wheel bolts FIAT DUCATO BASE CAMPER 2014 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2014Pages: 367, PDF Size: 20.39 MB

Page 195 of 367

BUMP STARTING

Never bump start the engine by

pushing, towing or driving downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.

WARNING

136) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

REPLACING A

WHEELGENERAL

INSTRUCTIONS

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

137) 138) 139) 140) 141)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

142)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒take the extension arm and the

wrench from the tool box/bag under

the passenger seat (see

“Compartment under front passenger

seat” in the “Know your vehicle”

section);

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒loosen the bolts on the wheel to be

replaced by one turn;

❒turn the ring nut to partly extend the

jack;

179

F1A0168

191

Page 197 of 367

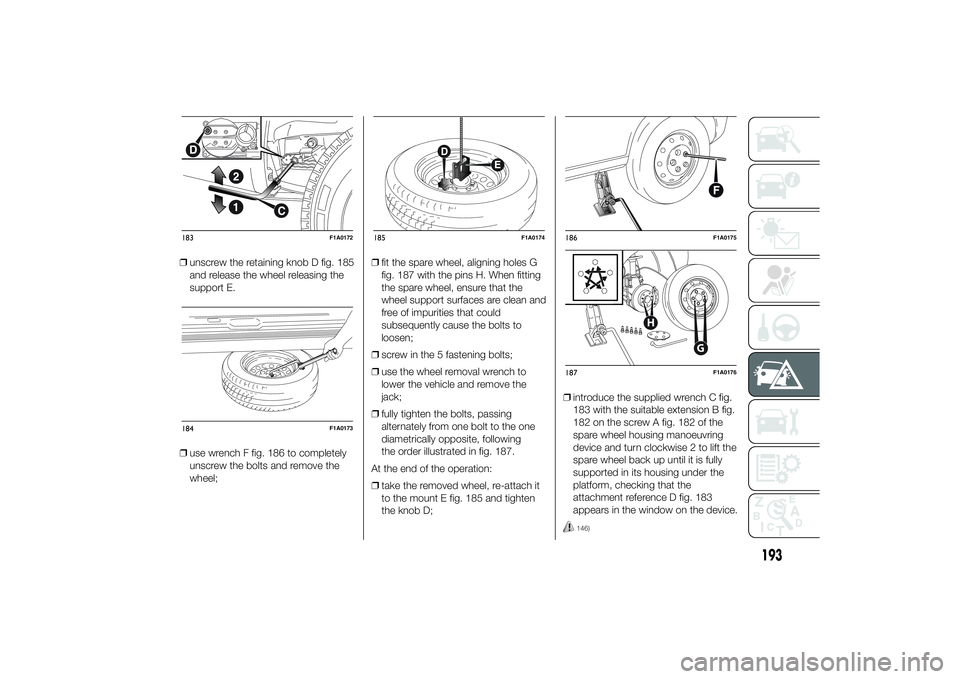

❒unscrew the retaining knob D fig. 185

and release the wheel releasing the

support E.

❒use wrench F fig. 186 to completely

unscrew the bolts and remove the

wheel;❒fit the spare wheel, aligning holes G

fig. 187 with the pins H. When fitting

the spare wheel, ensure that the

wheel support surfaces are clean and

free of impurities that could

subsequently cause the bolts to

loosen;

❒screw in the 5 fastening bolts;

❒use the wheel removal wrench to

lower the vehicle and remove the

jack;

❒fully tighten the bolts, passing

alternately from one bolt to the one

diametrically opposite, following

the order illustrated in fig. 187.

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 185 and tighten

the knob D;❒introduce the supplied wrench C fig.

183 with the suitable extension B fig.

182 on the screw A fig. 182 of the

spare wheel housing manoeuvring

device and turn clockwise 2 to lift the

spare wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 183

appears in the window on the device.

146)

183

F1A0172

184

F1A0173

185

F1A0174

186

F1A0175

G

H

187

F1A0176

193

Page 199 of 367

138) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

139) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

140) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

141) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.142) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.

143) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

144) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

145) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.146) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (white notch inside the

window on the device), the key

must be extracted, taking care not

to turn it in the wrong direction

to facilitate the extraction of the

key itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained fig.

188.

147) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

195