length FIAT PUNTO 1998 176 / 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1998, Model line: PUNTO, Model: FIAT PUNTO 1998 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 55 of 225

2A*10 SOHC (8-valve) petrol engine in-car repair procedures

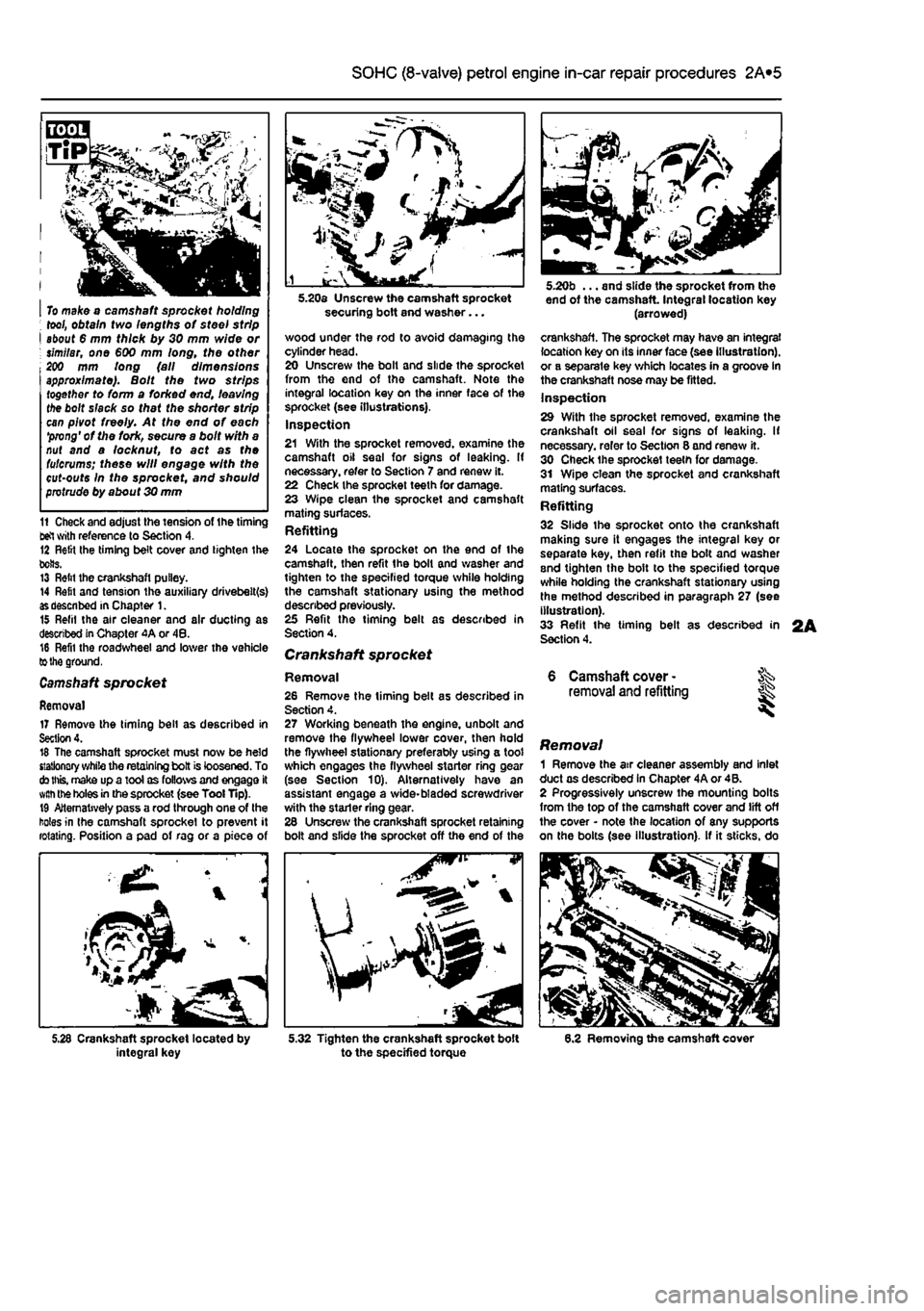

I To make o camshaft sprocket holding ; tool, obtain two lengths of steel strip I about 6 mm thick by 30 mm wide or ; similar, one €00 mm long, the other 200 mm long (all dimensions approximate). Bolt the two strips together to form a forked end, leaving the bolt slack so that the shorter strip can pivot freely. At the end of each 'prong' of the fork, secure a bolt with a nut and a locknut, to act as the fulcrums; these will engage with the cut-outs In the sprocket, and should protrude by about 30 mm

11 Check and adjust the tension of the timing tel with reference to Section 4. 12 Relit Ihe timing belt cover and tighten the bolts. 13 Relit the crankshaft pulley. 14 Refit and tension the auxiliary drivebelt(s)

as

described in Chapter 1. 15 Refil the air cleaner and air ducting as described in Chapter 4A or 48. 16 Refil the roadwheel and lower the vehicle

to the

ground.

Camshaft

sprocket

Removal 17 Remove the timing bell as described in Section 4. 16 The camshaft sprocket must now be held stationary while the retaining bolt is loosened. To

cto this,

make up a tool as follows and engage it

with the

holes

in

the sprocket (see Tool Tip). 19 Alternatively pass a rod through one of the holes in the camshaft sprocket to prevent it rotating. Position a pad of rag or a piece of

integral key

securing bolt and washer...

wood under the rod to avoid damaging the cylinder head. 20 Unscrew the bolt and slide the sprocket from the end of tho camshaft. Note the integral location key on the inner face of the sprocket (see illustrations). Inspection 21 With the sprocket removed, examine the camshaft oil seal for signs of leaking. If necessary, refer to Section 7 and renew it. 22 Check the sprocket teeth for damage. 23 Wipe clean the sprocket and camshaft mating surfaces. Refitting 24 Locate the sprocket on the end of the camshaft, then refit the bolt and washer and tighten to the specified torque while holding the camshaft stationary using the method described previously. 25 Refit the timing belt as described in Section 4.

Crankshaft sprocket

Removal 26 Remove the timing belt as described in Section 4. 27 Working beneath the engine, unbolt and remove the flywheel lower cover, then hold the flywheel stationary preferably using a toot which engages the flywheel starter ring gear (see Section 10). Alternatively have an assistant engage a wide-bladed screwdriver with the stader ring gear. 26 Unscrew the crankshaft sprocket retaining bolt and slide the sprocket off the end of the

^P

5.32 Tighten the crankshaft sprocket bolt to the specified torque

end of the camshaft Integral location key (arrowed)

crankshaft. The sprocket may have an integral location key on its inner face (see illustration), or a separate key which locates in a groove in the crankshaft nose may be fitted. Inspection 29 With the sprocket removed, examine the crankshaft oil seal for signs of leaking. If necessary, refer to Section 8 and renew it. 30 Check the sprocket teeth for damage. 31 Wipe clean the sprocket and crankshaft mating surfaces. Refitting 32 Slide the sprocket onto the crankshaft making sure it engages the integral key or separate key, then refit the bolt and washer and tighten the bolt to the specified torque while holding the crankshaft stationary using the method described in paragraph 27 (see illustration). 33 Refit the timing belt as described in Section 4.

6 Camshaft cover -removal and refitting

Removal 1 Remove the air cleaner assembly and inlet duct as described in Chapter 4A or 4B. 2 Progressively unscrew the mounting bolts from the top of the camshaft cover and lift off the cover • note the location of any supports on the bolts (see illustration). If it sticks, do

6.2 Removing the camshaft cover

Page 63 of 225

2B*3 DOHC (16-valve) petrol engine in-car repair procedures

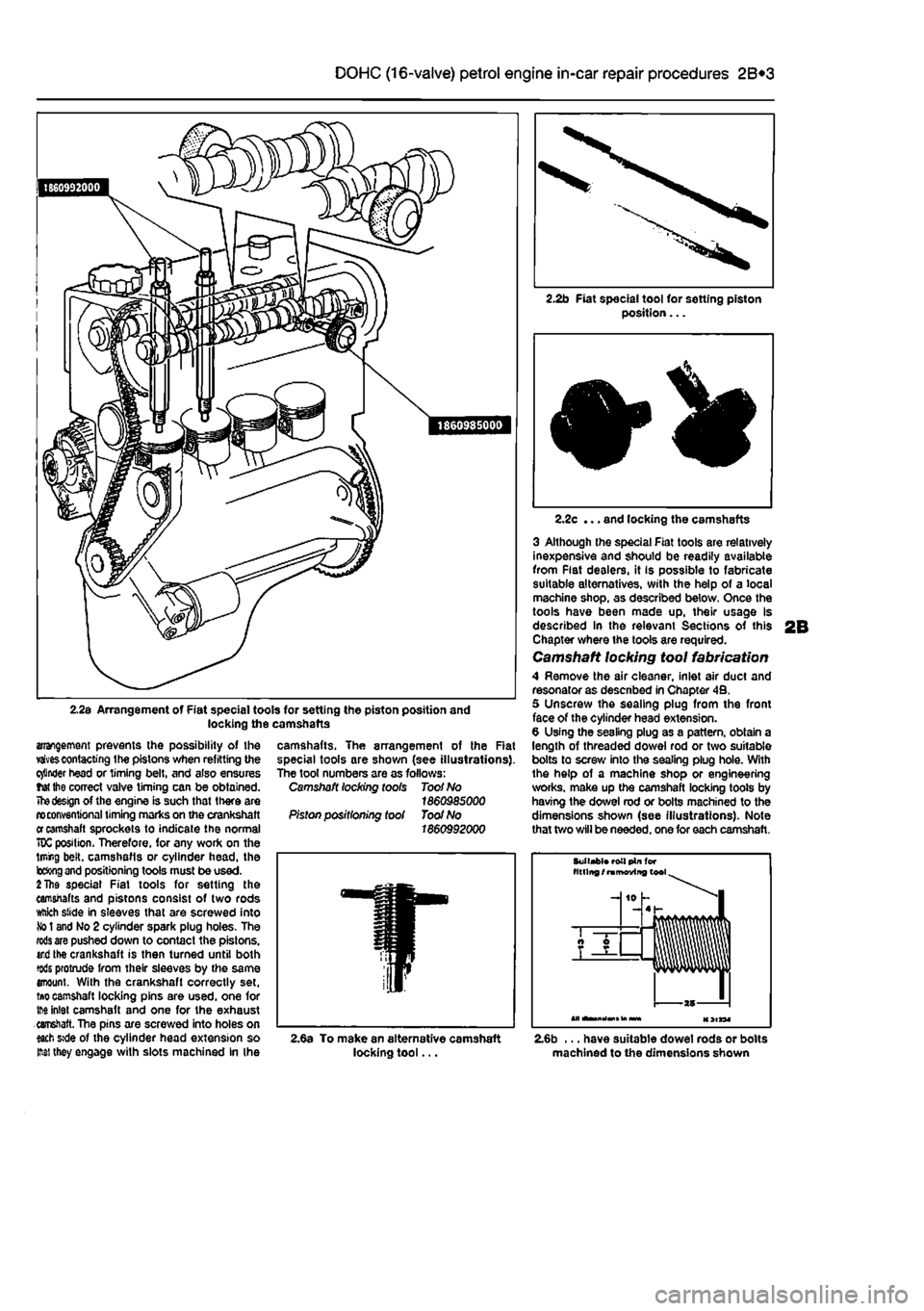

2.2s Arrangement of Fiat special tools for setting the piston position and locking the camshafts

arrangement prevents the possibility of the vaivescontacting the pistons when refitting the cinder head or timing belt, and also ensures tet the correct valve timing can be obtained.

The design

of the engine is such that there are n> conventional timing marks on the crankshaft

er

camshaft sprockets to indicate the normal 70C position. Therefore, for any work on the lining belt, camshafls or cylinder head, the b&ng

and

positioning tools must be used.

2 The

special Fiat tools for setting the camshafts and pistons consist of two rods ttikh slide in sleeves that are screwed into

So

t and No 2 cylinder spark plug holes. The

rods are

pushed down to contact the pistons, ird the crankshaft is then turned until both tods protrude from their sleeves by the same enount. With the crankshaft correctly set,

ti»o

camshaft locking pins are used, one for tM inlet camshaft and one for the exhaust earretaft. The pins are screwed into holes on *ach »de of the cylinder head extension so M they engage with slots machined In (he

2.2b Fiat special tool for setting piston position...

camshafts. The arrangement of the Rat special tools are shown (see illustrations). The tool numbers are as follows: Camshaft locking toots Toot No 1860985000 Piston positioning tool Toot No 1860992000

2.2c ... and locking the camshafts

3 Although the special Fiat tools are relatively inexpensive and should be readily available from Flat dealers, it is possible to fabricate suitable alternatives, with the help of a local machine shop, as described below. Once the tools have been made up, their usage Is described In the relevant Sections of this Chapter where the tools are required. Camshaft locking tool fabrication 4 Remove the air cleaner, inlet air duct and resonator as descnbed in Chapter 4B. 5 Unscrew the sealing plug from the front face of the cylinder head extension. 6 Using the sealing plug as a pattern, obtain a length of threaded dowel rod or two suitable bolts to screw into the sealing plug hole. With the help of a machine shop or engineering works, make up the camshaft locking toots by having the dowel rod or bolts machined to the dimensions shown (see illustrations). Note that two will be needed, one for each camshaft.

Suitabt* roll pin (or titling /

ramoviitg

tool

-J 10 h -4 h

AT —

T

—

2,6a To make an alternative camshaft locking tool... 2.6b ... have suitable dowel rods or bolts machined to the dimensions shown

Page 64 of 225

2B*4 DOHC (16-valve) petrol engine in-car repair procedures

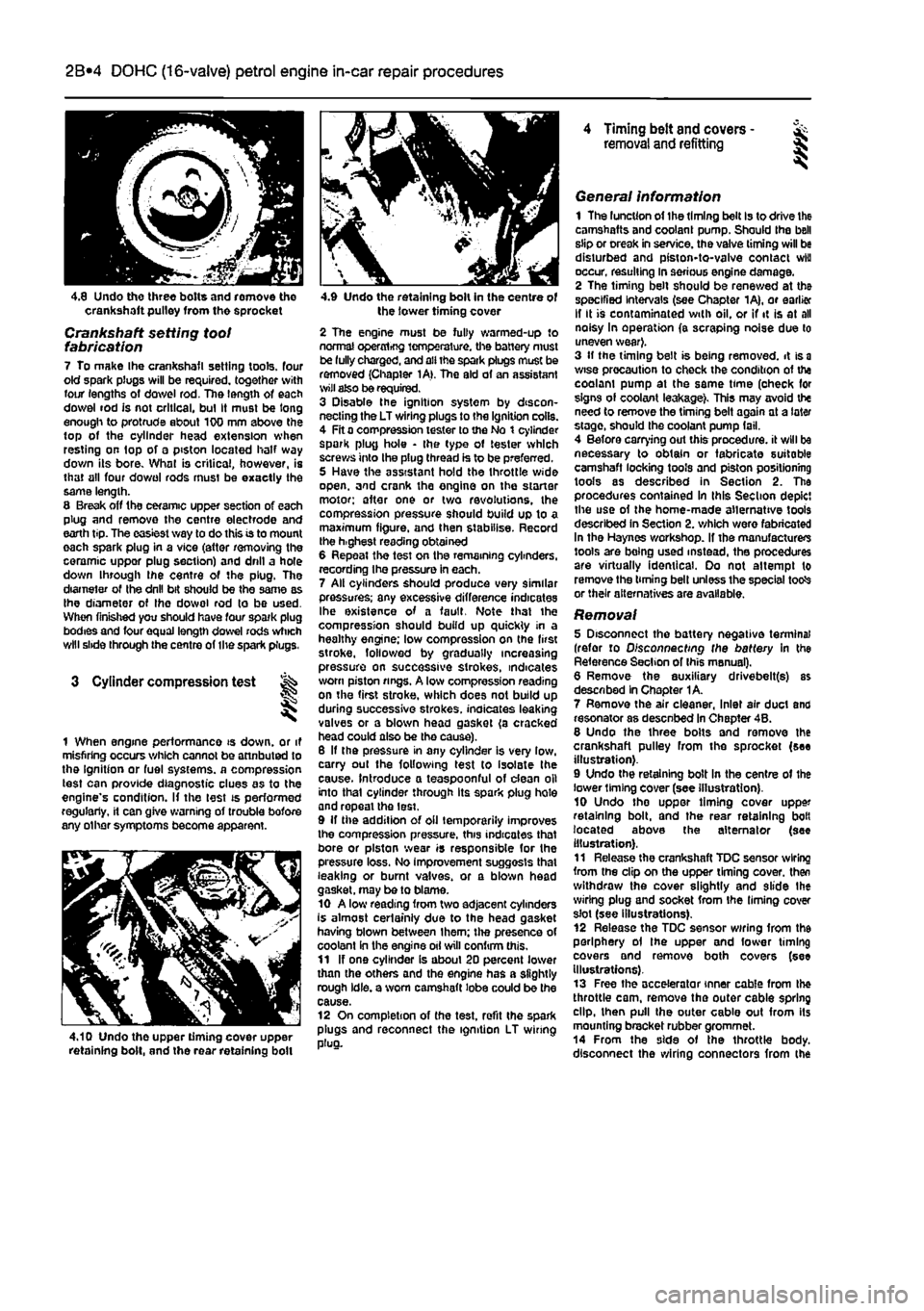

4.8 Undo three bolts and romove tho crankshaft pulley from the sprocket

Crankshaft setting toot fabrication 7 To make Ihe crankshafl setting tools, four old spark plugs will be required, together with four lengths of dowel rod. The length of each dowel rod is not critical, bul It must be long enough to protrude about 100 mm above the top of the cylinder head extension when resting on top of a piston located half way down its bore. What is critical, however, is that all four do wo I rods must be exactly the same length. 8 Break off the ceramic upper section of each plug and remove the centre electrode and earth tip. The easiest way to do this is to mount each spark plug in a vice (attar removing the ceramic uppor plug section) and drill a hole down through ihe centre of the plug. The diameter of Ihe drill bit should be the same as Ihe diameter of Ihe dowol rod to be used. When finished you should have four spark plug bodies and four equal length dowel rods which will slide through the centre of the spark plugs.

3 Cylinder compression test

1 When engine performance is down, or it misfiring occurs which cannot be attnbuted to the Ignition or fuel systems, a compression test can provide diagnostic clues as to the engine's condition. If the lest is performed regularly, it can give warning of trouble bofore any other symptoms become apparent.

4.10 Undo the upper timing cover upper retaining bolt, and the rear retaining boll

4.9 Undo the retaining bolt in the centre of the lower timing cover

2 The engine must be fully warmed-up to normal operxrtrfjg temperature, the battery must be fully charged, and all the spark plugs muse be removed (Chapter 1A>. The aid of an assistant wilt also be required. 3 Disable the ignition system by discon-necting the LT wiring plugs to the Ignition coils. 4 Fit a compression tester to the No t cylinder spark plug hole • the type of tester which screws into the plug thread is to be preferred. 5 Have the assistant hold the throttle wide open, and crank the engine on the starter motor; after one or two revolutions, the compression pressure should build up to a maximum figure, and then stabilise. Record the h.ghest reading obtained 6 Repeat the test on the remaining cylinders, recording Ihe pressure in each. 7 All cylinders should produce very similar pressures; any excessive difference indicates Ihe existence of a fault. Note that the compression should build up quickly in a healthy engine; low compression on (he first stroke, followed by gradually increasing pressure on successive strokes, indicates worn piston rings. A low compression reading on the first stroke, which does not build up during successive strokes, indicates leaking valves or a blown head gasket (a cracked head could also be tho cause). 6 If the pressure in any cylinder is very low, carry out the following test to isolate the cause. Introduce a teaspoonful of dean oil into that cylinder through its spark plug hole and repeal the lest. 9 If the addition of oil temporarily improves the compression pressure, this indicates that bore or piston wear is responsible for the pressure loss. No improvement suggests that leaking or burnt valves, or a blown head gasket, may be to blame. 10 A low reading from two adjacent cylinders is almost certainly due to the head gasket having blown between Ihem; the presence of coolant in the engine oil will confirm this. 11 If one cylinder is about 20 percent lower than the others and the engine has a slightly rough idle, a worn camshaft lobe could be the cause. 12 On completion of the test, refit the spark plugs and reconnect the ignition LT wiring plug.

4 Timing belt and covers -removal and refitting §

General information 1 The luncUon of the timing belt Is to drive the camshafts and coolant pump. Should the bell slip or creak in service, the valve timing will be disturbed and piston-to-valve contact wiu occur, resulting in serious engine damage. 2 The timing belt should be renewed at the specified Intervals (see Chapter 1A), or earlier If It is contaminated with oil, or if it is at all noisy In operation (a scraping noise due to uneven wear}. 3 If the timing belt is being removed, it is

a

wise precaution to check the condition of the coolam pump at the same time (oheck for signs of coolant leakage). This may avoid the need to remove the timing belt again at a later stage, should the coolant pump fail. 4 Before carrying out this procedure, it will be necessary to obtain or fabricate suitable camshaft locking tools and piston positioning tools as described in Section 2. The procedures contained In this Section depict the use of the home-made alternative tools described in Section 2. which were fabricated In the Haynes workshop. If the manufacturers tools are being used instead, the procedures are virtually identical. Oo not attempt to remove the timing bell unless the special totfs or their alternatives are available.

Removal 5 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of Ihis manual). 6 Remove the auxiliary drivebelt(s) as described In Chapter 1A. 7 Remove the air cleaner, Inlet air duct and resonator as desenbed In Chapter 4B. 8 Undo the three bolts and remove the crankshaft pulley from the sprocket (see illustration). 9 Undo the retaining bolt In the centre of the lower liming cover (see illustration). 10 Undo tho uppor timing cover upper retaining bolt, and the rear retaining bolt located above the alternator (see illustration). 11 Release the crankshaft TDC sensor wiring from the clip on the upper timing cover, then withdraw the cover slightly and slide Ihe wiring plug and socket from the liming cover slot (see illustrations). 12 Release the TDC sensor wiring from the periphery ol the upper and fower timing covers and remove both covers (see Illustrations). 13 Free the accelerator inner cable from the throttle cam, remove the outer cable spring dip, then pull the outer cable out from its mounting bracket rubber grommet. 14 From the side of the throttle body, disconnect the wiring connectors from the

Page 66 of 225

2B*6 DOHC (16-valve) petrol engine in-car repair procedures

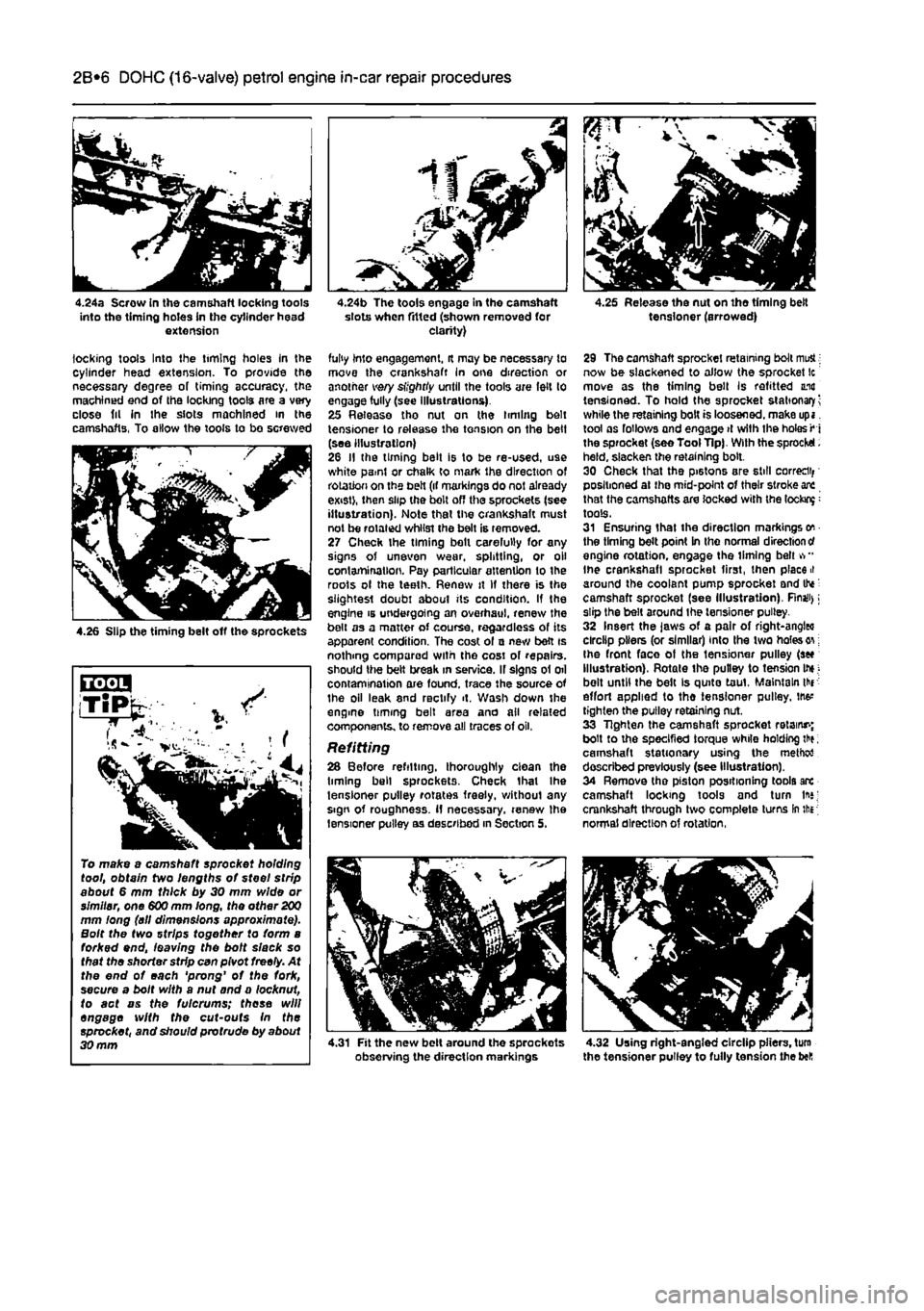

4.24a Scrow in the camshaft locking tools into the timing holes in the cylinder head extension

locking tools Into the timing holes in the cylinder head extension. To provide the necessary degree of timing accuracy, the machined end of the locking tools are a very close fit in the slots machined in the camshafts. To allow the tools to be screwed

4.26 Slip the timing belt off the sprockets

To make a camshaft sprocket holding tool, obtain two lengths of steel strip about 6 mm thick by 30 mm wide or simitar, one 600 mm long, the other

200

mm long (all dimensions approximate). Bolt the two strips together to form a forked end, leaving the bolt slack so that the shorter sfrfp can pivot freely. At the end of each 'prong' of the fork, secure a bolt with a nut and a locknut, to act as the fulcrums; these will engage with the cut-outs In the sprocket, and should profrude by about 30 mm

4.24b The tools engage in tho camshaft slots when fitted (shown removed for clarity)

fully into engagement, it may be necessary to move the crankshaft In one direction or another very slightiy until the tools are felt to engage fully (see illustrations). 25 Release tho nut on the timing belt tensioner to release the tension on the belt (see illustration) 26 II the timing belt is to be re-used, use white paml or chalk to mark the direction of rotation on the belt (if markings do not already exist), then slip the belt off the sprockets (see illustration). Note that the crankshaft must not be rotated whilst the belt is removed. 27 Check the timing belt carefully for any signs of uneven wear, splitting, or oil contamination. Pay particular attention to the roots ol the teeth. Renew it If there is the slightest doubt about its condition. If the engine is undergoing an overhaul, renew the belt as a matter of course, regardless of its apparent condition. The cost ol a new bett is nothing compared with the cosi of repairs, should the belt break in service. If signs of oil contamination are found, trace the source of the oil leak 8nd rectify it. Wash down the engme timing belt area and all related components, to remove all traces of oil,

Refitting 28 Before refilling, thoroughly clean the liming bell sprockets. Check that Ihe tensioner pulley rotates freely, without any sign of roughness. If necessary, renew Ihe tensioner pulley as described in Section 5,

4.31 Fit the new belt around the sprockots observing the direction markings

4.25 Release the nut on the timing belt tensioner (arrowed)

29 The camshaft sprocket retaining bolt mutt; now be slackened to allow the sprocket Ic move as the timing bell Is refitted una tensioned. To hold the sprocket stationary^ while the retaining bolt is loosened, make upi. tool os follows and engage

>t

with the holes ^ i the sprocket (see Tool Tip). With the sprocket. held, slacken the retaining bolt. 30 Check that the pi6tons are still correct positioned at ihe mid-point of their stroke are that the camshafts are locked with the lockup: tools. 31 Ensuring that the direction markings on the timing belt point in the normal direction

cf

engine rotation, engage the Umlng belt vr* Ihe crankshaft sprocket first, then placed around the coolant pump sprocket and tte: camshaft sprocket (see Illustration). Rnaii>; slip the belt around the tensioner pulley. 32 Insert the jaws of a pair of right-angleo clrclip pliers (or similar) into Ihe two holes on; Ihe front face of the tensioner pulley (sec Illustration). Rotate the pulley to tension Ihj; belt until the belt Is quite taut. Maintain thr effort applied to the tensioner pulley. JM* tighten the pulley retaining nut. 33 Tighten the camshaft sprocket retains; bolt to the specified torque while holding th?; camshaft stationary using the method described previously (see Illustration). 34 Remove the piston positioning tools arc camshaft locking tools and turn In*; crankshaft through two complete turns In the normal direction of rotation,

4.32 Using right-angled clrclip pliers, turn the tensioner pulley to fully tension the bell

Page 68 of 225

2B*8 DOHC (16-valve) petrol engine in-car repair procedures

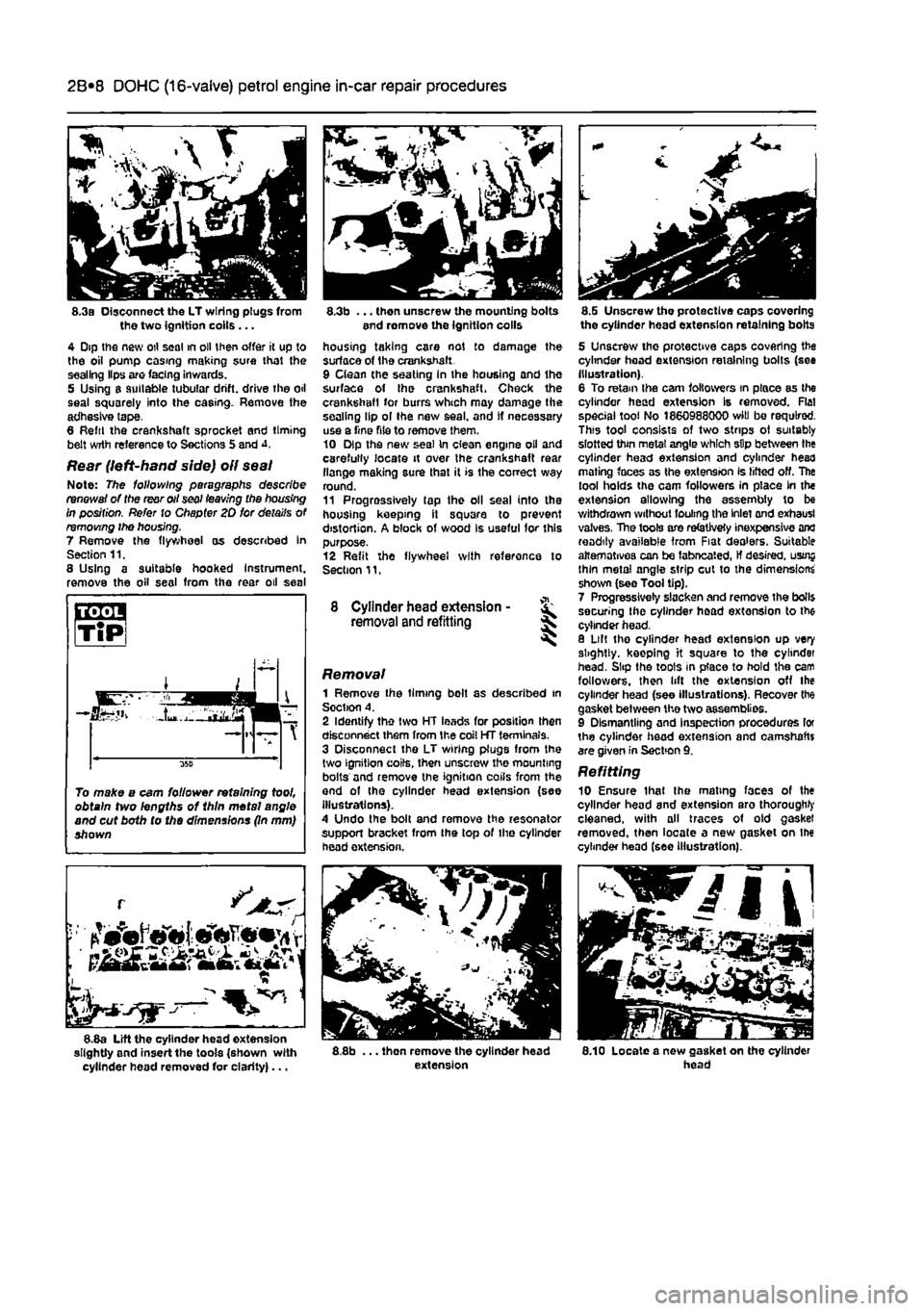

8.3a Disconnect the LT wiring plugs from the two Ignition coils ... 4 Dip the new oil seal in oil then offer it up to the oil pump casing making sure that the sealing Hps are facing inwards. 5 Using a suitable tubular drift, drive the oil seal squarely into the casing. Remove the adhesive tape, 8 Reftl the crankshaft sprocket and timing belt wrth reference to Sections 5 and

Rear (left-hand side) oil seal Note: The following paragraphs describe renewal of the rear oil seal leaving the housing in position. Refer to Chapter 20 for details of removing ihe housing. 7 Remove the flywheel as described In Section 11. 8 Using a suitable hooked Instrument, remove the oil seal from the rear oil seal

L •

~ 1 8.8a Lift the cylinder head extension slightly and insert the tools {shown with cylinder head removed for clarity)...

8.3b ... then unscrew the mounting bolts end romove the ignition colls housing taking care not to damage the surface of the crankshaft. 9 Clean the seating In the housing and the surface of Ihe crankshaft. Check the crankshaft for burrs which may damage the sealing lip ol Ihe new seal, and If necessary use a Tine file to remove them. 10 Dip the new seal In clean engine oil and carefully locate it over Ihe crankshaft rear flange making sure that it is the correct way round. 11 Progressively tap the oil seal into the housing keeping it square to prevent distortion. A block of wood Is useful for this purpose. 12 Refit the flywheel with reference to Section 11,

8 Cylinder head extension -removal and refitting ^

Removal 1 Remove the timing bolt as described in Soction A. 2 Identify the two HT leads for position then disconnect them from the coil HT terminals. 3 Disconnect the LT wiring plugs from the two ignition coils, then unscrew the mounting bolts and remove the ignition coils from the and of the cylinder head extension {see illustrations). A Undo the bolt and remove the resonator support bracket from Ihe top of the cylinder head extension,

8.8b ... thon remove the cylinder head extension

8.G Unscrew tho protective caps covering the cylinder head extension retaining bolts

5 Unscrew the protective caps covering the cylinder head extension retaining bolts (see Illustration). 6 To retain the cam followers in place as the cylinder head extension Is removed. Flat special tool No 1860988000 will bo required. This tool consists of two strips ol suitably slotted thin metal angle which sDp between the cylinder head extension and cylinder head mating faces as the extension Is lifted off. The tool holds the cam followers in place in the extension allowing the assembly to be withdrawn without fouling the Inlet and exhausl valves, The tools are refetJvety inexpensive and readily available from Fiat dealers. Suitable alternatives can be fabneated, If desired, usrnj thin metal angle strip cut to the dimensions shown (see Tool tip). 7 Progressively slacken and remove the boll$ securing the cylinder head extension to the cylinder head. 8 Lilt tho cylinder head extension up very slightly, keeping it square to the cylindei head. Slip the toots in place to hold the cam followers, then lift the extension off the cylinder head (see illustrations). Recover the gasket between the two assemblies. 9 Dismantling and Inspection procedures lor the cylinder head extension and camshafts are given in Section 9. Refitting 10 Ensure thai Ihe mating faces of the cylinder head and extension aro thorough^ cleaned, with all traces of old gasket removed, then locate a new gasket on Ihe cylinder head (see Illustration).

8.10 Locate a new gasket on the cylinder head

To make a cam follower retaining tool, obtain two lengths of 1hln metal angle and cut both to the dimensions (In mm) shown

Page 78 of 225

2C*2 Diesel engine in-car repair procedures

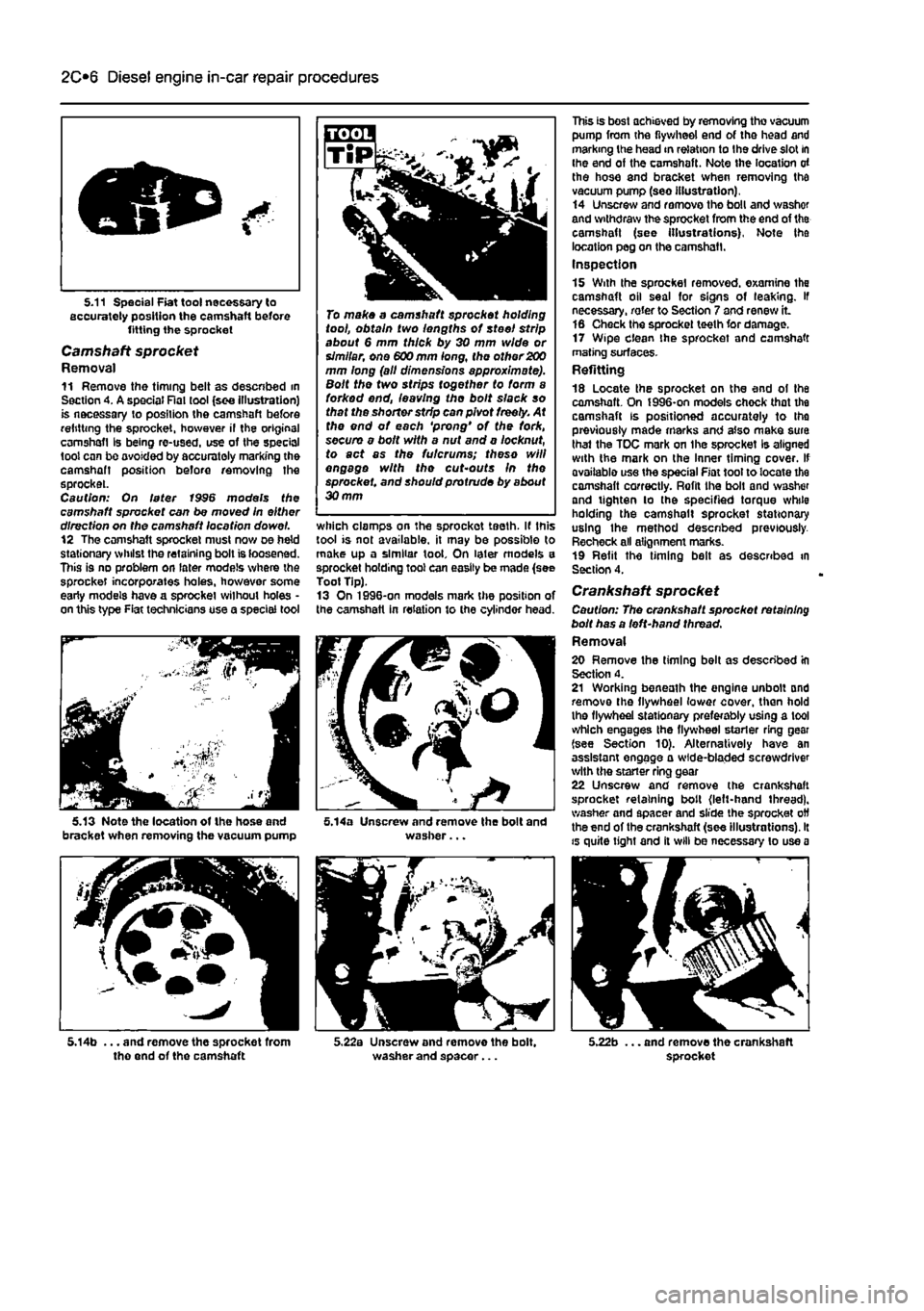

5.11 Special Fiat tool necessary to accurately position the camshaft before fitting the sprocket

Camshaft sprocket Removal 11 Remove the timing belt as descnbed in Section 4. A special Rat tool (see illustration) is necessary to position the camshaft before refitting the sprocket, however il the original camshafl Is being re-used, use of the special tool can be ovoided by accurately marking the camshaft position before removing the sprocket. Caution: On later 1996 models the camshaft sprocket can be moved In either direction on tho camshaft location dowel. 12 The camshaft sprocket must now oe held stationary whilst the retaining bolt is loosened. This is no problem on later models where the sprocket incorporates holes, however some early models have a sprocket without holes • on this type Fiat technicians use a special tool

V*— r^r

To make a camshaft sprocket holding tool, obtain two lengths of steel strip about 6 mm thick by 30 mm wide or simllar, one 600 mm long, the other 200 mm long (all dimensions approximate). Bolt the two strips together to form a forked end, leaving tho bolt slack so that the shorter strip can pivot freely. At the end of each 'prong' of the fork, secure a bolt with a nut and a locknut, to act as the futcrums; theso will engage with the cut'Outs In the sprocket, and should protrude by about 30 mm

which clamps on the sprockot teeth. If this tool is not available, it may be possible to make up a similar tool. On later models a sprocket holding tool can easily be made (see Toot Tip). 13 On 1996-on models mark the position of the camshaft in relation to the cylinder head.

5.14a Unscrew and remove the bolt and washer...

This is best achieved by removing tho vacuum pump from the flywheel end of the head and marking the head in relation to Ihe drive slot in ihe end of the camshaft. Note the location of the hose and bracket when removing tha vacuum pump (seo illustration). 14 Unscrew and remove tho boll and v/ashof and withdraw the sprocket from the end of tha camshaft (see Illustrations). Note tha location peg on the camshafl. Inspection 15 With the sprocket removed, examine the camshaft oil seal for signs of leaking. If necessary, rater to Section 7 and renew it 16 Check the sprocket teeth for damage. 17 Wipe clean the sprocket and camshaft mating surfaces-Refitting 18 Locate the sprocket on the end of the camshaft. On J996-on models chock that the camshaft is positioned accurately to tho previously made marks and also make sura thai the TOC mark on Ihe sprocket Is aligned with the mark on the Inner timing cover. If avoiiablo use the special Fiat toot to locate the camshaft correctly. Rofil the bolt and washer and tighten lo the specified torque while holding the camshalt sprocket stationary using the method descnbed previously. Recheck all alignment marks. 19 Refit the timing belt as described in Section 4.

Crankshaft sprocket Caution: The crankshaft sprockot retaining bolt has a left-hand thread. Removal 20 Remove the timing belt as described in Section 4. 21 Working beneath the engine unbolt and remove the flywheel lower cover, than hold the flywheel stationary preferably using a tool which engages the flywheel starter ring gear (see Section 10). Alternatively have an assistant engage a wide-bladed screwdriver with the starter ring gear 22 Unscrew and remove (he crankshaft sprocket retaining bolt (left-hand thread), washer and spacer and slide the sprocket off the end of the crankshaft (see illustrations). It is quite tight and il will be necessary to use a

5.14b ... and remove the sprocket from tho end of the camshaft 5.22a Unscrew and remove the bolt, washer and spacer... 5.22b ... and remove the crankshaft sprocket

Page 103 of 225

2D*10 Engine removal and overhaul procedures

Valves and associated components 35 Examine the head of each vaive for pitting, burning, cracks, and general wear. Check the valve stem for scoring and wear ridges. Rotate the valve, and check lor any obvious indication that it Is bent. Look tor pits or excessive wear on the tip of each valve stem. Renew any valve that shows any such signs of wear or damage. 36 if the valve appears satisfactory at this stage, measure the vaive stem diameter at several points using a micrometer. Any significant difference in the readings obtained Indicates wear of the valve stem. Should any of these conditions be apparent, the valve(s) must be renewed. 37 If the valves are In satisfactory condition, they should be ground (lapped) into their respective seats, to ensure a smooth, gas-tight seal. If the seat is only tightly pitted, or if it has been re-cut, fine grinding compound only should be used to produce the required finish. Coarse valve-grinding compound should nor be used, unless a seat is badly bumed or deeply pitted, If this is the case, the cylinder head and valves should be Inspected by an expert, to decldo whether seat re-cutting, or even the renewal of the valve or seat insert (where possible) is required. 38 Valve grinding Is carried out as follows. Place the cylinder head upside-down on blocks on a bench. 39 Smear a trace of (the appropriate grade of) valve-gnndtng compound on the seat face, and press a suction grinding tool onto the valve head. With a semi-rotary action, grind

6.48 Compressing the vaive spring and fitting the split collets

them

the valve head to its seat, lifting the valve occasionally to redistribute tho grinding compound (see Illustration). A light spring placed under the valve head will greatly ease this operation 40 If coarse grinding compound Is being used, v/ork only until a dull, matt even surface Is produced on both the valve seal and the valve, then wipe off tho used compound, and repeat the process with fine compound. When a smooth unbroken ring ol light grey malt finish Is produced on both the valve and seat, the grinding operation is complete. Do not grind-In the valves any further than absolutely necessary, or the seat will be prematurely sunk into the cylinder head. 41 When all the valves have been ground-m, carefully wash off all traces of grinding compound using paraffin or a suitable solvent, before reassembling the cylinder head. 42 Examine the valve springs for signs of damage ano discoloration, If possible compare the length of the springs with new ones and renew them if necessary. 43 Stand each spring on a flat surface, and check ft tor squareness. If any of the springs are damaged, distorted or have lost mar tension, obtain a complete new set of springs. It Is normal to renew the valve springs as a matter of course if a major overhaul is being earned out. 44 Renew (he valve stem oil seals regardless of their apparent condition.

Reassembly 45 Lubricate the stems of the valves, and insert the valves into their original locations

6.53 Tightening the camshaft bearing cap nuts (diesel engines)

6.46 Using a socket to press the valve stem seals onto the guides

(see illustration). If new valves are being fitted, insert them Into the locations to which they have been ground. 46 Refit the spring sea( then, working on the first valve, dip the new valve stem sesl in fresh engine oil. Carefully locate it over the valve and onto the guide. Take care not to damage the seal as it Is passed over the valve stem. Use a suitable socket or metal tube to press the seal firmly onto the guide (sea Illustration). 47 Locate the valve spring on top of its seat, then refit the spring retainer. 48 Compress the valve spring, and locate the split collets in the recess in the valve stem. Release the compressor, then repeat the procedure on the remaining valves (see illustration)

Use a dab o) grease to hold Uiejitts* the collets In position on the HlNT valve stem while the spring compressor is released.

49 With ail the valves Installed, place the cylinder head on blocks on the bench and, using a hammer and Interposed block ol wood, top the end of each valve stem to settle the components. 50 On diesel engines, refit the swirl chambers together with their washers and tighten the retaining collars to the specified torque. 51 Oil the cam followers and locate them In their correct positions in the cylinder head. Locate the shims In the cam followers making sure they are in their original positions. 52 Oil the journals then locate the camshaft m the cylinder head with the cam lobes of No 1 cylinder facing upwards (ie No 1 cylinder at TDC). 53 Refit the bearing caps In their correct positions and progressively tighten the nuts/bolts to the specified torque (sea illustration). On petrol engines locate the lubrication pipe on Ihe head and press in the oil feed stub before refitting the bolts. 54 On diesel engines fit a new oil sea) to the right-hand side mount, then refit both side mounts together with new gaskets, Tighten the right-hand mount bolts. Also refit the coolant cover and thermostat housing together with new gaskets (see illustrations).

Page 107 of 225

2D*10 Engine removal and overhaul procedures

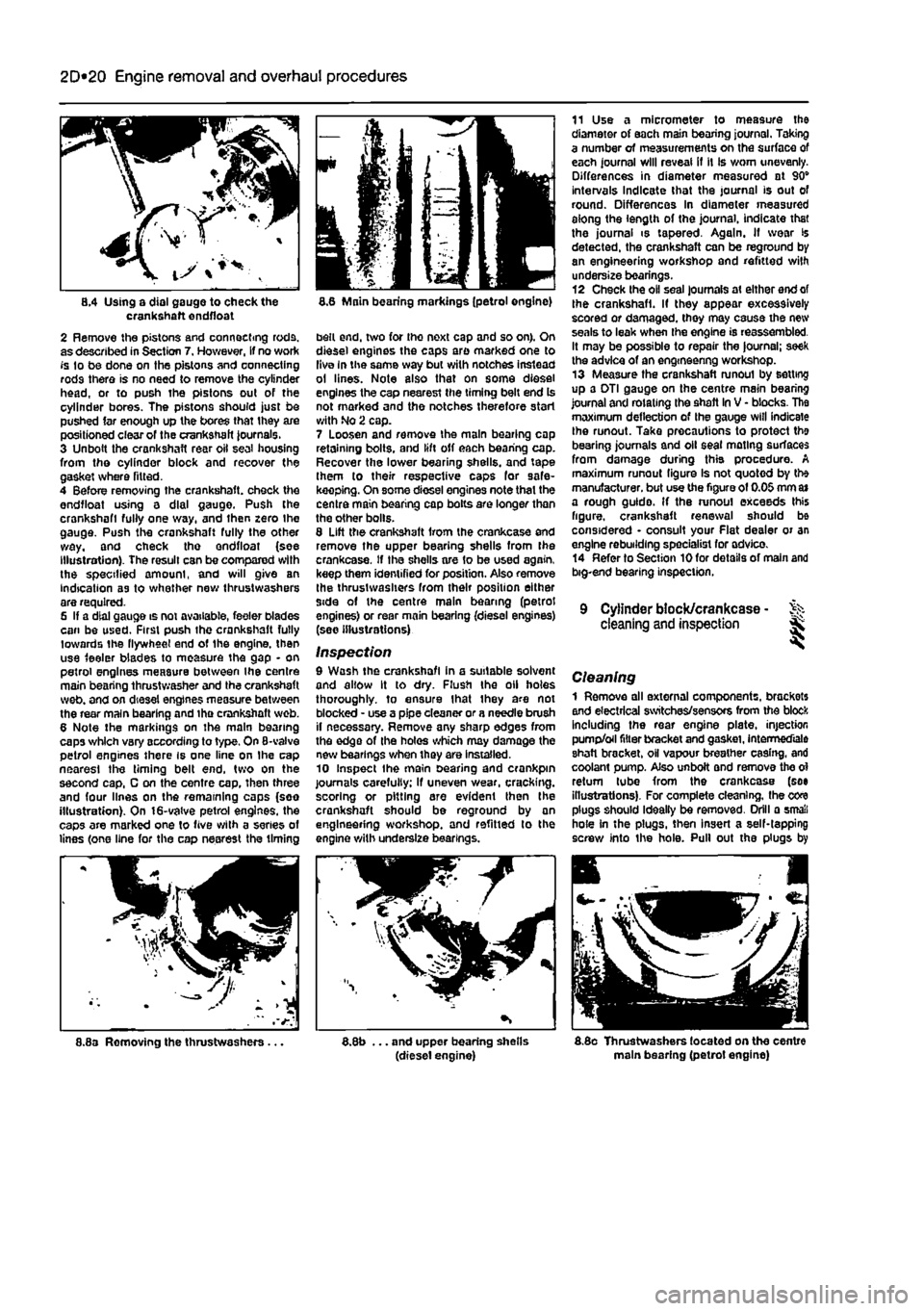

8.4 Using a dial gauge to check the crankshaft endfloat 2 Remove the pistons and connecting rods, as described in Section 7. However, If no work fs to be done on the pistons and connecting rods there is no need to remove the cylinder head, or to push the pistons out of the cylinder bores. The pistons should just be pushed far enough up the bores that they are positioned clear of the crankshaft Journals. 3 Unbolt the crankshaft rear oil seal housing from the cylinder block and recover the gasket where fitted. 4 Before removing the crankshaft, check the endfloat using a dial gauge. Push the crankshaft fully one way, and then zero Ihe gauge. Push the crankshaft fully the other way, and check tho endfloat (see Illustration). The result can be compared with the specified amount, and will give an indication as to whether new thrustwashers are required. 6 If a dial gauge is not available, feeler blades can be used. First push the crankshaft fully towards the flywheel end of the engine, then use feeler blades to measure the gap - on petrol engines measure between the centre main bearing thrust washer and the crankshaft web. and on diesel engines measure between the rear main bearing and tha crankshaft web. 6 Note the markings on the main bearing caps which vary according to type. On 8-valve petrol engines there is one line on Ihe cap nearest the timing belt end, two on the second cap, C on the centre cap, then three and four lines on the remaining caps (soo illustration). On 16-valve petrol engines, the caps are marked one to five with a series of lines (one line for the cap nearest the timing

8.6 Main bearing markings (petrol engine)

belt end, two for tho next cap and so on). On diesel engines the caps are marked one to live In the same way but with notches instead ol lines. Note also that on some diesel engines the cap nearest the timing belt end Is not marked and the notches therefore start with No 2 cap. 7 Loosen and remove the main bearing cop retaining bolts, and lift off each bearing cap. Recover the lower bearing shells, and tape them to their respective caps for safe-keeping. On some diesel engines note that the centre main bearing cap botts are longer than the other bolls. 8 Lift the crankshaft Irom the crankcase and remove the upper bearing shells from the crankcase. If the shells are 1o be used again, keep them identified for position. Also remove the thrustwashers from their position either side of the centre main bearing (petrol engines) or rear main bearing (diesel engines) (see illustrations)

Inspection 9 Wash the crankshaft in a suitable solvent and allow It to dry. Flush the oil holes thoroughly, to ensure that ihey are not blocked - use a pipe cleaner or a needle brush il necessary. Remove any sharp edges from the edge of the holes which may damage the new bearings when they are installed. 10 Inspect the main searing and crankpin journals carefully; if uneven wear, cracking, scoring or pitting are evident then the crankshaft should be reground by an engineering workshop, and refitted to the engine with underslze bearings.

11 Use a micrometer to measure the diameter of each main bearing journal. Taking a number of measurements on the surface of each journal will reveal if it Is worn unevenly. Differences in diameter measured at 90" intervals Indicate that the journal is out of round. Differences In diameter measured aiong the length of the journal, indicate that the journal is tapered. Again. If wear is detected, the crankshaft can be reground by an engineering workshop and refitted with undersize bearings. 12 Check the oil seal journals at either end of the crankshaft. If they appear excessively scored or damaged, they may cause the new seals to leak when the engine is reassembled. It may be possible to repair the |ournal; seek the advice of an engmeenng workshop. 13 Measure the crankshaft runoul by setting up a DTI gauge on the centre main bearing journal and rotating the shaft In V - blocks. The maximum deflection of the gauge will indicate Ihe runout. Take precautions to protect the bearing journals and oil seal mating surfaces from damage during this procedure. A maximum runout figure Is not quoted by the manufacturer, but use the figure of 0.05 mm

a»

a rough guido. If the runoul exceeds this figure, crankshaft renewal should be considered • consult your Flat dealer or an engine rebuilding specialist for advico. 14 Refer to Section 10 for details of main and big-end bearing inspection.

9 Cylinder block/crankcase - % cleaning and inspection Sk

Cleaning 1 Remove all external components, brackets and electrical switches/sensors from the block Including the rear engine plate, injection pump/oil filter bracket and gasket, Intermediate shaft bracket, oH vapour breather casing, and coolant pump. Also unboit and remove the ol return tube from the crankcase (see illustrations). For complete cleaning, the core plugs should Ideally be removed. Drill a small hole in the plugs, then insert a self-tapping screw into the hole. Pull out the plugs by

8.8a Removing the thrustwashers.. ... and upper bearing shells (diesel engine) 8.8o Thrustwashers located on the centre main bearing (petrol engine)

Page 110 of 225

2D*10 Engine removal and overhaul procedures

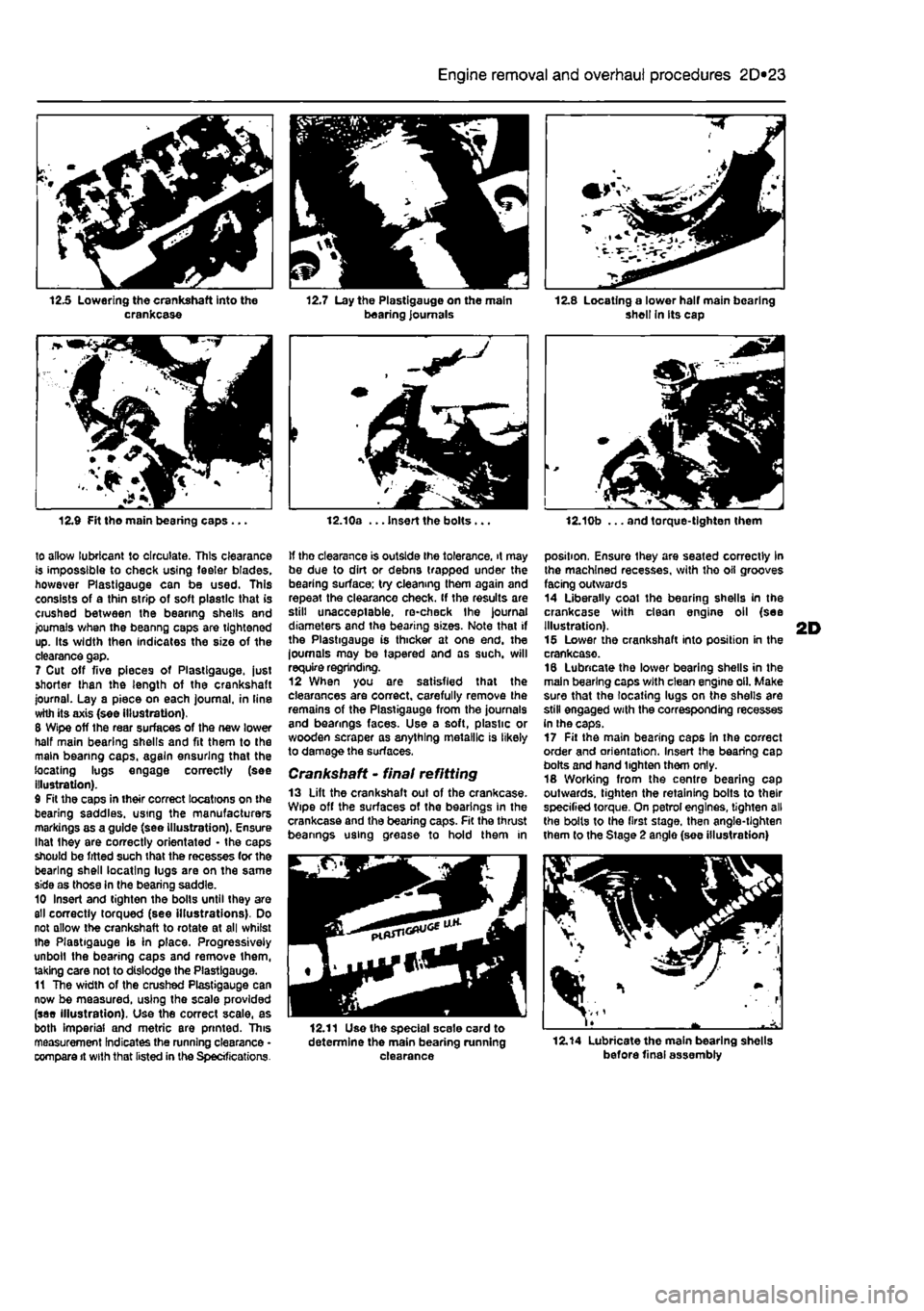

12.5 Lowering the crankshaft into the crankcase

12.9 Fit tho main bearing caps...

to allow lubricant to circulate. This clearance is impossible to check using feeler blades, however Plastlgauge can be used. This consists of a thin strip of soft plastic that is crushed between the bearing shells and journals when the beanng caps are tightened up. Its width then indicates the size of the clearance gap. 7 Cut off five pieces of Plastlgauge. just shorter than the length of the crankshaft journal. Lay a piece on each journal, in line with its axis (see Illustration). 8 Wipe off the rear surfaces of the new lower half main bearing shells and fit them to the main beanng caps, again ensuring that the locating lugs engage correctly (see illustration). 9 Fit the caps in their correct locations on the bearing saddles, using the manufacturers markings as a guide (see illustration). Ensure lhat Ihey are correctly orientated • the caps should be fitted such that the recesses (or the bearing shell locating lugs are on the same side as those in the bearing saddle. 10 Insert and tighten the bolls until they are

811

correctly torqued (see illustrations). Do not allow the crankshaft to rotate at all whilst ihe Plastlgauge is in place. Progressively unbolt the bearing caps and remove them, taking care not to dislodge the Plastlgauge. 11 The width of the crushed Plastigauge can now be measured, using the scale provided (see illustration). Use the correct scale, as both Imperial and metric are printed. This measurement Indicates the running clearance • compare it with that listed in the Specifications.

21 \ „ 12.7 Lay the Plastigauge on the main bearing journals

t

12.10a ... Insert the bolts...

If tho clearance is outside ihe tolerance, it may be due to dirt or debns trapped under the bearing surface; try cleaning them again and repeat the clearance check. If the results are still unacceptable, re-check Ihe journal diameters and the bearing sizes. Note that if the Plastigauge is thicker at one end. the loumals may be tapered and as such, will require regrinding. 12 When you are satisfied that the clearances are correct, carefully remove the remains of the Plastigauge from the journals and bearings faces. Use a soft, plastic or wooden scraper as anything metallic is likely to damage the surfaces.

Crankshaft • final refitting 13 Lift the crankshaft out of the crankcase. Wipe off the surfaces of the bearings in the crankcase and the bearing caps. Fit the thrust beanngs using grease to hold them in

12.11 Use the special scale card to determine the main bearing running clearance

shell In its cap

12.10b ... and torque-tighten them

position, Ensure they are seated correctly in the machined recesses, with tho oil grooves facing outwards 14 Liberally coat the bearing shells in the crankcase with dean engine oil (see Illustration). 15 Lower the crankshaft into position in the crankcase. 16 Lubricate the lower bearing shells in the main bearing caps with clean engine oil. Make sure that the locating lugs on the shells are still engaged with the corresponding recesses in the caps. 17 Fit the main bearing caps in the correct order and orientation. Insert the bearing cap bolts and hand tighten them only. 18 Working from the centre bearing cap outwards, tighten the retaining bolts to their specified torque. On petrol engines, tighten all the bolts to the first stage, then angle-tighten them to the Stage 2 anglo (see illustration)

12.14 Lubricate the main bearing shells before final assembly

Page 130 of 225

4A*2 Fuel system -

single-point

petrol Injection models

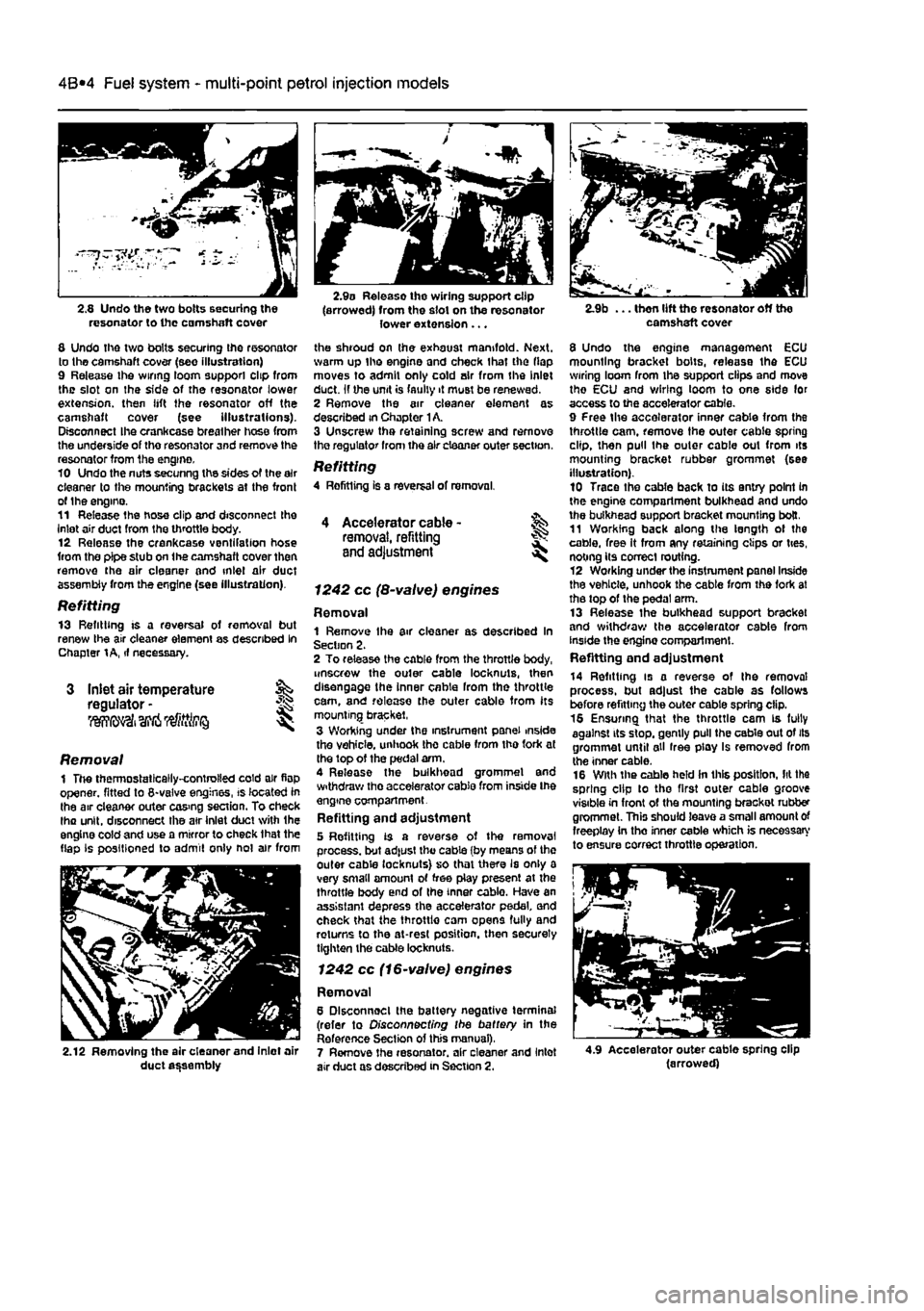

2.8 Undo tho two bolts securing the resonator to the camshaft cover

8 Undo the two bolts securing the resonator to the camshaft cover (see illustration) 9 Release ihe wiring loom support clip from the slot on the side of the resonator lower extension, then lift the resonator off the camshaft cover (see illustrations). Disconnect Ihe crankcase breather hose from the underside of tho resonator and remove the resonator from the engine. 10 Undo the nuts secunng the sides of the air cleaner to the mounting brackets at the front of the engino. 11 Release the hose clip and disconnect the inlet air duct from the throttle body. 12 Release the crankcase ventifation hose from the pipe stub on the camshaft cover then remove the air cleaner and inlet air duct assembly from the engine (see illustration).

Refitting 13 Refitting is a reversal of removal but renew the air cleaner element as described In Chapter

1 A,

if necessary.

Inlet air temperature regulator -liWfii' I

2.9o Release the wiring support clip (arrowed) from the slot on the resonator lower extension ...

the shroud on the exhaust manifold. Next, warm up tho engine and check that the flap moves to admit only cold air from the Inlet duct. If the unit is faulty it must be renewed. 2 Remove the air cleaner element as described in Chapter

1

A. 3 Unscrew tha retaining screw and remove tho regulator from the air cleaner outer section.

Refitting 4 Rofitting is a reversal of removal.

I

Removal 1 The thermostatically-controlled cold air flop opener, fitted to 8-valve engines, is located in the air cleaner outer cos>ng section. To check lha unit, disconnect the atr inlet duct with the engine cold and use a mirror to check that the flap Is positioned to admit only not air from

2.12 Removing the air cleaner and Inlet air duct assembly

4 Accelerator cable -removal, refitting and adjustment

1242 cc (8-valve) engines

Removal 1 Remove Ihe air cleaner as described In Section 2. 2 To release the cable from the throttle body, unscrew the outer cable locknuls, then disengage the inner cable from the throttle cam, and release the outer cable from its mounting bracket, 3 Wording under the instrument panel inside the vehicle, unhook the cable from tho fork at the top of the pedal arm. 4 Release the bulkhead grommel and withdraw tho accelerator cable from inside Ihe engine compartment. Refitting and adjustment 5 Refitting is a reverse of the removal process, but ad|ust the cable (by means of the outer cable locknuts} so that there Is only a very small amount of free play present at the throttle body end of the inner cablo. Have an assistant depress the accelerator pedal and check that the throttlo cam opens fully and returns to the at-rest position, then securely tighten the cable locknuts.

1242 cc (16-valve) engines

Removal 6 Dlsconnoel the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual), 7 Remove the resonator, air cleaner and Inlet air duct as described in Section 2.

camshaft cover

8 Undo the engine management ECU mounting bracket bolts, release the ECU wiring loom from Ihe support clips and move tho ECU and wiring loom to one side for access to the accelerator cable. 9 Free the accelerator inner cable from the throttle cam, remove the outer cable spring clip, then pull the outer cable out from its mounting bracket rubber grommet (see illustration). 10 Trace the cable back to its entry point in the engine compartment bulkhead and undo the bulkhead support bracket mounting bolt. 11 Working back along the length of the cable, free It from any retaining clips or ties, noting its correct routing. 12 Working under the instrument panel Inside the vehicle, unhook the cable from the fork at the top of the pedal arm. 13 Release the bulkhead support bracket and withdraw the accelerator cable from inside the engino compartment. Refitting end adjustment

14 Refitting is a reverse of the removal process, but adjust the cable as follows before refitting the outer cable spring clip. 16 Ensuring that the throttle cam is fully against its stop, gently pull the cable out of its grommet until all free play Is removed from the inner cable. 16 With the cable held in this position, lit the spring clip to tho first outer cable groove visible in front of the mounting brackot rubber grommet. This should leave a small amount of freeplay in tho inner cable which is necessary to ensure correct throttle operation.

4.9 Accelerator outer cable spring clip (arrowed)