Rear FIAT PUNTO 1998 176 / 1.G Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1998, Model line: PUNTO, Model: FIAT PUNTO 1998 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 173 of 225

8*2 Driveshafts

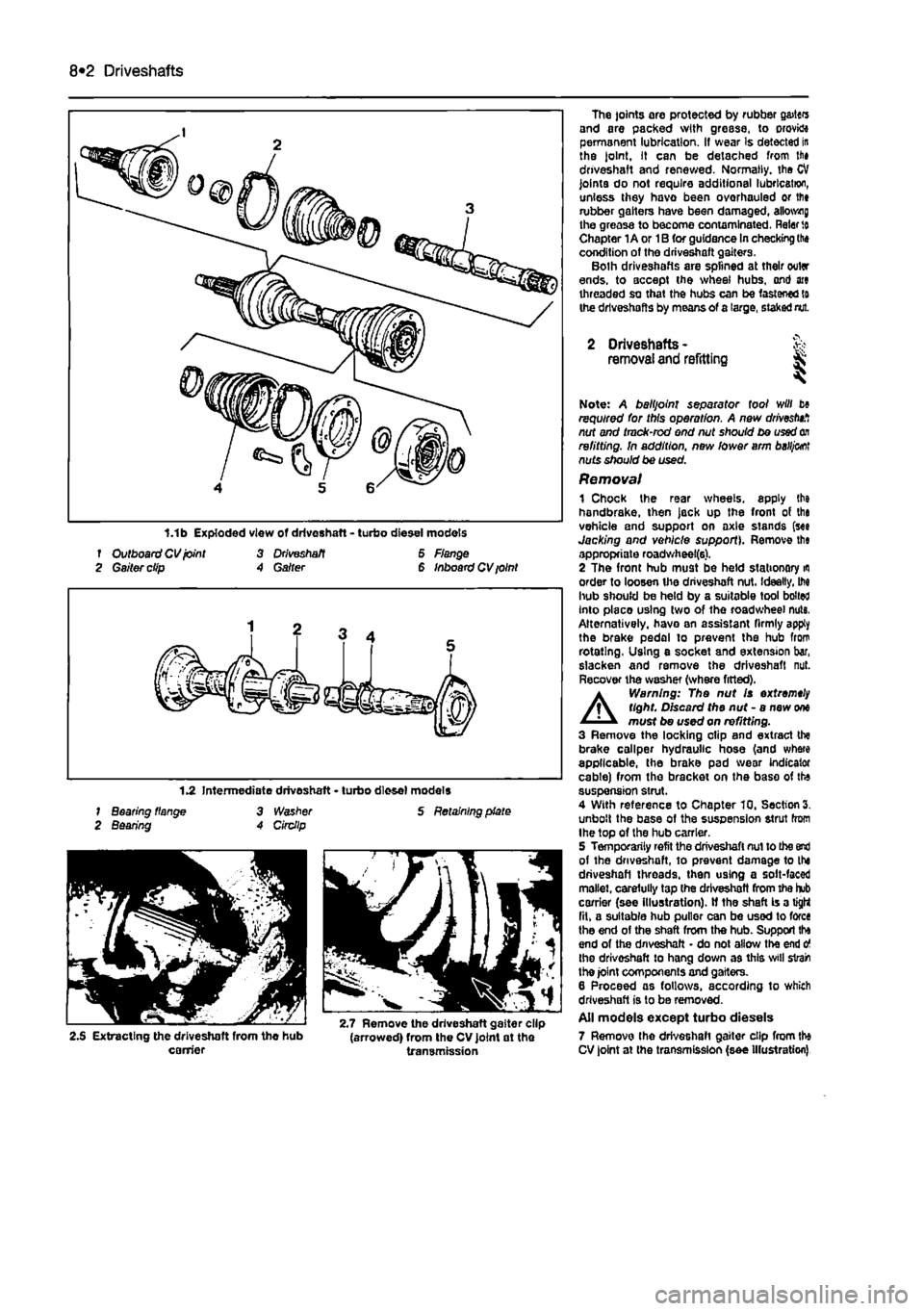

f Outboard CV joint 3 Driveshaft 6 Flange 2 Gaiter clip A Garter 6 Inboard CV ioint

1.2 Intermediate driveshaft • turbo diesel models 1 Bearing flange 3 Washer S Retaining plate 2 Bearing A Circllp

2.S Extracting the driveshaft from the hub (arrowed) from the CV joint at the carrier transmission

The joints are protected by rubber g&itcrs and are packed with grease, to orovktt permanent lubrication. If wear Is detected in the joint. It can be detached from lii» driveshaft and renewed. Normally, the CV joints do not require additional lubrication, unless they havo been overhauled or lfi» rubber gaiters have been damaged, allotting the greasa to become contaminated. Rater

to

Chapter 1A or 1B for guidance In checking the condition of the driveshaft gaiters. Bolh driveshafts are splined at their outer ends, to accept the wheel hubs, ond ate threaded so that the hubs can be fastened to the driveshafts by means of a large, staked nut.

2 Driveshafts -removal and refitting & ^

Note: A balljoint separator tool will b» required for this operation. A new drivestnf, nut and tmck-rod end nut should be used

on

refitting. In addition, new lower arm

baHj&ot

nuts should be used. Removal 1 Chock the rear wheels, apply the handbrake, then jack up the front of tha vehicle and support on axle stands (see Jacking and vehicle support). Remove th« appropriate roadwheel(6). 2 The front hub must be held stationary

m

order to loosen the driveshaft nut. Ideally, M hub should be held by a suitable tool bolted Into placo using two of the roadwheel nuts, Alternatively, havo an assistant firmly apply the brake pedal to prevent the hub from rotating. Using e socket and extension bar, slacken and remove the driveshaft nut. Recover the washer (where fitted).

A

Warning: The nut Is extremely tight. Discard the nut - a new

one

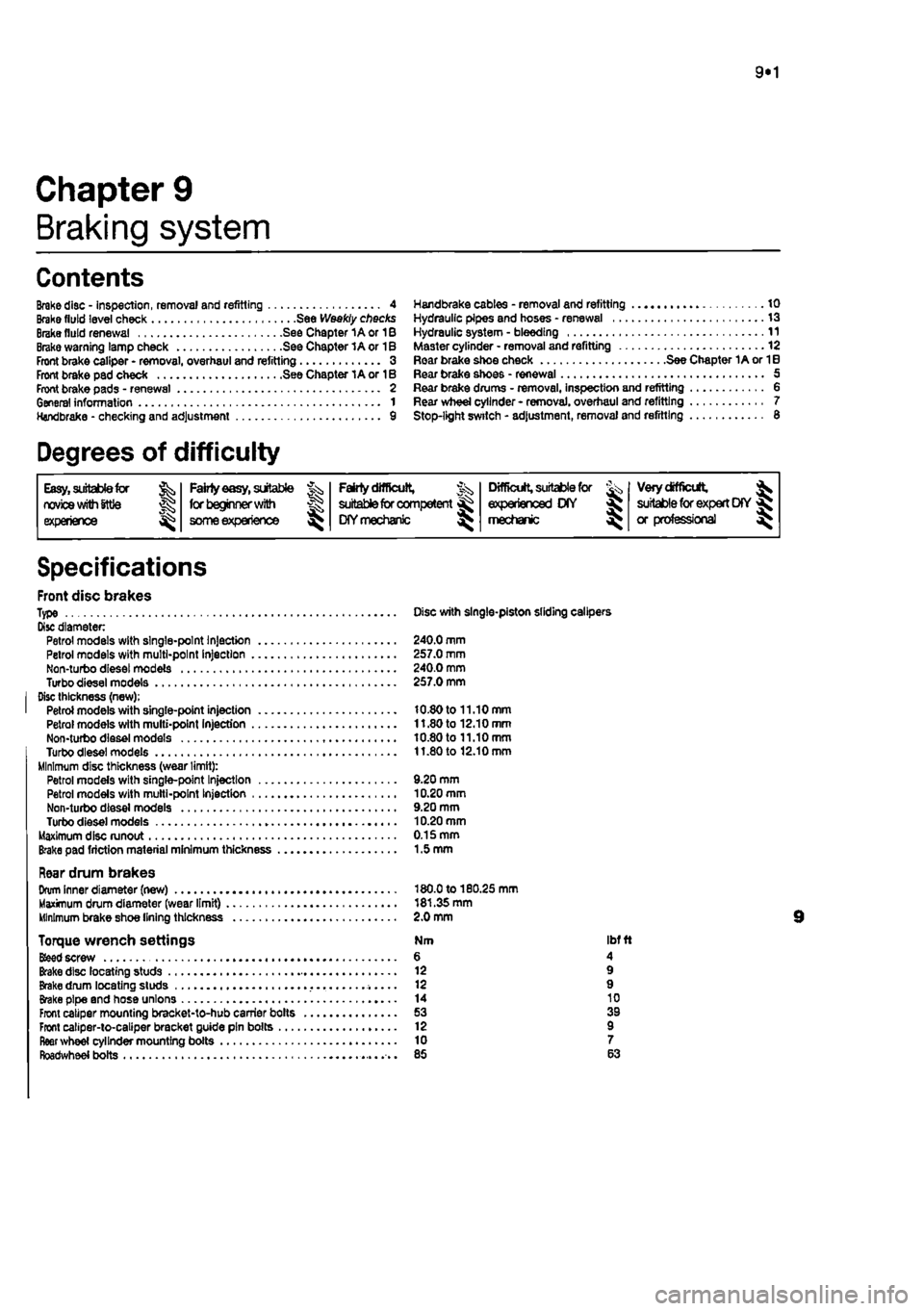

must be used on refitting. 3 Remove the locking clip and extract the brake caliper hydraulic hose (and where applicable, the brake pad wear indicator cable) from the bracket on the base of the suspension strut. 4 With reference to Chapter 10, Section 3. unbolt the base of the suspension strut from Ihe top of the hub carrier. 5 Temporarily refit the driveshaft nut to the end of the driveshaft, to prevent damage to the driveshaft threads, then using a solt-faced mallet, carefully tap the driveshaft from the hub carrier (see illustration). If the shaft is a tight fit, a suitable hub puller can be used to force the end of the shaft from the hub. Support tha end of the driveshaft • do not allow the end o the driveshaft to hang down as this svill strain the joint components and gaiters. 6 Proceed as follows, according to which driveshaft is to be removed. All models except turbo diesels 7 Remove the driveshaft gaiter clip from the CV joint at the transmission (see Illustration)

Page 177 of 225

9«1

Chapter 9

Braking system

Contents

Brake disc - inspection, removal and refitting 4 Brake fluid level check See Weekly checks Brake fluid renewal See Chapter 1A or 1B Brake warning lamp check See Chapter 1A or 1B Front brake caliper - removal, overhaul and refitting 3 Front brake pad check See Chapter 1A or 1B Front brake pads - renewal 2 General information 1 Handbrake - checking and adjustment 9

Handbrake cables - removal and refitting 10 Hydraulic pipes end hoses - renewal 13 Hydraulic system - bleeding 11 Master cylinder - removal and refitting 12 Roar brake shoe check See Chapter 1A or 1B Rear brake shoes - renewal 5 Rear brake drums - removal, inspection and refitting 6 Rear wheel cylinder - removal, overhaul and refitting 7 Stop-light switch - adjustment, removal and refitting 6

Degrees of difficulty

Easy, suitable

far

novice with Sttle

experience ^

Fairly

easy,

suitable ^ (orbeginnerwith ®

some

experience

Fairly difficult, suitable

for

compe«ent ^ CHYmechanlc ^

Difficult, suitable for

experienced DIY « mechanic ^

Very difficult, ^

suitable

for

expert DIY

or professional ^

Specifications

Front disc brakes Type Disc with single-piston sliding calipers Disc diameter Petrol models with single-point Injection 240.0 mm Petrol models with multi-point Injection 257.0 mm Non-turbo diesel models 240.0 mm Turbodieselmodels 257.0 mm Disc thickness (new); Petrol models with single-point injection 10.80 to 11.10 mm Petrol models with multi-point Injection 11.80 to 12.10 mm Non-turbo diesel models 10.80 to 11.10 mm Turbodieselmodels 11.80 to 12.10 mm Minimum disc thickness (wear limit): Petrol models with single-pant Injection 9.20 mm Petrol models with multi-point Injection 10.20 mm Non-turbo diesel models 9.20 mm Turbo diesel models 10.20 mm Maximum disc runout 0.15 mm Brake pad friction material minimum thickness 1.5 mm

Rear drum brakes Drum Inner diameter (new) 180.0 to 180.25 mm Maximum drum diameter (wear limit) 181.35 mm Minimum brake shoe lining thickness 2.0 mm

Torque wrench settings Nm ibf ft

Bfeed

screw 6 4 Brake disc locating studs 12 9 Brake drum locating studs 12 9 Brake pipe and hose unions 14 10 Front caliper mounting bracket-to-hub carrier bolts 53 39 Front caliper-to-caliper bracket guide pin bolts 12 9 fleer wheel cylinder mounting boils 10 7 Roadwheel bolts 85 63

Page 178 of 225

9*2 Braking system

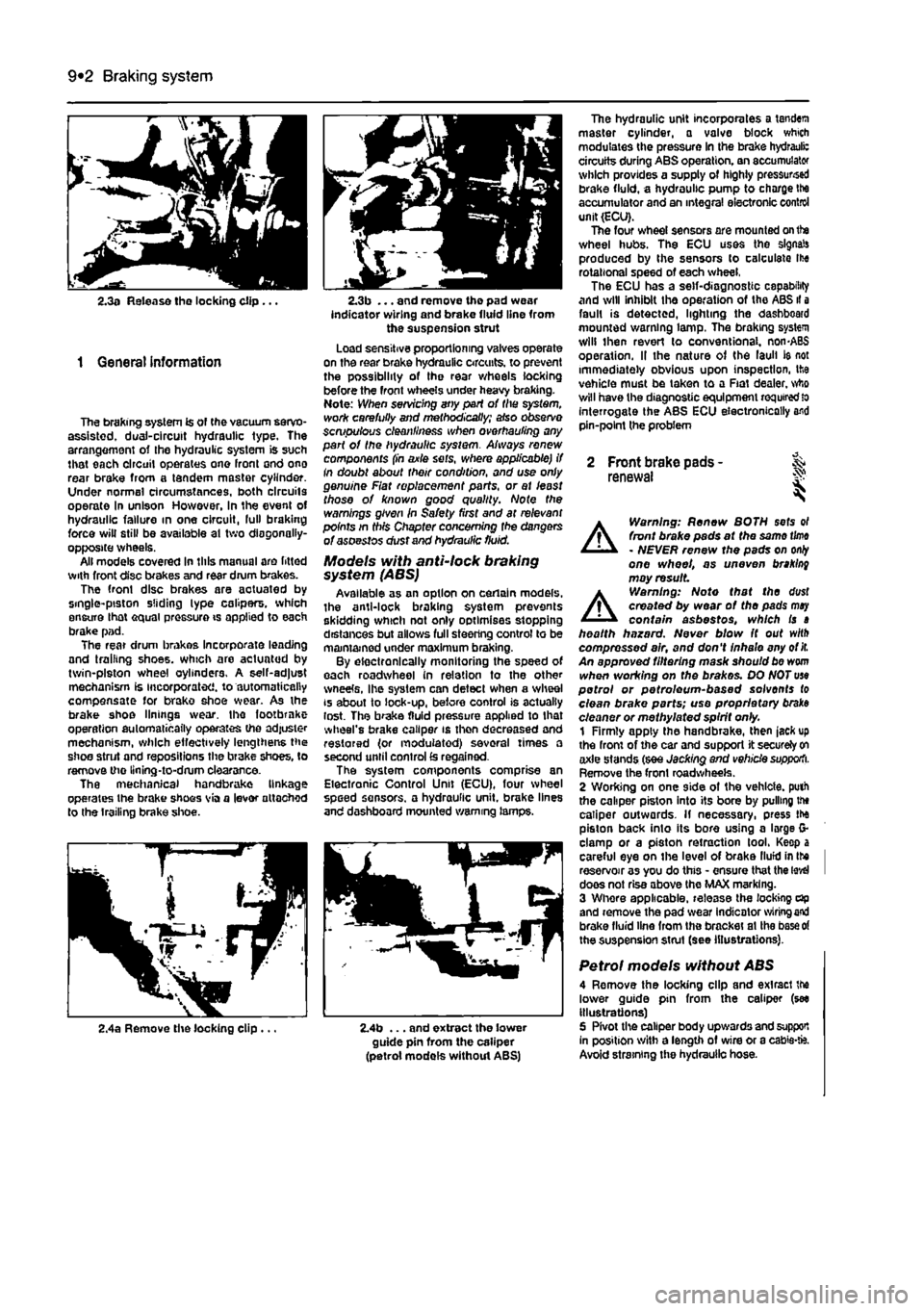

2.3a Release tho locking clip ...

1 General information

The braking system is of the vacuum servo-assisted. dual-circuit hydraulic type. The arrangement of Ihe hydraulic system is such that each circuit operates one front ond ono rear brake from a tandem master cylinder. Under normal circumstances, both circuits operate In unison However, in the event of hydraulic failure in one circuit, lull braking force will still be available at two diagonally-opposite wheels. All models covered in this manual are fitted with front disc brakes and rear drum brakes. The front disc brakes are aotuated by single-piston sliding lype calipers, which ensure lhat equal pressure is applied to each brake pad. The rear drum brakes incorporate leading and trailing shoes, which are actuated by twin-piston wheel cylinders. A self-adjust mechanism is incorporated, to automatically compensate for brako shoe wear. As the brake shoe linings wear, the footbrnke operation automatically operates the adjuster mechanism, which effectively lengthens the shoe strut and repositions the brake shoes, to remove the llning-to-drum clearance. The mechanical handbrake linkage operates the brake shoos via a lever attached to the trailing brake shoe.

2.3b ... and remove the pad wear indicator wiring and brake fluid line from the suspension strut Load sensitive proportioning valves operate on the rear brake hydraulic circuits, to prevent the possibility of the rear wheels locking before the front wheels under heavy braking. Note: When servicing any part of the system, work carefully and methodically; also observe scmpulous cleanliness when overhauling any part of the hydraulic sysiem. Always renew components (in axle sets, where applicable) if In doubt about their condition, and use only genuine Fiat replacement parts, or at least those of known good quality. Note the warnings given in Safety first and at relevant points in this Chapter concerning fhe dangers of asoestos dust and hydraulic fluid.

Models with anti-lock braking system (ABS) Available as an option on certain models, the anti-lock braking system prevents skidding which not only optimises stopping distances but allows full steering control to be maintained under maximum braking. By electronically monitoring the speed of each roadwheel in relation to the other wneete, Ihe system can detect when a wheel is about to lock-up, before control is actually lost. The brake fluid pressure applied to that wheel's brake caliper is then decreased and restored (or modulated) several times a second until control

£s

regained. The system components comprise an Electronic Control Unit (ECU), four wheel speed sensors, a hydraulic unit, brake lines and dashboard mounted warning lamps.

The hydraulic unit incorporates a tandem master cylinder, a valve block which modulates the pressure in the brake hydrauli: circuits during ABS operation, an accumulator which provides a supply of highly pressursed brake fluid, a hydraulic pump to charge Ihe accumulator and an integral electronic control unit (ECU). The four wheel sensors are mounted on the wheel hubs. The ECU uses the signals produced by the sensors to calculate Ihe rotational speed of each wheel, The ECU has a self-diagnostic capability and will inhibit the operation of the ABS il a fault is detected, lighting the dashboard mounted warning lamp. The braking system will then revert lo conventional. non-ABS operation. II the nature of the laull ie not immediately obvious upon inspection, the vehicle must be taken to a Fiat dealer, who will have the diagnostic equipment

required

lo interrogate the ABS ECU electronically and pin-point the problem

2 Front brake pads - & renewal S

A

Warning: Renew BOTH sets ol front brake pads at the same

time

- NEVER renew the pads on

only

one wheel, as uneven braking may result

A

Warning: Note that the dust created by wear of the pads

may

contain asbestos, which is a health hazard. Never blow It out with compressed air, and don't inhale any of

it.

An approved filtering mask should be worn when working on the brakes. DO NOT use petrol or petroleum-based solvents to clean brake parts; use proprietary braks cleaner or methylated spirit only. 1 Firmly apply the handbrake, then jack up the front of the car and support it securely

on

axle stands (see Jacking and vehicle supporti. Remove the front roadwheeis. 2 Wording on one side of the vehicle, puth the caliper piston into its bore by pulling the caliper outwards. If necessary, press the piston back into its bore using a large G-clamp or a piston retraction tool. Keep a careful eye on the level of brake llufd in Ihe I reservoir as you do this - ensure that the

level

I does not rise above the MAX marking. 3 Whore applicable, release the locking dp and remove the pad wear indicator

wiring end

brake fluid line from the bracket at Ihe

base of

the suspension strut (see illustrations).

Petrol models without ABS 4 Remove the locking clip and exlracl the lower guide pin from the caliper (see illustrations) 5 Pivot the caliper body upwards and support In position with a length of wire or a cabie-fc. Avoid straining the hydraulic hose.

2,4a Remove the locking clip ... 2.4b ... and extract the lower guide pin from the caliper (petrol models without ABS)

Page 180 of 225

9*4 Braking system

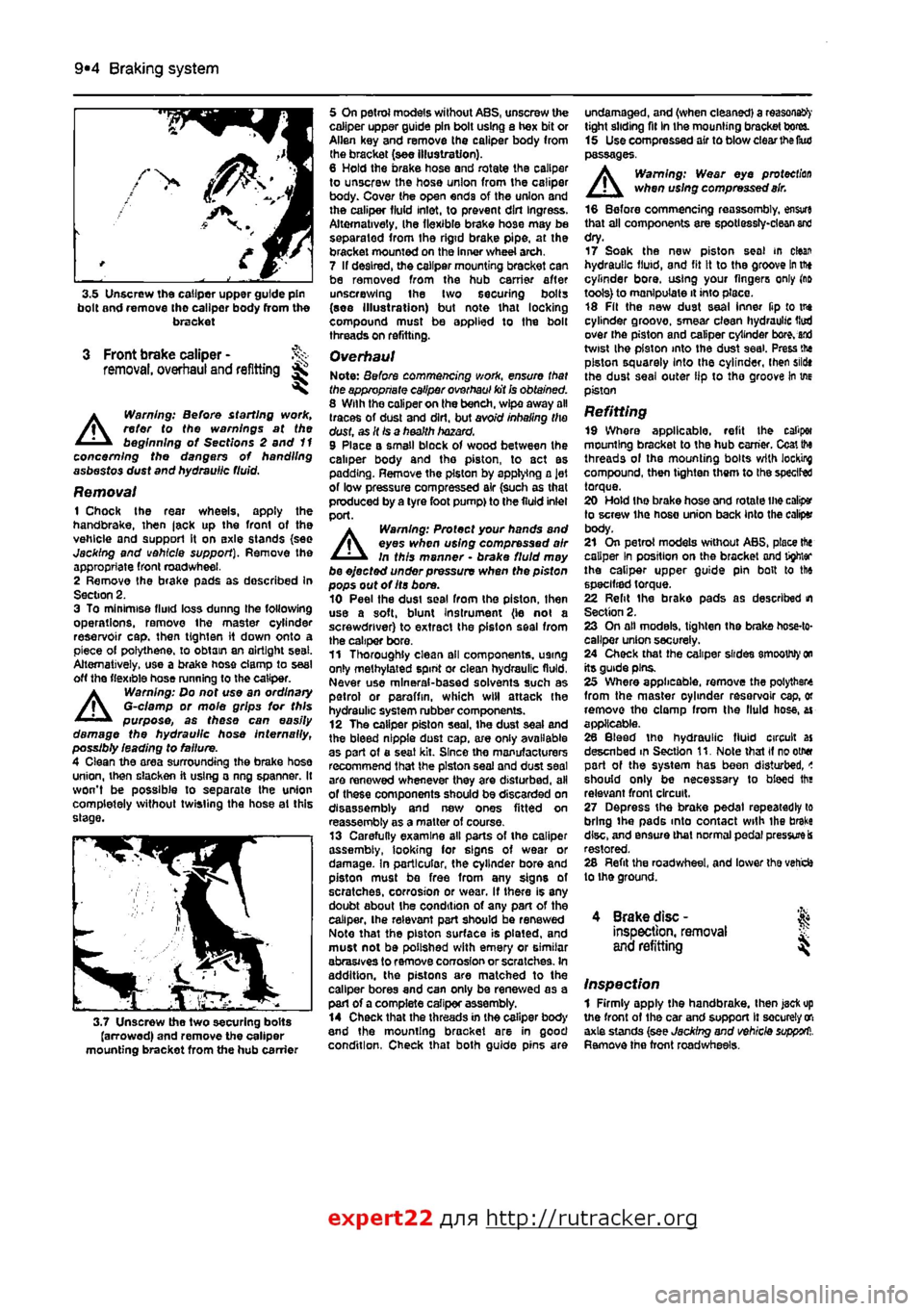

3.5 Unscrew the caliper upper guide pin bolt and remove tho caliper body (torn the bracket

3 Front brake caliper -removal, overhaul and refitting ^

A

Warning: Before starting work, refer to the warnings at the beginning of Sections 2 and 11 concerning the dangers of handling asbestos dust and hydraulic fluid.

Removal 1 Chock the rear wheels, apply the handbrake, then |ack up the front of the vehicle and support it on axle stands {see Jacking and vehicle support). Remove the appropriate front roadwheel. 2 Remove the brake pads as described In Section 2. 3 To minimise fluid loss dunng the following operations, remove the master cylinder reservoir cap. then

tig hi en

it down onto a piece of polythene, to obtain an airtight seat. Alternatively, use a brake hose clamp to seal off the flexible hose running to the caliper.

A

Warning: Do not use an ordinary G-clamp or mole grips for this purpose, as these can easily damage the hydraulic hose Internally, possibly leading to failure. 4 Clean the area surrounding the brake hose union, then slacken ft using a ring spanner. It won't be possible to separate the union completely without twisting the hose ai this slage.

3.7 Unscrew the two securing bolts (arrowed) and remove the caliper mounting bracket from the hub carrier

5 On petrol models without ABS, unscrew the caliper upper guide pin bolt using a hex bit or Allen key and remove the caliper body from the bracket (see illustration). 6 Hold the brake hose and rotate the caliper to unscrew the hose union from the caliper body. Cover the open ends of the union and the caliper fluid inlet, to prevent dirt Ingress. Alternatively, Ihe flexible brake hose may be separated from the rigid brake pipe, at the bracket mounted on the Inner wheel arch. 7 If desired, the caliper mounting bracket can be removed from the hub carrier after unscrewing ihe two securing bolts (see Illustration) but note that locking compound must be applied to the bolt threads on refitting.

Overhaul Note: Before commencing work, ensure that the appropriate caliper overhaul kit

Ss

obtained. 8 With the caliper on the bench, wipe away all (races of dust and dirt, but avoid inhaling the dust, as It

Is

a health hazard. 9 Place a small block of wood between the caliper body and tho piston, to act as padding. Remove the piston by applying a Jet of low pressure compressed air (such as that pioduced by a tyre foot pump) to the fluid inlel port.

A

Warning: Protect your hands and eyes when using compressed air In this manner • brake fluid moy be ejected under pressure when the pisfon pops out of Its bore. 10 Peel the dusi seal from the piston, then use a soft, blunt instrument (ie not a screwdriver) to extract the piston seal from the caliper bore. 11 Thoroughly clean all components, U9tng only methylated spint or clean hydraulic fluid, Never use mineral-based solvents such as petrol or paraffin, which will attack Ihe hydraulic system rubber components. 12 The caliper piston seal, the dust seal and the bleed nipple dust cap, a/e oniy available as part of a seat kit. Since the manufacturers recommend that the piston seal and dust seal are renewed whenever they are disturbed, all of these components should be discarded on disassembly and new ones fitted on reassembly as a matter of course. 13 Carefully examine all parts of the caliper assembly, looking for signs of wear or damage. In particular, the cylinder bore and piston must be free from any signs of scratches, corrosion or wear. If there is any doubt about ihe condition of any part of the caliper, the relevant port should be renewed Note that the piston surface is plated, and must not be polished with emery or similar abrasives to remove corrosion or scratches. In addition, the pistons are matched to the caliper bores and can only be renewed as a part of a complete caliper assembly. 14 Check that the threads in the caliper body and the mounting bracket are in good condition, Check that both guide pins are

undamaged, and (when cleaned) a reasons^' tight sliding fit In the mounting bracket bores. 15 UsecompressedairtOblow clear the IkuJ passages. Warning: Wear eye protection when using compressed

air.

16 Before commencing reassembly, en$vr« that all components are spotlessly-clean

and

dry. 17 Soak the new piston seal m clean hydraulic fluid, and fit it to the groove

In

tftt cylinder bore, using your fingers only (rift tools) to manipulate it into place. 18 Fit the new dust seal inner ftp to tne cylinder groove, smear clean hydraulic Hud over the piston and caliper cylinder

bore, and

twist ihe pfaton into the dust seal. Press tne piston squarely Into the cylinder, then sildt the dust seal outer lip to tho groove in we piston

Refitting 19 Where applicable, refit the caliper mounting bracket to thB hub earner. Ccaitto threads ol the mounting bolts with locking compound, then tighten them to the speclfed torque. 20 Hold the brake hose and rotate Ihe calip* to screw the hose union back Into the caliper body. 21 On petrol models without ABS, place the caliper In position on the bracket and tighter the caliper upper guide pin bolt to the specified torque. 22 Relit ihe brake pads as described m Section 2. 23 On all models, tighten the brake hose-to-callper union securely. 24 Check that the caliper slides smoothly

on

its guide pins. 25 Where applicable, remove the polytbste from the master oyhnder rasarvoir cap, or remove tho clomp from the fluid hose, ai applicable. 26 Bleed tho hydraulic fluid circuit as desenbed m Section 11. Note that if rootMf part of the system has been disturbed, < should only be necessary to bleed tha relevant front circuit, 27 Depress the brake pedal repeatedly to bring ihe pads into contact with ihe brake disc, and ensure that normal pedal

pressure is

restored. 28 Refit the roadwheel, and lower tha veti'cfc lo ihe ground.

4 Brake disc -

inspection,

removal

and

refitting

Inspection 1 Firmly apply the handbrake, then jaefcup the front of the car and support It securely

oft

axle stands (see Jacking and vehicle

support1,.

Remove the front roadwhesls.

expert22 f

a http://rutracker.org

Page 181 of 225

Braking system 9®5

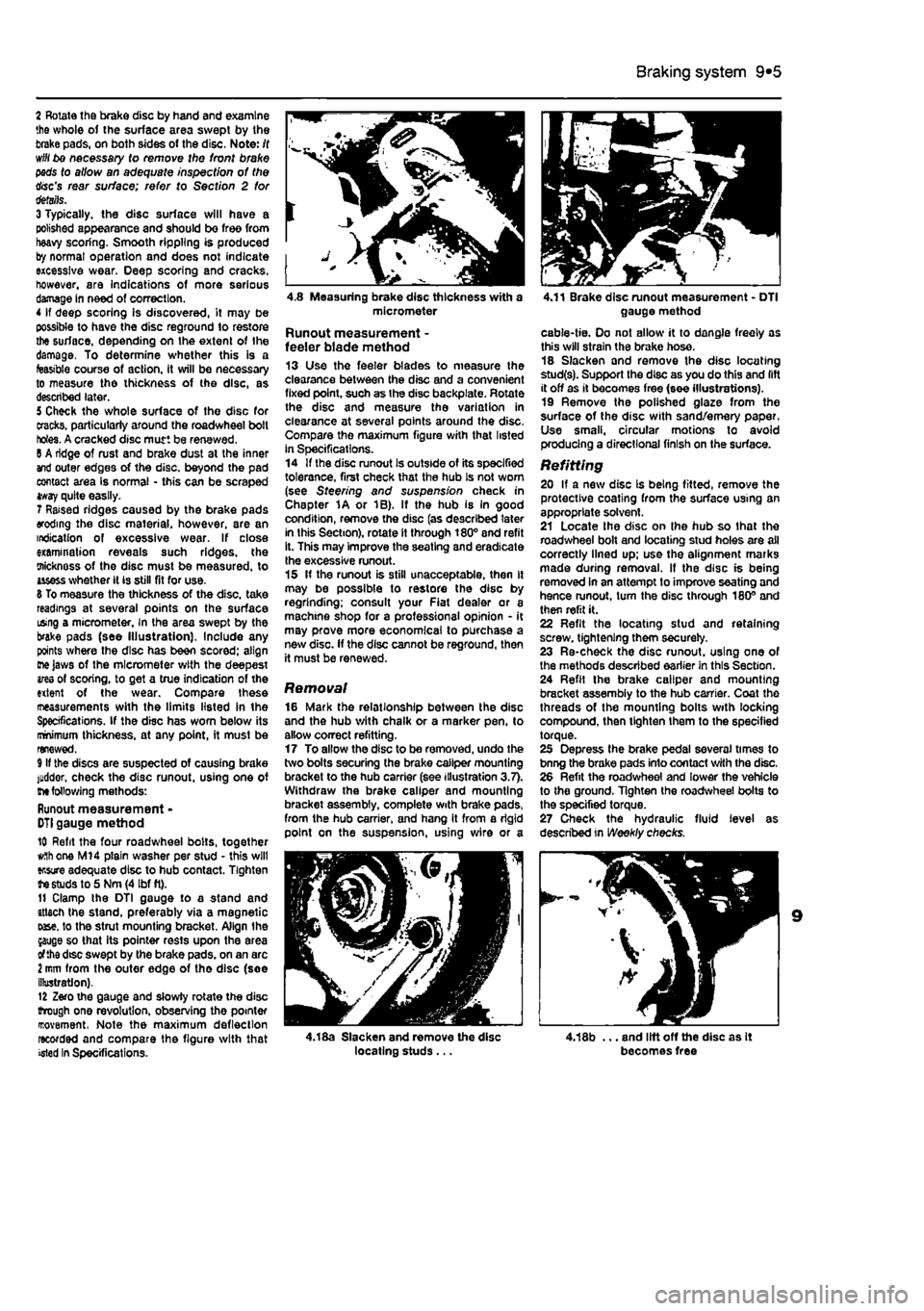

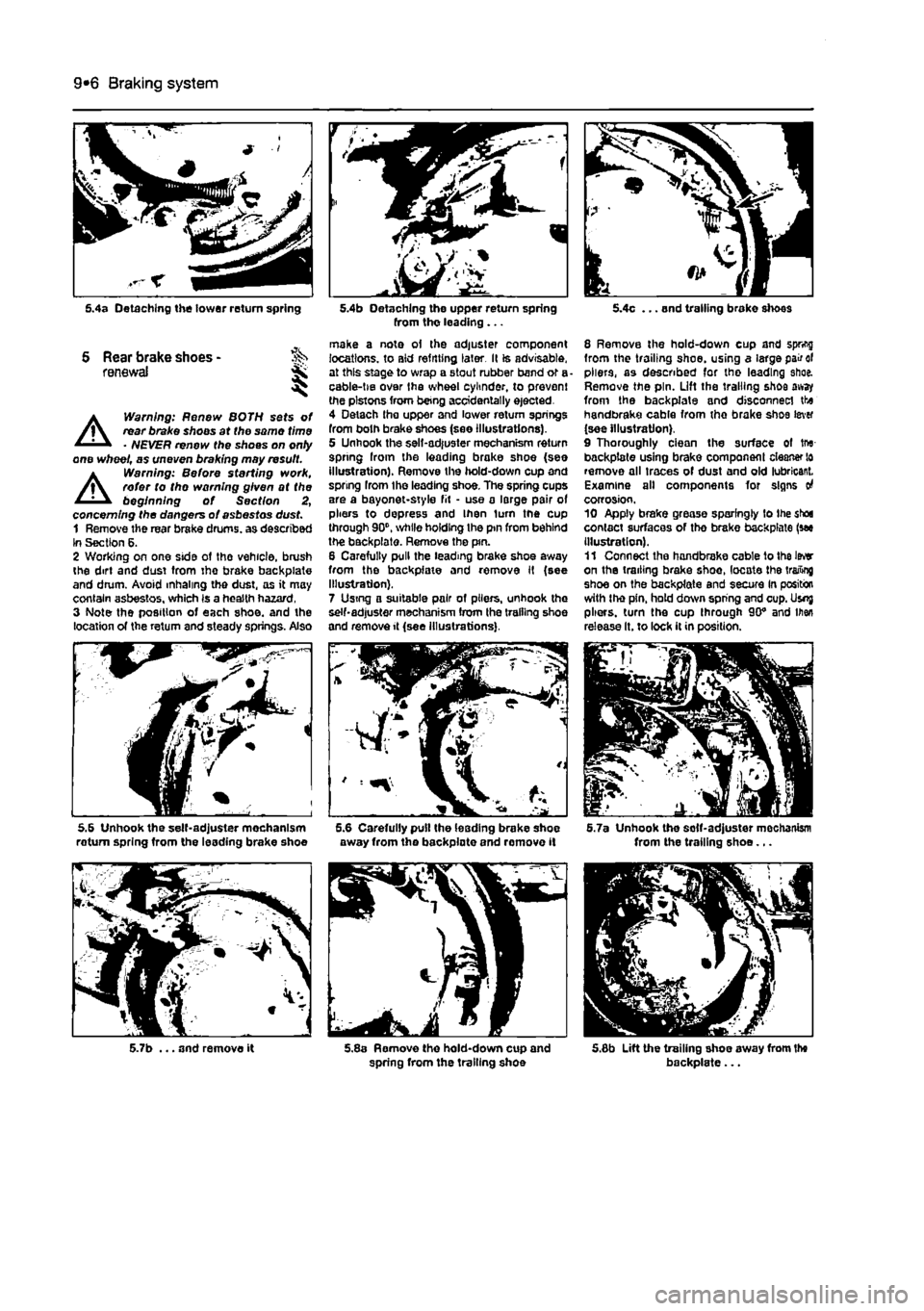

2 Rotate the brake disc by hand and examine the whole of the surface area swept by the brake pads, on both sides ot the disc. Note: /( will bo necessary to remove the front brake pads to allow an adequate inspection of the disc's rear surface; refer to Section 2 tor details. 3 Typically, the disc surface will have a polished appearance and should be free from heavy scoring. Smooth rippling is produced by normal operation and does not indicate excessive wear. Deep scoring and cracks, however, are indications of more serious damage in need of correction. 4 If deep scoring Is discovered, it may be possible to have the disc reground to restore the surface, depending on the extent of the damage. To determine whether this is a feasible course of action, it will be necessary to measure the thickness of the disc, as described later. 5 Check the whole surface of the disc for cracks, particularly around the roadwheel bolt holes. A cracked disc mutt be renewed. 6 A ridge of rust and brake dust at the inner and outer edges of the disc, beyond the pad contact area is normal - this can be scraped tway quite easily. 7 Raised ridges caused by the brake pads eroding the disc material, however, are an indication of excessive wear. If close examination reveals such ridges, the oiicknoss of the disc must be measured, to usess whether it is still fit for use. 8 To measure the thickness of the disc, take readings at several points on the surface using a micrometer. In the area swept by the brake pads (see Illustration). Include any points where the disc has been scored: align me Jaws of the micrometer with the deepest ares of scoring, to get a true indication of the extent of the wear. Compare these ineasurements with the limits listed in the Specifications. If the disc has worn below its minimum thickness, at any point, it must be renewed. 9 If the discs are suspected of causing brake luddor, check the disc runout, using one of

me

following methods: Runout measurement -

DTI

gauge method 10 Refit the four roadwheel bolts, together

w.1h

one M14 plain washer per stud • this will ensure adequate disc to hub contact. Tighten te studs to 5 Nm (4 Ibf ft). 11 Clamp the DTI gauge to a stand and attach the stand, preferably via a magnetic oase. to the strut mounting bracket. Align the jauge so that its pointer rests upon the area of the dtsc swept by the brake pads, on an arc i mm from the outer edge of tho disc (soe illustration). 12 Zero the gauge and slowly rotate the disc trough one revolution, observing tho pointer rcovement. Note the maximum deflection recorded and compare the figure with that >«ted In Specifications.

4.8 Measuring brake disc thickness with a micrometer

Runout measurement -feeler blade method 13 Use the feeler blades to measure the clearance between the disc and a convenient fixed point, such as the disc backplate. Rotate the disc and measure the variation in clearance at several points around the disc, Compare the maximum figure with that listed in Specifications. 14 If the disc runout Is outside of its specified tolerance, first check that the hub Is not worn (see Steering and suspension check in Chapter 1A or 1B). If the hub is In good condition, remove the disc (as described later in this Section), rotate it through 180° and refit it. This may improve the seating and eradicate Ihe excessive runout. 15 If the runout is still unacceptable, then It may be possible to restore the disc by regrinding; consult your Fiat dealer or a machine shop for a professional opinion - it may prove more economical to purchase a new disc. If the disc cannot be reground, then it must be renewed.

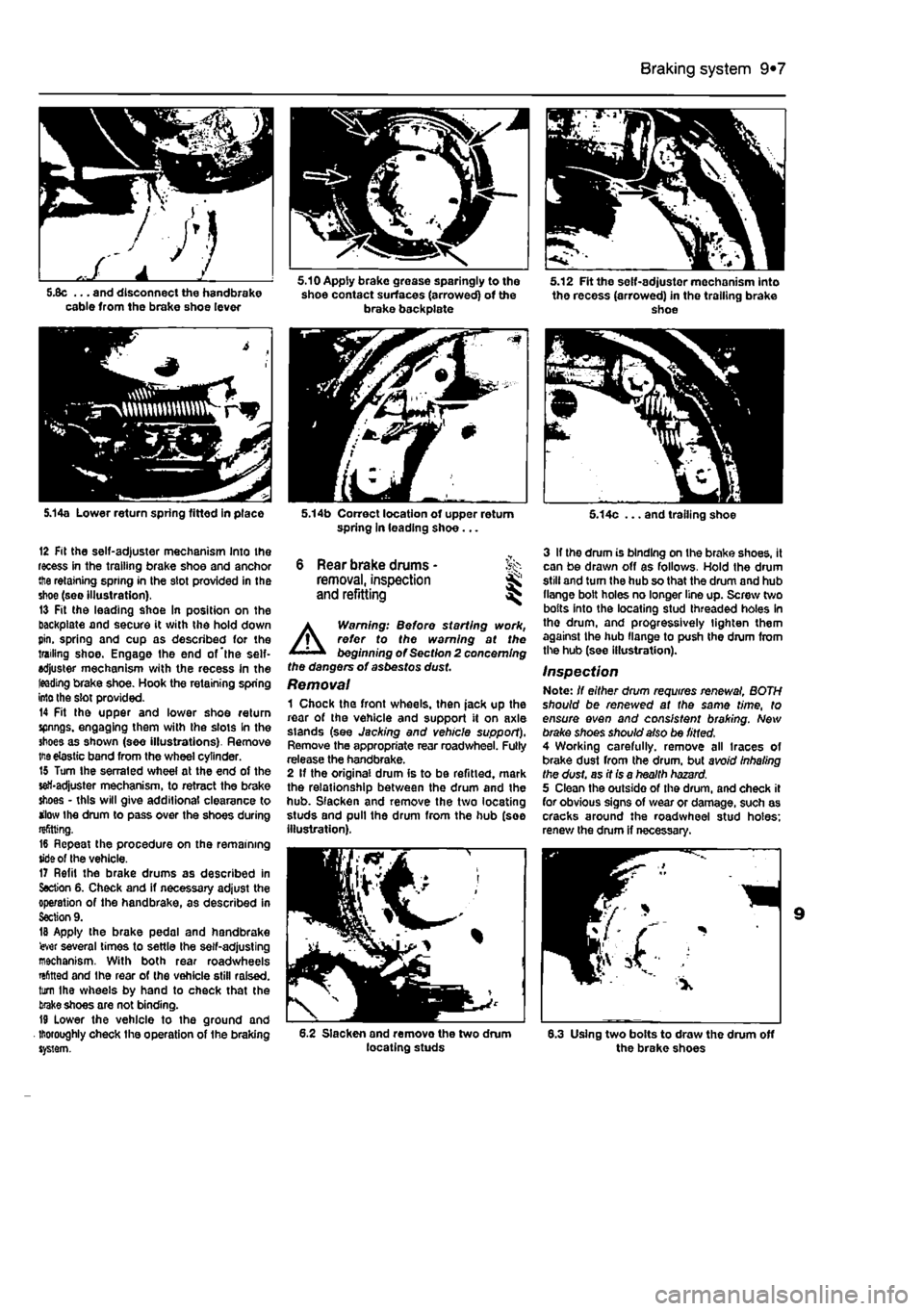

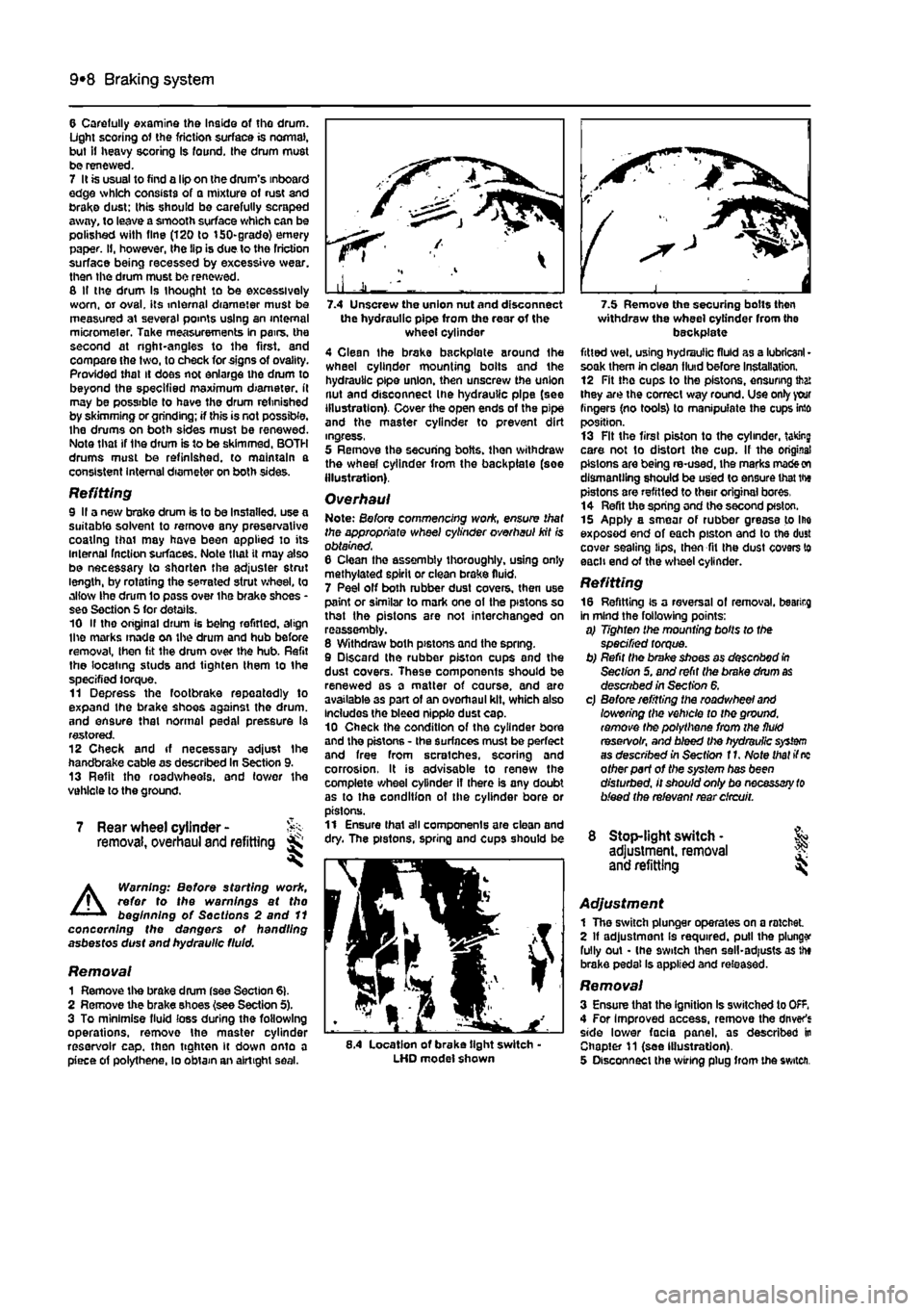

Removal 16 Mark the relationship between the disc and the hub with chalk or a marker pen, to allow correct refitting. 17 To allow the disc to be removed, undo the two bolts securing (he brake caliper mounting bracket to the hub carrier (see illustration 3.7). Withdraw the brake caliper and mounting bracket assembly, complete with brake pads, from the hub carrier, and hang it from a rigid point on the suspension, using v/lre or a

4.18a Slacken and remove the disc locating studs ...

4.11 Brake disc runout measurement - DTI gauge method

cable-tie. Oo not allow it to dangle freely as this will strain the brake hose. 18 Slacken and remove the disc locating stud(s). Support the disc as you do this and lift it off as it becomes free (see illustrations). 19 Remove the polished glaze from the surface of the disc with sand/emery paper. Use small, circular motions to avoid producing a directional finish on the surface.

Refitting 20 If a new disc Is being fitted, remove the protective coating from the surface U9ing an appropriate solvent. 21 Locate Ihe disc on ihe hub so that the roadwheel bolt and locating stud holes are all correctly lined up; use the alignment marks made during removal. If the disc is being removed in an attempt to improve seating and hence runout, turn the disc through 180° and then refit it. 22 Refit the locating stud and retaining screw, tightening them securely. 23 Re-check the disc runout, using one of the methods described earlier in this Section. 24 Refil the brake caliper and mounting bracket assembly to the hub carrier. Coat the threads of the mounting bolts with locking compound, then tighten them to the specified torque. 25 Depress the brake pedal several times to bnng the brake pads into contact with the disc. 26 Refit the roadwheel and lower the vehicle to the ground. Tighten the roadwheel bolts to the specified torque. 27 Check the hydraulic fluid level as described in Weekly checks.

4,18b ... and lift off the disc as It becomes free

Page 182 of 225

9*6 Braking system

5.4a Detaching the tower return spring

S Rear brake shoes -renewal ji,

A

Warning: Renew BOTH sets of rear brake shoos at the same time • NEVER renew the shoes on onty one wheel, as uneven braking may result.

A

Warning: Before sterling work, refer to tho warning given at the beginning of Section 2, concerning the dangers of asbestos dust. 1 Remove the rear brake drums, as described In Section 6. 2 Working on one side ot the vehicle, brush the dirt and dust tram tho brake backpiate and drum. Avoid inhaling the dust, as it may contain asbestos, which Is a health hazard, 3 Note the position of each shoe, and the location of the return and steady springs. Also

5.6 Unhook the self-adjuster mechanism roturn spring from the leading brake shoe

5.7b ... and remove it

5.4b Detaching the upper return spring from tho leading ...

make a note oi the adjuster component locations, to aid refitting later. Il is advisable, at this stage to wrap a stout rubber band or a cable-tie over Ihe wheel cylinder, to prevent the pistons from being accidentally ejected. 4 Detach tha upper and lower return springs from both brake shoes (see illustrations). 5 Unhook the sell-adjuster mechanism return spring Iroin the leading brake shoe (see illustration). Remove the hold-down cup and spring from the leading shoe. The spring cups are a bayonet-style fit • use a large pair of pliers to depress and Ihen turn the cup through 90", while holding Ihe pin from behind the backpiate. Remove the pin. 6 Carefully pull the leading brake shoe away from the backpfaie and remove It (see Illustration). 7 Using a suitable pair of pliers, unhook the self-adjuster mechanism from the trailing shoe and remove it (see Illustrations).

away from the backpiate and remove it

5.8a Remove the hold-down cup and spring from the trailing shoe

5.4c ... and trailing brake shoes

8 Remove the hold-down cup and spring from the trailing shoe, using a large pair of pliers, as described for the leading shoe. Remove the pin. Lift the trailing shoe away from the backpiate and disconnect the handbrake cable from the brake shoe lever (see illustration). 9 Thoroughly ciean the surface of tru-backpiate using brake component cleaner lo remove all traces of dust and old lubricant. Examine all components for signs o4 corrosion. 10 Apply brake grease sparingly to the shoe contact surfaces of tho brake backpiate (see Illustration). 11 Connect tha handbrake cable to the Iwr on the trailing brake shoe, locate the trailing shoe on the backpiate and secure In position with the pin, hold down spring and cup. Usnj pliers, turn the cup through 90" and men release It. to lock it in position.

5.7a Unhook the solf-adjuster mochanism from the trailing shoe...

5.6b Lift the trailing shoe away from the backpiate...

Page 183 of 225

Braking system 9®7

5JJc ... and disconnect the handbrake cable from the brake shoe lever

5.14a Lower return spring fitted in place

12 Fit the self-adjuster mechanism Into the recess in the trailing brake shoe and anchor the retaining spring in the slot provided in the shoe (see Illustration). 13 Fit the leading shoe In position on the backpiste and secure it with the hold down pin. spring and cup as described for the trailing shoe. Engage the end of'the self-adjuster mechanism with the recess In the leading brake shoe. Hook the retaining spring into the slot provided. 14 Fit the upper and lower shoe return spnngs. engaging them with the slots In the shoes as shown (see illustrations). Remove

me

elastic band from the wheel cylinder. 15 Turn Ihe serrated wheel at the end of the self-adjuster mechanism, to retract the brake shoes - this will give additional clearance to ilow Ihe drum to pass over the shoes during refitting. 16 Repeat the procedure on the remaining tide of the vehicle. 17 Refit the brake drums as described in Section 6. Check and if necessary adjust the operation of the handbrake, as described in Section 9. IB Apply the brake pedal and handbrake 'ever several times to settle the self-adjusting mechanism. With both rear roadwheels rsfitted and Ihe rear of the vehicle still raised, turn Ihe wheels by hand to check that the take shoes are not binding. 19 Lower the vehicle to the ground and thoroughly check the operation of the braking system.

5.10 Apply brake grease sparingly to the shoe contact surfaces (arrowed) of the brake backplate

5.14b Correct location of upper return spring In leading shoe...

6 Rear brake drums -removal, inspection and refitting ^

A

Warning: Before starting work, refer to the warning at the beginning of Section 2 concerning the dangers of asbestos dust Removal 1 Chock the front wheels, then jack up the roar of the vehicle and support it on axle stands (see Jacking and vehicle support). Remove the appropriate rear roadwheel. Fully release the handbrake. 2 If the original drum is to be refitted, mark the relationship between the drum and the hub. Slacken and remove the two locating studs and pull the drum from the hub (see illustration).

6.2 Slacken and remove the two drum locating studs

5.12 Fit the self-adjuster mechanism into the recess (arrowed) in the trailing brake shoe

5.14c ... and trailing shoe

3 If the drum is binding on Ihe brake shoes, it can be drawn off as follows. Hold the drum still and turn the hub so that the drum and hub flange bolt holes no longer line up. Screw two bofts into the locating stud threaded holes In tho drum, and progressively lighten them against the hub llange to push the drum from the hub (see illustration).

Inspection Note: If either drum requires renewal, BOTH should be renewed at the same time, to ensure even and consistent braking. New brake shoes should also be fitted. 4 Working carefully, remove all traces of brake dust from the drum, but avoid Inhaling the dust, as it is a health hazard. 5 Clean the outside of the drum, and check it for obvious signs of wear or damage, such as cracks around the roadwheel stud holes; renew the drum if necessary.

6.3 Using two bolts to draw the drum off the brake shoes

Page 184 of 225

9*8 Braking system

6 Carefully examine the Inside of tho drum. Light scoring of the friction surface is normal, but if heavy scoring Is found, the drum must be renewed. 7 It is usual to find a lip on the dmm's inboard edge which consists of a mixture of rust and brake dust: this should be carefully scraped away, to leave a smooth surface which can be polished with fine (120 to 150-grade) emery paper. If, however, the tip is due to the friction surface being recessed by excessive wear, then the drum must be renewed. 6 If the drum Is thought to be excessively worn, or oval, its internal diameter must be measured at several points using an internal micrometer. Take measurements In pairs, the second at right-angles to the first, and compare the two, to check for signs of ovality. Provided that it does not enlarge the dium to beyond the specified maximum diameter, it may be possible to have the drum refinished by skimming or grinding; if this is not possible, Ihe drums on both sides must be renewed. Note that if the drum is to be skimmed, BOTH drums must be refinished. to maintain a consistent Internal diameter on both sides.

Refitting 9 II a new brake drum is to be Installed, use a suitable solvent to remove any preservative coating thai may have been applied to its internal fnction surfaces. Note that it may also be necessary to shorten the adjuster strut length, by rotating the sedated strut wheel, lo allow Ihe drum lo poss over the brake shoes • see Section S for details. 10 II tho original dfum is being refitted, align the marks made on the drum and hub before removal, then lit the drum over the hub. Refit the locating studs and tighten them to the specified torque. 11 Depress the footbrake repeatedly to expand the brake shoes against the drum, and ensure that normal pedal pressure Is restored. 12 Check and if necessary adjust the handbrake cable as described In Section 9. 13 Refit tho roadwheels, and lower the vehicle to the ground.

7 Rear wheel cylinder -removal, overhaul and refitting jS

A

Warning: Before starting work, refer to the warnings at tho beginning of Sections 2 and 11 concerning the dangers ot handling asbestos dust and hydraulic fluid.

Removal 1 Remove the brake drum fsee Section 6). 2 Remove the brake shoes (see Section 5). 3 To minimise fluid loss during the following operations, remove the master cylinder reservoir cap. then tighten it down onto a piece of polythene, lo obtain an airtight seal.

the hydraulic pipe from the rear of the wheel cylinder 4 Clean the brake backplate around Ihe wheel cylinder mounting boits and the hydraulic pipe union, then unscrew the union nut and disconnect Ihe hydraulic pipe (see illustration). Cover the open ends of the pipe and the master cylinder to prevent dirt ingress, 5 Remove the securing bolts, then withdraw the wheel cylinder from the backplate (soe Illustration).

Overhaul Note: Before commencing woric, ensure that the appropriate wheel cylinder overhaul kit is obtained. 6 Clean tho assembly thoroughly, using only methylated spirit or clean brake fluid, 7 Peel off both rubber dust covers, then use paint or similar to mark one ot the pistons so that the pistons are not interchanged on reassembly. 8 Withdraw both pistons and tho spring. 9 Discard the rubber piston cups and the dust covers. These components should be renewed as a matter of course, and are available 3s part of an overhaul kit, which also Includes the bleed nipple dust cap. 10 Check the condition of the cylinder bore and the pistons - the surfaces must be perfect and free from scratches, scoring and corrosion, It is advisable to renew the complete wheel cylinder if there is any doubt as to the condition ot the cylinder bore or pistons. 11 Ensure thai all components are clean and dry. The pistons, spring and cups should be

8.4 Location of brake tight switch-LHD model shown

withdraw the wheel cylinder from the backplate fitted wet, using hydraulic fluid as a lubricant • soak them in clean fluid before installation. 12 Fit the cups to the pistons, ensuring that they are the correct way round. Use only your fingers (no tools) to manipulate the cups into position. 13 Fit the first piston to the cylinder, taking care not to distort the cup. If the original pistons are being re-used, ihe marks

made on

dismantling should be used to ensure that the pistons are refitted to their original bores, 14 Refit the spring and the second pfston. 15 Apply a smear of rubber grease to Ihe exposed end of each piston and to the dust cover sealing lips, then fit Ihe dust covers to each end of the wheel cylinder.

Refitting 16 Refitting is a reversal of removal, bearirg in mind the following points: a) Tighten the mounting bolts to the specified torque. b) Refit the brake shoes as desenbod

In

Section 5. and refit the brake drum

as

described in Section 6. c) Before refitting the roadwheel

and

lowering the vehicle to the ground, remove the polythene from the fluid reservoir, and bleed the hydraulic

system

as described in Section f

1.

Note that if

nc

other part of the system has been disturbed, it should only bo necessary

to

bleed the relevant rear circuit.

8 Stop-light switch • & adjustment, removal J? and refitting

Adjustment 1 The switch plunger operates on a ratchet 2 If adjustment Is required, pull the plunge fully out - (he 9witch then sell-adjusts as the brake pedal Is applied and released.

Removal 3 Ensure that the ignition Is switched to OfF. 4 For Improved access, remove the driver's side lower facia panel, as described in Chapter 11 (see Illustration). 5 Disconnect the wiring plug from the switch.

Page 185 of 225

Braking system 9®9

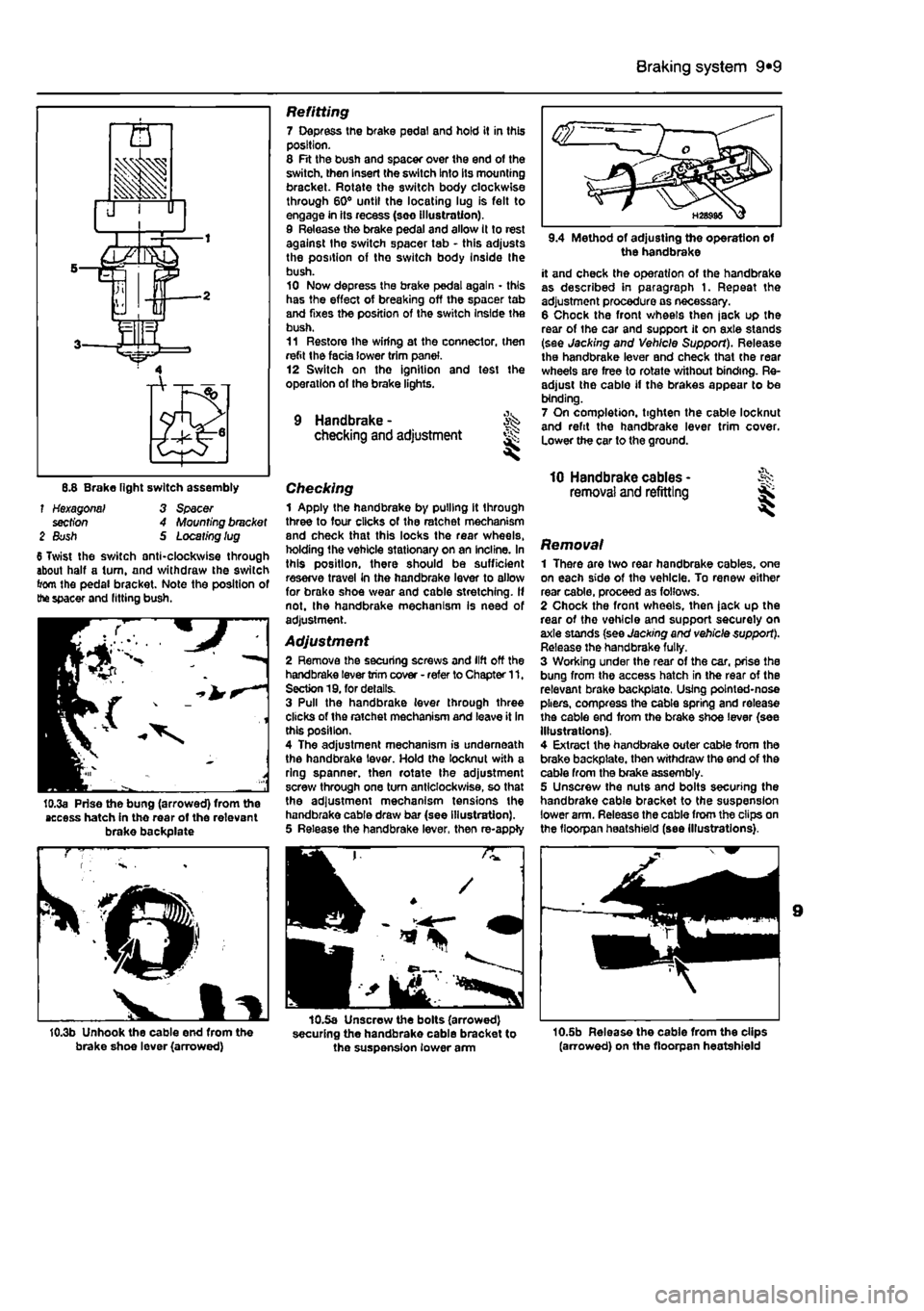

6.8 Brake light switch assembly f Hexagonal' 3 Spacer section 4 Mounting bracket 2 Bush S Locating lug 6 Twist the switch anti-clockwise through about half a turn, and withdraw the switch from the pedal bracket. Note the position of the spacer and fitting bush.

10.3a Prise the bung (arrowed) from the access hatch in the rear of the relevant brake backplate

10.3b Unhook the cable end from the brake shoe lever (arrowed)

Refitting 7 Depress the brake pedal and hold it in this position. 8 Fit the bush and spacer over the end of the switch, then Insert the switch Into its mounting bracket. Rotate the switch body clockwise through 60° until the locating lug is felt to engage in its recess (seo illustration). 9 Release the brake pedal and allow It to rest against the switch spacer tab - this adjusts the position of the switch body Inside Ihe bush. 10 Now depress the brake pedal again - this has the effect of breaking off the spacer tab and fixes the position of the switch Inside the bush. 11 Restore Ihe wiring at the connector, then refit the facia lower trim panel. 12 Switch on the ignition and test the operation of the brake lights.

9 Handbrake - ^ checking and adjustment

Checking 1 Apply the handbrake by pulling it through three to four clicks of the ratchet mechanism and check that this locks the rear wheels, holding the vehicle stationary on an incline. In this position, there should be sufficient reserve travel in the handbrake lever to allow for brako shoe wear and cable stretching. If not. Ihe handbrake mechanism Is need of adjustment.

Adjustment 2 Remove the securing screws and lift off the handbrake lever trim cover - refer to Chapter 11. Section 19. for details. 3 Pull the handbrake lever through three clicks of the ratchet mechanism and leave it in this position. 4 The adjustment mechanism is underneath the handbrake lever. Hold the locknut with a ring spanner, then rotate the adjustment screw through one turn anticlockwise, so that the adjustment mechanism tensions the handbrake cable draw bar (see illustration). 5 Release the handbrake lever, then re-apply

10.5a Unscrew the bolts (arrowed) securing the handbrake cable bracket to the suspension lower arm

the handbrake it and check the operation of the handbrake as described in paragraph 1. Repeat the adjustment procedure as necessary. 6 Chock the front wheels then |ack up the rear of the car and support it on axle stands (see Jacking and Vehicle Support). Release the handbrake lever and check that the rear wheels are free to rotate v/ithout binding. Re-adjust the cable if the brakes appear to be binding. 7 On completion, tighten the cable locknut and refit the handbrake lever trim cover. Lower the car to the ground.

10 Handbrake cables -removal and refitting

Removal 1 There are two rear handbrake cables, one on each side of the vehicle. To renew either rear cable, proceed as follows. 2 Chock the front wheels, then jack up the rear of tho vehicle and support securely on axle stands (see Jacking and vehicle support). Release the handbrake fully, 3 Working under the rear of the car, prise the bung from the access hatch in the rear of the relevant brake backplato, Using pointed-nose pliers, compress the cable spring and release the cable end from the brake shoe lever (see Illustrations). 4 Extract the handbrake outer cable from the brake backplate. then withdraw the end of the cable from the brake assembly. 5 Unscrew the nuts and bolts securing the handbrake cable bracket to the suspension lower arm. Release the cable from the clips on the floorpan heatshield (see Illustrations).

10.5b Release the cable from the clips (arrowed) on the floorpsn heatshield

Page 186 of 225

9*10 Braking system

10.6 Disconnect the relevant handbrake inner cable (arrowed) from the draw bar 6 Working inside ihe vehicle, remove Ihe screws and lift off the handbrake lever trim panel (refer to Section 9 for more detail). At the base of the handbrake lever, full/ slacken off the handbrake adjusting screw and locknut, to remove oil tension from the cable draw bar, then disconnect the relevant handbrake inner cable from the cable draw bar (see illustration) 7 Release the cable grommet from tho floor-pan, then withdraw the cable from the vehicle.

Refitting 8 Refitting Is a reversal of removal, bearing in mind the following points: a) Ensure that the cables are securely fastened In the clips on the floorpan beetshield and lower suspension a/m. b) On completion, check the handbrake adiustment, as described in Section 9.

11 Hydraulic system -bleeding

A

Warning: Hydraulic fluid is poisonous; wash off immediately and thoroughly In the case ot skin contact, and seek immediate medical advice if any fluid is swallowed, or gets into the eyes. Certain types of hydraulic fluid are Inflammable, and may ignite when allowed into contact with hot components. When servicing any hydraulic system, it Is safest to assume that the fluid IS inflammable, and to take precautions

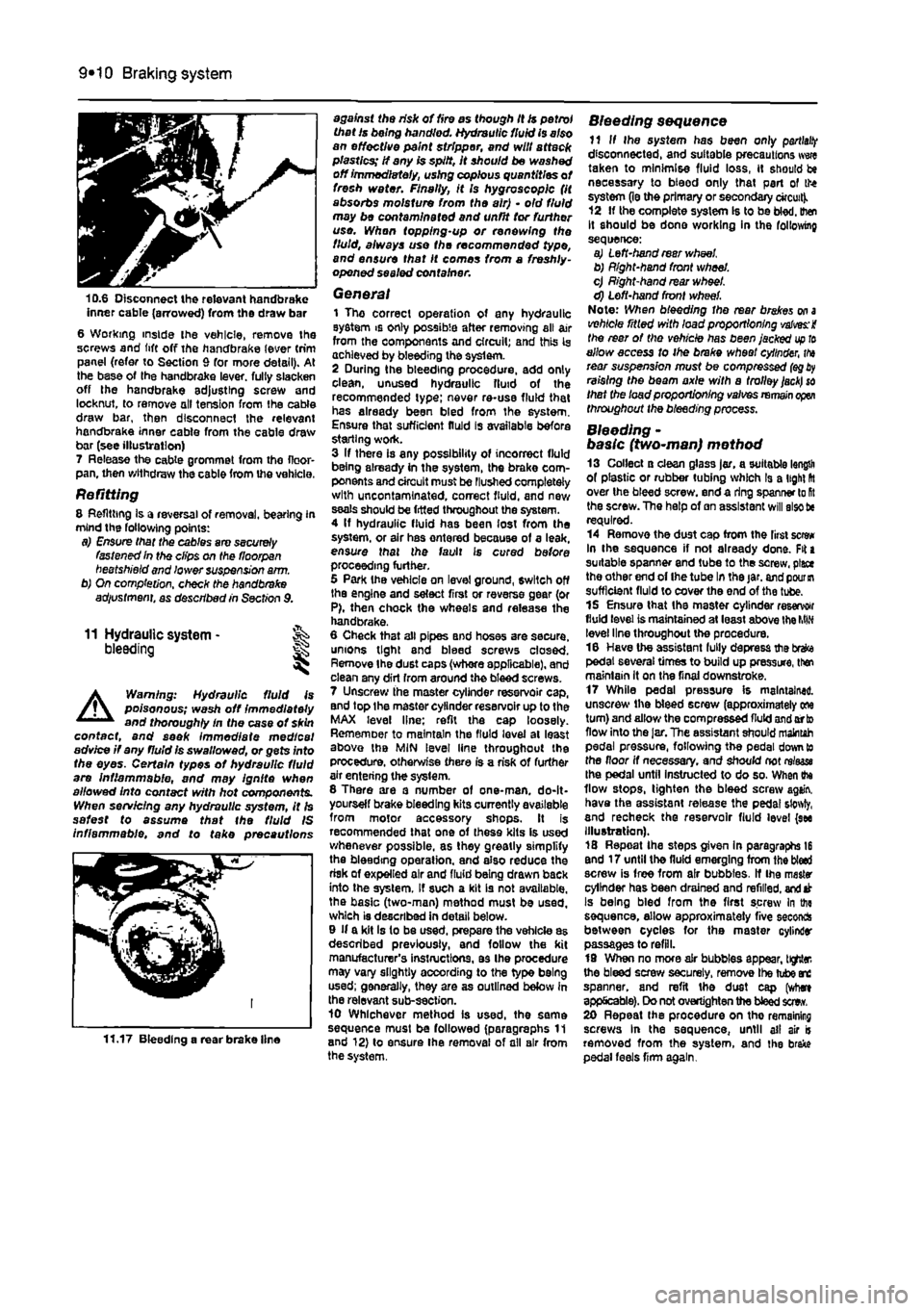

11.17 Bleeding a rear brake line

against the risk of fire as though it is petrol that Is being handled. Hydraulic fluid is also an effective paint stripper, and will attack plastics; If any is spilt, It should be washed off immediately, using copious quantities of fresh water. Finally, it Is hygroscopic (it absorbs moisture from the air) • old fluid may be contaminated and unfit tor further use. Whan topping-up or renewing the fluid, always use the recommended type, and ensure that It comes from a freshly-opened sealed container.

General 1 The correct operation of any hydraulic system is only possible after removing all air from the components and circuit; and this Is achieved by bleeding the syslem. 2 During the bleeding procedure, add only clean, unused hydraulic fluid of the recommended type; never re-use fluid that has already been bled from the system. Ensure that sufficient fluid is available before starting work. 3 If there is any possibility of incorrect fluid being already in the system, the brake com-ponents and circuit must be Flushed completely with uncontamlnated, correct fluid, and new seals should be fitted throughout the system. 4 If hydraulic fluid has been lost from the system, or air has ontered because of a leak, ensure that the fault is cured before proceeding further. 5 Park Ihe vehicle on level ground, switch off the engine and select first or reverse gear (or P), then chock the wheels and release the handbrake. 6 Cheek that all pipes and hoses are secure, unions tight and bleed screws closed. Remove Ihe dust caps (whore applicable), and clean any dirt from around the bleed screws. 7 Unscrew the master cylinder reservoir cap, and top Ihe master cylinder reservoir up to the MAX level line; refit the cap loosely. Rememoer to maintain the fluid level at least above the MIN level line throughout the procedure, otherwise there is a risk of further air entering the syslem. 8 There are a number of one-man. do-It-yourself brake bleeding kits currently available from motor accessory shops. It is recommended that one of these kits is used whenever possible, as they greatly simplify the bleeding operation, and also reduce the risk of expelled air and fluid being drawn back into the system. If such a kit is not available, the basic (two-man) method must be used, which is described in detail below. 9 If a kit Is to be used, prepare the vehicle as described previously, and follow the kit manufacturer's instructions, as Ihe procedure may vary slightly according to the type being used; generally, they are as outlined below in the relevant sub-section. 10 Whichever method is used, the same sequence must be followed (paragraphs 11 and 12) to ensure Ihe removal of all air from the system.

Bleeding sequence 11 If Ihe system has been only

partial!?

disconnected, and suitable precautions wwe taken to minimise fluid loss, it should be necessary to bteod only that part of the system (le the primary or secondary circuit). 12 If the complete system Is to be bled, then It should be done working in the following sequence: a) Left-hand rear wheel b) Right-hand front wheel. c) Right-hand rear wheel. d) Left-hand front wheel. Note: When bleeding the rear brakes

on a

vehicle ritled with load proportioning valves: i the rear of the vehicle has been jacked

up to

allow access to ihe brake wheel cylinder,

tha

rear suspension must be compressed

(eg

raising the beam axle with a trolley

jack) so

that the load proportioning valves

remain open

throughout the bleeding process.

Bleeding -basic (two~man) method 13 Collect a clean glass jar, a suitable length of plastic or rubber tubing which Is a light fit over the bleed screw, end a ring spanner lo

Rt

the screw. The help of an assistant will also tie required. 14 Remove the dust cap from the first screw In the sequence if not already done. Fit a suitable spanner and tube to the screw, place the other end of Ihe tube In the jar. and

pour in

sufficient fluid to cover the end of the tube. 15 Ensure that the master cylinder reservoir fluid level is maintained at least above the

MIN

level line throughout the procedure. 16 Have the assistant fully depress the brefce pedal several times to build up pressure, then maintain it on the final downstroke. 17 While pedal pressure is maintained, unscrew ihe bleed screw (approximately one turn) and allow the compressed fluid and orto flow into the

Jar,

The assistant should maintah pedal pressure, following the pedal down to the floor if necessary, and should not rrtaase Ihe pedal until instructed to do so. When ihe flow stops, tighten the bleed screw again, have the assistant retease the pedal sfowty, and recheck the reservoir fluid level (see Illustration). 18 Repeat Ihe steps given in paragraphs 16 end 17 until the fluid emerging from the bled screw is free from air bubbles. If Ihe master cylinder has been drained and refilled,

and

at Is being bled from the first screw In the sequence, allow approximately five seconds between cycles for the master cylinder passages to refill. 19 When no more air bubbles appear, tighter, the bleed screw securely, remove Ihe tube arc spanner, and refit the dust cap (where applicable). Do not overtighten the bleed sew. 20 Repeat the procedure on tho remaining screws In the sequence, until ail air is removed from the system, and the brake pedal feels firm again.