brake pads replacement FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 55 of 171

REAR SHOCK ABSORBERS • Job 48. Check wheel bolts for tightness.

Look for signs of leaks coming from underneath the top part

of

each

rear shock absorber and replace if necessary. Check

the

top and bottom rubber mounting bushes. If any are soft

or

split they must be replaced. Check that the bump stops are

present and correct.

BOUNCE TEST: Bounce-test the shock absorbers as in Job 43.

PART G: BRAKING SYSTEM

SAFETY FIRST!

• Job 49. Check front brakes.

You can

check the thickness of the brake pads by looking

through

the 'window' in the caliper. However, this isn't

recommended

unless you are experienced and know what you

are looking for,

and you can't check the caliper or clean out

accumulated

brake dust.

• Before raising the car, see Chapter 1, Safety First!

•

Also,

be sure to read the section on BRAKES AND

ASBESTOS in Chapter 1, Safety First! for further

important

information.

•

Your car's

brakes are its most important

safety-

related items.

Do NOT attempt any work on the

braking system unless

you are fully competent to do so.

• If you have not been trained in this work, but wish

to

carry

it out, we strongly recommend you have a

garage

or qualified mechanic check your work before

using

the car on the road.

•

Always

start by washing the brakes with a propri-

etary

brand of brake cleaner

-

brake drums removed

where

appropriate

-

and never use compressed air to

clean

off

brake

dust.

•

Always

replace brake pads and/or shoes in complete

'axle' sets

of four

-

never replace them on one wheel

only.

• After fitting new brake shoes or pads, avoid heavy

braking

for the first

150

to 200 miles (250 to 300 km),

except

in

an emergency.

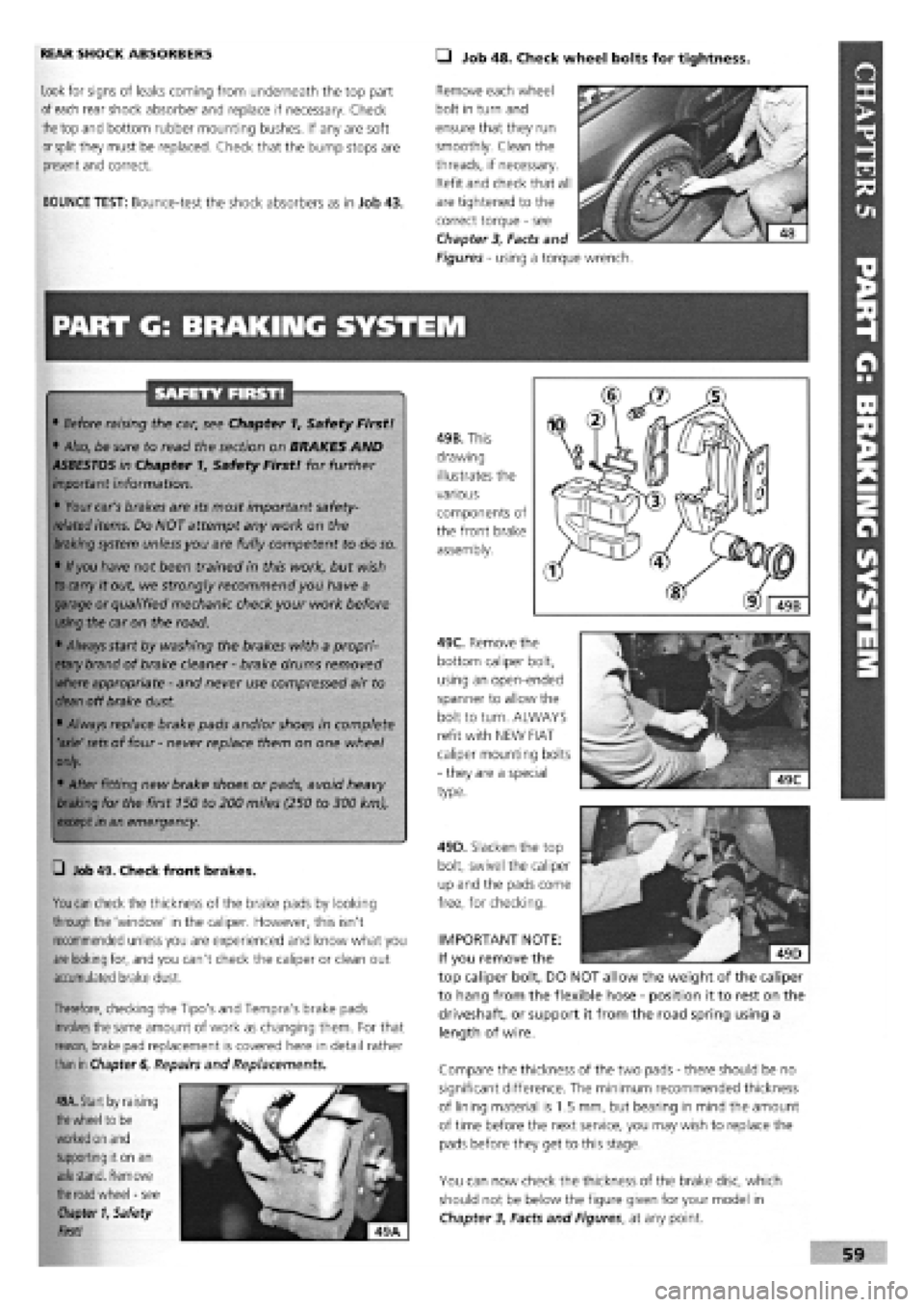

49B. This

drawing

illustrates the

various

components of

the front brake

assembly.

49C. Remove the

bottom caliper bolt,

using an open-ended

spanner to allow the

bolt to turn. ALWAYS

refit with NEW FIAT

caliper mounting bolts

-

they are a special

type.

Therefore,

checking the Tipo's and Tempra's brake pads

involves

the same amount of work as changing them. For that

reason, brake

pad replacement is covered here in detail rather

than in

Chapter

6,

Repairs and Replacements.

49A. Start by raising

the

wheel to

be

worked on and

supporting it on

an

axle stand. Remove

the road wheel

-

see

Chapter

1, Safety

First!

Compare the thickness of the two pads

-

there should be no

significant difference. The minimum recommended thickness

of lining material is 1.5 mm, but bearing in mind the amount

of time before the next service, you may wish to replace the

pads before they get to this stage.

You can now check the thickness of the brake disc, which

should not be below the figure given for your model in

Chapter

3,

Facts and Figures, at any point.

Remove each wheel

bolt in turn and

ensure that they run

smoothly. Clean the

threads, if necessary.

Refit and check that all

are tightened to the

correct torque

-

see

Chapter

3,

Facts and

Figures

-

using a torque wrench.

49D. Slacken the top

bolt, swivel the caliper

up and the pads come

free, for checking.

IMPORTANT NOTE:

If you remove the

top caliper bolt, DO NOT allow the weight of the caliper

to hang from the flexible hose

-

position it to rest on the

driveshaft, or support it from the road spring using a

length of wire.

Page 56 of 171

49H. ...and push out the nylon bush (arrowed). Reassemble

on the new pad and reattach the wire.

IMPORTANT NOTE: After fitting the pads, apply the

brakes firmly several times to adjust them.

• Job 50. Check rear brakes.

SAFETY FIRST!

Read SAFETY FIRST at the start of Job 49 before

proceeding!

GENERAL. The majority of Tipo/Tempra models are fitted with

rear drum-type rear brakes, but models with ABS anti-lock

braking have a disc-and-caliper arrangement instead.

Slacken the wheel bolts, raise the wheel, remove it and

support the car with an axle stand. Make sure that the wheels

remaining on the ground are chocked in both directions and

that the handbrake is off.

DRUM REAR BRAKES

If the drum

sticks,

try:

• screwing a pair of

bolts

into the two threaded

holes in the drum. Evenly

tightening the bolts will force the drum off the

shoes.

• tapping carefully around the drum with a hide

mallet to help loosen it.

s Vn order to fit new pads,

r> - the caliper piston must be

pushed back into the bore.

• Use an old battery hydrometer to draw about half

of the fluid from the master cylinder.

• Push the piston back into the caliper, using a G-

clamp.

• Keep an eye on the master cylinder so that it

doesn't overflow as fluid is pushed back up the pipe.

IMPORTANT NOTE: Be very sparing or grease could

migrate to the friction linings!

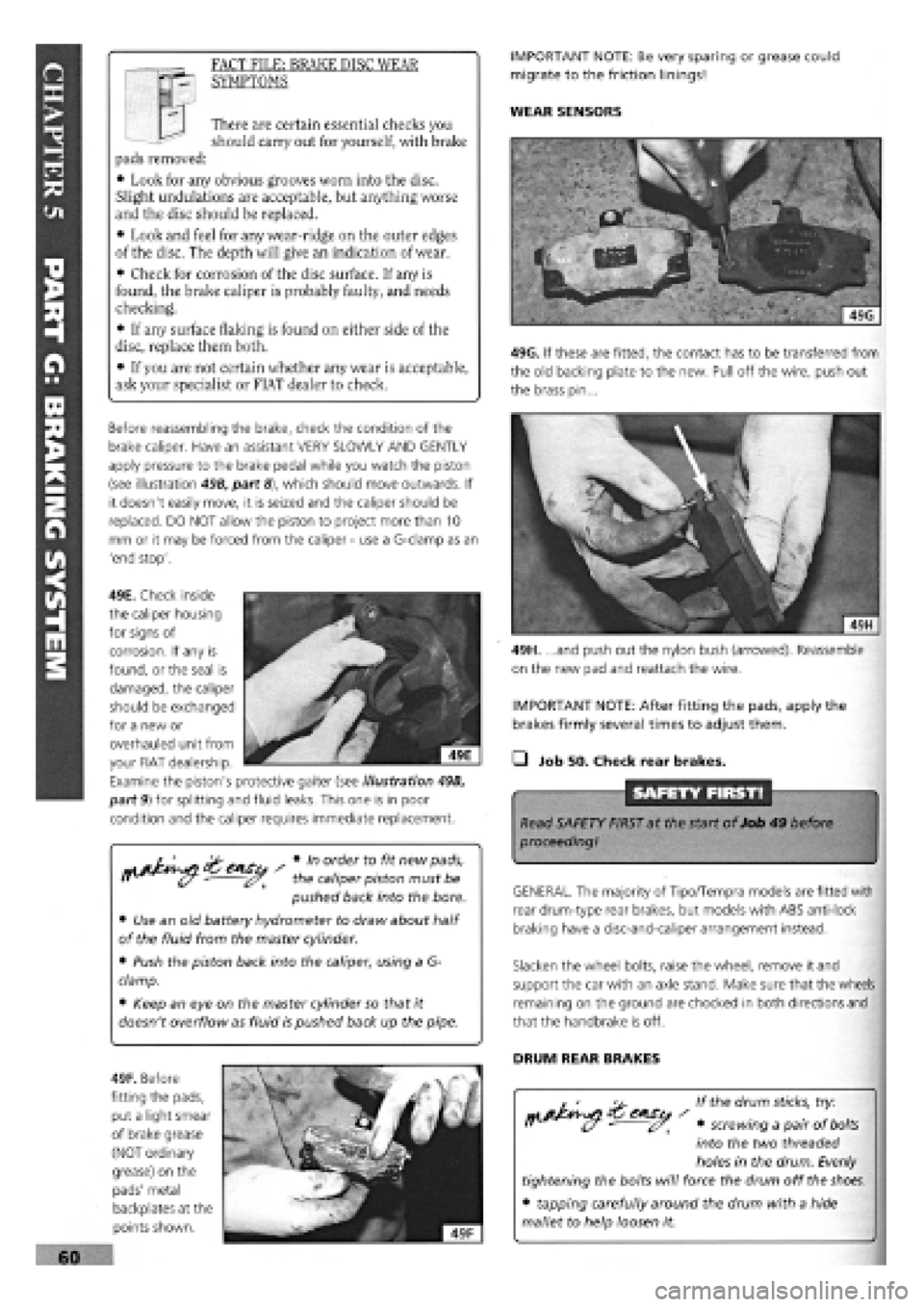

WEAR SENSORS I I There are certain essential checks you

should carry out for yourself, with brake

pads removed:

• Look for any obvious grooves worn into the disc.

Slight undulations are acceptable, but anything worse

and the disc should be replaced.

• Look and feel for any wear-ridge on the outer edges

of the disc. The depth will give an indication of wear.

• Check for corrosion of the disc surface. If any is

found, the brake caliper is probably faulty, and needs

checking.

• If any surface flaking is found on either side of the

disc, replace them both.

• If you are not certain whether any wear is acceptable,

ask your specialist or FIAT dealer to check.

FACT FILE: BRAKE DISC WEAR

SYMPTOMS

Before reassembling the brake, check the condition of the

brake caliper. Have an assistant VERY SLOWLY AND GENTLY

apply pressure to the brake pedal while you watch the piston

(see illustration 49B, part

8),

which should move outwards. If

it doesn't easily move, it is seized and the caliper should be

replaced. DO NOT allow the piston to project more than 10

mm or it may be forced from the caliper

-

use a G-clamp as an

'end stop'.

49F. Before

fitting the pads,

put a light smear

of brake grease

(NOT ordinary

grease) on the

pads' metal

backplates at the

points shown.

49G. If these are fitted, the contact has to be transferred from

the old backing plate to the new. Pull off the wire, push out

the brass pin...

49E. Check inside

the caliper housing

for signs of

corrosion. If any is

found, or the seal is

damaged, the caliper

should be exchanged

for a new or

overhauled unit from

your FIAT dealership.

Examine the piston's protective gaiter (see illustration 49B,

part 9) for splitting and fluid leaks. This one is in poor

condition and the caliper requires immediate replacement.

Page 57 of 171

50A. Remove the two

bolts

(one or both of

them also the wheel

positioning stud/s)...

50B. ...and remove

the

drum.

Clean the

inside of the drum and

the brake with aerosol

brake

cleaner. If the

drum is badly scored

or cracked,

replace it.

50F. So that you don't

have to bleed the

system, release and

disconnect the parking

brake cable (arrowed)

and lift the caliper out

of the way, suspending

it on a piece of wire so

that no strain is placed

on the flexible hydraulic

hose.

50G. The brake pads are simply lifted away.

50E. Using a pair of

spanners, as shown,

remove the two

retaining bolts. These

bolts are self-locking

and FIAT recommend

that they should be

replaced each time they

are removed or if they

become loose.

Examine the brake

shoes

for wear or oil

contamination. If the

latter, the wheel cylinder is probably leaking (see 50C) and the

shoes will

have to be scrapped. FIAT recommend a minimum

1.5 mm

shoe lining thickness, but it's advisable to replace

shoes

well before they're this thin.

50C. Fold back each of

the

two rubbers on

the wheel

cylinder.

Any

fluid

found inside

requires a new

cylinder. However,

newish cylinders will

have a

little of their

special grease still in

there.

. """

€

Sjjj

KV,1

| 50D|

50D. Take

special care

to wash

all the brake

dust

away from the

automatic adjuster

mechanism with

aerosol brake cleaner.

Make

sure that it is

not seized

but if it is,

you will

have to strip

down

the assembly (see Chapter

6,

Repairs and

Replacements)

and free off or replace. Add brake grease very

sparingly (NOT ordinary grease) to the mechanism.

IMPORTANT NOTE: For information on replacing missing

or damaged springs, brake shoes or wheel cylinders, see

Chapter

6,

Repairs and Replacements.

DISC REAR BRAKES

With

the rear of the car raised and safely supported (see

Chapter 1,

Safety First) and the rear wheels removed, brake

pad

inspection can be carried out by looking through the

aperture in the caliper body. However, as for the front brakes,

you are

recommended to remove the calipers. See notes at

the

start of Job

49.

The pads should be replaced as detailed in

Chapter 6,

Repairs and Replacements. Minimum thickness

is 1.5 mm -

but don't let them get this low!

• Job 51. Check/adjust handbrake.

The handbrake is intended to 'set' itself in use as the rear

brake self-adjusters operate. If the handbrake seems not to

work, even though lever travel is not excessive, remove the

rear drums and examine the brake shoes (see Job 50) and the

self-adjuster mechanism, to ensure that it has not seized. The

handbrake may need adjusting when, after a time, the

handbrake cable stretches or if the rear brake friction materials

are replaced.

IMPORTANT NOTE: On rear disc brake cars, the

handbrake-end of the mechanism is the same as for

drum brake cars. At the brakes, the clearance is adjusted

automatically, provided that the adjuster, built in to the

caliper assembly, has not seized. If it has, replace the

caliper.

SAFETY FIRST!

Raise the rear of the car to adjust the handbrake. It

is

ESSENTIAL to ensure the front wheels are securely

chocked in both directions, and that axle stands are

used to support the car.

IMPORTANT NOTE:

• Follow Job 49

carefully for further

information such as

on checking the

caliper seals, the

condition of the disc,

and lubricating the

pad backing plates.

• Before fitting new

pads, turn the caliper

piston clockwise until it goes fully in.

• Pump the brake pedal repeatedly to adjust the pad

positions and top up with fresh brake fluid.

Page 124 of 171

Job 2. Steering wheel - removal

and refitting.

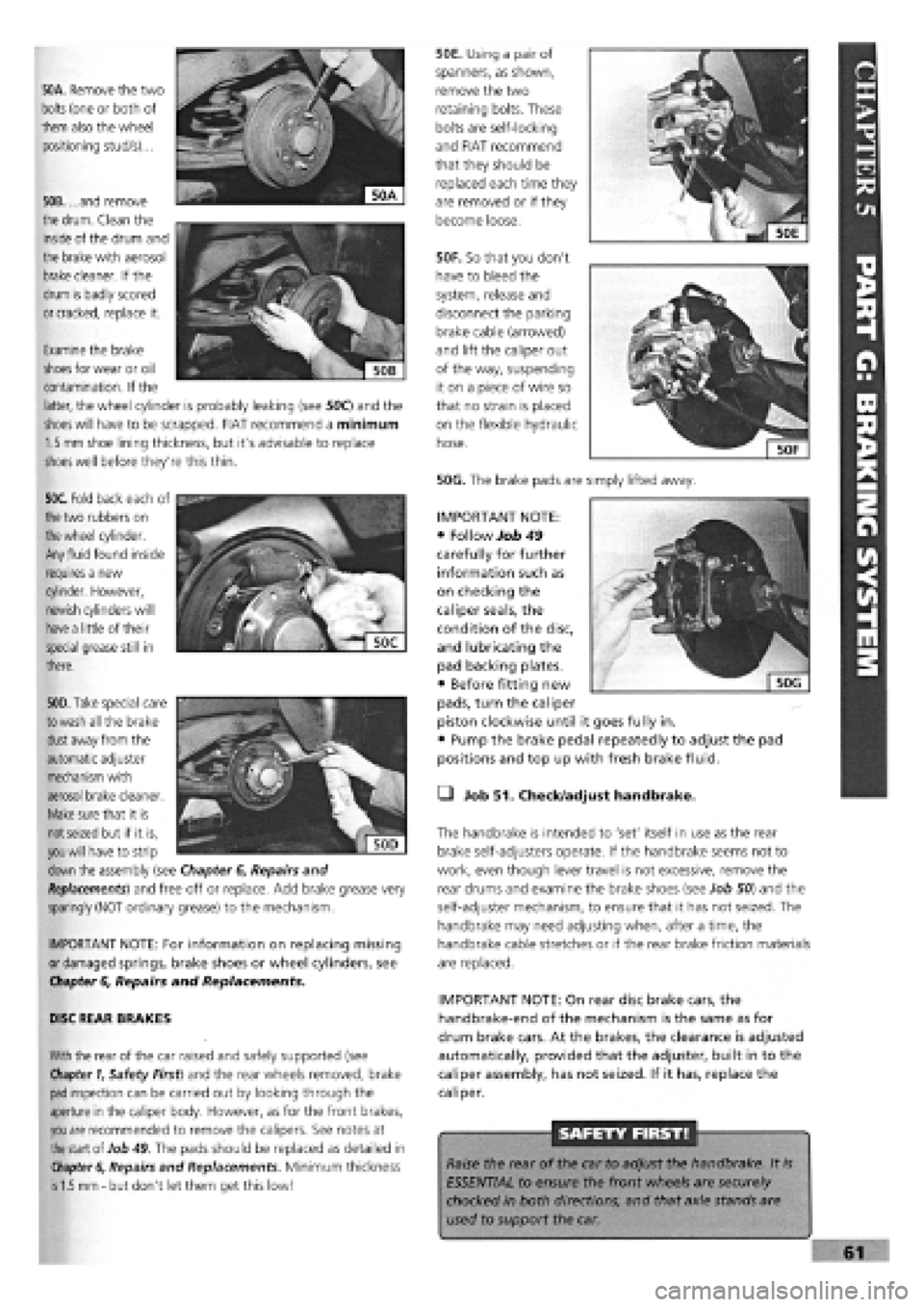

1 - coil spring 2 - trailing arm 3 - rubber bump stops 4 - handbrake cable 5 - axle beam

6 - anti-roll bar 7 - rear brake regulator 8 - shock absorber 9 - trailing arm hinge bolt

Job 1-1C

SAFETY FIRST!

• AIR BAGS. Because of the safety hazards, both

mechanical and chemical (the air bag contains an

explosive device)

-

we strongly recommend that a car

with an air bag fitted to its steering wheel should be

taken to a FIAT dealer to have its steering wheel

removed and refitted under controlled conditions.

STEERING WHEELS WITHOUT AIR BAGS ONLY

Q Point 1C: The rear suspension design shown here is

common to both Tipo and Tempra.

1 - beam axle 2 - rubber buffer pads 3 - shock absorber top bolt 4 - coil spring 5 - shock absorber 6 - bottom nut and bolt securing shock absorber to trailing arm 7 - trailing arm 8 - anti-roll bar 9 - nut and bolt securing trailing arm to beam axle 10 - stub axle/hub nut 11 - wheel hub 12 - stub axle 13

-

hub cap

Job 1-1D

Q Point 1D: This exploded drawing of the rear suspension

gives a clear view of how several of the assemblies are fitted.

• Step 3: Slacken the lock nut

(arrowed) on the track rod by just enough

to free the balljoint, but no

more.

• Step 4: Now undo the

balljoint to steering arm nut

until the bottom of the nut is

level with the end of the thread.

Job

3-3

Job 3. Track rod end balljoint -

replacement.

Q Step 1: Slacken the roadwheel nuts

on the side to be worked.

Q Step 2: Jack up and support the car

on axle stands and remove the road

wheel.

• Step 1: Undo the wheel

cover fixing bolts (positions

arrowed) from underneath.

• Step 2: Using a ring

spanner or socket and

supporting the wheel with the

other hand (see illustration

Job

2-1),

undo the centre

fixing nut and remove the

steering wheel.

H INSIDE INFORMATION!

Never use the steering column lock to stop the wheel

turning when removing and refitting the centre nut-this

could cause damage and would be a costly mistake. H

• Step 3: Refit in reverse order, tightening the fixing nut to

its specified torque. See Chapter

3,

Facts and Figures.

Page 130 of 171

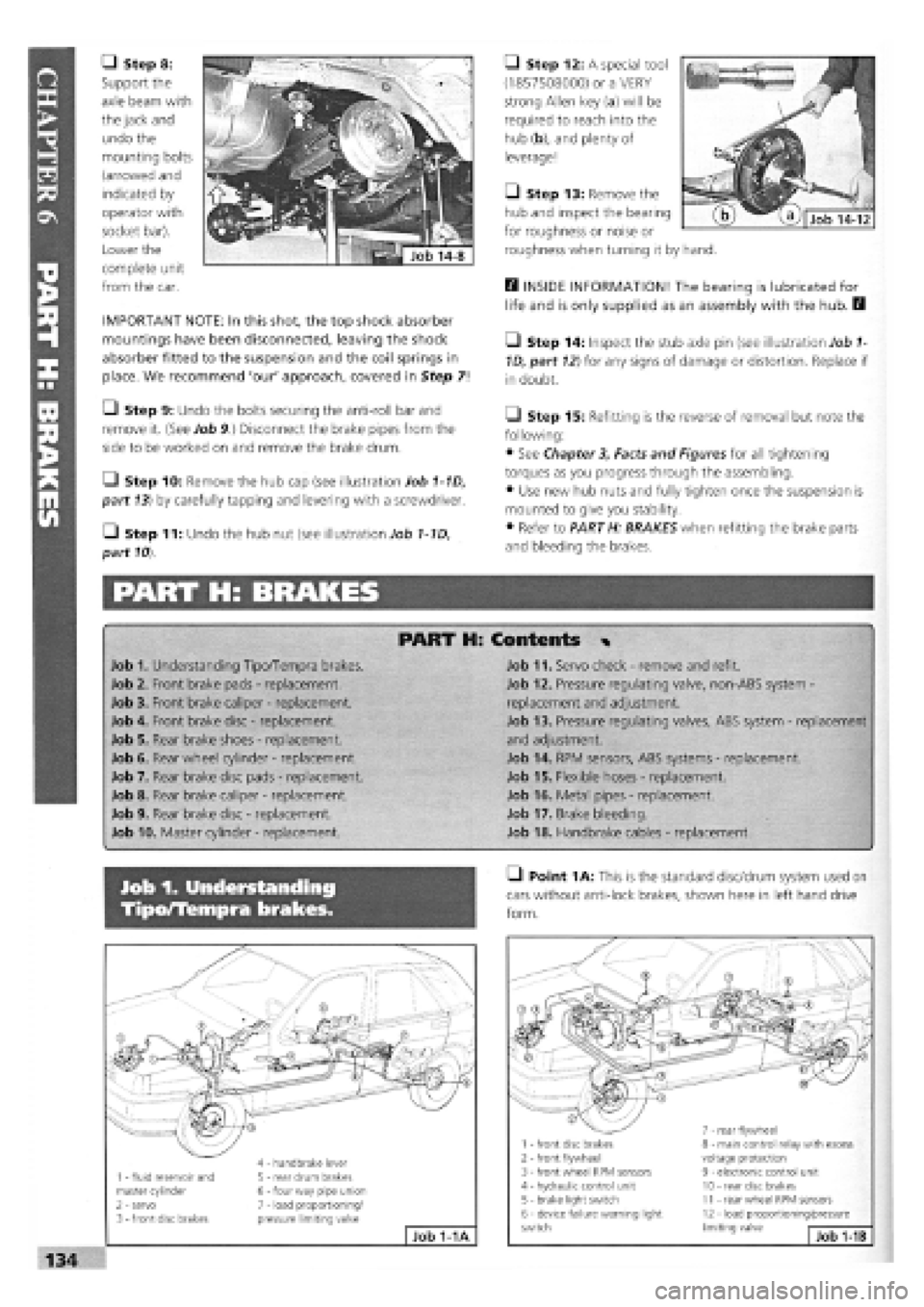

• Step 8:

Support the

axle beam with

the jack and

undo the

mounting bolts

(arrowed and

indicated by

operator with

socket bar).

Lower the

complete unit

from the car.

IMPORTANT NOTE: In this shot, the top shock absorber

mountings have been disconnected, leaving the shock

absorber fitted to the suspension and the coil springs in

place. We recommend 'our' approach, covered in Step 7!

• Step 9: Undo the bolts securing the anti-roll bar and

remove it. (See Job 9.) Disconnect the brake pipes from the

side to be worked on and remove the brake drum.

Q Step 10: Remove the hub cap (see illustration Job 1-1D,

part 13) by carefully tapping and levering with a screwdriver.

• Step 11: Undo the hub nut (see illustration Job 1-1D,

part

10).

PART H: BRAKES

• Step 12: A special tool

(1857508000) or a VERY

strong Allen key (a) will be

required to reach into the

hub (b), and plenty of

leverage!

Q Step 13: Remove the

hub and inspect the bearing

for roughness or noise or

roughness when turning it by hand.

E3 INSIDE INFORMATION! The bearing is lubricated for

life and is only supplied as an assembly with the hub. B

• Step 14: Inspect the stub axle pin (see illustration Job

1-

1D, part

12)

for any signs of damage or distortion. Replace if

in doubt.

Q Step 15: Refitting is the reverse of removal but note the

following:

• See Chapter

3,

Facts and Figures for all tightening

torques as you progress through the assembling.

• Use new hub nuts and fully tighten once the suspension is

mounted to give you stability.

• Refer to PART H: BRAKES when refitting the brake parts

and bleeding the brakes.

PART H: Contents %

Job 1. Understanding Tipo/Tempra brakes.

Job 2. Front brake pads

-

replacement.

Job 3. Front brake caliper

-

replacement.

Job 4. Front brake disc

-

replacement.

Job 5. Rear brake shoes

-

replacement.

Job 6. Rear wheel cylinder

-

replacement.

Job 7. Rear brake disc pads

-

replacement.

Job 8. Rear brake caliper

-

replacement.

Job 9. Rear brake disc

-

replacement.

Job 10. Master cylinder

-

replacement.

Job 11. Servo check

-

remove and refit.

Job 12. Pressure regulating valve, non-ABS system -

replacement and adjustment.

Job 13. Pressure regulating valves, ABS system

-

replacement

and adjustment.

Job 14. RPM sensors, ABS systems

-

replacement.

Job 15. Flexible hoses

-

replacement.

Job 16. Metal pipes

-

replacement.

Job 17. Brake bleeding.

Job 18. Handbrake cables

-

replacement.

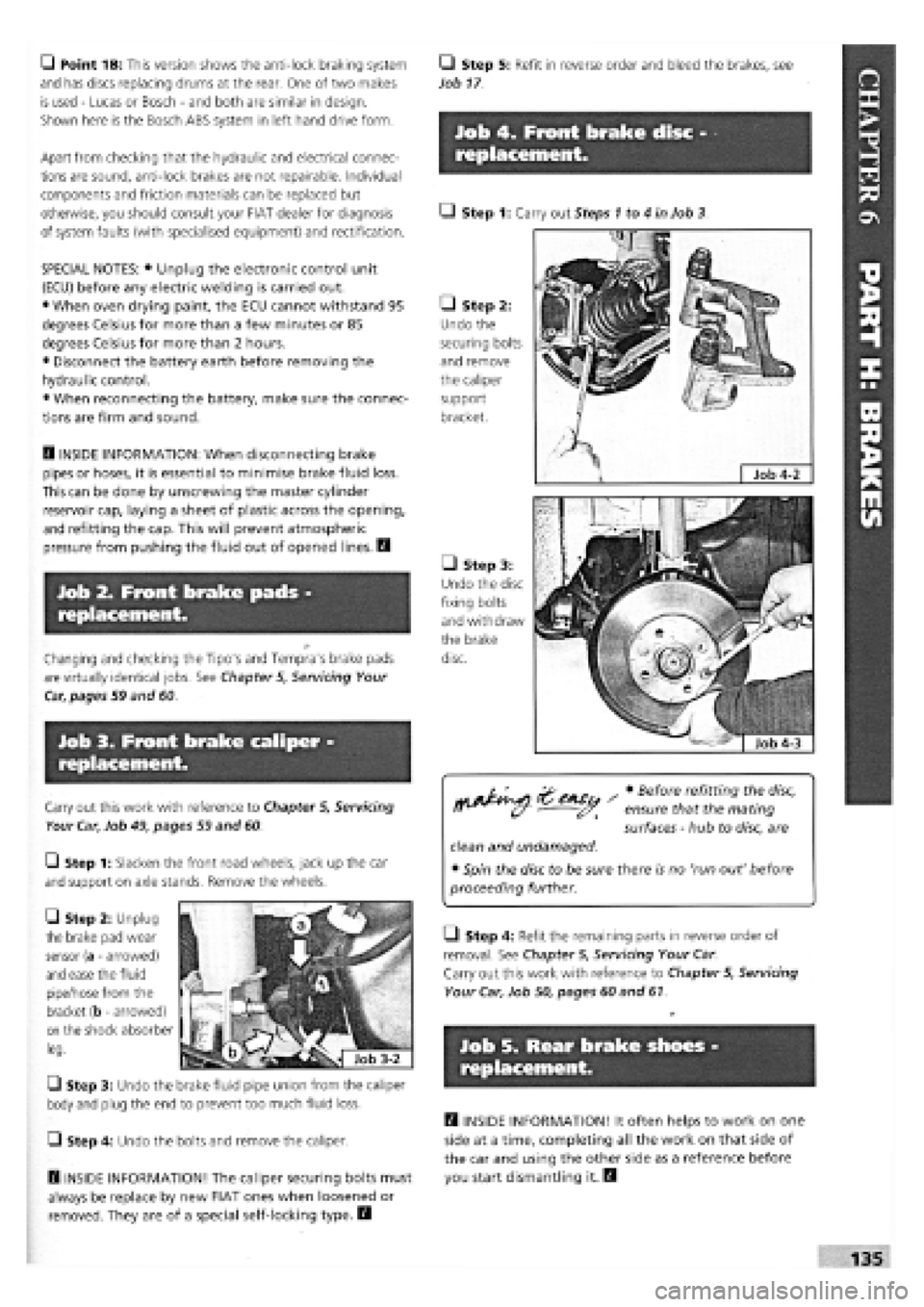

Job 1. Understanding

Tipo/Tempra brakes.

• Point

1

A: This is the standard disc/drum system used on

cars without anti-lock brakes, shown here in left hand drive

form.

1 - fluid reservoir and master cylinder 2 - servo 3

-

front disc brakes

4 - handbrake lever 5 - rear drum brakes 6

-

four way pipe union 7 - load proportioning/ pressure limiting valve

Job 1-1A

1 - front disc brakes 2

-

front flywheel 3 - front wheel RPM sensors 4 - hydraulic control unit 5 - brake light switch 6 - device failure warning light switch

7 - rear flywheel 8 - main control relay with excess voltage protection 9 - electronic control unit 10 - rear disc brakes 11 - rear wheel RPM sensors 12 - load proportioning/pressure limiting valve Job

1-1B

Page 131 of 171

Q Point 1B: This version shows the anti-lock braking system

and has discs replacing drums at the rear. One of two makes

is used

-

Lucas or Bosch

-

and both are similar in design.

Shown here is the Bosch ABS system in left hand drive form.

Apart from checking that the hydraulic and electrical connec-

tions are sound, anti-lock brakes are not repairable. Individual

components and friction materials can be replaced but

otherwise, you should consult your FIAT dealer for diagnosis

of system faults (with specialised equipment) and rectification.

SPECIAL NOTES: • Unplug the electronic control unit

(ECU) before any electric welding is carried out.

• When oven drying paint, the ECU cannot withstand 95

degrees Celsius for more than a few minutes or 85

degrees Celsius for more than 2 hours.

• Disconnect the battery earth before removing the

hydraulic control.

• When reconnecting the battery, make sure the connec-

tions are firm and sound.

Q INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is essential to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the opening,

and refitting the cap. This will prevent atmospheric

pressure from pushing the fluid out of opened lines. D

Job 2. Front brake pads -

replacement.

Changing and checking the Tipo's and Tempra's brake pads

are virtually identical jobs. See Chapter 5, Servicing Your

Car, pages 59 and 60

Job 3. Front brake caliper -

replacement.

Carry out this work with reference to Chapter 5, Servicing

Your Car, Job 49, pages 59 and 60.

Q Step 1: Slacken the front road wheels, jack up the car

and support on axle stands. Remove the wheels.

Q Step 2: Unplug

the brake pad wear

sensor (a

-

arrowed)

and ease the fluid

pipe/hose from the

bracket (b

-

arrowed)

on

the shock absorber

leg.

Q Step 3: Undo the brake fluid pipe union from the caliper

body and plug the end to prevent too much fluid loss.

Q Step 4: Undo the bolts and remove the caliper.

D INSIDE INFORMATION! The caliper securing bolts must

always be replace by new FIAT ones when loosened or

removed. They are of a special self-locking type. B

Q Step 5: Refit in reverse order and bleed the brakes, see

Job 17

Job 4. Front brake disc -

replacement.

Q Step 1: Carry out Steps 1 to 4 in Job 3.

• Step 2:

Undo the

securing bolts

and remove

the caliper

support

bracket.

• Step 3:

Undo the disc

fixing bolts

and withdraw

the brake

disc.

Q Step 4: Refit the remaining parts in reverse order of

removal. See Chapter 5, Servicing Your Car.

Carry out this work with reference to Chapter 5, Servicing

Your Car, Job 50, pages 60 and 61.

Job 5. Rear brake shoes -

replacement.

H INSIDE INFORMATION! It often helps to work on one

side at a time, completing all the work on that side of

the car and using the other side as a reference before

you start dismantling it. Q

• Before refitting the disc,

ensure that the mating

surfaces

-

hub to disc, are

clean and undamaged.

• Spin the disc to be sure there is no 'run out' before

proceeding further.

Job 4-2

Page 133 of 171

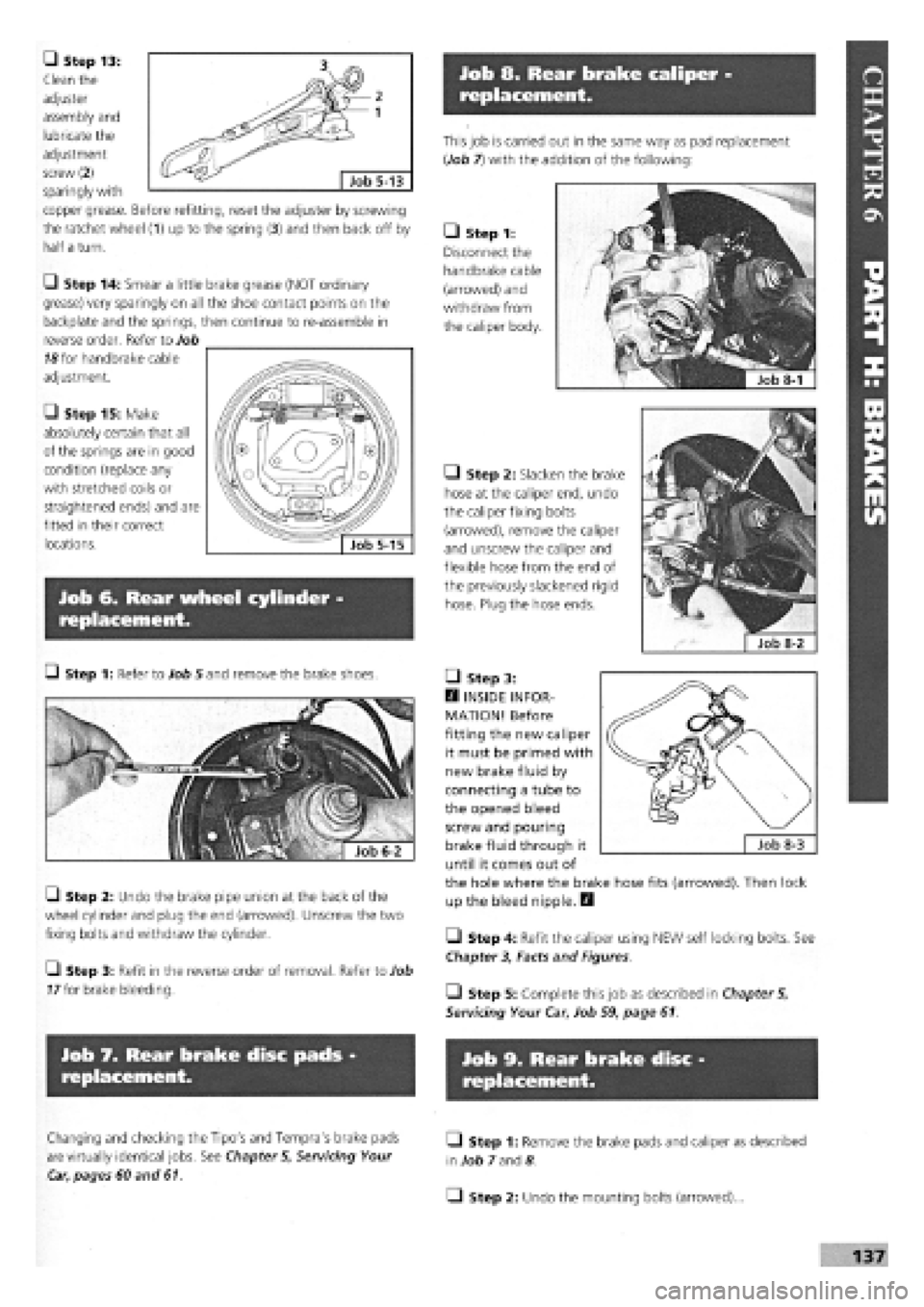

Job 8. Rear brake caliper -

replacement.

• Step 13:

Clean the

adjuster

assembly and

lubricate the

adjustment

screw (2) _ ^ Job 5_13

sparingly with

copper grease. Before refitting, reset the adjuster by screwing

the ratchet wheel (1) up to the spring (3) and then back off by

half a turn.

This job is carried out in the same way as pad replacement

{Job 7) with the addition of the following:

• Step 1:

Disconnect the

handbrake cable

(arrowed) and

withdraw from

the caliper body.

• Step 2: Slacken the brake

hose at the caliper end, undo

the caliper fixing bolts

(arrowed), remove the caliper

and unscrew the caliper and

flexible hose from the end of

the previously slackened rigid

hose. Plug the hose ends.

• Step 14: Smear a little brake grease (NOT ordinary

grease) very sparingly on all the shoe contact points on the

backplate and the springs, then continue to re-assemble in

reverse order. Refer to Job

18

for handbrake cable

adjustment.

• Step 15: Make

absolutely certain that all

of the springs are in good

condition (replace any

with stretched coils or

straightened ends) and are

fitted in their correct

locations.

Job 6. Rear wheel cylinder -

replacement.

Q Step 1: Refer to Job 5 and remove the brake shoes.

Q Step 2: Undo the brake pipe union at the back of the

wheel cylinder and plug the end (arrowed). Unscrew the two

fixing bolts and withdraw the cylinder.

Q Step 3: Refit in the reverse order of removal. Refer to Job

77

for brake bleeding.

• Step 3:

H INSIDE INFOR-

MATION! Before

fitting the new caliper

it must be primed with

new brake fluid by

connecting a tube to

the opened bleed

screw and pouring

brake fluid through it

until it comes out of

the hole where the brake hose fits (arrowed). Then lock

up the bleed nipple. Q

Q Step 4: Refit the caliper using NEW self locking bolts. See

Chapter 3, Facts and Figures

• Step 5: Complete this job as described in Chapter 5,

Servicing Your Car, Job 59, page 61.

Job 7. Rear brake disc pads

replacement.

Job 9. Rear brake disc

replacement.

Changing and checking the Tipo's and Tempra's brake pads

are virtually identical jobs. See Chapter 5, Servicing Your

Car, pages 60 and 61.

Q Step 1: Remove the brake pads and caliper as described

in

Job 7

and

8

• Step 2: Undo the mounting bolts (arrowed)...

Page 171 of 171

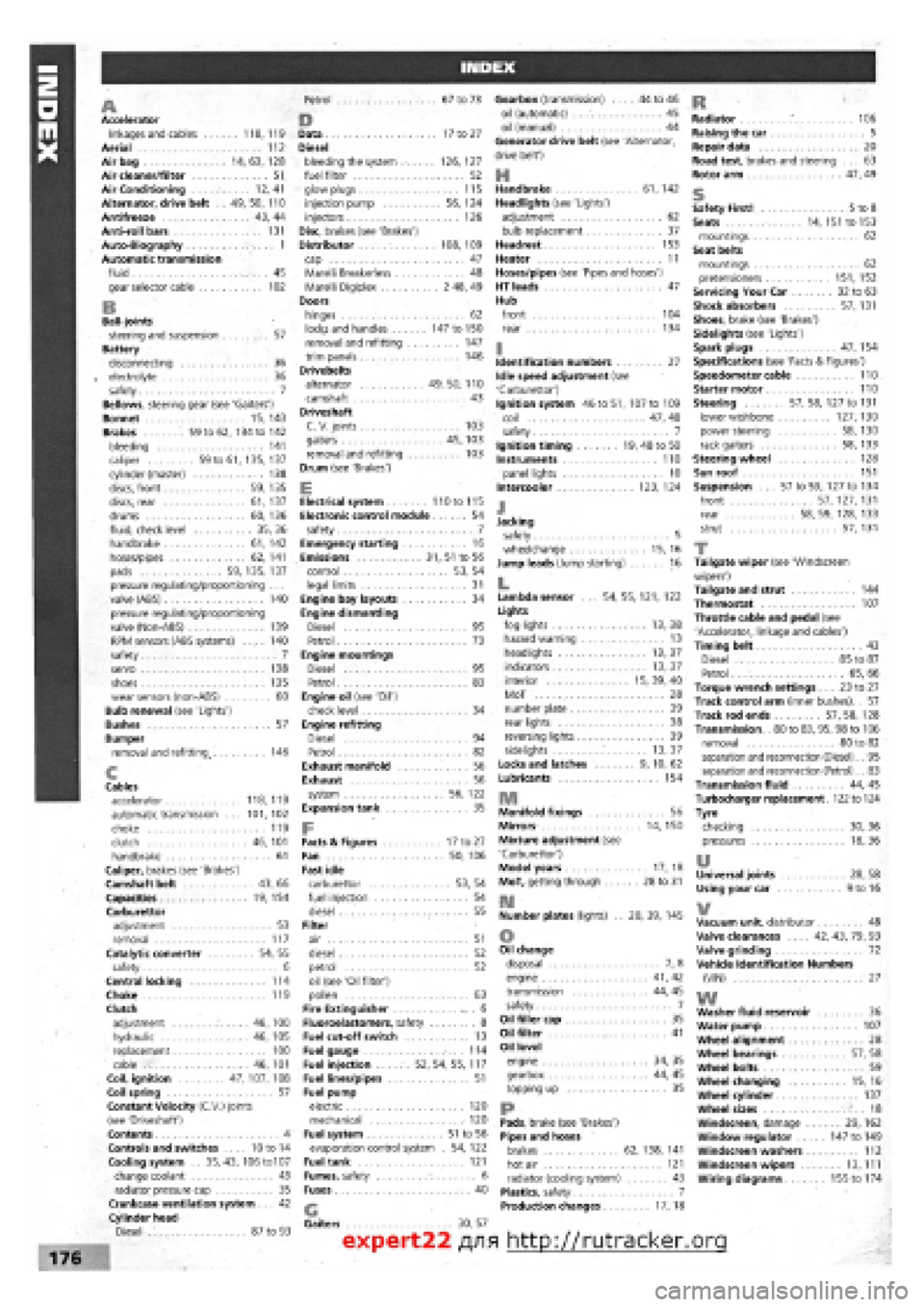

A Accelerator linkages and cables 118,119 Aerial 112 Airbag 14, 63, 128 Air cleaner/filter 51 Air Conditioning 12,41 Alternator, drive belt . . 49, 50, 110 Antifreeze 43, 44 Anti-roll bars 131 Auto-Biography 1 Automatic transmission fluid 45 gear selector cable 102

B Ball-joints steering and suspension 57 Battery disconnecting 36 electrolyte 36 safety 7 Bellows, steering gear (see 'Gaiters') Bonnet 15, 143 Brakes 59 to 62, 134 to 142 bleeding 141 caliper 59 to 61, 135, 137 cylinder (master) 138 discs, front 59, 135 discs, rear 61, 137 drums 60, 136 fluid, check level 35,36 handbrake 61, 142 hoses/pipes 62, 141 pads 59, 135, 137 pressure regulating/proportioning . . . valve (ABS) 140 pressure regulating/proportioning valve (Non-ABS) 139 RPM sensors (ABS systems) .... 140 safety 7 servo 138 shoes 135 wear sensors (non-ABS) 60 Bulb renewal (see 'Lights') Bushes 57 Bumper removal and refitting. 146

c Cables accelerator 118,119 automatic transmission ... 101, 102 choke 119 clutch 46, 101 handbrake 61 Caliper, brakes (see 'Brakes') Camshaft belt 43, 66 Capacities 19,154 Carburettor adjustment 53 removal 117 Catalytic converter 54, 55 safety 6 Central locking 114 Choke 119 Clutch adjustment 46, 100 hydraulic 46, 105 replacement 100 cable 46, 101 Coil, ignition 47, 107, 108 Coil spring 57 Constant Velocity (C.V.) joints (see 'Driveshaft') Contents 4 Controls and switches ... 10 to 14 Cooling system .. 35, 43, 106 to107 change coolant 43 radiator pressure cap 35 Crankcase ventilation system 42 Cylinder head Diesel 87 to 93

Petrol 67 to 73

D Data 17 to 27 Diesel bleeding the system 126,127 fuel filter 52 glow plugs 115 injection pump 56,124 injectors 126 Disc, brakes (see 'Brakes') Distributor 108, 109 cap 47 Marelli Breakerless 48 Marelli Digiplex 2 48, 49 Doors hinges 62 locKs and handles 147 to 150 removal and refitting 147 trim panels 146 Drivebelts alternator 49, 50, 110 camshaft 43 Driveshaft C.V. joints 103 gaiters 45, 103 removal and refitting 103 Drum (see 'Brakes')

E Electrical system 110 to 115 Electronic control module 54 safety 7 Emergency starting 16 Emissions 31, 51 to 56 control 53, 54 legal limits 31 Engine bay layouts 34 Engine dismantling Diesel 95 Petrol 73 Engine mountings Diesel 95 Petrol 83 Engine oil (see 'Oil') check level 34 Engine refitting Diesel 94 Petrol 82 Exhaust manifold 56 Exhaust 56 system 56, 122 Expansion tank 35

F Facts & Figures 17 to 27 Fan 50, 106 Fast idle carburettor 53, 54 fuel injection 54 diesel 55 Filter air 51 diesel 52 petrol 52 oil (see 'Oil filter') pollen 63 Fire Extinguisher . 6 Fluoroelastomers, safety 8 Fuel cut-off switch 13 Fuel gauge 114 Fuel injection 52, 54, 55, 117 Fuel lines/pipes 51 Fuel pump electric 120 mechanical 120 Fuel system 51 to 56 evaporation control system . 54,122 Fuel tank 121 Fumes, safety 6 Fuses 40

Gearbox (transmission) .... 44 to 46 oil (automatic) . . 45 oil (manual) 44 Generator drive belt (see 'Alternator, drive belt')

H Handbrake 61, 142 Headlights (see 'Lights') adjustment 62 bulb replacement 37 Headrest 153 Heater 11 Hoses/pipes (see 'Pipes and hoses') HT leads 47 Hub front 104 rear 134

I Identification numbers 27 Idle speed adjustment (see 'Carburettor') Ignition system 46 to 51, 107 to 109 coil 47,48 safety 7 Ignition timing 19, 48 to 50 Instruments 110 panel lights 10 Intercooler 123, 124

J Jacking safety 5 wheelchange 15, 16 Jump leads (Jump starting) 16

L Lambda sensor ... 54, 55, 121, 122 Lights fog lights 13, 38 hazard warning 13 headlights 13,37 indicators 13, 37 interior 15, 39, 40 MoT 28 number plate 39 rear lights 38 reversing lights 39 sidelights 13, 37 Locks and latches 9, 10, 62 Lubricants 154

m Manifold fixings 56 Mirrors 14, 150 Mixture adjustment (see 'Carburettor') Model years 17, 18 MoT, getting through 28 to 31

m Number plates (lights) . . 28, 39, 145

o Oil change disposal 7, 8 engine 41, 42 transmission 44, 45 safety 7 Oil filler cap 35 Oil filter 41 Oil level engine 34, 35 gearbox 44, 45 topping up 35

P-Pads, brake (see 'Brakes') Pipes and hoses brakes 62, 138, 141 hot air 121 radiator (cooling system) 43 Plastics, safety 7 Production changes 17, 18

ft Radiator .* 106 Raising the car 5 Repair data 20 Road test, brakes and steering ... 63 Rotor arm 47, 49

s Safety First! 5 to 8 Seats 14, 151 to 153 mountings 62 Seat belts mountings 62 pretensioners 151, 152 Servicing Your Car 32 to 63 Shock absorbers 57,131 Shoes, brake (see 'Brakes') Sidelights (see 'Lights') Spark plugs 47, 154 Specifications (see 'Facts & Figures') Speedometer cable 110 Starter motor 110 Steering 57, 58, 127 to 131 lower wishbone 127, 130 power steering 58, 130 rack gaiters 58, 133 Steering wheel 128 Sun roof 151 Suspension ... 57 to 59, 127 to 134 front 57, 127, 131 rear 58, 59, 128, 133 strut 57, 131

T Tailgate wiper (see 'Windscreen wipers') Tailgate and strut 144 Thermostat 107 Throttle cable and pedal (see 'Accelerator, linkage and cables') Timing belt 43 Diesel 85 to 87 Petrol 65, 66 Torque wrench settings ... 23 to 27 Track control arm (inner bushes). . 57 Track rod ends 57, 58, 128 Transmission. . 80 to 83, 95, 98 to 106 removal 80 to 82 separation and reconnection (Diesel). . 95 separation and reconnection (Petrol). . 83 Transmission fluid 44, 45 Turbocharger replacement 122 to 124 Tyre checking 30, 36 pressures 18,36

u Universal joints 28, 58 Using your car 9 to 16

¥ Vacuum unit, distributor 48 Valve clearances 42, 43, 79, 93 Valve grinding 72 Vehicle Identification Numbers (VIN) 27

w Washer fluid reservoir 36 Water pump 107 Wheel alignment 28 Wheel bearings 57, 58 Wheel bolts 59 Wheel changing 15,16 Wheel cylinder 137 Wheel sizes 18 Windscreen, damage 29,162 Window regulator 147 to 149 Windscreen washers 112 Windscreen wipers 13,111 Wiring diagrams 155 to 174

Gaiters 30, 57

expert22 fl/ia http://rutracker.org