ECU FIAT QUBO 2017 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: QUBO, Model: FIAT QUBO 2017 1.GPages: 260, PDF Size: 4.74 MB

Page 103 of 260

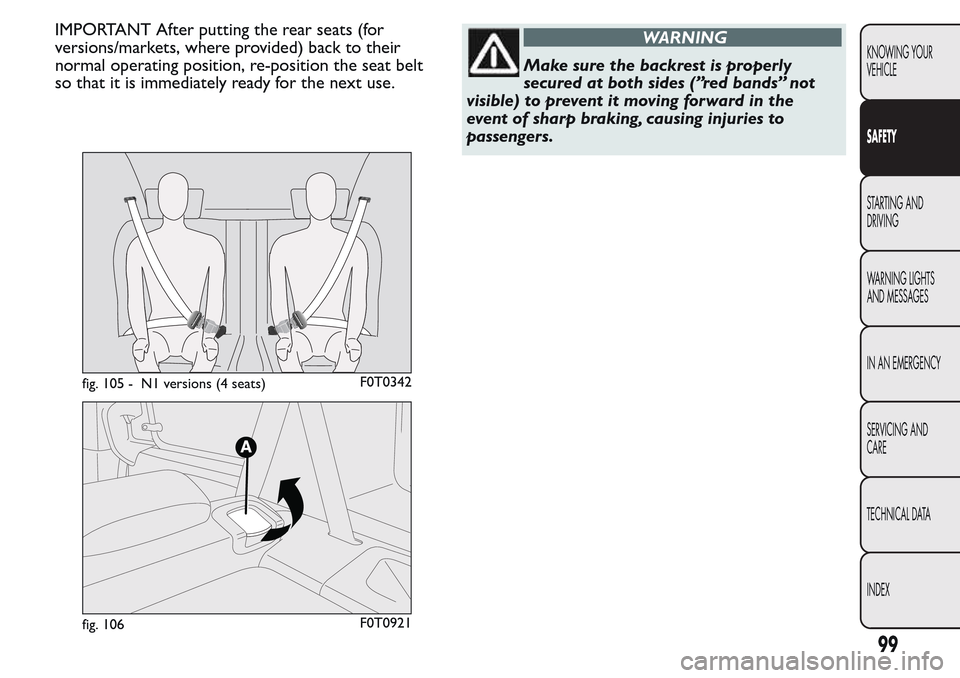

IMPORTANT After putting the rear seats (for

versions/markets, where provided) back to their

normal operating position, re-position the seat belt

so that it is immediately ready for the next use.WARNING

Make sure the backrest is properly

secured at both sides (”red bands” not

visible) to prevent it moving forward in the

event of sharp braking, causing injuries to

passengers.

fig. 105 - N1 versions (4 seats)F0T0342

fig. 106F0T0921

99

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 109 of 260

FITTING A CHILD RESTRAINT SYSTEM

WITH SEAT BELTS

WARNING

Incorrect fitting of the child restraint

system may result in an inefficient

protection system. In the event of an accident

the child restraint system may become loose

and the child may be injured, even fatally.When

fitting a restraint system for newborns or

children, strictly comply with the instructions

provided by the Manufacturer.

WARNING

When the child restraint system is not

used, secure it with the seat belt or with

the ISOFIX anchorages, or remove it from the

vehicle. Do not leave it unsecured inside the

passenger compar tment . In this way, in the case

of sudden braking or an accident , it will not

cause injuries to the occupants.

WARNING

After installing a child restraint system,

do not move the seat : always remove

the child restraint system before making any

adjustment .

WARNING

Always make sure that the diagonal

section of the seat belt does not pass

under the arms or behind the back of the child.

In the event of an accident the seat belt will

not be able to secure the child, with the risk of

injury, including fatal injury.Therefore the

child must always wear the seat belt correctly.

WARNING

The figures are only examples for fitting

purposes. Fit the child restraint system

according to the instructions, which must be

included.

105

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 129 of 260

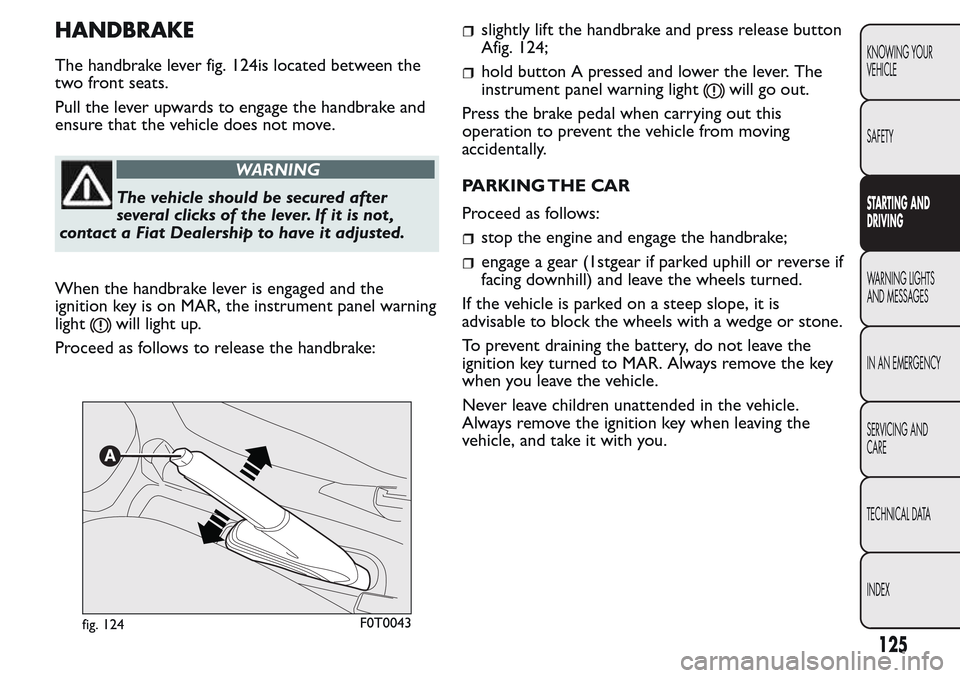

HANDBRAKE

The handbrake lever fig. 124is located between the

two front seats.

Pull the lever upwards to engage the handbrake and

ensure that the vehicle does not move.

WARNING

The vehicle should be secured after

several clicks of the lever. If it is not ,

contact a Fiat Dealership to have it adjusted.

When the handbrake lever is engaged and the

ignition key is on MAR, the instrument panel warning

light

will light up.

Proceed as follows to release the handbrake:

slightly lift the handbrake and press release button

Afig. 124;

hold button A pressed and lower the lever. The

instrument panel warning light

will go out.

Press the brake pedal when carrying out this

operation to prevent the vehicle from moving

accidentally.

PARKING THE CAR

Proceed as follows:

stop the engine and engage the handbrake;

engage a gear (1stgear if parked uphill or reverse if

facing downhill) and leave the wheels turned.

If the vehicle is parked on a steep slope, it is

advisable to block the wheels with a wedge or stone.

To prevent draining the battery, do not leave the

ignition key turned to MAR. Always remove the key

when you leave the vehicle.

Never leave children unattended in the vehicle.

Always remove the ignition key when leaving the

vehicle, and take it with you.

fig. 124F0T0043

125

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 152 of 260

WARNING

Use your hazard lights, warning triangle,

etc to show that your vehicle is

stationar y. Passengers should get out of the

vehicle, particularly if it is heavily loaded, and

wait for the wheel to be changed away from the

traffic . If you are on a slope or uneven surface,

place wedges or other suitable objects under

the wheels to secure the vehicle. Have the

wheel repaired and refitted as soon as possible.

Do not apply grease to the bolt threads before

fitting: they could come unscrewed.

WARNING

Use the jack only to replace wheels on

the vehicle with which it is supplied

or on other vehicles of the same model. Never

use the jack for other purposes, such as lifting

other models. Never use the jack to carr y out

repairs under the vehicle. Incorrect positioning

of the jack may cause the lifted vehicle to

fall. Do not use the jack for loads higher than

the one shown on its label.

WARNING

Incorrect hub cap assembly may cause it

to come off when the vehicle is moving.

Never tamper with the inflation valve. Never

introduce tools of any kind between rim and

tyre. Check tyre and space-saver wheel

pressures regularly, referring to the values

shown in the "Technical data" chapter.

Please note that:

the jack weight is 1.76 kg;

the jack requires no adjustment;

the jack cannot be repaired and in the event of a

fault it must be replaced by another genuine one;

no tool other than its cranking device may be

fitted on the jack.

To change a wheel, proceed as follows:

stop the vehicle in a position that is not dangerous

for oncoming traffic where you can change the

wheel safely. The ground must be flat and

sufficiently compact;

switch off the engine and pull the handbrake;

engage first gear or reverse;

wear the reflective safety jacket (compulsory by

law in certain countries) before getting out of

the vehicle;

148

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 156 of 260

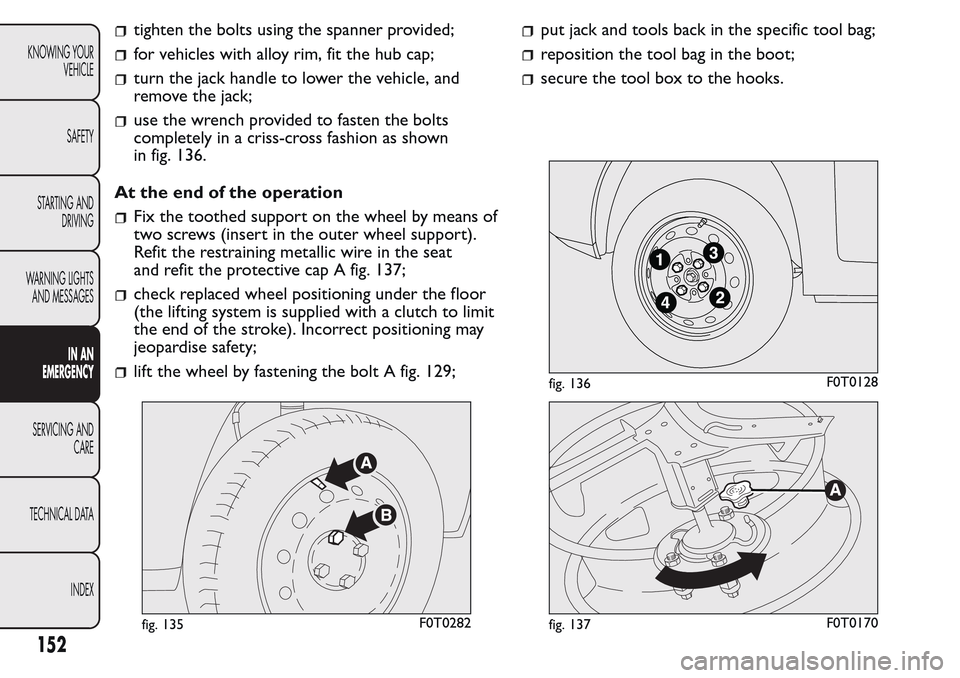

tighten the bolts using the spanner provided;

for vehicles with alloy rim, fit the hub cap;

turn the jack handle to lower the vehicle, and

remove the jack;

use the wrench provided to fasten the bolts

completely in a criss-cross fashion as shown

in fig. 136.

At the end of the operation

Fix the toothed support on the wheel by means of

two screws (insert in the outer wheel support).

Refit the restraining metallic wire in the seat

and refit the protective cap A fig. 137;

check replaced wheel positioning under the floor

(the lifting system is supplied with a clutch to limit

the end of the stroke). Incorrect positioning may

jeopardise safety;

lift the wheel by fastening the bolt A fig. 129;

put jack and tools back in the specific tool bag;

reposition the tool bag in the boot;

secure the tool box to the hooks.

fig. 135F0T0282

fig. 136F0T0128

fig. 137F0T0170

152

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 157 of 260

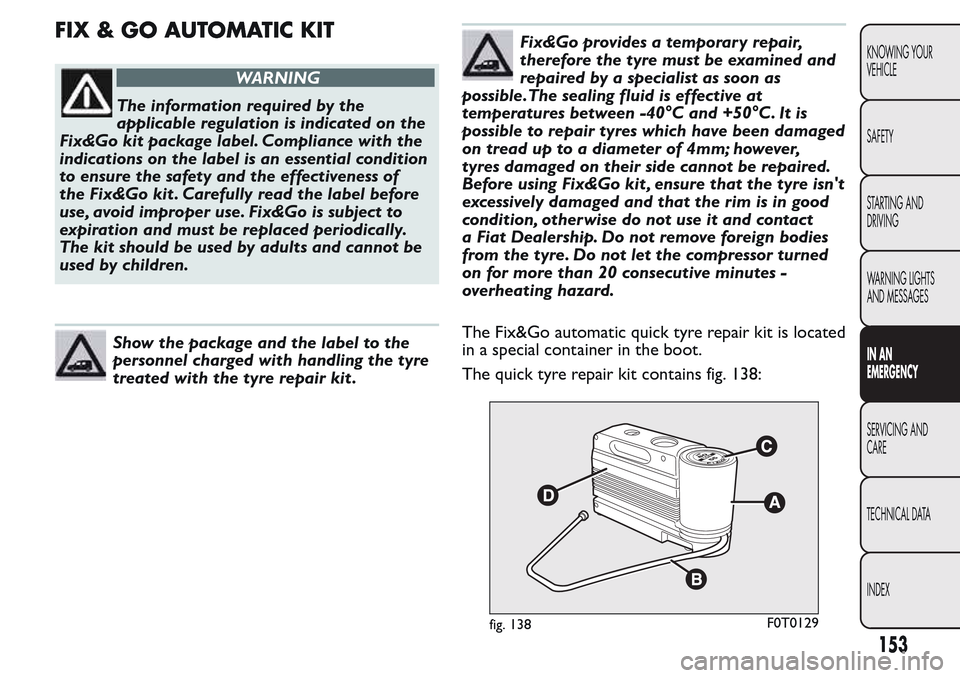

FIX & GO AUTOMATIC KIT

WARNING

The information required by the

applicable regulation is indicated on the

Fix&Go kit package label. Compliance with the

indications on the label is an essential condition

to ensure the safety and the effectiveness of

the Fix&Go kit . Carefully read the label before

use, avoid improper use. Fix&Go is subject to

expiration and must be replaced periodically.

The kit should be used by adults and cannot be

used by children.

Show the package and the label to the

personnel charged with handling the tyre

treated with the tyre repair kit .

Fix&Go provides a temporary repair,

therefore the tyre must be examined and

repaired by a specialist as soon as

possible.The sealing fluid is effective at

temperatures between -40°C and +50°C. It is

possible to repair tyres which have been damaged

on tread up to a diameter of 4mm; however,

tyres damaged on their side cannot be repaired.

Before using Fix&Go kit , ensure that the tyre isn't

excessively damaged and that the rim is in good

condition, otherwise do not use it and contact

a Fiat Dealership. Do not remove foreign bodies

from the tyre. Do not let the compressor turned

on for more than 20 consecutive minutes -

overheating hazard.

The Fix&Go automatic quick tyre repair kit is located

in a special container in the boot.

The quick tyre repair kit contains fig. 138:

fig. 138F0T0129

153

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 159 of 260

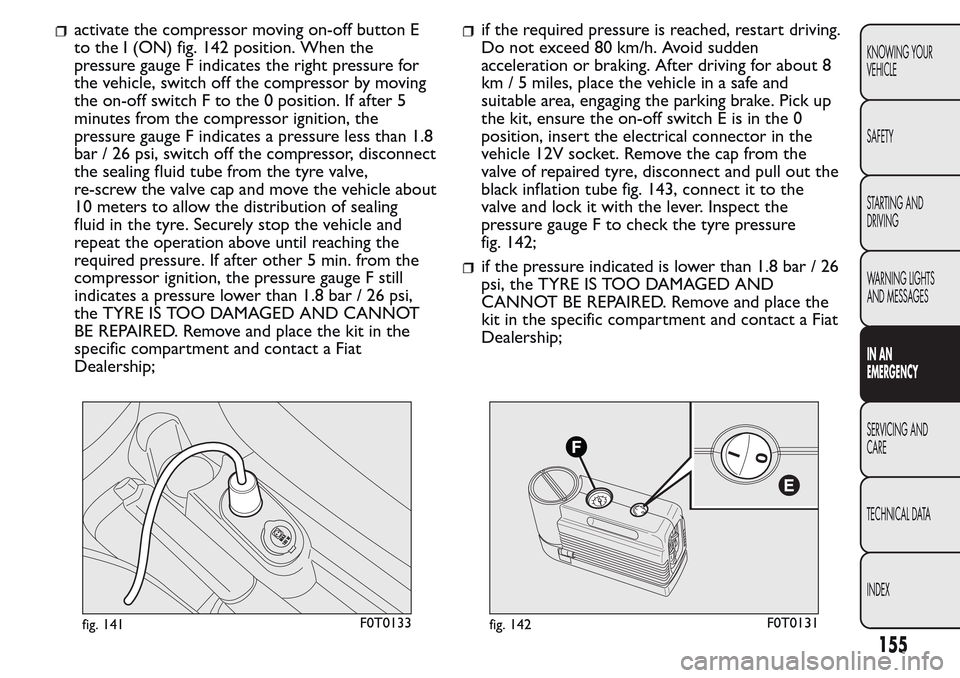

activate the compressor moving on-off button E

to the I (ON) fig. 142 position. When the

pressure gauge F indicates the right pressure for

the vehicle, switch off the compressor by moving

the on-off switch F to the 0 position. If after 5

minutes from the compressor ignition, the

pressure gauge F indicates a pressure less than 1.8

bar / 26 psi, switch off the compressor, disconnect

the sealing fluid tube from the tyre valve,

re-screw the valve cap and move the vehicle about

10 meters to allow the distribution of sealing

fluid in the tyre. Securely stop the vehicle and

repeat the operation above until reaching the

required pressure. If after other 5 min. from the

compressor ignition, the pressure gauge F still

indicates a pressure lower than 1.8 bar / 26 psi,

the TYRE IS TOO DAMAGED AND CANNOT

BE REPAIRED. Remove and place the kit in the

specific compartment and contact a Fiat

Dealership;if the required pressure is reached, restart driving.

Do not exceed 80 km/h. Avoid sudden

acceleration or braking. After driving for about 8

km / 5 miles, place the vehicle in a safe and

suitable area, engaging the parking brake. Pick up

the kit, ensure the on-off switch E is in the 0

position, insert the electrical connector in the

vehicle 12V socket. Remove the cap from the

valve of repaired tyre, disconnect and pull out the

black inflation tube fig. 143, connect it to the

valve and lock it with the lever. Inspect the

pressure gauge F to check the tyre pressure

fig. 142;

if the pressure indicated is lower than 1.8 bar / 26

psi, the TYRE IS TOO DAMAGED AND

CANNOT BE REPAIRED. Remove and place the

kit in the specific compartment and contact a Fiat

Dealership;

fig. 141F0T0133fig. 142F0T0131

155

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 170 of 260

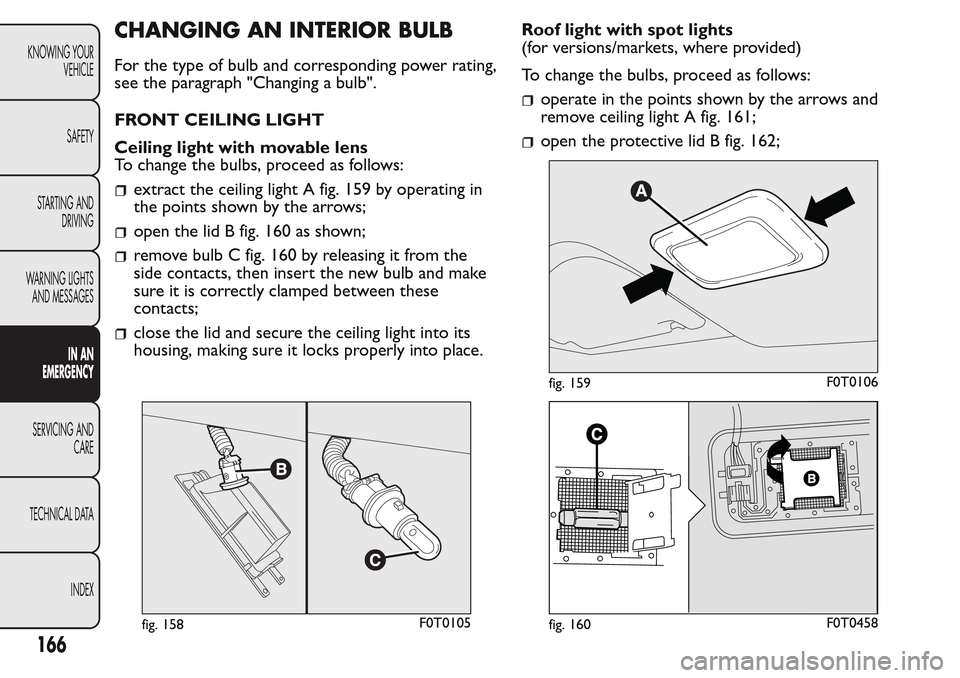

CHANGING AN INTERIOR BULB

For the type of bulb and corresponding power rating,

see the paragraph "Changing a bulb".

FRONT CEILING LIGHT

Ceiling light with movable lens

To change the bulbs, proceed as follows:

extract the ceiling light A fig. 159 by operating in

the points shown by the arrows;

open the lid B fig. 160 as shown;

remove bulb C fig. 160 by releasing it from the

side contacts, then insert the new bulb and make

sure it is correctly clamped between these

contacts;

close the lid and secure the ceiling light into its

housing, making sure it locks properly into place.Roof light with spot lights

(for versions/markets, where provided)

To change the bulbs, proceed as follows:

operate in the points shown by the arrows and

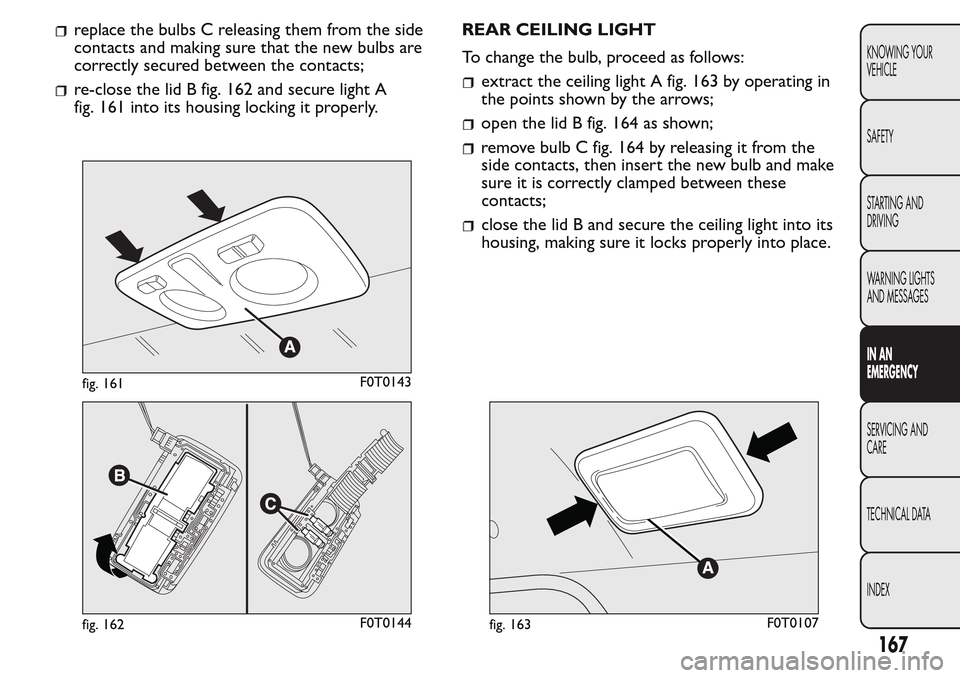

remove ceiling light A fig. 161;

open the protective lid B fig. 162;

fig. 158F0T0105

fig. 159F0T0106

fig. 160F0T0458

166

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 171 of 260

replace the bulbs C releasing them from the side

contacts and making sure that the new bulbs are

correctly secured between the contacts;

re-close the lid B fig. 162 and secure light A

fig. 161 into its housing locking it properly.REAR CEILING LIGHT

To change the bulb, proceed as follows:extract the ceiling light A fig. 163 by operating in

the points shown by the arrows;

open the lid B fig. 164 as shown;

remove bulb C fig. 164 by releasing it from the

side contacts, then insert the new bulb and make

sure it is correctly clamped between these

contacts;

close the lid B and secure the ceiling light into its

housing, making sure it locks properly into place.

fig. 161F0T0143

fig. 162F0T0144fig. 163F0T0107

167

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX

Page 180 of 260

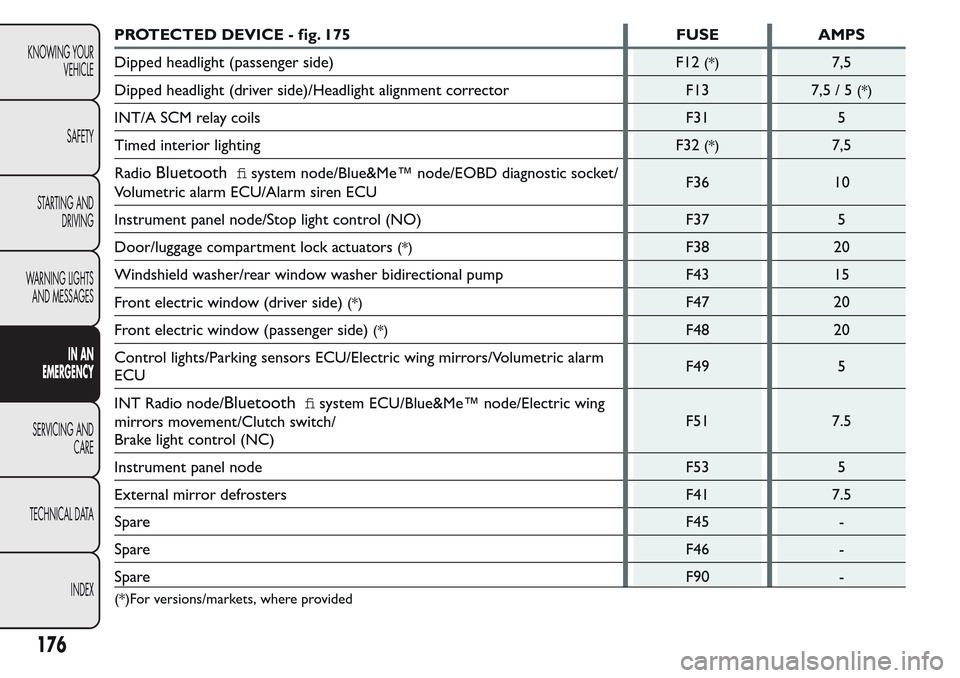

PROTECTED DEVICE - fig. 175 FUSE AMPS

Dipped headlight (passenger side)

F12

(*)7,5

Dipped headlight (driver side)/Headlight alignment corrector F13

7,5/5

(*)

INT/A SCM relay coils F31 5

Timed interior lighting

F32

(*)7,5

Radio

Bluetoothfisystem node/Blue&Me™ node/EOBD diagnostic socket/

Volumetric alarm ECU/Alarm siren ECUF36 10

Instrument panel node/Stop light control (NO) F37 5

Door/luggage compartment lock actuators

(*)F38 20

Windshield washer/rear window washer bidirectional pump F43 15

Front electric window (driver side)

(*)F47 20

Front electric window (passenger side)

(*)F48 20

Control lights/Parking sensors ECU/Electric wing mirrors/Volumetric alarm

ECUF49 5

INT Radio node/

Bluetoothfisystem ECU/Blue&Me™ node/Electric wing

mirrors movement/Clutch switch/

Brake light control (NC)F51 7.5

Instrument panel node F53 5

External mirror defrosters F41 7.5

SpareF45 -

SpareF46 -

SpareF90 -

(*)For versions/markets, where provided

176

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTS

AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

CARE

TECHNICAL DATA

INDEX