brakes FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 88 of 303

20By connecting a pressurised container to

the master cylinder fluid reservoir, bleeding is

then carried out by simply opening each bleed

screw in turn and allowing the fluid to run out,

rather like turning on a tap, until no air is

visible in the expelled fluid.

21By using this method, the large reserve of

hydraulic fluid provides a safeguard against

air being drawn into the master cylinder

during bleeding which often occurs if the fluid

level in the reservoir is not maintained.

22Pressure bleeding is particularly effective

when bleeding “difficult” systems or when

bleeding the complete system at time of

routine fluid renewal.

All methods

23When bleeding is completed, check and

top up the fluid level in the master cylinder

reservoir.

24Check the feel of the brake pedal. If it

feels at all spongy, air must still be present in

the system and further bleeding is indicated.

Failure to bleed satisfactorily after a

reasonable period of the bleeding operation,

may be due to worn master cylinder seals.

25Discard brake fluid which has been

expelled. lt is almost certain to be

contaminated with moisture, air and dirt

making it unsuitable for further use. Clean

fluid should always be stored in an airtight

container as it absorbs moisture readily

(hygroscopic) which lowers its boiling point

and could affect braking performance under

severe conditions.

13 Vacuum servo unit-

description

A vacuum servo unit is fitted into the brake

hydraulic circuit on 55 and 70 models in series

with the master cylinder, to provide assistance

to the driver when the brake pedal is

depressed. This reduces the effort required by

the driver to operate the brakes under all

braking conditions.

The unit operates by vacuum obtained from

the induction manifold and comprises basically

a booster diaphragm and non-return valve. The

servo unit and hydraulic master cylinder are

connected together so that the servo unit

piston rod acts as the master cylinder pushrod.

The driver’s braking effort is transmitted

through another pushrod to the servo unit

piston and its built-in control system. The servo

unit piston does not fit tightly into the cylinder,

but has a strong diaphragm to keep its edges

in constant contact with the cylinder wall, so

assuring an air tight seal between the two

parts. The forward chamber is held under

vacuum conditions created in the inlet manifold

of the engine and, during periods when the

brake pedal is not in use, the controls open a

passage to the rear chamber so placing it

under vacuum conditions as well. When the

brake pedal is depressed, the vacuum passageto the rear chamber is cut off and the chamber

opened to atmospheric pressure. The

consequent rush of air pushes the servo piston

forward in the vacuum chamber and operates

the main pushrod to the master cylinder.

The controls are designed so that

assistance is given under all conditions and,

when the brakes are not required, vacuum in

the rear chamber is established when the

brake pedal is released. All air from the

atmosphere entering the rear chamber is

passed through a small air filter.

Under normal operating conditions, the

vacuum servo unit is very reliable and does

not require overhaul except at very high

mileages. In this case, it is far better to obtain

a service exchange unit, rather than repair the

original unit.

It is emphasised that the servo unit assists

in reducing the braking effort required at the

foot pedal and in the event of its failure, the

hydraulic braking system is in no way affected

except that the need for higher pressures will

be noticed.

14 Vacuum servo unit-

servicing and testing

1Regularly, check that the vacuum hose

which runs between the servo unit and the

inlet manifold is in good condition and is a

tight fit at both ends.

2If broken or badly clogged, renew the air

filter which is located around the brake pedal

push rod. Access to this is obtained by

disconnecting the pushrod from the

cross-shaft or pedal arm, withdrawing the

pushrod, dust excluding boot and end cap.

3If the new filter is cut diagonally from its

centre hole, future renewal can be carried out

without the need for disconnection of the

pushrod.

4If the efficiency of the servo unit is suspect,

it can be checked out in the following way.

5Run the engine, then switch off the ignition.

Depress the footbrake pedal; the distinctive

in-rush of air into the servo should be clearly

heard. It should be possible to repeat this

operation several times before the vacuum in

the system is exhausted.

6Start the engine and have an assistant

apply the footbrake pedal and hold it down.

Disconnect the vacuuum hose from the servo.

There should not be any in-rush of air into the

servo through the connecting stub. lf there is,

the servo diaphragm is probably faulty. During

this test, expect the engine to idle roughly,

unless the open end of the hose to the inlet

manifold is plugged. Reconnect the hose.

7With the engine off, depress the brake

pedal fully. Start the engine with the brake

pedal still depressed; the pedal should be felt

to go down fractionally.

8If the results of these tests are not

satisfactory, remove the unit and fit a new one

as described in the next Section.

15 Vacuum servo unit-

removal and refitting

3

1Syphon as much fluid as possible out of the

master cylinder reservolr.

2Disconnect electrical leads from the

terminals in the reservoir cap then uncouple

the rigid pipelines from the master cylinder

body. Be prepared to catch leaking fluid and

plug the open ends of the pipelines.

3The master cylinder can be unbolted now

from the servo unit, or detached later when

the complete assembly is withdrawn.

4Working inside the car, disconnect the

servo pushrod from the pedal then remove the

servo mounting nuts.

5Withdraw the servo assembly into the

engine compartment, then remove it to the

bench. lf the master cylinder is still attached,

cover the wings with protective sheeting, in

case brake fluid is spilled during removal.

6Refitting is a reversal of the removal

process, but adjust the pushrod clearance as

described in Section 9. On completion of

refitting, bleed the complete hydraulic system

as described in Section 12. Note: Where the

help of an assistant is available, the servo

pushrod need not be disconnected from the

pedal. The rod is a sliding fit in the servo and

the servo can be simply pulled off the rod.

Refitting without having disconnected the rod

from the pedal can be difficult unless the help

of an assistant is available.

16 Handbrake- adjustment

1

Adjustment is normally automatic, by the

movement of the rear brake shoes on their

automatic adjusters.

However, owing to cable stretch,

supplementary adjustment is occasionally

required at the control lever adjuster nut. The

need for this adjustment is usually indicated

by excessive movement of the control lever

when fully applied.

1The rear brakes should be fully applied

when the handbrake control lever has been

pulled over four or five notches.

2If adjustment is required, release the

8•8 Braking system

16.2 Handbrake adjuster nuts

Page 89 of 303

locknut and turn the adjuster nut on the

handbrake primary rod (photo).

3Raise the rear roadwheels and check that

they turn freely when the handbrake lever is

fully released.

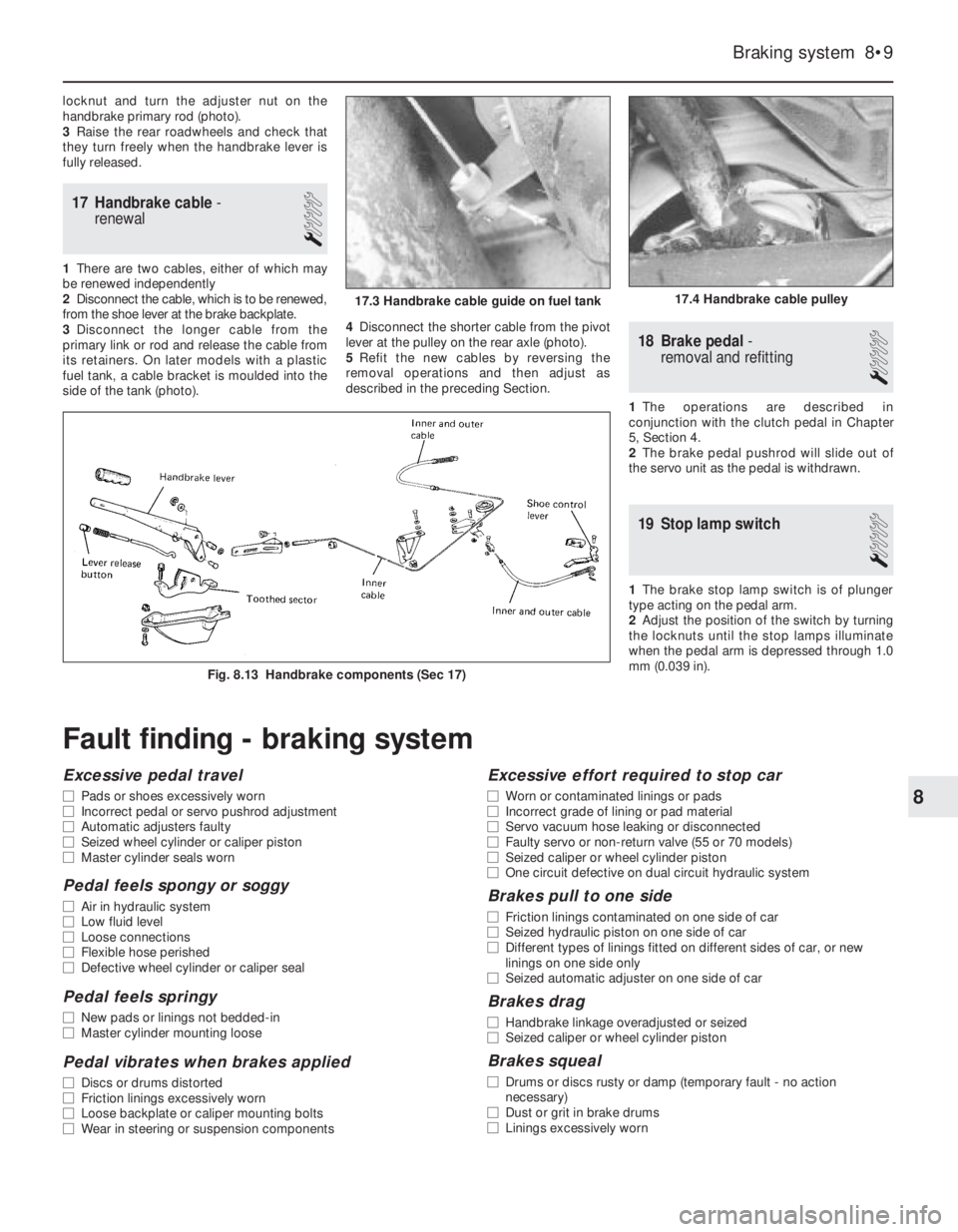

17 Handbrake cable-

renewal

1

1There are two cables, either of which may

be renewed independently

2Disconnect the cable, which is to be renewed,

from the shoe lever at the brake backplate.

3Disconnect the longer cable from the

primary link or rod and release the cable from

its retainers. On later models with a plastic

fuel tank, a cable bracket is moulded into the

side of the tank (photo).4Disconnect the shorter cable from the pivot

lever at the pulley on the rear axle (photo).

5Refit the new cables by reversing the

removal operations and then adjust as

described in the preceding Section.

18 Brake pedal-

removal and refitting

1

1The operations are described in

conjunction with the clutch pedal in Chapter

5, Section 4.

2The brake pedal pushrod will slide out of

the servo unit as the pedal is withdrawn.

19 Stop lamp switch

1

1The brake stop lamp switch is of plunger

type acting on the pedal arm.

2Adjust the position of the switch by turning

the locknuts until the stop lamps illuminate

when the pedal arm is depressed through 1.0

mm (0.039 in).

Braking system 8•9

Fig. 8.13 Handbrake components (Sec 17)

17.4 Handbrake cable pulley17.3 Handbrake cable guide on fuel tank

8

Fault finding - braking system

Excessive pedal travel

m mPads or shoes excessively worn

m mIncorrect pedal or servo pushrod adjustment

m mAutomatic adjusters faulty

m mSeized wheel cylinder or caliper piston

m mMaster cylinder seals worn

Pedal feels spongy or soggy

m

mAir in hydraulic system

m mLow fluid level

m mLoose connections

m mFlexible hose perished

m mDefective wheel cylinder or caliper seal

Pedal feels springy

m

mNew pads or linings not bedded-in

m mMaster cylinder mounting loose

Pedal vibrates when brakes applied

m

mDiscs or drums distorted

m mFriction linings excessively worn

m mLoose backplate or caliper mounting bolts

m mWear in steering or suspension components

Excessive effort required to stop car

m

mWorn or contaminated linings or pads

m mIncorrect grade of lining or pad material

m mServo vacuum hose leaking or disconnected

m mFaulty servo or non-return valve (55 or 70 models)

m mSeized caliper or wheel cylinder piston

m mOne circuit defective on dual circuit hydraulic system

Brakes pull to one side

m

mFriction linings contaminated on one side of car

m mSeized hydraulic piston on one side of car

m mDifferent types of linings fitted on different sides of car, or new

linings on one side only

m mSeized automatic adjuster on one side of car

Brakes drag

m

mHandbrake linkage overadjusted or seized

m mSeized caliper or wheel cylinder piston

Brakes squeal

m

mDrums or discs rusty or damp (temporary fault - no action

necessary)

m mDust or grit in brake drums

m mLinings excessively worn

Page 112 of 303

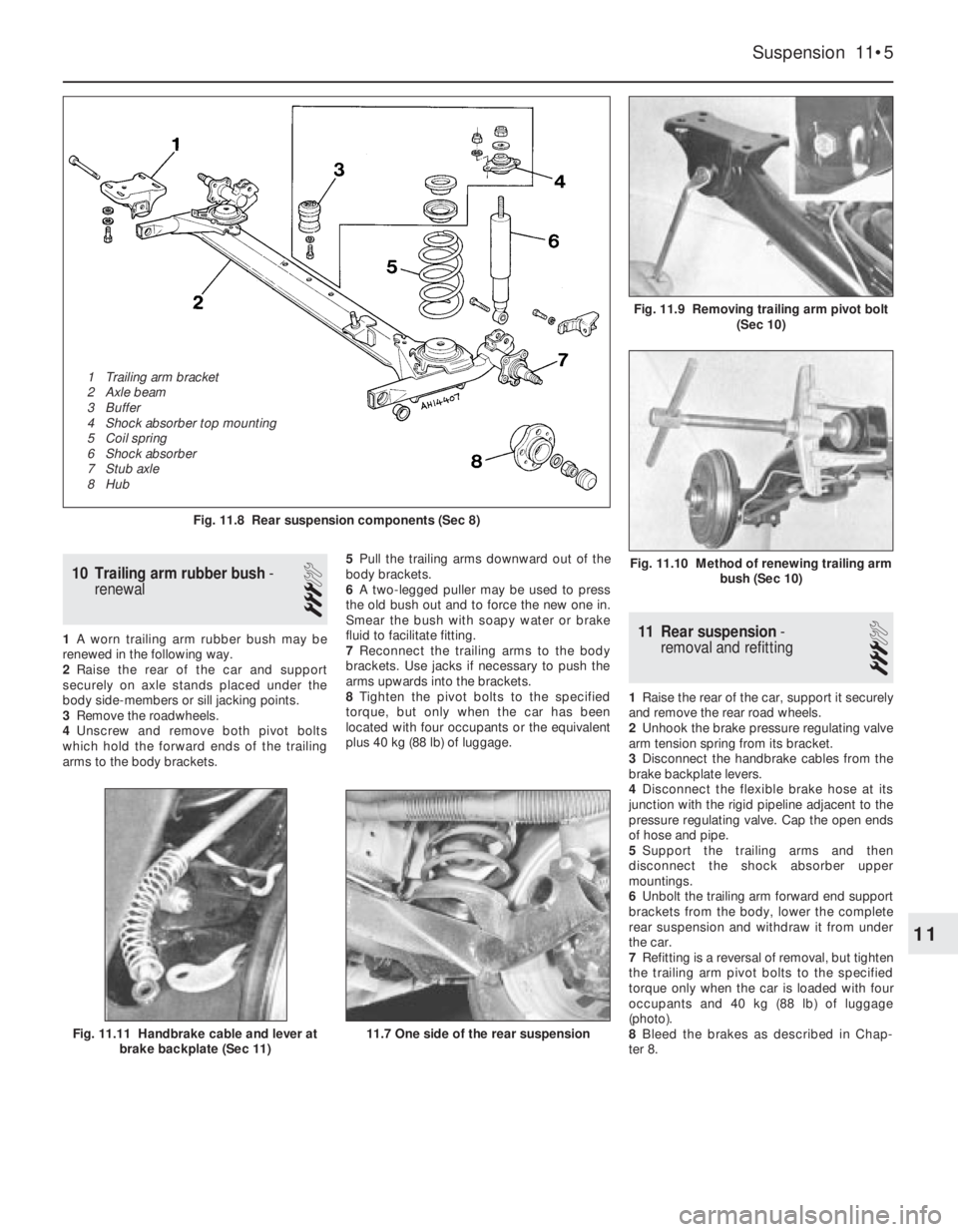

10 Trailing arm rubber bush-

renewal

3

1A worn trailing arm rubber bush may be

renewed in the following way.

2Raise the rear of the car and support

securely on axle stands placed under the

body side-members or sill jacking points.

3Remove the roadwheels.

4Unscrew and remove both pivot bolts

which hold the forward ends of the trailing

arms to the body brackets.5Pull the trailing arms downward out of the

body brackets.

6A two-legged puller may be used to press

the old bush out and to force the new one in.

Smear the bush with soapy water or brake

fluid to facilitate fitting.

7Reconnect the trailing arms to the body

brackets. Use jacks if necessary to push the

arms upwards into the brackets.

8Tighten the pivot bolts to the specified

torque, but only when the car has been

located with four occupants or the equivalent

plus 40 kg (88 lb) of luggage.11 Rear suspension-

removal and refitting

3

1Raise the rear of the car, support it securely

and remove the rear road wheels.

2Unhook the brake pressure regulating valve

arm tension spring from its bracket.

3Disconnect the handbrake cables from the

brake backplate levers.

4Disconnect the flexible brake hose at its

junction with the rigid pipeline adjacent to the

pressure regulating valve. Cap the open ends

of hose and pipe.

5Support the trailing arms and then

disconnect the shock absorber upper

mountings.

6Unbolt the trailing arm forward end support

brackets from the body, lower the complete

rear suspension and withdraw it from under

the car.

7Refitting is a reversal of removal, but tighten

the trailing arm pivot bolts to the specified

torque only when the car is loaded with four

occupants and 40 kg (88 lb) of luggage

(photo).

8Bleed the brakes as described in Chap-

ter 8.

Suspension 11•5

Fig. 11.9 Removing trailing arm pivot bolt

(Sec 10)

Fig. 11.8 Rear suspension components (Sec 8)

11.7 One side of the rear suspensionFig. 11.11 Handbrake cable and lever at

brake backplate (Sec 11)

Fig. 11.10 Method of renewing trailing arm

bush (Sec 10)

11

1 Trailing arm bracket

2 Axle beam

3 Buffer

4 Shock absorber top mounting

5 Coil spring

6 Shock absorber

7 Stub axle

8 Hub

Page 128 of 303

Braking system................................................................................. 14

Part A: Braking system general

Front brake pads all later models

Part B: Braking system - Turbo ie models

Description

Front disc pads - renewal

Front disc caliper - removal and refitting

Front disc caliper - overhaul

Front brake disc - inspection, renovation or renewal

Rear disc pads - renewal

Rear disc caliper - removal, overhaul and refitting

Rear brake disc - inspection, renovation and renewal

Pressure regulating valve

Brake pedal - removal and refitting

Vacuum servo unit and master cylinder - general

Antiskid system - description

Electrical system.............................................................................. 15

Alternator (999 cc models) - removal and refitting

Alternator (later models) - removal and refitting

Alternator brushes - renewal

Starter motor (999 cc models) - removal and refitting

Starter motor (1301 cc Turbo ie, 1372 cc ie, 1372 cc Turbo ie)

- removal and refitting

Starter motor brushes (later models) - renewal

Fuses - later models

Relays (Turbo ie models) - general

Headlamps - later models

Headlamp beam adjusters for load compensation - later models

Headlamp unit removal - later models

Headlamp dim-dip system - description

Front fog lamps bulb/unit - removal and refitting and beam

adjustment

Horn - relocation

Steering column combination switches (later models) - removal

and refittingInstrument panel (Turbo ie models) - removal and refitting

Facia-mounted switches (1301 cc Turbo ie model) - removal

and refitting

Instrument panel (later models) - removal and refitting

Auxiliary control panel (later models) - removal and refitting

Heater control panel (later models) - removal and refitting

Trip master

Interior roof mounted spotlamp, switch and/or clock - removal

and refitting

Central door locking system

Cigar lighter (later models) - removal and refitting

Electrically operated window switches - removal and refitting

Windscreen wiper motor (later models) - removal and refitting

Windscreen washer reservoir (Turbo) - removal and refitting

Tailgate wiper motor (later models) - removal and refitting

Radio Check control system sensors - description

Check control system sensors - testing

Suspension....................................................................................... 16

Front anti-roll bar - removal and refitting

Suspension strut later models

Bodywork.......................................................................................... 17

Plastic components

Rear view mirrors

Door armrest

Tailgate (Turbo ie model) - component removal and refitting

Radiator grille (1301 cc Turbo ie model) - removal and

refitting

Radiator grille (1372 cc ie and 1372 cc Turbo ie models) -

removal and refitting

Bumpers (1301 cc Turbo ie, 1372 cc ie and 1372 cc Turbo ie

models) - removal and refitting

Rear hinged windows - removal and refitting

Door trim panel (Turbo ie model) - removal and refitting

Supplement: Revisions and information on later models 13•3

13

1 Introduction

Since its introduction in 1983, the FIAT Uno

has had a number of modifications and

improvements including the fitting of a twin

choke carburettor, low profile tyres, tinted

windows and remotely-controlled central door

locking.

The major mechanical change was the

introduction of the FIRE (Fully Integrated

Robotised Engine) on 45 and 45S models to

be followed by a new 1108 cc “FIRE” engine

on the 60S model from 1989 on.

A 1301 cc Turbo ie engine model wasavailable for a short period. This model had a

Bosch LE2 Jetronic electronic fuel injection

(ie) and a turbocharger to give added

performance. To uprate the braking to suit,

disc brakes were fitted to the rear in place of

the original drum type brakes.

A 1372 cc engine model was introduced in

1989. Two versions were initially available. A

Bosch Mono-Jetronic single-point fuel

injection (SPi) system, as found on the 70 SX

model and Bosch L3.1 or L3.2 Jetronic

multi-point fuel injection (MPi) systems were

fitted to Turbo models. L3.2 MPi system

models were equipped with catalytic

converters, to improve exhaust emission. All

fuel injection engines are fitted with electroni-

cally controlled engine management systems.

A new style instrument panel, switchgearand a revised facia layout was introduced in

1989.

During 1992, SPi fuel systems were fitted to

the 999 cc and 1108 cc engines, along with

catalytic converters for improved exhaust

emissions.

Five speed transmissions were introduced

to 999 cc models in 1993.

It is recommended that this Supplement is

always referred to before the main Chapters

of the Manual.

Project vehicles

The vehicles used in the preparation of this

supplement, and appearing in many of the

photographic sequences were a 1986 Uno

45S FIRE, a 1988 1301 cc Uno Turbo ie and a

1991 1372 cc Uno SXie.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 140 of 303

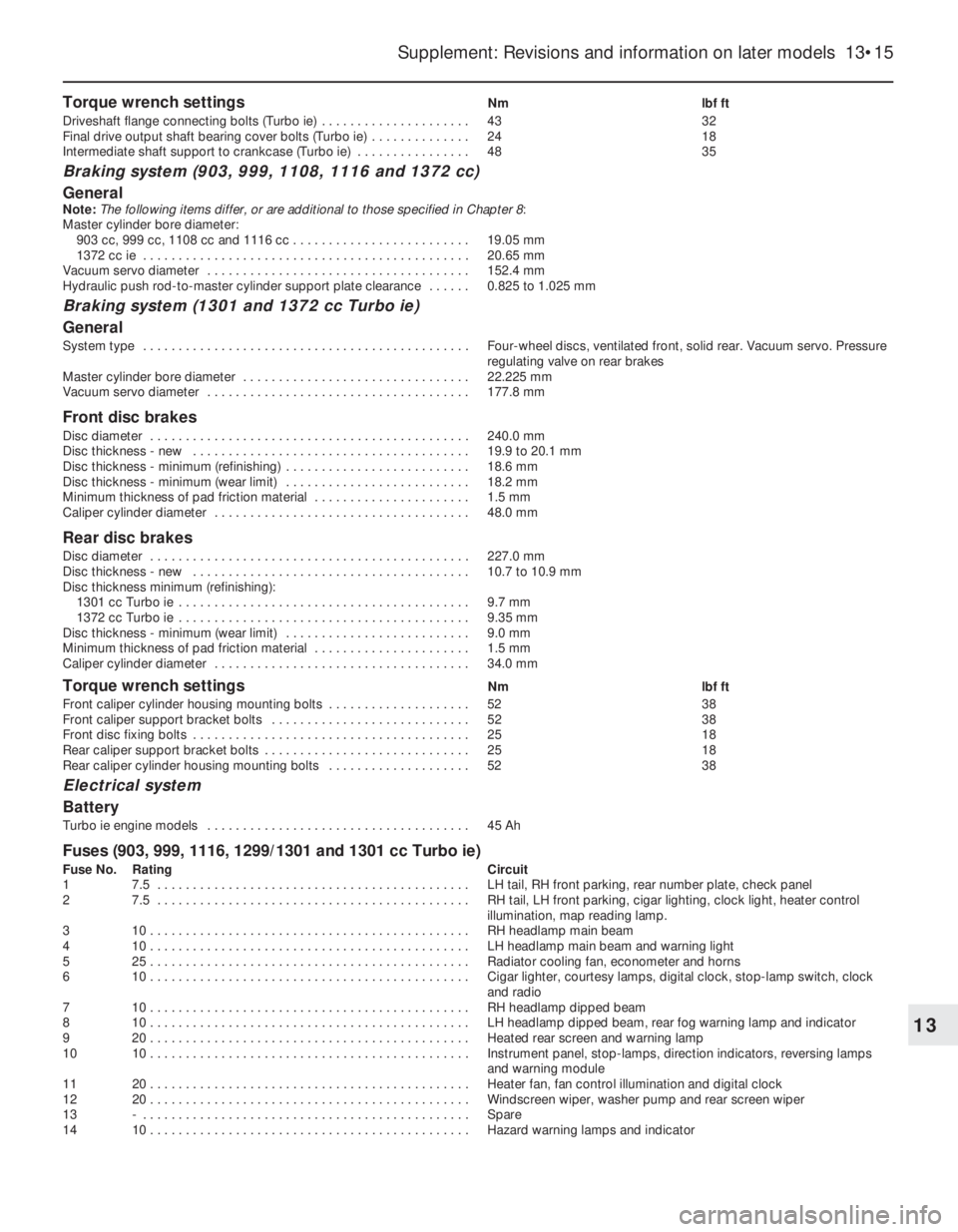

Torque wrench settingsNm lbf ft

Driveshaft flange connecting bolts (Turbo ie) . . . . . . . . . . . . . . . . . . . . . 43 32

Final drive output shaft bearing cover bolts (Turbo ie) . . . . . . . . . . . . . . 24 18

Intermediate shaft support to crankcase (Turbo ie) . . . . . . . . . . . . . . . . 48 35

Braking system (903, 999, 1108, 1116 and 1372 cc)

General

Note:The following items differ, or are additional to those specified in Chapter 8:

Master cylinder bore diameter:

903 cc, 999 cc, 1108 cc and 1116 cc . . . . . . . . . . . . . . . . . . . . . . . . . 19.05 mm

1372 cc ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.65 mm

Vacuum servo diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152.4 mm

Hydraulic push rod-to-master cylinder support plate clearance . . . . . . 0.825 to 1.025 mm

Braking system (1301 and 1372 cc Turbo ie)

General

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-wheel discs, ventilated front, solid rear. Vacuum servo. Pressure

regulating valve on rear brakes

Master cylinder bore diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.225 mm

Vacuum servo diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177.8 mm

Front disc brakes

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240.0 mm

Disc thickness - new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.9 to 20.1 mm

Disc thickness - minimum (refinishing) . . . . . . . . . . . . . . . . . . . . . . . . . . 18.6 mm

Disc thickness - minimum (wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . 18.2 mm

Minimum thickness of pad friction material . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Caliper cylinder diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48.0 mm

Rear disc brakes

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227.0 mm

Disc thickness - new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.7 to 10.9 mm

Disc thickness minimum (refinishing):

1301 cc Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.7 mm

1372 cc Turbo ie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.35 mm

Disc thickness - minimum (wear limit) . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 mm

Minimum thickness of pad friction material . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Caliper cylinder diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.0 mm

Torque wrench settingsNm lbf ft

Front caliper cylinder housing mounting bolts . . . . . . . . . . . . . . . . . . . . 52 38

Front caliper support bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 38

Front disc fixing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Rear caliper support bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 18

Rear caliper cylinder housing mounting bolts . . . . . . . . . . . . . . . . . . . . 52 38

Electrical system

Battery

Turbo ie engine models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Ah

Fuses (903, 999, 1116, 1299/1301 and 1301 cc Turbo ie)

Fuse No. Rating Circuit

1 7.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH tail, RH front parking, rear number plate, check panel

2 7.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH tail, LH front parking, cigar lighting, clock light, heater control

illumination, map reading lamp.

3 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH headlamp main beam

4 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH headlamp main beam and warning light

5 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Radiator cooling fan, econometer and horns

6 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cigar lighter, courtesy lamps, digital clock, stop-lamp switch, clock

and radio

7 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RH headlamp dipped beam

8 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LH headlamp dipped beam, rear fog warning lamp and indicator

9 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heated rear screen and warning lamp

10 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Instrument panel, stop-lamps, direction indicators, reversing lamps

and warning module

11 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heater fan, fan control illumination and digital clock

12 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Windscreen wiper, washer pump and rear screen wiper

13 - . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Spare

14 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hazard warning lamps and indicator

Supplement: Revisions and information on later models 13•15

13

Page 143 of 303

13•18 Supplement: Revisions and information on later models

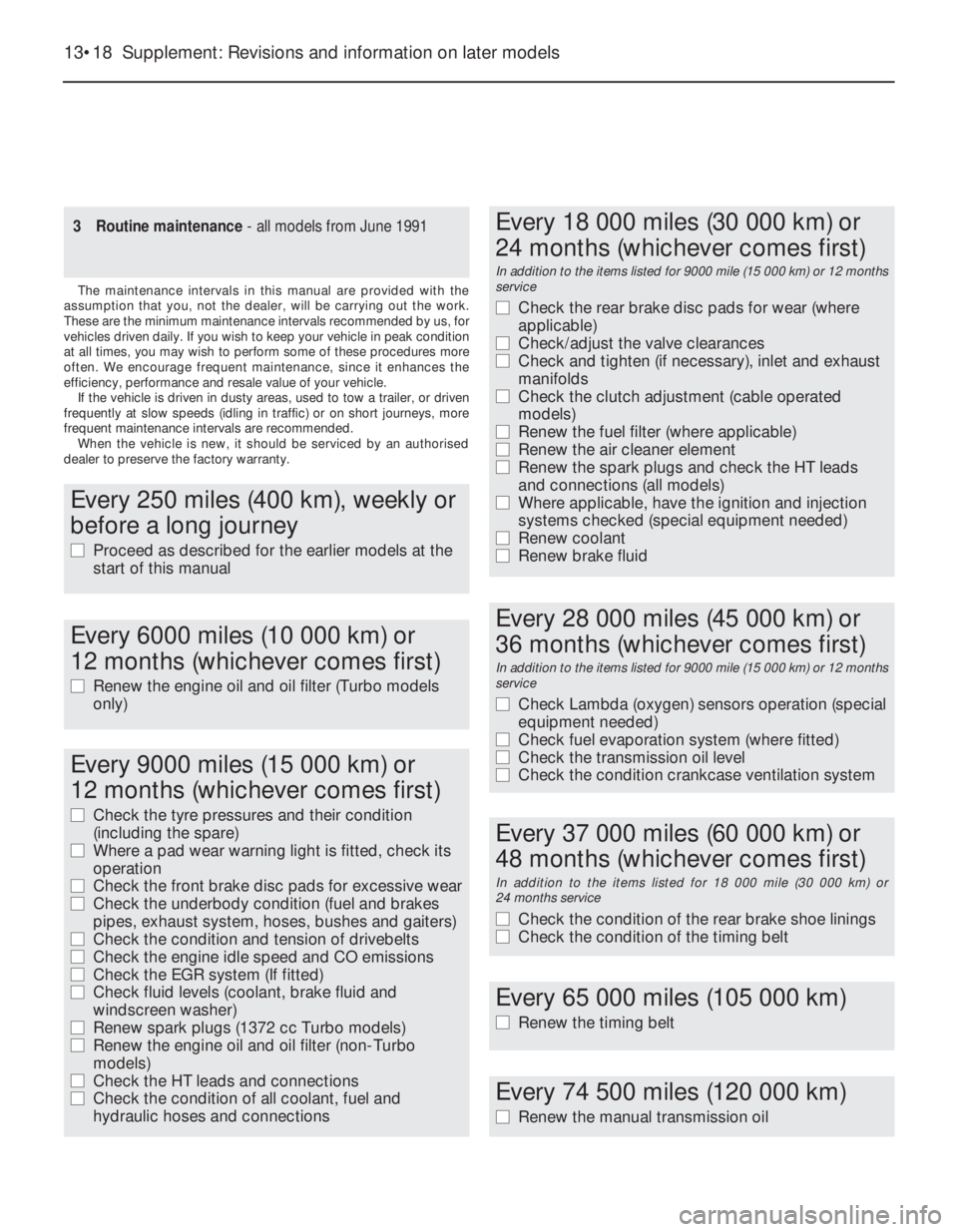

Every 9000 miles (15 000 km) or

12 months (whichever comes first)

m mCheck the tyre pressures and their condition

(including the spare)

m mWhere a pad wear warning light is fitted, check its

operation

m mCheck the front brake disc pads for excessive wear

m mCheck the underbody condition (fuel and brakes

pipes, exhaust system, hoses, bushes and gaiters)

m mCheck the condition and tension of drivebelts

m mCheck the engine idle speed and CO emissions

m mCheck the EGR system (If fitted)

m mCheck fluid levels (coolant, brake fluid and

windscreen washer)

m mRenew spark plugs (1372 cc Turbo models)

m mRenew the engine oil and oil filter (non-Turbo

models)

m mCheck the HT leads and connections

m mCheck the condition of all coolant, fuel and

hydraulic hoses and connections

Every 18 000 miles (30 000 km) or

24 months (whichever comes first)

In addition to the items listed for 9000 mile (15 000 km) or 12 months

service

m mCheck the rear brake disc pads for wear (where

applicable)

m mCheck/adjust the valve clearances

m mCheck and tighten (if necessary), inlet and exhaust

manifolds

m mCheck the clutch adjustment (cable operated

models)

m mRenew the fuel filter (where applicable)

m mRenew the air cleaner element

m mRenew the spark plugs and check the HT leads

and connections (all models)

m mWhere applicable, have the ignition and injection

systems checked (special equipment needed)

m mRenew coolant

m mRenew brake fluid

Every 28 000 miles (45 000 km) or

36 months (whichever comes first)

In addition to the items listed for 9000 mile (15 000 km) or 12 months

service

m mCheck Lambda (oxygen) sensors operation (special

equipment needed)

m mCheck fuel evaporation system (where fitted)

m mCheck the transmission oil level

m mCheck the condition crankcase ventilation system

Every 37 000 miles (60 000 km) or

48 months (whichever comes first)

In addition to the items listed for 18 000 mile (30 000 km) or

24 months service

m mCheck the condition of the rear brake shoe linings

m mCheck the condition of the timing belt

Every 65 000 miles (105 000 km)

m

mRenew the timing belt

Every 74 500 miles (120 000 km)

m

mRenew the manual transmission oil

Every 250 miles (400 km), weekly or

before a long journey

m mProceed as described for the earlier models at the

start of this manual

Every 6000 miles (10 000 km) or

12 months (whichever comes first)

m mRenew the engine oil and oil filter (Turbo models

only)

3 Routine maintenance- all models from June 1991

The maintenance intervals in this manual are provided with the

assumption that you, not the dealer, will be carrying out the work.

These are the minimum maintenance intervals recommended by us, for

vehicles driven daily. If you wish to keep your vehicle in peak condition

at all times, you may wish to perform some of these procedures more

often. We encourage frequent maintenance, since it enhances the

efficiency, performance and resale value of your vehicle.

If the vehicle is driven in dusty areas, used to tow a trailer, or driven

frequently at slow speeds (idling in traffic) or on short journeys, more

frequent maintenance intervals are recommended.

When the vehicle is new, it should be serviced by an authorised

dealer to preserve the factory warranty.

Page 225 of 303

20When reassembling, pack the joint with

special FIAT Tutela MRM2 lubricant; if this is not

available, use molybdenum disulphide grease.

21The reference groove on the outer track

must be assembled so that it is towards the

final drive when refitted (photo).

22Pack the joint and the inside of the boot

liberally with the specified grease.

23If a new joint is being fitted to the shaft,

make sure that the joint and shaft colour

codes match.

Shaft colour Joint colour

Blue Blue or white

Red Red or white

Right-hand driveshaft damper

weight (1108 cc and

1372 cc ie models) -

removal and refitting

#

24A damper weight is fitted to the longer,

right-hand driveshaft to reduce vibration (photo).25It should not be necessary to remove the

damper weight unless the driveshaft is to be

renewed, or the weight has been damaged.

26The weight is in two halves, and can be

removed by simply unscrewing the two clamp

bolts securing the two halves to the

driveshaft. Note that the weight locates on a

rubber mounting which is split along its

length, and can simply be pulled from the

driveshaft for renewal if necessary.

27Refitting is a reversal of removal, but

ensure that the damper weight is positioned

exactly as shown in Fig. 13.101.

14 Braking system

PART A: BRAKING

SYSTEM - GENERAL

Front brake pads - all later

models

1The front brake pads have modified

anti-vibration plates and a wire spring fitted to

prevent them from vibrating and knocking in

operation. 2On some models the clip securing the disc

pad locking block is located on the inboard

end, rather than the outer end (shown in

Chapter 8). To ensure correct reassembly,

check the location of the original block

retaining clip before dismantling the brake

unit. The alternative fixing arrangement is

shown in the accompanying photos, in this

instance on a 1372 cc ie model (photos).

PART B: BRAKING SYSTEM

- TURBO IE MODELS

Description

1Disc brakes are fitted to all four wheels on

the Turbo ie models. The front disc brakes are

of different design from those used on other

models, in that the wear in the pads can be

checked without the need to remove the

caliper cylinder housing.

Front disc pads - renewalª

2Raise the front of the car and remove the

roadwheels.

3Check the thickness of the friction material

on the pads through the aperture in the caliper

cylinder body. If the thickness of the material

is 1.5 mm or less, then the pads on both sides

must be renewed (photo).

13•100 Supplement: Revisions and information on later models

14B.3 Front disc pads (arrowed) on Turbo

ie model14A.2B Front brake locking block

orientation with inboard retaining clip14A.2A Front brake pad locking block is

secured by a clip on the inboard end of the

brake unit on certain models

Fig. 13.101 Correct position of driveshaft damper weight on 1108 cc and 1372 cc ie

models (Sec 13)

Dimensions in mm

13.24 Right-hand driveshaft damper weight

13.21 Outer track reference groove

Page 260 of 303

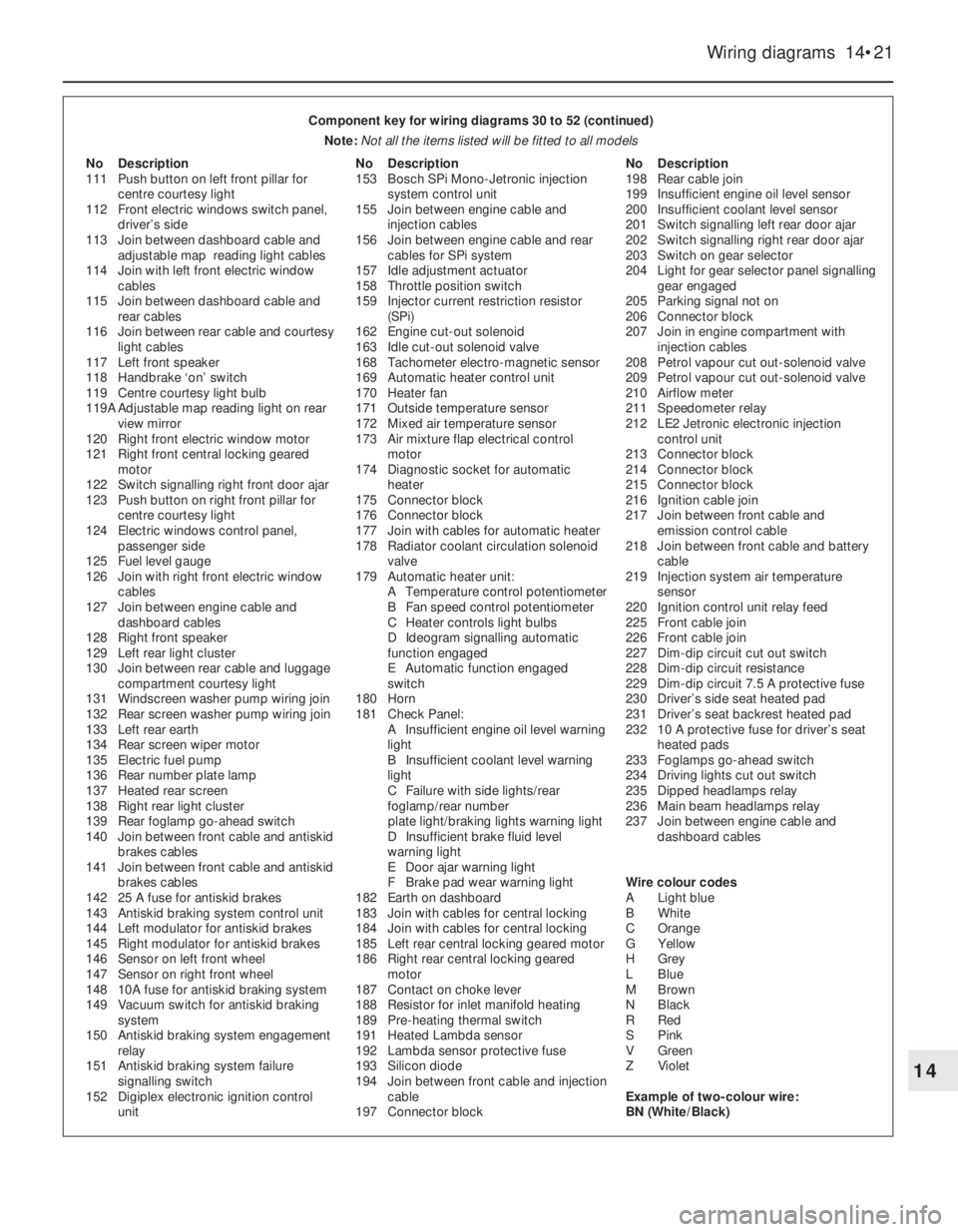

Wiring diagrams 14•21

14

Component key for wiring diagrams 30 to 52 (continued)

Note: Not all the items listed will be fitted to all models

No Description

111 Push button on left front pillar for

centre courtesy light

112 Front electric windows switch panel,

driver’s side

113 Join between dashboard cable and

adjustable map reading light cables

114 Join with left front electric window

cables

115 Join between dashboard cable and

rear cables

116 Join between rear cable and courtesy

light cables

117 Left front speaker

118 Handbrake ‘on’ switch

119 Centre courtesy light bulb

119A Adjustable map reading light on rear

view mirror

120 Right front electric window motor

121 Right front central locking geared

motor

122 Switch signalling right front door ajar

123 Push button on right front pillar for

centre courtesy light

124 Electric windows control panel,

passenger side

125 Fuel level gauge

126 Join with right front electric window

cables

127 Join between engine cable and

dashboard cables

128 Right front speaker

129 Left rear light cluster

130 Join between rear cable and luggage

compartment courtesy light

131 Windscreen washer pump wiring join

132 Rear screen washer pump wiring join

133 Left rear earth

134 Rear screen wiper motor

135 Electric fuel pump

136 Rear number plate lamp

137 Heated rear screen

138 Right rear light cluster

139 Rear foglamp go-ahead switch

140 Join between front cable and antiskid

brakes cables

141 Join between front cable and antiskid

brakes cables

142 25 A fuse for antiskid brakes

143 Antiskid braking system control unit

144 Left modulator for antiskid brakes

145 Right modulator for antiskid brakes

146 Sensor on left front wheel

147 Sensor on right front wheel

148 10A fuse for antiskid braking system

149 Vacuum switch for antiskid braking

system

150 Antiskid braking system engagement

relay

151 Antiskid braking system failure

signalling switch

152 Digiplex electronic ignition control

unitNo Description

153 Bosch SPi Mono-Jetronic injection

system control unit

155 Join between engine cable and

injection cables

156 Join between engine cable and rear

cables for SPi system

157 Idle adjustment actuator

158 Throttle position switch

159 Injector current restriction resistor

(SPi)

162 Engine cut-out solenoid

163 Idle cut-out solenoid valve

168 Tachometer electro-magnetic sensor

169 Automatic heater control unit

170 Heater fan

171 Outside temperature sensor

172 Mixed air temperature sensor

173 Air mixture flap electrical control

motor

174 Diagnostic socket for automatic

heater

175 Connector block

176 Connector block

177 Join with cables for automatic heater

178 Radiator coolant circulation solenoid

valve

179 Automatic heater unit:

A Temperature control potentiometer

B Fan speed control potentiometer

C Heater controls light bulbs

D Ideogram signalling automatic

function engaged

E Automatic function engaged

switch

180 Horn

181 Check Panel:

A Insufficient engine oil level warning

light

B Insufficient coolant level warning

light

C Failure with side lights/rear

foglamp/rear number

plate light/braking lights warning light

D Insufficient brake fluid level

warning light

E Door ajar warning light

F Brake pad wear warning light

182 Earth on dashboard

183 Join with cables for central locking

184 Join with cables for central locking

185 Left rear central locking geared motor

186 Right rear central locking geared

motor

187 Contact on choke lever

188 Resistor for inlet manifold heating

189 Pre-heating thermal switch

191 Heated Lambda sensor

192 Lambda sensor protective fuse

193 Silicon diode

194 Join between front cable and injection

cable

197 Connector blockNo Description

198 Rear cable join

199 Insufficient engine oil level sensor

200 Insufficient coolant level sensor

201 Switch signalling left rear door ajar

202 Switch signalling right rear door ajar

203 Switch on gear selector

204 Light for gear selector panel signalling

gear engaged

205 Parking signal not on

206 Connector block

207 Join in engine compartment with

injection cables

208 Petrol vapour cut out-solenoid valve

209 Petrol vapour cut out-solenoid valve

210 Airflow meter

211 Speedometer relay

212 LE2 Jetronic electronic injection

control unit

213 Connector block

214 Connector block

215 Connector block

216 Ignition cable join

217 Join between front cable and

emission control cable

218 Join between front cable and battery

cable

219 Injection system air temperature

sensor

220 Ignition control unit relay feed

225 Front cable join

226 Front cable join

227 Dim-dip circuit cut out switch

228 Dim-dip circuit resistance

229 Dim-dip circuit 7.5 A protective fuse

230 Driver’s side seat heated pad

231 Driver’s seat backrest heated pad

232 10 A protective fuse for driver’s seat

heated pads

233 Foglamps go-ahead switch

234 Driving lights cut out switch

235 Dipped headlamps relay

236 Main beam headlamps relay

237 Join between engine cable and

dashboard cables

Wire colour codes

A Light blue

B White

C Orange

G Yellow

H Grey

L Blue

M Brown

N Black

R Red

S Pink

V Green

Z Violet

Example of two-colour wire:

BN (White/Black)

Page 294 of 303

Engine cuts out suddenly –

ignition fault

m mLoose or disconnected LT wires

m mWet HT leads or distributor cap (after

traversing water splash)

m mCoil failure (check for spark)

m mOther ignition fault (see Chapter 4)

Engine misfires before cutting out

– fuel fault

m mFuel tank empty

m mFuel pump defective or filter blocked

(check for delivery)

m mFuel tank filler vent blocked (suction will be

evident on releasing cap)

m mCarburettor needle valve sticking

m mCarburettor jets blocked (fuel contami-

nated)

m mOther fuel system fault (see Chapter 3)

Engine cuts out – other causes

m

mSerious overheating

m mMajor mechanical failure (eg camshaft

drive)

Ignition (no-charge) warning light

illuminated

m mSlack or broken drivebelt — retension or

renew (Chapter 9)

Ignition warning light not

illuminated

m mCoolant loss due to internal or external

leakage (see Chapter 2)

m mThermostat defective

m mLow oil level

m mBrakes binding

m mRadiator clogged externally or internally

m mElectric cooling fan not operating correctly

m mEngine waterways clogged

m mIgnition timing incorrect or automatic

advance malfunctioning

m mMixture too weak

Note: Do not add cold water to an overheated

engine or damage may result

Note: Low oil pressure in a high-mileage

engine at tickover is not necessarily a cause

for concern. Sudden pressure loss at speed is

far more significant. In any event check the

gauge or warning light sender before

condemning the engine.

Gauge reads low or warning light

illuminated with engine running

m mOil level low or incorrect grade

m mDefective gauge or sender unit m mWire to sender unit earthed

m mEngine overheating

m mOil filter clogged or bypass valve defective

m mOil pressure relief valve defective

m mOil pick-up strainer clogged

m mOil pump worn or mountings loose

m mWorn main or big-end bearings

Pre-ignition (pinking) on

acceleration

m mIncorrect grade of fuel

m mIgnition timing incorrect

m mDistributor faulty or worn

m mWorn or maladjusted carburettor

m mExcessive carbon build-up in engine

Whistling or wheezing noises

m

mLeaking vacuum hose

m mLeaking carburettor or manifold gasket

m mBlowing head gasket

Tapping or rattling

m

mIncorrect valve clearances (where appli-

cable)

m mWorn valve gear

m mWorn timing chain or belt

m mBroken piston ring (ticking noise)

Knocking or thumping

m

mUnintentional mechanical contact (eg fan

blades)

m mWorn drivebelt

m mPeripheral component fault (generator,

water pump, etc)

m mWorn big-end bearings (regular heavy

knocking, perhaps less under load)

m mWorn main bearings (rumbling and

knocking, perhaps worsening under load)

m mPiston slap (most noticeable when cold)

Engine noises

Low engine oil pressure

Engine overheatsEngine cuts out and will not restart

Fault FindingREF•11

REF

Crank engine and check for spark. Note

use of insulated tool

Page 296 of 303

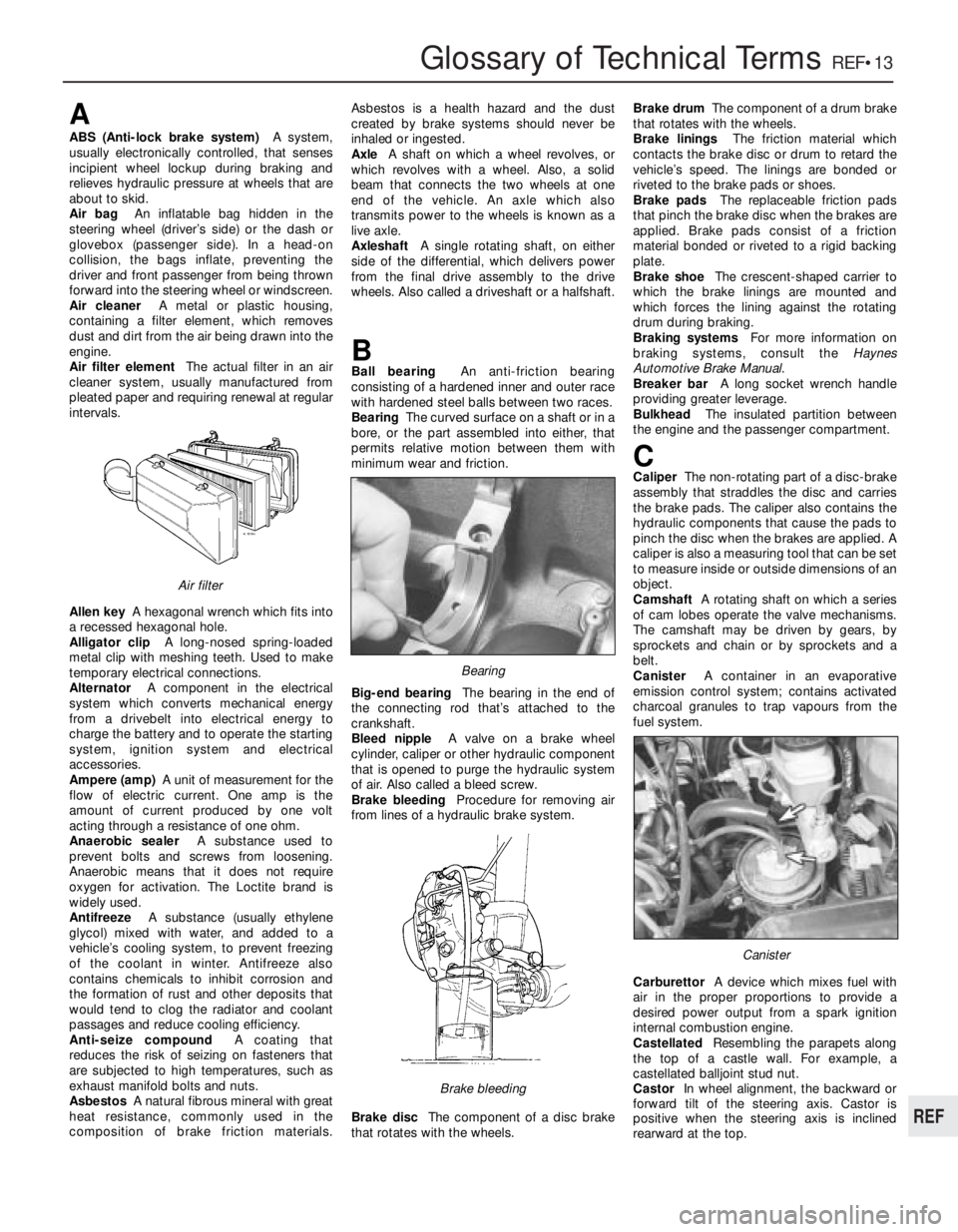

Glossary of Technical TermsREF•13

REF

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter