boot FIAT TIPO 4DOORS 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2020, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2020Pages: 252, PDF Size: 7.29 MB

Page 9 of 252

KNOWING YOUR CAR

In-depth knowledge of your new vehicle

starts here.

The booklet that you are reading simply

and directly explains how it is made and

how it works.

That’s why we advise you to read it

seated comfortably on board, so that

you can see immediately what is

described here for yourself.INSTRUMENT PANEL...........8

THE KEYS.................10

IGNITION DEVICE............11

FIAT CODE.................12

DOORS...................12

SEATS....................14

HEADRESTS................17

STEERING WHEEL............18

REAR VIEW MIRRORS.........19

EXTERNAL LIGHTS...........20

INTERIOR LIGHTS............23

WINDSCREEN WASHER / WIPER . .24

CLIMATE CONTROL SYSTEM.....26

ELECTRIC WINDOWS..........31

BONNET..................32

DUALDRIVE ELECTRIC POWER

STEERING.................33

BOOT....................34

VERSION WITH LPG SYSTEM....36

7

Page 36 of 252

WARNING

28)It is absolutely forbidden to carry out

any after-market operation involving

steering system or steering column

modifications (e.g. installation of anti-theft

device) that could adversely affect

performance, invalidate the warranty, cause

serious safety problems and also result in

the car not meeting type-approval

requirements.

29)Before performing any maintenance

operations, always turn off the engine and

remove the key from the ignition to lock the

steering column (especially when the car

wheels are not touching the ground). If this

is not possible (for example if the key

needs to be turned to MAR or the engine

must be running), remove the main fuse

that protects the electric power steering.

BOOT

9)

IMPORTANT When travelling, do not

put any object on the rear parcel shelf

because they can injure passengers in

the event of an accident or sudden

braking.

OPENING

30)

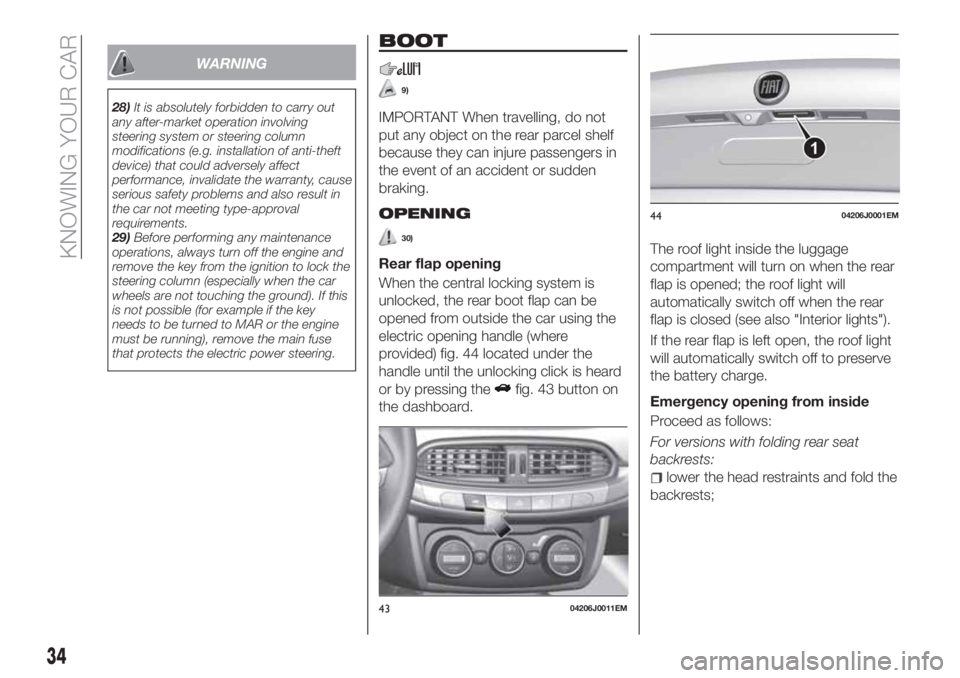

Rear flap opening

When the central locking system is

unlocked, the rear boot flap can be

opened from outside the car using the

electric opening handle (where

provided) fig. 44 located under the

handle until the unlocking click is heard

or by pressing the

fig. 43 button on

the dashboard.The roof light inside the luggage

compartment will turn on when the rear

flap is opened; the roof light will

automatically switch off when the rear

flap is closed (see also "Interior lights").

If the rear flap is left open, the roof light

will automatically switch off to preserve

the battery charge.

Emergency opening from inside

Proceed as follows:

For versions with folding rear seat

backrests:

lower the head restraints and fold the

backrests;

4304206J0011EM

4404206J0001EM

34

KNOWING YOUR CAR

Page 37 of 252

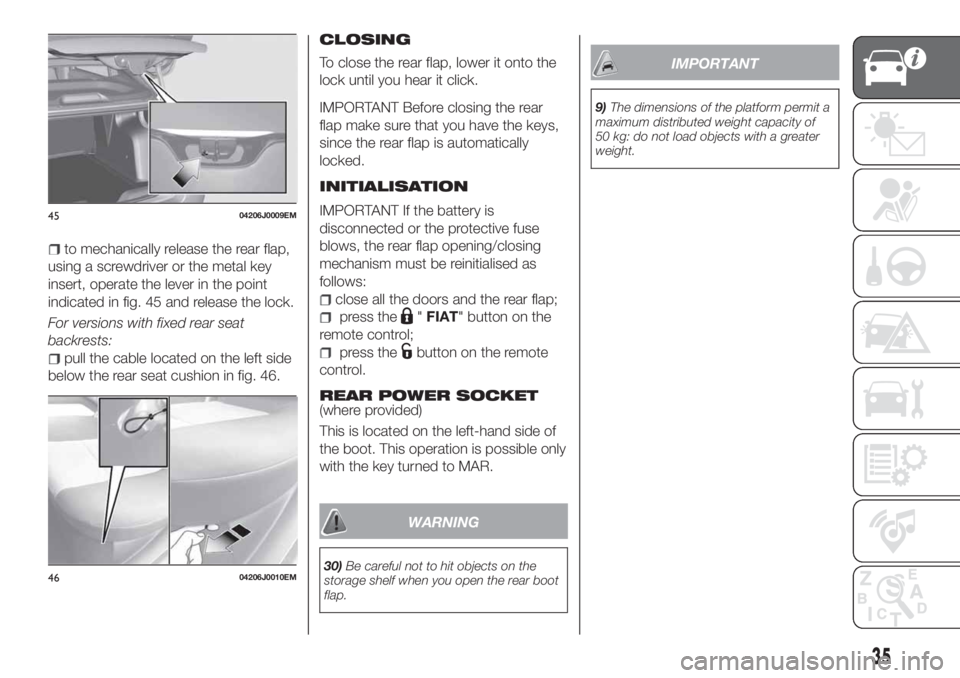

to mechanically release the rear flap,

using a screwdriver or the metal key

insert, operate the lever in the point

indicated in fig. 45 and release the lock.

For versions with fixed rear seat

backrests:

pull the cable located on the left side

below the rear seat cushion in fig. 46.

CLOSING

To close the rear flap, lower it onto the

lock until you hear it click.

IMPORTANT Before closing the rear

flap make sure that you have the keys,

since the rear flap is automatically

locked.

INITIALISATION

IMPORTANT If the battery is

disconnected or the protective fuse

blows, the rear flap opening/closing

mechanism must be reinitialised as

follows:

close all the doors and the rear flap;

press the"FIAT" button on the

remote control;

press thebutton on the remote

control.

REAR POWER SOCKET(where provided)

This is located on the left-hand side of

the boot. This operation is possible only

with the key turned to MAR.

WARNING

30)Be careful not to hit objects on the

storage shelf when you open the rear boot

flap.

IMPORTANT

9)The dimensions of the platform permit a

maximum distributed weight capacity of

50 kg: do not load objects with a greater

weight.

4504206J0009EM

4604206J0010EM

35

Page 124 of 252

AdBlue®

(UREA) storage

AdBlue®

(UREA) is considered a very

stable product with a long shelf life.

Stored at temperatures LOWER than

32°C, it has a shelf life of at least one

year.

Follow the instructions on the label of

the container.

Fuel storage - Diesel Fuel

127)

In case of the storage of massive

amounts of fuel, good maintenance is

essential. The fuel contaminated with

water favours the proliferation of

"microbes". These microbes create a

"slime" that can clog the filter system

and fuel pipes. Remove water from the

supply tank and regularly replace the

filter pipe.

NOTE When a Diesel engine runs out

of fuel, air is blown through the fuel

system.

Emergency refuelling

If there is no fuel in the car or the supply

circuit is completely empty, proceed as

follows to reintroduce fuel to the tank:

open the boot and take adaptor 3

fig. 108, located in the tool box or in the

Fix&Go kit container (according to the

versions);

open flap 1 fig. 106, as described

previously;

introduce the adaptor in the filler as

shown and refuel;

after refuelling, remove the adapter

and close the flap;

finally refit the adaptor in the boot.

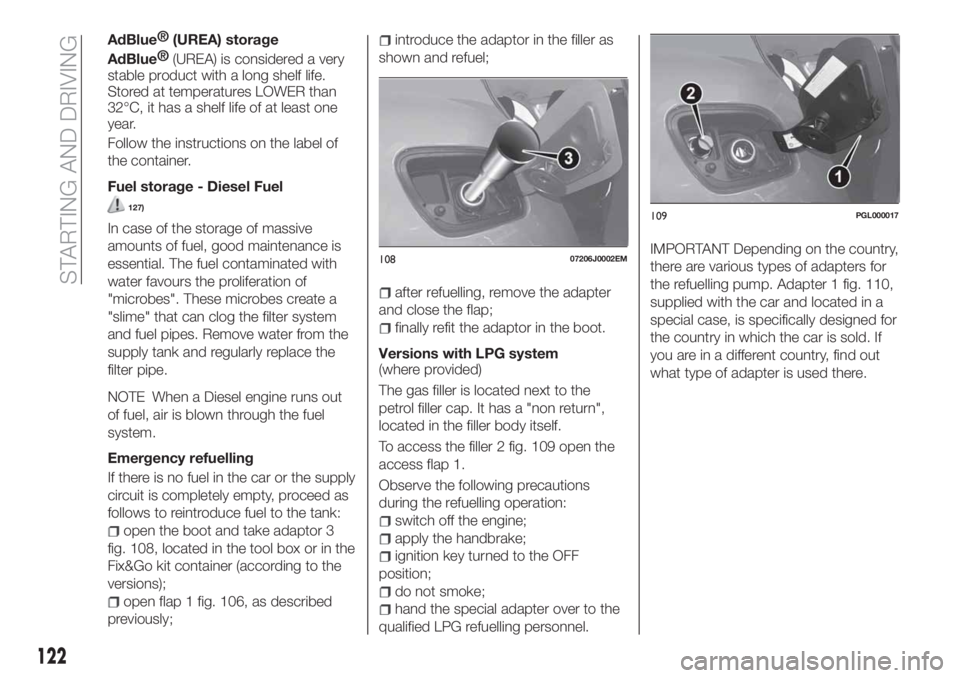

Versions with LPG system

(where provided)

The gas filler is located next to the

petrol filler cap. It has a "non return",

located in the filler body itself.

To access the filler 2 fig. 109 open the

access flap 1.

Observe the following precautions

during the refuelling operation:

switch off the engine;

apply the handbrake;

ignition key turned to the OFF

position;

do not smoke;

hand the special adapter over to the

qualified LPG refuelling personnel.

IMPORTANT Depending on the country,

there are various types of adapters for

the refuelling pump. Adapter 1 fig. 110,

supplied with the car and located in a

special case, is specifically designed for

the country in which the car is sold. If

you are in a different country, find out

what type of adapter is used there.10807206J0002EM

109PGL000017

122

STARTING AND DRIVING

Page 130 of 252

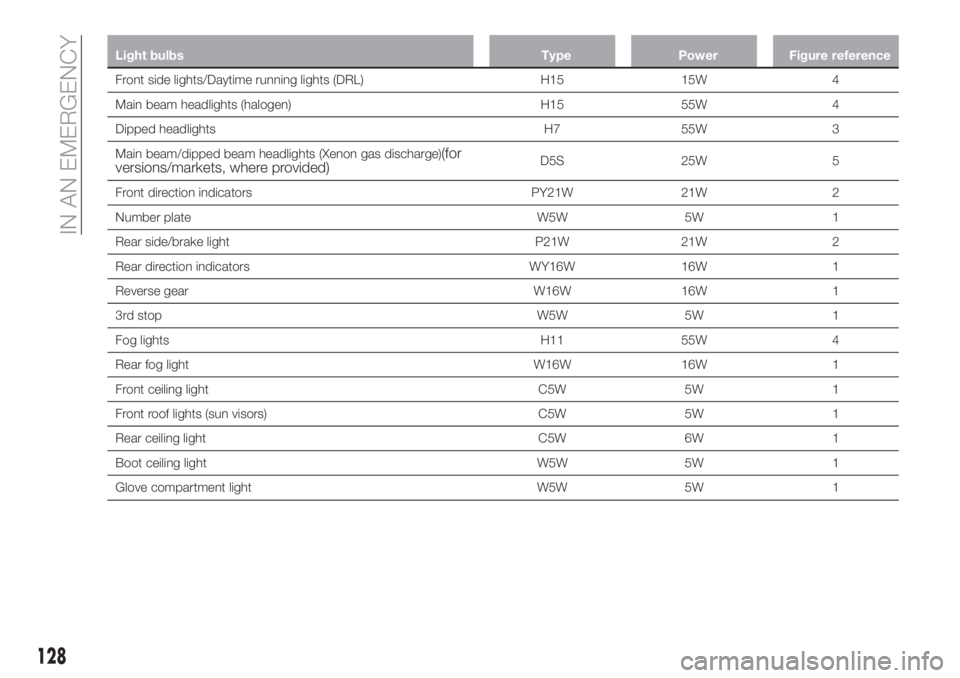

Light bulbs Type Power Figure reference

Front side lights/Daytime running lights (DRL) H15 15W 4

Main beam headlights (halogen) H15 55W 4

Dipped headlights H7 55W 3

Main beam/dipped beam headlights (Xenon gas discharge)

(for

versions/markets, where provided)D5S 25W 5

Front direction indicators PY21W 21W 2

Number plate W5W 5W 1

Rear side/brake light P21W 21W 2

Rear direction indicators WY16W 16W 1

Reverse gear W16W 16W 1

3rd stop W5W 5W 1

Fog lights H11 55W 4

Rear fog light W16W 16W 1

Front ceiling light C5W 5W 1

Front roof lights (sun visors) C5W 5W 1

Rear ceiling light C5W 6W 1

Boot ceiling light W5W 5W 1

Glove compartment light W5W 5W 1

128

IN AN EMERGENCY

Page 135 of 252

WARNING

129)Before replacing the bulb, wait for the

exhaust ducts to cool down: DANGER OF

SCALDING!

130)Modifications or repairs to the electric

system that are not carried out properly or

do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

131)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

132)Only replace the light bulbs when the

engine is off and in a position that does not

interfere with traffic and lets you safely

replace them (see the description in the

“Replacement” paragraph). Also ensure

that the engine is cold, to prevent the risk

of burns.

IMPORTANT

50)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb dry.

REPLACING FUSES

GENERAL INFORMATION

133) 134) 135) 136)

51)

Fuses protect the electrical system:

they intervene (blow) in the event of a

failure or improper action on the

system.

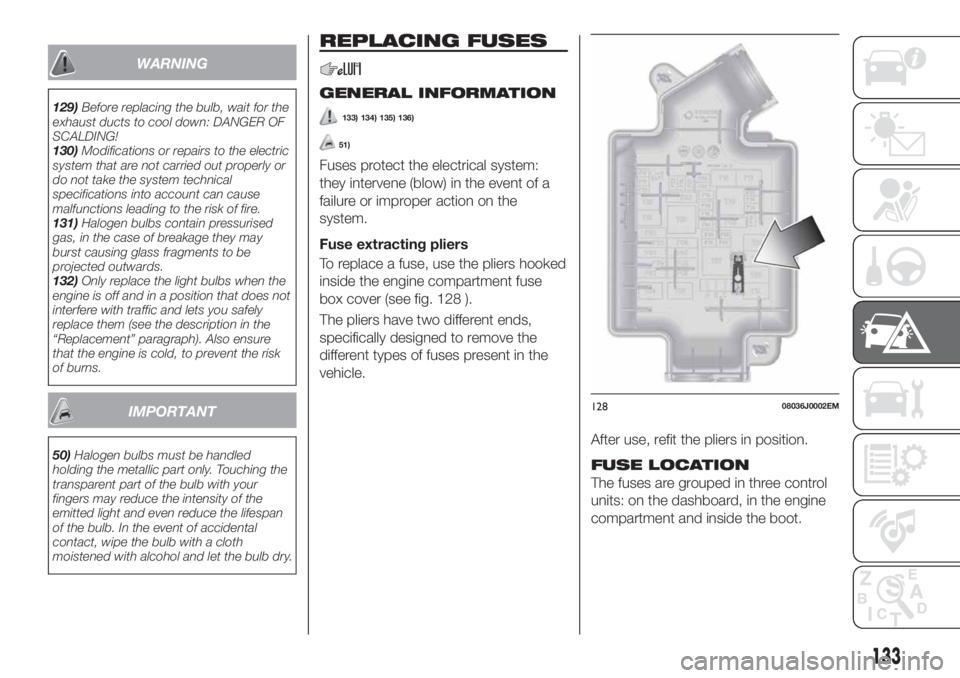

Fuse extracting pliers

To replace a fuse, use the pliers hooked

inside the engine compartment fuse

box cover (see fig. 128 ).

The pliers have two different ends,

specifically designed to remove the

different types of fuses present in the

vehicle.

After use, refit the pliers in position.

FUSE LOCATION

The fuses are grouped in three control

units: on the dashboard, in the engine

compartment and inside the boot.

12808036J0002EM

133

Page 143 of 252

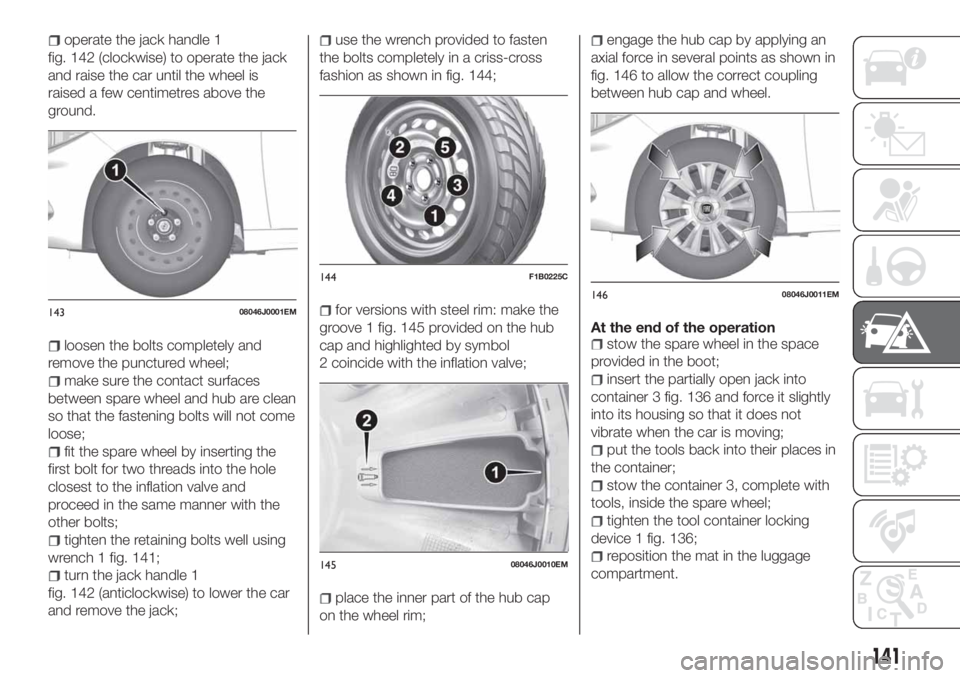

operate the jack handle 1

fig. 142 (clockwise) to operate the jack

and raise the car until the wheel is

raised a few centimetres above the

ground.

loosen the bolts completely and

remove the punctured wheel;

make sure the contact surfaces

between spare wheel and hub are clean

so that the fastening bolts will not come

loose;

fit the spare wheel by inserting the

first bolt for two threads into the hole

closest to the inflation valve and

proceed in the same manner with the

other bolts;

tighten the retaining bolts well using

wrench 1 fig. 141;

turn the jack handle 1

fig. 142 (anticlockwise) to lower the car

and remove the jack;

use the wrench provided to fasten

the bolts completely in a criss-cross

fashion as shown in fig. 144;

for versions with steel rim: make the

groove 1 fig. 145 provided on the hub

cap and highlighted by symbol

2 coincide with the inflation valve;

place the inner part of the hub cap

on the wheel rim;

engage the hub cap by applying an

axial force in several points as shown in

fig. 146 to allow the correct coupling

between hub cap and wheel.

At the end of the operation

stow the spare wheel in the space

provided in the boot;

insert the partially open jack into

container 3 fig. 136 and force it slightly

into its housing so that it does not

vibrate when the car is moving;

put the tools back into their places in

the container;

stow the container 3, complete with

tools, inside the spare wheel;

tighten the tool container locking

device 1 fig. 136;

reposition the mat in the luggage

compartment.

14308046J0001EM

144F1B0225C

14508046J0010EM

14608046J0011EM

141

Page 144 of 252

NOTE If replacing a wheel with alloy

rim, stove it temporarily into the spare

wheel compartment with the cosmetic

side facing upwards.

IMPORTANT NOTESTyres with unidirectional tread can be

recognised by arrows on the side of the

tyre which indicate the direction of

rotation. It is compulsory to comply with

this direction. Only in this way can the

tyres maintain their characteristics in

terms of grip, noise, resistance to wear

and drainage on wet surfaces.

If, after a puncture, it is necessary to

fit such a tyre the wrong way round, it

will be necessary to continue driving

with great care, since the tyre’s

performance is limited in these

conditions. This precaution must be

borne in mind above all when the road

surface is wet.

In order to benefit completely from

the unidirectional tread, it is advisable to

restore all wheels to the correct

direction of rotation as soon as

possible.

WARNING

137)If left in the passenger compartment,

the punctured wheel and jack constitute a

serious risk to the safety of occupants in

the event of accidents or sharp braking.

Therefore, always place both the jack and

punctured wheel in the dedicated housing

in the boot.

138)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

139)Alert other drivers that the car is

stationary in compliance with local

regulations: hazard warning lights, warning

triangle, etc. Any passengers on board

should leave the car, especially if it is

heavily laden. Passengers should stay

away from on-coming traffic while the

wheel is being changed. For safety

reasons, always block the wheels with the

chocks provided.140)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. Any other use,

e.g. to jack up other vehicle models or

different things, is strictly prohibited. Never

use it to carry out maintenance or repairs

under the vehicle or to change

summer/winter wheels and vice versa: we

advise you to contact a Fiat Dealership.

Never go under the raised vehicle: use it

only in the positions indicated. Do not use

the jack for loads higher than the one

shown on its label. Never start the engine

with vehicle raised. If the vehicle is raised

more than necessary, everything can

become more unstable, with the risk of the

vehicle dropping violently. Thus, lift the car

only as needed in order to access the

spare wheel.

141)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

142

IN AN EMERGENCY

Page 145 of 252

142)A 16” spare wheel is provided with

17” and 18” tyres. The space-saver wheel

(for versions/markets where provided) is

specific to your car, do not use it on other

models, or use the space-saver wheel of

other models on your car. The space-saver

wheel must only be used in the event of an

emergency. Never use it for more than

strictly necessary and never exceed

80 km/h. Important! For temporary use

only! 80km/h max! Replace with standard

wheel as soon as possible. Never remove

or cover the sticker on the space-saver

wheel. Never apply a wheel cap on a

space-saver wheel. The vehicle's driving

characteristics will be modified with the

space-saver wheel fitted. Avoid violent

acceleration and braking, abrupt steering

and fast cornering. Have the wheel

repaired and refitted as soon as possible.

Using two or more spare wheels at the

same time is forbidden. Do not apply

grease to the bolt threads before fitting:

they could come unscrewed.

IMPORTANT

53)When turning the jack handle make

sure that it can turn freely without scraping

your hand against the ground. The moving

components of the jack ("worm screw" and

joints) can also cause injuries: avoid

touching them. If you come into contact

with lubricating grease, clean yourself

thoroughly.

54)Contact a Fiat Dealership as soon as

possible to have the correct tightening of

the wheel bolts checked.

FIX&GO KIT

(where provided)

143) 144)

55)

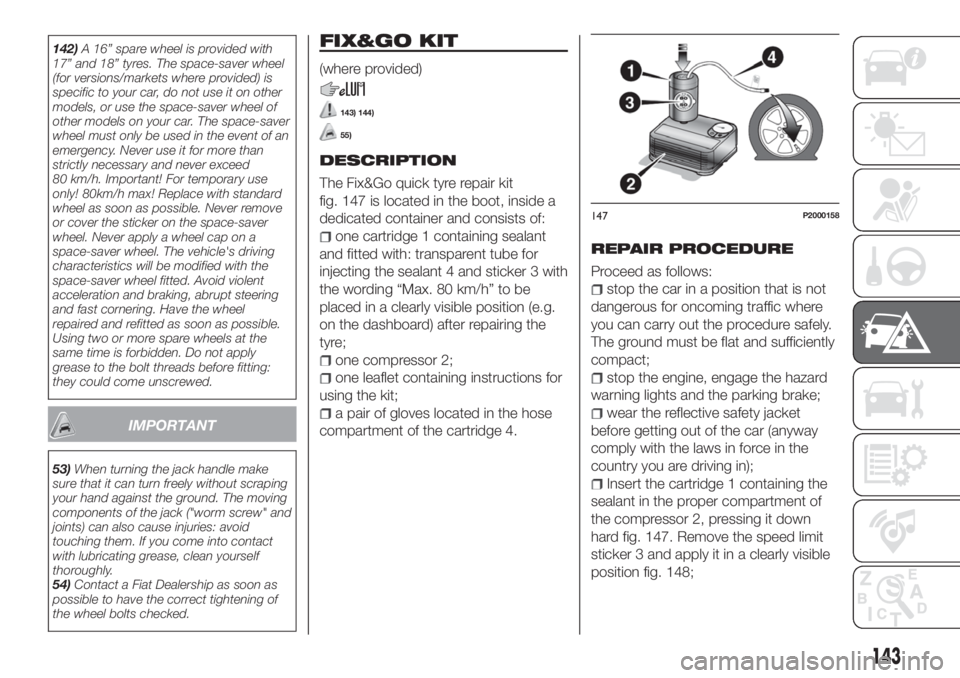

DESCRIPTION

The Fix&Go quick tyre repair kit

fig. 147 is located in the boot, inside a

dedicated container and consists of:

one cartridge 1 containing sealant

and fitted with: transparent tube for

injecting the sealant 4 and sticker 3 with

the wording “Max. 80 km/h” to be

placed in a clearly visible position (e.g.

on the dashboard) after repairing the

tyre;

one compressor 2;

one leaflet containing instructions for

using the kit;

a pair of gloves located in the hose

compartment of the cartridge 4.

REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can carry out the procedure safely.

The ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

Insert the cartridge 1 containing the

sealant in the proper compartment of

the compressor 2, pressing it down

hard fig. 147. Remove the speed limit

sticker 3 and apply it in a clearly visible

position fig. 148;

147P2000158

143

Page 152 of 252

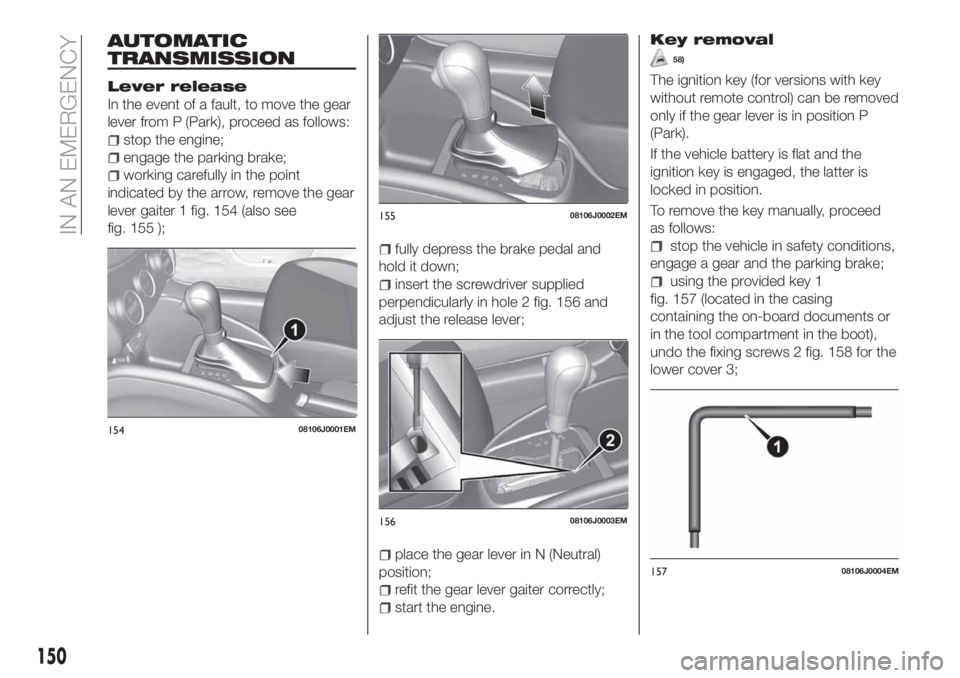

AUTOMATIC

TRANSMISSION

Lever release

In the event of a fault, to move the gear

lever from P (Park), proceed as follows:

stop the engine;

engage the parking brake;

working carefully in the point

indicated by the arrow, remove the gear

lever gaiter 1 fig. 154 (also see

fig. 155 );

fully depress the brake pedal and

hold it down;

insert the screwdriver supplied

perpendicularly in hole 2 fig. 156 and

adjust the release lever;

place the gear lever in N (Neutral)

position;

refit the gear lever gaiter correctly;

start the engine.

Key removal

58)

The ignition key (for versions with key

without remote control) can be removed

only if the gear lever is in position P

(Park).

If the vehicle battery is flat and the

ignition key is engaged, the latter is

locked in position.

To remove the key manually, proceed

as follows:

stop the vehicle in safety conditions,

engage a gear and the parking brake;

using the provided key 1

fig. 157 (located in the casing

containing the on-board documents or

in the tool compartment in the boot),

undo the fixing screws 2 fig. 158 for the

lower cover 3;

15408106J0001EM

15508106J0002EM

15608106J0003EM

15708106J0004EM

150

IN AN EMERGENCY