technical specifications FIAT STILO 2006 1.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2006, Model line: STILO, Model: FIAT STILO 2006 1.GPages: 274, PDF Size: 4.76 MB

Page 235 of 274

234

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

To correctly wash the car:

❒ remove the aerial from the roof to pre-

vent damage to it if the car is washed in

an automatic system;

❒wash the body using a low pressure jet

of water;

❒ wipe a sponge with a slightly soapy so-

lution over the bodywork, frequently

rinsing with the sponge;

❒ rinse well with water and dry with a jet

of air or a chamois leather.

When drying, take particular care with the

less visible parts like door surrounds, bon-

net and around the headlights where wa-

ter may stagnate. The car should not be

taken to a closed area immediately, but left

in the open so that residual water can

evaporate.Exterior plastic parts must be cleaned in

the same way as the rest of the car.

Where possible, do not park under trees;

the resinous substance many species re-

lease give the paint a dull appearance and

increase the possibility of triggering rust

processes.

IMPORTANT Bird droppings must be

washed off immediately and thoroughly as

the acid they contain is particularly ag-

gressive.Front headlights

IMPORTANT Never use aromatic sub-

stances (e.g.: petrol) or ketones (e.g.: ace-

tone) for cleaning front headlight plastic

lens.

Windows

Use specific window cleaner products.

Use also clean cloths to avoid scratching

the glass or damaging the transparency.

IMPORTANT The inside of the

rearscreen should be wiped gently with a

cloth in the direction of the filaments to

avoid damaging the heating device.

Engine compartment

At the end of the winter the engine com-

partment should be carefully washed,

without directing the jet against electron-

ic control units. Contact a specialised

workshop to have this done.

IMPORTANT The car should be washed

with the engine cold and the ignition key

at STOP. After washing make sure that

the various protections (e.g. rubber caps

and various covers) have not been dam-

aged or removed. Detergents cause water

pollution. Therefore the car

should be washed in areas

equipped for collecting and

purifying the liquid used in the wash-

ing process.

Do not wash the car after it has been left

in the sun or with the bonnet hot: this may

alter the shine of the paintwork.

Page 236 of 274

235

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

INTERIORS

Periodically check that water is not trapped

under the mats (due to water dripping off

shoes, umbrellas, etc.) which could cause

oxidisation of the sheet metal.

CLEANING SEATS AND FABRIC

AND VELVET PARTS

Use a soft brush or vacuum cleaner to re-

move dust. Velvet is cleaned better if the

brush is moistened.

Rub the seats with a sponge moistened

with a solution of water and neutral de-

tergent.CLEANING LEATHER SEATS

Remove dried on dirt with lightly moist-

ened chamois leather or cloth without

pressing too hard.

Remove liquid or grease stains with a dry

absorbent cloth without rubbing. Then

wipe with a soft cloth or chamois leather

with water and neutral soap.

If the stain persists, use specific products,

carefully following the instructions for use.

IMPORTANT Never use spirit or alcohol-

based products.Fabric upholstery of your car

is purpose-made to withstand

common wear resulting from

normal use of the car. It is

however absolutely necessary to pre-

vent hard and/or prolonged scratch-

ing/scraping caused by clothing acces-

sories like metallic buckles, studs, “Vel-

cro” fixings, etc. that stressing locally

the fabric could break yarns and dam-

age the upholstery as a consequence.

Page 237 of 274

236

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

INTERIOR PLASTIC PARTS

For routine cleaning of interior plastic

parts use a soft cloth moistened with wa-

ter and neutral soap. Remove grease or

persisting stains using appropriate solvent-

free products designed to preserve ap-

pearance and colour of plastic compo-

nents.

IMPORTANT Never use spirit or petro-

leum to clean the instrument panel.STEERING WHEEL/GEAR LEVER

KNOB WITH GENUINE

LEATHER COVERING

These components shall only be cleaned

with water and neutral soap. Never use

spirit or alcohol-based products.

Before using special products for clean-

ing interiors, read carefully label instruc-

tions and indications to make sure they

are free from spirit and/or alcohol-based

substances.

If when cleaning the windscreen with spe-

cial glass products, some drops fall on the

leather covering of the steering wheel/gear

lever knob remove them immediately and

then clean with water and neutral soap.

IMPORTANT Take the utmost care when

engaging the steering lock to prevent

scratching the leather covering.

Do not keep aerosol cans in

the car: they might explode.

Aerosol cans must never be exposed

to a temperature above 50°C. The

temperature inside the car exposed

to the sun may go well beyond that

figure.

WARNING

Never use flammable prod-

ucts like oil ether or rectified

petrol for cleaning car interiors. Elec-

trostatic discharges generated by rub-

bing during cleaning operations could

cause fire.

WARNING

Page 238 of 274

237

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IDENTIFICATION DATA ................................................... 238

ENGINE CODES - BODYWORK VERSIONS .............. 240

ENGINE .................................................................................... 241

FUEL FEED/IGNITION ........................................................ 243

TRANSMISSION .................................................................... 243

BRAKES ..................................................................................... 244

SUSPENSIONS......................................................................... 244

STEERING ................................................................................. 244

WHEELS .................................................................................... 245

DIMENSIONS .......................................................................... 250

PERFORMANCE ..................................................................... 253

WEIGHTS ................................................................................. 254

CAPACITIES ........................................................................... 257

FLUIDS AND LUBRICANTS ............................................... 259

FUEL CONSUMPTION ........................................................ 261

CO

2EMISSIONS .................................................................... 263

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

Page 239 of 274

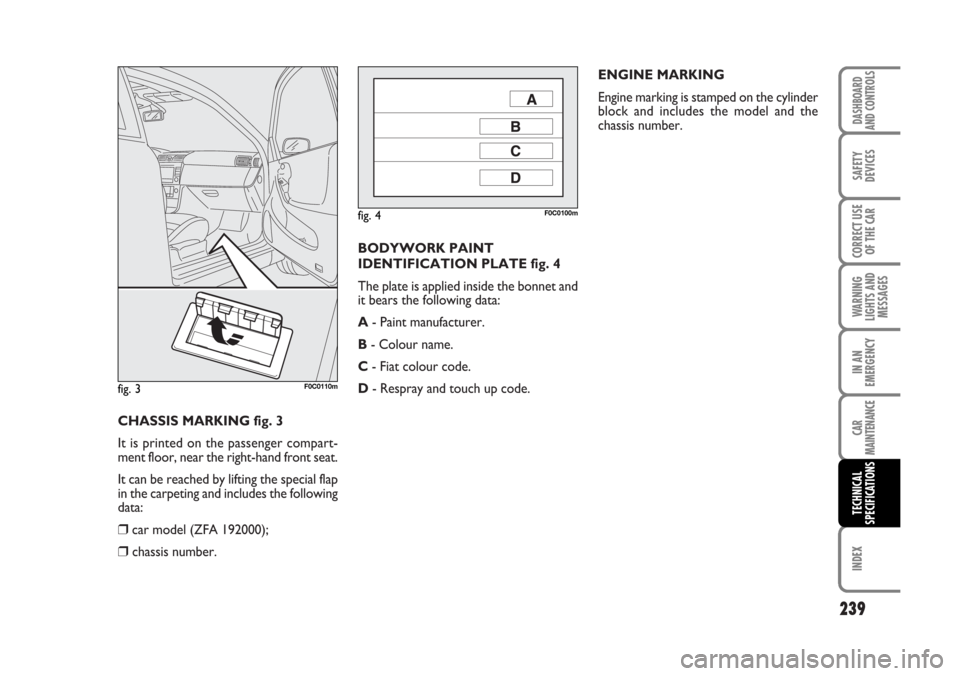

MODEL PLATE fig. 2

The plate is to be found on the front

crossmember of the engine compartment

and bears the following identification da-

ta:

AManufacturer’ name.

BHomologation number.

CVehicle type code.

DChassis number.

EMaximum vehicle weight fully loaded.

FMaximum vehicle weight fully loaded

with trailer.GMaximum vehicle weight on front axle.

HMaximum vehicle weight on rear axle.

IEngine type.

LBody version code.

MSpare part code.

NSmoke opacity index (for diesel en-

gines).

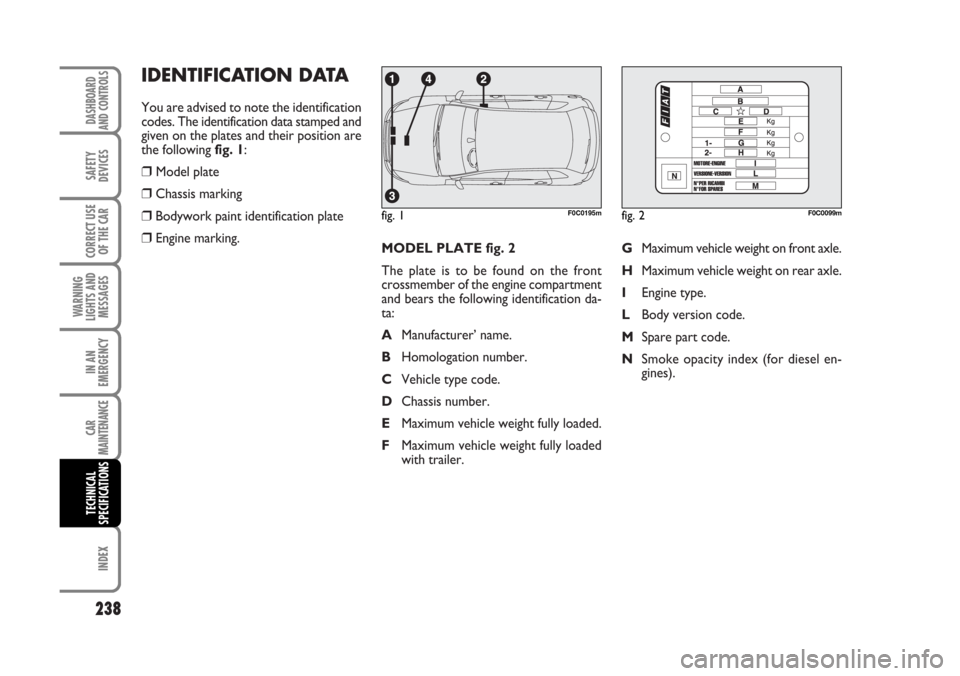

IDENTIFICATION DATA

You are advised to note the identification

codes. The identification data stamped and

given on the plates and their position are

the following fig. 1:

❒ Model plate

❒Chassis marking

❒Bodywork paint identification plate

❒Engine marking.

238

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

fig. 1F0C0195mfig. 2F0C0099m

Page 240 of 274

BODYWORK PAINT

IDENTIFICATION PLATE fig. 4

The plate is applied inside the bonnet and

it bears the following data:

A- Paint manufacturer.

B- Colour name.

C- Fiat colour code.

D- Respray and touch up code.ENGINE MARKING

Engine marking is stamped on the cylinder

block and includes the model and the

chassis number.

CHASSIS MARKING fig. 3

It is printed on the passenger compart-

ment floor, near the right-hand front seat.

It can be reached by lifting the special flap

in the carpeting and includes the following

data:

❒car model (ZFA 192000);

❒ chassis number.

239

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

fig. 4F0C0100m

fig. 3F0C0110m

Page 241 of 274

240

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

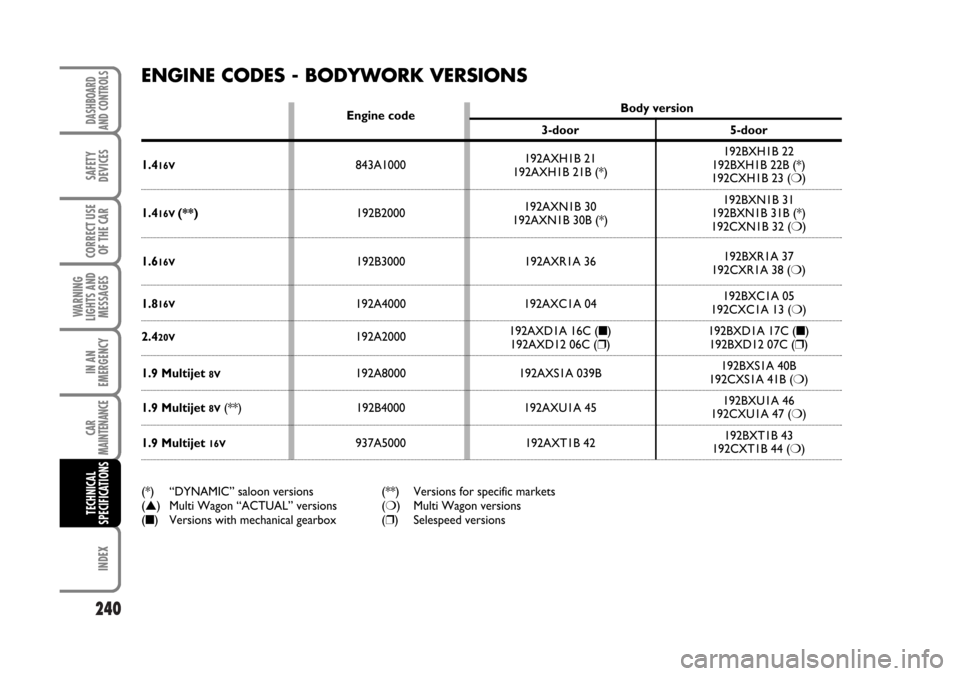

(*) “DYNAMIC” saloon versions (**) Versions for specific markets

(▲) Multi Wagon “ACTUAL” versions (❍) Multi Wagon versions

(■) Versions with mechanical gearbox (❒) Selespeed versions

ENGINE CODES - BODYWORK VERSIONS

Engine codeBody version

3-door 5-door

192AXH1B 21192BXH1B 22

1.4

16V843A1000

192AXH1B 21B (*)192BXH1B 22B (*)192CXH1B 23 (❍)

192AXN1B 30192BXN1B 31

1.4

16V (**)192B2000

192AXN1B 30B (*)192BXN1B 31B (*)192CXN1B 32 (❍)

192BXR1A 37

1.6

16V192B3000 192AXR1A 36

192CXR1A 38 (❍)

1.816V192A4000 192AXC1A 04192BXC1A 05192CXC1A 13 (❍)

2.4

20V192A2000192AXD1A 16C (■) 192BXD1A 17C (■)192AXD12 06C (❒) 192BXD12 07C (❒)

1.9 Multijet

8V192A8000 192AXS1A 039B192BXS1A 40B192CXS1A 41B (❍)

1.9 Multijet

8V(**) 192B4000 192AXU1A 45192BXU1A 46192CXU1A 47 (❍)

1.9 Multijet

16V937A5000 192AXT1B 42192BXT1B 43192CXT1B 44 (❍)

Page 242 of 274

241

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

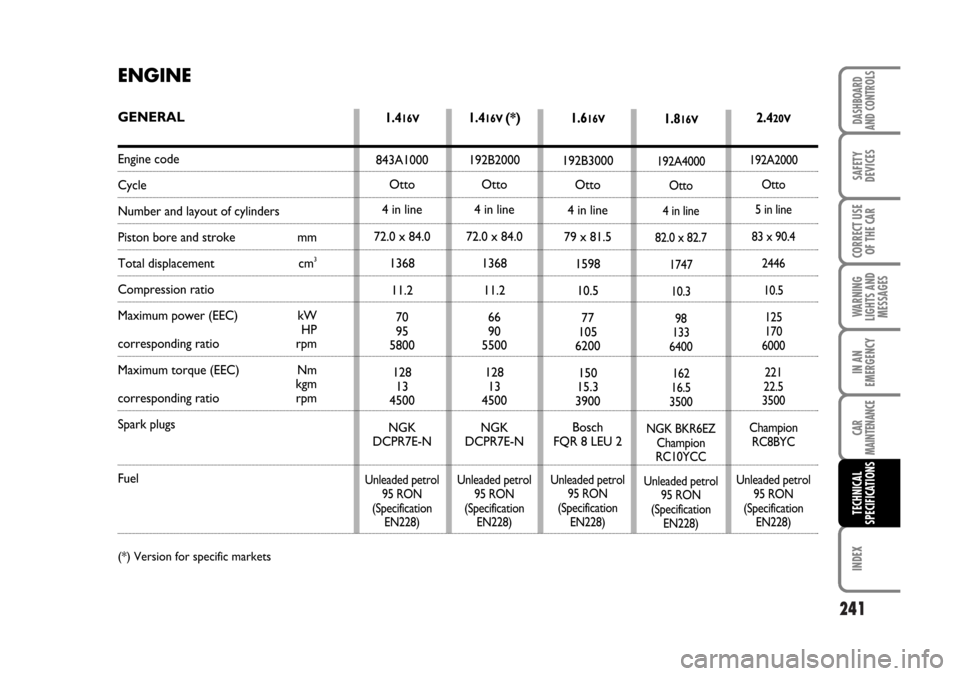

ENGINE

GENERAL

Engine code

Cycle

Number and layout of cylinders

Piston bore and stroke mm

Total displacement cm3

Compression ratio

Maximum power (EEC) kW

HP

corresponding ratio rpm

Maximum torque (EEC) Nm

kgm

corresponding ratio rpm

Spark plugs

Fuel

1.416V

843A1000

Otto

4 in line

72.0 x 84.0

1368

11.2

70

95

5800

128

13

4500

NGK

DCPR7E-N

Unleaded petrol

95 RON

(Specification

EN228)

1.416V (*)

192B2000

Otto

4 in line

72.0 x 84.0

1368

11.2

66

90

5500

128

13

4500

NGK

DCPR7E-N

Unleaded petrol

95 RON

(Specification

EN228)

1.616V

192B3000

Otto

4 in line

79 x 81.5

1598

10.5

77

105

6200

150

15.3

3900

Bosch

FQR 8 LEU 2

Unleaded petrol

95 RON

(Specification

EN228)

1.816V

192A4000

Otto

4 in line

82.0 x 82.7

1747

10.3

98

133

6400

162

16.5

3500

NGK BKR6EZ

Champion

RC10YCC

Unleaded petrol

95 RON

(Specification

EN228)

2.420V

192A2000

Otto

5 in line

83 x 90.4

2446

10.5

125

170

6000

221

22.5

3500

Champion

RC8BYC

Unleaded petrol

95 RON

(Specification

EN228)

(*) Version for specific markets

Page 243 of 274

242

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

(*) Version for specific markets

GENERAL

Engine code

Cycle

Number and layout of cylinders

Piston bore and stroke mm

Total displacement cm3

Compression ratio

Maximum power (EEC) kW

HP

corresponding ratio rpm

Maximum torque (EEC) Nm

kgm

corresponding ratio rpm

Fuel

1.9 Multijet 8V

192A8000

Diesel

4 in line

82.0 x 90.4

1910

18

88

120

4000

255

26

2000

Diesel fuel for

motor vehicles

(Specification EN590)

1.9 Multijet 16V

937A5000

Diesel

4 in line

82.0 x 90.4

1910

17.5

110

150

4000

305

31

2000

Diesel fuel for

motor vehicles

(Specification EN590)

1.9 Multijet 8V (*)

192B4000

Diesel

4 in line

82.0 x 90.4

1910

18

85

115

4000

255

26

2000

Diesel fuel for

motor vehicles

(Specification EN590)

1.9 Multijet 16V (*)

Diesel

4 in line

82.0 x 90.4

1910

17.5

100

136

4000

305

31

2000

Diesel fuel for

motor vehicles

(Specification EN590)

Page 244 of 274

243

WARNING

LIGHTS AND

MESSAGES

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE CAR

IN AN

EMERGENCY

CAR

MAINTENANCE

TECHNICAL

SPECIFICATIONS

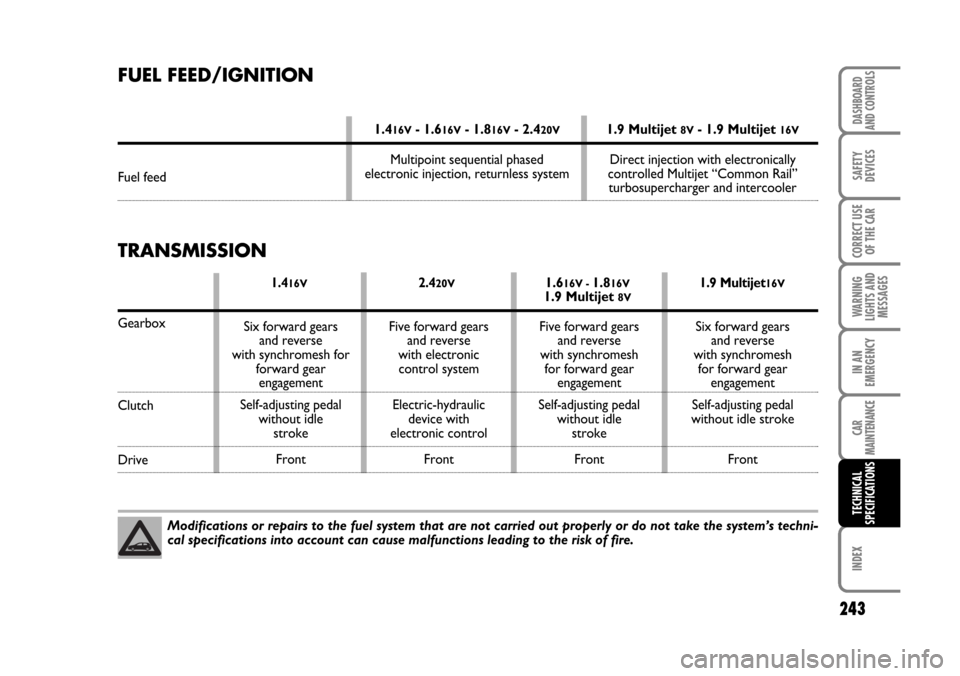

FUEL FEED/IGNITION

1.416V- 1.616V- 1.816V- 2.420V1.9 Multijet 8V- 1.9 Multijet 16V

Fuel feedMultipoint sequential phased Direct injection with electronically

electronic injection, returnless system controlled Multijet “Common Rail”turbosupercharger and intercooler

TRANSMISSION

1.416V2.420V1.616V - 1.816V1.9 Multijet16V1.9 Multijet 8V

Gearbox

Clutch

Drive

Modifications or repairs to the fuel system that are not carried out properly or do not take the system’s techni-

cal specifications into account can cause malfunctions leading to the risk of fire.

Six forward gears

and reverse

with synchromesh for

forward gear

engagement

Self-adjusting pedal

without idle

stroke

FrontFive forward gears

and reverse

with electronic

control system

Electric-hydraulic

device with

electronic control

FrontFive forward gears

and reverse

with synchromesh

for forward gear

engagement

Self-adjusting pedal

without idle

stroke

FrontSix forward gears

and reverse

with synchromesh

for forward gear

engagement

Self-adjusting pedal

without idle stroke

Front