engine FIAT FIORINO 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2019, Model line: FIORINO, Model: FIAT FIORINO 2019Pages: 220, PDF Size: 6.22 MB

Page 106 of 220

CRUISE CONTROL

(constant speed

regulator)

(for versions/markets, where provided)

This is an electronic driving aid that

allows you to drive at a speed of above

30 km/h on long and straight dry roads

with few driving changes (e.g.

motorways) at a preset speed without

having to press the accelerator pedal. It

is therefore not recommended to use

this device on extra-urban roads with

traffic. Do not use the device in town.

Turning the device on

When the device is activated, light

comes on together with the relevant

message on the instrument panel (for

versions/markets, where provided).

The speed adjustment function cannot

be activated in 1

stor reverse gear; it

is advisable to activate the function in

4

thor higher gears.

When travelling downhill with the device

activated, the vehicle speed may

exceed the memorised one.

Storing vehicle speed

Proceed as follows:

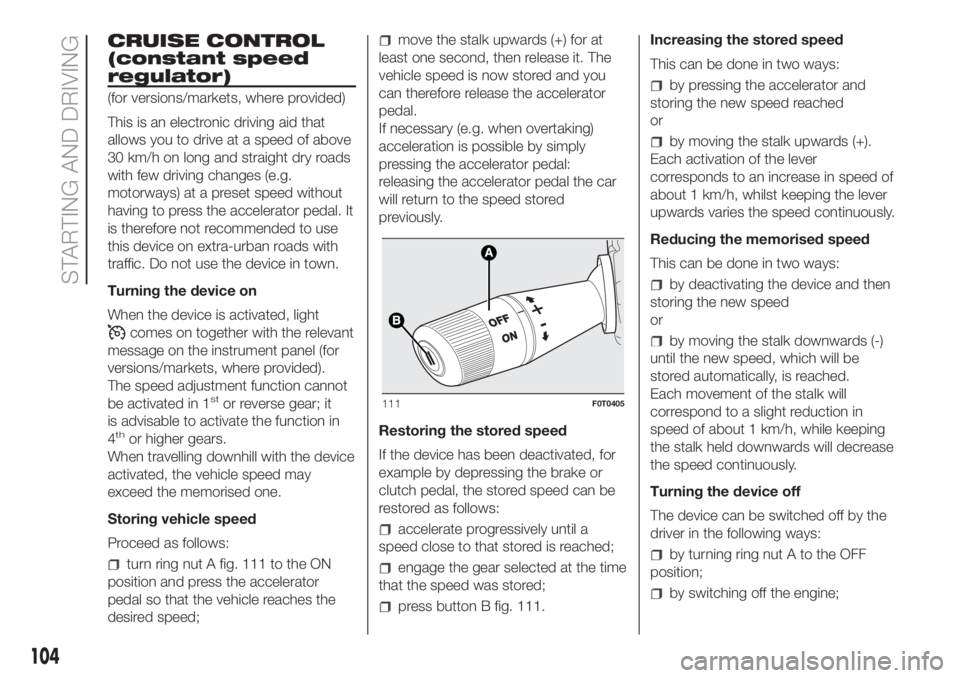

turn ring nut A fig. 111 to the ON

position and press the accelerator

pedal so that the vehicle reaches the

desired speed;

move the stalk upwards (+) for at

least one second, then release it. The

vehicle speed is now stored and you

can therefore release the accelerator

pedal.

If necessary (e.g. when overtaking)

acceleration is possible by simply

pressing the accelerator pedal:

releasing the accelerator pedal the car

will return to the speed stored

previously.

Restoring the stored speed

If the device has been deactivated, for

example by depressing the brake or

clutch pedal, the stored speed can be

restored as follows:

accelerate progressively until a

speed close to that stored is reached;

engage the gear selected at the time

that the speed was stored;

press button B fig. 111.Increasing the stored speed

This can be done in two ways:

by pressing the accelerator and

storing the new speed reached

or

by moving the stalk upwards (+).

Each activation of the lever

corresponds to an increase in speed of

about 1 km/h, whilst keeping the lever

upwards varies the speed continuously.

Reducing the memorised speed

This can be done in two ways:

by deactivating the device and then

storing the new speed

or

by moving the stalk downwards (-)

until the new speed, which will be

stored automatically, is reached.

Each movement of the stalk will

correspond to a slight reduction in

speed of about 1 km/h, while keeping

the stalk held downwards will decrease

the speed continuously.

Turning the device off

The device can be switched off by the

driver in the following ways:

by turning ring nut A to the OFF

position;

by switching off the engine;

111F0T0405

104

STARTING AND DRIVING

Page 110 of 220

Start&Stop SYSTEM

(for versions/markets, where provided)

106) 107) 108) 109)

IN BRIEF

The Start&Stop device automatically

stops the engine each time the

vehicle is stationary and all the

conditions for automatic switch-off

have been met, and starts it again

when the driver wants to move off.

This improves the efficiency of the

vehicle by reducing fuel consumption,

the emission of harmful gases and

noise pollution.

OPERATING MODE

Stopping the engine

Versions with manual transmission

With the vehicle stationary, the engine

stops with the gearbox in neutral and

the clutch pedal released.Versions with Comfort-matic

transmission

With the vehicle stationary and the

brake pedal pressed, the engine stops

if the gear lever is in position other

thanR. In the event of stops uphill,

engine switching off is disabled to make

the "Hill Holder" function available

(works only with the engine running).

The warning light on the instrument

panel switches on to signal that the

engine has stopped.

Restarting the engine

Versions with manual transmission

Depress the clutch pedal to restart

the engine.

Versions with Comfort-matic

transmission

Releasing the brake pedal the engine

restarts automatically; the icon switches

off on the display. If the engine is

restarted with the “Hill Holder” function

off, move the lever towards (+), (-)or

Rand the engine restarts.MANUAL ACTIVATION

AND DEACTIVATION

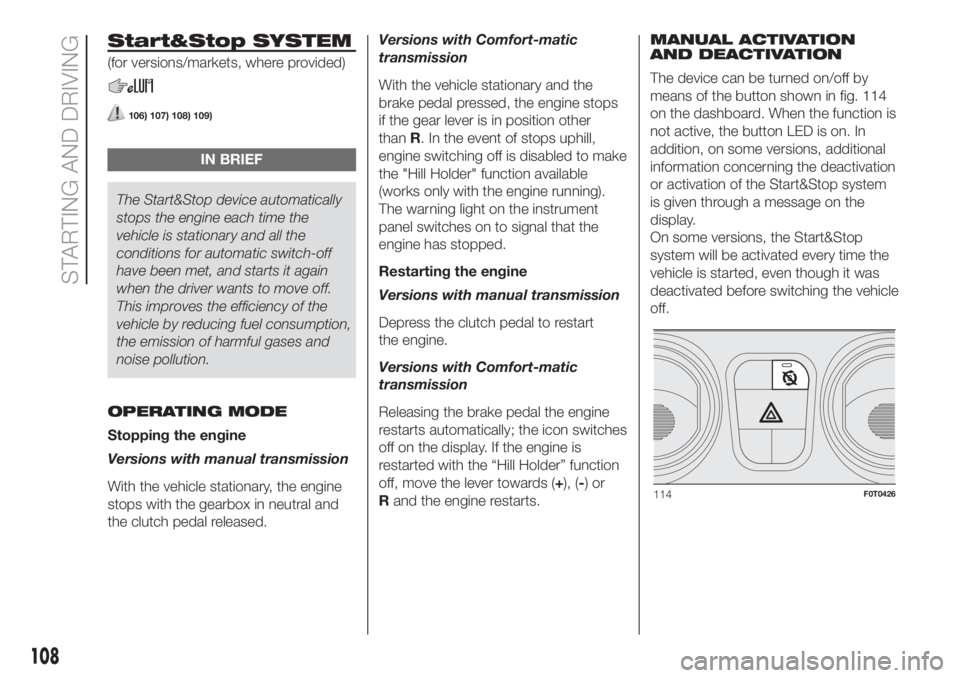

The device can be turned on/off by

means of the button shown in fig. 114

on the dashboard. When the function is

not active, the button LED is on. In

addition, on some versions, additional

information concerning the deactivation

or activation of the Start&Stop system

is given through a message on the

display.

On some versions, the Start&Stop

system will be activated every time the

vehicle is started, even though it was

deactivated before switching the vehicle

off.

114F0T0426

108

STARTING AND DRIVING

Page 111 of 220

SAFETY FUNCTIONS

In engine cut-out conditions through

the Start&Stop system, if the driver

unfastens his/her seat belt and opens

the driver's door or the passenger door,

the engine can be restarted only by

using the key. The driver is notified of

this condition by a buzzer, through the

instrument panel warning light fig.

115 flashing and, where provided, by a

message in the display.

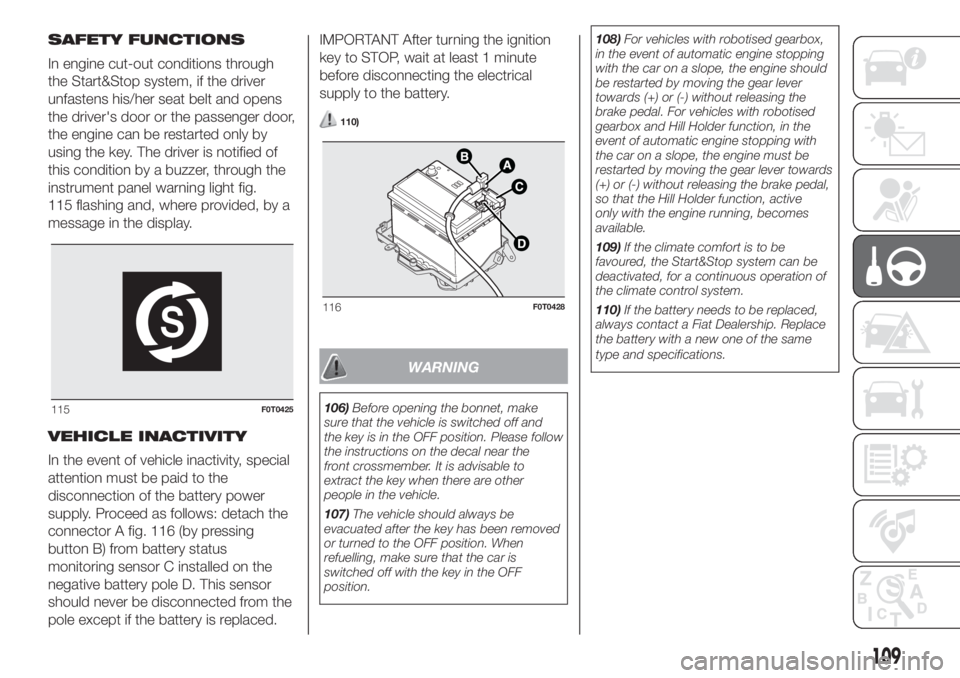

VEHICLE INACTIVITY

In the event of vehicle inactivity, special

attention must be paid to the

disconnection of the battery power

supply. Proceed as follows: detach the

connector A fig. 116 (by pressing

button B) from battery status

monitoring sensor C installed on the

negative battery pole D. This sensor

should never be disconnected from the

pole except if the battery is replaced.IMPORTANT After turning the ignition

key to STOP, wait at least 1 minute

before disconnecting the electrical

supply to the battery.

110)

WARNING

106)Before opening the bonnet, make

sure that the vehicle is switched off and

the key is in the OFF position. Please follow

the instructions on the decal near the

front crossmember. It is advisable to

extract the key when there are other

people in the vehicle.

107)The vehicle should always be

evacuated after the key has been removed

or turned to the OFF position. When

refuelling, make sure that the car is

switched off with the key in the OFF

position.108)For vehicles with robotised gearbox,

in the event of automatic engine stopping

with the car on a slope, the engine should

be restarted by moving the gear lever

towards (+) or (-) without releasing the

brake pedal. For vehicles with robotised

gearbox and Hill Holder function, in the

event of automatic engine stopping with

the car on a slope, the engine must be

restarted by moving the gear lever towards

(+) or (-) without releasing the brake pedal,

so that the Hill Holder function, active

only with the engine running, becomes

available.

109)If the climate comfort is to be

favoured, the Start&Stop system can be

deactivated, for a continuous operation of

the climate control system.

110)If the battery needs to be replaced,

always contact a Fiat Dealership. Replace

the battery with a new one of the same

type and specifications.115F0T0425

116F0T0428

109

Page 112 of 220

REFUELLING THE

VEHICLE

111)

25) 26)

PETROL ENGINES

Use unleaded petrol only, with an

octane number (R.O.N.) not lower than

95.

IMPORTANT Never introduce leaded

petrol to the tank, even in small

amounts in an emergency, as this

would damage the catalytic converter

beyond repair.

DIESEL ENGINES

Only use Diesel for motor vehicles

(EN590 specification).

Operation at low temperatures

In order to avoid these problems,

different types of diesel are distributed

according to the season: summer type,

winter type and arctic type (cold/

mountain areas).If refuelling with diesel whose

specifications are not suitable for the

usage temperature, it is advisable

to mix PETRONAS DURANCE DIESEL

ART additive in the proportions shown

on the container with the fuel. Pour

the additive into the tank before the

fuel.

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel fuel.

In this case, it is also advisable to keep

the tank over 50% full.

REFUELLING CAPACITY

To ensure that you fill the tank

completely, top up twice after the first

click of the fuel supply gun. Further

top-ups could cause faults in the fuel

feeding system.

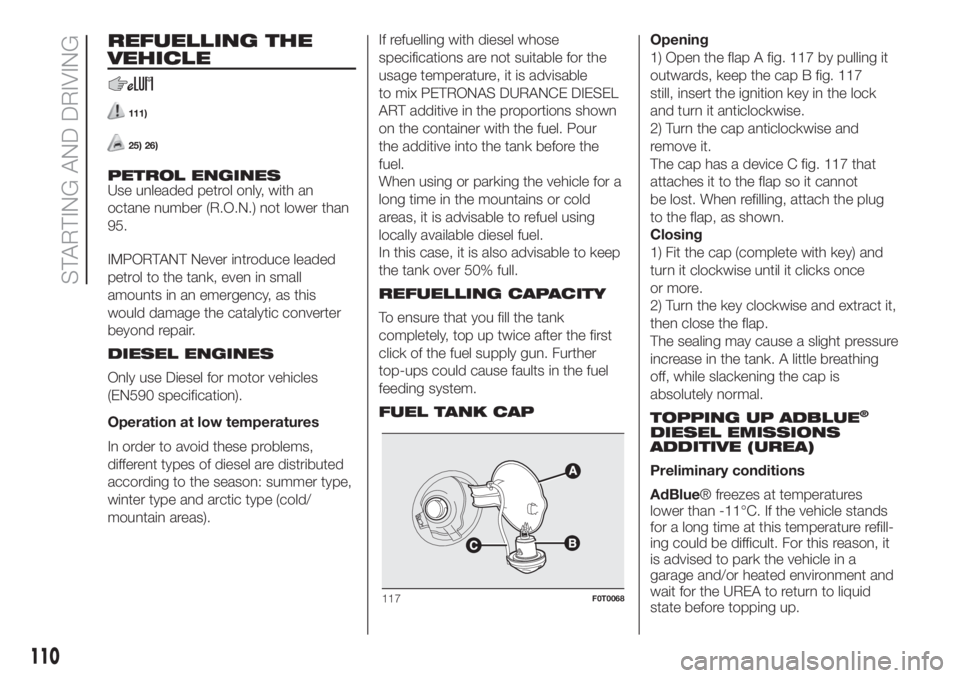

FUEL TANK CAPOpening

1) Open the flap A fig. 117 by pulling it

outwards, keep the cap B fig. 117

still, insert the ignition key in the lock

and turn it anticlockwise.

2) Turn the cap anticlockwise and

remove it.

The cap has a device C fig. 117 that

attaches it to the flap so it cannot

be lost. When refilling, attach the plug

to the flap, as shown.

Closing

1) Fit the cap (complete with key) and

turn it clockwise until it clicks once

or more.

2) Turn the key clockwise and extract it,

then close the flap.

The sealing may cause a slight pressure

increase in the tank. A little breathing

off, while slackening the cap is

absolutely normal.

TOPPING UP ADBLUE

®

DIESEL EMISSIONS

ADDITIVE (UREA)

Preliminary conditions

AdBlue® freezes at temperatures

lower than -11°C. If the vehicle stands

for a long time at this temperature refill-

ing could be difficult. For this reason, it

is advised to park the vehicle in a

garage and/or heated environment and

wait for the UREA to return to liquid

state before topping up.

117F0T0068

110

STARTING AND DRIVING

Page 113 of 220

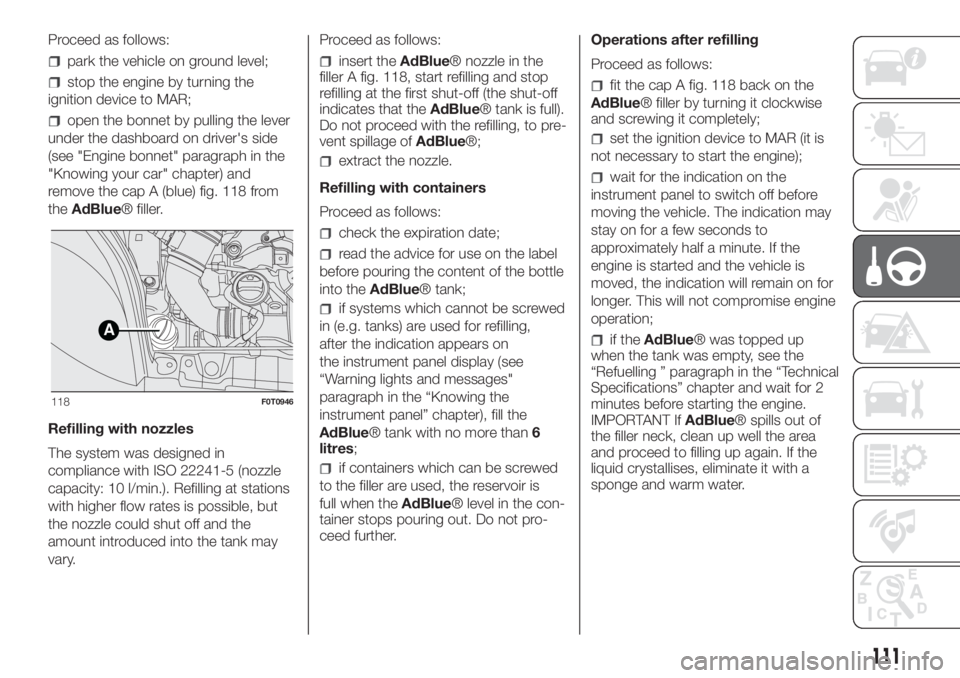

Proceed as follows:

park the vehicle on ground level;

stop the engine by turning the

ignition device to MAR;

open the bonnet by pulling the lever

under the dashboard on driver's side

(see "Engine bonnet" paragraph in the

"Knowing your car" chapter) and

remove the cap A (blue) fig. 118 from

theAdBlue® filler.

Refilling with nozzles

The system was designed in

compliance with ISO 22241-5 (nozzle

capacity: 10 l/min.). Refilling at stations

with higher flow rates is possible, but

the nozzle could shut off and the

amount introduced into the tank may

vary.Proceed as follows:

insert theAdBlue® nozzle in the

filler A fig. 118, start refilling and stop

refilling at the first shut-off (the shut-off

indicates that theAdBlue® tank is full).

Do not proceed with the refilling, to pre-

vent spillage ofAdBlue®;

extract the nozzle.

Refilling with containers

Proceed as follows:

check the expiration date;

read the advice for use on the label

before pouring the content of the bottle

into theAdBlue® tank;

if systems which cannot be screwed

in (e.g. tanks) are used for refilling,

after the indication appears on

the instrument panel display (see

“Warning lights and messages"

paragraph in the “Knowing the

instrument panel” chapter), fill the

AdBlue® tank with no more than

litres;

if containers which can be screwed

to the filler are used, the reservoir is

full when theAdBlue® level in the con-

tainer stops pouring out. Do not pro-

ceed further.Operations after refilling

Proceed as follows:

fit the cap A fig. 118 back on the

AdBlue® filler by turning it clockwise

and screwing it completely;

set the ignition device to MAR (it is

not necessary to start the engine);

wait for the indication on the

instrument panel to switch off before

moving the vehicle. The indication may

stay on for a few seconds to

approximately half a minute. If the

engine is started and the vehicle is

moved, the indication will remain on for

longer. This will not compromise engine

operation;

if theAdBlue® was topped up

when the tank was empty, see the

“Refuelling ” paragraph in the “Technical

Specifications” chapter and wait for 2

minutes before starting the engine.

IMPORTANT IfAdBlue® spills out of

the filler neck, clean up well the area

and proceed to filling up again. If the

liquid crystallises, eliminate it with a

sponge and warm water.A

118F0T0946

111

6

Page 114 of 220

IMPORTANT

DO NOT EXCEED THE

MAXIMUM LEVEL: this could cause

damage to the reservoir. UREA

freezes at under -11 °C. Although

the system is designed to operate

below the freezing point of the

UREA, it is advisable not to fill the

tank beyond the maximum level

because if the UREA freezes the

system can be damaged. Follow the

instructions in the “Topping up

AdBlue® diesel emissions additive

(UREA)” paragraph in this chapter.

If the UREA is spilled on painted

surfaces or aluminium, immediately

clean the area with water and use

absorbent material to collect the

fluid that has been spilled on the

ground.

Do not try to start the engine if

UREA was accidentally added to

the Diesel fuel tank, this can result

in serious engine damage, contact

a Fiat Dealership.

Do not add additives or other

fluids to AdBlue®, doing so could

damage the system.

The use of non-conforming or

degraded AdBlue® may lead to

indications appearing on the instru-

ment panel display (see “Warning

lights and messages" paragraph in

the “Knowing the instrument panel”

chapter).

Never pour AdBlue® into

another container: it could be con-

taminated.

In case of damage to the

sewage system of exhaust gas

resulting from the use of additives /

tap water, the introduction of diesel

fuel, or at least by not fulfilling the

requirements, the warranty expires.

If the AdBlue® runs out, see

“Warning lights and messages"

paragraph in the “Knowing the

instrument panel” chapter to con-

tinue using the vehicle normally.

AdBlue® (UREA) storage

AdBlue® (UREA) is a very stable prod-

uct with a long shelf life. Stored at tem-

peratures LOWER than 32 °C, it has a

shelf life of at least one year.

Follow the instructions on the label of

the container.

112)

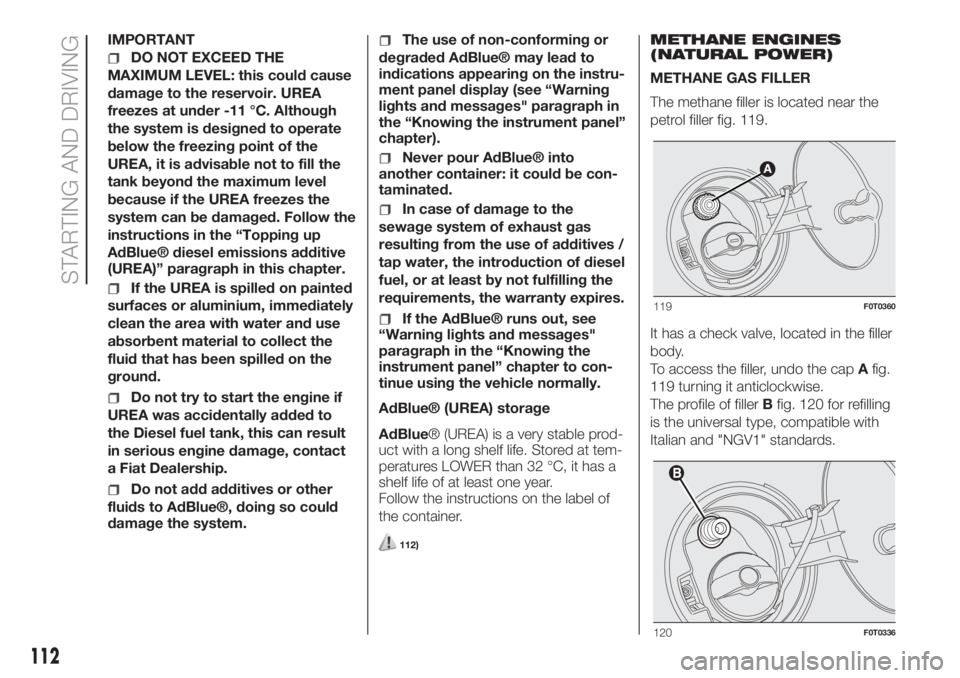

METHANE ENGINES

(NATURAL POWER)

METHANE GAS FILLER

The methane filler is located near the

petrol filler fig. 119.

It has a check valve, located in the filler

body.

To access the filler, undo the capAfig.

119 turning it anticlockwise.

The profile of fillerBfig. 120 for refilling

is the universal type, compatible with

Italian and "NGV1" standards.

119F0T0360

120F0T0336

112

STARTING AND DRIVING

Page 116 of 220

WARNING

111)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

112)If

AdBlue® overheats for a pro-

longed period inside the tank to over 50 °C

(for example, due to direct solar irradiation),

AdBlue® can decompose ammonia

vapours. Ammonia vapours have a pungent

odour when the cap of the

AdBlue®tank

is unscrewed, therefore be careful not to

inhale any ammonia vapours in the tank

outlet. In this concentration, however, the

ammonia vapors are not harmful or danger-

ous to health.

WARNING

25)For diesel engines, use only diesel fuel

for motor vehicles in accordance with

EN590 European specifications. The use of

other products or mixtures may damage

the engine beyond repair and

consequently invalidate the warranty, due

to the damage caused. If you accidentally

introduce other types of fuel into the tank,

do not start the engine. Empty the tank.

If the engine has been run for even an

extremely limited amount of time, you must

not only drain the fuel tank, but the rest of

the supply circuit as well.26)You must not open the right sliding side

door with the fuel cap open while

refuelling. Check that the fuel cap is closed

while opening/closing the sliding side

door.

27)Methane refuelling stations are not

authorised to refill the cylinders when the

inspection date has expired. The check

valve prevents the methane from flowing

back to the fuel filler.

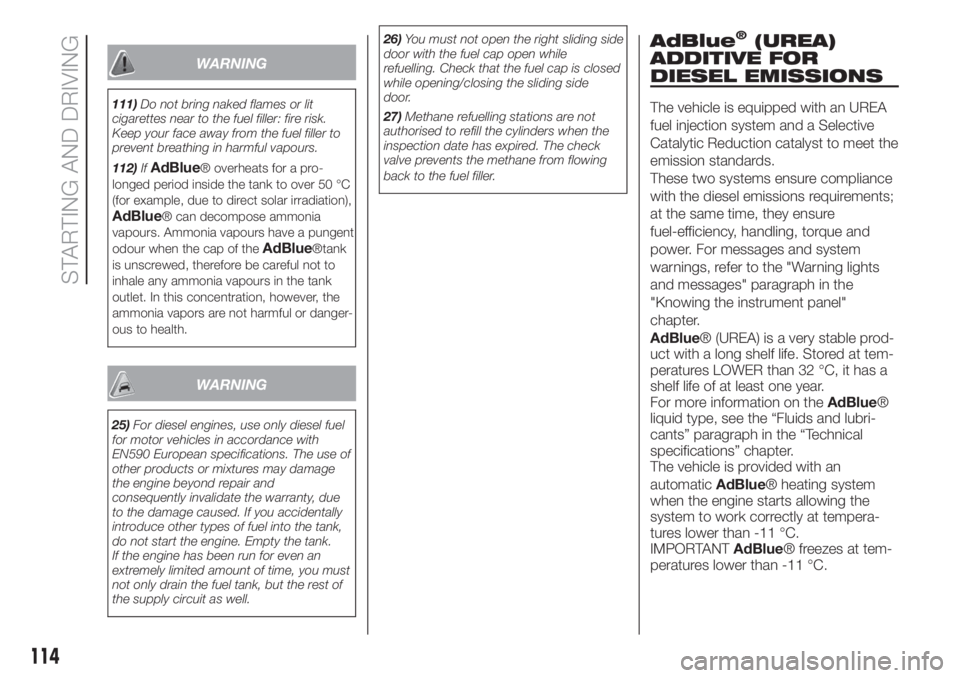

AdBlue®(UREA)

ADDITIVE FOR

DIESEL EMISSIONS

The vehicle is equipped with an UREA

fuel injection system and a Selective

Catalytic Reduction catalyst to meet the

emission standards.

These two systems ensure compliance

with the diesel emissions requirements;

at the same time, they ensure

fuel-efficiency, handling, torque and

power. For messages and system

warnings, refer to the "Warning lights

and messages" paragraph in the

"Knowing the instrument panel"

chapter.

AdBlue® (UREA) is a very stable prod-

uct with a long shelf life. Stored at tem-

peratures LOWER than 32 °C, it has a

shelf life of at least one year.

For more information on theAdBlue®

liquid type, see the “Fluids and lubri-

cants” paragraph in the “Technical

specifications” chapter.

The vehicle is provided with an

automaticAdBlue® heating system

when the engine starts allowing the

system to work correctly at tempera-

tures lower than -11 °C.

IMPORTANTAdBlue® freezes at tem-

peratures lower than -11 °C.

114

STARTING AND DRIVING

Page 120 of 220

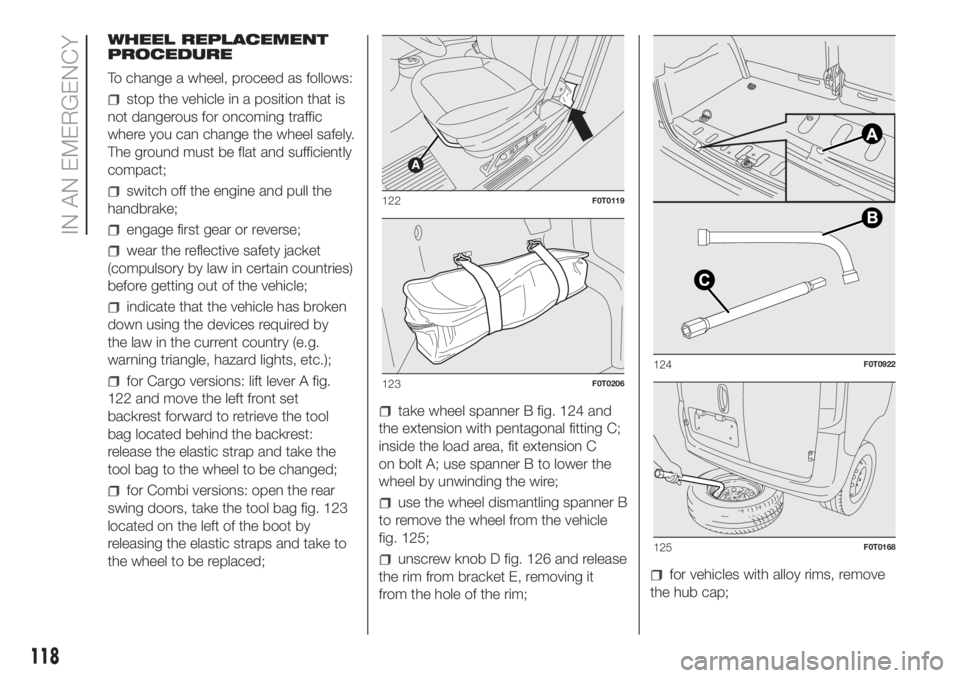

WHEEL REPLACEMENT

PROCEDURE

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

for Cargo versions: lift lever A fig.

122 and move the left front set

backrest forward to retrieve the tool

bag located behind the backrest:

release the elastic strap and take the

tool bag to the wheel to be changed;

for Combi versions: open the rear

swing doors, take the tool bag fig. 123

located on the left of the boot by

releasing the elastic straps and take to

the wheel to be replaced;

take wheel spanner B fig. 124 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

use the wheel dismantling spanner B

to remove the wheel from the vehicle

fig. 125;

unscrew knob D fig. 126 and release

the rim from bracket E, removing it

from the hole of the rim;for vehicles with alloy rims, remove

the hub cap;

122F0T0119

123F0T0206

124F0T0922

125F0T0168

118

IN AN EMERGENCY

Page 123 of 220

117)The space-saver wheel (for

versions/markets, where provided) is

specific to your vehicle, do not use it on

other models, or use the space-saver

wheel of other models on your vehicle. The

space-saver wheel must only be used in

the event of an emergency. Never use it for

more than strictly necessary and never

exceed 80 km/h. "Warning! For temporary

use only! 80km/h max! Replace with

standard wheel as soon as possible. Never

remove or cover the sticker on the

space-saver wheel. Never apply a wheel

cap on a space-saver wheel. The driving

characteristics of the vehicle will be

modified with the space-saver wheel fitted.

Avoid violent acceleration and braking,

abrupt steering and fast cornering.

118)Use your hazard lights, warning

triangle, etc to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. If you are on

a slope or uneven surface, place wedges

or other suitable objects under the wheels

to secure the vehicle. Have the wheel

repaired and refitted as soon as possible.

Do not apply grease to the bolt threads

before fitting: they could come unscrewed.119)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other

use, e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change summer/

winter wheels and vice versa: we advise

you to contact a Fiat Dealership. Never go

under the raised vehicle: use it only in

the positions indicated. Do not use the jack

for loads higher than the one shown on

its label. Never start the engine with vehicle

raised. If the vehicle is raised more than

necessary, everything can become more

unstable, with the risk of the vehicle

dropping violently. Thus, lift the vehicle only

as needed in order to access the spare

wheel.

120)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

space-saver wheel pressures regularly,

referring to the values shown in the

"Technical data" chapter.

WARNING

28)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw"

and joints) can also cause injuries: do not

touch them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

29)Contact a Fiat Dealership as soon as

possible to have the correct tightening

of the fixing bolts checked.

121

Page 124 of 220

FIX&GO

AUTOMATIC KIT

121) 122)

30)

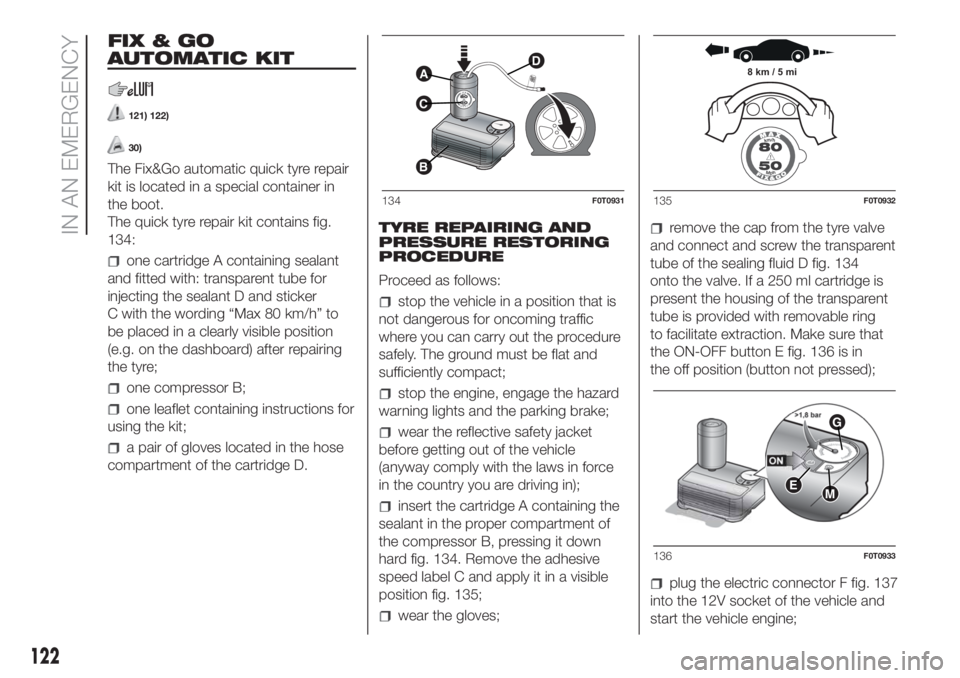

The Fix&Go automatic quick tyre repair

kit is located in a special container in

the boot.

The quick tyre repair kit contains fig.

134:

one cartridge A containing sealant

and fitted with: transparent tube for

injecting the sealant D and sticker

C with the wording “Max 80 km/h” to

be placed in a clearly visible position

(e.g. on the dashboard) after repairing

the tyre;

one compressor B;

one leaflet containing instructions for

using the kit;

a pair of gloves located in the hose

compartment of the cartridge D.TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

Proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can carry out the procedure

safely. The ground must be flat and

sufficiently compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the vehicle

(anyway comply with the laws in force

in the country you are driving in);

insert the cartridge A containing the

sealant in the proper compartment of

the compressor B, pressing it down

hard fig. 134. Remove the adhesive

speed label C and apply it in a visible

position fig. 135;

wear the gloves;

remove the cap from the tyre valve

and connect and screw the transparent

tube of the sealing fluid D fig. 134

onto the valve. If a 250 ml cartridge is

present the housing of the transparent

tube is provided with removable ring

to facilitate extraction. Make sure that

the ON-OFF button E fig. 136 is in

the off position (button not pressed);

plug the electric connector F fig. 137

into the 12V socket of the vehicle and

start the vehicle engine;

A

C

B

D

134F0T0931

8 km / 5 mi

135F0T0932

EM

G

136F0T0933

122

IN AN EMERGENCY