connector I FIAT MAREA 2001 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 101 of 330

Marea- Marea Weekend 9™

2000 range (§)

4F015XJ03

Engine

Fuel feed system

ijo.

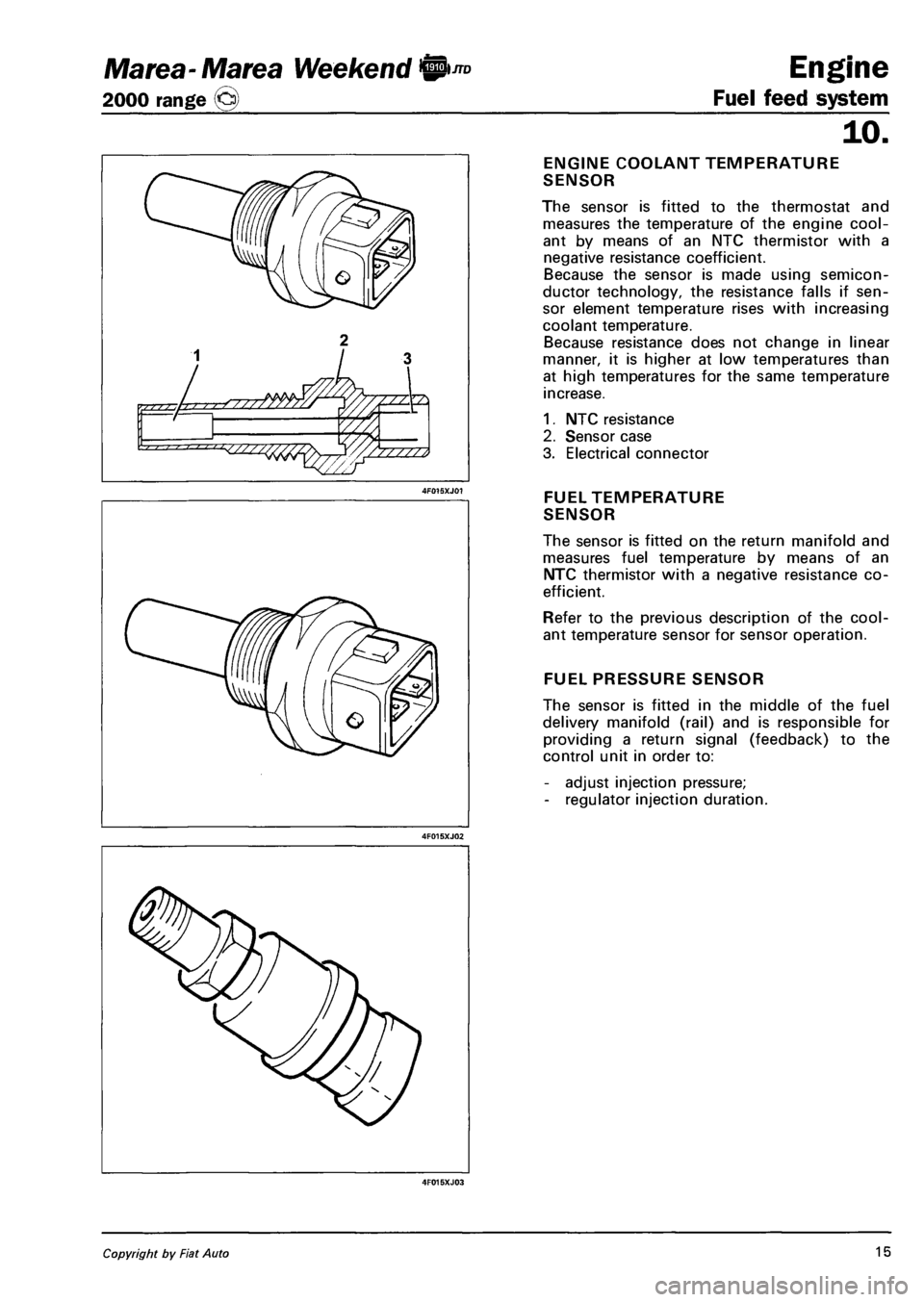

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor is fitted to the thermostat and

measures the temperature of the engine cool

ant by means of an NTC thermistor with a

negative resistance coefficient.

Because the sensor is made using semicon

ductor technology, the resistance falls if sen

sor element temperature rises with increasing

coolant temperature.

Because resistance does not change in linear

manner, it is higher at low temperatures than

at high temperatures for the same temperature

increase.

1. NTC resistance

2. Sensor case

3. Electrical connector

FUEL TEMPERATURE

SENSOR

The sensor is fitted on the return manifold and

measures fuel temperature by means of an

NTC thermistor with a negative resistance co

efficient.

Refer to the previous description of the cool

ant temperature sensor for sensor operation.

FUEL PRESSURE SENSOR

The sensor is fitted in the middle of the fuel

delivery manifold (rail) and is responsible for

providing a return signal (feedback) to the

control unit in order to:

- adjust injection pressure;

- regulator injection duration.

Copyright by Fiat Auto 15

Page 102 of 330

![FIAT MAREA 2001 1.G User Guide Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea FIAT MAREA 2001 1.G User Guide Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea](/img/10/4653/w960_4653-101.png)

Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1

UNIT

The glow plugs are controlled by means of a

preheating control unit under the direct con

trol of the injection control unit.

The preheating control unit contains a smart

relay that sends a return response (feedback)

to the injection control unit, which is thus in

formed of faults in the preheating control unit

or glow plug short-circuits to earth.

The figure shows the connectors on the base

of the preheating control unit and the pin-out

1. Earth

2. Injection control unit (pin 22)

3. Power supply from main injection relay

4. Not connected

5. Injection control unit (pin 62)

8. Positive from battery (+30)

G. Glow plugs (only four outputs are used)

ACCELERATOR

PEDAL POTENTIOMETER

Accelerator pedal position is converted to an

electrical voltage signal and send to the injec

tion control unit by a potentiometer connected

to the accelerator pedal.

Accelerator pedal position is processed to

gether with rpm information to provide injec

tion times and pressure.

The sensor consists of a case (1) secured to

the pedal by a flange, which contains an axi-

ally-positioned shaft (2) connected to two

potentiometers (3): main and safety potenti

ometers.

A coil spring on the shaft ensures the correct

resistance to pressure while a second spring

ensures return upon release.

16 Publication no. 506.763/24

Page 103 of 330

Marea-Marea Weekend 9 -™ Engine

2000 range (j§) Fuel feed system

10.

I I TEST

4F017XJ01

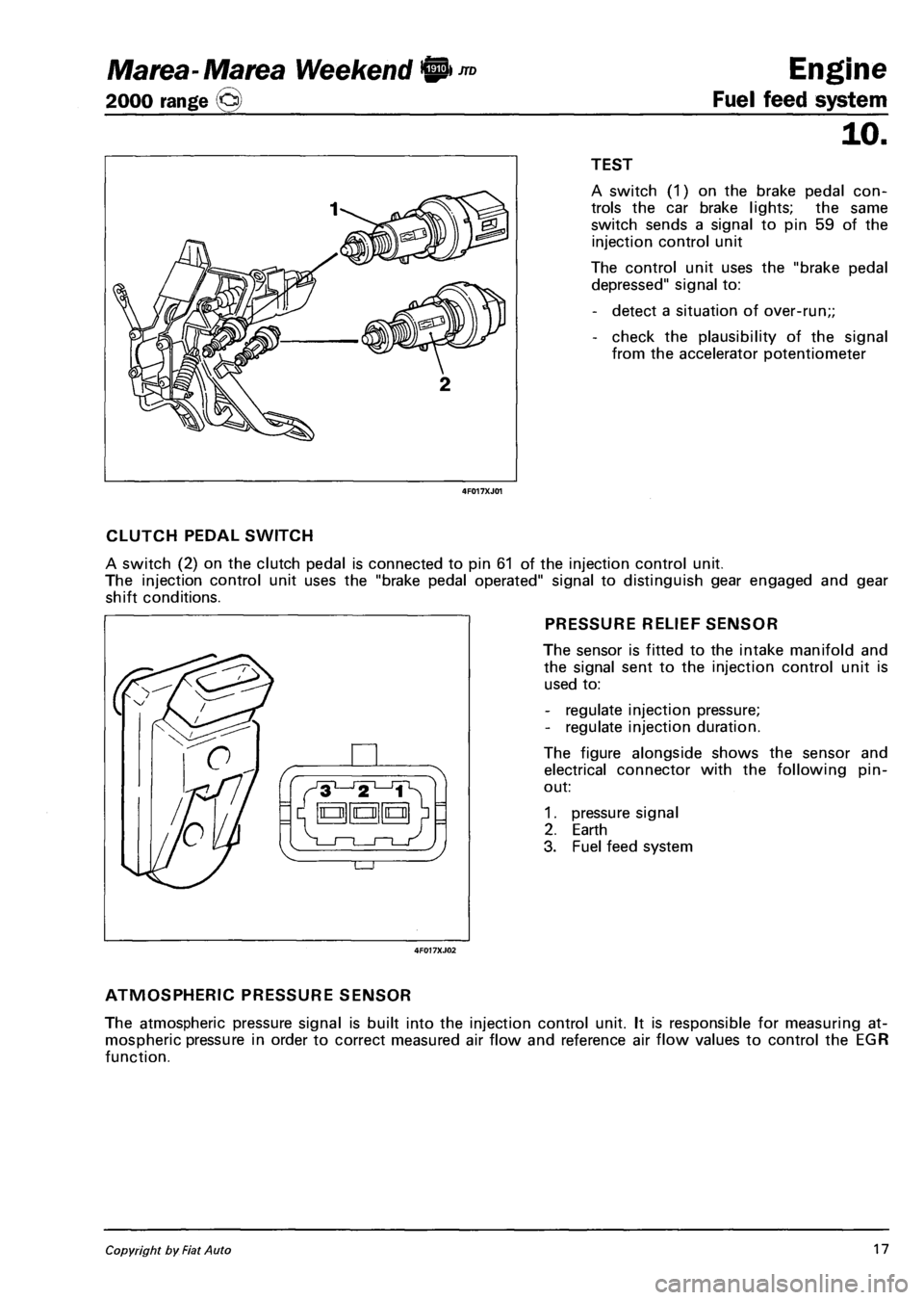

A switch (1) on the brake pedal con

trols the car brake lights; the same

switch sends a signal to pin 59 of the

injection control unit

The control unit uses the "brake pedal

depressed" signal to:

- detect a situation of over-run;;

- check the plausibility of the signal

from the accelerator potentiometer

CLUTCH PEDAL SWITCH

A switch (2) on the clutch pedal is connected to pin 61 of the injection control unit.

The injection control unit uses the "brake pedal operated" signal to distinguish gear engaged and gear

shift conditions.

PRESSURE RELIEF SENSOR

The sensor is fitted to the intake manifold and

the signal sent to the injection control unit is

used to:

- regulate injection pressure;

- regulate injection duration.

The figure alongside shows the sensor and

electrical connector with the following pin-

out:

1. pressure signal

2. Earth

3. Fuel feed system

ATMOSPHERIC PRESSURE SENSOR

The atmospheric pressure signal is built into the injection control unit. It is responsible for measuring at

mospheric pressure in order to correct measured air flow and reference air flow values to control the EGR

function.

Copyright by Fiat Auto 17

Page 116 of 330

Engine

Fuel feed system

Marea-Marea Weekend

2000 range ©

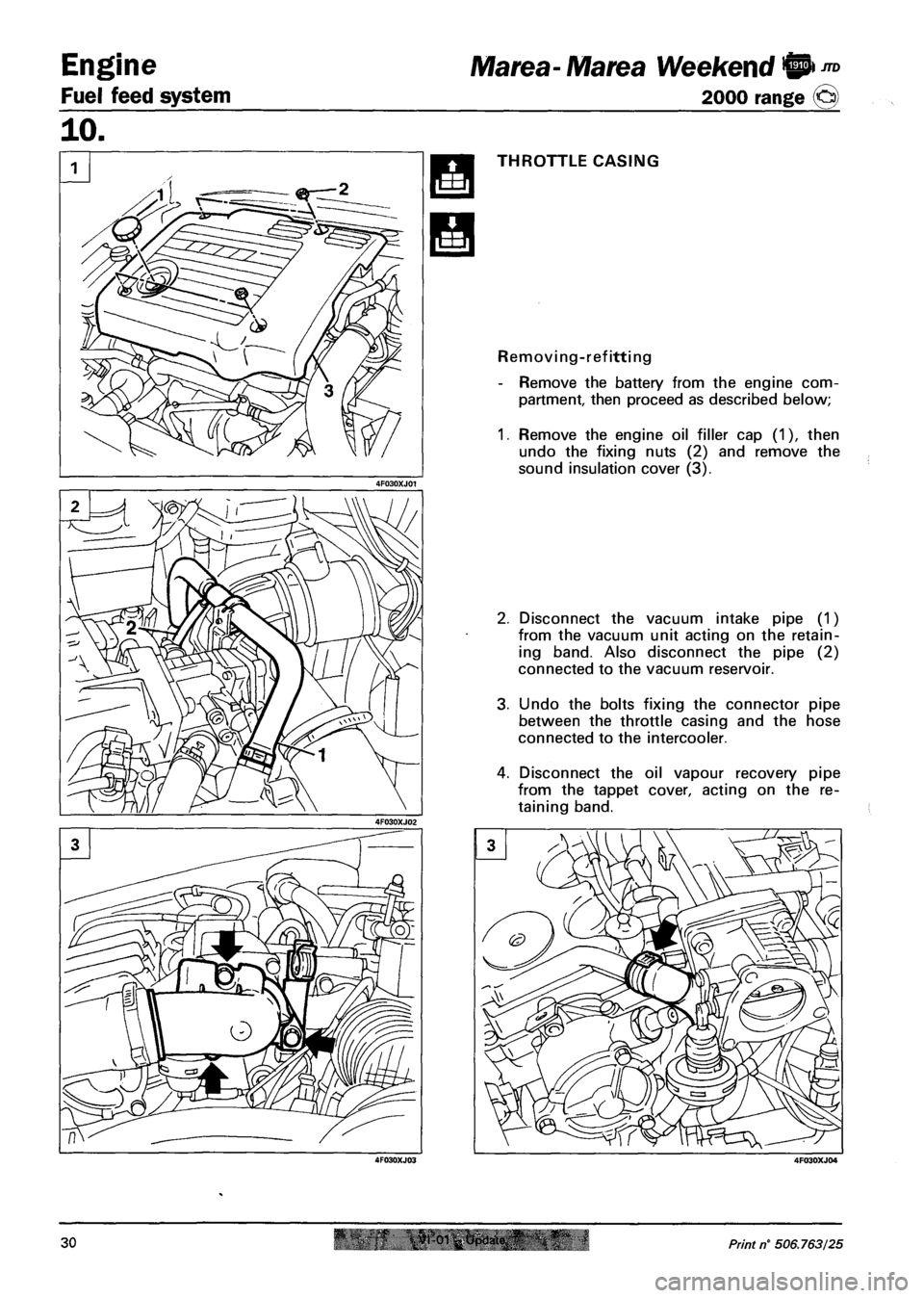

THROTTLE CASING

Removing-refitting

- Remove the battery from the engine com

partment, then proceed as described below;

1. Remove the engine oil filler cap (1), then

undo the fixing nuts (2) and remove the

sound insulation cover (3).

2. Disconnect the vacuum intake pipe (1)

from the vacuum unit acting on the retain

ing band. Also disconnect the pipe (2)

connected to the vacuum reservoir.

3. Undo the bolts fixing the connector pipe

between the throttle casing and the hose

connected to the intercooler.

4. Disconnect the oil vapour recovery pipe

from the tappet cover, acting on the re

taining band.

30 Print n° 506.763/25

Page 120 of 330

Engine

Fuel feed system

Marea- Marea Weekend 9 ™

2000 range ©

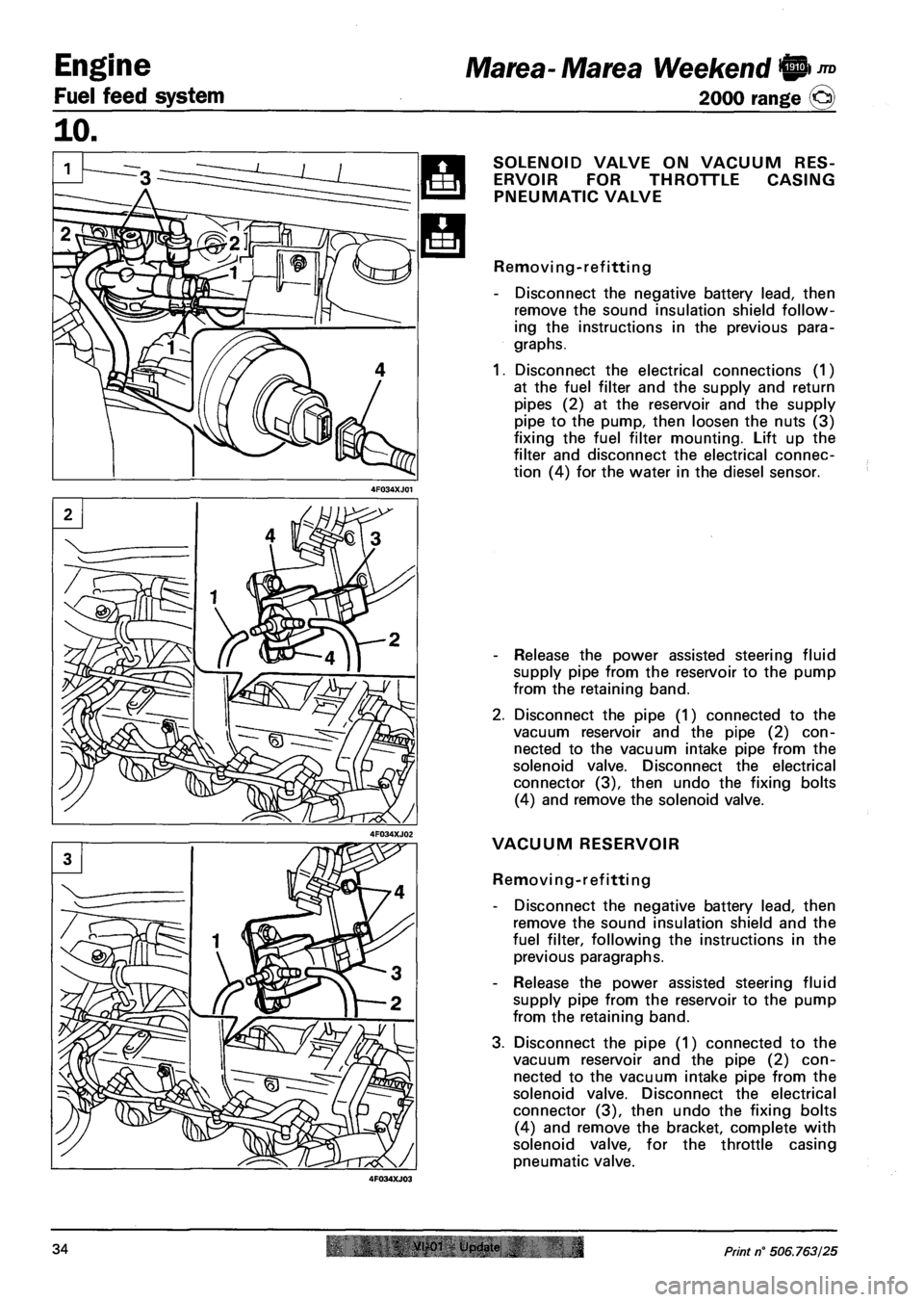

SOLENOID VALVE ON VACUUM RES

ERVOIR FOR THROTTLE CASING

PNEUMATIC VALVE

Removing-refitting

- Disconnect the negative battery lead, then

remove the sound insulation shield follow

ing the instructions in the previous para

graphs.

1. Disconnect the electrical connections (1)

at the fuel filter and the supply and return

pipes (2) at the reservoir and the supply

pipe to the pump, then loosen the nuts (3)

fixing the fuel filter mounting. Lift up the

filter and disconnect the electrical connec

tion (4) for the water in the diesel sensor.

- Release the power assisted steering fluid

supply pipe from the reservoir to the pump

from the retaining band.

2. Disconnect the pipe (1) connected to the

vacuum reservoir and the pipe (2) con

nected to the vacuum intake pipe from the

solenoid valve. Disconnect the electrical

connector (3), then undo the fixing bolts

(4) and remove the solenoid valve.

VACUUM RESERVOIR

Removing-refitting

- Disconnect the negative battery lead, then

remove the sound insulation shield and the

fuel filter, following the instructions in the

previous paragraphs.

- Release the power assisted steering fluid

supply pipe from the reservoir to the pump

from the retaining band.

3. Disconnect the pipe (1) connected to the

vacuum reservoir and the pipe (2) con

nected to the vacuum intake pipe from the

solenoid valve. Disconnect the electrical

connector (3), then undo the fixing bolts

(4) and remove the bracket, complete with

solenoid valve, for the throttle casing

pneumatic valve.

34 VI-01 Update IN Print n° 506.763/25

Page 121 of 330

Ma tea- Marea Weekend 9 m

2000 range ©)

Engine

Fuel feed system

10.

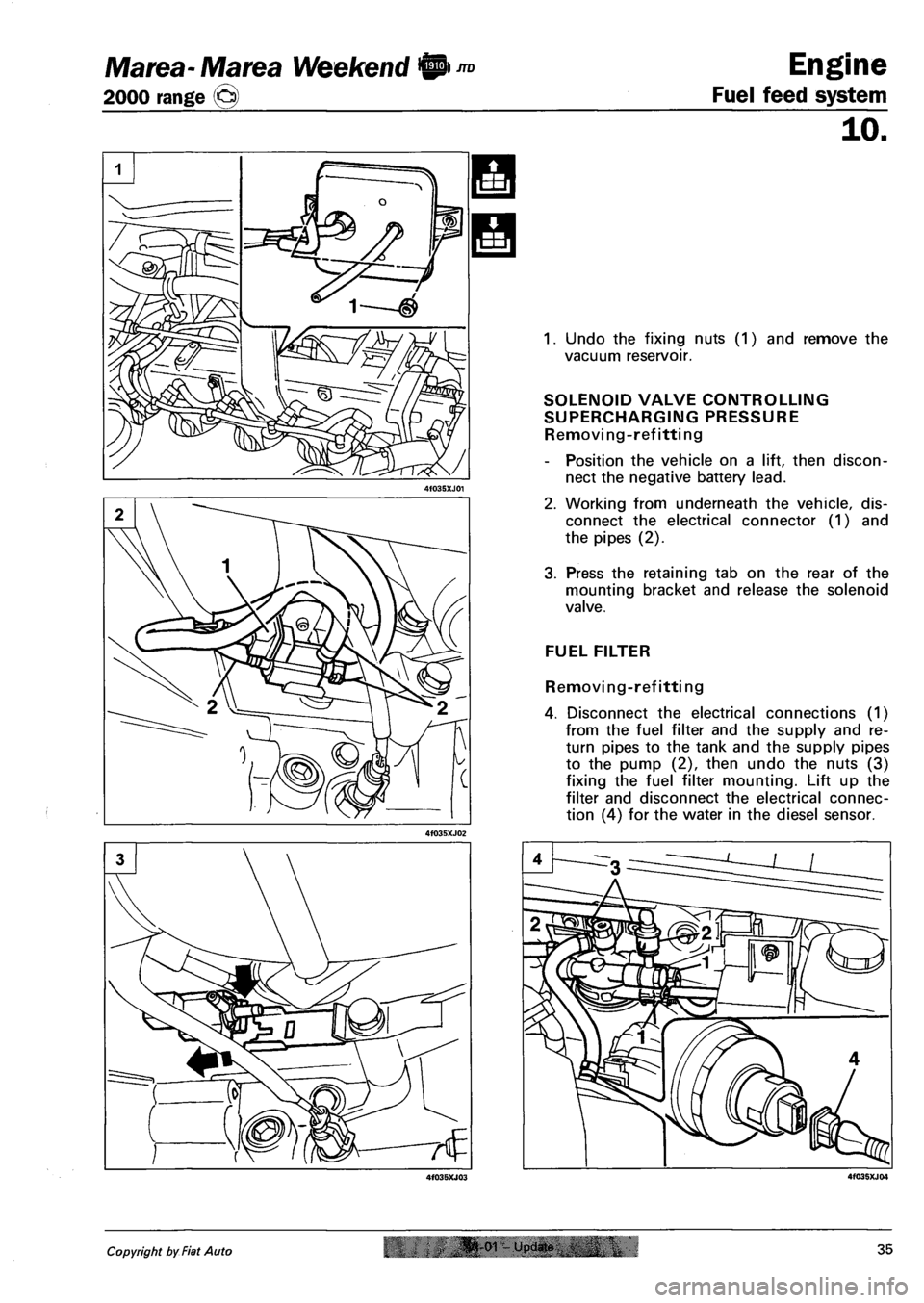

1. Undo the fixing nuts (1) and remove the

vacuum reservoir.

SOLENOID VALVE CONTROLLING

SUPERCHARGING PRESSURE

Removing-refitting

- Position the vehicle on a lift, then discon

nect the negative battery lead.

2. Working from underneath the vehicle, dis

connect the electrical connector (1) and

the pipes (2).

3. Press the retaining tab on the rear of the

mounting bracket and release the solenoid

valve.

FUEL FILTER

Removing-refitting

4. Disconnect the electrical connections (1)

from the fuel filter and the supply and re

turn pipes to the tank and the supply pipes

to the pump (2), then undo the nuts (3)

fixing the fuel filter mounting. Lift up the

filter and disconnect the electrical connec

tion (4) for the water in the diesel sensor.

Copyright by Fiat Auto oi upjdin 35

Page 122 of 330

Engine

Fuel feed system

Marea- Marea Weekend @ ™

2000 range ©

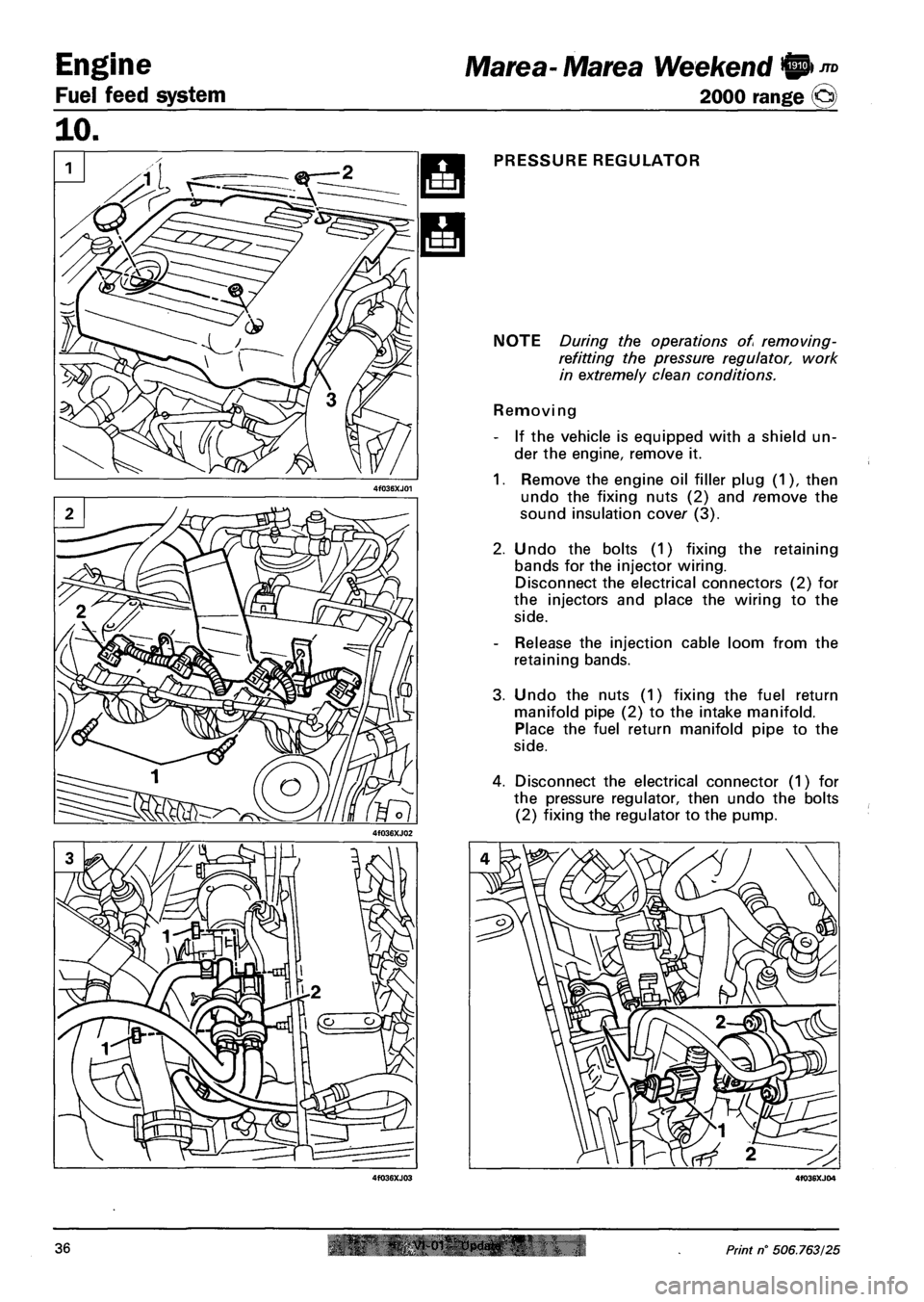

PRESSURE REGULATOR

NOTE During the operations of removing-

refitting the pressure regulator, work

in extremely clean conditions.

Removing

- If the vehicle is equipped with a shield un

der the engine, remove it.

1. Remove the engine oil filler plug (1), then

undo the fixing nuts (2) and remove the

sound insulation cover (3).

2. Undo the bolts (1) fixing the retaining

bands for the injector wiring.

Disconnect the electrical connectors (2) for

the injectors and place the wiring to the

side.

- Release the injection cable loom from the

retaining bands.

3. Undo the nuts (1) fixing the fuel return

manifold pipe (2) to the intake manifold.

Place the fuel return manifold pipe to the

side.

4. Disconnect the electrical connector (1) for

the pressure regulator, then undo the bolts

(2) fixing the regulator to the pump.

36 Print n° 506.763/25

Page 123 of 330

Marea-Marea Weekend H nD Engine

2000 range (Q) Fuel feed system

10.

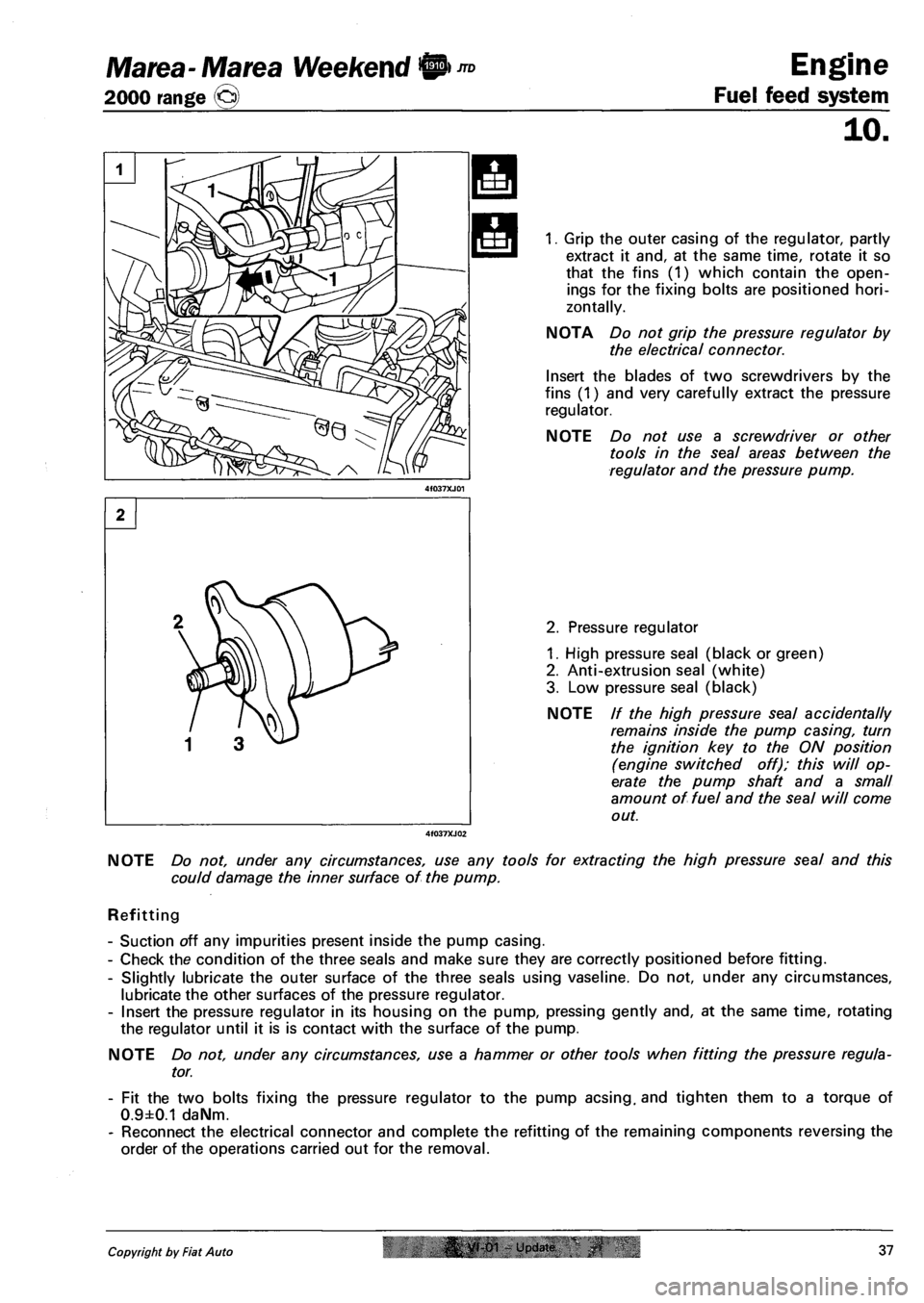

1. Grip the outer casing of the regulator, partly

extract it and, at the same time, rotate it so

that the fins (1) which contain the open

ings for the fixing bolts are positioned hori

zontally.

NOTA Do not grip the pressure regulator by

the electrical connector.

Insert the blades of two screwdrivers by the

fins (1) and very carefully extract the pressure

regulator.

NOTE Do not use a screwdriver or other

tools in the seal areas between the

regulator and the pressure pump.

2. Pressure regulator

1. High pressure seal (black or green)

2. Anti-extrusion seal (white)

3. Low pressure seal (black)

NOTE // the high pressure seal accidentally

remains inside the pump casing, turn

the ignition key to the ON position

(engine switched off); this will op

erate the pump shaft and a small

amount of fuel and the seal will come

out.

NOTE Do not, under any circumstances, use any tools for extracting the high pressure seal and this

could damage the inner surface of the pump.

Refitting

- Suction off any impurities present inside the pump casing.

- Check the condition of the three seals and make sure they are correctly positioned before fitting.

- Slightly lubricate the outer surface of the three seals using vaseline. Do not, under any circumstances,

lubricate the other surfaces of the pressure regulator.

- Insert the pressure regulator in its housing on the pump, pressing gently and, at the same time, rotating

the regulator until it is is contact with the surface of the pump.

NOTE Do not, under any circumstances, use a hammer or other tools when fitting the pressure regula

tor.

- Fit the two bolts fixing the pressure regulator to the pump acsing. and tighten them to a torque of

0.9±0.1 daNm.

- Reconnect the electrical connector and complete the refitting of the remaining components reversing the

order of the operations carried out for the removal.

Copyright by Fiat Auto |& yt-01 - Update 37

Page 134 of 330

Electrical equipment

Junction unit

Marea-Marea Weekend

2000 range ©

55.

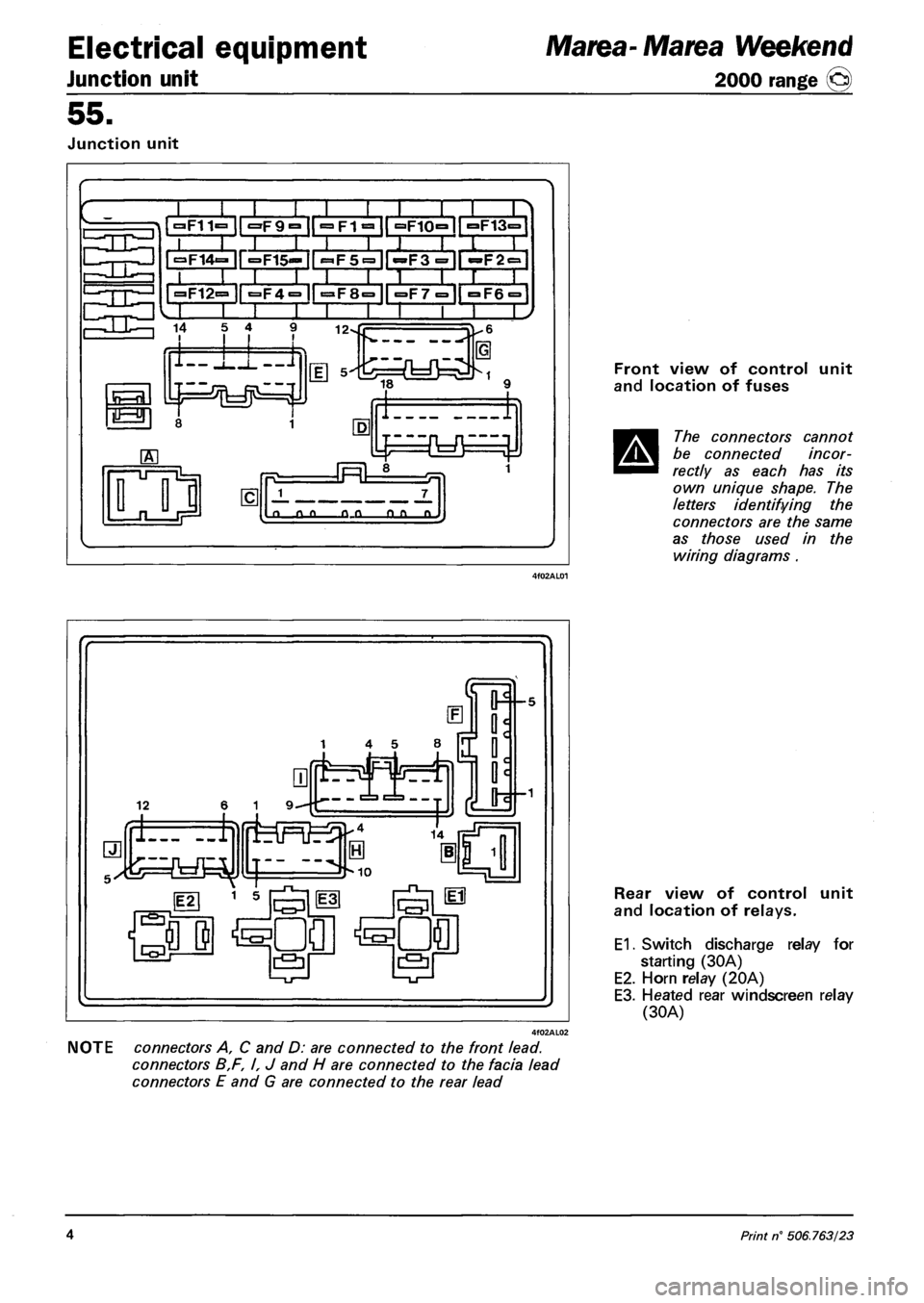

Junction unit

»F11=

~T~ II l;

•F9° |["^FT^1| °F10°ir°F13=

| ^14=- ir=F15«=- II

»F12=

SLHHItHia r i i i •

3F4= ir^F8=1l =F7="|| °F6 = 1

I I I I I 1 I '

14 5 4 12-

lor

1-11-J

I 1

J 7_

a o_o o_o OLD n.

Front view of control unit

and location of fuses

The connectors cannot

be connected incor

rectly as each has its

own unique shape. The

letters identifying the

connectors are the same

as those used in the

wiring diagrams .

NOTE connectors A, C and D: are connected to the front lead.

connectors B,F, I, J and H are connected to the facia lead

connectors E and G are connected to the rear lead

Rear view of control unit

and location of relays.

E1. Switch discharge relay for

starting (30A)

E2. Horn relay (20A)

E3. Heated rear windscreen relay

(30A)

4 Print n° 506.763/23

Page 135 of 330

Marea-Marea Weekend

2000 range Q

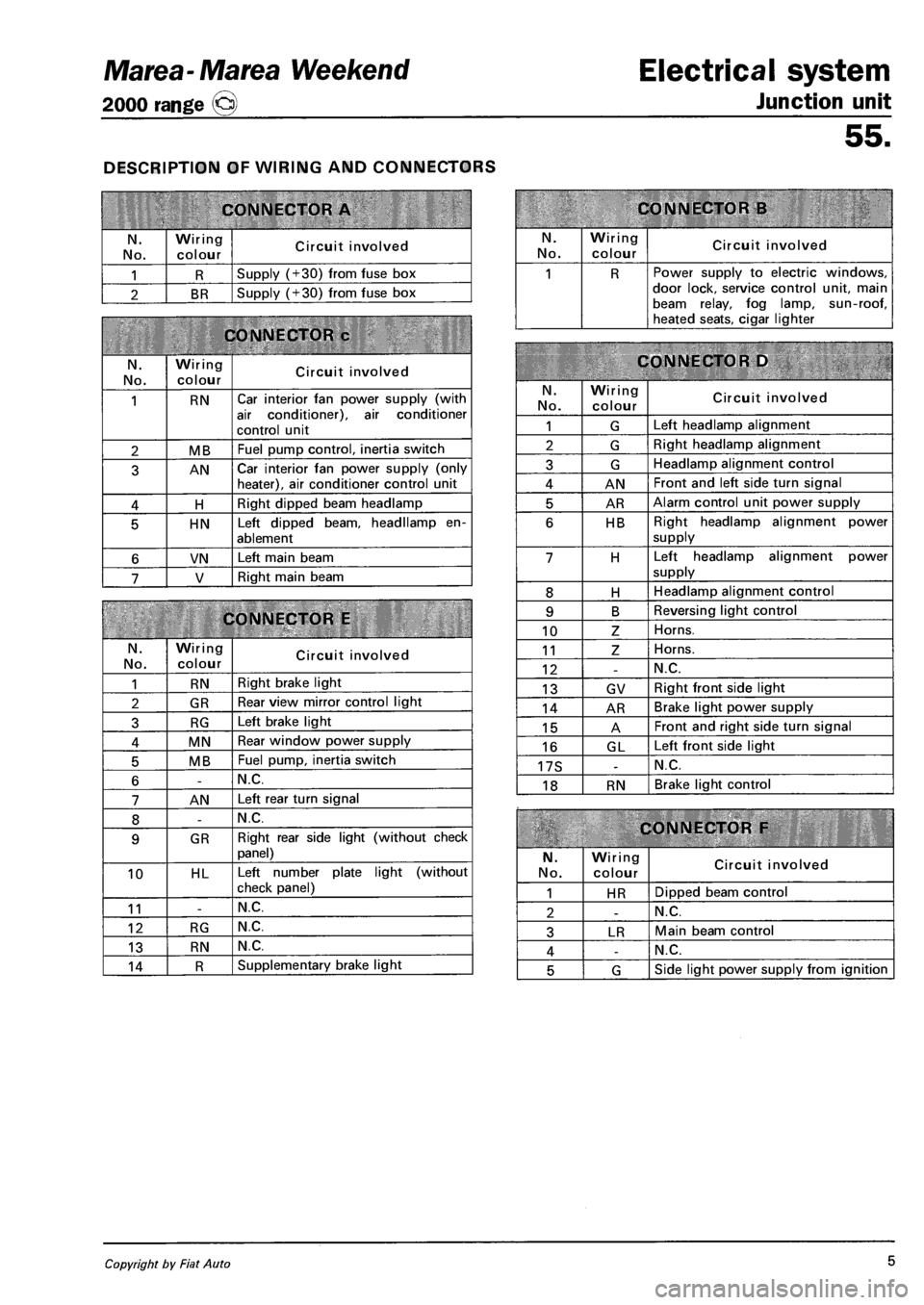

DESCRIPTION OF WIRING AND CONNECTORS

CONNECTOR A

N.

No.

Wiring

colour Circuit involved

1 R Supply (+30) from fuse box

2 BR Supply (+30) from fuse box

CONNECTOR c

N. No.

Wiring colour Circuit involved

1 RN Car interior fan power supply (with

air conditioner), air conditioner

control unit

2 MB Fuel pump control, inertia switch

3 AN Car interior fan power supply (only heater), air conditioner control unit

4 H Right dipped beam headlamp

5 HN Left dipped beam, headllamp en

ablement

6 VN Left main beam

7 V Right main beam

CONNECTOR E

N.

No.

Wiring colour Circuit involved

1 RN Right brake light

2 GR Rear view mirror control light

3 RG Left brake light

4 MN Rear window power supply

5 MB Fuel pump, inertia switch

6 -N.C.

7 AN Left rear turn signal

8 -N.C.

9 GR Right rear side light (without check

panel)

10 HL Left number plate light (without

check panel)

11 -N.C.

12 RG N.C.

13 RN N.C.

14 R Supplementary brake light

Electrical system

Junction unit

55.

CONNECTOR B

N. No.

Wiring

colour Circuit involved

1 R Power supply to electric windows, door lock, service control unit, main beam relay, fog lamp, sun-roof, heated seats, cigar lighter

CONNECTOR D

N.

No.

Wiring colour Circuit involved

1 G Left headlamp alignment

2 G Right headlamp alignment

3 G Headlamp alignment control

4 AN Front and left side turn signal

5 AR Alarm control unit power supply

6 HB Right headlamp alignment power

supply

7 H Left headlamp alignment power

supply

8 H Headlamp alignment control

9 B Reversing light control

10 Z Horns.

11 Z Horns.

12 -N.C.

13 GV Right front side light

14 AR Brake light power supply

15 A Front and right side turn signal

16 GL Left front side light

17S -N.C.

18 RN Brake light control

CONNECTOR F

N.

No.

Wiring colour Circuit involved

1 HR Dipped beam control

2 -N.C.

3 LR Main beam control

4 -N.C.

5 G Side light power supply from ignition

Copyright by Fiat Auto 5