ECO mode FIAT UNO 1983 Service Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 97 of 303

20 Interior lamps-

bulb renewal

1

Courtesy lamp

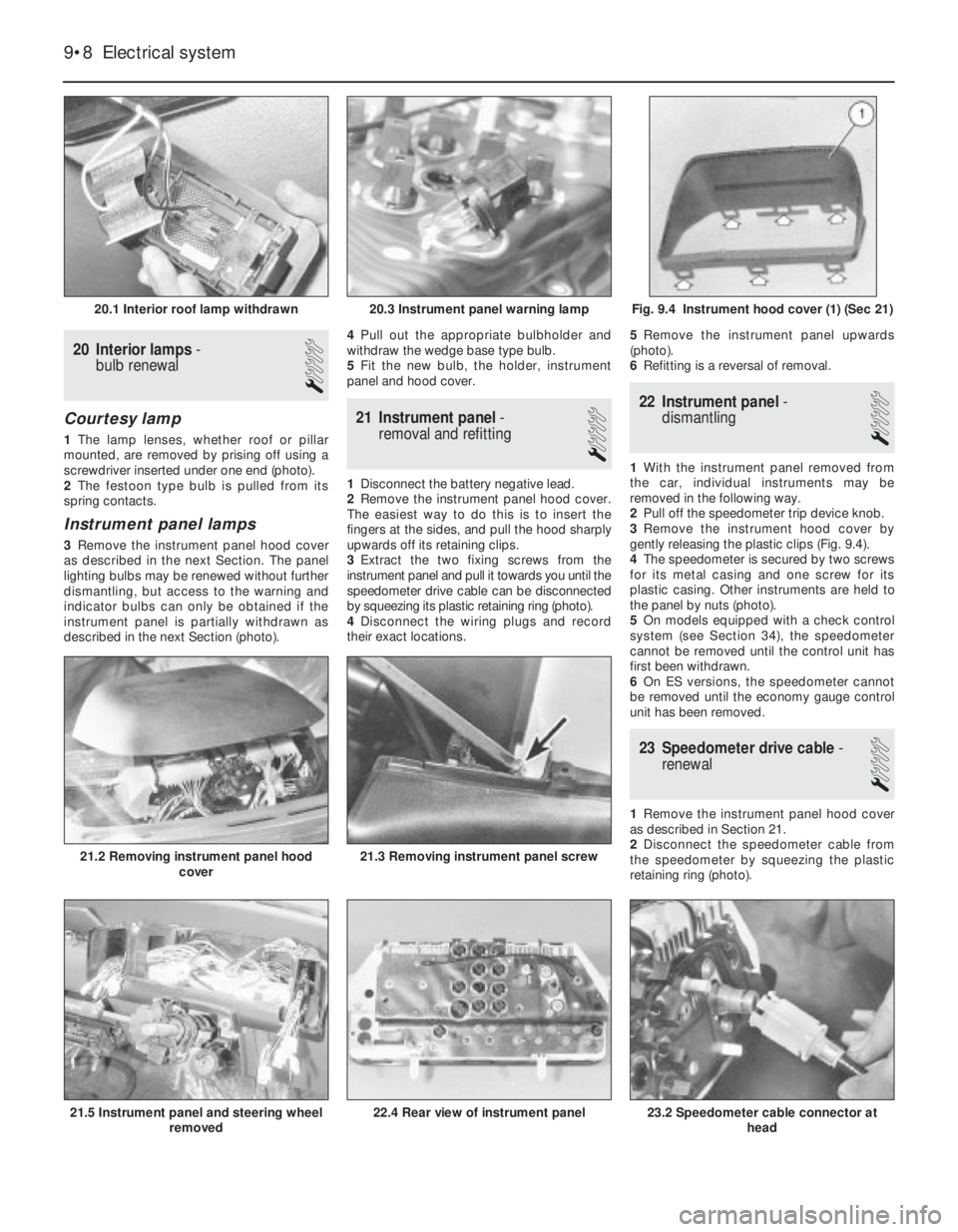

1The lamp lenses, whether roof or pillar

mounted, are removed by prising off using a

screwdriver inserted under one end (photo).

2The festoon type bulb is pulled from its

spring contacts.

Instrument panel lamps

3Remove the instrument panel hood cover

as described in the next Section. The panel

lighting bulbs may be renewed without further

dismantling, but access to the warning and

indicator bulbs can only be obtained if the

instrument panel is partially withdrawn as

described in the next Section (photo). 4Pull out the appropriate bulbholder and

withdraw the wedge base type bulb.

5Fit the new bulb, the holder, instrument

panel and hood cover.

21 Instrument panel-

removal and refitting

1

1Disconnect the battery negative lead.

2Remove the instrument panel hood cover.

The easiest way to do this is to insert the

fingers at the sides, and pull the hood sharply

upwards off its retaining clips.

3Extract the two fixing screws from the

instrument panel and pull it towards you until the

speedometer drive cable can be disconnected

by squeezing its plastic retaining ring (photo).

4Disconnect the wiring plugs and record

their exact locations. 5Remove the instrument panel upwards

(photo).

6Refitting is a reversal of removal.

22 Instrument panel-

dismantling

1

1With the instrument panel removed from

the car, individual instruments may be

removed in the following way.

2Pull off the speedometer trip device knob.

3Remove the instrument hood cover by

gently releasing the plastic clips (Fig. 9.4).

4The speedometer is secured by two screws

for its metal casing and one screw for its

plastic casing. Other instruments are held to

the panel by nuts (photo).

5On models equipped with a check control

system (see Section 34), the speedometer

cannot be removed until the control unit has

first been withdrawn.

6On ES versions, the speedometer cannot

be removed until the economy gauge control

unit has been removed.

23 Speedometer drive cable-

renewal

1

1Remove the instrument panel hood cover

as described in Section 21.

2Disconnect the speedometer cable from

the speedometer by squeezing the plastic

retaining ring (photo).

9•8 Electrical system

23.2 Speedometer cable connector at

head22.4 Rear view of instrument panel21.5 Instrument panel and steering wheel

removed

21.3 Removing instrument panel screw21.2 Removing instrument panel hood

cover

Fig. 9.4 Instrument hood cover (1) (Sec 21)20.3 Instrument panel warning lamp20.1 Interior roof lamp withdrawn

Page 99 of 303

27 Tailgate wiper motor-

removal and refitting

1

1Remove the blade and arm as previously

described. Unscrew the drive spindle bezel

nut.

2Open the tailgate fully.

3Unclip and remove the wiper motor cover.

4Unscrew the mounting screws, withdraw

the motor and disconnect the wiring plug

(photo).

5Refitting is a reversal of removal.

28 Washer system

1

1The washer system for the windscreen and

the tailgate operates from a bag type fluid

reservoir within the engine compartment

(photo).

2The reservoir bag is fitted with two pumps,

one for each system (photo).

3Use screen cleaning fluid mixed in the

recommended proportion in the washer fluid

reservoir and in very cold weather add a small

quantity of methylated spirit.

4To clear a blocked washer jet nozzle or to

adjust the wash jet glass-striking pattern,

insert a pin part way into the jet nozzle.

29 Heated tailgate window-

precautions and repair

2

1The heater element inside the tailgate glass

should be treated with care.

2Clean only with a damp cloth and wipe in

the direction in which the filaments run. Avoid

scratching with rings on the fingers, or by

allowing luggage to rub on the glass. Never

stick adhesive labels over the heater element.

3Should one of the heater filaments be

broken it can be repaired using one of the

special silver paints available, but follow the

manufacturer’s instructions carefully.

30 Radio/cassette- fitting

2

1In-car entertainment equipment is not

provided as standard on the models covered

by this Manual.

2However, the centre console is designed to

receive a radio set after removing the blanking

plate behind which a power lead is already

provided.

3The ignition system and other electrical

components are suppressed during

production of the car and further suppression

should not be required other than earthing the

wiper motor.

Receiver

4Fit the radio/cassette using the installation

kit supplied with the equipment.

5On Comfort models, fit an in-line fuse in the

power feed. On Super models the radio

supply is protected by fuse number 12.

6Make sure that the radio is well earthed to a

metal body component.

Aerial

7The recommended locations for the aerial

are towards the rear of the right-hand front

wing or on the windscreen pillar.

8Fitting instructions for Fiat aerials are

supplied with them, but the following general

advice will help if using non-Fiat equipment.9Motorised automatic aerials rise when the

equipment is switched on and retract at

switch-off. They require more fitting space

and supply leads, and can be a source of

trouble.

10There is no merit in choosing a very long

aerial as, for example, the type about three

metres in length which hooks or clips on to

the rear of the car, since part of this aerial will

inevitably be located in an interference field.

For VHF/FM radios the best length of aerial is

about one metre. Active aerials have a

transistor amplifier mounted at the base and

this serves to boost the received signal. The

aerial rod is sometimes rather shorter than

normal passive types.

11A large loss of signal can occur in the

aerial feeder cable, especially over the Very

High Frequency (VHF) bands. The design of

feeder cable is invariably in the co-axial form,

ie a centre conductor surrounded by a flexible

copper braid forming the outer (earth)

conductor. Between the inner and outer

conductors is an insulator material which can

be in solid or stranded form. Apart from

insulation, its purpose is to maintain the

correct spacing and concentricity. Loss of

signal occurs in this insulator, the loss usually

being greater in a poor quality cable. The

quality of cable used is reflected in the price

of the aerial with the attached feeder cable.

12The capacitance of the feeder should be

within the range 65 to 75 picofarads (pF)

approximately (95 to 100 pF for Japanese and

American equipment), otherwise the

adjustment of the car radio aerial trimmer may

not be possible. An extension cable is

necessary for a long run between aerial and

receiver. If this adds capacitance in excess of

the above limits, a connector containing a

series capacitor will be required, or an

extension which is labelled as

“capacity-compensated”.

13Fitting the aerial will normally involve

making a 7/8 in (22 mm) diameter hole in the

bodywork, but read the instructions that come

with the aerial kit. Once the hole position has

been selected, use a centre punch to guide

the drill. Use sticky masking tape around the

area for this helps with marking out and drill

location, and gives protection to the

9•10 Electrical system

Fig. 9.8 Radio housing and power lead (A)

(Sec 30)

28.2 Washer pumps28.1 Washer fluid reservoir27.4 Tailgate wiper motor

Page 100 of 303

paintwork should the drill slip. Three methods

of making the hole are in use:

a) Use a hole saw in the electric drill. This is,

in effect, a circular hacksaw blade

wrapped round a former with a centre

pilot drill.

b) Use a tank cutter which also has cutting

teeth, but is made to shear the metal by

tightening with an Allen key.

c) The hard way of drilling out the circle is

using a small drill, say 1/8 in (3 mm), so

that the holes overlap. The centre metal

drops out and the hole is finished with

round and half-round files.

14Whichever method is used, the burr is

removed from the body metal and paint

removed from the underside. The aerial is fitted

tightly ensuring that the earth fixing, usually a

serrated washer, ring or clamp, is making a

solid connection. This earth connection is

important in reducing interference. Cover any

bare metal with primer paint and topcoat, and

follow by underseal if desired.

15Aerial feeder cable routing should avoid

the engine compartment and areas where

stress might occur, eg under the carpet where

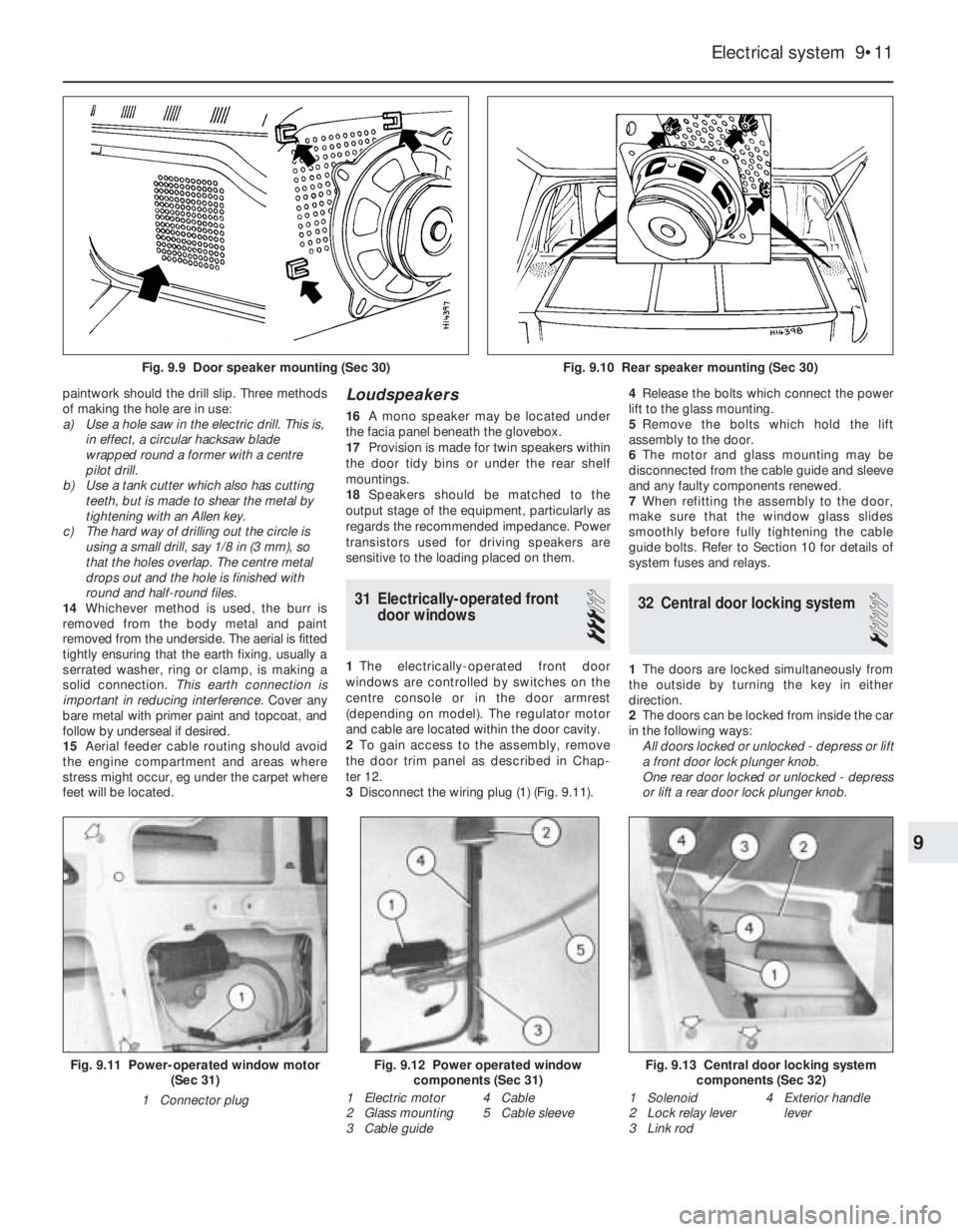

feet will be located.Loudspeakers

16A mono speaker may be located under

the facia panel beneath the glovebox.

17Provision is made for twin speakers within

the door tidy bins or under the rear shelf

mountings.

18Speakers should be matched to the

output stage of the equipment, particularly as

regards the recommended impedance. Power

transistors used for driving speakers are

sensitive to the loading placed on them.

31 Electrically-operated front

door windows

3

1The electrically-operated front door

windows are controlled by switches on the

centre console or in the door armrest

(depending on model). The regulator motor

and cable are located within the door cavity.

2To gain access to the assembly, remove

the door trim panel as described in Chap-

ter 12.

3Disconnect the wiring plug (1) (Fig. 9.11).4Release the bolts which connect the power

lift to the glass mounting.

5Remove the bolts which hold the lift

assembly to the door.

6The motor and glass mounting may be

disconnected from the cable guide and sleeve

and any faulty components renewed.

7When refitting the assembly to the door,

make sure that the window glass slides

smoothly before fully tightening the cable

guide bolts. Refer to Section 10 for details of

system fuses and relays.

32 Central door locking system

1

1The doors are locked simultaneously from

the outside by turning the key in either

direction.

2The doors can be locked from inside the car

in the following ways:

All doors locked or unlocked - depress or lift

a front door lock plunger knob.

One rear door locked or unlocked - depress

or lift a rear door lock plunger knob.

Electrical system 9•11

Fig. 9.9 Door speaker mounting (Sec 30)Fig. 9.10 Rear speaker mounting (Sec 30)

Fig. 9.13 Central door locking system

components (Sec 32)Fig. 9.12 Power operated window

components (Sec 31)Fig. 9.11 Power-operated window motor

(Sec 31)

1 Connector plug

1 Electric motor

2 Glass mounting

3 Cable guide4 Cable

5 Cable sleeve1 Solenoid

2 Lock relay lever

3 Link rod4 Exterior handle

lever

9

Page 101 of 303

3The centralised door locking system can

operate independently of the key.

4To gain access to the lock solenoid and

linkage, remove the front door trim panel as

described in Chapter 12.

5Disconnect the battery negative lead.

6Disconnect the electrical wiring plugs from

the solenoid within the door cavity.

7Disconnect the solenoid from the lock lever

by removing the clip.

8Unscrew the two bolts which secure the

solenoid to the door and remove it.

9Renew the solenoid or switch as necessary.

10Refitting is a reversal of removal.

11Refer to Section 10 for details of system

fuses and relays.

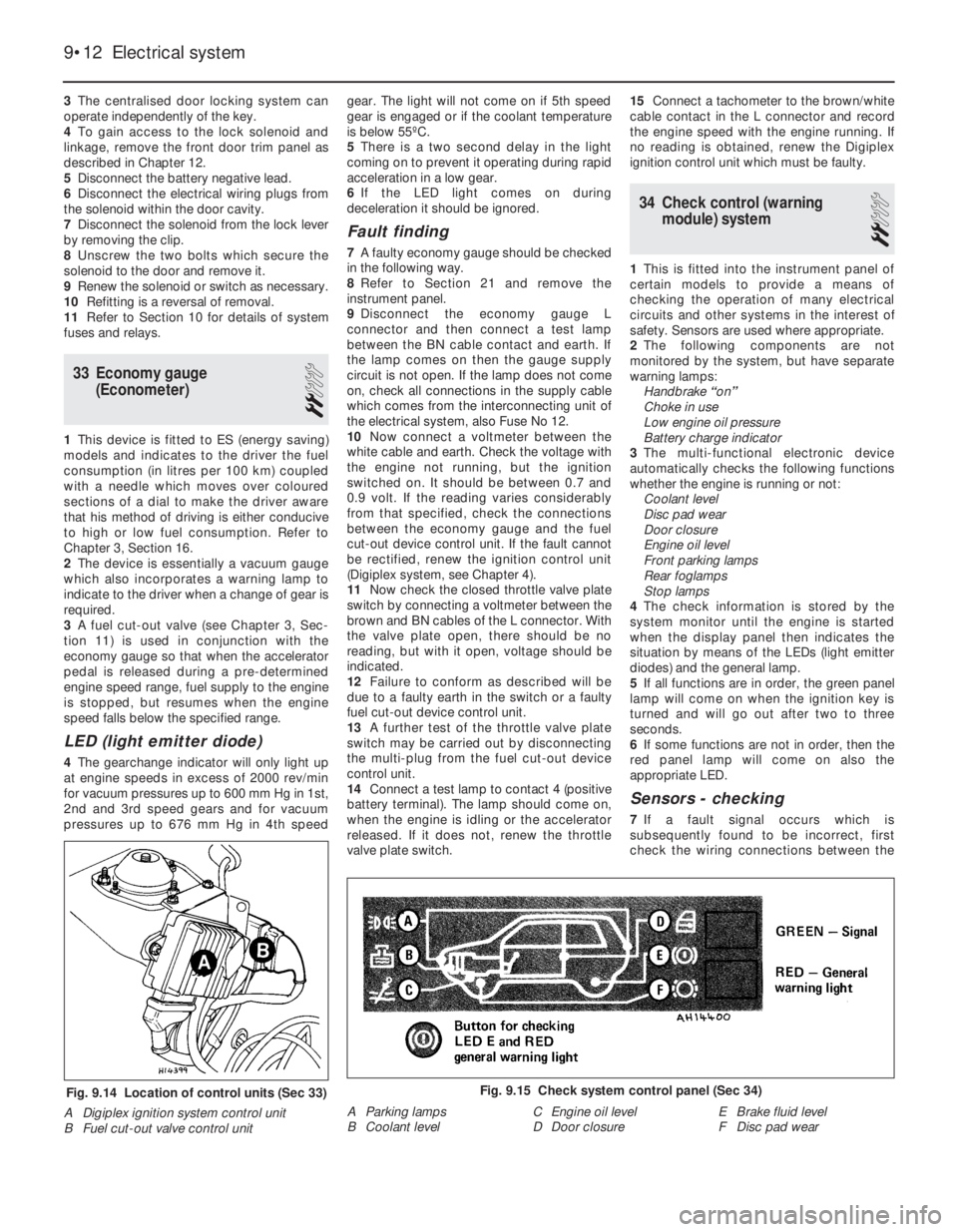

33 Economy gauge

(Econometer)

2

1This device is fitted to ES (energy saving)

models and indicates to the driver the fuel

consumption (in litres per 100 km) coupled

with a needle which moves over coloured

sections of a dial to make the driver aware

that his method of driving is either conducive

to high or low fuel consumption. Refer to

Chapter 3, Section 16.

2The device is essentially a vacuum gauge

which also incorporates a warning lamp to

indicate to the driver when a change of gear is

required.

3A fuel cut-out valve (see Chapter 3, Sec-

tion 11) is used in conjunction with the

economy gauge so that when the accelerator

pedal is released during a pre-determined

engine speed range, fuel supply to the engine

is stopped, but resumes when the engine

speed falls below the specified range.

LED (light emitter diode)

4The gearchange indicator will only light up

at engine speeds in excess of 2000 rev/min

for vacuum pressures up to 600 mm Hg in 1st,

2nd and 3rd speed gears and for vacuum

pressures up to 676 mm Hg in 4th speedgear. The light will not come on if 5th speed

gear is engaged or if the coolant temperature

is below 55ºC.

5There is a two second delay in the light

coming on to prevent it operating during rapid

acceleration in a low gear.

6If the LED light comes on during

deceleration it should be ignored.

Fault finding

7A faulty economy gauge should be checked

in the following way.

8Refer to Section 21 and remove the

instrument panel.

9Disconnect the economy gauge L

connector and then connect a test lamp

between the BN cable contact and earth. If

the lamp comes on then the gauge supply

circuit is not open. If the lamp does not come

on, check all connections in the supply cable

which comes from the interconnecting unit of

the electrical system, also Fuse No 12.

10Now connect a voltmeter between the

white cable and earth. Check the voltage with

the engine not running, but the ignition

switched on. It should be between 0.7 and

0.9 volt. If the reading varies considerably

from that specified, check the connections

between the economy gauge and the fuel

cut-out device control unit. If the fault cannot

be rectified, renew the ignition control unit

(Digiplex system, see Chapter 4).

11Now check the closed throttle valve plate

switch by connecting a voltmeter between the

brown and BN cables of the L connector. With

the valve plate open, there should be no

reading, but with it open, voltage should be

indicated.

12Failure to conform as described will be

due to a faulty earth in the switch or a faulty

fuel cut-out device control unit.

13A further test of the throttle valve plate

switch may be carried out by disconnecting

the multi-plug from the fuel cut-out device

control unit.

14Connect a test lamp to contact 4 (positive

battery terminal). The lamp should come on,

when the engine is idling or the accelerator

released. If it does not, renew the throttle

valve plate switch.15Connect a tachometer to the brown/white

cable contact in the L connector and record

the engine speed with the engine running. If

no reading is obtained, renew the Digiplex

ignition control unit which must be faulty.

34 Check control (warning

module) system

2

1This is fitted into the instrument panel of

certain models to provide a means of

checking the operation of many electrical

circuits and other systems in the interest of

safety. Sensors are used where appropriate.

2The following components are not

monitored by the system, but have separate

warning lamps:

Handbrake “on”

Choke in use

Low engine oil pressure

Battery charge indicator

3The multi-functional electronic device

automatically checks the following functions

whether the engine is running or not:

Coolant level

Disc pad wear

Door closure

Engine oil level

Front parking lamps

Rear foglamps

Stop lamps

4The check information is stored by the

system monitor until the engine is started

when the display panel then indicates the

situation by means of the LEDs (light emitter

diodes) and the general lamp.

5If all functions are in order, the green panel

lamp will come on when the ignition key is

turned and will go out after two to three

seconds.

6If some functions are not in order, then the

red panel lamp will come on also the

appropriate LED.

Sensors - checking

7If a fault signal occurs which is

subsequently found to be incorrect, first

check the wiring connections between the

9•12 Electrical system

Fig. 9.15 Check system control panel (Sec 34)

A Parking lamps

B Coolant levelC Engine oil level

D Door closureE Brake fluid level

F Disc pad wearFig. 9.14 Location of control units (Sec 33)

A Digiplex ignition system control unit

B Fuel cut-out valve control unit

Page 102 of 303

sensors, lamp circuits and the control unit.

Corrosion at the terminals may also be a

contributory cause.

8Never short circuit a sensor supply wire or

the electronic module will be damaged.

Check control unit and monitor -

removal and refitting

9Remove the instrument panel as described

in Section 21.

10Unbolt the control unit housing from the

instrument panel.

11Access to the monitor can only be

obtained after removing the tachometer andthe red and green general warning lamps.

Unscrew the two monitor fixing bolts.

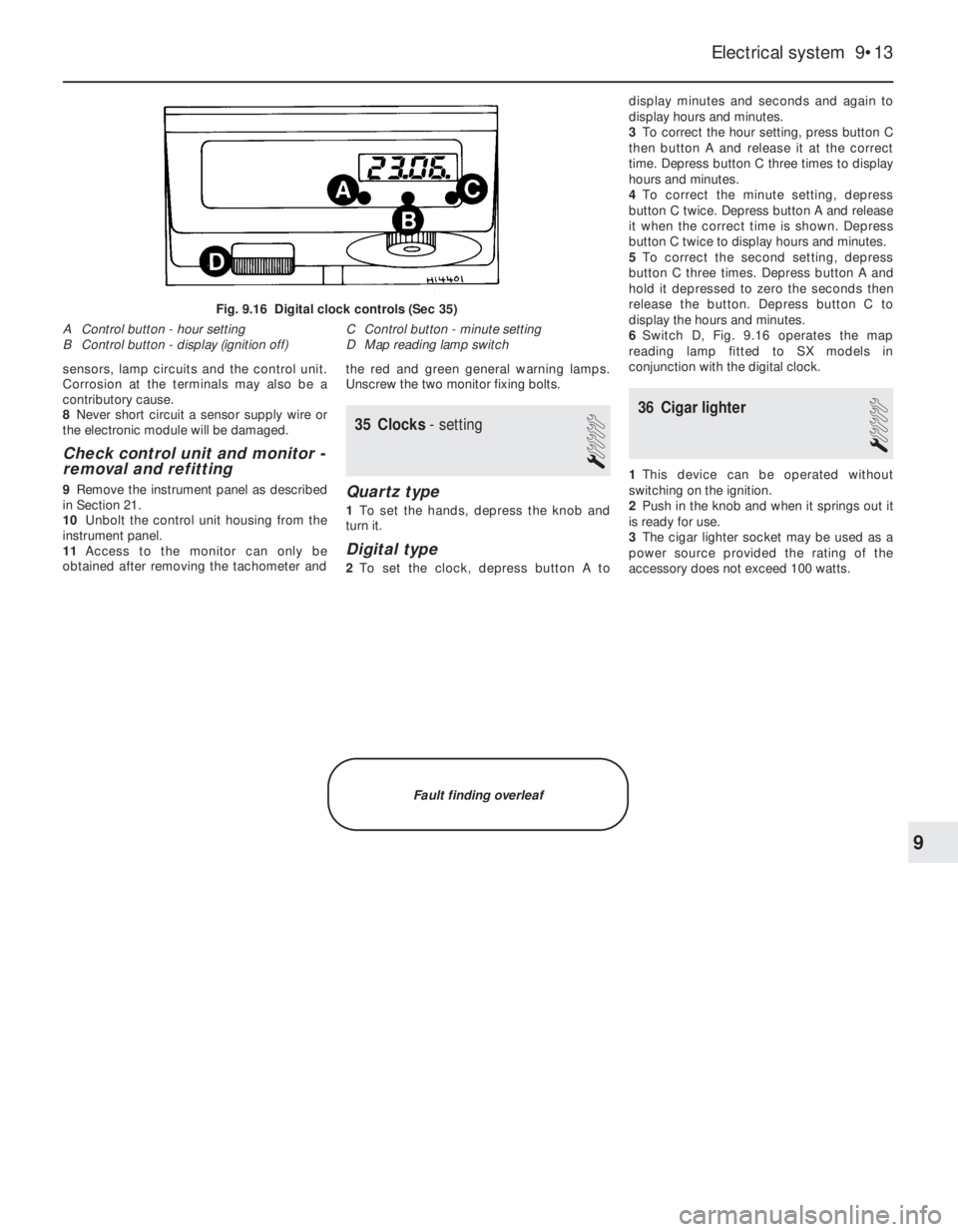

35 Clocks- setting

1

Quartz type

1To set the hands, depress the knob and

turn it.

Digital type

2To set the clock, depress button A todisplay minutes and seconds and again to

display hours and minutes.

3To correct the hour setting, press button C

then button A and release it at the correct

time. Depress button C three times to display

hours and minutes.

4To correct the minute setting, depress

button C twice. Depress button A and release

it when the correct time is shown. Depress

button C twice to display hours and minutes.

5To correct the second setting, depress

button C three times. Depress button A and

hold it depressed to zero the seconds then

release the button. Depress button C to

display the hours and minutes.

6Switch D, Fig. 9.16 operates the map

reading lamp fitted to SX models in

conjunction with the digital clock.

36 Cigar lighter

1

1This device can be operated without

switching on the ignition.

2Push in the knob and when it springs out it

is ready for use.

3The cigar lighter socket may be used as a

power source provided the rating of the

accessory does not exceed 100 watts.

Electrical system 9•13

Fig. 9.16 Digital clock controls (Sec 35)

A Control button - hour setting C Control button - minute setting

B Control button - display (ignition off) D Map reading lamp switch

9

Fault finding overleaf

Page 106 of 303

13Stake the lower end of the tube to retain

the bush.

14Reassembly is a reversal of removal,

noting that the universal joint coupling

pinch-bolts should pass smoothly through the

grooves in the steering shaft.

15Fit the steering wheel when the

roadwheels are in the straight-ahead position.

16Tighten all nuts and bolts to the specified

torque. Reconnect the battery.

6 Steering rack-

removal and refitting

4

1Set the steering in the straight-ahead

mode.

2Working inside the car, disconnect thesteering shaft lower coupling by unscrewing

and removing the pinch-bolt (photo).

3Disconnect the tie-rod end balljoints from

the steering arms as described earlier in this

Chapter.

4Unscrew and remove the rack clamp

mounting bolts and withdraw the steering

gear from the car crossmember (photo).

5Refitting is a reversal of removal, but on

completion check the front wheel alignment

as described in Section 8.

7 Steering gear- overhaul

4

1A worn steering gear should not be

overhauled, but a new or factory

reconditioned unit fitted.

2After a high mileage, the following

adjustment may be needed however.

Rack damper - adjustment

3The slipper in the rack housing presses the

rack into mesh with the pinion. This cuts out

any backlash between the gears. Also, due to

its pressure, it introduces some stiffness into

the rack, which cuts out excessive reaction

from the road to the steering wheel.

4In due course, wear reduces the pressures

exerted by the slipper. The pressure is

controlled by the cover plate and a spring.

5The need for resetting of the slipper is not

easy to detect. On bumpy roads, the shockinduced through the steering will give a feeling

of play, and sometimes faint clonking can be

heard. In extreme cases, free play in the

steering may be felt, though this is rare. If the

steering is compared with that of a new rack

on another car, the lack of friction damping is

quite apparent in the ease of movement of the

steering wheel of the worn one.

6Centralise the steering rack. Do this by

counting the number of turns lock-to-lock and

then turning the steering wheel from one lock

through half the number of turns counted.

7Take the cover plate off the damping

slipper, remove the spring and shims, and refit

the cover plate.

8Screw in the cover plate bolts just enough

to hold the slipper against the rack.

9Measure the gap between the cover plate

and the rack housing using feeler blades.

10Select shims from the thicknesses

available (0.10, 0.125 and 0.30 mm) to provide

a shim pack thicker than the gap by between

0.05 and 0.13 mm.

11Remove the cover plate, fit the spring and

bolt on the cover plate with the selected shims.

8 Steering angles and front

wheel alignment

4

1Accurate front wheel alignment is essential

to provide good steering and roadholding char-

acteristics and to ensure slow and even tyre

Steering 10•3

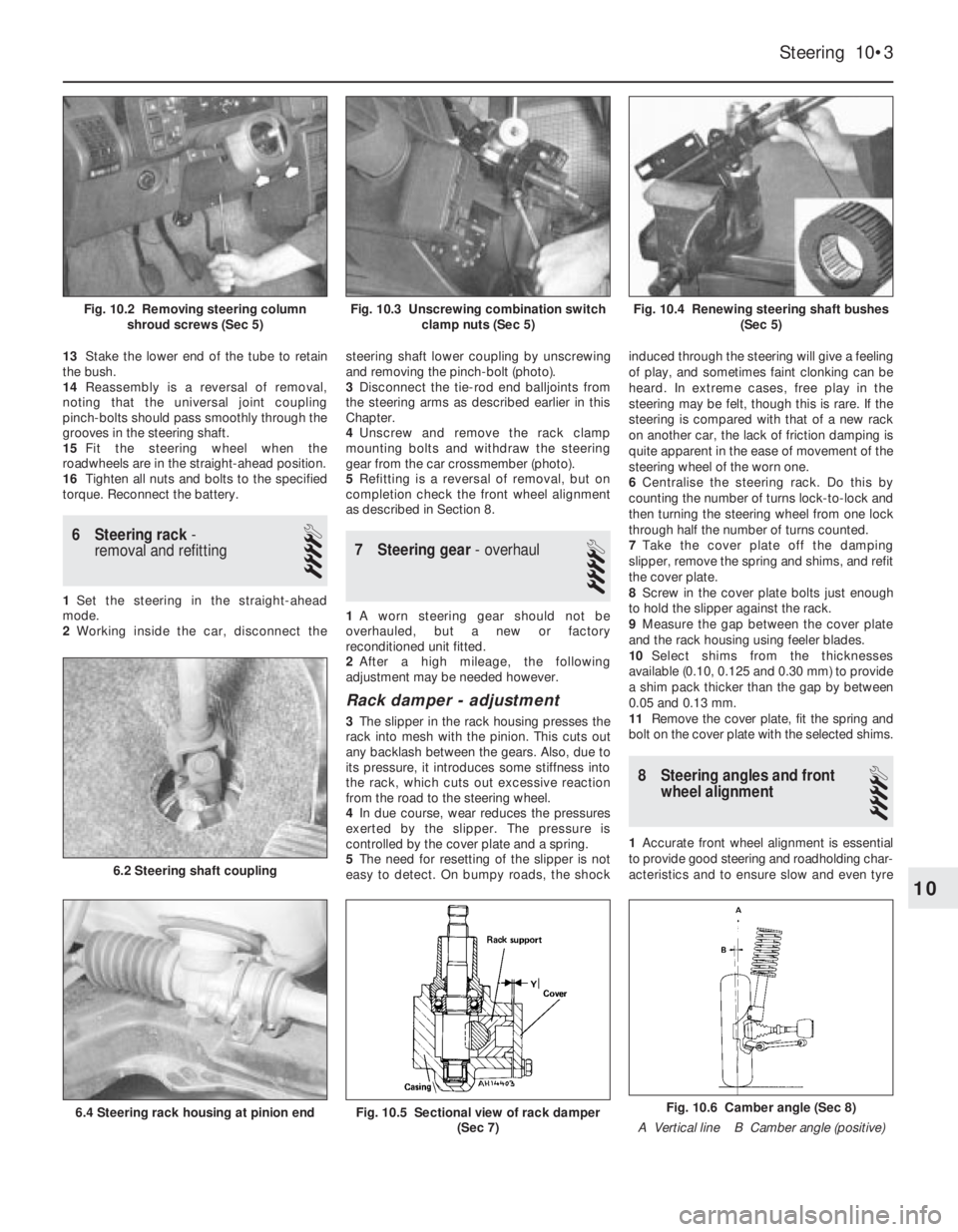

Fig. 10.4 Renewing steering shaft bushes

(Sec 5)Fig. 10.3 Unscrewing combination switch

clamp nuts (Sec 5)Fig. 10.2 Removing steering column

shroud screws (Sec 5)

Fig. 10.6 Camber angle (Sec 8)

A Vertical line B Camber angle (positive)Fig. 10.5 Sectional view of rack damper

(Sec 7)6.4 Steering rack housing at pinion end

10

6.2 Steering shaft coupling

Page 114 of 303

12

For dimensions, weights etc. refer to the Introductory Section of this Manual.

Chapter 12 Bodywork

For modifications, and information applicable to later models, see Supplement at end of manual

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Bonnet - lock and release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 21

Door - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Door trim panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 11

Facia panel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fixed side window (five-door) - removal and refitting . . . . . . . . . . . . 17

Front bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 9

Front seat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Front wing - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Grab handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . 2Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . 3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Opening side window (three-door) - removal and refitting . . . . . . . . 18

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 6

Rear bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 26

Rear seat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rear view mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Roof rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Seat belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Sunroof - operation and maintenance . . . . . . . . . . . . . . . . . . . . . . . 28

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Tailgate glass - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 16

Windscreen glass - removal and refitting . . . . . . . . . . . . . . . . . . . . . 15

12•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

1 General description

The Uno is an all steel, welded Hatchback

of unitary construction available in three- or

five-door versions.

Various levels of trim and equipment are

available depending upon model.

Factory fitted options include a sunroof,

central door locking and electrically-operated

front windows.

2 Maintenance-

bodywork and underframe

1

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts

of the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the

underframe of the vehicle steam-cleaned,

engine compartment included, so that a

thorough inspection can be carried out to see

what minor repairs and renovations are

necessary. Steam-cleaning is available at

many garages, and is necessary for the

removal of the accumulation of oily grime,

which sometimes is allowed to become thick

in certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-applied; the dirt can then be simply hosed off.

Note that these methods should not be used

on vehicles with wax-based underbody

protective coating, or the coating will be

removed. Such vehicles should be inspected

annually, preferably just prior to Winter, when

the underbody should be washed down, and

any damage to the wax coating repaired.

Ideally, a completely fresh coat should be

applied. It would also be worth considering

the use of such wax-based protection for

injection into door panels, sills, box sections,

etc, as an additional safeguard against rust

damage, where such protection is not

provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish

will give added protection against chemical

pollutants in the air. If the paintwork sheen

has dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

Page 121 of 303

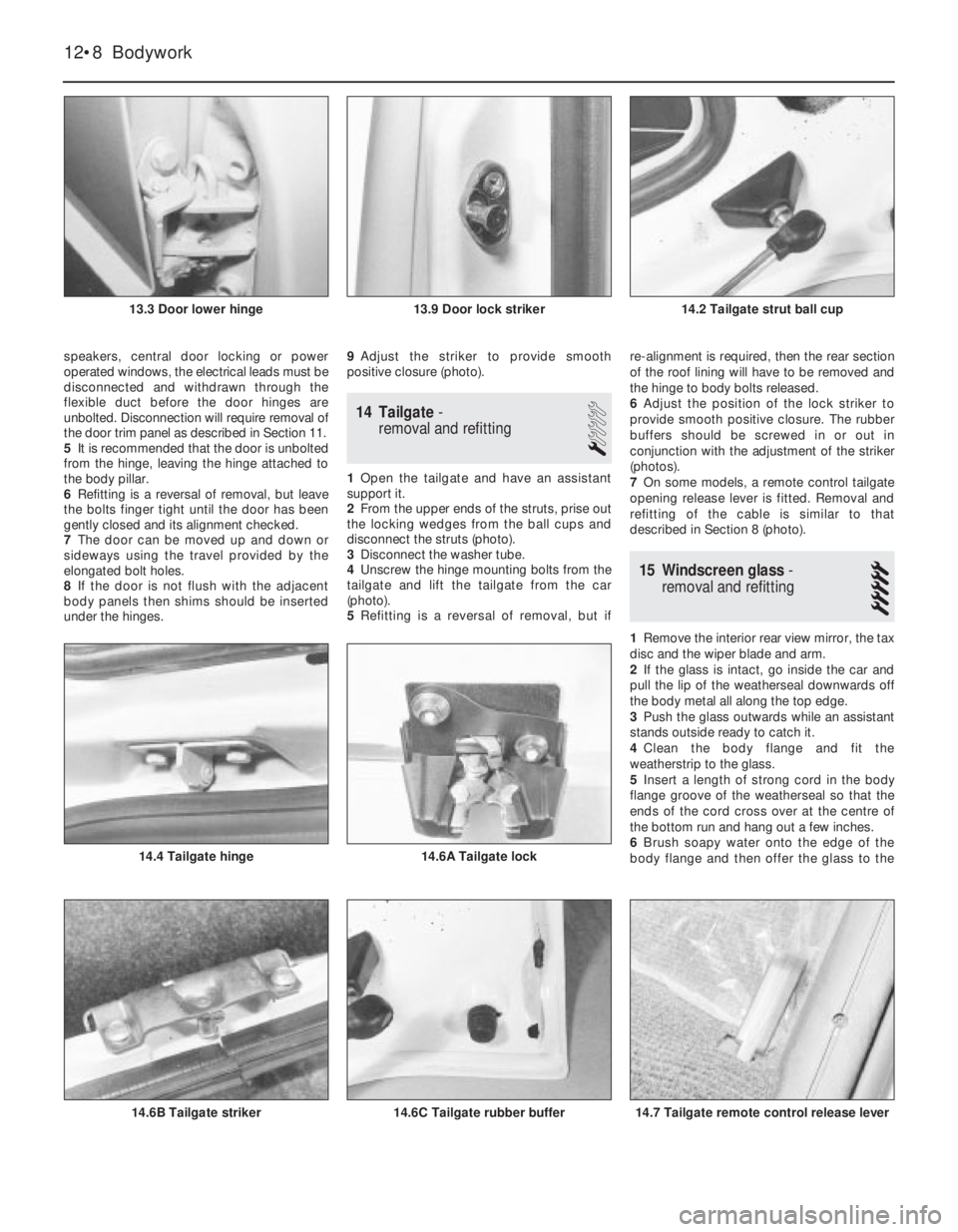

speakers, central door locking or power

operated windows, the electrical leads must be

disconnected and withdrawn through the

flexible duct before the door hinges are

unbolted. Disconnection will require removal of

the door trim panel as described in Section 11.

5It is recommended that the door is unbolted

from the hinge, leaving the hinge attached to

the body pillar.

6Refitting is a reversal of removal, but leave

the bolts finger tight until the door has been

gently closed and its alignment checked.

7The door can be moved up and down or

sideways using the travel provided by the

elongated bolt holes.

8If the door is not flush with the adjacent

body panels then shims should be inserted

under the hinges.9Adjust the striker to provide smooth

positive closure (photo).

14 Tailgate-

removal and refitting

1

1Open the tailgate and have an assistant

support it.

2From the upper ends of the struts, prise out

the locking wedges from the ball cups and

disconnect the struts (photo).

3Disconnect the washer tube.

4Unscrew the hinge mounting bolts from the

tailgate and lift the tailgate from the car

(photo).

5Refitting is a reversal of removal, but ifre-alignment is required, then the rear section

of the roof lining will have to be removed and

the hinge to body bolts released.

6Adjust the position of the lock striker to

provide smooth positive closure. The rubber

buffers should be screwed in or out in

conjunction with the adjustment of the striker

(photos).

7On some models, a remote control tailgate

opening release lever is fitted. Removal and

refitting of the cable is similar to that

described in Section 8 (photo).

15 Windscreen glass-

removal and refitting

5

1Remove the interior rear view mirror, the tax

disc and the wiper blade and arm.

2If the glass is intact, go inside the car and

pull the lip of the weatherseal downwards off

the body metal all along the top edge.

3Push the glass outwards while an assistant

stands outside ready to catch it.

4Clean the body flange and fit the

weatherstrip to the glass.

5Insert a length of strong cord in the body

flange groove of the weatherseal so that the

ends of the cord cross over at the centre of

the bottom run and hang out a few inches.

6Brush soapy water onto the edge of the

body flange and then offer the glass to the

12•8 Bodywork

14.7 Tailgate remote control release lever14.6C Tailgate rubber buffer14.6B Tailgate striker

14.6A Tailgate lock14.4 Tailgate hinge

14.2 Tailgate strut ball cup13.9 Door lock striker13.3 Door lower hinge

Page 126 of 303

13

Chapter 13 Supplement:

Revisions and information on later models

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Routine maintenance - all models from June 1991 . . . . . . . . . . . 3

Engine 903 and 1299/1301 cc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sump pan sealing strips (903 cc engine) - modification

1299 cc engine - description

Rocker cover (903 cc engine) - removal

Cylinder head (903 cc engine) - refitting

Engine - 999 and 1108 cc (FIRE) . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Part A: General

Description

Part B: Operations possible with engine in car

Valve clearances - adjustment

Timing belt - renewal

Camshaft - removal and refitting

Cylinder head - removal and refitting

Sump pan - removal and refitting

Oil pump - removal, checking and refitting

Pistons/connecting rods - removal and refitting

Pistons/connecting rods - separation and piston ring renewal

Engine/transmission mountings - renewal

Part C: Engine removal and dismantling

Method of removal - general

Engine/transmission - removal and separation

Dismantling - general

Complete dismantling

Examination and renovation

Part D: Engine reassembly and refitting

Reassembly - general

Complete reassembly

Engine/transmission - reconnection and refitting

Initial start-up after major overhaul

Engine 1301 cc Turbo ie.................................................................. 6

Part A: General

Description

Lubrication system - description

Part B: Operations possible with engine in car

Camshaft and camshaft carrier - removal and refitting

Cylinder head - removal and refitting

Piston rings

Engine mountings - renewal

Timing belt - renewal

Oil pump drivegear cover plate

Engine oil cooler - removal and refittingPart C: Engine removal, dismantling, reassembly and refitting

Engine/transmission - removal and separation

Engine - dismantling and reassembly

Engine/transmission - reconnection and refitting

Initial start-up after major overhaul

Engine 1372 cc ie and 1372 cc Turbo ie......................................... 7

Part A: General

Description

Maintenance

Part B: Operations possible with the engine in car

Valve clearances - checking and adjustment

Timing belt, tensioner and sprockets - removal and refitting

Camshaft front oil seal - renewal

Camshaft, housing and followers - removal and refitting

Camshaft housing, camshaft and cam followers - dismantling,

inspection and reassembly

Cylinder head (1372 cc ie engine) - removal and refitting

Cylinder head (1372 cc Turbo ie engine) - removal and refitting

Cylinder head - inspection and renovation

Crankshaft front oil seal - removal and renewal

Crankshaft rear oil seal - removal and renewal

Flywheel - removal, inspection and refitting

Sump - removal and refitting

Oil pump - removal, checking and refitting

Pistons/connecting rods - removal and refitting

Pistons/connecting rods - examination and renovation

Engine/transmission mountings - renewal

Part C: Engine removal and dismantling

Method of removal - general

1372 cc ie engine/transmission - removal and separation

1372 cc Turbo ie engine/transmission - removal and separation

Engine dismantling - general

Auxiliary shaft - removal, inspection and refitting

Engine - complete dismantling

Crankshaft and main bearings - removal

Engine components - examination and renovation

Part D: Engine reassembly

Reassembly - general

Crankshaft and main bearings - refitting

Pistons and connecting rods - refitting

Oil pump - refitting

Sump - refitting

Flywheel - refitting

Auxiliary shaft - refitting

Cylinder head - refitting

Timing belt and covers - refitting

Engine/transmission - reconnection and refitting

Initial start-up after major overhaul

13•1

Contents

Page 128 of 303

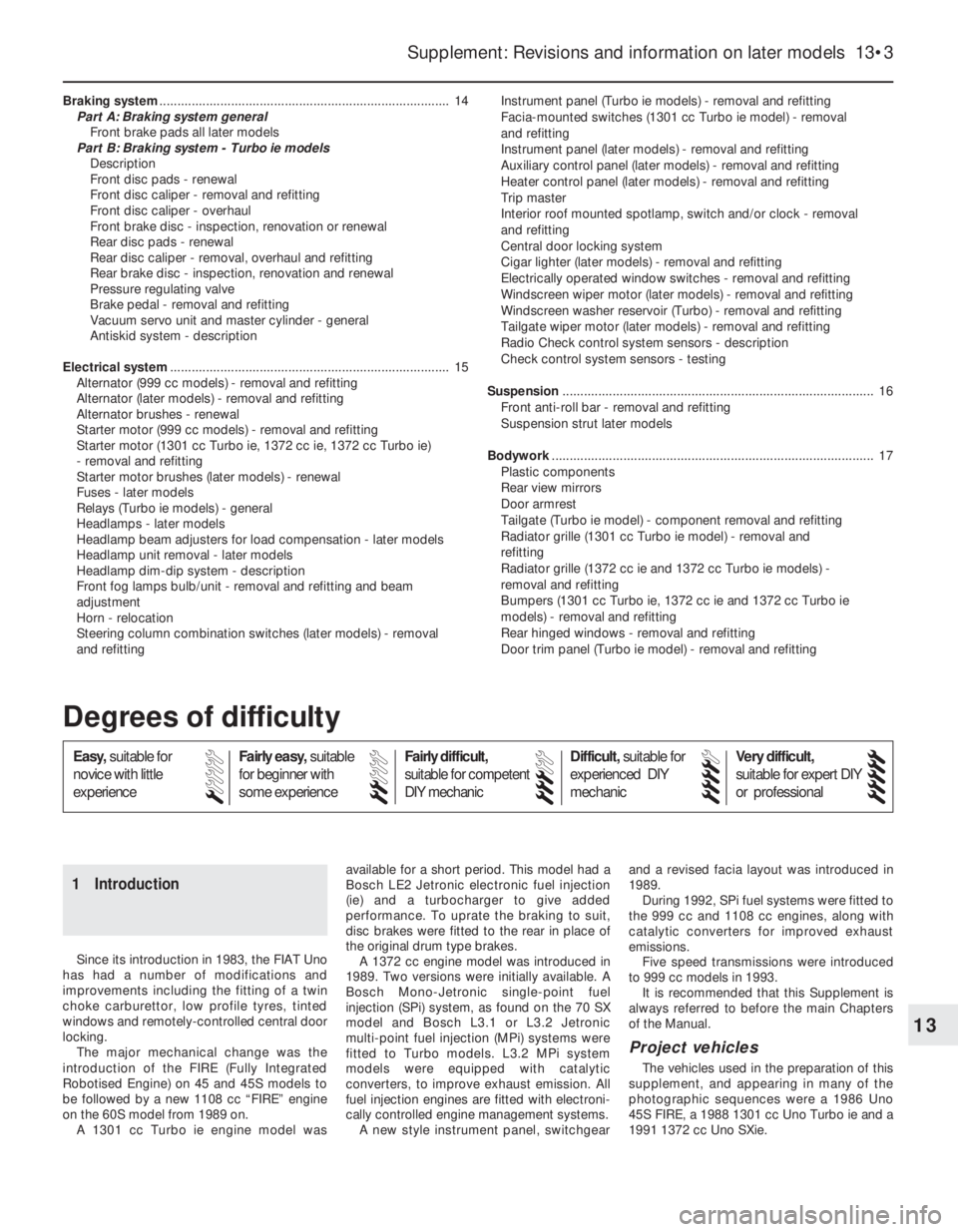

Braking system................................................................................. 14

Part A: Braking system general

Front brake pads all later models

Part B: Braking system - Turbo ie models

Description

Front disc pads - renewal

Front disc caliper - removal and refitting

Front disc caliper - overhaul

Front brake disc - inspection, renovation or renewal

Rear disc pads - renewal

Rear disc caliper - removal, overhaul and refitting

Rear brake disc - inspection, renovation and renewal

Pressure regulating valve

Brake pedal - removal and refitting

Vacuum servo unit and master cylinder - general

Antiskid system - description

Electrical system.............................................................................. 15

Alternator (999 cc models) - removal and refitting

Alternator (later models) - removal and refitting

Alternator brushes - renewal

Starter motor (999 cc models) - removal and refitting

Starter motor (1301 cc Turbo ie, 1372 cc ie, 1372 cc Turbo ie)

- removal and refitting

Starter motor brushes (later models) - renewal

Fuses - later models

Relays (Turbo ie models) - general

Headlamps - later models

Headlamp beam adjusters for load compensation - later models

Headlamp unit removal - later models

Headlamp dim-dip system - description

Front fog lamps bulb/unit - removal and refitting and beam

adjustment

Horn - relocation

Steering column combination switches (later models) - removal

and refittingInstrument panel (Turbo ie models) - removal and refitting

Facia-mounted switches (1301 cc Turbo ie model) - removal

and refitting

Instrument panel (later models) - removal and refitting

Auxiliary control panel (later models) - removal and refitting

Heater control panel (later models) - removal and refitting

Trip master

Interior roof mounted spotlamp, switch and/or clock - removal

and refitting

Central door locking system

Cigar lighter (later models) - removal and refitting

Electrically operated window switches - removal and refitting

Windscreen wiper motor (later models) - removal and refitting

Windscreen washer reservoir (Turbo) - removal and refitting

Tailgate wiper motor (later models) - removal and refitting

Radio Check control system sensors - description

Check control system sensors - testing

Suspension....................................................................................... 16

Front anti-roll bar - removal and refitting

Suspension strut later models

Bodywork.......................................................................................... 17

Plastic components

Rear view mirrors

Door armrest

Tailgate (Turbo ie model) - component removal and refitting

Radiator grille (1301 cc Turbo ie model) - removal and

refitting

Radiator grille (1372 cc ie and 1372 cc Turbo ie models) -

removal and refitting

Bumpers (1301 cc Turbo ie, 1372 cc ie and 1372 cc Turbo ie

models) - removal and refitting

Rear hinged windows - removal and refitting

Door trim panel (Turbo ie model) - removal and refitting

Supplement: Revisions and information on later models 13•3

13

1 Introduction

Since its introduction in 1983, the FIAT Uno

has had a number of modifications and

improvements including the fitting of a twin

choke carburettor, low profile tyres, tinted

windows and remotely-controlled central door

locking.

The major mechanical change was the

introduction of the FIRE (Fully Integrated

Robotised Engine) on 45 and 45S models to

be followed by a new 1108 cc “FIRE” engine

on the 60S model from 1989 on.

A 1301 cc Turbo ie engine model wasavailable for a short period. This model had a

Bosch LE2 Jetronic electronic fuel injection

(ie) and a turbocharger to give added

performance. To uprate the braking to suit,

disc brakes were fitted to the rear in place of

the original drum type brakes.

A 1372 cc engine model was introduced in

1989. Two versions were initially available. A

Bosch Mono-Jetronic single-point fuel

injection (SPi) system, as found on the 70 SX

model and Bosch L3.1 or L3.2 Jetronic

multi-point fuel injection (MPi) systems were

fitted to Turbo models. L3.2 MPi system

models were equipped with catalytic

converters, to improve exhaust emission. All

fuel injection engines are fitted with electroni-

cally controlled engine management systems.

A new style instrument panel, switchgearand a revised facia layout was introduced in

1989.

During 1992, SPi fuel systems were fitted to

the 999 cc and 1108 cc engines, along with

catalytic converters for improved exhaust

emissions.

Five speed transmissions were introduced

to 999 cc models in 1993.

It is recommended that this Supplement is

always referred to before the main Chapters

of the Manual.

Project vehicles

The vehicles used in the preparation of this

supplement, and appearing in many of the

photographic sequences were a 1986 Uno

45S FIRE, a 1988 1301 cc Uno Turbo ie and a

1991 1372 cc Uno SXie.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321