYRES

Pressed steel or alloy rims. Tubeless

radial carcass tyres. All approved tyres

are listed in the registration document.

IMPORTANT If there are any

discrepancies between the Owner

Handbook and the registration

document, take the information from

the latter.

For safe driving, the vehicle must be

fitted with tyres of the same make and

type on all wheels.

IMPORTANT Do not use air chambers

with tubeless tyres.

SPARE WHEEL

Pressed steel rim. Tubeless tyre.

WHEEL GEOMETRY

Front wheel toe-in measured from rim

to rim: -1±1mm.

The values refer to the vehicle in

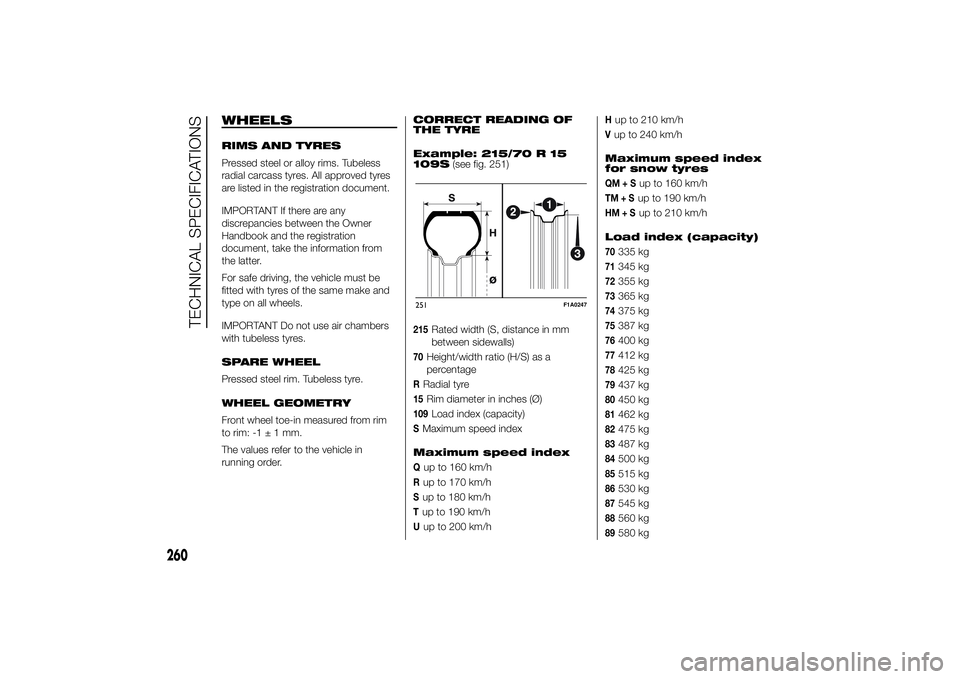

running order.CORRECT READING OF

THE TYRE

Example: 215/70 R 15

109S(see fig. 251)

215

Rated width (S, distance in mm

between sidewalls)

70

Height/width ratio (H/S) as a

percentage

RRadial tyre15

Rim diameter in inches (Ø)

109

Load index (capacity)

SMaximum speed index

Maximum speed indexQup to 160 km/hRup to 170 km/hSup to 180 km/hTup to 190 km/hUup to 200 km/h

Hup to 210 km/hVup to 240 km/h

Maximum speed index

for snow tyresQM+S

up to 160 km/h

TM+S

up to 190 km/h

HM+S

up to 210 km/h

Load index (capacity)

70

335 kg

71

345 kg

72

355 kg

73

365 kg

74

375 kg

75

387 kg

76

400 kg

77

412 kg

78

425 kg

79

437 kg

80

450 kg

81

462 kg

82

475 kg

83

487 kg

84

500 kg

85

515 kg

86

530 kg

87

545 kg

88

560 kg

89

580 kg

251

F1A0247

260

TECHNICAL SPECIFICATIONS