check engine FIAT UNO 1983 Service Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 204 of 303

optimum engine operating efficiency. In the

event of a system sensor malfunction, errors

in data passed to the ECU are overcome by

an emergency operation, whereby the ECU

supplies the injectors with one of two set

injection periods independent of the sensors.

One period (2.2 ms) is for idle speed and the

other (2.5 ms) is for speeds above idle

(actuated when the idle speed contact is

opened).

4An injection system relay and a fuel pump

relay are fitted and are located in the engine

compartment, adjacent to the ECU on the left-

hand inner wing panel. In the event of the

engine not being started within two seconds of

the ignition being switched to the “ON”

position, the fuel pump relay is deactivated.

The fuel pump circuit fuse is located in the

main fuse block located under the facia within

the car. Note: To avoid possible damage to the

ECU, it is essential that the ignition is switched

off before disconnecting (or connecting) the

wiring multi-plug from the ECU.A Lambda (or

oxygen) sensor is fitted to L3.2 equipped

models, to measure exhaust gas oxygen

content. In sending signals to the ECU,

optimum catalyst operation is maintained.

Fuel system -

depressurisationÁ

5The fuel system should always be

depressurised whenever any fuel hoses

and/or system components are disconnected

and/or removed. This can easily be achieved

as follows.

6The fuel pump relay is located next to the

ECU and airflow meter in the engine

compartment. Carefully pull free the fuel

pump relay, then start the engine and run it

until it stops. The fuel system is now

depressurised. Turn the ignition off before

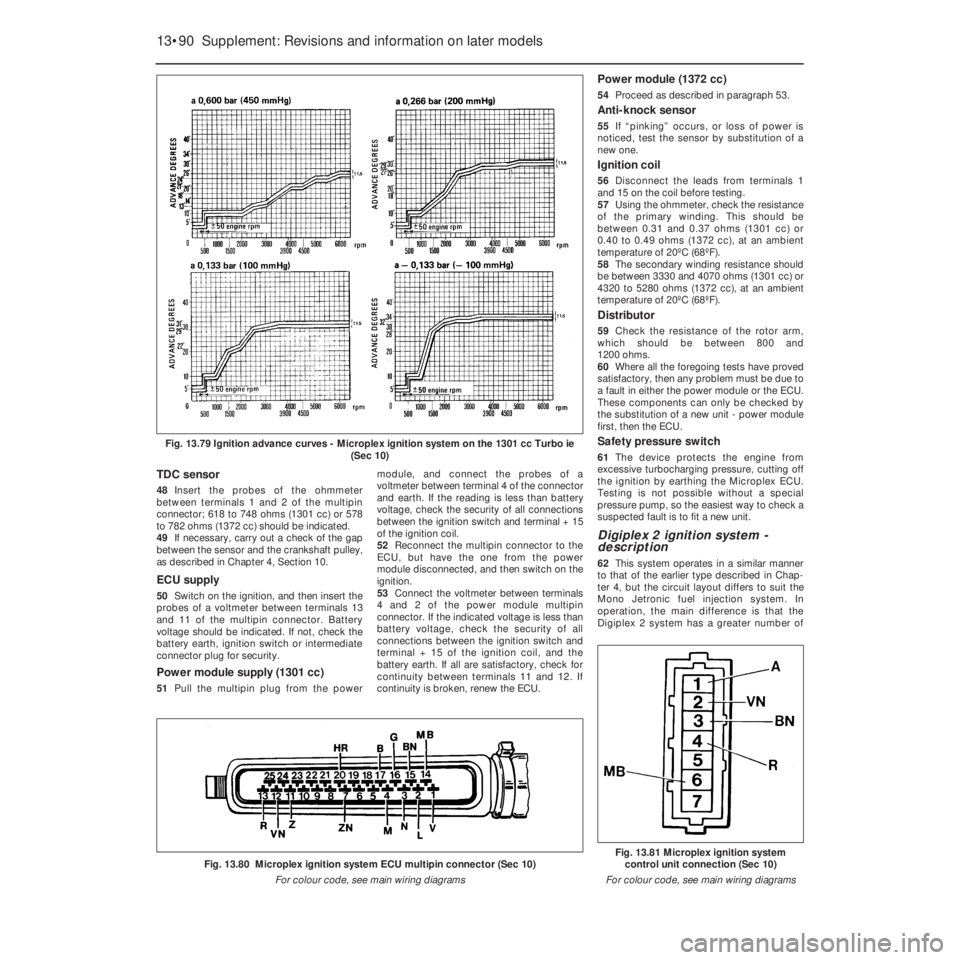

removing/dismantling any components.

7Do not refit the fuel pump relay or turn the

ignition on until the system is fully

reconnected. When the engine is ready to be

restarted, refit the relay and its cover, then

restart the engine in the normal manner.

MaintenanceÁ

8Regularly check the condition and security

of the system hoses and connections. Also

check the system wiring connections for

condition and security.9At the specified intervals, renew the air

cleaner element and the fuel filter.

Fuel filter - renewalÁ

10This is located in the engine compartment

on the right-hand side. Disconnect the fuel

inlet and outlet hoses, but be prepared for the

loss of fuel. Loosen off the clamp and remove

the filter.

11Reverse the removal procedure to fit the

new filter, but ensure that the arrow indicating

fuel flow is pointing towards the fuel injector rail.

Air cleaner element -

renewalÁ

12Prise free the four retaining clips, then

remove the cover and the air cleaner element.13Wipe clean the inside surfaces of the air

cleaner housing, then insert the new element,

refit the cover and secure it with the four

retaining clips.

Checks and adjustments°

Engine idle speed and mixture

adjustment

14Before carrying out any adjustments, the

engine must be at its normal operating

temperature, the cooling fan having cut into

Supplement: Revisions and information on later models 13•79

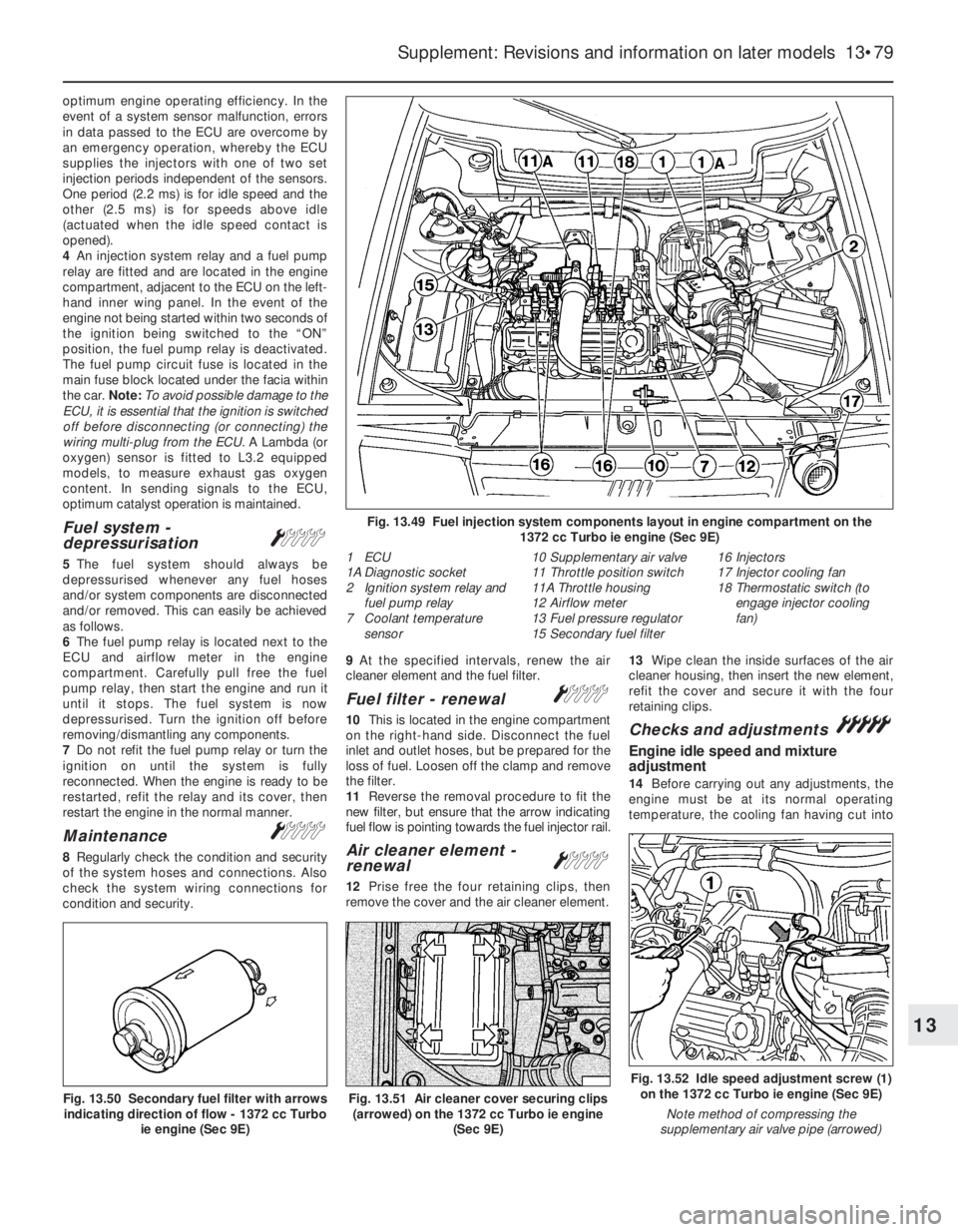

Fig. 13.49 Fuel injection system components layout in engine compartment on the

1372 cc Turbo ie engine (Sec 9E)

1 ECU

1A Diagnostic socket

2 Ignition system relay and

fuel pump relay

7 Coolant temperature

sensor10 Supplementary air valve

11 Throttle position switch

11A Throttle housing

12 Airflow meter

13 Fuel pressure regulator

15 Secondary fuel filter16 Injectors

17 Injector cooling fan

18 Thermostatic switch (to

engage injector cooling

fan)

Fig. 13.52 Idle speed adjustment screw (1)

on the 1372 cc Turbo ie engine (Sec 9E)

Note method of compressing the

supplementary air valve pipe (arrowed)

Fig. 13.51 Air cleaner cover securing clips

(arrowed) on the 1372 cc Turbo ie engine

(Sec 9E)Fig. 13.50 Secondary fuel filter with arrows

indicating direction of flow - 1372 cc Turbo

ie engine (Sec 9E)

13

Page 205 of 303

operation twice. Also prior to making

adjustments ensure that the supplementary

air valve pipe is in good condition, with no

leaks. Compress the air valve pipe using a

pair of grips to prevent incorrect adjustment

caused by a defective supplementary air

valve.

15The air cleaner must be connected when

checking and/or adjusting the engine idle

speed. To adjust, turn the adjuster screw in

the required direction to set the engine idle

speed to that specified.

16It is unlikely that the mixture will require

adjustment and unless this is proven by

measuring the exhaust gases using a CO

content analyser, its setting should not be

altered. As with idle speed adjustment, the

engine must be at its normal operating

temperature when making this check and

adjustment. It is also necessary to ensure that

the ignition idle advance is as specified.

Checking and adjustment must not be made

with the engine cooling fan, air conditioning

(where fitted) or other related items switched

on.

17If adjustment to the mixture is required,

prise free the tamperproof plug from the front

of the mixture adjustment screw in the control

unit, then turn the screw as required. Turn the

screw inwards (clockwise) to increase the CO

content or outwards (anti-clockwise) to

weaken it.

Throttle position switch adjustment

18This switch will not normally require

adjustment having been set during

production. The switch should not be

loosened off or reset unless absolutely

necessary.

19If a new switch is fitted it can be set by

loosely fitting the securing bolts, turning the

switch fully anti-clockwise, then clockwise

until one of the internal contacts is felt to click

into engagement. Hold the switch in this

position and tighten the retaining screws.

Reconnect the wiring multiplug to the switch.

Accelerator cable adjustment

20If the accelerator cable is removed or

detached from the support bracket at the

throttle control housing at any time, care must

be taken to adjust it correctly. When the inner

cable is connected to the throttle quadrant,

set the outer cable in the bracket so that the

inner cable has a minimal amount of free play,

yet does not prevent the throttle valve from

fully closing.

21When the engine is restarted, check that

the engine idle speed is as specified and that

the action of the accelerator is satisfactory.

Fuel pump and supply system checks

22Although the following basic checks can

be made to the fuel pump and fuel supply

system, specialised equipment is required to

undertake full and accurate tests of the fuel

supply system. Such checks must therefore

be entrusted to a FIAT dealer or a fuel

injection specialist.

23If the fuel pump is suspected of

malfunction, a basic check can be made by

turning the ignition on and listening around

the area of the pump unit to hear if it is

operating. The pump is located on the

underside of the car, just forward of the fuel

tank. If the pump fails to operate, check thatthe pump fuse is sound and that its

connection (and also that the relay) are clean

and secure.

24The pump can be further checked as

described previously for the LE2 fuel injection

system fuel pump in Part C of this Section.

Supplementary air valve check

25With the engine at its normal operating

temperature, allow it to idle, then pinch the

supplementary air valve hose using suitable

pliers as shown in Fig. 13.52 and check to see

if the engine speed drops by more than 50

rpm. If it does, the supplementary air valve is

defective and in need of renewal.

Injection system

components -

removal and refitting

Á

Warning: Refer to the beginning

of this Section before starting

any work.

26With the exception of the items mentioned

below, the various components of the fuel

injection system are removed in the same

manner as that described for the equivalent

items in Part C of this Chapter.

27Disconnect the battery negative lead

before carrying out any of the removal and

refitting operations. Where fuel lines are to be

disconnected it will first be necessary to

depressurise the injection system.

Airflow meter

28Release the retaining clips and detach the

air intake and outlet ducts from the airflow

meter.

29Ensure that the ignition is switched off,

then disconnect the multiplug from the ECU.

Unscrew the retaining bolts and remove the

airflow meter complete with the ECU.

30If required, the ECU can be separated

from the airflow meter by undoing the

securing bolts.

Throttle valve housing/inlet manifold

31Loosen off the retaining clip and detach

the air intake duct from the throttle housing,

the air cooling hoses for the injectors and the

supplementary air valve.

32Detach the accelerator cable from the

throttle linkage.

13•80 Supplement: Revisions and information on later models

Fig. 13.56 Disconnecting the injector air

cooling hoses and the supplementary air

valve hose on the 1372 cc Turbo ie engine

(Sec 9E)Fig. 13.55 Disconnecting the air intake

duct and accelerator cable from the

throttle housing on the 1372 cc Turbo ie

engine (Sec 9E)

Fig. 13.54 Accelerator cable adjustment

on the 1372 cc Turbo ie engine (Sec 9E)

1 Adjuster 3 Quadrant support

2 Inner cableFig. 13.53 Mixture adjustment screw

location on the 1372 cc Turbo ie engine

(Sec 9E)

Page 206 of 303

33Detach the vacuum pick-up pipes from

the points indicated in Fig. 13.57.

34Detach the wiring connector from the

throttle position switch.

35Unscrew and remove the inlet manifold

mounting bracket-to-cylinder head retaining

bolt shown in Fig. 13.58.

36Unscrew and remove the injector cable

shield retaining screws. Detach the cables

from the injectors.

37Disconnect the earth leads and the air

intake sensor lead shown in Fig. 13.59.

38Release and withdraw the injector cable

shield from the left-hand underside of the

throttle housing.

39Unscrew and detach the injector fuel

supply pipe and disconnect the fuel pressure

regulator pipe from its inlet manifold union.

40Disconnect the injector cooling fan

thermostatic switch lead.

41Unscrew the securing bolts and remove

the fuel pressure regulator.

42Unscrew and remove the heat

shield-to-exhaust manifold retaining bolts.

Unscrew the retaining bolts at the rear and

withdraw the heat shield.

43Undo the inlet manifold retaining

bolts/nuts and carefully withdraw the

manifold/throttle housing. Remove the gasket

from the mating face.

Injectors and fuel rail

44Depressurise the system as described

previously. 45Disconnect the fuel supply line from the

fuel rail.

46Disconnect the fuel return line from the

base of the fuel pressure regulator. Unbolt

and remove the pressure regulator from the

fuel rail.

47Unscrew and remove the injector cable

shield retaining screws. Detach the cables

from the injectors.

48Disconnect the fuel rail/injector unit and

withdraw the fuel rail, together with the

injectors, from the engine.

49With the injectors and the fuel rail

removed, one or more injectors can be

removed and renewed as described below.

Note that the connecting hoses will be

destroyed during removal and these together

with the injector seals will therefore need to be

renewed.

Injector(s) and connecting hoses

50Remove the injectors and the injector fuel

rail as described in the previous sub-Section

and secure the fuel rail in a vice, but do not

overtighten.

51Cut free the hose between the fuel rail and

the injector. Make the cut in-line with the hose

and cut the hose as close as possible to the

fuel rail connection, then pull the hose free

from its retaining cap. Once the hose is

detached, the retaining cap is released.

52Repeat the procedure and release the

hose and its retaining cap from the injector.

53Whether or not the injector unit itself is tobe renewed, the injector O-ring seals must

always be renewed when disturbed.

54Check that the connections of the fuel rail

and the injector are clean, then push the new

injector with retaining cap onto the new hose.

Ensure that the hose is fully located in the

retaining cap.

55Check that the fuel rail-to-hose retaining

cap is located on the connector, then push

the other end of the injector hose over the fuel

rail connector. Ensure that the hose is fully

located in the retaining cap.

56The interconnecting hose between the

fuel rail sections can be removed and

renewed in the same manner as that

described above for the injector hoses.

Electronic control unit (ECU)

57The ECU is mounted on the top face of

the airflow meter. Ensure that the ignition is

switched off before disconnecting the

multiplug from the ECU. Disconnect the wiring

multiplug connector by compressing the tag

and pulling the connector free from the unit.

Undo the retaining screws and remove the

ECU from the airflow meter. Handle the unit

with care and if removed for an extensive

period, store it in a safe place where it will not

get knocked or damaged.

Fuel pump - removal and refitting

58Depressurise the fuel system as

described previously.

59Raise the car at the rear and support it on

axle stands. Detach and remove the

Supplement: Revisions and information on later models 13•81

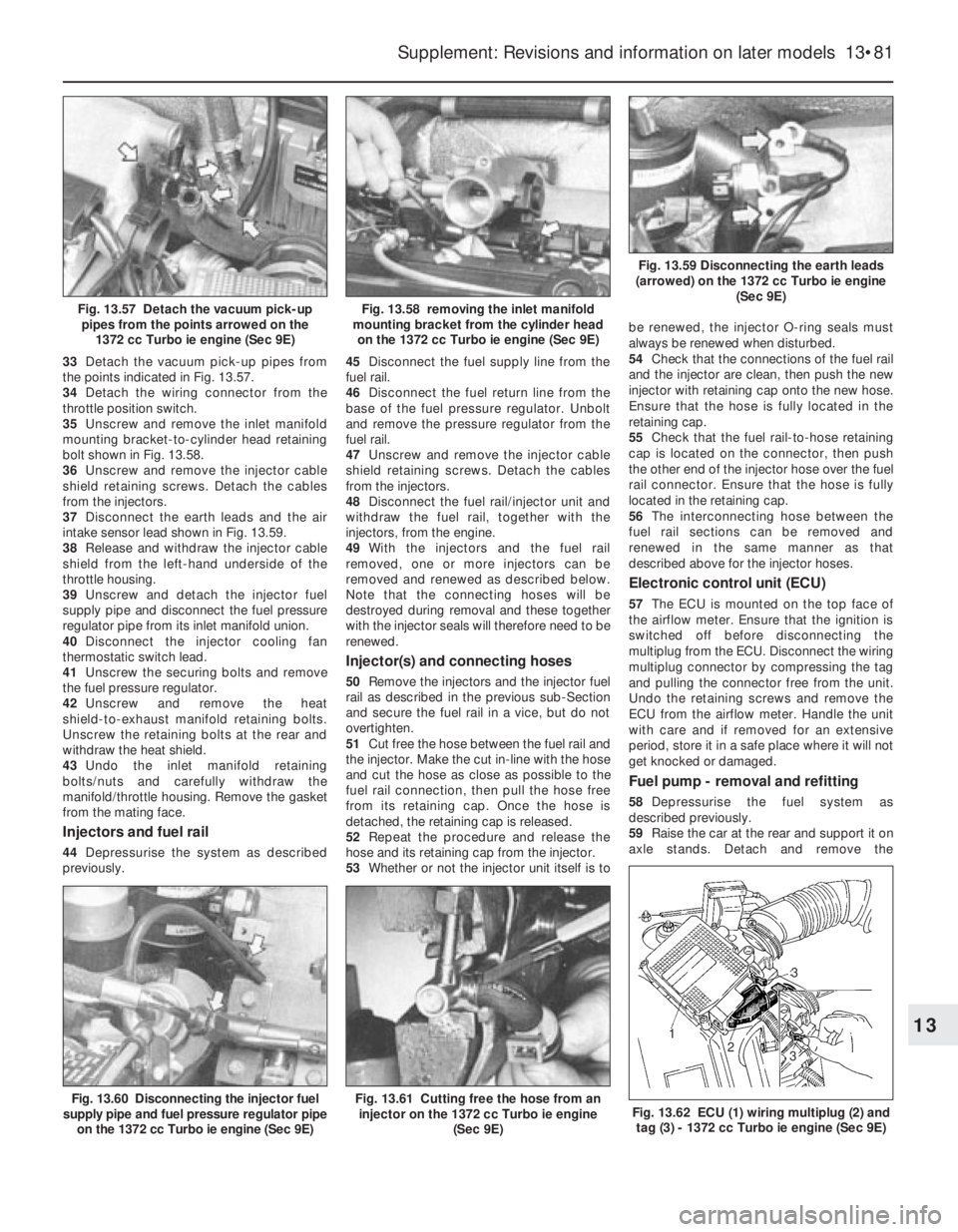

Fig. 13.59 Disconnecting the earth leads

(arrowed) on the 1372 cc Turbo ie engine

(Sec 9E)

Fig. 13.58 removing the inlet manifold

mounting bracket from the cylinder head

on the 1372 cc Turbo ie engine (Sec 9E)Fig. 13.57 Detach the vacuum pick-up

pipes from the points arrowed on the

1372 cc Turbo ie engine (Sec 9E)

Fig. 13.62 ECU (1) wiring multiplug (2) and

tag (3) - 1372 cc Turbo ie engine (Sec 9E)Fig. 13.61 Cutting free the hose from an

injector on the 1372 cc Turbo ie engine

(Sec 9E)Fig. 13.60 Disconnecting the injector fuel

supply pipe and fuel pressure regulator pipe

on the 1372 cc Turbo ie engine (Sec 9E)

13

2

3

3

1

Page 207 of 303

protective shield to gain access to the pump

which is located forward of the fuel tank.

60Disconnect the fuel hoses and the wiring

connector, release the retaining clamp and

withdraw the pump unit.

Refitting all components

61Refitting of all components is a reversal of

the removal procedure, but note the following

specific points.

62Ensure that all components are clean prior

to refitting and where applicable, use new

seals and gaskets. Ensure that all connectionsare securely and correctly made.

63Do not reconnect the battery until all the

refitting procedures are complete.

64When the engine is restarted, check

around the fuel injection system for any signs

of leakage from the fuel supply and return

components.

Lambda sensor - general

65The sensor is screwed into the exhaust in

front of the catalytic converter.

66A faulty sensor can damage the converter,

therefore it must be checked regularly (see

Maintenance schedule, Section 3) by a dealer

using special equipment.

67Use of leaded fuel will also damage this

sensor, as well the converter.

PART F:

TURBOCHARGER SYSTEM

Description

1A turbocharger is fitted to certain 1301 and

1372 cc ie engines. The accompanying

photographs are all taken from a 1301 cc

engine, but the system is much the same for

both engine types.

2The turbocharger is basically a shaft with an

exhaust gas-driven turbine at one end, and a

compressor located at the other end which

draws in outside air and forces it into the inlet

manifold. By compressing the incoming air, a

larger charge can be let into each cylinder,

and greater power output is achieved than

with normal aspiration.3Lubrication of the turbocharger shaft

bearings is provided by pressurised engine

oil, and the unit is cooled by the coolant from

the engine cooling system.

4A wastegate valve is incorporated in the

turbocharger to divert excessive exhaust gas

pressure from the turbine into the exhaust

pipe at a predetermined pressure level.

5A maximum air pressure switch is located in

the inlet manifold. Its purpose is to cut the

ignition system off when the turbocharger

system pressure continues to increase

beyond 0.86 bars (12.5 lbf/in

2). This would

otherwise damage the engine, due to high

combustion temperatures and pressures

(photo).

6An intercooler (heat exchanger) is located

between the turbocharger and the inlet

manifold. Its function is to cool the inlet

charge, thus increasing its density, to provide

greater power output.

7A mechanical bypass valve is located

between the low-pressure pipe (downstream)

and the high-pressure pipe (upstream), which

reduces the inherent noise from the

turbocharger when the accelerator pedal is

released (photo).

8None of the components of the

turbocharger system can be repaired and

parts are not available. Any fault will therefore

mean that the turbocharger or associated

assemblies will have to be renewed complete.

Precautions

9The following precautions should be

observed when using a turbocharged vehicle.

a) Never operate the engine without the air

cleaner fitted.

b) Never switch off the engine before its

speed has dropped to idling. If the car

has been driven hard, allow it to idle for a

few minutes before switching off. Failure

to observe these recommendations can

cause damage to the turbocharger due to

lack of lubrication.

10Always keep the fuel injection system

well-maintained and tuned. Operating on a

weak mixture can cause overheating of the

turbocharger.

Turbocharger

(1301 cc ie engine) -

removal and refitting

Á

11Disconnect and remove the airflow meter

as described in Section 9C.

12Disconnect the spiral-wound hose from

the fuel injector cooling duct.

13Remove the turbocharger air hoses from

within the left-hand side of the engine

compartment. Note particularly their routing.

14Remove the throttle housing/inlet

manifold as described in Section 9C, also the

fuel rail, injectors and inlet manifold branch

pipe stubs. Remove the alternator heat shield

(photo).

15Remove the exhaust heat shield.

16Unscrew the turbocharger-to-exhaust

pipe flange nuts (photos).

13•82 Supplement: Revisions and information on later models

9F.16A Turbocharger-to-exhaust flange

nut (arrowed)9F.14 Alternator heat shield

9F.7 Bypass valve9F.5 Maximum air pressure switch

(arrowed)

Fig. 13.63 Fuel pump and sender unit

location on the 1372 cc Turbo ie engine

(Sec 9E)

1 Fuel level gauge sender connector

2 Fuel pump connector

3 Fuel return hose

4 Fuel supply hose

Page 210 of 303

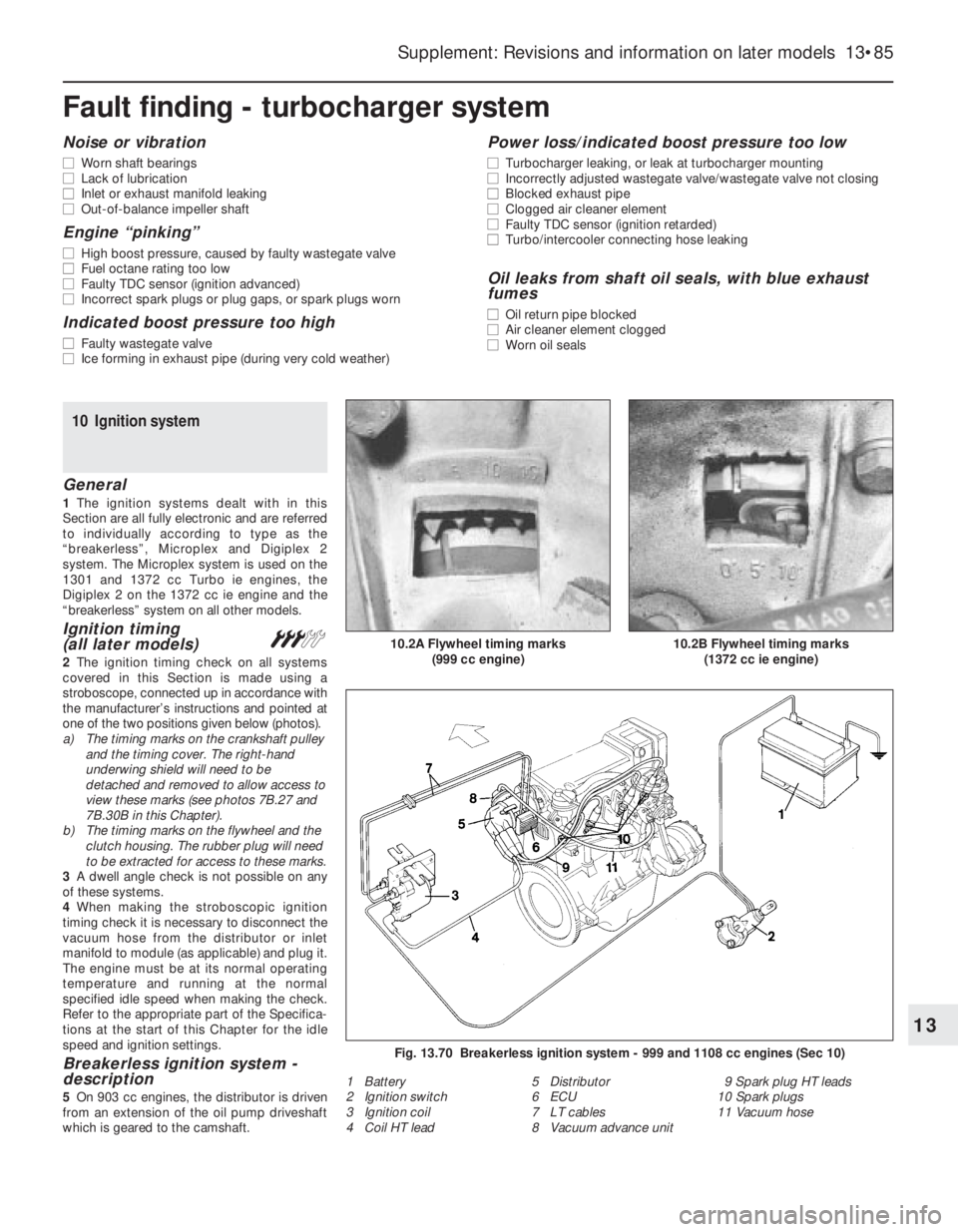

Fault finding - turbocharger system

Supplement: Revisions and information on later models 13•85

13

Noise or vibration

m mWorn shaft bearings

m mLack of lubrication

m mInlet or exhaust manifold leaking

m mOut-of-balance impeller shaft

Engine “pinking”

m

mHigh boost pressure, caused by faulty wastegate valve

m mFuel octane rating too low

m mFaulty TDC sensor (ignition advanced)

m mIncorrect spark plugs or plug gaps, or spark plugs worn

Indicated boost pressure too high

m

mFaulty wastegate valve

m mIce forming in exhaust pipe (during very cold weather)

Power loss/indicated boost pressure too low

m

mTurbocharger leaking, or leak at turbocharger mounting

m mIncorrectly adjusted wastegate valve/wastegate valve not closing

m mBlocked exhaust pipe

m mClogged air cleaner element

m mFaulty TDC sensor (ignition retarded)

m mTurbo/intercooler connecting hose leaking

Oil leaks from shaft oil seals, with blue exhaust

fumes

m mOil return pipe blocked

m mAir cleaner element clogged

m mWorn oil seals

10 Ignition system

General

1The ignition systems dealt with in this

Section are all fully electronic and are referred

to individually according to type as the

“breakerless”, Microplex and Digiplex 2

system. The Microplex system is used on the

1301 and 1372 cc Turbo ie engines, the

Digiplex 2 on the 1372 cc ie engine and the

“breakerless” system on all other models.

Ignition timing

(all later models)#

2The ignition timing check on all systems

covered in this Section is made using a

stroboscope, connected up in accordance with

the manufacturer’s instructions and pointed at

one of the two positions given below (photos).

a) The timing marks on the crankshaft pulley

and the timing cover. The right-hand

underwing shield will need to be

detached and removed to allow access to

view these marks (see photos 7B.27 and

7B.30B in this Chapter).

b) The timing marks on the flywheel and the

clutch housing. The rubber plug will need

to be extracted for access to these marks.

3A dwell angle check is not possible on any

of these systems.

4When making the stroboscopic ignition

timing check it is necessary to disconnect the

vacuum hose from the distributor or inlet

manifold to module (as applicable) and plug it.

The engine must be at its normal operating

temperature and running at the normal

specified idle speed when making the check.

Refer to the appropriate part of the Specifica-

tions at the start of this Chapter for the idle

speed and ignition settings.

Breakerless ignition system -

description

5On 903 cc engines, the distributor is driven

from an extension of the oil pump driveshaft

which is geared to the camshaft.

10.2B Flywheel timing marks

(1372 cc ie engine)10.2A Flywheel timing marks

(999 cc engine)

Fig. 13.70 Breakerless ignition system - 999 and 1108 cc engines (Sec 10)

1 Battery

2 Ignition switch

3 Ignition coil

4 Coil HT lead5 Distributor

6 ECU

7 LT cables

8 Vacuum advance unit9 Spark plug HT leads

10 Spark plugs

11 Vacuum hose

Page 211 of 303

6On 999, 1108 and 1372 cc engines, the

distributor is driven from the rear end of the

camshaft.

7On the 1116 and 1299/1301 cc engines, the

distributor is driven from an extension of the

oil pump driveshaft which is geared to the

auxiliary shaft.

8The distributor contains a reluctor mounted

on its shaft, and a magnet and stator fixed to

the baseplate.

9Ignition advance is controlled in the

conventional way mechanically by centrifugal

weights and a diaphragm unit for vacuum

advance.

10Instead of the conventional method of

interrupting the low tension circuit to generate

high tension voltage in the coil by means of a

mechanical contact breaker, when the

electronic ignition is switched on, the

switching of the transistors in the electronic

control unit (ECU) prevents current flow in the

coil primary windings.

11Once the crankshaft rotates, the reluctor

moves through the magnetic field created by

the stator and when the reluctor teeth are in

alignment with the stator projections a small

AC voltage is created. The ECU amplifies this

voltage and applies it to switch the transistors

and so provide an earth path for the primary

circuit.

12As the reluctor teeth move out of

alignment with the stator projections the AC

voltage changes, the transistors in the ECU

are switched again to interrupt the primary

circuit earth path. This causes a high voltage

to be induced in the secondary winding.

Distributor

(breakerless type) -

removal and refitting

#

13Removal of the distributor on the 903,1116, 1299 and 1301 cc engines is as

described in Chapter 4, Section 6.

14On 999, 1108 and 1372 cc engines, mark

the position of the distributor clamp plate in

relation to the cylinder head surface.

15Unclip the distributor cap and move it to

one side with the HT leads attached.

16Disconnect the LT lead plug and, where

applicable, the vacuum hose (photo).

17Unscrew the distributor fixing nuts and

withdraw the unit.

18The distributor drive is by means of an

offset dog no special procedure is required to

refit it. Providing the dog engages in its slot

and the distributor body is turned to align the

marks made before removal, the timing will

automatically be correct.

19If a new distributor is being fitted (body

unmarked), set No. 4 piston at TDC (0º) by

turning the crankshaft pulley bolt until the

timing marks on the crankshaft pulley and

engine front cover are in alignment.

20Align the drive dog and fit the distributor

then turn the distributor body until the contact

end of the rotor is aligned with the arrow on

the distributor dust shield.

21Tighten the distributor clamp nuts. Refit the

cap and disconnected components and then

check ignition timing using a stroboscope.

Distributor (breakerless

type) - overhaul#

22It is recommended that a worn out or

faulty distributor is renewed. However,

individual components such as the cap, rotor,

reluctor, magnet/stator/baseplate assembly,

vacuum diaphragm unit, and drive gear or dog

are available separately.

Breakerless

ignition system

components - testing

ª

23A voltmeter and an ohmmeter will be

required for this work.

Primary circuit voltage

24Turn on the ignition, and using a voltmeter

check the voltage at the ignition coil LT

terminals. Any deviation from battery voltage

will indicate a faulty connection, or if these are

satisfactory, then the coil is unserviceable.

Magnetic impulse generator winding

25Remove the distributor and ECU and

disconnect their connecting leads.

26Connect an ohmmeter to the impulse

generator terminals and note the reading. The

resistance should be as given in the Specifi-

cations at the beginning of this Chapter.

27Now check between one of the impulse

generator terminals and the metal body of the

distributor. Infinity should be indicated on the

ohmmeter. If it is not, renew the impulse

generator carrier plate. Note: When carrying out

this test it is imperative that the connections are

remade as originally observed. Also ensure that

there is no possibility of the ECU supply (red)

cable and earth cable making contact in service.

Ignition coil winding resistance

28Check the resistance using an ohmmeter

between the coil LT terminals. Refer to the

Specifications for the expected coil resistance.

29Check the resistance between the LT lead

socket on the coil and each of the LT

terminals. Refer to the Specifications for the

expected coil resistance.

30The rotor arm resistance should be

approximately 5000 ohms.

Microplex ignition system -

description

31This system is fitted to the 1301 and

1372 cc Turbo ie models, and comprises the

following components.

Electro-magnetic sensors

32Two sensors are used to pick up engine

speed and TDC position directly from the

crankshaft.

Pressure and vacuum sensor

33This converts inlet manifold vacuum

pressure into an electrical signal for use by

the electronic control unit (ECU).

Anti-knock sensor

34This converts “pinking” detonations which

occur within the combustion chambers into

an electrical signal for use by the ECU (photo).

Electronic Control Unit (ECU)

35This computes the optimum ignition

advance angle from the sensor signals

received, and controls the action of the

ignition unit (photo).

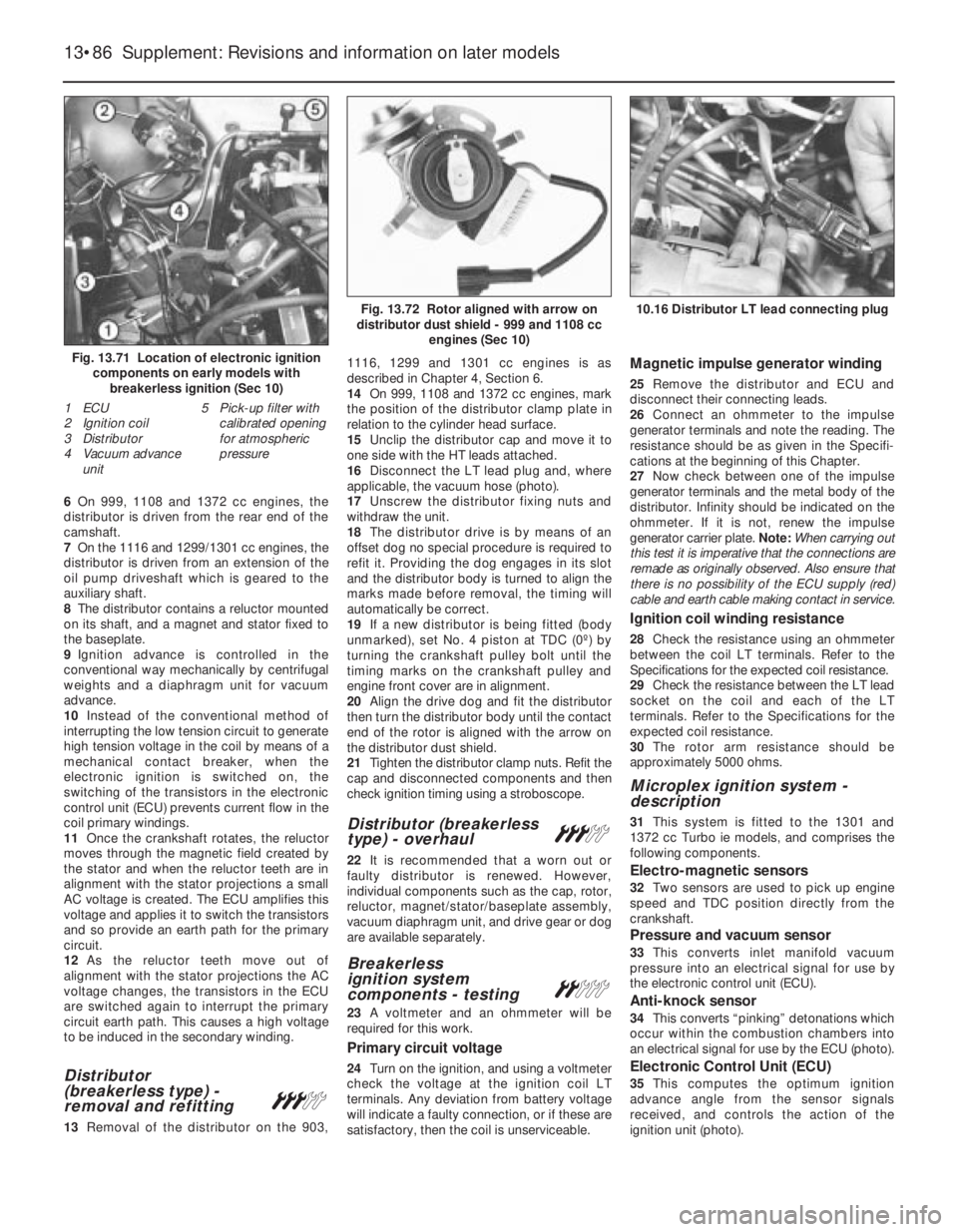

13•86 Supplement: Revisions and information on later models

Fig. 13.72 Rotor aligned with arrow on

distributor dust shield - 999 and 1108 cc

engines (Sec 10)

1 ECU

2 Ignition coil

3 Distributor

4 Vacuum advance

unit5 Pick-up filter with

calibrated opening

for atmospheric

pressure

Fig. 13.71 Location of electronic ignition

components on early models with

breakerless ignition (Sec 10)

10.16 Distributor LT lead connecting plug

Page 214 of 303

Ignition unit

36This comprises four elements (photo).

a) Power module - receives the ignition

advance command and controls the

conduction angle of the primary current

and energy stored in the coil.

b) Dissipater plate - eliminates the heat

which is generated by the high volume of

current.

c) Ignition coil with low primary resistance.

d) Distributor - a means of distributing high

tension to the spark plugs. The rotor is

driven in an anti-clockwise direction

(viewed from transmission) by a dog on

the end of the camshaft.

37The system incorporates a safety

pressure switch, which cuts out the ignition if

the turbocharging pressure exceeds a value

of between 0.84 and 0.93 bars (12.2 and

13.5 lbf/in

2) above atmospheric pressure.

Distributor (Microplex) -

removal and refitting#

38Remove the distributor cap and place it to

one side, complete with spark plug leads

(photo).

39Turn the crankshaft by means of the

pulley nut, or by raising and turning a front

wheel with top gear engaged, until No. 4

piston is on its firing stroke. This will be

indicated when the contact end of the rotorarm is aligned with the mark on the distributor

body rim, and the lug on the crankshaft pulley

is aligned with the timing pointer on the

engine. The right-hand underwing shield will

have to be removed in order to see the marks

(photo).

40Unscrew the distributor fixing nuts and

withdraw the distributor.

41When fitting the distributor, the offset

drive dog will automatically locate the

distributor rotor in its correct position, but the

distributor body may require rotating in order

to align the rim mark with the rotor. The

elongated slots for the fixing studs are to

permit initial alignment, not for subsequent

adjustment, as advance angle alterations are

carried out automatically by the system ECU

(photos).

42Tighten the nuts and refit the cap with

leads.

43Unless a stroboscope and a vacuum

pressure gauge are available, it will not be

possible to check the advance values with the

engine running. Where these instruments are

available, connect the vacuum gauge to the

inlet manifold, and the stroboscope in

accordance with the equipment manufac-

turer’s instructions. Refer to Fig. 13.79

according to the inlet manifold vacuum

pressure indicated.

Microplex ignition system

components - testing ª

44An ohmmeter and a voltmeter will be

required for these tests.

45Remove the multipin plug from the ECU.

Engine speed sensor

46Insert the probes of an ohmmeter

between terminals 3 and 16 of the multipin

connector; 618 to 748 ohms (1301 cc) or

578 to 782 ohms (1372 cc) should be

indicated.

47If necessary, carry out a check of the gap

between the sensor and flywheel teeth as

described in Chapter 4, Section 10.

Supplement: Revisions and information on later models 13•89

10.39 Crankshaft pulley timing marks

(arrowed)10.38 Removing the distributor cap10.36 Ignition coil (1) and power module (2)

on 1301 cc Turbo ie engine

Fig. 13.78 Rotor aligned with distributor

body rim mark - Microplex ignition system

(Sec 10)

10.41A Distributor body showing elongated

slots in the mounting lugs

Fig. 13.77 Crankshaft pulley timing mark

aligned with timing pointer - Microplex

ignition system (Sec 10)

1 TDC sensor10.41B Distributor drive dog

13

Page 215 of 303

TDC sensor

48Insert the probes of the ohmmeter

between terminals 1 and 2 of the multipin

connector; 618 to 748 ohms (1301 cc) or 578

to 782 ohms (1372 cc) should be indicated.

49If necessary, carry out a check of the gap

between the sensor and the crankshaft pulley,

as described in Chapter 4, Section 10.

ECU supply

50Switch on the ignition, and then insert the

probes of a voltmeter between terminals 13

and 11 of the multipin connector. Battery

voltage should be indicated. If not, check the

battery earth, ignition switch or intermediate

connector plug for security.

Power module supply (1301 cc)

51Pull the multipin plug from the powermodule, and connect the probes of a

voltmeter between terminal 4 of the connector

and earth. If the reading is less than battery

voltage, check the security of all connections

between the ignition switch and terminal + 15

of the ignition coil.

52Reconnect the multipin connector to the

ECU, but have the one from the power

module disconnected, and then switch on the

ignition.

53Connect the voltmeter between terminals

4 and 2 of the power module multipin

connector. If the indicated voltage is less than

battery voltage, check the security of all

connections between the ignition switch and

terminal + 15 of the ignition coil, and the

battery earth. If all are satisfactory, check for

continuity between terminals 11 and 12. If

continuity is broken, renew the ECU.

Power module (1372 cc)

54Proceed as described in paragraph 53.

Anti-knock sensor

55If “pinking” occurs, or loss of power is

noticed, test the sensor by substitution of a

new one.

Ignition coil

56Disconnect the leads from terminals 1

and 15 on the coil before testing.

57Using the ohmmeter, check the resistance

of the primary winding. This should be

between 0.31 and 0.37 ohms (1301 cc) or

0.40 to 0.49 ohms (1372 cc), at an ambient

temperature of 20ºC (68ºF).

58The secondary winding resistance should

be between 3330 and 4070 ohms (1301 cc) or

4320 to 5280 ohms (1372 cc), at an ambient

temperature of 20ºC (68ºF).

Distributor

59Check the resistance of the rotor arm,

which should be between 800 and

1200 ohms.

60Where all the foregoing tests have proved

satisfactory, then any problem must be due to

a fault in either the power module or the ECU.

These components can only be checked by

the substitution of a new unit - power module

first, then the ECU.

Safety pressure switch

61The device protects the engine from

excessive turbocharging pressure, cutting off

the ignition by earthing the Microplex ECU.

Testing is not possible without a special

pressure pump, so the easiest way to check a

suspected fault is to fit a new unit.

Digiplex 2 ignition system -

description

62This system operates in a similar manner

to that of the earlier type described in Chap-

ter 4, but the circuit layout differs to suit the

Mono Jetronic fuel injection system. In

operation, the main difference is that the

Digiplex 2 system has a greater number of

13•90 Supplement: Revisions and information on later models

Fig. 13.81 Microplex ignition system

control unit connection (Sec 10)

For colour code, see main wiring diagramsFig. 13.80 Microplex ignition system ECU multipin connector (Sec 10)

For colour code, see main wiring diagrams

Fig. 13.79 Ignition advance curves - Microplex ignition system on the 1301 cc Turbo ie

(Sec 10)

Page 216 of 303

advance points than the earlier system.

Comparison of Fig. 13.82 with Fig. 4.2

illustrates the difference in layout. Note that

the distributor is mounted on the rear end of

the cylinder head and is driven by the

camshaft.

63When working on the Digiplex 2 ignition

system or associated components, the

precautionary notes outlined in Section 9 of

Chapter 4 must be adhered to.

64As with the earlier system, test

procedures possible on the Digiplex 2 system

are restricted due to the need for specialised

testing equipment. The following checks are

possible, however, using a conventional test

meter.

Ignition coil check

65To check the resistance of the coil’s

primary windings, connect the probes of an

ohmmeter between the positive terminal and

the negative terminal as shown in Fig. 13.83,

and check that the resistance reading at 18 to

28ºC is 0.45 ohms ± 10% (photo).66To check the resistance of the coil’s

secondary windings, connect the probes of an

ohmmeter between the positive terminal and

the HT lead terminal as shown in Fig. 13.84.

Check that the resistance reading at 18 to

28ºC (64 to 82ºF) is 4800 ohms ± 10%.

Ignition timing check

67Refer to paragraph 2 in this Section.

Engine speed and TDC sensor check

68To check the resistance between the

sensor and the ECU, detach the wiring

connector (photo). Connect the probes of an

ohmmeter to the connector terminals and

check that the resistance reading is between

600 and 760 ohms at 20ºC (68ºF). If the

reading is not as specified, the sensor must

be renewed.

69The gap between the sensor and the pins

on the rear face of the flywheel must be

between 0.2 and 0.8 mm. Any deviation

outside of this clearance will be due to

mechanical damage to the sensor andnecessitates its renewal. The sensor is

accurately positioned during manufacture and

secured with tamperproof screws; it does not

require any adjustment during servicing. If it is

necessary to renew the sensor, a special gap

setting tool is required and the task is

therefore best entrusted to a FIAT dealer.

Supplement: Revisions and information on later models 13•91

Fig. 13.82 Digiplex 2 ignition system wiring circuits and components (Sec 10)

10.68 ECU location on the 1372 cc ie

engine10.65 Ignition coil and connections on the

1372 cc ie engineFig. 13.84 Test connections for ignition

coil secondary windings check - Digiplex 2

ignition system (Sec 10)

Fig. 13.83 Test connections for ignition

coil primary windings check - Digiplex 2

ignition system (Sec 10)

13

1 Connection point (lines connected to

the intake manifold)

2 ECU

3 Ignition coil

4 Distributor

5 Engine flywheel (with

five pins)

6 On/off switch (if fitted)

for advance reduction

7 On/off switch 2 (if fitted)

for curves

8 Battery

9 Spark plugs

10 Tachometer

11 Diagnostic socket

12 Engine speed and TDC sensor

13 To check actuator idle speed

14 To terminal no. 1 of injection control unit

(rpm signal)

Page 218 of 303

mounted in-line with and just forward of the

clutch pedal. The operating cylinder is

mounted within a housing on top of the

transmission. The fluid reservoir is located in

the engine compartment and is mounted on

the left-hand side near the bulkhead. No

settings or specific procedures are given by

the manufacturer at the time of writing.

Maintenance

(hydraulic clutch)Á

7Periodically check the fluid level in the

reservoir. If the level has dropped, top it up

with the specified fluid. The fluid level must

not be allowed to drop below the MIN level

mark on the side of the reservoir (photos). If

the fluid level drops by a significant amount, it

is indicative of a leak in the hydraulic circuit

and this must therefore be traced and

repaired at the earliest opportunity.

8Inspect the fluid lines and connections for

security and any signs of leaks.

Clutch master cylinder -

removal, overhaul

and refitting

#

9If the cylinder is to be dismantled, it will first

be necessary to obtain a cylinder repair kit.

Start by detaching and removing the trim

panel from the underside of the facia on the

driver’s side.

10Place a suitable covering over the floor

carpet to prevent staining in the event of fluid

spillage. Clamp the fluid supply hose at the

master cylinder end, then unscrew the

retaining clip and detach the hose from the

cylinder. Position the hose out of the way and

with its end pointing up.

11Detach the operating rod clevis from the

brake pedal.

12Unscrew and detach the hydraulic pipe to

the operating cylinder from the master

cylinder (photo).

13Undo the two retaining nuts and withdraw

the master cylinder.

14To dismantle the cylinder, prise free and

pull back the dust boot, extract the retainer

and withdraw the operating rod.

15Invert the cylinder and shake free the

piston and seal assembly. If it is stuck inside

the cylinder, apply moderate air pressure

(from a foot pump) into the tail end and catchthe assembly in a clean cloth as it is ejected.

16Remove the seals noting their orientation.

Clean all components in methylated spirits or

new hydraulic fluid. If the cylinder is damaged,

scored or badly worn it must be renewed. The

seals must always be renewed once they are

removed.

17Assemble the new seals to the piston and

lubricate the cylinder, seals and piston

assembly with new hydraulic fluid (of the

specified type) before assembling them.

Ensure that the seals are fitted the correct

way round (as noted during removal).

18Renew the dust boot, fit and secure the

operating rod into position with the retainer,

then refit the dust boot over the cylinder.

19If the intake pipe connector was removed,

this must be refitted using a new seal.

20Refit the cylinder in the reverse order of

removal. Connect and hand tighten the

hydraulic pipe to the operating cylinder before

fully tightening the cylinder securing nuts. The

hydraulic pipe can then be fully tightened.21Reconnect the fluid supply hose to the

cylinder and tighten the retaining clip to

secure. Release the clamp.

22Top up the clutch fluid level in the

reservoir then bleed the system as described

later in this Section.

Clutch operating cylinder -

removal, overhaul

and refitting

¢

23If the cylinder is to be dismantled once it

is removed, it will first be necessary to obtain

a cylinder repair kit. Access is much improved

by first detaching the appropriate ducts and

hoses from the areas directly above the

cylinder, on top of the transmission/clutch

housing.

24To avoid excessive fluid loss when the

hydraulic line is detached from the operating

cylinder, remove the filler cap from the

reservoir, place a clean piece of polythene

sheet over the filler neck and refit the reservoir

cap.

Supplement: Revisions and information on later models 13•93

Fig. 13.88 Exploded view of the hydraulic clutch components (Sec 11)

1 Filler cap

2 Fluid reservoir

3 Hose

4 Master cylinder5 Cover

6 Clip

7 Bracket

8 Hose9 Operating cylinder

10 Bracket

11 Circlip

12 Operating lever

11.12 Clutch master cylinder and hydraulic

pipe connections11.7B Topping up the fluid level in the

clutch fluid reservoir11.7A Clutch hydraulic fluid reservoir

showing MIN and MAX markings

13