ECU FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 42 of 303

from the suspension struts and then remove

the bolts which secure the hub carriers to the

U-clamps at the base of the suspension

struts.

23Pull the tops of the hub carriers down and

then outwards and push the driveshafts from

them.

24Unbolt the driveshaft inboard boot

retainers and then remove the driveshafts

from the transmission.

25Support the engine on a hoist or use a

trolley jack under the engine/transmission.

Remove the bottom mounting and then the

upper left and right-hand ones.

26Lower the power unit to the floor by

pushing it to the left-hand side to clear the

right-hand mounting bracket and then swivel

the gearbox towards the rear of the car.

Withdraw the engine/transmission from under

the car.

27External dirt and grease should now be

removed using paraffin and a stiff brush or a

water-soluble solvent.

28Unbolt and remove the engine mounting

brackets and the starter motor.

29Unbolt and remove the cover plate with

the gearchange ball stud strut from the lower

front face of the flywheel housing.

30With the engine resting squarely on its

sump pan, unscrew the flywheel housing

connecting bolts, noting the location of any

lifting lugs and hose and wiring clips.

31Support the weight of the transmission

and withdraw it in a straight line from the

engine.

36 Engine- dismantling (general)

Refer to Section 14, Part 2.

37 Engine ancillary components

- removal

Refer to Section 15, Part 2 and also remove

the intake manifold.

38 Engine-

complete dismantling

3

1Have the engine resting squarely and

supported securely on the work surface.

2Unbolt and remove the timing belt cover.

3Grip the now exposed timing belt with the

hands and loosen the camshaft sprocket.

4Release the timing belt tensioner pulley

centre bolt, then slip the belt from the pulley

and sprockets to remove it. Note which way

round the belt is fitted, usually so that the

lettering on the belt can be read from the

crankshaft pulley end of the engine.

5Remove the camshaft sprocket.6Unbolt and remove the camshaft timing belt

cover backing plate.

7Unbolt and remove the camshaft carrier

cover.

8Unbolt the camshaft carrier and lift it off

very slowly, at the same time pushing the cam

followers and their shims down with the

fingers securely onto their respective valve

springs. It is easy to remove the camshaft

carrier too quickly with some of the cam

followers stuck in it and as the carrier is lifted

away, the cam followers will fall out. If this

happens, the valve clearances will be upset as

the cam followers and shims cannot be

returned, with any certainty, to their original

positions. Keep the cam followers and shims

in their originally fitted order.

9Unscrew and remove the cylinder head

bolts and nuts, grip the manifold, rock the

head and remove the complete cylinder

head/manifold/carburettor assembly. Remove

and discard the cylinder head gasket.

10Unbolt the coolant pump from the side of

the cylinder block and remove it complete

with coolant distribution pipe. Remove the

crankcase breather.

11Remove the distributor/oil pump

driveshaft. This is simply carried out by

inserting a finger into the hole vacated by the

distributor and wedging it in the hole in the

end of the driveshaft. Lift the shaft out of

mesh with the auxiliary shaft. Where the

distributor is driven by the camshaft, a cover

plate retains the oil pump driveshaft in

position.

12Unbolt and remove the sprocket from the

end of the auxiliary shaft. The sprocket is held

to the shaft with a Woodruff key.

13Unbolt the auxiliary shaft retainer and

withdraw the shaft from the crankcase.

14Unscrew and remove the crankshaft

pulley nut. This is very tight and the flywheel

starter ring gear will have to be jammed with a

cold chisel or a suitably bent piece of steel to

prevent the crankshaft rotating.

15Withdraw the crankshaft sprocket, which

is located by the Woodruff key.

16Unbolt the front engine mounting bracket

from the cylinder block, together with the

timing belt cover screw anchor bush. Unbolt

and remove the timing belt tensioner pulley.

17Unscrew the flywheel securing bolts. Thestarter ring gear will again have to be jammed

to prevent the crankshaft rotating as the bolts

are unscrewed. Mark the flywheel position in

relation to the crankshaft mounting flange,

then remove it.

18Unbolt the front and rear crankshaft oil

seal retainer bolts from the crankcase and the

sump. Remove the oil seal retainers.

19Turn the engine on its side, extract the

remaining sump bolts and remove the sump.

If it is stuck, try tapping it gently with a

soft-faced hammer. If this fails, cut all round

the sump-to-gasket flange with a sharp knife.

Do not try prising with a large screwdriver; this

will only distort the sump mating flange.

20With the sump removed, unbolt and

remove the oil pump.

21Grip the oil pick-up pipe and twist or rock

it from its hole in the crankcase. It is an

interference fit in the hole.

22Remove the piston/connecting rods as

described in Section 32.

23Before unbolting the main bearing caps,

note that they are marked with one, two, three

or four notches. No. 5 main bearing cap is

unmarked. Note that the notches are nearer

the auxiliary shaft side.

24Unbolt and remove the main bearing

caps. If the bearing shells are to be used

again, tape them to their respective caps. The

bearing shell at the centre position is plain,

the others have a lubricating groove.

25Carefully, lift the crankshaft from the

crankcase, noting the thrust washers at No. 5

main bearing. These control the crankshaft

endfloat.

39 Cylinder head- dismantling

and decarbonising

4

1The operations are similar to those

described for the ohv engine in Section 17 in

respect of decarbonising and valve grinding.

2To remove a valve, use a valve spring

compressor to compress the first valve and

then extract the split collets (photo).

3Release the valve spring compressor.

4Withdraw the valve spring cap and the

double valve springs (photos).

5Remove the valve (photo).

1•28 1116 cc and 1301 cc engine

39.4A Valve spring cap39.2 Valve spring compressor and split

collets

Page 43 of 303

6Remove the spring seat (photo).

7Discard the valve stem oil seal and fit a new

one (photo).

8Remove the remaining valves in a similar

way and keep the components in their

originally fitted sequence.

9Reassembly is a reversal of removal. Refit

the components to their original positions, but

renew the valve springs if their free length is

less than that of a new spring or if the

springs have been in operation for more than

80 000 km (50 000 miles).

10The original valve clearance adjusting

shims will no longer provide the correct

clearances if the valves have been ground in

or the seats recut. Only where dismantling of

a valve was carried out to renew a spring is

there any purpose in returning the shims to

their original locations. Try to obtain the loan

of eight thin shims from your dealer and insert

them into the tappets (cam followers) before

assembling the cam followers to the carrier,

where they should be retained with thick

grease (photo).

11Fit the camshaft carrier, complete with

cam followers and shims to the cylinder head.

12Adjust the valve clearances as described

in Section 26.

40 Examination and renovation

4

1The procedures are similar to those

described in Section 18 covering the

following:

Cylinder block and crankcase

Crankshaft and bearings

Pistons and piston rings

Flywheel

2The following additional items must also be

examined.

Oil pump

3Carefully, clamp the pump housing in a

vice, shaft downwards.

4Take off the pump cover, with the suction

pipe. This will release the oil pressure relief

valve inside. Also inside is a filter.

5Remove the internal cover plate.6Take out the driveshaft and the gears.

7Clean and examine all the parts. Measure

the clearances against the Specifications. The

end clearance is measured by putting a

straight-edge across the cover face.

8The oil pump should only need

replacements after very long mileage, when

the rest of the engine is showing great signs

of wear.

9The length of a new gear can be measured

against the old gear to see if a new gear will

restore the end clearance to the Specifica-

tions. Otherwise the housing must be

changed.

10The driven gear shaft is mounted in the

housing with an interference fit. If there is any

slackness, a new housing (which will come

with shaft fitted) must be used.

11The oil pump shares its drive with the

distributor.

Camshaft, cam followers and

shims

12The camshaft journals and cams should

be smooth, without grooves or scores.

13Wear in the camshaft carrier bearings can

only be rectified by renewal of the carrier.

14Cam follower wear is usually very small

and when they show slackness in their bores,

it is probably the light alloy of the camshaft

carrier which has worn.

15Always measure the thickness of the valve

clearance shims using a metric micrometer.

Any grooving or wear marks in the shims

should be rectified by renewal with ones of

similar thickness.

Auxiliary shaft

16The shaft journals, the fuel pump

eccentric, and the drivegear for the distributor

and oil pump should be smooth and shiny. If

not, the shaft will have to be renewed.

17The bushes should still be tight in the

cylinder block, their oil holes lined up with

those in the block.

18Measure the bearing clearance. If

excessive, the bushes will have to be

renewed. They are a press fit, and require

reaming with a special reamer after fitting.

This is a job best done by a Fiat agent with the

special tools.

19Ensure the new bushes are fitted with the

oil holes lined up.

20Also check the driven gear and its bush.

21It is recommended a new oil seal is fitted

in the endplate. Hold the shaft in a vice, and

remove the pulley. Fit the new oil seal in the

endplate, lips inwards.

Timing belt tensioner

22Check the bearing revolves smoothly and

freely, and has no play. Do not immerse it in

cleaning fluid, as it is partially sealed. Wipe

the outside, and then smear in some new

general purpose grease.

23The action of the spring will have been felt

when the belt was taken off. It should be

cleaned, and oiled, to prevent seizure through

dirt and rust.

24Note the circlip on the engine right-hand

mounting bracket. This retains the timing belt

tensioner plunger.

1116 cc and 1301 cc engine 1•29

39.6 Valve spring seat39.5 Removing a valve39.4B Double valve springs

39.10 Cam followers fitted to camshaft

carrier39.7 Valve stem oil seal

1

Page 45 of 303

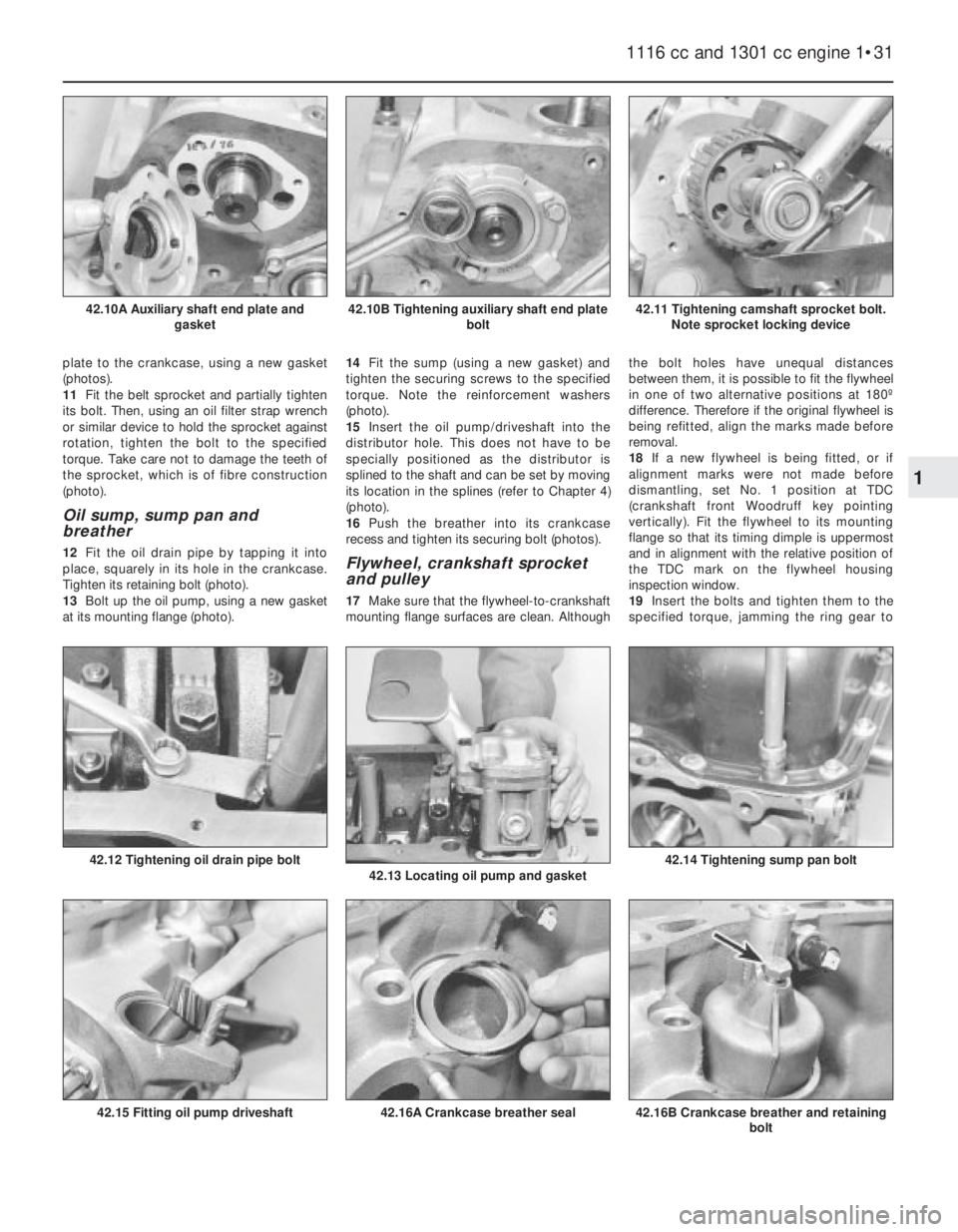

plate to the crankcase, using a new gasket

(photos).

11Fit the belt sprocket and partially tighten

its bolt. Then, using an oil filter strap wrench

or similar device to hold the sprocket against

rotation, tighten the bolt to the specified

torque. Take care not to damage the teeth of

the sprocket, which is of fibre construction

(photo).

Oil sump, sump pan and

breather

12Fit the oil drain pipe by tapping it into

place, squarely in its hole in the crankcase.

Tighten its retaining bolt (photo).

13Bolt up the oil pump, using a new gasket

at its mounting flange (photo).14Fit the sump (using a new gasket) and

tighten the securing screws to the specified

torque. Note the reinforcement washers

(photo).

15Insert the oil pump/driveshaft into the

distributor hole. This does not have to be

specially positioned as the distributor is

splined to the shaft and can be set by moving

its location in the splines (refer to Chapter 4)

(photo).

16Push the breather into its crankcase

recess and tighten its securing bolt (photos).Flywheel, crankshaft sprocket

and pulley

17Make sure that the flywheel-to-crankshaft

mounting flange surfaces are clean. Althoughthe bolt holes have unequal distances

between them, it is possible to fit the flywheel

in one of two alternative positions at 180º

difference. Therefore if the original flywheel is

being refitted, align the marks made before

removal.

18If a new flywheel is being fitted, or if

alignment marks were not made before

dismantling, set No. 1 position at TDC

(crankshaft front Woodruff key pointing

vertically). Fit the flywheel to its mounting

flange so that its timing dimple is uppermost

and in alignment with the relative position of

the TDC mark on the flywheel housing

inspection window.

19Insert the bolts and tighten them to the

specified torque, jamming the ring gear to

1116 cc and 1301 cc engine 1•31

42.11 Tightening camshaft sprocket bolt.

Note sprocket locking device42.10B Tightening auxiliary shaft end plate

bolt42.10A Auxiliary shaft end plate and

gasket

42.16B Crankcase breather and retaining

bolt42.16A Crankcase breather seal42.15 Fitting oil pump driveshaft

42.14 Tightening sump pan bolt42.13 Locating oil pump and gasket42.12 Tightening oil drain pipe bolt

1

Page 54 of 303

towards the engine. Slip the belt off the

pulleys. If this is difficult, turn the crankshaft

pulley using a spanner on its retaining nut

while pressing the belt over the edge of the

pulley rim. Use this method to fit the new belt

after first having engaged it with the coolant

pump and alternator pulley grooves.

5Tension the belt as previously described.

6The tension of a new belt should be

checked and adjusted after the first few

hundred miles of running.

9 Coolant pump- removal,

overhaul and refitting

4

Note: The design of the pump differs between

the 903 cc and the other two engines, but the

removal, overhaul and refitting operations are

essentially similar.

1To gain access to the coolant pump, open

the bonnet and remove the air cleaner.

2Slacken the alternator pivot and adjustment

nuts, push the alternator in towards the

engine and slip the drivebelt from the coolant

pump pulley. Unplug and remove the

alternator.3Drain the cooling system as previously

described.

4Disconnect the hoses from the coolant

pump, also the metal coolant transfer pipe

(photo).

5Unscrew and remove the coolant pump

securing bolts, and lift the pump from the

engine. Peel away and discard the old gasket.

6Clean away external dirt.

7The pump is likely to need overhaul for

worn or noisy bearings, or if the gland is

leaking. There is a drain hole between the

gland and the bearings to prevent

contamination of the bearing grease by leaks,

and possible damage to the bearings. Glandleaks are usually worse when the engine is not

running. Once started, a leak is likely to get

worse quickly, so should be dealt with soon.

Worn bearings are likely to be noted first due

to noise. To check them, the pulley should be

rocked firmly, when any free movement can

be felt despite the belt. But if the bearings are

noisy, yet there is not apparently any free

play, then the belt should be removed so the

pump can be rotated by hand to check the

smoothness of the bearings.

8Dismantling and assembly of the pump

requires the use of a press, and it is preferable

to fit a new pump.

9For those having the necessary facilities,

overhaul can be carried out as follows.

10Remove the retaining nuts and separate

the two halves of the pump.

11The pump shaft is an interference fit in the

impeller, bearings, and pulley boss. How the

pump is dismantled depends on whether only

the gland needs renewing or the bearings as

well, and what puller or press is available to

get everything apart.

12Assuming complete dismantling is

required, proceed as follows. Supporting it

close in at the boss, press the shaft out of the

pulley. Pull the impeller off the other end of

the shaft.

13Take out the bearing stop screw.

14From the impeller end, press the shaft

with the bearings out of the cover half of the

housing.

15Press the shaft out of the bearings, take

off the spacer, the circlip, and the shouldered

ring.

16Do not immerse the bearings in cleaning

2•4 Cooling and heating systems

1 Pump body

2 Pump cover

3 Impeller

4 Connector for hose from

outlet to pump

5 Seal

6 Gasket7 Circlip

8 Bearing shoulder washer

9 Inner seal

10 Inner bearing

11 Bearing retainment screw

and lock washer12 Spacer

13 Outer seal

14 Outer bearing

15 Lock washer

16 Pulley

17 Pump shaft

Fig. 2.5 Sectional views of 1116 cc and 1301 cc engine coolant pump (Sec 9)

Fig. 2.4 Sectional view of 903 cc engine coolant pump (Sec 9)

9.4 Coolant distribution tube at rear of

pump

1 Pump cover

2 Bearing spacer

3 Bearing stop screw

4 Cover nuts

5 Lifting bracket

6 Housing

7 Impeller

8 Gland (seal)

9 Circlip

10 Gasket

11 Shouldered ring

12 Grommets

13 Bearing

14 Pulley

15 Shaft

Page 56 of 303

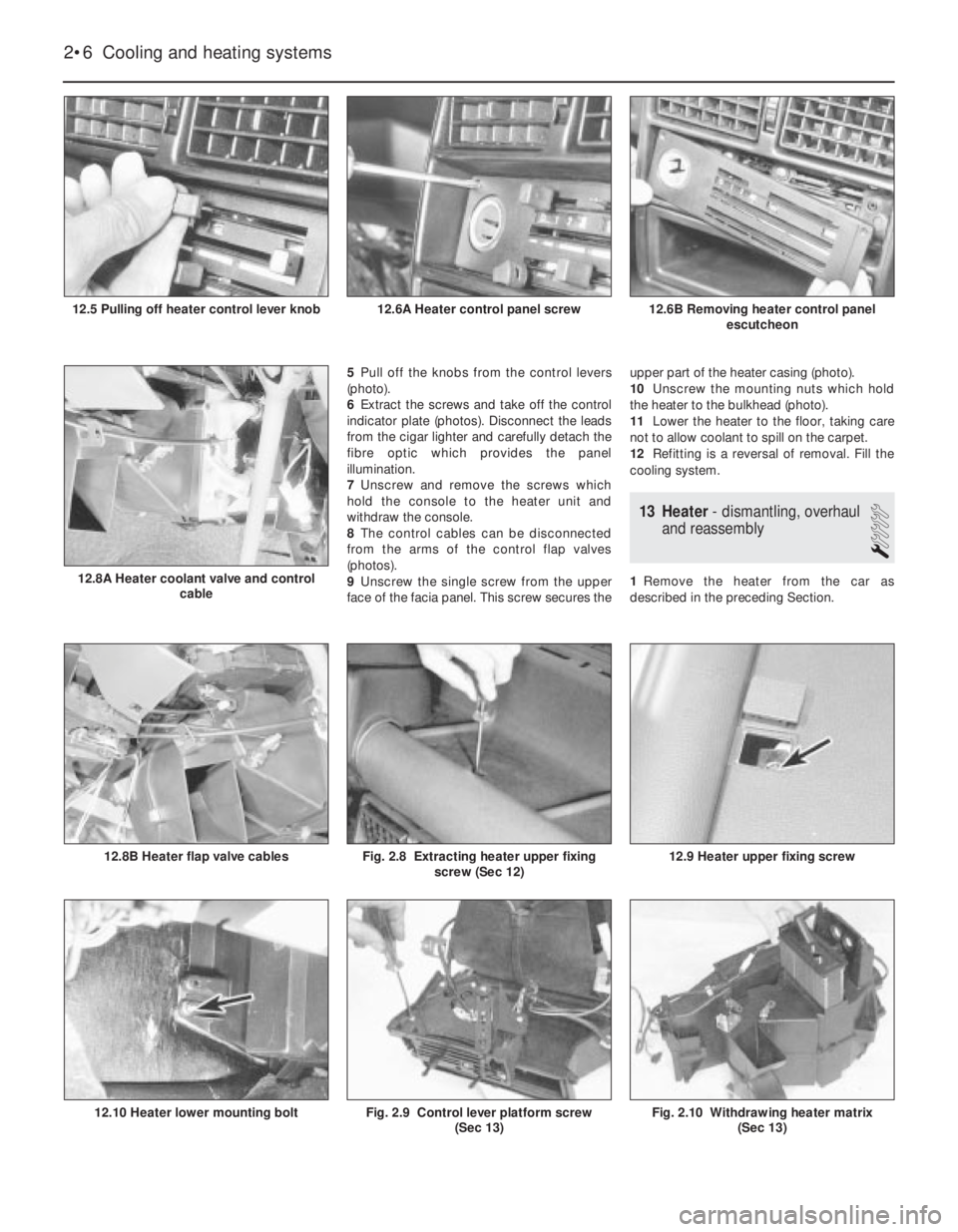

5Pull off the knobs from the control levers

(photo).

6Extract the screws and take off the control

indicator plate (photos). Disconnect the leads

from the cigar lighter and carefully detach the

fibre optic which provides the panel

illumination.

7Unscrew and remove the screws which

hold the console to the heater unit and

withdraw the console.

8The control cables can be disconnected

from the arms of the control flap valves

(photos).

9Unscrew the single screw from the upper

face of the facia panel. This screw secures theupper part of the heater casing (photo).

10Unscrew the mounting nuts which hold

the heater to the bulkhead (photo).

11Lower the heater to the floor, taking care

not to allow coolant to spill on the carpet.

12Refitting is a reversal of removal. Fill the

cooling system.

13 Heater- dismantling, overhaul

and reassembly

1

1Remove the heater from the car as

described in the preceding Section.

2•6 Cooling and heating systems

Fig. 2.10 Withdrawing heater matrix

(Sec 13)Fig. 2.9 Control lever platform screw

(Sec 13)12.10 Heater lower mounting bolt

12.9 Heater upper fixing screw

12.8A Heater coolant valve and control

cable

Fig. 2.8 Extracting heater upper fixing

screw (Sec 12)12.8B Heater flap valve cables

12.6B Removing heater control panel

escutcheon12.6A Heater control panel screw12.5 Pulling off heater control lever knob

Page 62 of 303

Engine idle speed

At normal operating temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 to 850 rev/min

CO percentage at idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 maximum

Torque wrench settingsNm lbf ft

Exhaust manifold nuts (903 cc) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

Exhaust and intake manifold nuts (1116 cc, 1301 cc) . . . . . . . . . . . . . . 28 20

Fuel pump nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 20

Carburettor mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

3•4 Fuel system

2.11B Air cleaner mounting bracket and

pipe clip2.11A Air cleaner mounting studs (1116 cc)2.9 Crankcase vent hose at air cleaner

1 Description and

maintenance

1

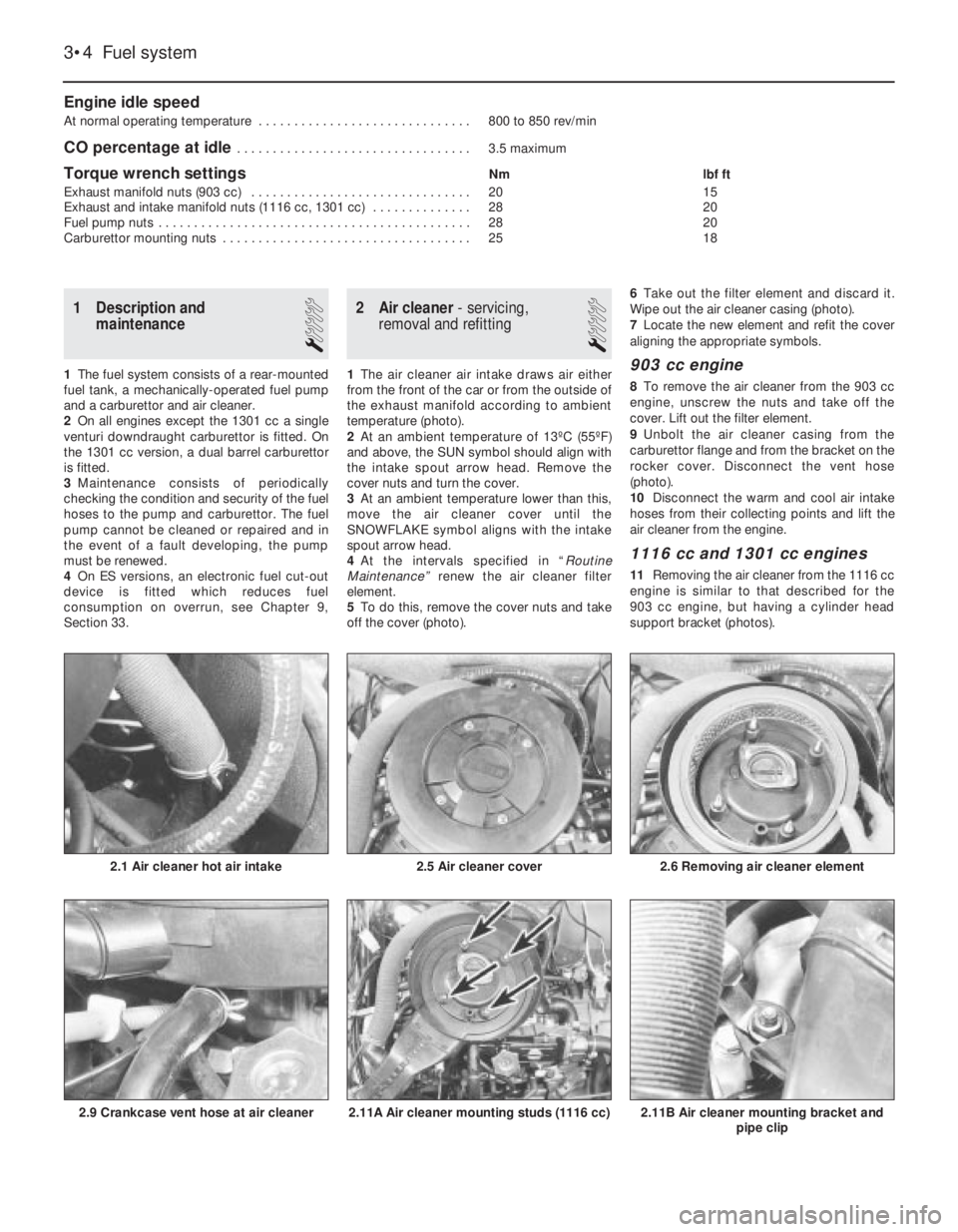

1The fuel system consists of a rear-mounted

fuel tank, a mechanically-operated fuel pump

and a carburettor and air cleaner.

2On all engines except the 1301 cc a single

venturi downdraught carburettor is fitted. On

the 1301 cc version, a dual barrel carburettor

is fitted.

3Maintenance consists of periodically

checking the condition and security of the fuel

hoses to the pump and carburettor. The fuel

pump cannot be cleaned or repaired and in

the event of a fault developing, the pump

must be renewed.

4On ES versions, an electronic fuel cut-out

device is fitted which reduces fuel

consumption on overrun, see Chapter 9,

Section 33.

2 Air cleaner- servicing,

removal and refitting

1

1The air cleaner air intake draws air either

from the front of the car or from the outside of

the exhaust manifold according to ambient

temperature (photo).

2At an ambient temperature of 13ºC (55ºF)

and above, the SUN symbol should align with

the intake spout arrow head. Remove the

cover nuts and turn the cover.

3At an ambient temperature lower than this,

move the air cleaner cover until the

SNOWFLAKE symbol aligns with the intake

spout arrow head.

4At the intervals specified in “Routine

Maintenance” renew the air cleaner filter

element.

5To do this, remove the cover nuts and take

off the cover (photo).6Take out the filter element and discard it.

Wipe out the air cleaner casing (photo).

7Locate the new element and refit the cover

aligning the appropriate symbols.903 cc engine

8To remove the air cleaner from the 903 cc

engine, unscrew the nuts and take off the

cover. Lift out the filter element.

9Unbolt the air cleaner casing from the

carburettor flange and from the bracket on the

rocker cover. Disconnect the vent hose

(photo).

10Disconnect the warm and cool air intake

hoses from their collecting points and lift the

air cleaner from the engine.

1116 cc and 1301 cc engines

11Removing the air cleaner from the 1116 cc

engine is similar to that described for the

903 cc engine, but having a cylinder head

support bracket (photos).

2.6 Removing air cleaner element

2.5 Air cleaner cover2.1 Air cleaner hot air intake

Page 63 of 303

12The air cleaner on the 1301 cc engine is

mounted on the four flange studs of the

carburettors, their nuts being accessible after

the air cleaner lid has been removed and the

filter element extracted.

13Refitting of all types of air cleaner is a

reversal of removal.

3 Fuel pump-

removal and refitting

2

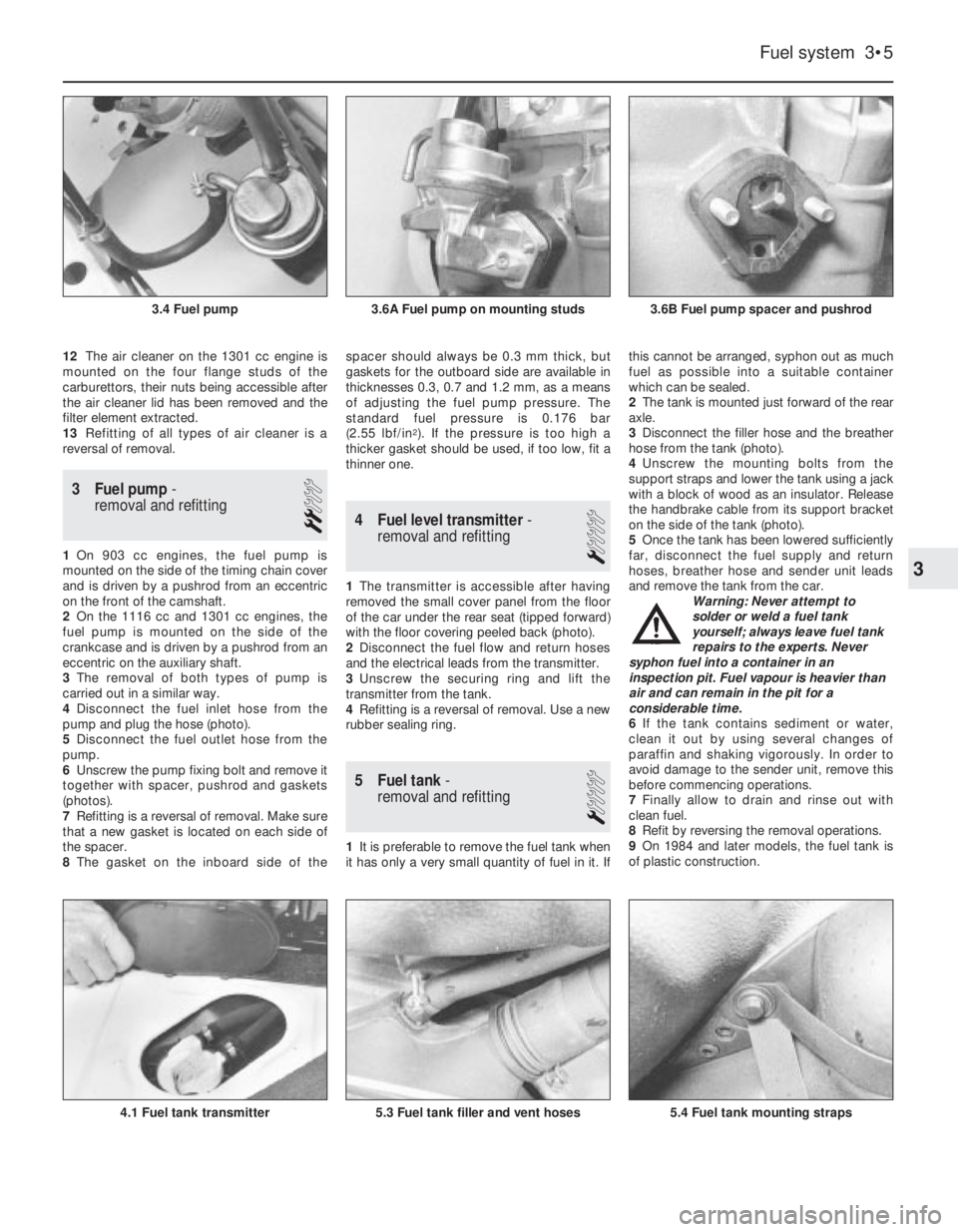

1On 903 cc engines, the fuel pump is

mounted on the side of the timing chain cover

and is driven by a pushrod from an eccentric

on the front of the camshaft.

2On the 1116 cc and 1301 cc engines, the

fuel pump is mounted on the side of the

crankcase and is driven by a pushrod from an

eccentric on the auxiliary shaft.

3The removal of both types of pump is

carried out in a similar way.

4Disconnect the fuel inlet hose from the

pump and plug the hose (photo).

5Disconnect the fuel outlet hose from the

pump.

6Unscrew the pump fixing bolt and remove it

together with spacer, pushrod and gaskets

(photos).

7Refitting is a reversal of removal. Make sure

that a new gasket is located on each side of

the spacer.

8The gasket on the inboard side of thespacer should always be 0.3 mm thick, but

gaskets for the outboard side are available in

thicknesses 0.3, 0.7 and 1.2 mm, as a means

of adjusting the fuel pump pressure. The

standard fuel pressure is 0.176 bar

(2.55 lbf/in

2). If the pressure is too high a

thicker gasket should be used, if too low, fit a

thinner one.

4 Fuel level transmitter-

removal and refitting

1

1The transmitter is accessible after having

removed the small cover panel from the floor

of the car under the rear seat (tipped forward)

with the floor covering peeled back (photo).

2Disconnect the fuel flow and return hoses

and the electrical leads from the transmitter.

3Unscrew the securing ring and lift the

transmitter from the tank.

4Refitting is a reversal of removal. Use a new

rubber sealing ring.

5 Fuel tank-

removal and refitting

1

1It is preferable to remove the fuel tank when

it has only a very small quantity of fuel in it. Ifthis cannot be arranged, syphon out as much

fuel as possible into a suitable container

which can be sealed.

2The tank is mounted just forward of the rear

axle.

3Disconnect the filler hose and the breather

hose from the tank (photo).

4Unscrew the mounting bolts from the

support straps and lower the tank using a jack

with a block of wood as an insulator. Release

the handbrake cable from its support bracket

on the side of the tank (photo).

5Once the tank has been lowered sufficiently

far, disconnect the fuel supply and return

hoses, breather hose and sender unit leads

and remove the tank from the car.

Warning: Never attempt to

solder or weld a fuel tank

yourself; always leave fuel tank

repairs to the experts. Never

syphon fuel into a container in an

inspection pit. Fuel vapour is heavier than

air and can remain in the pit for a

considerable time.

6If the tank contains sediment or water,

clean it out by using several changes of

paraffin and shaking vigorously. In order to

avoid damage to the sender unit, remove this

before commencing operations.

7Finally allow to drain and rinse out with

clean fuel.

8Refit by reversing the removal operations.

9On 1984 and later models, the fuel tank is

of plastic construction.

Fuel system 3•5

3.6B Fuel pump spacer and pushrod3.6A Fuel pump on mounting studs3.4 Fuel pump

5.4 Fuel tank mounting straps5.3 Fuel tank filler and vent hoses4.1 Fuel tank transmitter

3

Page 76 of 303

5 Condenser (capacitor)-

removal, testing and refitting

1

The purpose of the condenser (sometimes

known as the capacitor) is to ensure that when

the contact breaker points open there is no

sparking across them which would weaken

the spark and cause rapid deterioration of the

points.

The condenser is fitted in parallel with the

contact breaker points. If it develops a short

circuit it will cause ignition failure as the points

will be prevented from interrupting the low

tension circuit.

1If the engine becomes very difficult to start

(or begins to misfire whilst running) and the

breaker points show signs of excessive

burning, suspect the condenser has failed

with open circuit. A test can be made by

separating the points by hand with the ignition

switched on. If this is accompanied by a

bright spark at the contact points, it is

indicative that the condenser has failed.

2Without special test equipment, the only

sure way to diagnose condenser trouble is to

replace a suspected unit with a new one and

note if there is any improvement.

3To remove the condenser from the

distributor, take out the screw which secures

it to the distributor body and disconnect its

leads from the terminals.

4When fitting the condenser, it is vital to

ensure that the fixing screw is secure. The

lead must be secure on the terminal with no

chance of short circuiting.

6 Distributor-

removal and refitting

3

1Remove the spark plug from No. 4 cylinder

and then turn the crankshaft either by

applying a spanner to the pulley nut or by

jacking up a front wheel, engaging top gear

and turning the wheel in the forward direction

of travel.

2Place a finger over the plug hole and feel

the compression being generated as the

piston rises up the cylinder bore.

3Alternatively, if the rocker cover is off,

check that the valves on No. 1 cylinder are

closed.

4Continue turning the crankshaft until the

flywheel and flywheel housing (BTDC) ignition

timing marks are in alignment. Number 4

piston is now in firing position.

5Remove the distributor cap and place it to

one side complete with high tension leads.

6Disconnect the distributor vacuum hose

and low tension lead (photo).

7Mark the distributor pedestal mounting

plinth in relation to the crankcase. Also mark

the contact end of the rotor in relation to the

rim of the distributor body.8Unbolt the clamp plate and withdraw the

distributor.

9Refit by having No. 4 piston at its firing

position and the distributor rotor and pedestal

marks aligned, then push the distributor into

position, mating it to the splined driveshaft.

10If a new distributor is being fitted then of

course alignment marks will not be available

to facilitate installation in which case, hold the

unit over its mounting hole and observe the

following.

903 cc engine: Distributor cap high tension

lead sockets pointing towards alternator and

at 90º to centre line of rocker cover. Contact

end of rotor arm pointing towards No. 4

contact in distributor cap (when fitted).

1116 cc and 1301 cc engine: Distributor

vacuum unit pointing downwards at 135º to

rear edge of timing belt cover. Contact end of

rotor arm pointing towards No. 4 contact in

distributor cap (when fitted).

11Tighten the distributor clamp bolt,

reconnect the vacuum hose and the low

tension leads. Refit the distributor cap. Screw

in the spark plug.

12Check the ignition timing as described in

Section 4.

7 Distributor (mechanical

breaker type)- overhaul

3

Ducellier

1The cap must have no flaws or cracks and

the HT terminal contacts should not be

severely corroded. The centre spring-loaded

carbon contact is renewable. If in any doubt

about the cap, buy a new one.

2The rotor deteriorates minimally, but with

age the metal conductor tip may corrode. It

should not be cracked or chipped and the

metal conductor must not be loose. If in

doubt, renew it. Always fit a new rotor if fitting

a new cap.

3With the distributor removed as described

in the preceding Section, take off the rotor

and contact breaker.4To remove the contact breaker movable

arm, extract the clip and take off the washer

from the top of the pivot post.

5Extract the screw and remove the fixed

contact arm.

6Carefully record the setting of the advance

toothed segment and then remove the spring

clip and vacuum capsule fixing screws and

withdraw the capsule with link rod.

7Pick out the lubrication pad from the recess

in the top of the distributor shaft. Unscrew the

screw now exposed.

8Mark the relationship of the cam to the

counterweight pins and then remove the cam

assembly.

9There is no way to test the bob weight

springs other than by checking the

performance of the distributor on special test

equipment, so if in doubt, fit new springs

anyway. If the springs are loose where they

loop over the posts, it is more than possible

that the post grooves are worn. In this case,

the various parts which include the shaft will

need renewal. Wear to this extent would mean

that a new distributor is probably the best

solution in the long run. Be sure to make note

of the engine number and any serial number

on the distributor when ordering.

10If the mainshaft is slack in its bushes or

the cam on the spindle, allowing sideways

play, it means that the contact points gap

setting can only be a compromise; the cam

position relative to the cam follower on the

moving point arm is not constant. It is not

practical to re-bush the distributor body

unless you have a friend who can bore and

bush it for you. The shaft can be removed by

driving out the roll pin from the retaining collar

at the bottom. (The collar also acts as an oil

slinger to prevent excess engine oil creeping

up the shaft.)

Marelli

11With the distributor removed from the

engine, take off the spark shield and rotor.

12Remove the contact breaker and carrier

as described in Section 2.

13Refer to paragraphs 9 and 10 for details of

counterweight springs and shaft bushes

(photo).

Ignition system 4•5

6.6 Distributor LT connection4.5 Distributor clamp plate nut

4

Page 82 of 303

3.4 Removing the caliper unit

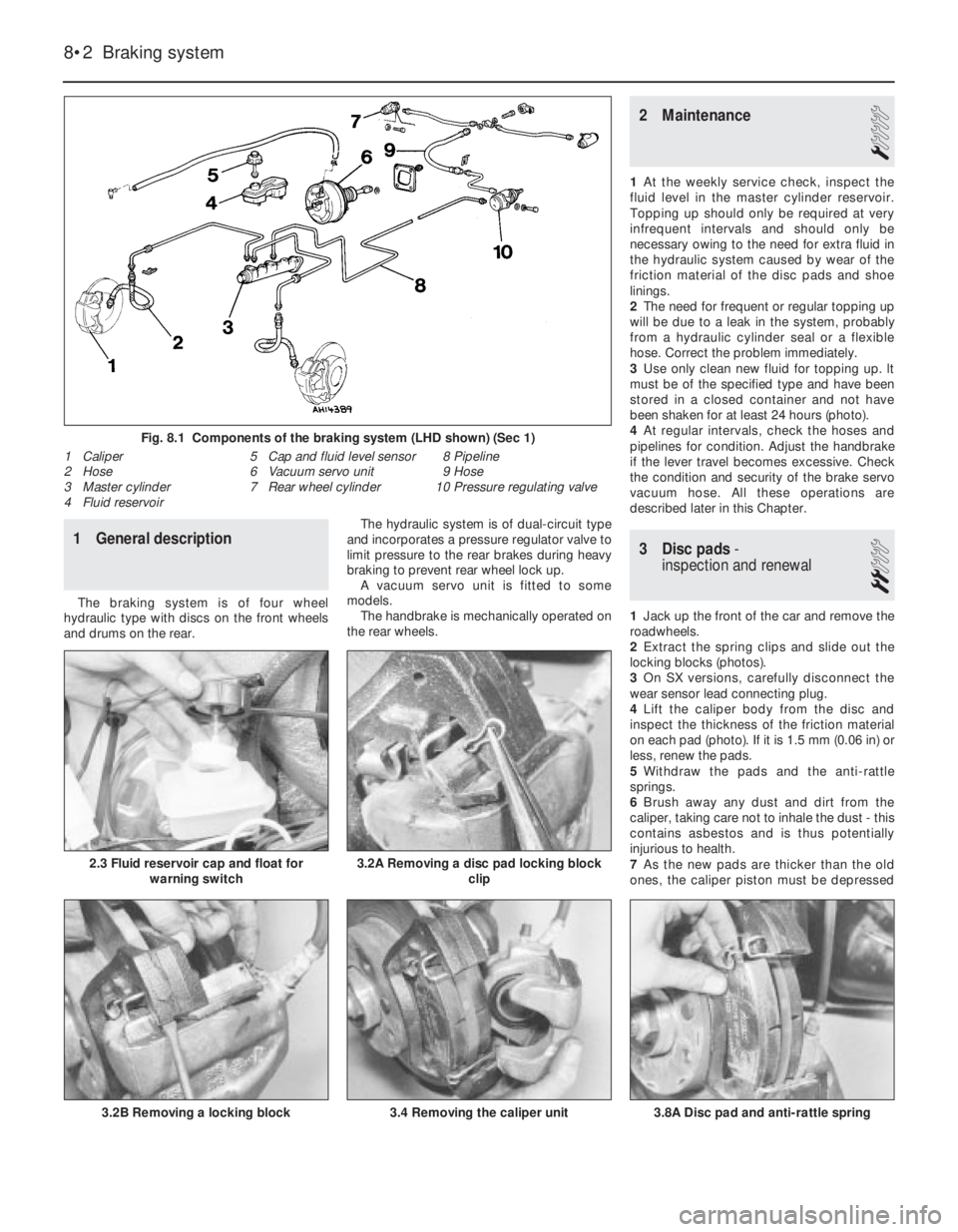

1 General description

The braking system is of four wheel

hydraulic type with discs on the front wheels

and drums on the rear.The hydraulic system is of dual-circuit type

and incorporates a pressure regulator valve to

limit pressure to the rear brakes during heavy

braking to prevent rear wheel lock up.

A vacuum servo unit is fitted to some

models.

The handbrake is mechanically operated on

the rear wheels.

2 Maintenance

1

1At the weekly service check, inspect the

fluid level in the master cylinder reservoir.

Topping up should only be required at very

infrequent intervals and should only be

necessary owing to the need for extra fluid in

the hydraulic system caused by wear of the

friction material of the disc pads and shoe

linings.

2The need for frequent or regular topping up

will be due to a leak in the system, probably

from a hydraulic cylinder seal or a flexible

hose. Correct the problem immediately.

3Use only clean new fluid for topping up. lt

must be of the specified type and have been

stored in a closed container and not have

been shaken for at least 24 hours (photo).

4At regular intervals, check the hoses and

pipelines for condition. Adjust the handbrake

if the lever travel becomes excessive. Check

the condition and security of the brake servo

vacuum hose. All these operations are

described later in this Chapter.

3 Disc pads-

inspection and renewal

2

1Jack up the front of the car and remove the

roadwheels.

2Extract the spring clips and slide out the

locking blocks (photos).

3On SX versions, carefully disconnect the

wear sensor lead connecting plug.

4Lift the caliper body from the disc and

inspect the thickness of the friction material

on each pad (photo). If it is 1.5 mm (0.06 in) or

less, renew the pads.

5Withdraw the pads and the anti-rattle

springs.

6Brush away any dust and dirt from the

caliper, taking care not to inhale the dust - this

contains asbestos and is thus potentially

injurious to health.

7As the new pads are thicker than the old

ones, the caliper piston must be depressed

8•2 Braking system

3.8A Disc pad and anti-rattle spring

Fig. 8.1 Components of the braking system (LHD shown) (Sec 1)

1 Caliper

2 Hose

3 Master cylinder

4 Fluid reservoir5 Cap and fluid level sensor

6 Vacuum servo unit

7 Rear wheel cylinder8 Pipeline

9 Hose

10 Pressure regulating valve

3.2B Removing a locking block

3.2A Removing a disc pad locking block

clip2.3 Fluid reservoir cap and float for

warning switch

Page 83 of 303

into its cylinder to accommodate them. This

will cause the fluid level to rise in the reservoir.

Anticipate this by syphoning some out

beforehand, but take care not to let it drip

onto the paintwork - it acts as an effective

paint stripperl

8Refit the anti-rattle springs, the pads

(friction lining-to-disc), the cylinder body, the

locking blocks and their retaining clips

(photos).

9Refit the roadwheel and apply the footbrake

hard, several times, to bring the pads into

contact with the brake disc.

10Renew the pads on the opposite brake.

The pads should always be renewed in axle

sets.

11Top up the fluid reservoir.

4 Rear brake shoes-

inspection and renewal

2

1Jack up the rear of the car and remove the

roadwheels.

2Fully release the handbrake.

3Unscrew and remove the drum securing

bolts. One of these is a long locating spigot

for the roadwheel.

4Pull off the drum. lf it is tight, clean off the

rust at its joint with the hub flange, and apply

a little penetrating fluid. Two bolts may be

screwed into the drum securing bolt holes if

necessary and the drum thus eased off the

hub. The securing bolt holes are tapped for

this purpose.

5Brush away all the dust and dirt from the

shoes and operating mechanism, taking care

not to inhale it.

6The friction linings fitted as original

equipment are of the bonded type and the

rivet heads normally used as a guide to wear

are not, of course, fitted. However, if the

thickness of the friction linings is down to

1.5 mm (0.06 in) or less, the shoes must be

renewed. Always purchase new or factory

relined brake shoes.

7Before removing the brake shoes, note the

way in which the shoes are positioned, with

respect to leading and trailing ends (the end

of the shoe not covered by lining material).Note also into which holes in the shoe web

the return springs are connected. Sketch the

shoes or mark the holes on the new shoes

with quick drying paint if you are doubtful

about remembering (photo).

8Undo the steady springs by depressing and

rotating their caps a quarter turn to disengage

the slot from the pin. On later models a

U-shaped steady spring is used. Depress and

slide it out.

9Rotate the hub until the cut-outs in its rear

flange face are in alignment with the shoe

self-adjusters.

10Pivot the trailing shoe on the self-adjuster

post and disengage the ends of the shoe from

the slot in the wheel cylinder tappet and from

the lower anchor block.

11Work the shoe up the self-adjuster pivot

post until the self-adjuster boss enters the

cut-out in the hub flange. The shoe can now

be withdrawn (photo).

12Once off the self-adjuster post, the

pull-off spring tension is eased, as the shoe

can move towards the other, so the springs

can be unhooked.

13Remove the leading shoe in a similar way.

14The new shoes will already be fitted with

new self-adjusters.

15Fit the new shoes to their self-adjuster

posts, making sure that the handbrake shoe

lever is correctly located. Engage the ends of

the shoes.

16Using a wooden or plastic-faced mallet,

tap the shoes inwards against the friction of

their self-adjuster coil springs. This will havethe effect of reducing the overall diameter of

the shoes to facilitate fitting of the shoe return

springs and to allow the brake drum to slide

over them.

17Using pliers, reconnect the upper (longer)

and lower shoe return springs.

18Hold the steady pins in position from the

rear of the backplate. Fit the small coil springs

and the retaining cap, again using pliers to

grip the cap and to depress and turn it to

engage the pin. On later models fit the

U-shaped springs.

19Before refitting the drum, clean it out and

examine it for grooves or scoring (refer to

Section 8).

20Fit the drum and the roadwheel.

21Apply the brakes two or three times to

position the shoes close to the drum.

22Renew the shoes on the opposite brake in

a similar way.

23The handbrake should be automatically

adjusted by the action of the shoe adjuster. If

the handbrake control lever has excessive

travel, refer to Section 16 for separate

adjusting instructions.

5 Caliper- removal,

overhaul and refitting

4

Note: Purchase a repair kit in advance of

overhaul.

1Jack up the front roadwheel and remove it.

2Brush away all dirt from the caliper

Braking system 8•3

4.11 Rear hub showing cut-outs on rear

face for shoe self-adjuster bosses4.7 Rear brake assembly3.8B Cylinder body located on caliper

bracket

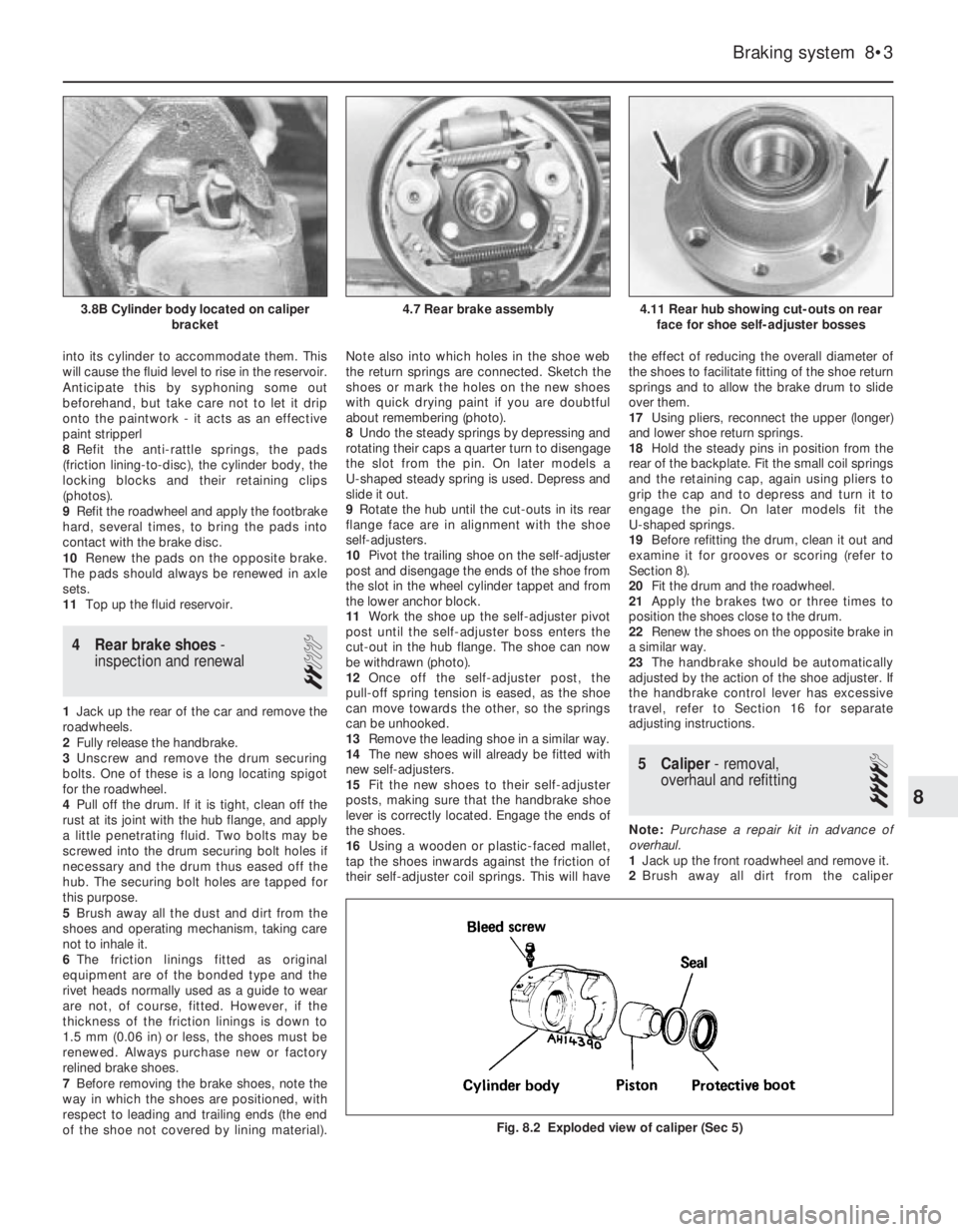

Fig. 8.2 Exploded view of caliper (Sec 5)

8