stop start FIAT FREEMONT 2011 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2011, Model line: FREEMONT, Model: FIAT FREEMONT 2011Pages: 267, PDF Size: 5.16 MB

Page 194 of 267

vehicle has tires of a different size than the size indi-

cated on the vehicle placard or tire inflation pressure

label, you should determine the proper tire inflation

pressure for those tires.)

As an added safety feature, your vehicle has been

equipped with a tire pressure monitoring system

(TPMS) that illuminates a low tire pressure telltale

when one or more of your tires is significantly under-

inflated. Accordingly, when the low tire pressure tell-

tale light illuminates, you should stop and check your

tires as soon as possible, and inflate them to the proper

pressure. Driving on a significantly under-inflated tire

causes the tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency and tire

tread life, and may affect the vehicle’s handling and

stopping ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s respon-

sibility to maintain correct tire pressure, even if under-

inflation has not reached the level to trigger illumina-

tion of the TPMS low tire pressure telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is

not operating properly. The TPMS malfunction indica-

tor is combined with the low tire pressure telltale.

When the system detects a malfunction, the telltale

will flash for approximately one minute and then re-

main continuously illuminated. This sequence will con-

tinue upon subsequent vehicle start-ups as long as the

malfunction exists. When the malfunction indicator isilluminated, the system may not be able to detect or

signal low tire pressure as intended. TPMS malfunctions

may occur for a variety of reasons, including the instal-

lation of replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from functioning

properly. Always check the TPMS malfunction telltale

light after replacing one or more tires or wheels on

your vehicle to ensure that the replacement or alter-

nate tires and wheels allow the TPMS to continue to

function properly.

The TPMS has been optimized for the

original equipment tires and wheels.

TPMS pressures and warning have been

established for the tire size equipped on your

vehicle. Undesirable system operation or sensor

damage may result when using replacement

equipment that is not of the same size, type,

and/or style.Aftermarket wheels can cause sensor

damage. Do not use aftermarket tire sealants or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result . (Re-

fer to “Tire Inflation Pressures” under “Tires —

General Information” and to “Tire Pressure Moni-

tor System (TPMS)” in “Technical Specifications”

for further information).

10. Seat Belt Reminder Light When the ignition switch is first turned to ON/

RUN, this light will turn on for four to eight

seconds as a bulb check. During the bulb check,

187KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVINGWARNING

LIGHTS AND

MESSAGESIN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 195 of 267

if the driver's seat belt is unbuckled, a chime will sound.

After the bulb check or when driving, if the driver seat

belt remains unbuckled, the Seat Belt Warning Light

will flash or remain on continuously. Refer to “Occu-

pant Restraints” in “Safety” for further information.

11. Brake Warning LightThis light monitors various brake functions,

including brake fluid level and parking brake

application. If the brake light turns on it may

indicate that the parking brake is applied, that

the brake fluid level is low, or that there is a problem

with the anti-lock brake system reservoir.

If the light remains on when the parking brake has been

disengaged, and the fluid level is at the full mark on the

master cylinder reservoir, it indicates a possible brake

hydraulic system malfunction or that a problem with

the Brake Booster has been detected by the Anti-Lock

Brake System (ABS) / Electronic Stability Program

(ESP) system. In this case, the light will remain on until

the condition has been corrected. If the problem is

related to the brake booster, the ABS pump will run

when applying the brake and a brake pedal pulsation

may be felt during each stop.

The dual brake system provides a reserve braking

capacity in the event of a failure to a portion of the

hydraulic system. A leak in either half of the dual brake

system is indicated by the Brake Warning Light, which

will turn on when the brake fluid level in the master

cylinder has dropped below a specified level.

The light will remain on until the cause is corrected. NOTE:

The light may flash momentarily during sharp

cornering maneuvers, which change fluid level condi-

tions. The vehicle should have service performed, and

the brake fluid level checked.

If brake failure is indicated, immediate repair is neces-

sary.

WARNING!

Driving a vehicle with the red brake light

on is dangerous. Part of the brake sys-

tem may have failed. It will take longer to stop

the vehicle. You could have a collision. Have the

vehicle checked immediately.

Vehicles equipped with the Anti-Lock Brake System

(ABS), are also equipped with Electronic Brake Force

Distribution (EBD). In the event of an EBD failure, the

Brake Warning Light will turn on along with the ABS

Light. Immediate repair to the ABS system is required.

Operation of the Brake Warning Light can be checked

by turning the ignition switch from the OFF position to

the ON/RUN position. The light should illuminate for

approximately two seconds. The light should then turn

off unless the parking brake is applied or a brake fault is

detected. If the light does not illuminate, have the light

inspected by an authorized dealer.

The light also will turn on when the parking brake is

applied with the ignition switch in the ON/RUN posi-tion.

188

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVINGWARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 210 of 267

4. Firmly grasp the bulb by the two side latches andsqueeze them together to unlock the bulb from the

back of the lamp housing.

5. Pull the bulb straight out from the keyed opening in the housing

6. Remove the bulb from the connector socket and install the replacement bulb.

7. Align the index tabs of the replacement rear fog lamp bulb/socket assembly with the slots in the

collar of the bulb opening on the back of the lamphousing.

8. Insert bulb into the lamp housing until the index tabs are engaged in the slots of the collar.

9. Firmly and evenly push the bulb straight into the lamp housing until both side latches lock firmly into

place.

10. Reinstall the fog lamp housing.

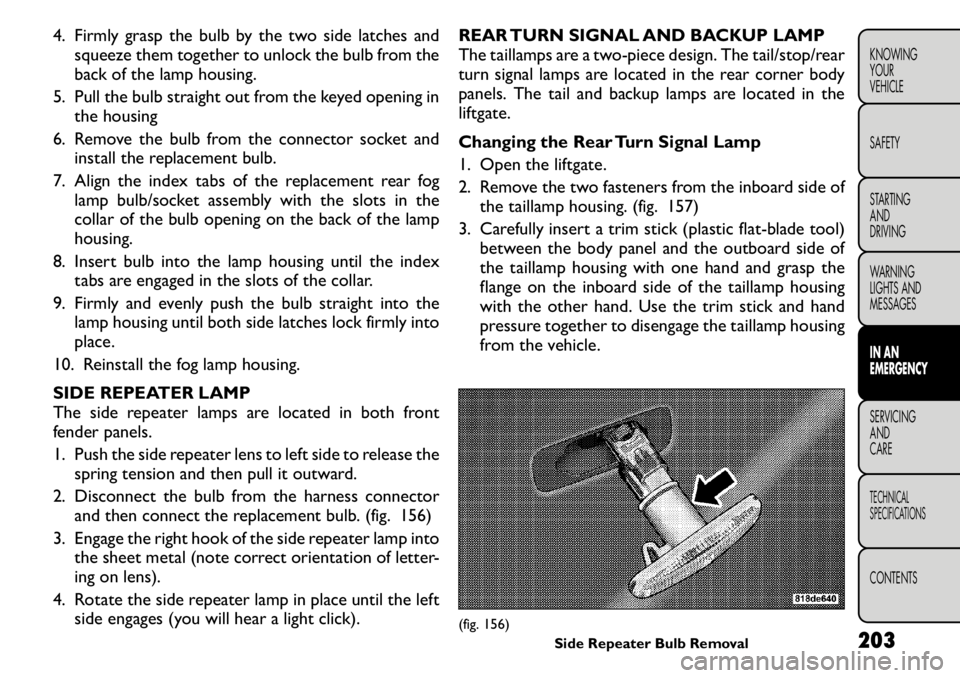

SIDE REPEATER LAMP

The side repeater lamps are located in both front

fender panels.

1. Push the side repeater lens to left side to release the spring tension and then pull it outward.

2. Disconnect the bulb from the harness connector and then connect the replacement bulb. (fig. 156)

3. Engage the right hook of the side repeater lamp into the sheet metal (note correct orientation of letter-

ing on lens).

4. Rotate the side repeater lamp in place until the left side engages (you will hear a light click). REAR TURN SIGNAL AND BACKUP LAMP

The taillamps are a two-piece design. The tail/stop/rear

turn signal lamps are located in the rear corner body

panels. The tail and backup lamps are located in the

liftgate.

Changing the Rear Turn Signal Lamp

1. Open the liftgate.

2. Remove the two fasteners from the inboard side of

the taillamp housing. (fig. 157)

3. Carefully insert a trim stick (plastic flat-blade tool) between the body panel and the outboard side of

the taillamp housing with one hand and grasp the

flange on the inboard side of the taillamp housing

with the other hand. Use the trim stick and hand

pressure together to disengage the taillamp housing

from the vehicle.

(fig. 156) Side Repeater Bulb Removal 203

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING

LIGHTS AND

MESSAGESIN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 217 of 267

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand, or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around

the front wheels. Then shift back and forth between

DRIVE/1st and REVERSE. Using the least accelerator

pedal pressure to maintain the rocking motion without

spinning the wheels is most effective.

Racing the engine or spinning the wheels

may lead to transmission overheating

and failure. Allow the engine to idle with

the shift lever in NEUTRAL for at least one min-

ute after every five rocking-motion cycles. This

will minimize overheating and reduce the risk of

transmission failure during prolonged efforts to

free a stuck vehicle.

NOTE: If your vehicle is equipped with

Traction Control, turn the system OFF be-

fore attempting to “rock” the vehicle. Refer

to “Electronic Stability Program (ESP)” in

“Knowing Your Vehicle” for further information.

When “rocking” a stuck vehicle by mov-

ing between DRIVE/1st and REVERSE, do

not spin the wheels faster than 24 km/h,

or drivetrain damage may result .

Revving the engine or spinning the wheels too

fast may lead to transmission overheating and

failure. It can also damage the tires. Do not spin

the wheels above 48 km/h while in gear (no trans-

mission shifting occurring).

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure, of the

axle and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels faster

than 48 km/h or for longer than 30 seconds

continuously without stopping when you are

stuck and do not let anyone near a spinning

wheel, no matter what the speed.

210

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 219 of 267

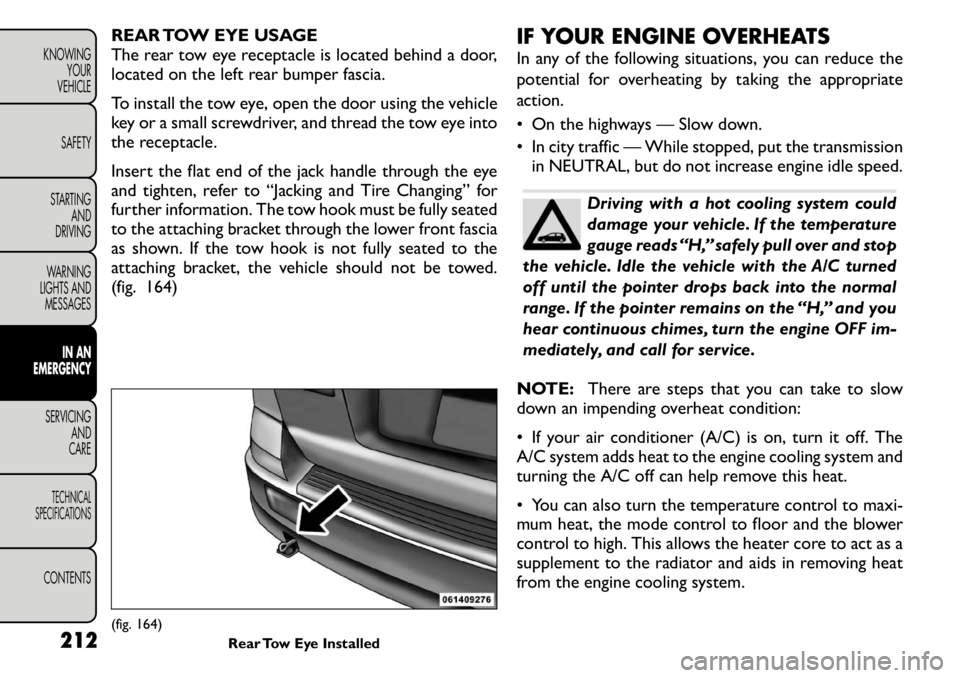

REAR TOW EYE USAGE

The rear tow eye receptacle is located behind a door,

located on the left rear bumper fascia.

To install the tow eye, open the door using the vehicle

key or a small screwdriver, and thread the tow eye into

the receptacle.

Insert the flat end of the jack handle through the eye

and tighten, refer to “Jacking and Tire Changing” for

further information. The tow hook must be fully seated

to the attaching bracket through the lower front fascia

as shown. If the tow hook is not fully seated to the

attaching bracket, the vehicle should not be towed.

(fig. 164)IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate

action.

• On the highways — Slow down.

• In city traffic — While stopped, put the transmission

in NEUTRAL, but do not increase engine idle speed.

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads “H,” safely pull over and stop

the vehicle. Idle the vehicle with the A/C turned

off until the pointer drops back into the normal

range. If the pointer remains on the “H,” and you

hear continuous chimes, turn the engine OFF im-

mediately, and call for service.

NOTE: There are steps that you can take to slow

down an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The

A/C system adds heat to the engine cooling system and

turning the A/C off can help remove this heat.

• You can also turn the temperature control to maxi-

mum heat, the mode control to floor and the blower

control to high. This allows the heater core to act as a

supplement to the radiator and aids in removing heat

from the engine cooling system.

(fig. 164) Rear Tow Eye Installed

212

KNOWING

YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 226 of 267

MAINTENANCE PROCEDURES

The pages that follow contain therequiredmainte-

nance services determined by the engineers who de-

signed your vehicle.

Besides those maintenance items specified in the fixed

maintenance schedule, there are other components

which may require servicing or replacement in the

future.

Failure to properly maintain your ve-

hicle or perform repairs and service when

necessary could result in more costly re-

pairs, damage to other components or negatively

impact vehicle performance. Immediately have

potential malfunctions examined by an autho-

rized dealership or qualified repair center.

Your vehicle has been built with improved fluids

that protect the performance and durability of

your vehicle and also allow extended mainte-

nance intervals. Do not use chemical flushes in

these components as the chemicals can damage

your engine, transmission, power steering or air

conditioning. Such damage is not covered by the

New Vehicle Limited Warranty. If a flush is needed

because of component malfunction, use only the

specified fluid for the flushing procedure. ENGINE OIL

Checking Oil Level – 2.0L Diesel Engine

To assure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the oil

level at regular intervals, such as every fuel stop.

The best time to check the engine oil level is about five

minutes after a fully warmed engine is shut off or

before starting the engine after it has sat overnight.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Maintain

the oil level between the MIN and MAX markings on

the dipstick. Adding 1.0 qt (1.0 l) of oil when the

reading is at the MIN mark will result in a MAX reading

on these engines.

Change Engine Oil – 2.0L Diesel Engine

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Engine Oil Viscosity – 2.0L Diesel Engine

For best performance and maximum protection under

all types of operating conditions, the manufacturer

recommends Fully Synthetic Low Ash 5W-30 engine

oils that meet the requirements of FIAT 9.55535-S1

spec and ACEA C1/C2.

Materials Added To Engine Oil

Do not add any supplemental materials, other than leak

detection dyes, to the engine oil. Engine oil is an

engineered product and its performance may be im-

paired by supplemental additives.

219

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 228 of 267

It is essential when replacing the cables

on the battery that the positive cable is

attached to the positive post and the

negative cable is attached to the negative post .

Battery posts are marked positive (+) and nega-

tive (-) and identified on the battery case. Cable

clamps should be tight on the terminal posts and

free of corrosion.

If a “fast charger ” is used while the battery is in

the vehicle, disconnect both vehicle battery cables

before connecting the charger to the battery. Do

not use a “fast charger ” to provide starting volt-

age as battery damage can result .

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This service

should include cleaning of the condenser fins and a

performance test. Drive belt tension should also be

checked at this time.Do not use chemical flushes in your air

conditioning system as the chemicals can

damage your air conditioning compo-

nents. Such damage is not covered by the New

Vehicle Limited Warranty.

WARNING!

Use only refrigerants and compressor

lubricants approved by the manufac-

turer for your air conditioning system. Some un-

approved refrigerants are flammable and can

explode, injuring you. Other unapproved refrig-

erants or lubricants can cause the system to fail,

requiring costly repairs.

The air conditioning system contains refriger-

ant under high pressure.To avoid risk of personal

injury or damage to the system, adding refriger-

ant or any repair requiring lines to be discon-

nected should be done by an experienced

technician.

Refrigerant Recovery And Recycling

R-134a Air Conditioning Refrigerant is a hydrofluoro-

carbon (HFC) that is endorsed by the Environmental

Protection Agency and is an ozone-saving product.

However, the manufacturer recommends that air con-

ditioning service be performed by authorized dealers

or other service facilities using recovery and recyclingequipment.

NOTE: Use only manufacturer approved A/C system

sealers, stop leak products, seal conditioners, com-

pressor oil, and refrigerants.

A/C AIR FILTER — IF EQUIPPED

Refer to the “Maintenance Schedule” for the proper

maintenance intervals. 221

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 232 of 267

rating information can be found on most washer fluid

containers.

The fluid reservoir will hold nearly 4 Liters of washer

fluid when the message “LoWASH” appears in the

instrument cluster.

WARNING!

Commercially available windshield

washer solvents are flammable. They

could ignite and burn you. Care must be exer-

cised when filling or working around the washer

solution.

EXHAUST SYSTEM

The best protection against carbon monoxide entry

into the vehicle body is a properly maintained engine

exhaust system.

Whenever a change is noticed in the sound of the

exhaust system, when exhaust fumes can be detected

inside the vehicle, or when the underside or rear of the

vehicle is damaged, have a competent technician in-

spect the complete exhaust system and adjacent body

areas for broken, damaged, deteriorated, or misposi-

tioned parts. Open seams or loose connections could

permit exhaust fumes to seep into the passenger com-

partment. In addition, inspect the exhaust system each

time the vehicle is raised for lubrication or oil change.

Replace as required.

WARNING!

Exhaust gases can injure or kill. They

contain carbon monoxide (CO), which is

colorless and odorless. Breathing it can make you

unconscious and can eventually poison you. To

avoid breathing CO, refer to “Safety Tips/Exhaust

Gas” in “Safety” for further information.

NOTE: Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

WARNING!

A hot exhaust system can start a fire if

you park over materials that can burn.

Such materials might be grass or leaves coming

into contact with your exhaust system. Do not

park or operate your vehicle in areas where your

exhaust system can contact anything that canburn.

In unusual situations involving grossly malfunctioning

engine operation, a scorching odor may indicate severe

and abnormal catalyst overheating. If this occurs, safely

bring the vehicle to a complete stop, shut the engine

OFF, and allow the vehicle to cool. Thereafter, obtain

service, including a tune-up to manufacturer's specifi-

cations immediately.

225

KNOWING

YOURVEHICLE SAFETY

STARTING ANDDRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 235 of 267

Coolant Level

The radiator normally remains completely full, so there

is no need to remove the radiator cap unless checking

for coolant freeze point or replacing coolant. Advise

your service attendant of this. As long as the engine

operating temperature is satisfactory, the coolant

bottle need only be checked once a month. When

additional coolant is needed to maintain the proper

level, it should be added to the coolant bottle. Do not

overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles

(kilometers) of operation, you may observe vapor

coming from the front of the engine compartment.

This is normally a result of moisture from rain, snow, or

high humidity accumulating on the radiator and being

vaporized when the thermostat opens, allowing hot

coolant to enter the radiator.

If an examination of your engine compartment shows

no evidence of radiator or hose leaks, the vehicle may

be safely driven. The vapor will soon dissipate.

• Do not overfill the coolant recovery bottle.

• Check coolant freeze point in the radiator and in the coolant recovery bottle. If antifreeze needs to be

added, contents of coolant recovery bottle must also

be protected against freezing.

• If frequent coolant additions are required, or if the level in the coolant recovery bottle does not drop

when the engine cools, the cooling system should be

pressure tested for leaks. • Make sure that the radiator and coolant recovery

bottle overflow hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Win- ter operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs

may result in unsatisfactory coolant performance,

poor gas mileage, and increased emissions.

BRAKE SYSTEM

In order to assure brake system performance, all brake

system components should be inspected periodically.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake fail-

ure and possibly an accident . Driving

with your foot resting or riding on the brake

pedal can result in abnormally high brake tem-

peratures, excessive lining wear, and possible

brake damage.You would not have your full brak-

ing capacity in an emergency.

Master Cylinder – Brake Fluid Level Check

Check the fluid level in the master cylinder immediately

if the “Brake Warning Light” indicates system failure.

Check the fluid level in the master cylinder when

performing underhood services.

228

KNOWING

YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCYSERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS

Page 245 of 267

LIMITED-USE SPARE – IF EQUIPPED

The limited-use spare tire is for temporary emergency

use only. This tire is identified by a label located on the

limited-use spare wheel. This label contains the driving

limitations for this spare. This tire may look like the

original equipped tire on the front or rear axle of your

vehicle, but it is not. Installation of this limited-use

spare tire affects vehicle handling. Since it is not the

same as your original equipment tire, replace (or re-

pair) the original equipment tire and reinstall on the

vehicle at the first opportunity.

WARNING!

Limited-use spares are for emergency

use only. Installation of this limited-use

spare tire affects vehicle handling.With this tire,

do not drive more than the speed listed on the

limit-use spare wheel. Keep inflated to the cold

tire inflation pressure listed on your Tire and

Loading Information Placard located on the driv-

er ’s side door opening. Replace (or repair) the

original equipment tire at the first opportunity

and reinstall it on your vehicle. Failure to do so

could result in loss of vehicle control.

TIRE SPINNING

When stuck in mud, sand, snow, or icy conditions, do

not spin your vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds continuously

without stopping. Refer to “Freeing A Stuck Vehicle” in “In An Emer-

gency” for further information.

WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause tire damage or failure. A tire

could explode and injure someone. Do not spin

your vehicle's wheels faster than 48 km/h or for

more than 30 seconds continuously when you are

stuck, and do not let anyone near a spinning

wheel, no matter what the speed.

TREAD WEAR INDICATORS

Tread wear indicators are in the original equipment

tires to help you in determining when your tires should

be replaced. (fig. 172)

These indicators are molded into the bottom of the

tread grooves. They will appear as bands when the

tread depth becomes 2 mm. When the tread is worn to

the tread wear indicators, the tire should be replaced.

LIFE OF TIRE

The service life of a tire is dependent upon varying

factors including but not limited to:

• Driving style

• Tire pressure

• Distance driven

238

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARETECHNICAL

SPECIFICATIONSCONTENTS