exhaust FIAT MAREA 2000 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 112 of 330

Engine

Fuel feed system

JTD Marea- Marea Weekend 9

2000 range @

10.

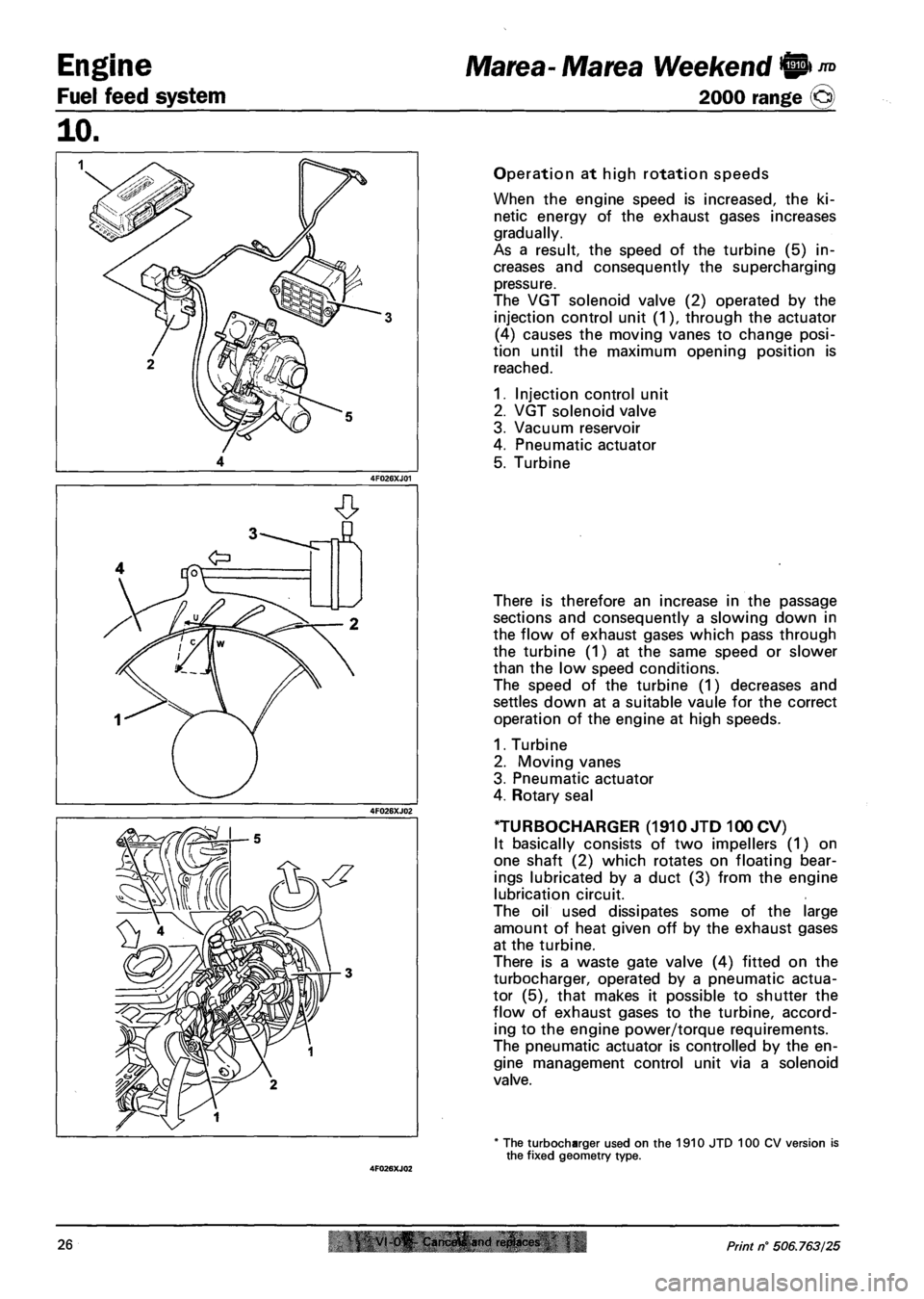

Operation at high rotation speeds

When the engine speed is increased, the ki

netic energy of the exhaust gases increases

gradually.

As a result, the speed of the turbine (5) in

creases and consequently the supercharging

pressure.

The VGT solenoid valve (2) operated by the

injection control unit (1), through the actuator

(4) causes the moving vanes to change posi

tion until the maximum opening position is

reached.

1. Injection control unit

2. VGT solenoid valve

3. Vacuum reservoir

4. Pneumatic actuator

5. Turbine

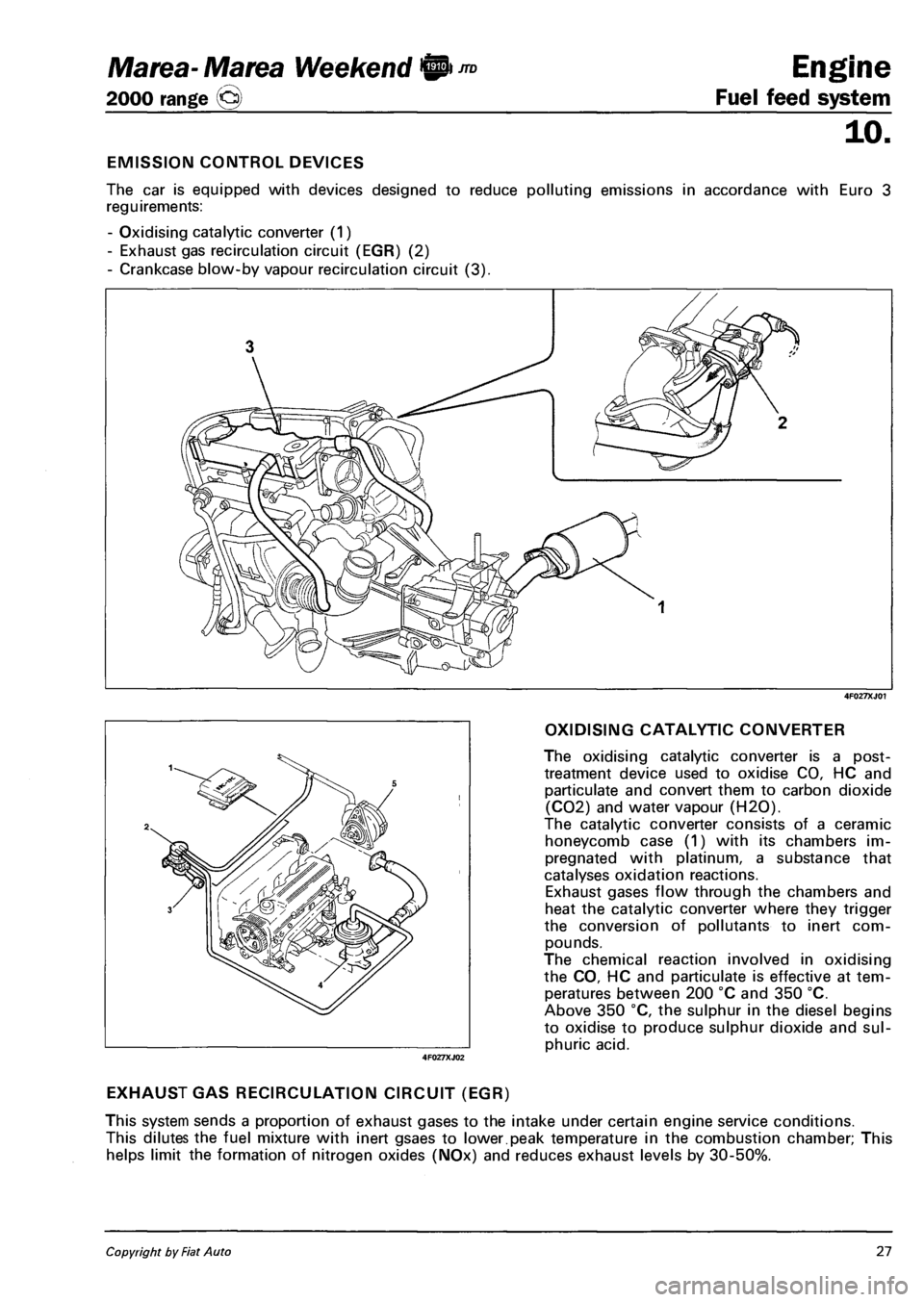

There is therefore an increase in the passage

sections and consequently a slowing down in

the flow of exhaust gases which pass through

the turbine (1) at the same speed or slower

than the low speed conditions.

The speed of the turbine (1) decreases and

settles down at a suitable vaule for the correct

operation of the engine at high speeds.

1. Turbine

2. Moving vanes

3. Pneumatic actuator

4. Rotary seal

TURBOCHARGER (1910 JTD 100 CV)

It basically consists of two impellers (1) on

one shaft (2) which rotates on floating bear

ings lubricated by a duct (3) from the engine

lubrication circuit.

The oil used dissipates some of the large

amount of heat given off by the exhaust gases

at the turbine.

There is a waste gate valve (4) fitted on the

turbocharger, operated by a pneumatic actua

tor (5), that makes it possible to shutter the

flow of exhaust gases to the turbine, accord

ing to the engine power/torque requirements.

The pneumatic actuator is controlled by the en

gine management control unit via a solenoid

valve.

* The turbocharger used on the 1910 JTD 100 CV version is the fixed geometry type.

26 VI 0^ Cam.frtfi and ri!plact<& Print n° 506.763/25

Page 113 of 330

Marea- Marea Weekend 0 *° Engine

2000 range @ Fuel feed system

10.

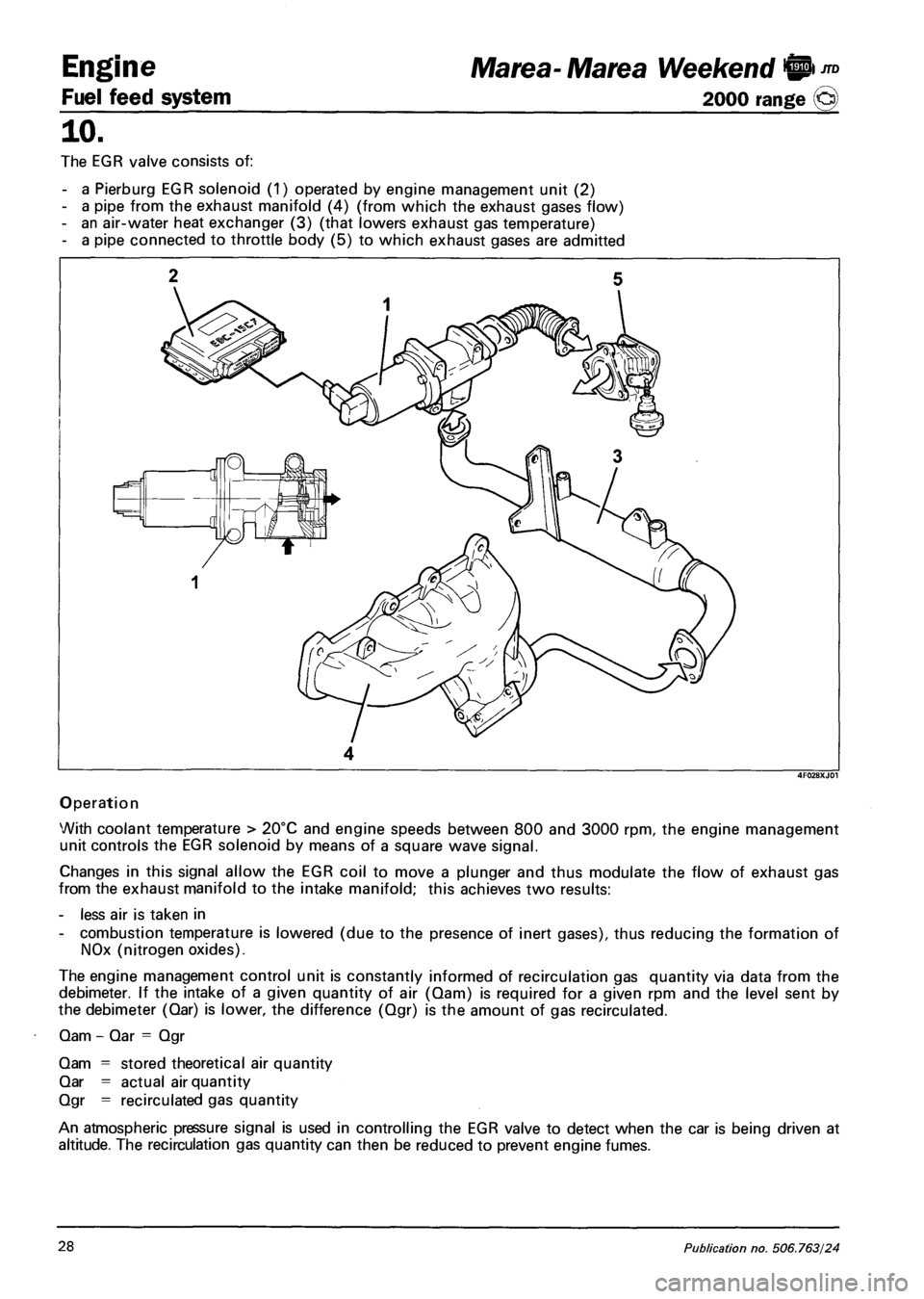

EMISSION CONTROL DEVICES

The car is equipped with devices designed to reduce polluting emissions in accordance with Euro 3

reguirements:

- Oxidising catalytic converter (1)

- Exhaust gas recirculation circuit (EGR) (2)

- Crankcase blow-by vapour recirculation circuit (3).

4F027XJ01

OXIDISING CATALYTIC CONVERTER

The oxidising catalytic converter is a post-

treatment device used to oxidise CO, HC and

particulate and convert them to carbon dioxide

(C02) and water vapour (H20).

The catalytic converter consists of a ceramic

honeycomb case (1) with its chambers im

pregnated with platinum, a substance that

catalyses oxidation reactions.

Exhaust gases flow through the chambers and

heat the catalytic converter where they trigger

the conversion of pollutants to inert com

pounds.

The chemical reaction involved in oxidising

the CO, HC and particulate is effective at tem

peratures between 200 °C and 350 °C.

Above 350 °C, the sulphur in the diesel begins

to oxidise to produce sulphur dioxide and sul

phuric acid.

EXHAUST GAS RECIRCULATION CIRCUIT (EGR)

This system sends a proportion of exhaust gases to the intake under certain engine service conditions.

This dilutes the fuel mixture with inert gsaes to lower.peak temperature in the combustion chamber; This

helps limit the formation of nitrogen oxides (NOx) and reduces exhaust levels by 30-50%.

4F027XJ02

Copyright by Fiat Auto 27

Page 114 of 330

Engine Marea- Marea Weekend IP ™

Fuel feed system 2000 range o

10.

The EGR valve consists of:

- a Pierburg EGR solenoid (1) operated by engine management unit (2)

- a pipe from the exhaust manifold (4) (from which the exhaust gases flow)

- an air-water heat exchanger (3) (that lowers exhaust gas temperature)

- a pipe connected to throttle body (5) to which exhaust gases are admitted

4

Operation

With coolant temperature > 20°C and engine speeds between 800 and 3000 rpm, the engine management

unit controls the EGR solenoid by means of a square wave signal.

Changes in this signal allow the EGR coil to move a plunger and thus modulate the flow of exhaust gas

from the exhaust manifold to the intake manifold; this achieves two results:

- less air is taken in

- combustion temperature is lowered (due to the presence of inert gases), thus reducing the formation of

NOx (nitrogen oxides).

The engine management control unit is constantly informed of recirculation gas quantity via data from the

debimeter. If the intake of a given quantity of air (Qam) is required for a given rpm and the level sent by

the debimeter (Qar) is lower, the difference (Qgr) is the amount of gas recirculated.

Qam - Qar = Qgr

Qam = stored theoretical air quantity

Qar = actual air quantity

Qgr = recirculated gas quantity

An atmospheric pressure signal is used in controlling the EGR valve to detect when the car is being driven at

altitude. The recirculation gas quantity can then be reduced to prevent engine fumes.

28 Publication no. 506.763/24

Page 118 of 330

Engine

Fuel feed system

JTD Marea-Marea Weekend 9

2000 range ©

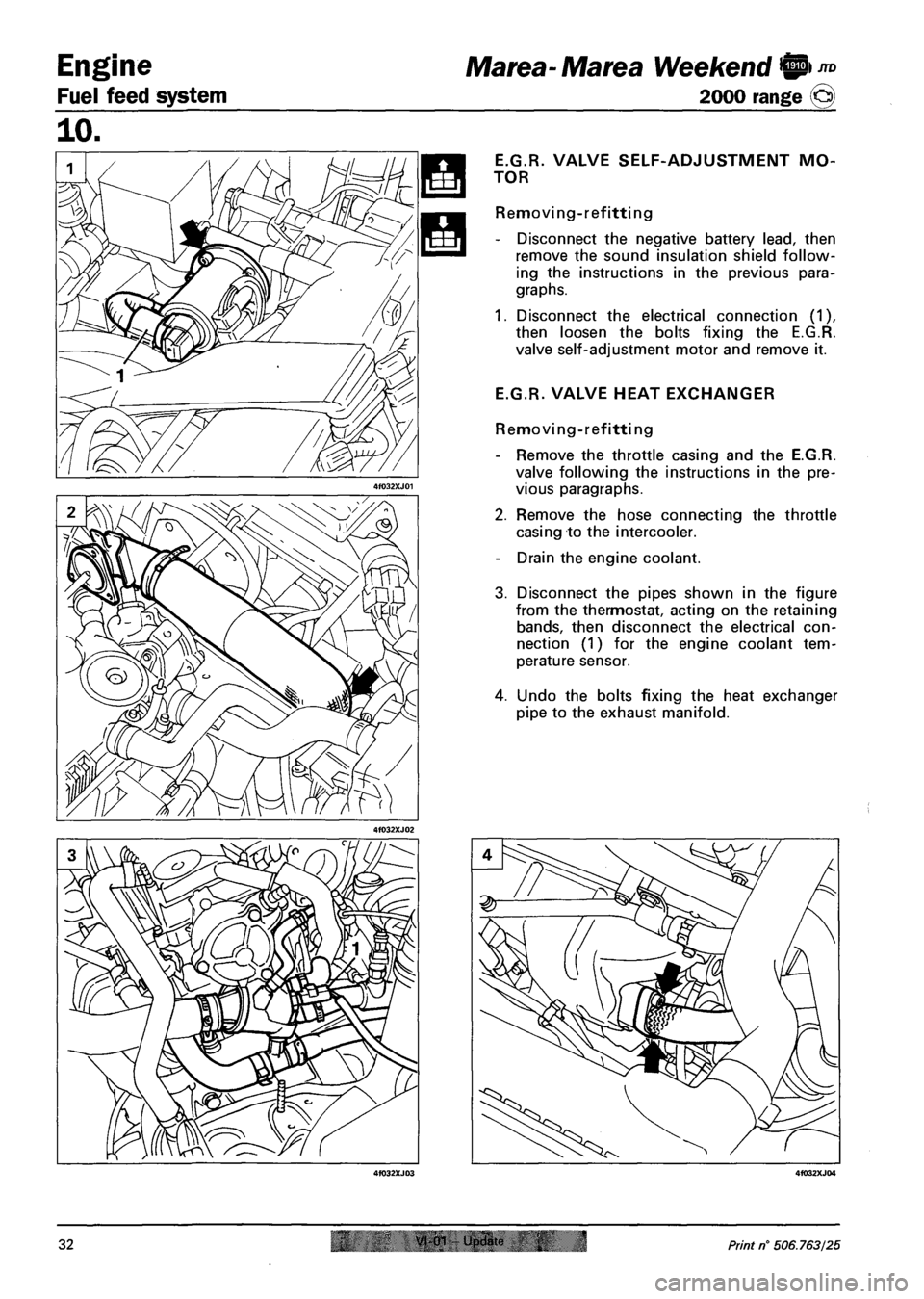

E.G.R.

TOR

VALVE SELF-ADJUSTMENT MO-

Removing-refitting

- Disconnect the negative battery lead, then

remove the sound insulation shield follow

ing the instructions in the previous para

graphs.

1. Disconnect the electrical connection (1),

then loosen the bolts fixing the E.G.R.

valve self-adjustment motor and remove it.

E.G.R. VALVE HEAT EXCHANGER

Removi ng - ref itti ng

- Remove the throttle casing and the E.G.R.

valve following the instructions in the pre

vious paragraphs.

2. Remove the hose connecting the throttle

casing to the intercooler.

- Drain the engine coolant.

3. Disconnect the pipes shown in the figure

from the thermostat, acting on the retaining

bands, then disconnect the electrical con

nection (1) for the engine coolant tem

perature sensor.

4. Undo the bolts fixing the heat exchanger

pipe to the exhaust manifold.

32 0"" Und«r 4 Print n° 506.763/25