wheel FIAT IDEA 2009 1.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: IDEA, Model: FIAT IDEA 2009 1.GPages: 210, PDF Size: 3.62 MB

Page 166 of 210

165

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

YEARLY INSPECTION

PLAN

The following yearly inspection plan is re-

commended for cars clocking less than

20,000 km a year (e.g. approximately

15.000 km):

❒check tyre conditions/wear and pres-

sure (included spare wheel)

❒check lighting system operation (head-

lights, direction indicators, hazard li-

ghts, boot, passenger compartment,

instrument panel warning lights, etc.)

❒check windscreen wiper/washer

(nozzle direction and blade wear)

❒check front disk brake pad conditions

and wear;

❒visually inspect the conditions of: en-

gine, gearbox, flexible and stiff piping

(exhaust, fuel feed, brakes), rubber

parts (boots, sleeves, bushings, etc.)

❒check cleanness of locks, bonnet and

boot and lever cleanness and lubrica-

tion

❒check battery charge;

❒visually check the various drive belt

conditions;

❒check and top up liquids if required

(engine coolant, brakes, windscreen

washer, battery, etc.)

❒change engine oil;

❒change engine oil filter;

❒change pollen filter (where provided).

ADDITIONAL

INTERVENTIONS

Every 1,000 km or before long journeys,

check and, if necessary, top up:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions.

Every 3,000 km check and, if necessary,

top up: engine oil level.

You are recommended to use FL Selenia

products, designed and produced specifi-

cally for Fiat cars (see table “Capacities”

in section “Technical specifications”).

Page 176 of 210

175

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

WHEELS AND TYRES

Check the pressure of each tyre, including

the spare wheel, approximately once

every two weeks and before setting off on

a long journey: this check must be perfor-

med with the tyre rested and cold.

It is normal for pressure to increase when

the car is used. For the correct tyre in-

flation pressure, see “Wheels” in “Tech-

nical specifications” section.

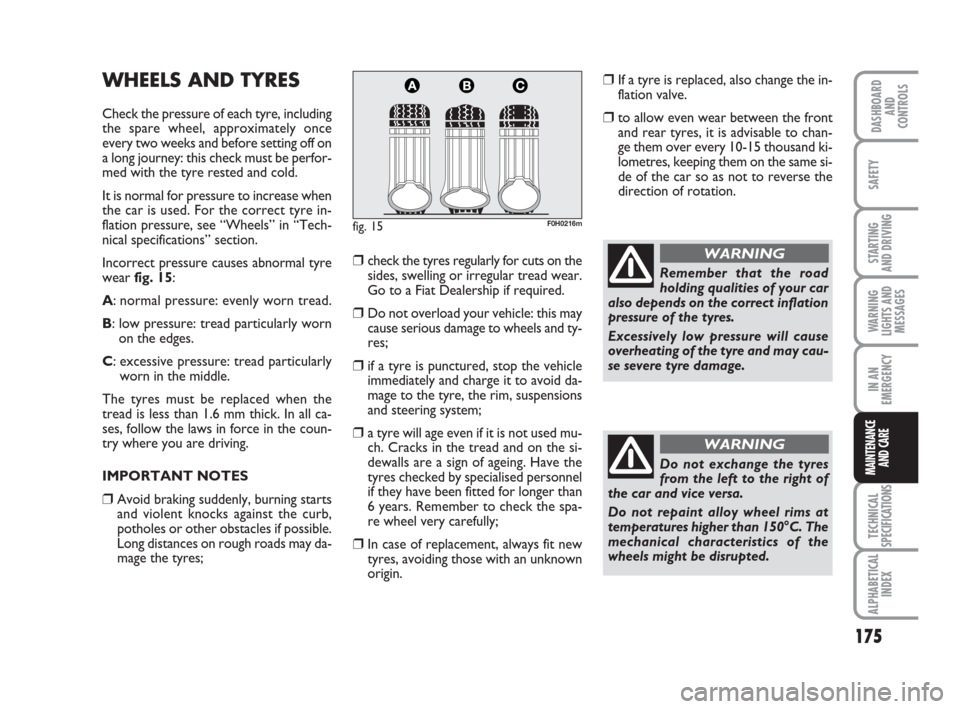

Incorrect pressure causes abnormal tyre

wearfig. 15:

A: normal pressure: evenly worn tread.

B: low pressure: tread particularly worn

on the edges.

C: excessive pressure: tread particularly

worn in the middle.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In all ca-

ses, follow the laws in force in the coun-

try where you are driving.

IMPORTANT NOTES

❒Avoid braking suddenly, burning starts

and violent knocks against the curb,

potholes or other obstacles if possible.

Long distances on rough roads may da-

mage the tyres;

❒check the tyres regularly for cuts on the

sides, swelling or irregular tread wear.

Go to a Fiat Dealership if required.

❒Do not overload your vehicle: this may

cause serious damage to wheels and ty-

res;

❒if a tyre is punctured, stop the vehicle

immediately and charge it to avoid da-

mage to the tyre, the rim, suspensions

and steering system;

❒a tyre will age even if it is not used mu-

ch. Cracks in the tread and on the si-

dewalls are a sign of ageing. Have the

tyres checked by specialised personnel

if they have been fitted for longer than

6 years. Remember to check the spa-

re wheel very carefully;

❒In case of replacement, always fit new

tyres, avoiding those with an unknown

origin.

fig. 15F0H0216m

Remember that the road

holding qualities of your car

also depends on the correct inflation

pressure of the tyres.

Excessively low pressure will cause

overheating of the tyre and may cau-

se severe tyre damage.

WARNING

Do not exchange the tyres

from the left to the right of

the car and vice versa.

Do not repaint alloy wheel rims at

temperatures higher than 150°C. The

mechanical characteristics of the

wheels might be disrupted.

WARNING

❒If a tyre is replaced, also change the in-

flation valve.

❒to allow even wear between the front

and rear tyres, it is advisable to chan-

ge them over every 10-15 thousand ki-

lometres, keeping them on the same si-

de of the car so as not to reverse the

direction of rotation.

Page 181 of 210

180

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

INTERIORS

Periodically check that water is not trap-

ped under the mats (due to water drip-

ping off shoes, umbrellas, etc.) which could

cause oxidisation of the sheet metal.

CLEANING SEATS AND FABRIC

PARTS

Remove dust with a soft brush or a va-

cuum cleaner. It is advisable to use a moi-

st brush on velvet upholstery.

Rub the seats with a sponge moistened

with a solution of water and neutral de-

tergent.

LEATHER SEATS

Remove dry dirt with a moist chamois

leather or cloth without pressing too hard.

Remove stains of liquid or grease with a

dry absorbing cloth. Do not rub. Then wi-

pe with a soft cloth or chamois leather

dipped in water and mild soap.

Use specific products for persistent stains

paying attention to instructions for use.

IMPORTANT Never use alcohol. Make

sure that the products used do not con-

tain alcohol or derivates, even in low con-

centrations. INTERIOR PLASTIC PARTS

It is advisable to clean interior parts with

a moist cloth and a solution of water and

mild soap. Use specific products for clea-

ning plastic, without solvents and specifi-

cally designed to prevent damage to the

appearance and colour of the treated parts

to remove grease and tough stains.

IMPORTANT Never use spirit or petro-

leum to clean the instrument panel tran-

sparent cover or other plastic parts.

Do not keep aerosol cans in

the car: risk of explosion. Ae-

rosol cans must not be exposed to a

temperature exceeding 50°C. When

the vehicle is exposed to sunlight, in-

ner temperature can greatly exceed

this value.

WARNING

The fabric upholstery of your

car is designed to withstand

the normal wear and tear of

your car for a long time. So-

me precautions are however needed.

Avoid prolonged rubbing against

clothing accessories, such as metal

buckles, Velcro strips and the like, whi-

ch by applying a high pressure on the

fabric in a small area could cause the

breakage of some threads and damage

the upholstery.

LEATHER STEERING

WHEEL/GEAR KNOB

These components must be cleaned with

mild soap and water only. Never use spi-

rit and/or alcohol based products. Read

the product label carefully before using

specific products for cleaning the interiors:

make sure the product does not contain

alcohol or alcohol based substances.

If window cleaner accidentally drips onto

the steering wheel or gear lever knob, wi-

pe away immediately and then wash the

concerned area with mild soap and water.

IMPORTANT Be careful when arranging

a steering wheel lock device, where ap-

plicable, to prevent damaging the leather

upholstery by rubbing.

Page 182 of 210

181

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

IDENTIFICATION DATA ................................................. 182

ENGINE CODES - BODYWORK VERSIONS ............. 184

ENGINE ................................................................................. 185

FUEL FEED/IGNITION ....................................................... 187

TRANSMISSION UNIT ...................................................... 187

BRAKES .................................................................................. 188

SUSPENSIONS ..................................................................... 188

STEERING SYSTEM ............................................................. 188

WHEELS ................................................................................. 189

DIMENSIONS ....................................................................... 193

PERFORMANCE .................................................................. 193

WEIGHTS .............................................................................. 194

CAPACITIES ......................................................................... 195

FLUIDS AND LUBRICANTS ............................................ 196

FUEL CONSUMPTION ...................................................... 198

CO

2EMISSIONS .................................................................. 199

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

Page 189 of 210

188

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

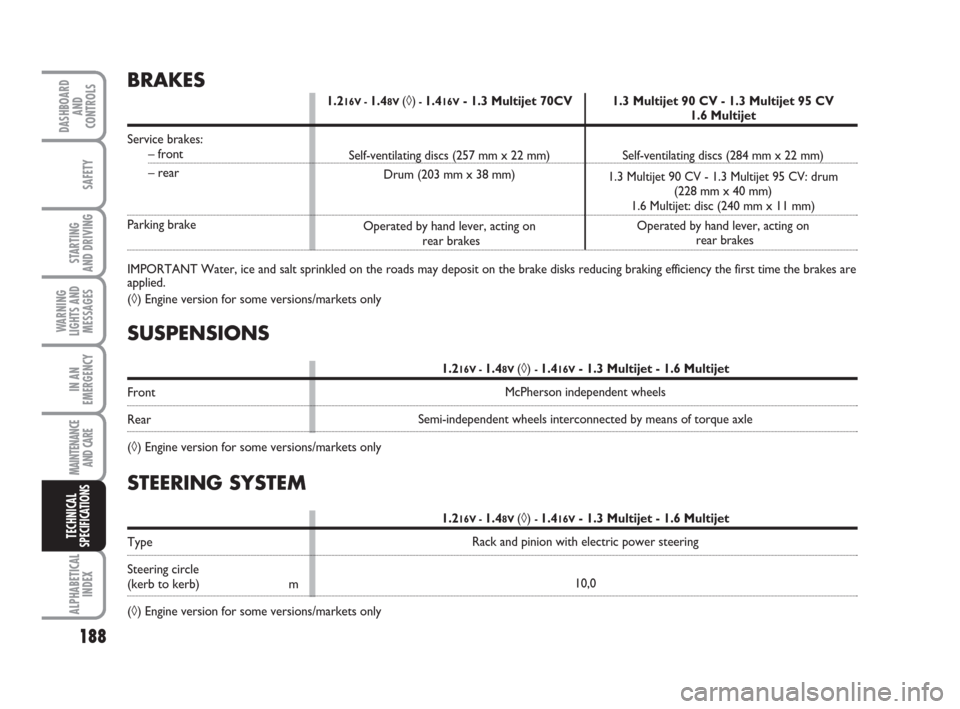

SUSPENSIONS

Front

Rear

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

McPherson independent wheels

Semi-independent wheels interconnected by means of torque axle

STEERING SYSTEM

Type

Steering circle

(kerb to kerb) m

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

Rack and pinion with electric power steering

10,0

BRAKES

Service brakes:– front

– rear

Parking brake

IMPORTANT Water, ice and salt sprinkled on the roads may deposit on the brake disks reducing braking efficiency the first time the brakes are

applied.

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊)- 1.416V- 1.3 Multijet 70CV

Self-ventilating discs (257 mm x 22 mm)

Drum (203 mm x 38 mm)

Operated by hand lever, acting on

rear brakes1.3 Multijet 90 CV - 1.3 Multijet 95 CV

1.6 Multijet

Self-ventilating discs (284 mm x 22 mm)

1.3 Multijet 90 CV - 1.3 Multijet 95 CV: drum

(228 mm x 40 mm)

1.6 Multijet: disc (240 mm x 11 mm)

Operated by hand lever, acting on

rear brakes

Page 190 of 210

189

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

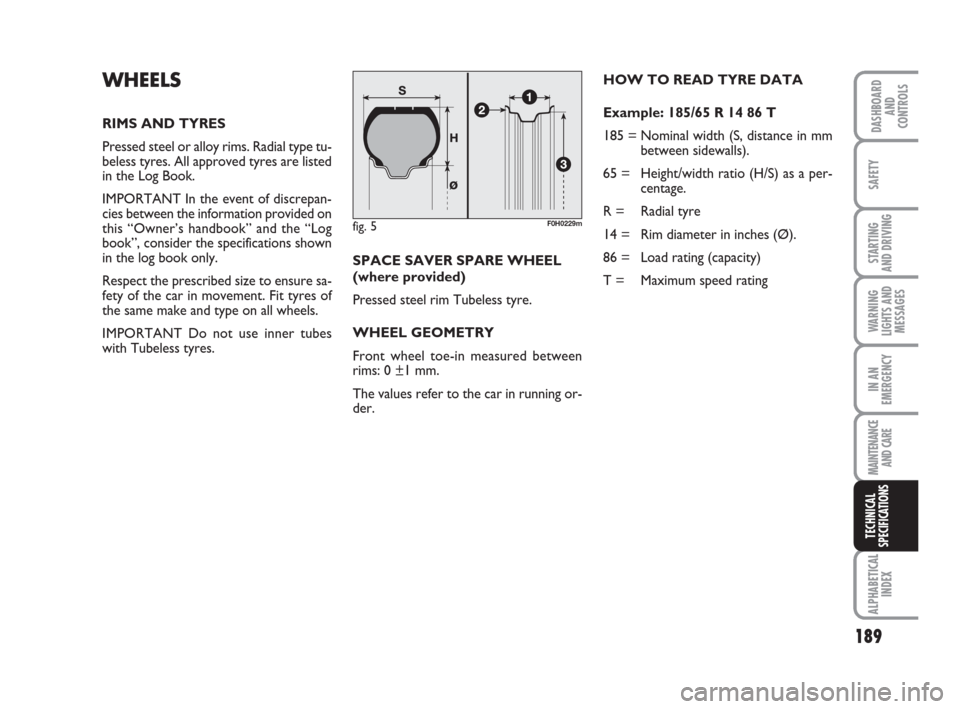

fig. 5F0H0229m

WHEELS

RIMS AND TYRES

Pressed steel or alloy rims. Radial type tu-

beless tyres. All approved tyres are listed

in the Log Book.

IMPORTANT In the event of discrepan-

cies between the information provided on

this “Owner’s handbook” and the “Log

book”, consider the specifications shown

in the log book only.

Respect the prescribed size to ensure sa-

fety of the car in movement. Fit tyres of

the same make and type on all wheels.

IMPORTANT Do not use inner tubes

with Tubeless tyres.HOW TO READ TYRE DATA

Example: 185/65 R 14 86 T

185 = Nominal width (S, distance in mm

between sidewalls).

65 = Height/width ratio (H/S) as a per-

centage.

R = Radial tyre

14 = Rim diameter in inches (Ø).

86 = Load rating (capacity)

T = Maximum speed rating SPACE SAVER SPARE WHEEL

(where provided)

Pressed steel rim Tubeless tyre.

WHEEL GEOMETRY

Front wheel toe-in measured between

rims: 0 ±1 mm.

The values refer to the car in running or-

der.

Page 191 of 210

190

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

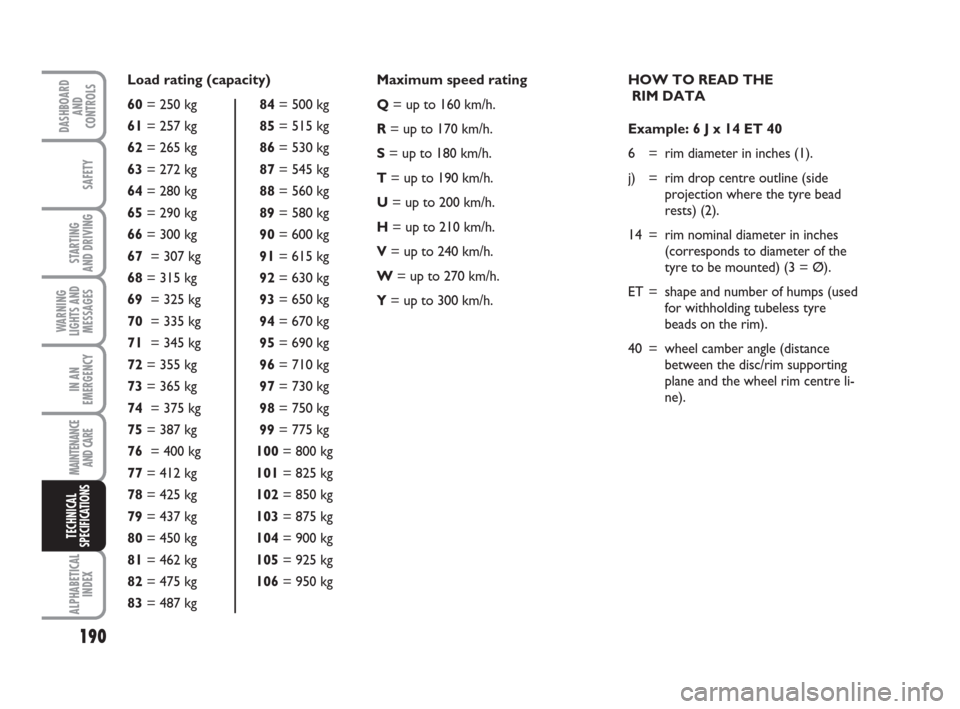

Maximum speed rating

Q= up to 160 km/h.

R= up to 170 km/h.

S= up to 180 km/h.

T= up to 190 km/h.

U= up to 200 km/h.

H= up to 210 km/h.

V= up to 240 km/h.

W= up to 270 km/h.

Y= up to 300 km/h.HOW TO READ THE

RIM DATA

Example: 6 J x 14 ET 40

6 = rim diameter in inches (1).

j) = rim drop centre outline (side

projection where the tyre bead

rests) (2).

14 = rim nominal diameter in inches

(corresponds to diameter of the

tyre to be mounted) (3 = Ø).

ET = shape and number of humps (used

for withholding tubeless tyre

beads on the rim).

40 = wheel camber angle (distance

between the disc/rim supporting

plane and the wheel rim centre li-

ne). Load rating (capacity)

60= 250 kg 84= 500 kg

61= 257 kg 85= 515 kg

62= 265 kg 86= 530 kg

63= 272 kg 87= 545 kg

64= 280 kg 88= 560 kg

65= 290 kg 89= 580 kg

66= 300 kg 90= 600 kg

67 = 307 kg 91= 615 kg

68= 315 kg 92= 630 kg

69 = 325 kg 93= 650 kg

70 = 335 kg 94= 670 kg

71 = 345 kg 95= 690 kg

72= 355 kg 96= 710 kg

73= 365 kg 97= 730 kg

74 = 375 kg 98= 750 kg

75= 387 kg 99= 775 kg

76 = 400 kg 100= 800 kg

77= 412 kg

101= 825 kg

78= 425 kg 102= 850 kg

79= 437 kg 103= 875 kg

80= 450 kg 104= 900 kg

81= 462 kg 105= 925 kg

82= 475 kg 106= 950 kg

83= 487 kg

Page 192 of 210

191

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

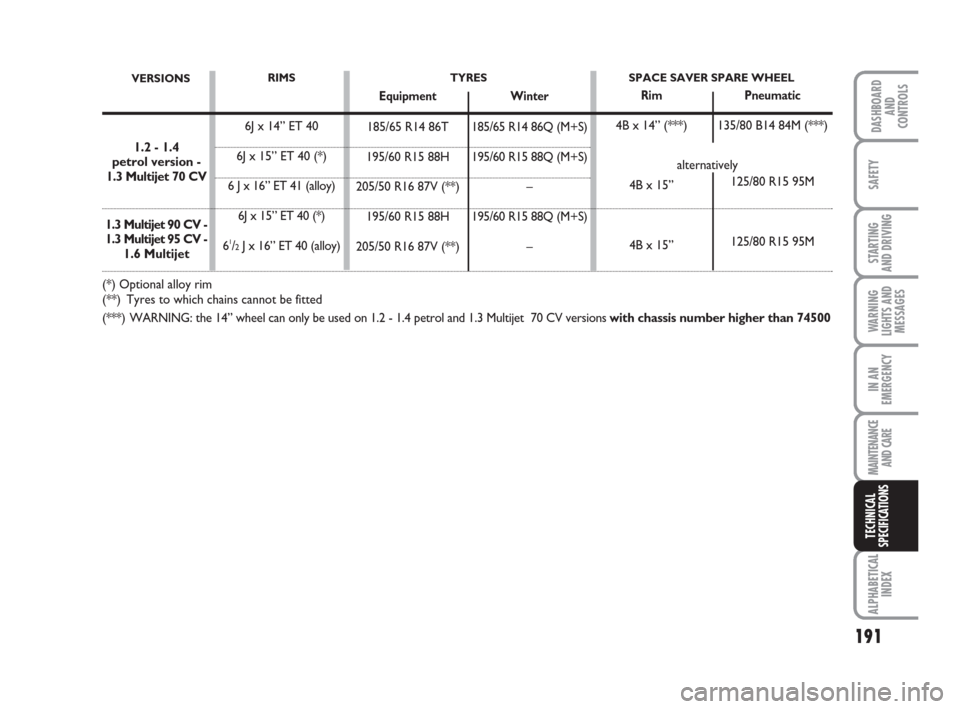

1.2 - 1.4

petrol version -

1.3 Multijet 70 CV

1.3 Multijet 90 CV -

1.3 Multijet 95 CV -

1.6 Multijet

(*) Optional alloy rim

(**) Tyres to which chains cannot be fitted

(***) WARNING: the 14” wheel can only be used on 1.2 - 1.4 petrol and 1.3 Multijet 70 CV versions with chassis number higher than 74500

RIMS

6J x 14” ET 40

6J x 15” ET 40 (*)

6 J x 16” ET 41 (alloy)

6J x 15” ET 40 (*)

6

1/2J x 16” ET 40 (alloy)

TYRES

Equipment

185/65 R14 86T

195/60 R15 88H

205/50 R16 87V (**)

195/60 R15 88H

205/50 R16 87V (**)

Winter

185/65 R14 86Q (M+S)

195/60 R15 88Q (M+S)

–

195/60 R15 88Q (M+S)

–

SPACE SAVER SPARE WHEEL

Rim

4B x 14” (***)

4B x 15”

4B x 15”

Pneumatic

135/80 B14 84M (***)

125/80 R15 95M

125/80 R15 95M

VERSIONS

alternatively

Page 193 of 210

192

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

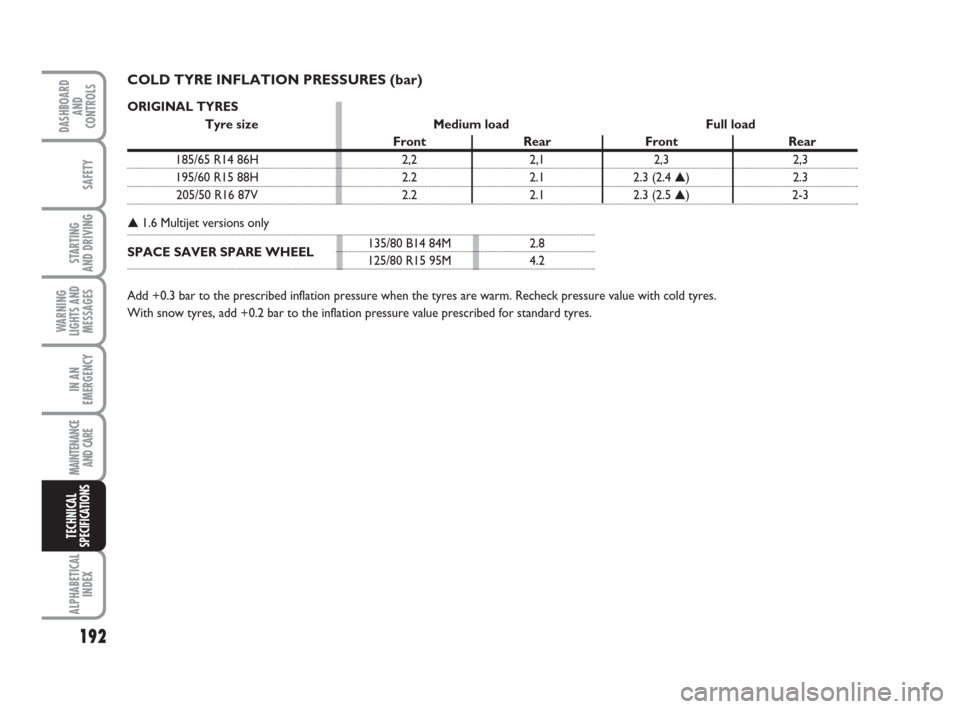

COLD TYRE INFLATION PRESSURES (bar)

ORIGINAL TYRES

Tyre size Medium load Full load

Front Rear Front Rear

185/65 R14 86H 2,2 2,1 2,3 2,3

195/60 R15 88H 2.2 2.1 2.3 (2.4 ▲) 2.3

205/50 R16 87V 2.2 2.1 2.3 (2.5 ▲) 2-3

▲1.6 Multijet versions only

SPACE SAVER SPARE WHEEL135/80 B14 84M 2.8125/80 R15 95M 4.2

Add +0.3 bar to the prescribed inflation pressure when the tyres are warm. Recheck pressure value with cold tyres.

With snow tyres, add +0.2 bar to the inflation pressure value prescribed for standard tyres.

Page 198 of 210

197

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

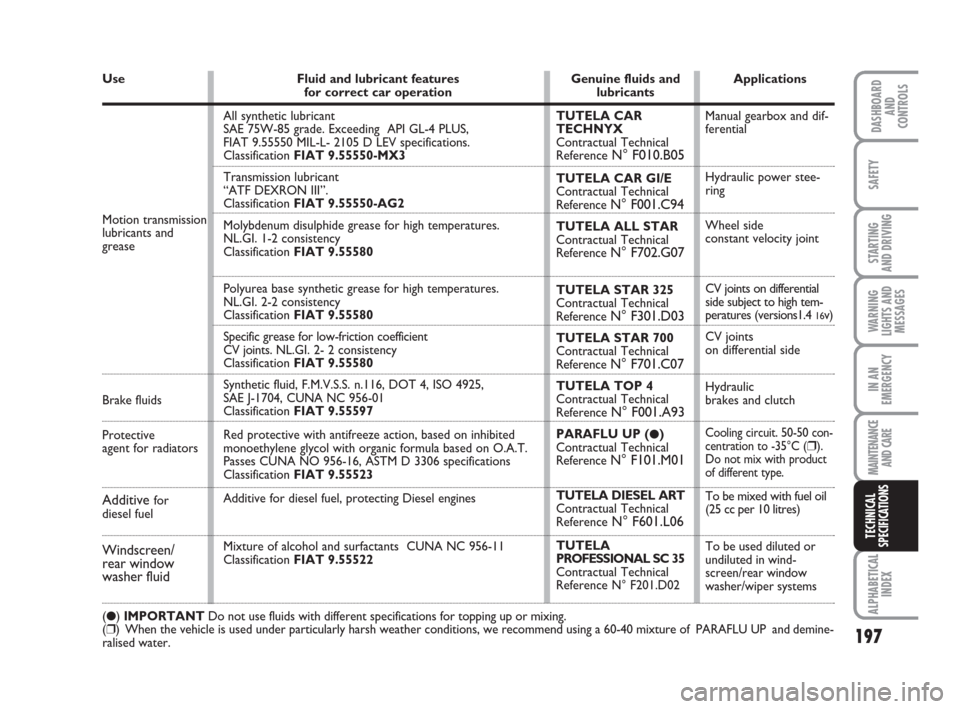

Use

Motion transmission

lubricants and

grease

Brake fluids

Protective

agent for radiators

Additive for

diesel fuel

Windscreen/

rear window

washer fluid

(●)IMPORTANT Do not use fluids with different specifications for topping up or mixing.

(❒) When the vehicle is used under particularly harsh weather conditions, we recommend using a 60-40 mixture of PARAFLU UP and demine-

ralised water.Fluid and lubricant features

for correct car operation

All synthetic lubricant

SAE 75W-85 grade. Exceeding API GL-4 PLUS,

FIAT 9.55550 MIL-L- 2105 D LEV specifications.

ClassificationFIAT 9.55550-MX3

Transmission lubricant

“ATF DEXRON III”.

ClassificationFIAT 9.55550-AG2

Molybdenum disulphide grease for high temperatures.

NL.GI. 1-2 consistency

ClassificationFIAT 9.55580

Polyurea base synthetic grease for high temperatures.

NL.GI. 2-2 consistency

ClassificationFIAT 9.55580

Specific grease for low-friction coefficient

CV joints. NL.GI. 2- 2 consistency

ClassificationFIAT 9.55580

Synthetic fluid, F.M.V.S.S. n.116, DOT 4, ISO 4925,

SAE J-1704, CUNA NC 956-01

Classification FIAT 9.55597

Red protective with antifreeze action, based on inhibited

monoethylene glycol with organic formula based on O.A.T.

Passes CUNA NO 956-16, ASTM D 3306 specifications

Classification FIAT 9.55523

Additive for diesel fuel, protecting Diesel engines

Mixture of alcohol and surfactants CUNA NC 956-11

Classification FIAT 9.55522Genuine fluids and

lubricants

TUTELA CAR

TECHNYX

Contractual Technical

Reference

N° F010.B05

TUTELA CAR GI/E

Contractual Technical

Reference

N° F001.C94

TUTELA ALL STAR

Contractual Technical

Reference

N° F702.G07

TUTELA STAR 325

Contractual Technical

Reference

N° F301.D03

TUTELA STAR 700

Contractual Technical

Reference

N° F701.C07

TUTELA TOP 4

Contractual Technical

Reference

N° F001.A93

PARAFLU UP (●)

Contractual Technical

Reference

N° F101.M01

TUTELA DIESEL ART

Contractual Technical

Reference

N° F601.L06

TUTELA

PROFESSIONAL SC 35

Contractual Technical

Reference N° F201.D02Applications

Manual gearbox and dif-

ferential

Hydraulic power stee-

ring

Wheel side

constant velocity joint

CV joints on differential

side subject to high tem-

peratures (versions1.4

16v)

CV joints

on differential side

Hydraulic

brakes and clutch

Cooling circuit. 50-50 con-

centration to -35°C (❒).

Do not mix with product

of different type.

To be mixed with fuel oil

(25 cc per 10 litres)

To be used diluted or

undiluted in wind-

screen/rear window

washer/wiper systems