tailgate FIAT UNO 1983 Service User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 122 of 303

body so that the bottom edge of the rubber

seal engages over the metal flange.

7With an assistant pressing on the outside of

the glass, go inside and pull the cords evenly.

This will draw the lip of the weatherseal over

the body flange and seat the glass.

8Tap the glass with the palm of the hand to

settle it.

9If the weatherseal is in good condition then

it should prove waterproof, but if there is any

doubt, apply sealant with a gun between the

rubber and the glass and the rubber and the

body flange.

10Refit the mirror, tax disc and wiper.

16 Tailgate glass-

removal and refitting

5

1The operations are very similar to those

described for the windscreen, but disconnect

the leads from the heater element terminals.

17 Fixed side window

(five-door)-

removal and refitting

5

1The operations are similar to those

described for the windscreen in Section 15.

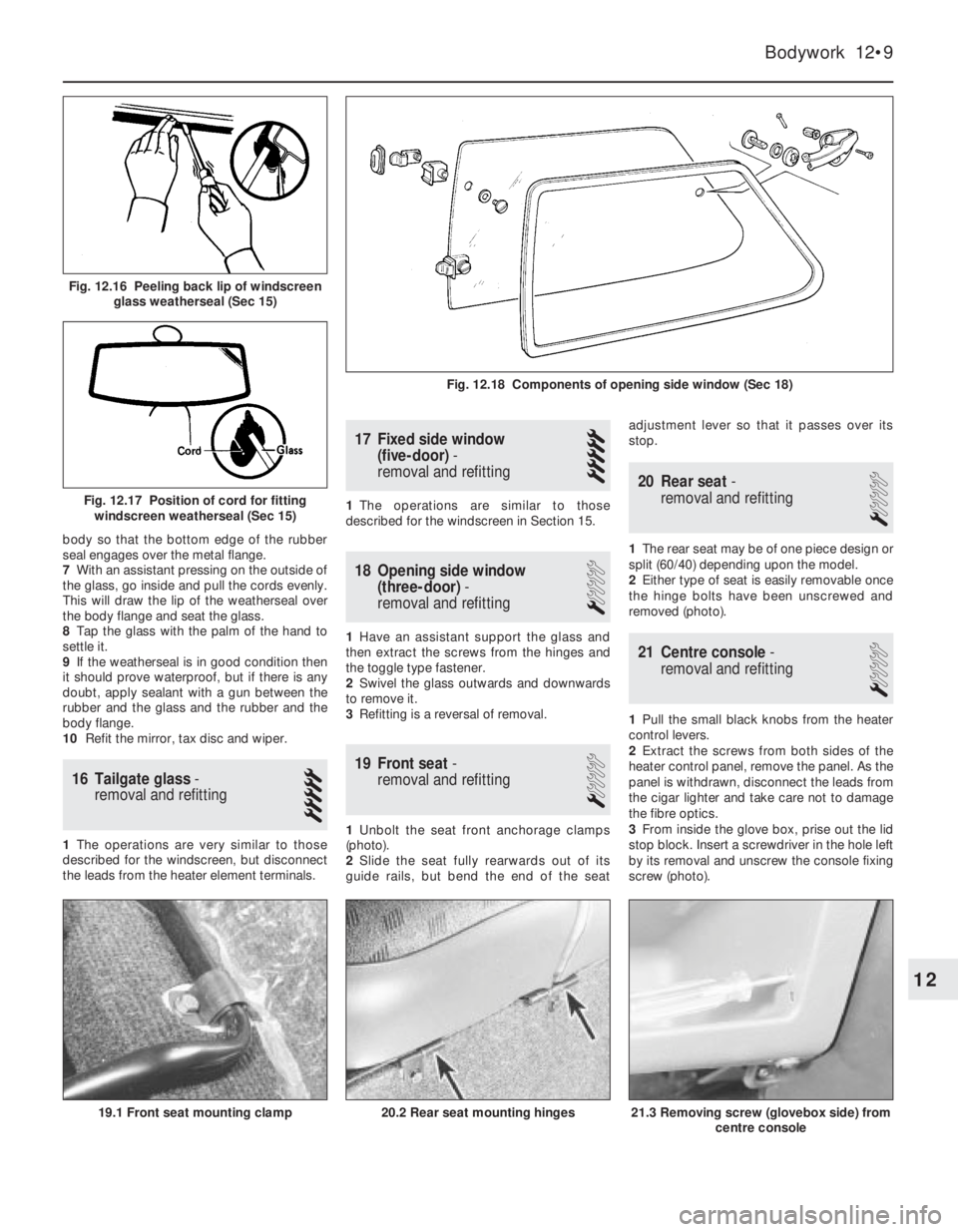

18 Opening side window

(three-door)-

removal and refitting

1

1Have an assistant support the glass and

then extract the screws from the hinges and

the toggle type fastener.

2Swivel the glass outwards and downwards

to remove it.

3Refitting is a reversal of removal.

19 Front seat-

removal and refitting

1

1Unbolt the seat front anchorage clamps

(photo).

2Slide the seat fully rearwards out of its

guide rails, but bend the end of the seatadjustment lever so that it passes over its

stop.

20 Rear seat-

removal and refitting

1

1The rear seat may be of one piece design or

split (60/40) depending upon the model.

2Either type of seat is easily removable once

the hinge bolts have been unscrewed and

removed (photo).

21 Centre console-

removal and refitting

1

1Pull the small black knobs from the heater

control levers.

2Extract the screws from both sides of the

heater control panel, remove the panel. As the

panel is withdrawn, disconnect the leads from

the cigar lighter and take care not to damage

the fibre optics.

3From inside the glove box, prise out the lid

stop block. Insert a screwdriver in the hole left

by its removal and unscrew the console fixing

screw (photo).

Bodywork 12•9

Fig. 12.18 Components of opening side window (Sec 18)

Fig. 12.17 Position of cord for fitting

windscreen weatherseal (Sec 15)

Fig. 12.16 Peeling back lip of windscreen

glass weatherseal (Sec 15)

21.3 Removing screw (glovebox side) from

centre console20.2 Rear seat mounting hinges19.1 Front seat mounting clamp

12

Page 124 of 303

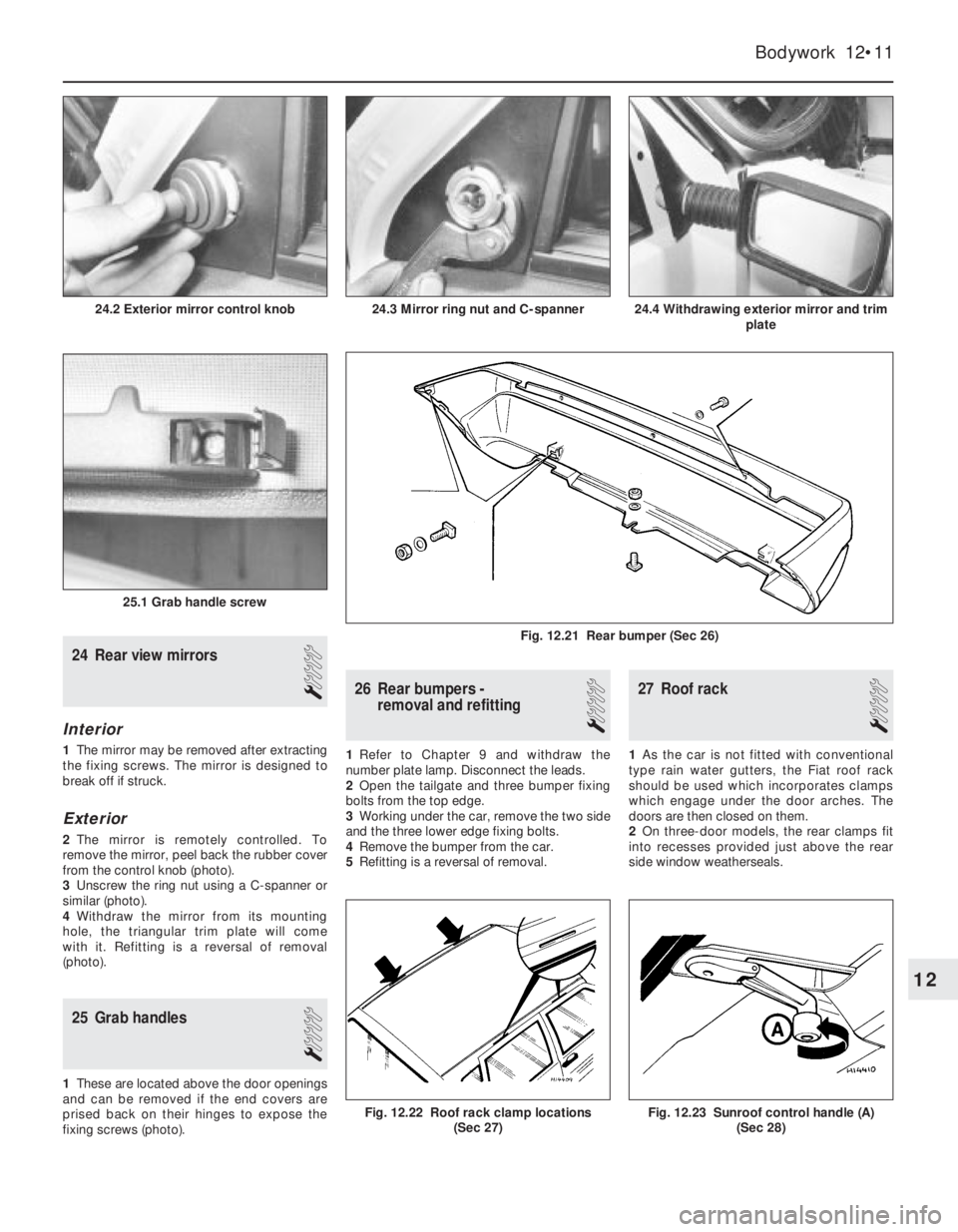

24 Rear view mirrors

1

Interior

1The mirror may be removed after extracting

the fixing screws. The mirror is designed to

break off if struck.

Exterior

2The mirror is remotely controlled. To

remove the mirror, peel back the rubber cover

from the control knob (photo).

3Unscrew the ring nut using a C-spanner or

similar (photo).

4Withdraw the mirror from its mounting

hole, the triangular trim plate will come

with it. Refitting is a reversal of removal

(photo).

25 Grab handles

1

1These are located above the door openings

and can be removed if the end covers are

prised back on their hinges to expose the

fixing screws (photo).

26 Rear bumpers -

removal and refitting

1

1Refer to Chapter 9 and withdraw the

number plate lamp. Disconnect the leads.

2Open the tailgate and three bumper fixing

bolts from the top edge.

3Working under the car, remove the two side

and the three lower edge fixing bolts.

4Remove the bumper from the car.

5Refitting is a reversal of removal.

27 Roof rack

1

1As the car is not fitted with conventional

type rain water gutters, the Fiat roof rack

should be used which incorporates clamps

which engage under the door arches. The

doors are then closed on them.

2On three-door models, the rear clamps fit

into recesses provided just above the rear

side window weatherseals.

Bodywork 12•11

24.4 Withdrawing exterior mirror and trim

plate

25.1 Grab handle screw

24.3 Mirror ring nut and C-spanner24.2 Exterior mirror control knob

Fig. 12.23 Sunroof control handle (A)

(Sec 28)Fig. 12.22 Roof rack clamp locations

(Sec 27)

Fig. 12.21 Rear bumper (Sec 26)

12

Page 128 of 303

Braking system................................................................................. 14

Part A: Braking system general

Front brake pads all later models

Part B: Braking system - Turbo ie models

Description

Front disc pads - renewal

Front disc caliper - removal and refitting

Front disc caliper - overhaul

Front brake disc - inspection, renovation or renewal

Rear disc pads - renewal

Rear disc caliper - removal, overhaul and refitting

Rear brake disc - inspection, renovation and renewal

Pressure regulating valve

Brake pedal - removal and refitting

Vacuum servo unit and master cylinder - general

Antiskid system - description

Electrical system.............................................................................. 15

Alternator (999 cc models) - removal and refitting

Alternator (later models) - removal and refitting

Alternator brushes - renewal

Starter motor (999 cc models) - removal and refitting

Starter motor (1301 cc Turbo ie, 1372 cc ie, 1372 cc Turbo ie)

- removal and refitting

Starter motor brushes (later models) - renewal

Fuses - later models

Relays (Turbo ie models) - general

Headlamps - later models

Headlamp beam adjusters for load compensation - later models

Headlamp unit removal - later models

Headlamp dim-dip system - description

Front fog lamps bulb/unit - removal and refitting and beam

adjustment

Horn - relocation

Steering column combination switches (later models) - removal

and refittingInstrument panel (Turbo ie models) - removal and refitting

Facia-mounted switches (1301 cc Turbo ie model) - removal

and refitting

Instrument panel (later models) - removal and refitting

Auxiliary control panel (later models) - removal and refitting

Heater control panel (later models) - removal and refitting

Trip master

Interior roof mounted spotlamp, switch and/or clock - removal

and refitting

Central door locking system

Cigar lighter (later models) - removal and refitting

Electrically operated window switches - removal and refitting

Windscreen wiper motor (later models) - removal and refitting

Windscreen washer reservoir (Turbo) - removal and refitting

Tailgate wiper motor (later models) - removal and refitting

Radio Check control system sensors - description

Check control system sensors - testing

Suspension....................................................................................... 16

Front anti-roll bar - removal and refitting

Suspension strut later models

Bodywork.......................................................................................... 17

Plastic components

Rear view mirrors

Door armrest

Tailgate (Turbo ie model) - component removal and refitting

Radiator grille (1301 cc Turbo ie model) - removal and

refitting

Radiator grille (1372 cc ie and 1372 cc Turbo ie models) -

removal and refitting

Bumpers (1301 cc Turbo ie, 1372 cc ie and 1372 cc Turbo ie

models) - removal and refitting

Rear hinged windows - removal and refitting

Door trim panel (Turbo ie model) - removal and refitting

Supplement: Revisions and information on later models 13•3

13

1 Introduction

Since its introduction in 1983, the FIAT Uno

has had a number of modifications and

improvements including the fitting of a twin

choke carburettor, low profile tyres, tinted

windows and remotely-controlled central door

locking.

The major mechanical change was the

introduction of the FIRE (Fully Integrated

Robotised Engine) on 45 and 45S models to

be followed by a new 1108 cc “FIRE” engine

on the 60S model from 1989 on.

A 1301 cc Turbo ie engine model wasavailable for a short period. This model had a

Bosch LE2 Jetronic electronic fuel injection

(ie) and a turbocharger to give added

performance. To uprate the braking to suit,

disc brakes were fitted to the rear in place of

the original drum type brakes.

A 1372 cc engine model was introduced in

1989. Two versions were initially available. A

Bosch Mono-Jetronic single-point fuel

injection (SPi) system, as found on the 70 SX

model and Bosch L3.1 or L3.2 Jetronic

multi-point fuel injection (MPi) systems were

fitted to Turbo models. L3.2 MPi system

models were equipped with catalytic

converters, to improve exhaust emission. All

fuel injection engines are fitted with electroni-

cally controlled engine management systems.

A new style instrument panel, switchgearand a revised facia layout was introduced in

1989.

During 1992, SPi fuel systems were fitted to

the 999 cc and 1108 cc engines, along with

catalytic converters for improved exhaust

emissions.

Five speed transmissions were introduced

to 999 cc models in 1993.

It is recommended that this Supplement is

always referred to before the main Chapters

of the Manual.

Project vehicles

The vehicles used in the preparation of this

supplement, and appearing in many of the

photographic sequences were a 1986 Uno

45S FIRE, a 1988 1301 cc Uno Turbo ie and a

1991 1372 cc Uno SXie.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 235 of 303

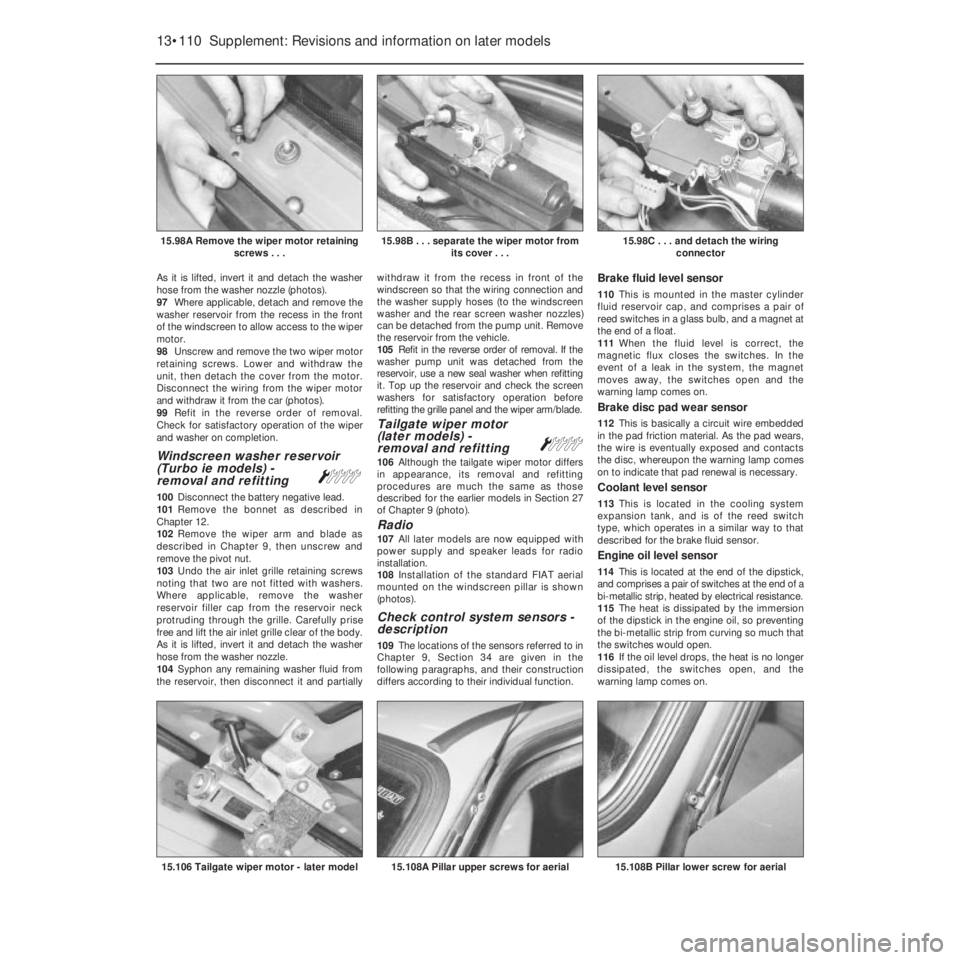

As it is lifted, invert it and detach the washer

hose from the washer nozzle (photos).

97Where applicable, detach and remove the

washer reservoir from the recess in the front

of the windscreen to allow access to the wiper

motor.

98Unscrew and remove the two wiper motor

retaining screws. Lower and withdraw the

unit, then detach the cover from the motor.

Disconnect the wiring from the wiper motor

and withdraw it from the car (photos).

99Refit in the reverse order of removal.

Check for satisfactory operation of the wiper

and washer on completion.

Windscreen washer reservoir

(Turbo ie models) -

removal and refitting

Á

100Disconnect the battery negative lead.

101Remove the bonnet as described in

Chapter 12.

102Remove the wiper arm and blade as

described in Chapter 9, then unscrew and

remove the pivot nut.

103Undo the air inlet grille retaining screws

noting that two are not fitted with washers.

Where applicable, remove the washer

reservoir filler cap from the reservoir neck

protruding through the grille. Carefully prise

free and lift the air inlet grille clear of the body.

As it is lifted, invert it and detach the washer

hose from the washer nozzle.

104Syphon any remaining washer fluid from

the reservoir, then disconnect it and partiallywithdraw it from the recess in front of the

windscreen so that the wiring connection and

the washer supply hoses (to the windscreen

washer and the rear screen washer nozzles)

can be detached from the pump unit. Remove

the reservoir from the vehicle.

105Refit in the reverse order of removal. If the

washer pump unit was detached from the

reservoir, use a new seal washer when refitting

it. Top up the reservoir and check the screen

washers for satisfactory operation before

refitting the grille panel and the wiper arm/blade.

Tailgate wiper motor

(later models) -

removal and refitting

Á

106Although the tailgate wiper motor differs

in appearance, its removal and refitting

procedures are much the same as those

described for the earlier models in Section 27

of Chapter 9 (photo).

Radio

107All later models are now equipped with

power supply and speaker leads for radio

installation.

108Installation of the standard FIAT aerial

mounted on the windscreen pillar is shown

(photos).

Check control system sensors -

description

109The locations of the sensors referred to in

Chapter 9, Section 34 are given in the

following paragraphs, and their construction

differs according to their individual function.

Brake fluid level sensor

110This is mounted in the master cylinder

fluid reservoir cap, and comprises a pair of

reed switches in a glass bulb, and a magnet at

the end of a float.

111When the fluid level is correct, the

magnetic flux closes the switches. In the

event of a leak in the system, the magnet

moves away, the switches open and the

warning lamp comes on.

Brake disc pad wear sensor

112This is basically a circuit wire embedded

in the pad friction material. As the pad wears,

the wire is eventually exposed and contacts

the disc, whereupon the warning lamp comes

on to indicate that pad renewal is necessary.

Coolant level sensor

113This is located in the cooling system

expansion tank, and is of the reed switch

type, which operates in a similar way to that

described for the brake fluid sensor.

Engine oil level sensor

114This is located at the end of the dipstick,

and comprises a pair of switches at the end of a

bi-metallic strip, heated by electrical resistance.

115The heat is dissipated by the immersion

of the dipstick in the engine oil, so preventing

the bi-metallic strip from curving so much that

the switches would open.

116If the oil level drops, the heat is no longer

dissipated, the switches open, and the

warning lamp comes on.

13•110 Supplement: Revisions and information on later models

15.108B Pillar lower screw for aerial15.108A Pillar upper screws for aerial15.106 Tailgate wiper motor - later model

15.98C . . . and detach the wiring

connector15.98B . . . separate the wiper motor from

its cover . . .15.98A Remove the wiper motor retaining

screws . . .

Page 237 of 303

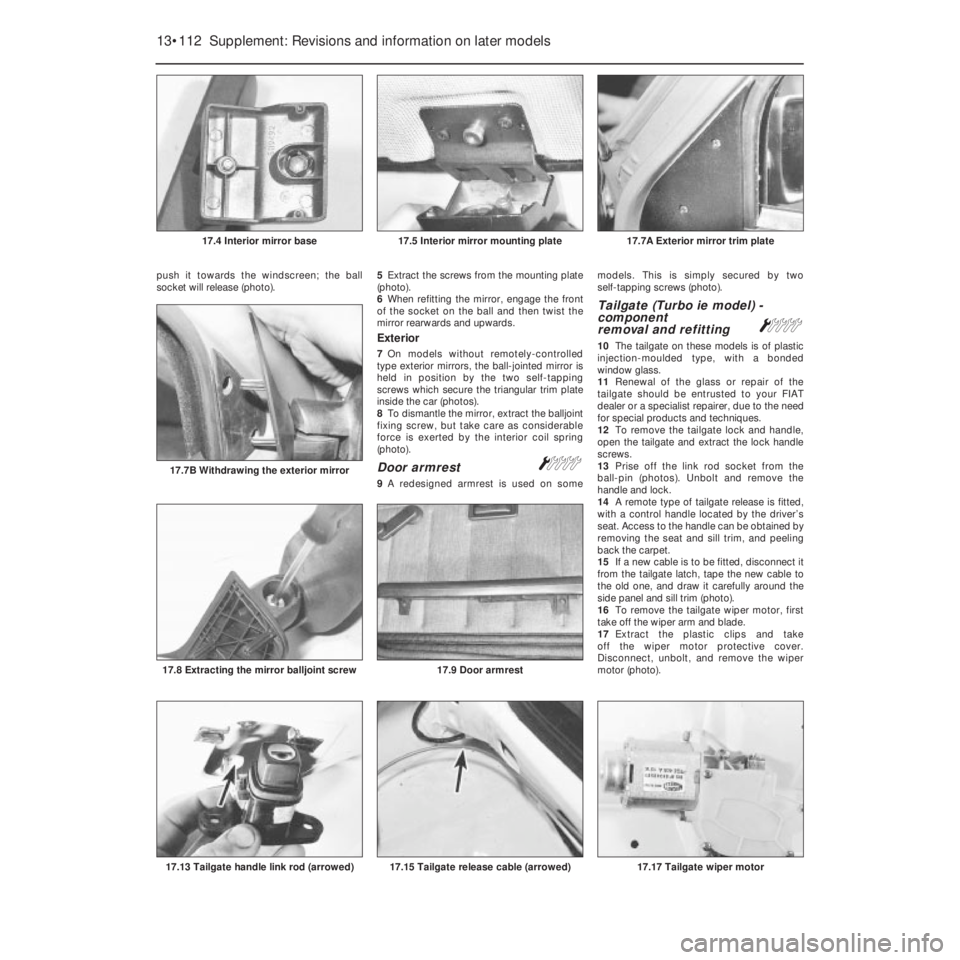

push it towards the windscreen; the ball

socket will release (photo).5Extract the screws from the mounting plate

(photo).

6When refitting the mirror, engage the front

of the socket on the ball and then twist the

mirror rearwards and upwards.

Exterior

7On models without remotely-controlled

type exterior mirrors, the ball-jointed mirror is

held in position by the two self-tapping

screws which secure the triangular trim plate

inside the car (photos).

8To dismantle the mirror, extract the balljoint

fixing screw, but take care as considerable

force is exerted by the interior coil spring

(photo).

Door armrestÁ

9A redesigned armrest is used on somemodels. This is simply secured by two

self-tapping screws (photo).

Tailgate (Turbo ie model) -

component

removal and refitting

Á

10The tailgate on these models is of plastic

injection-moulded type, with a bonded

window glass.

11Renewal of the glass or repair of the

tailgate should be entrusted to your FIAT

dealer or a specialist repairer, due to the need

for special products and techniques.

12To remove the tailgate lock and handle,

open the tailgate and extract the lock handle

screws.

13Prise off the link rod socket from the

ball-pin (photos). Unbolt and remove the

handle and lock.

14A remote type of tailgate release is fitted,

with a control handle located by the driver’s

seat. Access to the handle can be obtained by

removing the seat and sill trim, and peeling

back the carpet.

15If a new cable is to be fitted, disconnect it

from the tailgate latch, tape the new cable to

the old one, and draw it carefully around the

side panel and sill trim (photo).

16To remove the tailgate wiper motor, first

take off the wiper arm and blade.

17Extract the plastic clips and take

off the wiper motor protective cover.

Disconnect, unbolt, and remove the wiper

motor (photo).

13•112 Supplement: Revisions and information on later models

17.17 Tailgate wiper motor17.15 Tailgate release cable (arrowed)17.13 Tailgate handle link rod (arrowed)

17.9 Door armrest17.8 Extracting the mirror balljoint screw

17.7B Withdrawing the exterior mirror

17.7A Exterior mirror trim plate17.5 Interior mirror mounting plate17.4 Interior mirror base

Page 238 of 303

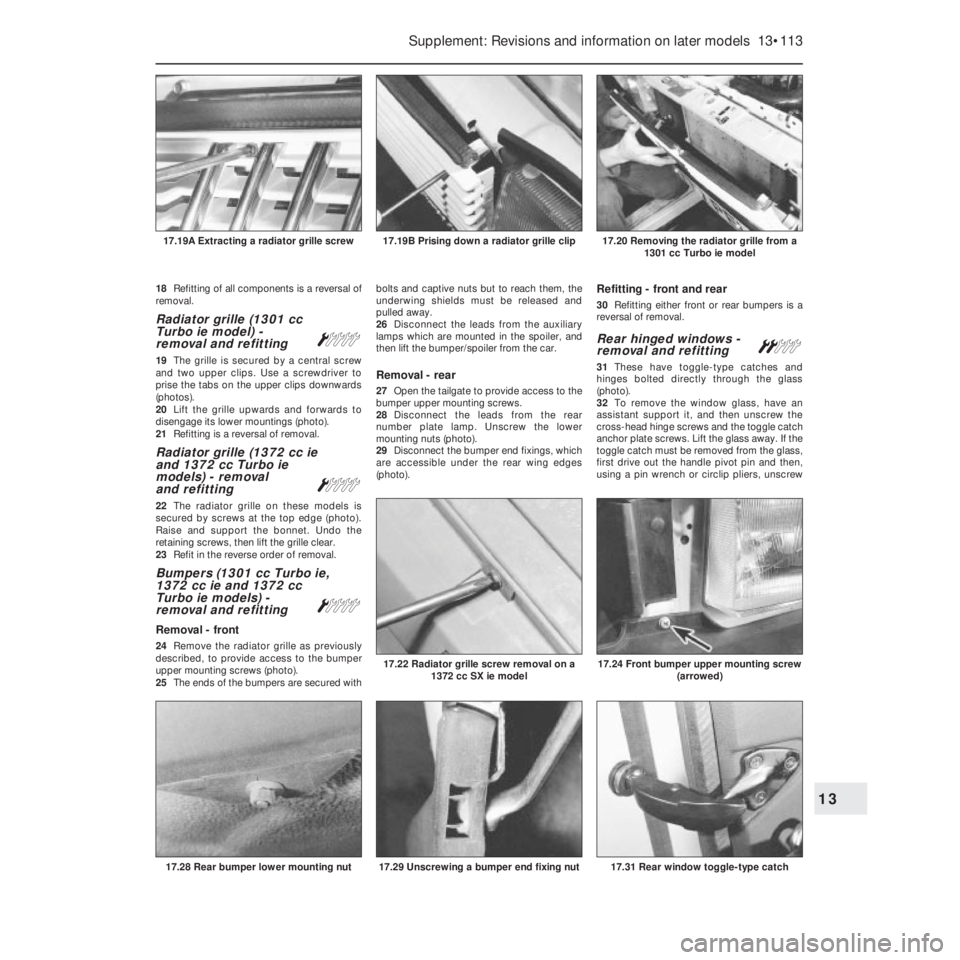

18Refitting of all components is a reversal of

removal.

Radiator grille (1301 cc

Turbo ie model) -

removal and refitting

Á

19The grille is secured by a central screw

and two upper clips. Use a screwdriver to

prise the tabs on the upper clips downwards

(photos).

20Lift the grille upwards and forwards to

disengage its lower mountings (photo).

21Refitting is a reversal of removal.

Radiator grille (1372 cc ie

and 1372 cc Turbo ie

models) - removal

and refitting

Á

22The radiator grille on these models is

secured by screws at the top edge (photo).

Raise and support the bonnet. Undo the

retaining screws, then lift the grille clear.

23Refit in the reverse order of removal.

Bumpers (1301 cc Turbo ie,

1372 cc ie and 1372 cc

Turbo ie models) -

removal and refitting

Á

Removal - front

24Remove the radiator grille as previously

described, to provide access to the bumper

upper mounting screws (photo).

25The ends of the bumpers are secured withbolts and captive nuts but to reach them, the

underwing shields must be released and

pulled away.

26Disconnect the leads from the auxiliary

lamps which are mounted in the spoiler, and

then lift the bumper/spoiler from the car.

Removal - rear

27Open the tailgate to provide access to the

bumper upper mounting screws.

28Disconnect the leads from the rear

number plate lamp. Unscrew the lower

mounting nuts (photo).

29Disconnect the bumper end fixings, which

are accessible under the rear wing edges

(photo).

Refitting - front and rear

30Refitting either front or rear bumpers is a

reversal of removal.

Rear hinged windows -

removal and refittingª

31These have toggle-type catches and

hinges bolted directly through the glass

(photo).

32To remove the window glass, have an

assistant support it, and then unscrew the

cross-head hinge screws and the toggle catch

anchor plate screws. Lift the glass away. If the

toggle catch must be removed from the glass,

first drive out the handle pivot pin and then,

using a pin wrench or circlip pliers, unscrew

Supplement: Revisions and information on later models 13•113

17.20 Removing the radiator grille from a

1301 cc Turbo ie model17.19B Prising down a radiator grille clip17.19A Extracting a radiator grille screw

17.31 Rear window toggle-type catch17.29 Unscrewing a bumper end fixing nut

17.24 Front bumper upper mounting screw

(arrowed)17.22 Radiator grille screw removal on a

1372 cc SX ie model

17.28 Rear bumper lower mounting nut

13

Page 295 of 303

Buying spare parts

Spare parts are available from many

sources, for example, FIAT garages, other

garages and accessory shops, and motor

factors. Our advice regarding spare parts is as

follows:

Officially appointed FIAT garages -This is

the best source of parts which are peculiar to

your car and otherwise not generally available

(eg complete cylinder heads, internal gearbox

components, badges, interior trim etc). It is

also the only place at which you should buy

parts if your vehicle is still under warranty;

non-FlAT components may invalidate the

warranty. To be sure of obtaining the correct

parts it will always be necessary to give the

partsman your car’s engine number, chassis

number and number for spares, and if

possible, to take the old part along for positive

identification. Many parts are available under

a factory exchange scheme - any parts

returned should always be clean. It obviously

makes good sense to go straight to the

specialists on your car for this type of part for

they are best equipped to supply you. They

will also be able to provide their own FIATservice manual for your car should you require

one.

Other garages and accessory shops - These

are often very good places to buy material

and components needed for the maintenance

of your car (eg oil filters, spark plugs, bulbs,

drivebelts, oils and grease, touch-up paint,

filler paste etc). They also sell accessories,

usually have convenient opening hours,

charge lower prices and can often be found

not far from home.

Motor factors - Good factors stock all of the

more important components which wear out

relatively quickly (eg clutch components,

pistons, valves, exhaust systems, brake

pipes/seals/shoes and pads etc). Motor

factors will often provide new or reconditioned

components on a part exchange basis - this

can save a considerable amount of money.

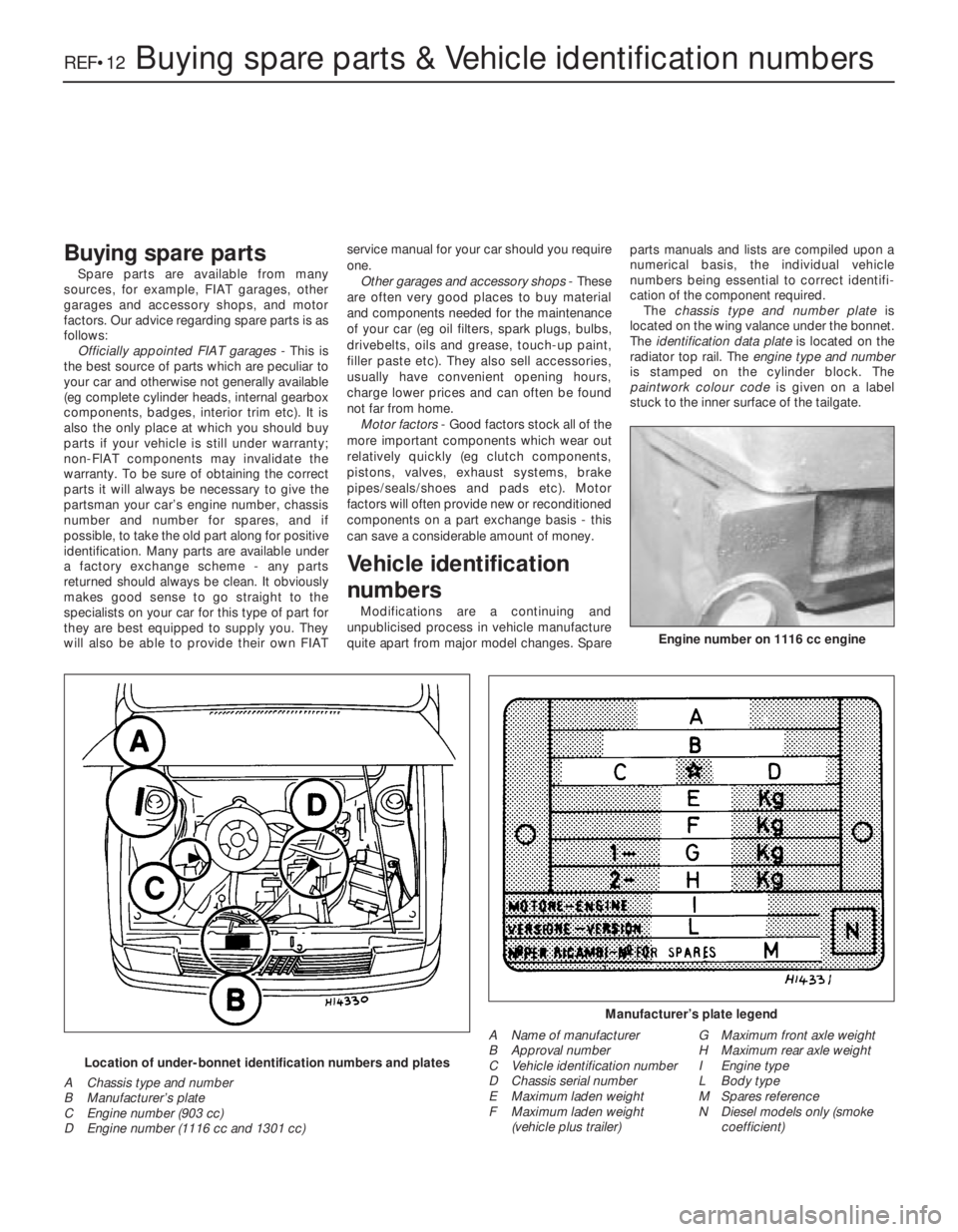

Vehicle identification

numbers

Modifications are a continuing and

unpublicised process in vehicle manufacture

quite apart from major model changes. Spareparts manuals and lists are compiled upon a

numerical basis, the individual vehicle

numbers being essential to correct identifi-

cation of the component required.

The chassis type and number plate is

located on the wing valance under the bonnet.

The identification data plate is located on the

radiator top rail. The engine type and number

is stamped on the cylinder block. The

paintwork colour code is given on a label

stuck to the inner surface of the tailgate.

REF•12Buying spare parts & Vehicle identification numbers

Manufacturer’s plate legend

Location of under-bonnet identification numbers and plates

A Chassis type and number

B Manufacturer’s plate

C Engine number (903 cc)

D Engine number (1116 cc and 1301 cc)

Engine number on 1116 cc engine

A Name of manufacturer

B Approval number

C Vehicle identification number

D Chassis serial number

E Maximum laden weight

F Maximum laden weight

(vehicle plus trailer)G Maximum front axle weight

H Maximum rear axle weight

I Engine type

L Body type

M Spares reference

N Diesel models only (smoke

coefficient)

Page 301 of 303

F

Facia - 12•10, 13•107

Fan -2•3, 13•57, 13•71, 13•84

Fast idle adjustment -3•7, 3•9, 3•10, 3•11,

13•64

Fault finding- REF`•9et seq

Fault finding - braking system -8•9

Fault finding - clutch -5•3

Fault finding - cooling and heating systems

-2•8

Fault finding - driveshafts and hubs -7•6

Fault finding - Econometer -9•12

Fault finding - electrical system -9•14,

REF•9

Fault finding - engine -1•35, 1•36, 2•8,

3•13, 4•9, 13•92, REF•10, REF•11

Fault finding - fuel system -3•9, 3•13,

13•84

Fault finding - ignition system -4•9,

REF•11

Fault finding - Microplex ignition system -

13•92

Fault finding - steering - 10•4

Fault finding - suspension - 11•6

Fault finding - transmission -6•4

Fault finding - turbocharger system - 13•84

Filling - 12•3

Final drive output shafts - 13•94

Fire -0•5

Float adjustment -3•7, 3•8, 3•10, 3•11,

13•64, 13•66

Flywheel -1•19, 1•21, 1•31, 13•46, 13•53

Fog lamps - 13•106

Fuel evaporation control system - 13•78

Fuel filter - 13•67, 13•72, 13•74, 13•79

Fuel gauge fault -9•14

Fuel injection electronic control unit (ECU)

- 13•77

Fuel injection system - 13•68, 13•69

Fuel injection system fault finding - 13•84

Fuel injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Fuel level transmitter -3•5

Fuel pressure regulator - 13•70

Fuel pump -3•5, 13•61, 13•69, 13•72,

13•76, 13•80, 13•81

Fuel rail - 13•70, 13•81

Fuel system-3•1et seq, 13•60, REF•4

Fuel system fault finding -3•9, 3•13

Fuel tank -3•5, 13•61, 13•72

Fume or gas intoxication -0•5

Fuses -9•5, 13•105

G

Gaiters -7•2, 10•2, 13•98

Gashes in bodywork - 12•2

Gaskets -1•20

Gearbox - SeeTransmission

Gearchange lever -6•2

Gearchange linkage - 13•94, 13•95

Glossary of technical terms- REF•13et seq

Grille - 12•3, 13•113

H

Handbrake -8•8, 8•9, REF•1

Handles - 12•11

HC emissions - REF•4

Headlamp -9•6, 9•7, 13•105, 13•106

Heated tailgate window -9•10

Heater -2•5, 2•6, 13•58, 13•59, 13•108

Heater fault -2•8

Horn -9•6, 13•106

Horn fault -9•14

HT leads - 13•92

Hubs -7•3, 7•4, 11•3

Hydraulic hoses and pipes -8•6

Hydraulic system -8•7

Hydrofluoric acid -0•5

I

Idle speed adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

Idling fault -1•36, 3•13, 13•84

Ignition coil - 13•86, 13•90, 13•91

Ignition switch -4•8

Ignition system-4•1et seq, 13•85

Ignition system fault finding -4•9, 9•14,

REF•11

Ignition unit - 13•89

Indicators -9•7

Injectors - 13•69, 13•70, 13•71, 13•76,

13•77, 13•81, 13•84

Inlet manifold - 13•70, 13•77, 13•80

Instrument panel -9•8, 13•107

Intercooler - 13•84

Interior lamps -9•5, 9•8

Introduction to the Fiat Uno -0•4

J

Jacking -0•8

Joint mating faces and gaskets - REF•8

Jump starting -0•7

L

Lambda sensor - 13•82

Lamps -9•6, 9•7, 9•8

Leaks -0•9, 1•36, 13•84

LED (light emitter diode) -9•12

Lights fault -9•14

Locknuts,locktabs and washers - REF•8

Locks -9•11, 10•4, 12•4, 12•6, 12•7,

13•109

Loudspeakers -9•11

Lubricants and fluids -0•13

M

Magnetic impulse generator winding -

13•86

Main bearings -1•20, 1•30, 13•52

Maintenance -0•10, 13•18

Manifolds -3•12, 13•70, 13•77, 13•80

Master cylinder -8•5, 13•103, 13•93

Microplex ignition system - 13•86, 13•89Microplex ignition system fault finding -

13•92

Mirrors - 12•11, 13•111, REF•1

Misfire -1•35, 4•9, REF•11

Mixture adjustment -3•7, 13•62, 13•65,

13•68, 13•75, 13•79

MOT test checks- REF•1et seq

Mountings -1•13, 1•27, 13•26, 13•35,

13•49

N

Needle valve - 13•66

Number plate lamp -9•7

O

Oil cooler - 13•36

Oil filter -1•8

Oil level sensor - 13•110, 13•111

Oil pressure fault -1•36, REF•11

Oil pump -1•13, 1•19, 1•22, 1•26, 1•29,

13•24, 13•30, 13•35, 13•46, 13•53

Oil seals -1•20, 13•41, 13•44, 13•45,

13•94, REF•8

Oil,engine -0•6, 0•13, 1•3, 1•4, 1•8

Oil,transmission -0•6, 0•13, 6•1, 13•14,

13•95

Overheating -2•8, 4•9, REF•11

P

Pad wear sensor - 13•110

Pads -8•2, 13•100, 13•101

Parking lamp -9•7

Pedals -5•2, 8•9, 13•92, 13•102

Pinking -1•36, 13•84, REF•11

Pistons -1•12, 1•18, 1•22, 1•26, 1•30,

13•25, 13•26, 13•30, 13•35, 13•47,

13•48, 13•53

Plastic components - 13•111

Points -4•2, 4•3

Poisonous or irritant substances -0•5

Power module - 13•90

Pre-ignition -1•36, 13•84, REF•11

Pressure regulating valve -8•6, 13•102

Pressure sensor - 13•86

R

Radiator -2•3, 12•3, 13•57, 13•113

Radio -9•10, 13•110

Rear lamp cluster -9•7

Regulator (voltage) -9•4

Regulator (window) - 12•7

Relays -9•5, 13•71, 13•105

Repair procedures - REF•8

Respraying - 12•3

Rocker cover - 13•19

Rockers -1•19

Roof rack - 12•11

Routine maintenance -0•10, 13•18

Rust holes in bodywork - 12•2

REF•18Index

Page 302 of 303

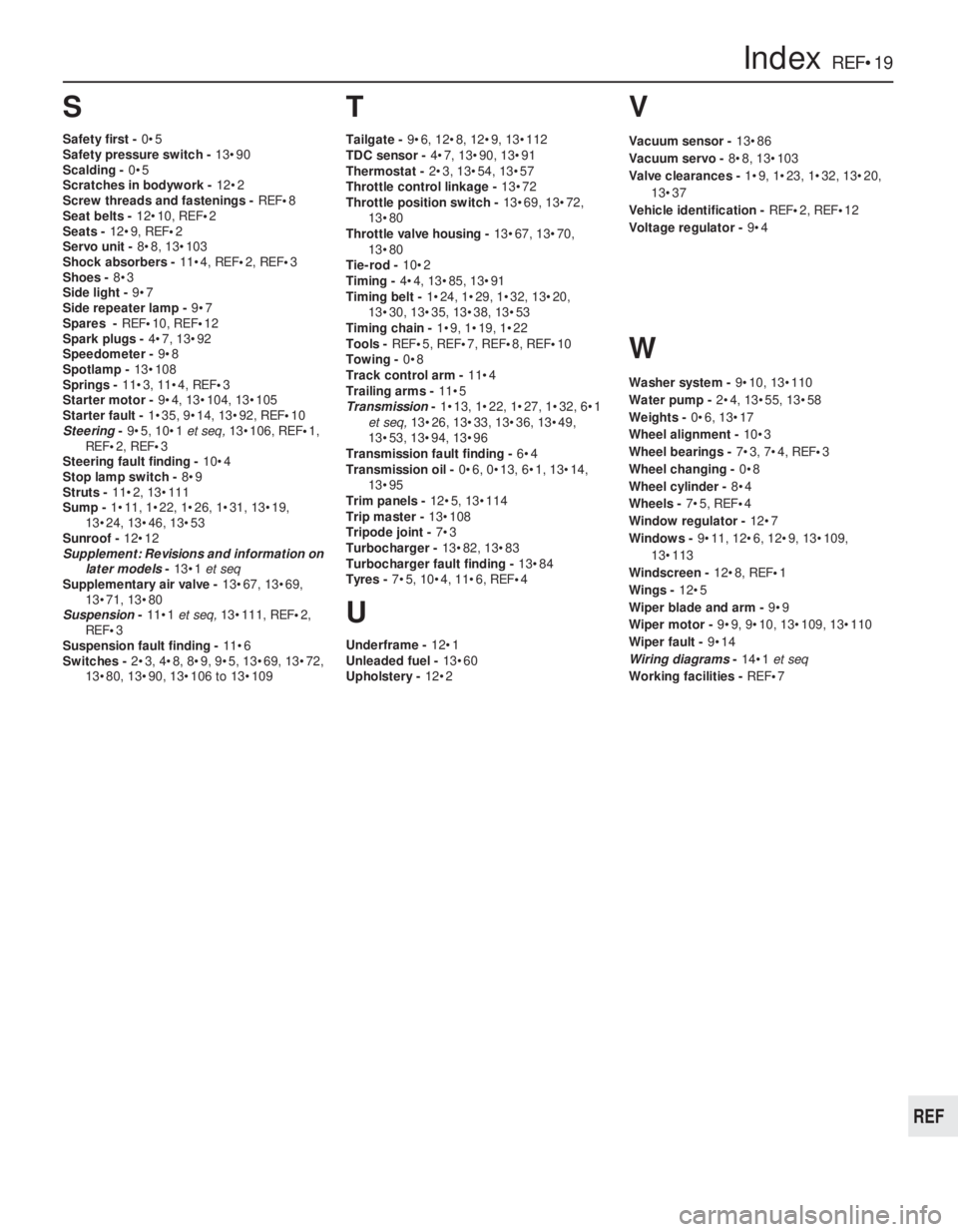

S

Safety first -0•5

Safety pressure switch - 13•90

Scalding -0•5

Scratches in bodywork - 12•2

Screw threads and fastenings - REF•8

Seat belts - 12•10, REF•2

Seats - 12•9, REF•2

Servo unit -8•8, 13•103

Shock absorbers - 11•4, REF•2, REF•3

Shoes -8•3

Side light -9•7

Side repeater lamp -9•7

Spares - REF•10, REF•12

Spark plugs -4•7, 13•92

Speedometer -9•8

Spotlamp - 13•108

Springs - 11•3, 11•4, REF•3

Starter motor -9•4, 13•104, 13•105

Starter fault -1•35, 9•14, 13•92, REF•10

Steering-9•5, 10•1et seq, 13•106, REF•1,

REF•2, REF•3

Steering fault finding - 10•4

Stop lamp switch -8•9

Struts - 11•2, 13•111

Sump -1•11, 1•22, 1•26, 1•31, 13•19,

13•24, 13•46, 13•53

Sunroof - 12•12

Supplement: Revisions and information on

later models- 13•1et seq

Supplementary air valve - 13•67, 13•69,

13•71, 13•80

Suspension- 11•1et seq, 13•111, REF•2,

REF•3

Suspension fault finding - 11•6

Switches -2•3, 4•8, 8•9, 9•5, 13•69, 13•72,

13•80, 13•90, 13•106 to 13•109

T

Tailgate -9•6, 12•8, 12•9, 13•112

TDC sensor -4•7, 13•90, 13•91

Thermostat -2•3, 13•54, 13•57

Throttle control linkage - 13•72

Throttle position switch - 13•69, 13•72,

13•80

Throttle valve housing - 13•67, 13•70,

13•80

Tie-rod - 10•2

Timing -4•4, 13•85, 13•91

Timing belt -1•24, 1•29, 1•32, 13•20,

13•30, 13•35, 13•38, 13•53

Timing chain -1•9, 1•19, 1•22

Tools - REF•5, REF•7, REF•8, REF•10

Towing -0•8

Track control arm - 11•4

Trailing arms - 11•5

Transmission-1•13, 1•22, 1•27, 1•32, 6•1

et seq, 13•26, 13•33, 13•36, 13•49,

13•53, 13•94, 13•96

Transmission fault finding -6•4

Transmission oil -0•6, 0•13, 6•1, 13•14,

13•95

Trim panels - 12•5, 13•114

Trip master - 13•108

Tripode joint -7•3

Turbocharger - 13•82, 13•83

Turbocharger fault finding - 13•84

Tyres -7•5, 10•4, 11•6, REF•4

U

Underframe - 12•1

Unleaded fuel - 13•60

Upholstery - 12•2

V

Vacuum sensor - 13•86

Vacuum servo -8•8, 13•103

Valve clearances -1•9, 1•23, 1•32, 13•20,

13•37

Vehicle identification - REF•2, REF•12

Voltage regulator -9•4

W

Washer system -9•10, 13•110

Water pump -2•4, 13•55, 13•58

Weights -0•6, 13•17

Wheel alignment - 10•3

Wheel bearings -7•3, 7•4, REF•3

Wheel changing -0•8

Wheel cylinder -8•4

Wheels -7•5, REF•4

Window regulator - 12•7

Windows -9•11, 12•6, 12•9, 13•109,

13•113

Windscreen - 12•8, REF•1

Wings - 12•5

Wiper blade and arm -9•9

Wiper motor -9•9, 9•10, 13•109, 13•110

Wiper fault -9•14

Wiring diagrams- 14•1et seq

Working facilities - REF•7

IndexREF•19

REF