ECO mode FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 83 of 303

into its cylinder to accommodate them. This

will cause the fluid level to rise in the reservoir.

Anticipate this by syphoning some out

beforehand, but take care not to let it drip

onto the paintwork - it acts as an effective

paint stripperl

8Refit the anti-rattle springs, the pads

(friction lining-to-disc), the cylinder body, the

locking blocks and their retaining clips

(photos).

9Refit the roadwheel and apply the footbrake

hard, several times, to bring the pads into

contact with the brake disc.

10Renew the pads on the opposite brake.

The pads should always be renewed in axle

sets.

11Top up the fluid reservoir.

4 Rear brake shoes-

inspection and renewal

2

1Jack up the rear of the car and remove the

roadwheels.

2Fully release the handbrake.

3Unscrew and remove the drum securing

bolts. One of these is a long locating spigot

for the roadwheel.

4Pull off the drum. lf it is tight, clean off the

rust at its joint with the hub flange, and apply

a little penetrating fluid. Two bolts may be

screwed into the drum securing bolt holes if

necessary and the drum thus eased off the

hub. The securing bolt holes are tapped for

this purpose.

5Brush away all the dust and dirt from the

shoes and operating mechanism, taking care

not to inhale it.

6The friction linings fitted as original

equipment are of the bonded type and the

rivet heads normally used as a guide to wear

are not, of course, fitted. However, if the

thickness of the friction linings is down to

1.5 mm (0.06 in) or less, the shoes must be

renewed. Always purchase new or factory

relined brake shoes.

7Before removing the brake shoes, note the

way in which the shoes are positioned, with

respect to leading and trailing ends (the end

of the shoe not covered by lining material).Note also into which holes in the shoe web

the return springs are connected. Sketch the

shoes or mark the holes on the new shoes

with quick drying paint if you are doubtful

about remembering (photo).

8Undo the steady springs by depressing and

rotating their caps a quarter turn to disengage

the slot from the pin. On later models a

U-shaped steady spring is used. Depress and

slide it out.

9Rotate the hub until the cut-outs in its rear

flange face are in alignment with the shoe

self-adjusters.

10Pivot the trailing shoe on the self-adjuster

post and disengage the ends of the shoe from

the slot in the wheel cylinder tappet and from

the lower anchor block.

11Work the shoe up the self-adjuster pivot

post until the self-adjuster boss enters the

cut-out in the hub flange. The shoe can now

be withdrawn (photo).

12Once off the self-adjuster post, the

pull-off spring tension is eased, as the shoe

can move towards the other, so the springs

can be unhooked.

13Remove the leading shoe in a similar way.

14The new shoes will already be fitted with

new self-adjusters.

15Fit the new shoes to their self-adjuster

posts, making sure that the handbrake shoe

lever is correctly located. Engage the ends of

the shoes.

16Using a wooden or plastic-faced mallet,

tap the shoes inwards against the friction of

their self-adjuster coil springs. This will havethe effect of reducing the overall diameter of

the shoes to facilitate fitting of the shoe return

springs and to allow the brake drum to slide

over them.

17Using pliers, reconnect the upper (longer)

and lower shoe return springs.

18Hold the steady pins in position from the

rear of the backplate. Fit the small coil springs

and the retaining cap, again using pliers to

grip the cap and to depress and turn it to

engage the pin. On later models fit the

U-shaped springs.

19Before refitting the drum, clean it out and

examine it for grooves or scoring (refer to

Section 8).

20Fit the drum and the roadwheel.

21Apply the brakes two or three times to

position the shoes close to the drum.

22Renew the shoes on the opposite brake in

a similar way.

23The handbrake should be automatically

adjusted by the action of the shoe adjuster. If

the handbrake control lever has excessive

travel, refer to Section 16 for separate

adjusting instructions.

5 Caliper- removal,

overhaul and refitting

4

Note: Purchase a repair kit in advance of

overhaul.

1Jack up the front roadwheel and remove it.

2Brush away all dirt from the caliper

Braking system 8•3

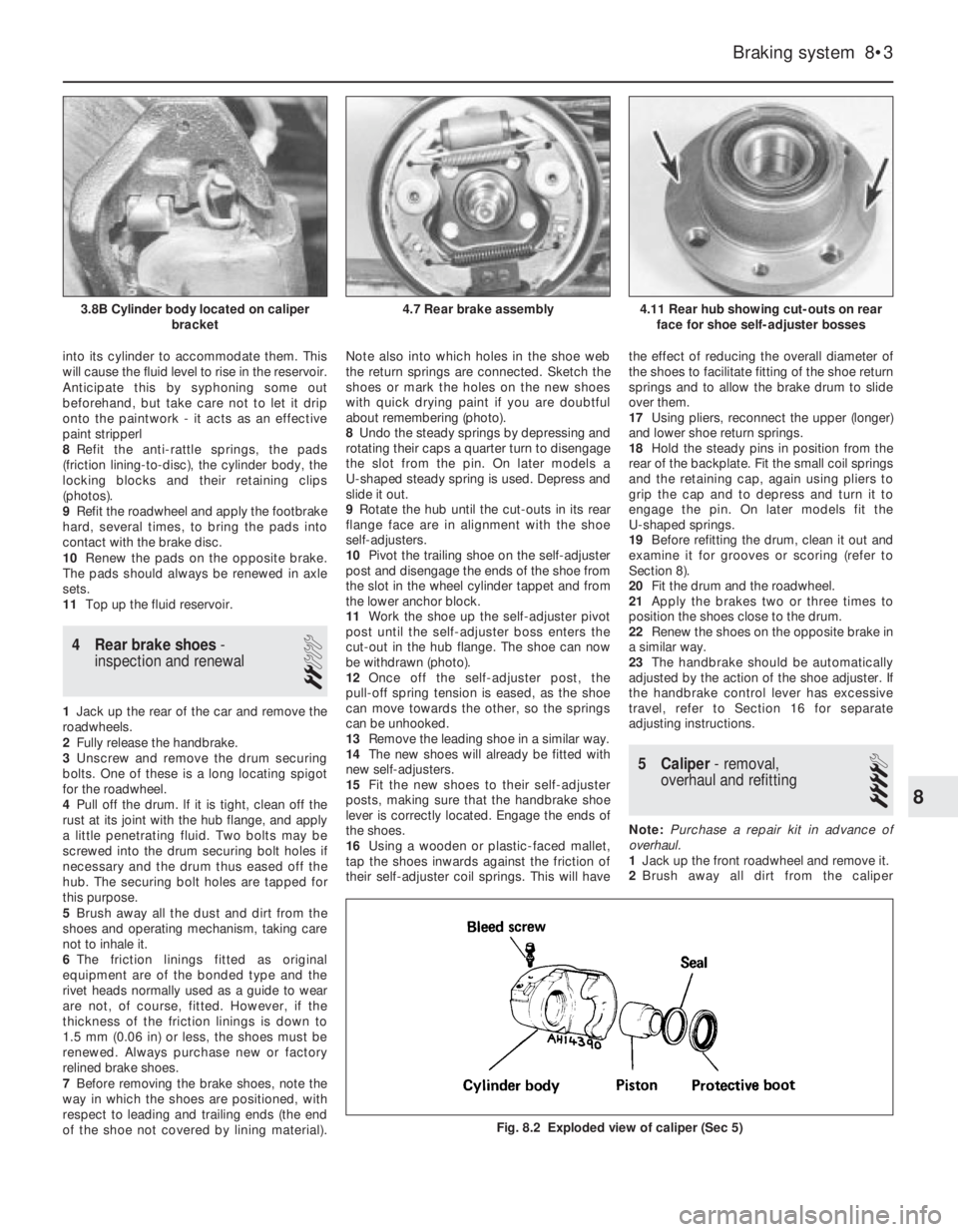

4.11 Rear hub showing cut-outs on rear

face for shoe self-adjuster bosses4.7 Rear brake assembly3.8B Cylinder body located on caliper

bracket

Fig. 8.2 Exploded view of caliper (Sec 5)

8

Page 85 of 303

9 Master cylinder- removal,

overhaul and refitting

4

Note: Purchase a repair kit in advance of

overhaul.

1The master cylinder is mounted on the front

face of the brake vacuum servo unit (55 and

70 models) or directly to the bulkhead (45

models).

2Cover the front wings with polythene

sheeting or similar material, in case hydraulic

fluid spills onto the paintwork of the car during

removal of the cylinder.

3Detach the leads from the terminals on the

reservoir cap, then unscrew and remove the

cap and float.

4Unscrew the pipe unions and prise the

pipes carefully away from the master cylinder.

Cap the open ends of the pipes and catch any

fluid leaking from the master cylinder in a

suitable container.

5Unscrew the mounting nuts and withdraw

the master cylinder from the bulkhead or from

the servo unit.

6Clean away all external dirt and tip out the

fluid from the reservoir and cylinder body.

7The fluid reservoirs need not be removed

from the master cylinder but if they are, renew

the rubber sealing collars when refitting.

8Grip the master cylinder in a vice, then

unscrew and remove the end plug. Catch the

coil spring.

9Using a thin rod, apply pressure to the end

of the primary piston then unscrew and

remove the two stop bolts and sealing

washers.

10The internal piston assemblies with seals

and springs can now be pushed out of the

cylinder body. Keep all the components in

Braking system 8•5

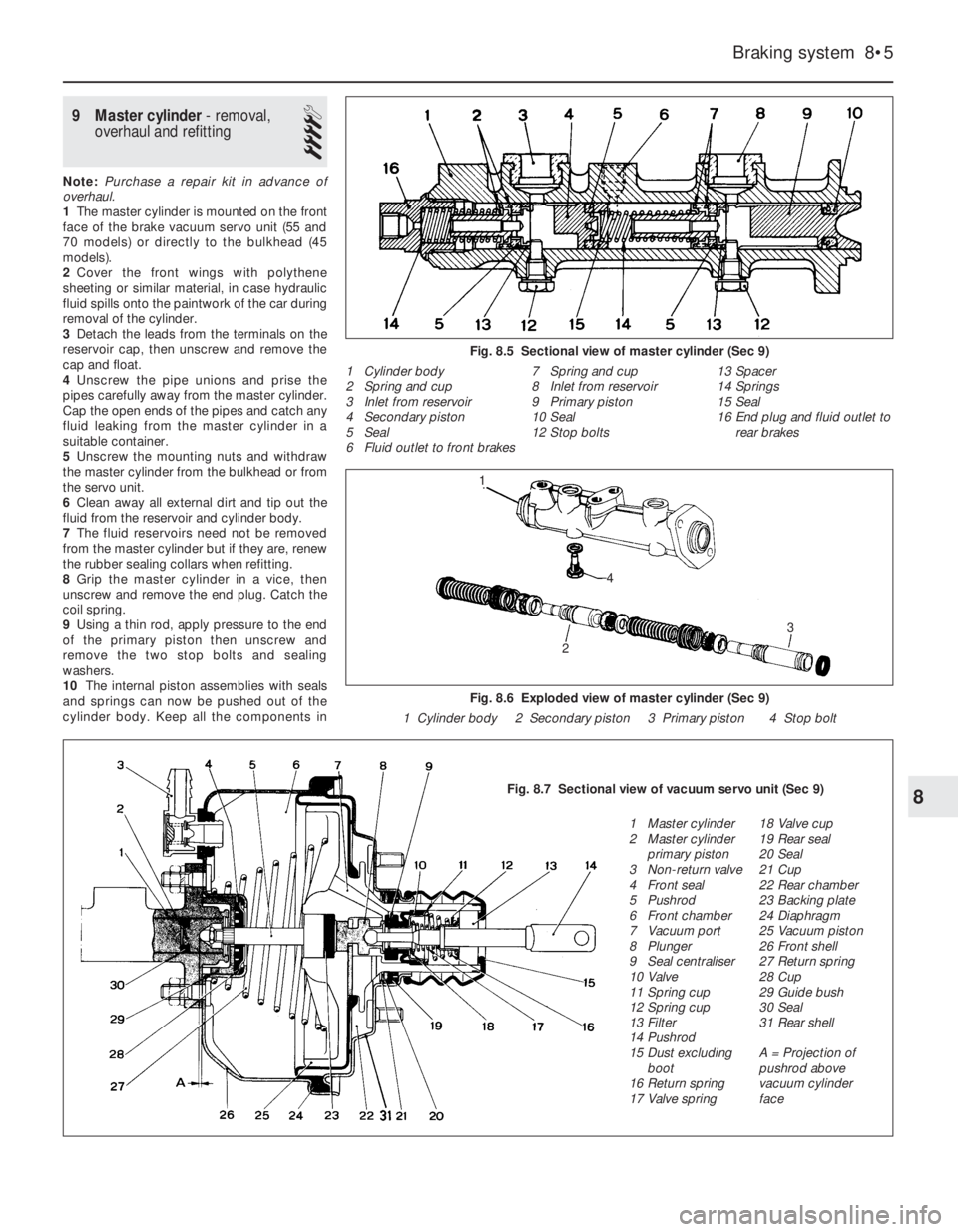

Fig. 8.5 Sectional view of master cylinder (Sec 9)

1 Cylinder body

2 Spring and cup

3 Inlet from reservoir

4 Secondary piston

5 Seal

6 Fluid outlet to front brakes7 Spring and cup

8 Inlet from reservoir

9 Primary piston

10 Seal

12 Stop bolts13 Spacer

14 Springs

15 Seal

16 End plug and fluid outlet to

rear brakes

Fig. 8.6 Exploded view of master cylinder (Sec 9)

1 Cylinder body 2 Secondary piston 3 Primary piston 4 Stop bolt

8Fig. 8.7 Sectional view of vacuum servo unit (Sec 9)

1 Master cylinder

2 Master cylinder

primary piston

3 Non-return valve

4 Front seal

5 Pushrod

6 Front chamber

7 Vacuum port

8 Plunger

9 Seal centraliser

10 Valve

11 Spring cup

12 Spring cup

13 Filter

14 Pushrod

15 Dust excluding

boot

16 Return spring

17 Valve spring18 Valve cup

19 Rear seal

20 Seal

21 Cup

22 Rear chamber

23 Backing plate

24 Diaphragm

25 Vacuum piston

26 Front shell

27 Return spring

28 Cup

29 Guide bush

30 Seal

31 Rear shell

A = Projection of

pushrod above

vacuum cylinder

face

2

3

1

4

Page 86 of 303

their originally fitted sequence and note in

which direction the seal lips are located.

11Inspect the surfaces of the piston and

cylinder bore. If scoring, corrosion or

metal-to-metal rubbing areas are evident,

renew the master cylinder complete.

12If the components are in good condition,

discard the oil seals and manipulate the new

ones into position, using the fingers only.

13Refit by reversing the removal operations;

apply pressure to the piston ends so that the

stop bolts can be fitted, then tighten the end

plug. Make sure that the grooves in the

pistons engage in the stop bolts.

14Before refitting the master cylinder to the

servo, measure the projection of the servo

piston pushrod. When the master cylinder is

fitted, there must be a clearance (see A in

Fig. 8.7) between the end of the pushrod and

the primary piston end face of between 0.825

and 1.025 mm (0.03 and 0.04 in). A depth

gauge will be required for these

measurements, the reference point being the

mating surfaces of the master cylinder and the

vacuum servo.

15Alter the adjusting screw on the servo as

necessary and lock it by applying locking fluid

to the threads on completion.16Bolt the master cylinder to the vacuum

servo or bulkhead, then reconnect the

pipelines and reservoir cap leads.

17Bleed the complete hydraulic system, as

described in Section 12.

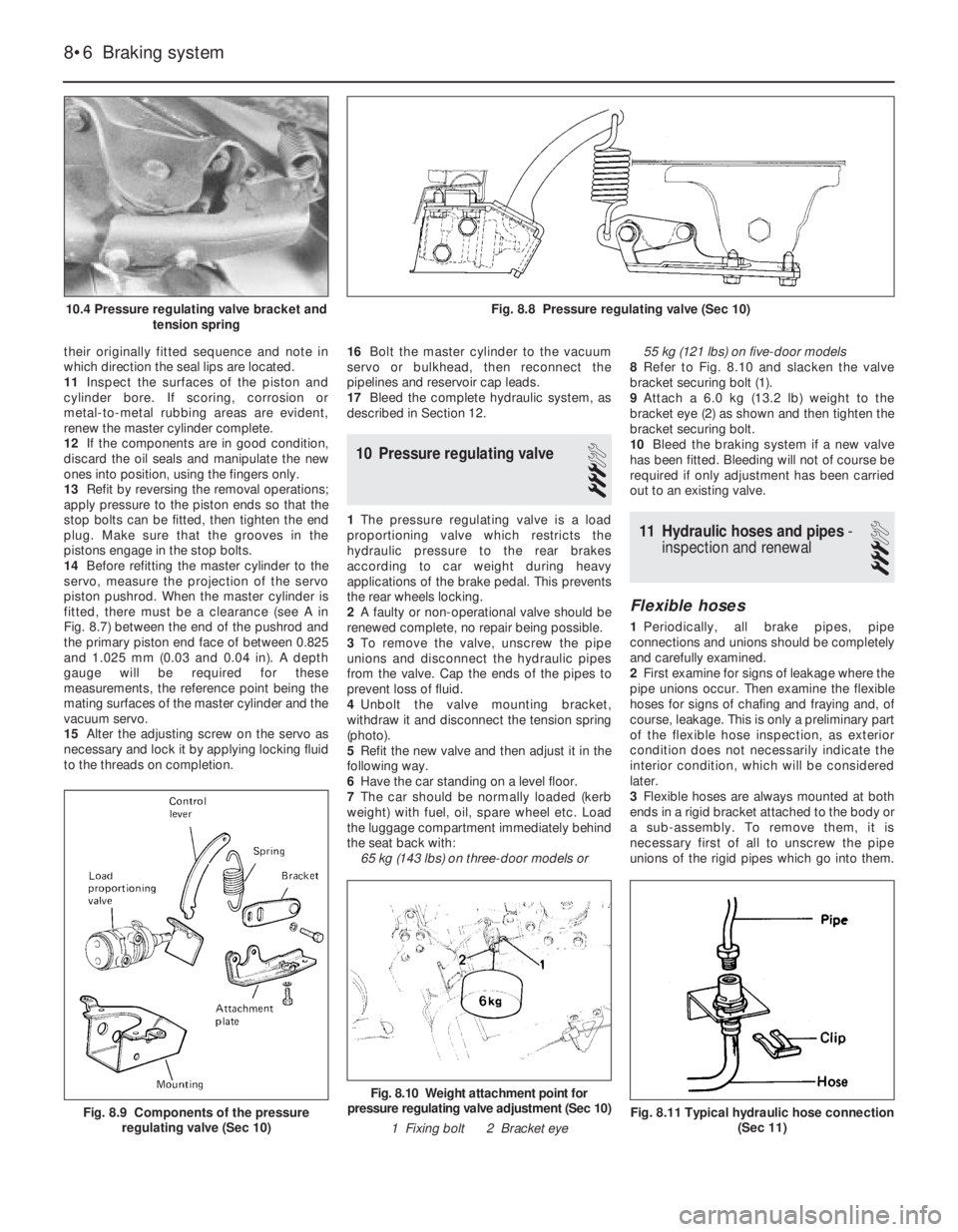

10 Pressure regulating valve

3

1The pressure regulating valve is a load

proportioning valve which restricts the

hydraulic pressure to the rear brakes

according to car weight during heavy

applications of the brake pedal. This prevents

the rear wheels locking.

2A faulty or non-operational valve should be

renewed complete, no repair being possible.

3To remove the valve, unscrew the pipe

unions and disconnect the hydraulic pipes

from the valve. Cap the ends of the pipes to

prevent loss of fluid.

4Unbolt the valve mounting bracket,

withdraw it and disconnect the tension spring

(photo).

5Refit the new valve and then adjust it in the

following way.

6Have the car standing on a level floor.

7The car should be normally loaded (kerb

weight) with fuel, oil, spare wheel etc. Load

the luggage compartment immediately behind

the seat back with:

65 kg (143 lbs) on three-door models or 55 kg (121 lbs) on five-door models

8Refer to Fig. 8.10 and slacken the valve

bracket securing bolt (1).

9Attach a 6.0 kg (13.2 lb) weight to the

bracket eye (2) as shown and then tighten the

bracket securing bolt.

10Bleed the braking system if a new valve

has been fitted. Bleeding will not of course be

required if only adjustment has been carried

out to an existing valve.11 Hydraulic hoses and pipes-

inspection and renewal

3

Flexible hoses

1Periodically, all brake pipes, pipe

connections and unions should be completely

and carefully examined.

2First examine for signs of leakage where the

pipe unions occur. Then examine the flexible

hoses for signs of chafing and fraying and, of

course, leakage. This is only a preliminary part

of the flexible hose inspection, as exterior

condition does not necessarily indicate the

interior condition, which will be considered

later.

3Flexible hoses are always mounted at both

ends in a rigid bracket attached to the body or

a sub-assembly. To remove them, it is

necessary first of all to unscrew the pipe

unions of the rigid pipes which go into them.

8•6 Braking system

Fig. 8.11 Typical hydraulic hose connection

(Sec 11)

Fig. 8.10 Weight attachment point for

pressure regulating valve adjustment (Sec 10)

1 Fixing bolt 2 Bracket eye

Fig. 8.9 Components of the pressure

regulating valve (Sec 10)

Fig. 8.8 Pressure regulating valve (Sec 10)10.4 Pressure regulating valve bracket and

tension spring

Page 87 of 303

The hose ends can then be unclipped from

the brackets. The mounting brackets,

particularly on the body frame, are not very

heavy gauge and care must be taken not to

wrench them off (photo).

4With the flexible hose removed, examine

the internal bore. If it is blown through first, it

should be possible to see through it. Any

specks of rubber which come out, or signs of

restriction in the bore, mean that the inner

lining is breaking up and the pipe must be

renewed.

5When refitting the flexible hoses check they

cannot be under tension, or rub, when the

wheels are at the full range of suspension or

steering movement.

6Bleed the system (see Section 12) on

completion.

Rigid pipes

7Inspect the condition of the braking system

rigid pipelines at frequent intervals. They must

be cleaned off and examined for any signs of

dents (or other percussive damage) and rust

and corrosion. Rust and corrosion should be

scraped off and, if the depth of pitting in the

pipes is significant, they will need renewal.

This is particularly likely in those areas

underneath the car body and along the rear

axle where the pipes are exposed to the full

force of road and weather conditions.

8Rigid pipe removal is usually straight-

forward. The unions at each end are undone,

the pipe and union pulled out, and the centre

sections of the pipe removed from the body

clips where necessary. Underneath the car,

exposed unions can sometimes be very tight.

As one can use only an open-ended spanner

and the unions are not large, burring of the

flats is not uncommon when attempting to

undo them. For this reason, a self-locking grip

wrench (Mole) is often the only way to remove

a stubborn union.

9Rigid pipes which need renewal can usually

be purchased at any garage where they have

the pipe, unions and special tools to make

them up. All they need to know is the total

length of the pipe, the type of flare used at

each end with the union, and the length and

thread of the union. Fiat is metric, remember.

10Fitting your new pipes is a straightforwardreversal of the removal procedure. If the rigid

pipes have been made up, it is best to get all

the sets bends in them before trying to fit

them. Also, if there are any acute bends ask

your supplier to put these in for you on a tube

bender. Otherwise, you may kink the pipe and

thereby restrict the bore area and fluid flow.

11Bleed the system (see Section 12) on

completion.

12 Hydraulic system-

bleeding

3

1If the master cylinder or the pressure

regulating valve has been disconnected and

reconnected then the complete system (both

circuits) must be bled.

2If a component of one circuit has been

disturbed then only that particular circuit need

be bled.

3The two disc brakes comprise the front

circuit and the two rear brakes the rear circuit.

4Unless the pressure bleeding method is

being used, do not forget to keep the fluid

level in the master cylinder reservoir topped

up to prevent air from being drawn into the

system which would make any work done

worthless.

5Before commencing operations, check that

all system hoses and pipes are in good

condition with all unions tight and free from

leaks.

6Take great care not to allow hydraulic fluid

to come into contact with the vehicle

paintwork as it is an effective paint stripper.

Wash off any spilled fluid immediately with

cold water.

7As the system on 55 and 70 models

incorporates a vacuum servo, destroy the

vacuum by giving several applications of the

brake pedal in quick succession. The car

should be loaded with enough weight to

actuate the pressure regulating valve before

bleeding commences.

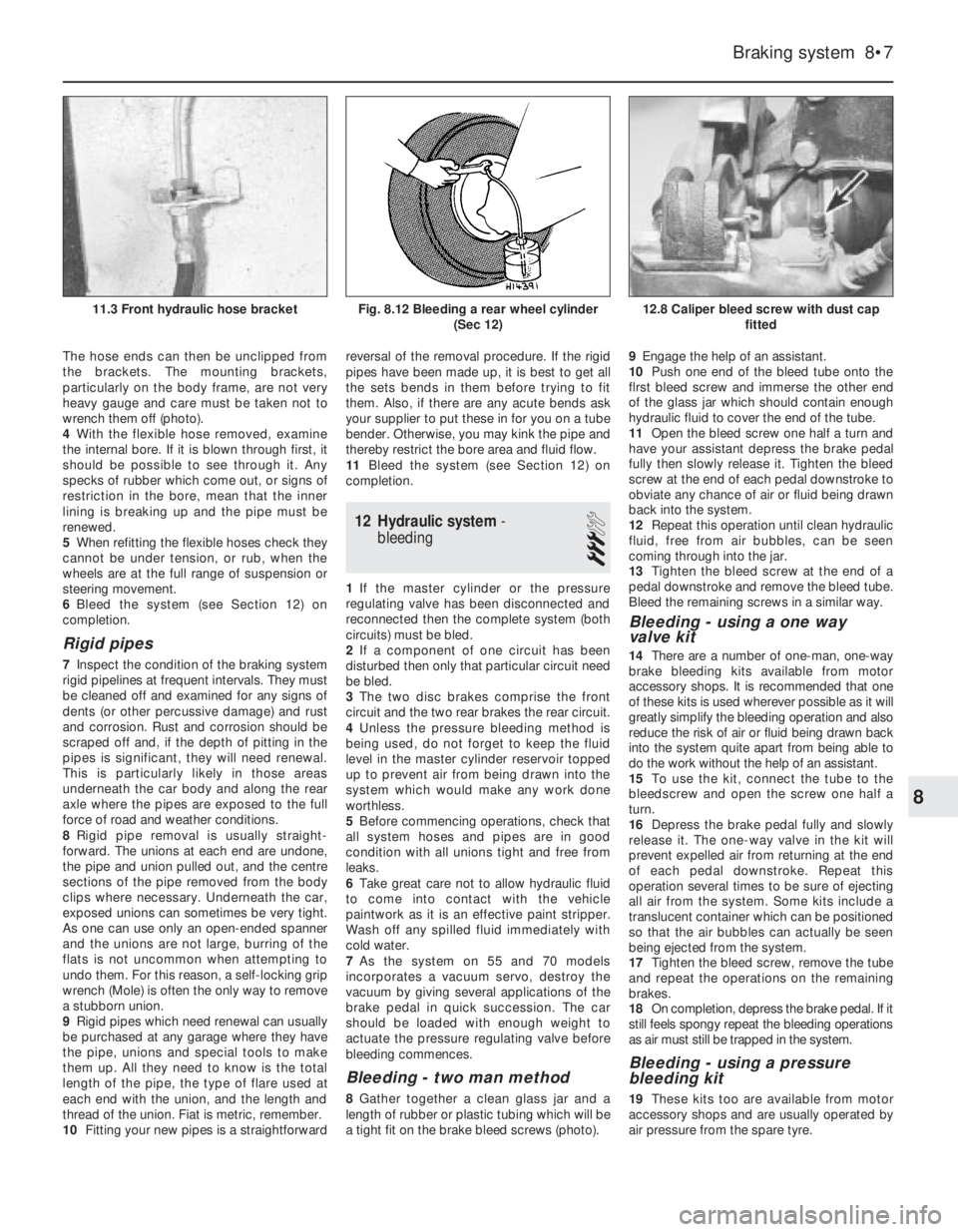

Bleeding - two man method

8Gather together a clean glass jar and a

length of rubber or plastic tubing which will be

a tight fit on the brake bleed screws (photo).9Engage the help of an assistant.

10Push one end of the bleed tube onto the

flrst bleed screw and immerse the other end

of the glass jar which should contain enough

hydraulic fluid to cover the end of the tube.

11Open the bleed screw one half a turn and

have your assistant depress the brake pedal

fully then slowly release it. Tighten the bleed

screw at the end of each pedal downstroke to

obviate any chance of air or fluid being drawn

back into the system.

12Repeat this operation until clean hydraulic

fluid, free from air bubbles, can be seen

coming through into the jar.

13Tighten the bleed screw at the end of a

pedal downstroke and remove the bleed tube.

Bleed the remaining screws in a similar way.

Bleeding - using a one way

valve kit

14There are a number of one-man, one-way

brake bleeding kits available from motor

accessory shops. It is recommended that one

of these kits is used wherever possible as it will

greatly simplify the bleeding operation and also

reduce the risk of air or fluid being drawn back

into the system quite apart from being able to

do the work without the help of an assistant.

15To use the kit, connect the tube to the

bleedscrew and open the screw one half a

turn.

16Depress the brake pedal fully and slowly

release it. The one-way valve in the kit will

prevent expelled air from returning at the end

of each pedal downstroke. Repeat this

operation several times to be sure of ejecting

all air from the system. Some kits include a

translucent container which can be positioned

so that the air bubbles can actually be seen

being ejected from the system.

17Tighten the bleed screw, remove the tube

and repeat the operations on the remaining

brakes.

18On completion, depress the brake pedal. If it

still feels spongy repeat the bleeding operations

as air must still be trapped in the system.

Bleeding - using a pressure

bleeding kit

19These kits too are available from motor

accessory shops and are usually operated by

air pressure from the spare tyre.

Braking system 8•7

12.8 Caliper bleed screw with dust cap

fittedFig. 8.12 Bleeding a rear wheel cylinder

(Sec 12)11.3 Front hydraulic hose bracket

8

Page 88 of 303

20By connecting a pressurised container to

the master cylinder fluid reservoir, bleeding is

then carried out by simply opening each bleed

screw in turn and allowing the fluid to run out,

rather like turning on a tap, until no air is

visible in the expelled fluid.

21By using this method, the large reserve of

hydraulic fluid provides a safeguard against

air being drawn into the master cylinder

during bleeding which often occurs if the fluid

level in the reservoir is not maintained.

22Pressure bleeding is particularly effective

when bleeding “difficult” systems or when

bleeding the complete system at time of

routine fluid renewal.

All methods

23When bleeding is completed, check and

top up the fluid level in the master cylinder

reservoir.

24Check the feel of the brake pedal. If it

feels at all spongy, air must still be present in

the system and further bleeding is indicated.

Failure to bleed satisfactorily after a

reasonable period of the bleeding operation,

may be due to worn master cylinder seals.

25Discard brake fluid which has been

expelled. lt is almost certain to be

contaminated with moisture, air and dirt

making it unsuitable for further use. Clean

fluid should always be stored in an airtight

container as it absorbs moisture readily

(hygroscopic) which lowers its boiling point

and could affect braking performance under

severe conditions.

13 Vacuum servo unit-

description

A vacuum servo unit is fitted into the brake

hydraulic circuit on 55 and 70 models in series

with the master cylinder, to provide assistance

to the driver when the brake pedal is

depressed. This reduces the effort required by

the driver to operate the brakes under all

braking conditions.

The unit operates by vacuum obtained from

the induction manifold and comprises basically

a booster diaphragm and non-return valve. The

servo unit and hydraulic master cylinder are

connected together so that the servo unit

piston rod acts as the master cylinder pushrod.

The driver’s braking effort is transmitted

through another pushrod to the servo unit

piston and its built-in control system. The servo

unit piston does not fit tightly into the cylinder,

but has a strong diaphragm to keep its edges

in constant contact with the cylinder wall, so

assuring an air tight seal between the two

parts. The forward chamber is held under

vacuum conditions created in the inlet manifold

of the engine and, during periods when the

brake pedal is not in use, the controls open a

passage to the rear chamber so placing it

under vacuum conditions as well. When the

brake pedal is depressed, the vacuum passageto the rear chamber is cut off and the chamber

opened to atmospheric pressure. The

consequent rush of air pushes the servo piston

forward in the vacuum chamber and operates

the main pushrod to the master cylinder.

The controls are designed so that

assistance is given under all conditions and,

when the brakes are not required, vacuum in

the rear chamber is established when the

brake pedal is released. All air from the

atmosphere entering the rear chamber is

passed through a small air filter.

Under normal operating conditions, the

vacuum servo unit is very reliable and does

not require overhaul except at very high

mileages. In this case, it is far better to obtain

a service exchange unit, rather than repair the

original unit.

It is emphasised that the servo unit assists

in reducing the braking effort required at the

foot pedal and in the event of its failure, the

hydraulic braking system is in no way affected

except that the need for higher pressures will

be noticed.

14 Vacuum servo unit-

servicing and testing

1Regularly, check that the vacuum hose

which runs between the servo unit and the

inlet manifold is in good condition and is a

tight fit at both ends.

2If broken or badly clogged, renew the air

filter which is located around the brake pedal

push rod. Access to this is obtained by

disconnecting the pushrod from the

cross-shaft or pedal arm, withdrawing the

pushrod, dust excluding boot and end cap.

3If the new filter is cut diagonally from its

centre hole, future renewal can be carried out

without the need for disconnection of the

pushrod.

4If the efficiency of the servo unit is suspect,

it can be checked out in the following way.

5Run the engine, then switch off the ignition.

Depress the footbrake pedal; the distinctive

in-rush of air into the servo should be clearly

heard. It should be possible to repeat this

operation several times before the vacuum in

the system is exhausted.

6Start the engine and have an assistant

apply the footbrake pedal and hold it down.

Disconnect the vacuuum hose from the servo.

There should not be any in-rush of air into the

servo through the connecting stub. lf there is,

the servo diaphragm is probably faulty. During

this test, expect the engine to idle roughly,

unless the open end of the hose to the inlet

manifold is plugged. Reconnect the hose.

7With the engine off, depress the brake

pedal fully. Start the engine with the brake

pedal still depressed; the pedal should be felt

to go down fractionally.

8If the results of these tests are not

satisfactory, remove the unit and fit a new one

as described in the next Section.

15 Vacuum servo unit-

removal and refitting

3

1Syphon as much fluid as possible out of the

master cylinder reservolr.

2Disconnect electrical leads from the

terminals in the reservoir cap then uncouple

the rigid pipelines from the master cylinder

body. Be prepared to catch leaking fluid and

plug the open ends of the pipelines.

3The master cylinder can be unbolted now

from the servo unit, or detached later when

the complete assembly is withdrawn.

4Working inside the car, disconnect the

servo pushrod from the pedal then remove the

servo mounting nuts.

5Withdraw the servo assembly into the

engine compartment, then remove it to the

bench. lf the master cylinder is still attached,

cover the wings with protective sheeting, in

case brake fluid is spilled during removal.

6Refitting is a reversal of the removal

process, but adjust the pushrod clearance as

described in Section 9. On completion of

refitting, bleed the complete hydraulic system

as described in Section 12. Note: Where the

help of an assistant is available, the servo

pushrod need not be disconnected from the

pedal. The rod is a sliding fit in the servo and

the servo can be simply pulled off the rod.

Refitting without having disconnected the rod

from the pedal can be difficult unless the help

of an assistant is available.

16 Handbrake- adjustment

1

Adjustment is normally automatic, by the

movement of the rear brake shoes on their

automatic adjusters.

However, owing to cable stretch,

supplementary adjustment is occasionally

required at the control lever adjuster nut. The

need for this adjustment is usually indicated

by excessive movement of the control lever

when fully applied.

1The rear brakes should be fully applied

when the handbrake control lever has been

pulled over four or five notches.

2If adjustment is required, release the

8•8 Braking system

16.2 Handbrake adjuster nuts

Page 90 of 303

9System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 negative earth, battery alternator and pre-engaged starter

Battery

Except 70S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Ah

70S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 Ah

Alternator

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli, Valeo or Bosch 45A, 55A or 65A, with integral voltage

regulator

Nominal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 V

Minimum brush (wear) length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 mm (0.236 in)

Starter motor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Marelli, Bosch or Femsa pre-engaged

Nominal power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 kW or 1.0 kW

Armature shaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1 to 0.5 mm (0.0039 to 0.0197 in)

Minimum brush (wear) length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.39 in)

Wiper blades

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-4801 (19 in) or X-4503 (18 in)

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion X-3303

Chapter 9 Electrical system

For modifications, and information applicable to later models, see Supplement at end of manual

Alternator - maintenance and precautions . . . . . . . . . . . . . . . . . . . . 3

Alternator - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Battery - inspection, charging, removal and refitting . . . . . . . . . . . . 2

Central door locking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Check control (warning module) system . . . . . . . . . . . . . . . . . . . . . . 34

Cigar lighter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Clocks - setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Courtesy lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Economy gauge (Econometer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Electrically-operated front door windows . . . . . . . . . . . . . . . . . . . . . 31

Exterior lamps - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fault finding - electrical system . . . . . . . . . . . . . . See end of Chapter

Fuses and relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Headlamp - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Headlamp beam - alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Headlamp bulb - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Heated tailgate window - precautions and repair . . . . . . . . . . . . . . . 29Horns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Instrument panel - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Instrument panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 21

Interior lamps - bulb renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Radio/cassette - fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rocker and push-button switches . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Speedometer drive cable - renewal . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starter motor - description and testing . . . . . . . . . . . . . . . . . . . . . . . 7

Starter motor - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering column combination switch . . . . . . . . . . . . . . . . . . . . . . . . 11

Tailgate contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tailgate wiper blade and arm - removal and refitting . . . . . . . . . . . . 26

Tailgate wiper motor - removal and refitting . . . . . . . . . . . . . . . . . . . 27

Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Washer system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Windscreen wiper blade and arm - removal and refitting . . . . . . . . . 24

Windscreen wiper motor - removal and refitting . . . . . . . . . . . . . . . . 25

9•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 91 of 303

1 General description

The electrical system is of 12 volt negative

earth type and employs a belt-driven

alternator and a pre-engaged type starter

motor.

The models in the range are all adequately

equipped with electrical accessories, while SX

versions also have power windows and

centralised door locking plus a check control

system (Section 34).

2 Battery- inspection, charging,

removal and refitting

2

1The battery is of maintenance-free type and

under normal circumstances, no topping up

will be required, but regularly check that the

electrolyte level is between the minimum and

maximum lines on the translucent battery

casing.

2If the electrolyte level does drop below theminimum line, suspect a leak in the battery

casing or that the alternator is overcharging. If

the latter is the case, rectify the alternator fault

and then prise out the two rectangular plugs

from the top of the battery and top up with

distilled or purified water.

3Always keep the battery terminals clean

and smear them with petroleum jelly to

prevent corrosion.

4The battery will normally be kept fully

charged by the alternator, but it is possible for

the battery to become discharged if the daily

mileage is very low with much use being

made of the starter and electrical accessories.

5When the battery begins to deteriorate with

age it may also require a boost from a mains

charger.

6Disconnect both battery leads before

connecting the mains charger. 7To remove the battery from the car, first

disconnect the leads from the battery

terminals (earth first) and then unscrew the

securing clamp from the casing projection at

the base of the casing (photo).

8Lift the battery from its mounting platform.

Refitting is a reversal of removal. Reconnect

the earth cable last.

Fuses

Circuit protected Fuse rating (A)

1 Stop lamps, direction indicator lamps, instrument panel warning

lamps, tachometer economy gauge, check control system . . . . . . 10

2 Windscreen wiper and washer, rear screen wiper/washer, check

system panel illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 Left front parking, right rear tail lamp, cigar lighter illumination,

heater control and clock, digital clock illumination . . . . . . . . . . . . . 7.5

4 Right front parking lamp and left rear tail lamp, instrument panel

illumination and rear number plate lamp . . . . . . . . . . . . . . . . . . . . . 7.5

5 Left-hand dipped headlamp, rear foglamps . . . . . . . . . . . . . . . . . . 10

6 Right-hand dipped headlamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Left-hand headlamp (main beam) . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Right-hand headlamp (main beam) . . . . . . . . . . . . . . . . . . . . . . . . . 10

9 Engine cooling fan and horn (Comfort) . . . . . . . . . . . . . . . . . . . . . . 25

10 Heater booster fan, digital clock map reading lamp . . . . . . . . . . . . 20

11 Heated tailgate glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

12 Courtesy lamps, cigar lighter, radio power feed, disc pad

sensors, economy gauge (ES models) . . . . . . . . . . . . . . . . . . . . . . 10

13 Hazard warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

14 Spare (Comfort), Horn (Super) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

BulbsWattage

Headlamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40/45 or Halogen H4 60/55

Front parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Side repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Reversing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear foglamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Direction indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rear number plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Courtesy lamp (roof) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Courtesy lamp (pillar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warning and indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Wedge base

Torque wrench settingsNm lbf ft

Alternator mounting and adjustment nuts . . . . . . . . . . . . . . . . . . . . . . . 50 87

Starter motor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 35

9•2 Electrical system

2.7 Battery clamp

If battery terminal corrosion

has occurred, it may be

neutralised by applying

sodium bicarbonate or

household ammonia.

Page 92 of 303

3 Alternator-

maintenance and precautions

1

To avoid damage to the alternator, the

following precautions should be observed.

1Disconnect the leads from the battery

before connecting a mains charger to the

battery terminals.

2Never stop the engine by pulling off one of

the battery leads.

3Disconnect the battery if electric welding is

to be carried out on the vehicle.

4If using booster cables from another battery

to start the car, make sure that they are

connected positive to positive and negative to

negative.

5Maintenance consists of keeping the

outside of the alternator clean, the electrical

connections secure and the drivebelt correctly

tensioned, see Chapter 2, Section 8.

4 Alternator-

removal and refitting

1

Note: Depending on the model, access to the

alternator from above may be poor in which

case it will be necessary to work from the

underside of the vehicle, through the

right-hand wheel arch (after removing the

roadwheel and the lower undershield). Refer

to Chapter 13 for details.

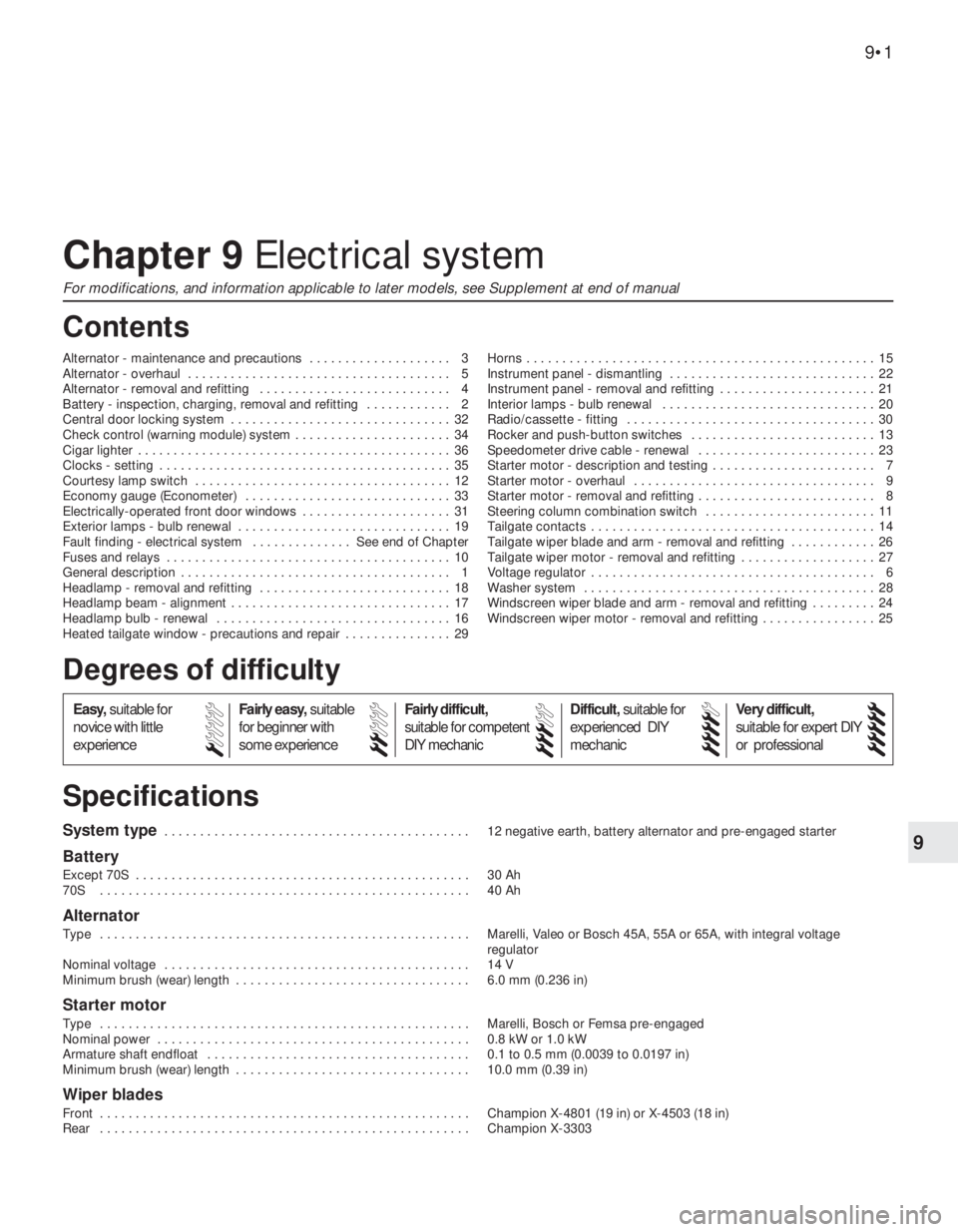

1Disconnect the leads from the rear of the

alternator.2Release the mounting and adjuster link nuts

and push the alternator as far as it will go in

towards the engine (photos).

3Slip the drivebelt from the pulley.

4Remove the mounting and adjuster bolts

and lift the alternator from the brackets on the

engine. Remove downwards on 1116 cc and

1301 cc models.

5Refitting is a reversal of removal, tension

the drivebelt as described in Chapter 2,

Section 8.

5 Alternator- overhaul

3

1Overhaul of the alternator should be limited

to renewal of the brushes. If the unit has

covered a high mileage, it will be found moreeconomical to exchange it for a new or

factory-reconditioned one, rather than renew

worn components on the original unit.

Brush renewal

(Marelli alternator)

2Unscrew the nuts and take off the rear cover.

3Unscrew the two small bolts and withdraw

the brush holder (photos).

4Fit the new brush holder which is supplied

complete with brushes, by reversing the

removal operations.

Brush renewal

(Bosch alternator)

5Where applicable, remove the radio

suppression condenser (capacitor) from the

rear end frame (one screw and washer, and a

plug-in connection).

6Undo the two screws which retain the brush

holder to the rear frame of the alternator, then

Electrical system 9•3

5.3A Alternator brush holder bolt4.2B Alternator adjuster bolt4.2A Alternator mounting

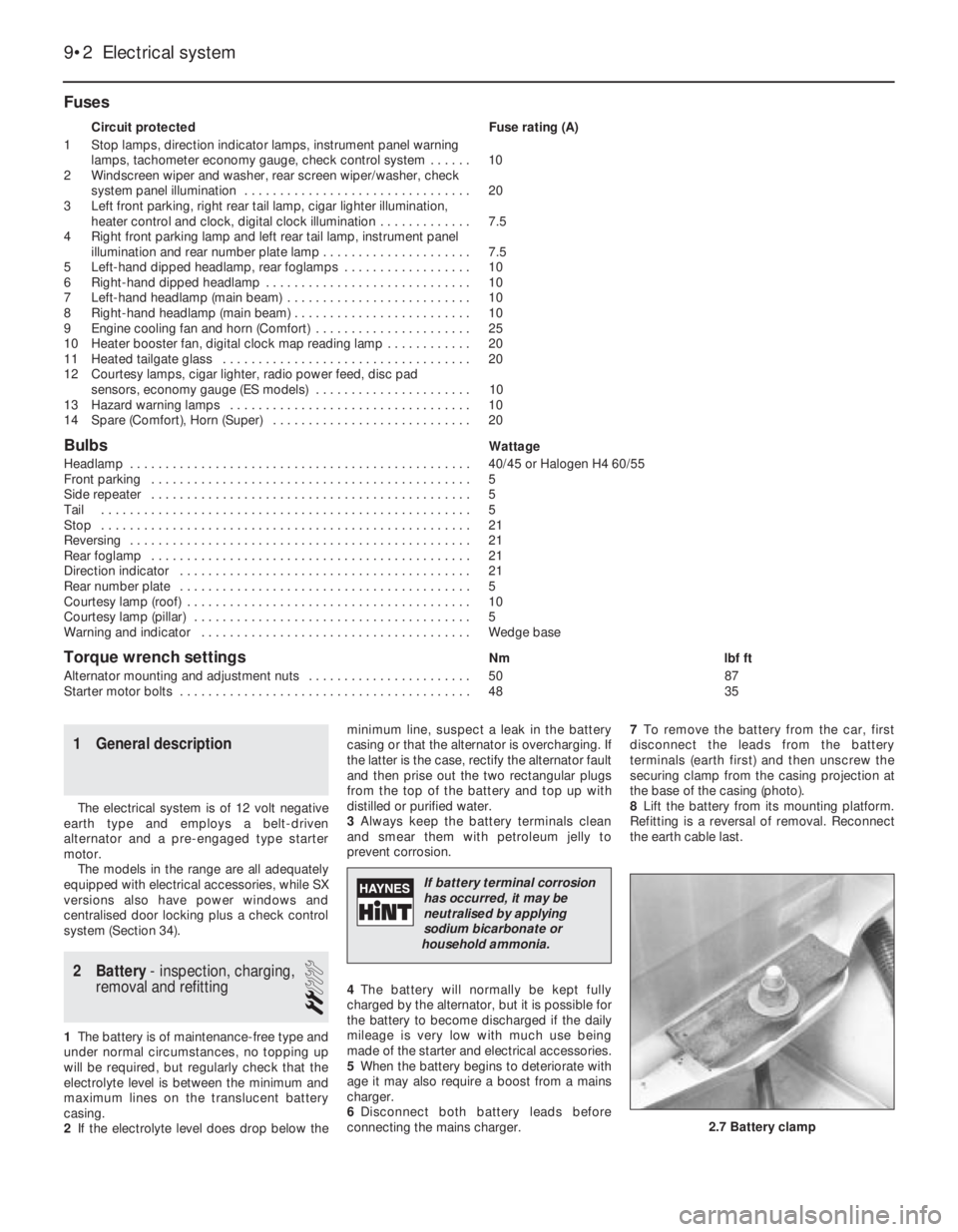

Fig. 9.1 Exploded view of typical alternator (Sec 5)

1 Pulley

2 Fan

3 Bolts

4 Washers

5 Drive-end bracket

6 Stator windings

7 Plate screw

8 Diode plate

(rectifier pack)9 Body

10 Brush

11 Spring

12 Brush holder

13 Condenser

14 Screws and

washers

15 Screws and

washers16 Screws and

washers

17 Plug socket

18 Suppressor

19 Shaft nut

20 Spring washer

21 Thrust ring

22 Bearing

23 Retainer plate24 Thrust ring

25 Spring washer

26 Screw and washer

27 Key

28 Rotor

29 Bearing

30 Backing washer

31 Shield (where

applicable)

5.3B Removing alternator brush holder

9

Page 93 of 303

ease the holder out of the alternator. Inspect

the brushes and if worn below the specified

minimum length, they must be renewed.

7Disconnect the brush leads by unsoldering

or carefully cutting them.

8When soldering the new brush leads, do

not allow solder to run down them or their

flexibility will be ruined.

9When inspecting or renewing brushes,

check the surface of the slip rings. Clean them

with solvent or if they are very discoloured,

use very fine glasspaper.

6 Voltage regulator

1This is of integral type and is part of the

brushholder assembly.

2No provision is made for adjustment or

overhaul.

7 Starter motor-

description and testing

2

1The starter motor may be one of two

different makes. Both are of pre-engaged

type.

2This type of starter motor incorporates a

solenoid mounted on top of the starter motor

body. When the ignition switch is operated,

the solenoid moves the starter drive pinion,

through the medium of the shift lever, into

engagement with the flywheel starter ring

gear. As the solenoid reaches the end of its

stroke, and with the pinion by now partially

engaged with the flywheel ring gear, the main

fixed and moving contacts close and engage

the starter motor to rotate the engine.

3This pre-engagement of the starter drive

does much to reduce the wear on the flywheel

ring gear associated with inertia type starter

motors.

4If the starter fails, some fault-finding can be

done with it still on the car. Check the ignition

warning light comes on, and does not go out

when the starter is switched on. If it goes out,

the fault is probably in the battery. If it stays

bright, get an assistant to work the switch,whilst listening to the starter. Listen to find out

if the solenoid clicks into position. If it does

not, pull off the solenoid wire, and check it

with a test bulb. If the wire is live when the key

is turned, but the solenoid does not move,

take off the starter and remove it to the bench

for overhaul.

8 Starter motor-

removal and refitting

1

1Disconnect the battery negative lead.

2Disconnect the lead from the starter motor

(photo).

3Unscrew the fixing bolts and withdraw the

starter motor, downwards on 1116 cc and

1301 cc models (photo).

4Refitting is a reversal of the removal

procedure.

9 Starter motor- overhaul

3

1As with the alternator, the operations

should normally be limited to renewal of the

brushes. If the unit has covered a high

mileage it will usually be more economical to

purchase a new or factory-reconditioned one

rather than renew several components of the

original unit.

2Owing to the possibility that a fault can

develop in the starter motor solenoid or drive

assembly, full dismantling procedures are

given later in this Section.

Brush - renewal

3Slide off the cover band.

4Using a hooked piece of wire, pull up the

springs so that the brushes can be withdrawn

and their lengths checked for wear. If they

have worn below the specified minimum

length, renew them by extracting the brush

lead connecting screws (photo).

Solenoid

5Disconnect the field connecting wire from

the solenoid.

6Unscrew the bolts which hold the solenoid

to the end-frame.

7Unscrew the yoke tie-rod nuts.

9•4 Electrical system

9.4 Starter motor brush partly withdrawn

8.2 Starter motor connections8.3 Removing starter motor

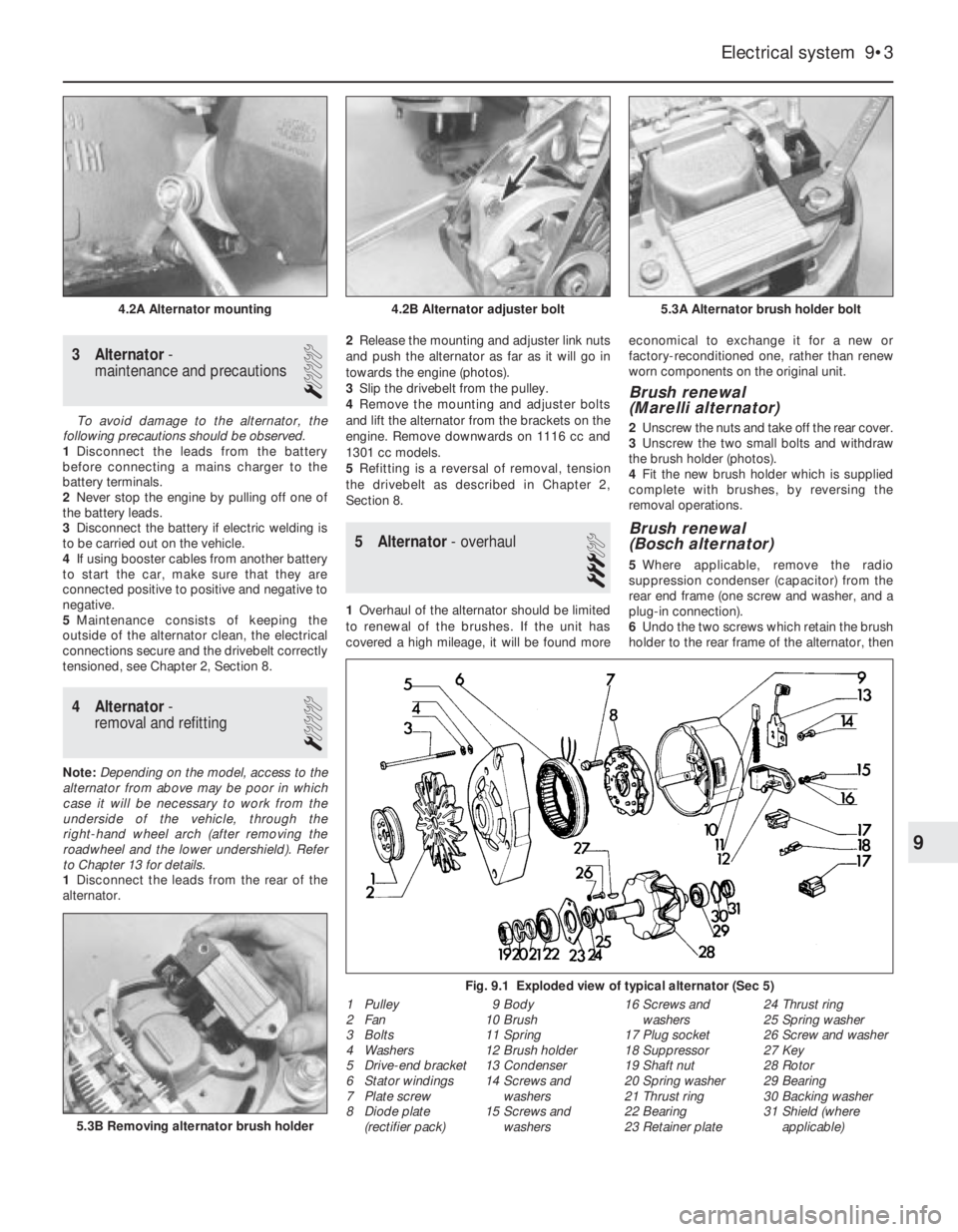

Fig. 9.2 Exploded view of typical starter motor (Sec 9)

1 Armature

2 Drive pinion/clutch3 Drive end bracket

4 Shift lever5 Solenoid

6 Brush endplate7 Brush

8 Field windings

Gripping the brush leads with

a pair of pliers to act as a

heat sink will prevent heat

transfer to the internal

components of the alternator.

Page 94 of 303

8Withdraw the solenoid and yoke off the

armature and from the drive end bracket.

Note the steel and fibre washers and the

shims on the armature shaft (photo).

9Extract the split pin and tap out the

engagement lever pivot pin.

10Pull the rubber packing piece from the

drive end bracket.

11Withdraw the armature with solenoid

plunger, coil spring and engagement lever.

12Clean the commutator with a fuel soaked

rag or very fine glass paper. Do not undercut

the mica insulators on the commutator.

Drive

13To remove the drive assembly from the

armature shaft, use a piece of tubing to tap

the stop collar down the shaft to expose the

snap ring. Remove the snap ring and stop

collar and slide the drive assembly from the

shaft.

14Refitting is a reversal of removal, but use a

new snap ring to secure the drive to the

armature shaft.

10 Fuses and relays

1

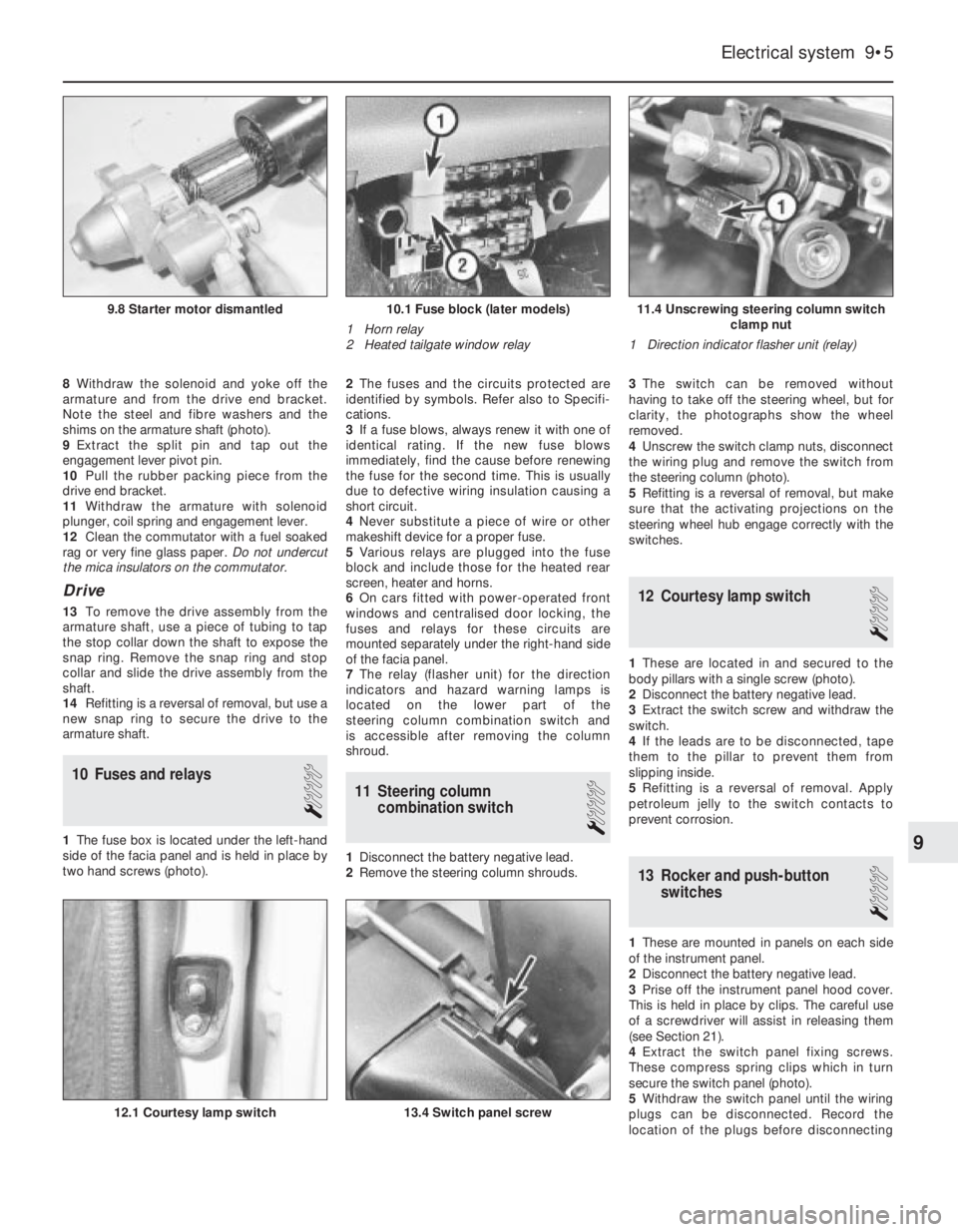

1The fuse box is located under the left-hand

side of the facia panel and is held in place by

two hand screws (photo).2The fuses and the circuits protected are

identified by symbols. Refer also to Specifi-

cations.

3If a fuse blows, always renew it with one of

identical rating. If the new fuse blows

immediately, find the cause before renewing

the fuse for the second time. This is usually

due to defective wiring insulation causing a

short circuit.

4Never substitute a piece of wire or other

makeshift device for a proper fuse.

5Various relays are plugged into the fuse

block and include those for the heated rear

screen, heater and horns.

6On cars fitted with power-operated front

windows and centralised door locking, the

fuses and relays for these circuits are

mounted separately under the right-hand side

of the facia panel.

7The relay (flasher unit) for the direction

indicators and hazard warning lamps is

located on the lower part of the

steering column combination switch and

is accessible after removing the column

shroud.

11 Steering column

combination switch

1

1Disconnect the battery negative lead.

2Remove the steering column shrouds. 3The switch can be removed without

having to take off the steering wheel, but for

clarity, the photographs show the wheel

removed.

4Unscrew the switch clamp nuts, disconnect

the wiring plug and remove the switch from

the steering column (photo).

5Refitting is a reversal of removal, but make

sure that the activating projections on the

steering wheel hub engage correctly with the

switches.

12 Courtesy lamp switch

1

1These are located in and secured to the

body pillars with a single screw (photo).

2Disconnect the battery negative lead.

3Extract the switch screw and withdraw the

switch.

4If the leads are to be disconnected, tape

them to the pillar to prevent them from

slipping inside.

5Refitting is a reversal of removal. Apply

petroleum jelly to the switch contacts to

prevent corrosion.

13 Rocker and push-button

switches

1

1These are mounted in panels on each side

of the instrument panel.

2Disconnect the battery negative lead.

3Prise off the instrument panel hood cover.

This is held in place by clips. The careful use

of a screwdriver will assist in releasing them

(see Section 21).

4Extract the switch panel fixing screws.

These compress spring clips which in turn

secure the switch panel (photo).

5Withdraw the switch panel until the wiring

plugs can be disconnected. Record the

location of the plugs before disconnecting

Electrical system 9•5

11.4 Unscrewing steering column switch

clamp nut

1 Direction indicator flasher unit (relay)10.1 Fuse block (later models)

1 Horn relay

2 Heated tailgate window relay9.8 Starter motor dismantled

13.4 Switch panel screw12.1 Courtesy lamp switch

9