torque FORD CAPRI 1974 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1974, Model line: CAPRI, Model: FORD CAPRI 1974Pages: 205, PDF Size: 43.75 MB

Page 98 of 205

Chapter 5

Contents

CIUICh il$scmhty '"SIJoCcl'Qn . Clu\(;11 assembly 'Urn!!ll!) Clutch llsscmhly lemOY," C lutc h cilhle .efluwal._

Clutch

Clutch !Jedal rClllovnl illld ,cflltl"U

Specifictions

Genera l Type ..... Clutch (lise (hamClcr lining tlnckncss Clutch pedal hcc "

Gene.al description

,

5 3 1 8

All manu:!1 transmission madllis covered by this manual nrc lilted Wilh a singlo dl3phrilgll SpllJlg clutch. The unit COlllt)riscs il steel cover which is dowelled and bolted to the tear lace of the lIywheci ilnd conla i.lS the pressure plnte. diaphragm spring and fulCrum .ings . The clutc h " iClio n disc is

ee to slice along the splineJ gearllox

Inpu t Shillt and is held in posi t,on between the flywheel and the pressure plate by the pressure of the pressure plate spring , Friction linIng materiill is riveled 10 the d,sc and II has a spring cushioned hull to absorb transmission shocks and to help ensure a smoo th take oft. The circular diaphrilUm spring is mounted on shoulder pins ilnd

'Ield in place in the cover b.,. two fulcrum rings . The spring is also held ,0 th e pressure platc by three spling steel clips which are rive ted in

posi tion .

The

clu tC h ,s aCluated b.,. a cable controlled b.,. the clulCh pedal.

Clutch '0Ie,150 bCilfl"U -remova' and wl,u,"g Filult (ioilU"OS'S -clutch Generill descllptlon . noutlilc rn,untenanco .

SlIlgle (Iry plate. dlill)hragm sprong. cilhle ·ope.ated 241,3 rnm (95 Ill) 381 nun (0 15 In) 27.01 40mm (1.OG:i 0 .16,n)

No. Ib l It 16 to 20 12 10 15

G 9 1 2

The clutch release mechanism consists 01 a .elease leve. and a bearing which conwcts the lelease Imgers on the pressure plilte assembl.,.. The eHect of an.,. wear of the friction ma terial in the clutch is adjuSled out b.,. means 01 a cable adjuster at the lowel end 01 the cable where it

passes through the bell housing .

Dep.ess lng the clutch pedal actuates the clutch release leve. b.,. means of the cable . The lelease level pushes the lelease bearing

forward to bear against thO release l ingels so moving the centre of the diaphf()gm sprong within the annular rings which act as fulcrum points.

A s th e centrO of thO spring is pushed in. the outside of the Spling is pushed OUI. so Illoving Ihe pressure plme backward and disengaging the p.essu.e plate flom the /tielion disc . When the Clutch pedJI is Icleased. the diaptllaglll spring torces the plessule plate into contac t w ith the frictIon linings on the d,sc and at the saIne t,me pushes it a flactlon 01 an InCh fOlward on I\S splines . The

disc is now fuml.,. sandwic h ed between the plcsswe plnte Dnd the

flywheel. so the d.ive IS laken up.

procarmanuals.com

Page 104 of 205

Chapter 6 Manual gearbo x and automatic tran smissio n

F1VO.Sp()od \joiuhox:

'" 2nd 3rd 41h .. 51h f\ovr;,so

Laysh aft cluster gear (f our-speed gearbox )

Elldfio

Luh"(.

InplIl shafT hoaun» 11,IJIIUlr ExtellSl!lIl hous',,» ... Sf:h,ClOr Shilh IJJil~kel . Sciccto! housinO cove, .... Extension housin\1 cover . GeJlhO x casc cover

Flve·spccdgc,lfbox Guide sloeve Ex lOnsion housing. Geol,hox top cover Seleclor locking mechanism .... FilII), plu(1 51h He,ll cull,H nul 5th

Type

Torque converter

if! IWtlO

Transmis s io n ra tios

1 st 2nd. 3'd . Reverse

Lubricant

C~pacily (ilpprOX) . Type :

Early models (blnck dipsl ic k ) Laler Illodels (red dipstic k) ..

T orque wrench settings Torque convcrter 10 dr;veplille .

Do wnshift cable brac ke l

Downshift lever nUl: Duler. Inner.

Inhibito r swilCh

R'ake b;"Uld ~d!usling screw loc knu l .. .

lid l ine .... ... .. ...... ........................... .... . ULI cooler Ime . AU10lllilllC t",n~lI1ission t o engine. To rque conveilei drJin plug

3.36 : 1 1.81.1 1.26: 1 1 ,

0.825. 3.365 :

0.15100.45 mill (0.006 to 0.018 in)

1 .55 to 1.60 m!11 (0.061100.063 in)

SAE 80 EP oil 10 Ford spociflCatlon SCM 2C 9008 A

20 lit,e (35 pim) 1.9 lilH! (3.3 PUlt)

NIl

39104 8 30 to 37 35 to 4 1 17 10 2 1 54 to 61 71010 161021 9 to 11 17 to 21

9 to 11 4 5 10 49 9 to 11

17 to 19

231027 12010150 21 to 26

2 1 1026

Ford C3

Tnlock (hydrnulic)

222.1

2.47 : 1.4 7 : 1: 1 2 11 : 1

7 .5

htre ( 1 3 2 pUl1)

Ih l It

29 10 35 22 to 27 261030 12 to 15 40 to 4 5 5107 12 10 15

7 to 8 1 2 10 15

7108 331036 7 to 8 13 10 1 4

17 1 0 20 89101 1 1 1610 19

16101 9

ATF to Ford spec,fIC~lion SaM 2C 9007 AA ATF to Ford specification SCM 2C 9010 A

N m Ill f It

361041 27 10 30

16 to 2 4 1

2 to 18

1

010 15 7

to 1 1 41 1054 3010 40

1 6 10 20 12 10 15

4 7

10 61 35 10 45

9 10 1 4 7 10 10

1610

20 12 10 1 5

3010 37 22 1

0 2 7

2 7

10 40 2

0 to 30

, . ,

!

.5 ________________ ........... ........

procarmanuals.com

Page 112 of 205

Chapter 6 Manual gearbox and automatic transmiss ion 111

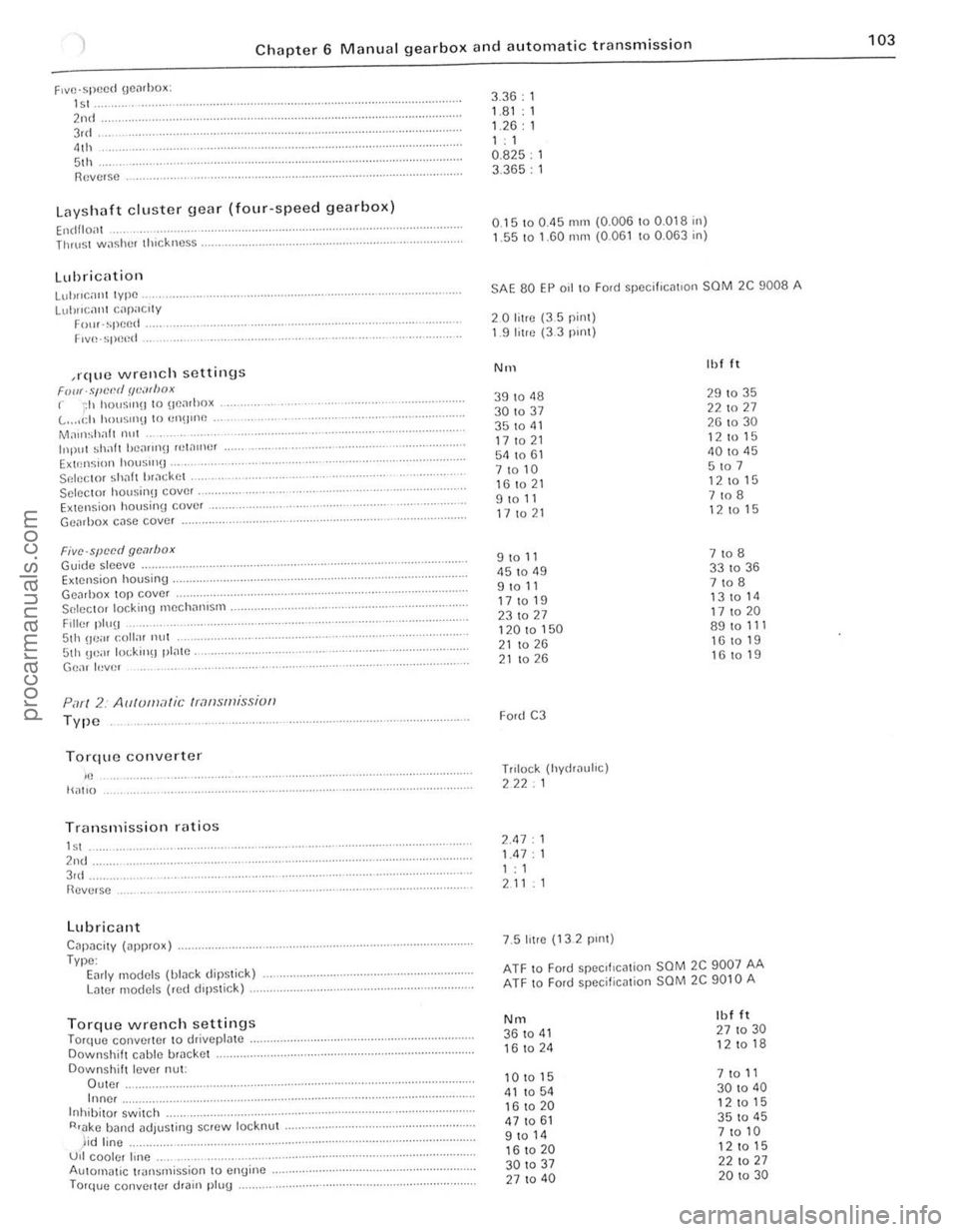

24 Chec k the plilY between the selector finger and 3.d/top geM selC{;lOr .a,1 (F,O. 6 .1 6) . lh,s d,mens,on shou ld be 0.9 mm (0.035 in). lo m"ke t he chec k. move the selec to. leve. up to the .everse gea. SlOp. Us.ng a lever. push 3.d/top gear selector .all \0 the rear and then

measure th e clea .ance by rnsel1lng leeler gauges betwee n 3rd/top gear selector rild "nd seleClOr finger. If th e cleM,mce 's no t ns specified. it shou ld he conecled by chnnging lhe .everse interlock geM plunger for one whIch will give the ,'PI).opria te clearance. 25 F,t a new gasket 10 the e~lension housing cover. Posilion the

cove •. ,nSOI I the fi~ing bolts nnd lighten Ihem 10 Ihe torque wrench Solt1inlJ g,ven in the Specifications. 26 M,1kc su, e th atthe geMl>o~ dmin plug is I,tted and tigh tened where apphc, 1hlc. then I,ll the uenlbo~ 10 the COffect level with the specl l'ed

,,'

10 Gcnrchnnge lever (4,sjleccl ) - m odificnlions

1 To ,mp,ovelhe \]flnr ch nngc movemcntlJctwecn lh(: Hea.s. , smallm CO".,r levcl Sl)!"'g ,s 1'lIr,<:I. the new 51)/,nU d,amclr'!' bc inU 20 mill (008 aga,nst the orig,n;r l sp.,n!) IIiarllctm 01 2.5 nUll (0 .1 0 inl.

Fig. 6 .15 Cover. d ewnt balls and sprinus (Sec 9)

Fig. 6.1 7 Gearchange lever components (Se c 10)

A Spliny B Rct.1illiny pin C Pf;JSlic C ilP

Dlillcnsion X mUSI be gloater Ilran dimension Y

2 To renew Ihis sp.ing. lir sl remove the gear lever unit from the trnnsmission as given in Section 3. 3 Press or drive out the roll pin and remove the plastic cup (F ig . 6.17 ) ;rnd spring .

4 When reassembhng. check that the pin di('!meter is less thiln the width 01 th e slots (X ,n Fig. 6.17), II necessary grind down the pin and

d e·llUrr the slots by ca.e ful filing . When filled the pin slotS mus t face upwMds. 5 If the gear leve. was loose when in use. an O-ring can be filled in placo o f Ihe retainer sOill as shown in Fig. 6.1 8 .

6 When this flng ,s fmed an(I the gear leve. reIOCalr:!d. screw the retainer cap inlO pos,tlon so th ilt It jus t touches th e O·ring . Mark the relntlve pOSitions of tile cap

1 Clean the e~tello. 01 Ihe gearbox w.th paraffin .,nd w.pe d.y. 2 Remove the clutch release beallng and allli lele",ng 10 Chapter 5.

0035;11 10.9 mill}

Fig. 6.16 Plav between selec to r finuer and 3rd/4th geM selector rail (Sec 9)

.. : . :,'. :", .

fLJ

··· ..

A

Fig. 6 .18 Cross· section of gear lever showing 0 ·rin9 (A) location (Sec 10)

i

i

procarmanuals.com

Page 115 of 205

Chapter 6 Manual g ea rbox and automatic transmission

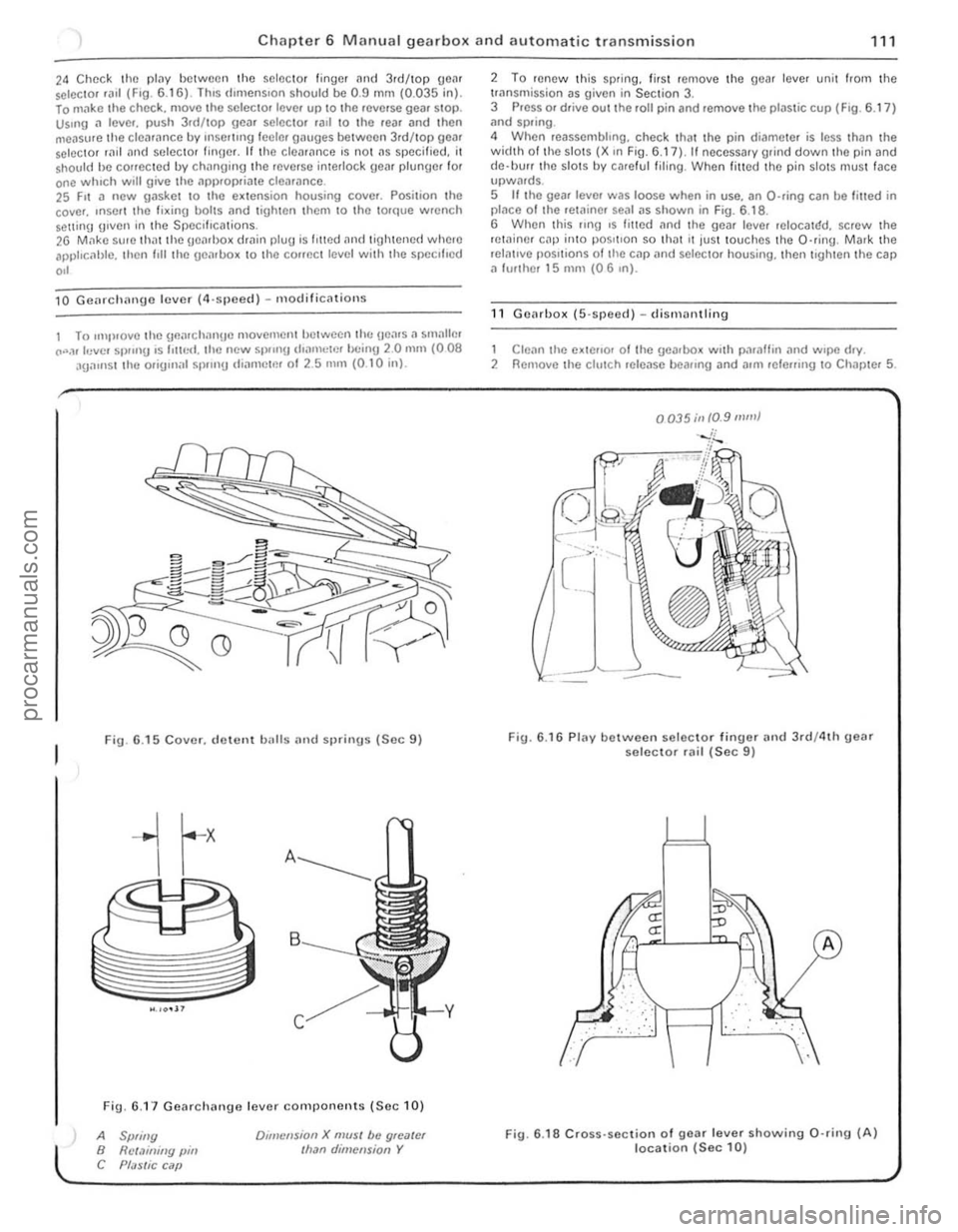

18 EXlra ct the r."dp and pull the 5th gcar synchronise r ur1lt f'orn the

rnn in c,lsm\1. Icavlllg I t loose on thtl mninshaft (photos). 19 S II(le 51h IlcM from the synchroniser unit huh {photo) 20 S elect 3rd gem and either 1st or 2nd gear by pushin\) the re~peclivc synchronsrcr sleeves this will lock the mainshllft

24 US"'(I;' ~oft·f;,r.ed Ill;-rllm. wp the intermedrate hOtJS"'~1 (,,!e of tl,,; ",<1111 c

.I,' ,i.li. J

hO(lSII1\1

layshilft rearwards to <11101'11 the \ .wm d,,~tn' t o he lowered 10 the hottoot 01 tlHl cas,,'U .

2G Ease tlte input Shaft f'om the frOllt 01 tlHl c;-rSlng, if oecess

29 Wllhdr,lW th e I,lyshalt ,11lel 0"_" eh";t,,, I,om Ihe 111<1111 C;-rSlIlg (phOlO)

30 In:;'''I; ' sUlwble bOl t (M8 x GO) Illto Ih" ,,,v',,:;c !Je,1( ,die, shnft. alld

11 18A Exlrar.t,nn 5th geM synchro ci,clip 11.18B 5th u em syl,(IHU hul) 11 18C 51h ~Je;-rr synclH O

11.19 SlId l"!J 5th !/tlar from "'

Page 120 of 205

) Chapter 6 Manual gearbox and automatic transmission 119

11. 1~) 2nd (Ie", [Inti thrust w,1shcf h.1l1. showioO t .. llloctltinu hole

(",,()w~d)

20 Slide 3ul \jC,lf 01110 the f,aiH 01 the mninsh

13 Input sh(lf( (S·speed) -dismantling Dnd reassembly

!'ld!;! to Section 6

11 GCil,ho)l ([i·spced) -C)lamin,lIion [In(1 rcnov[ltioll

Ref or 10501:[ '0 118 hut now the lollowlng pOllltS :

(,1)

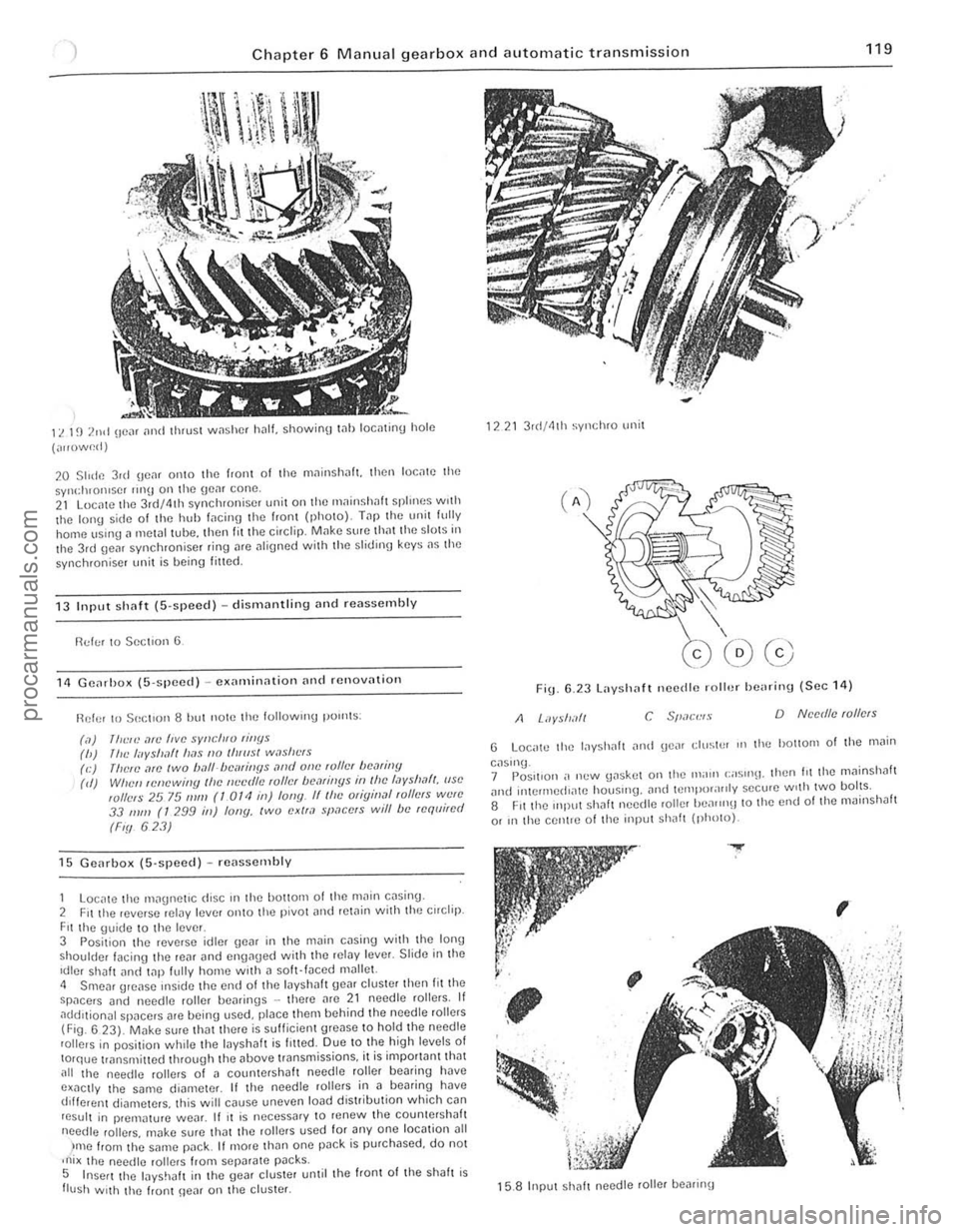

111<:,,) ,1fI! five sYllcll,v rillYs (h) /IlL' I"yshlft lI[1s 110 IIIlIIsl w,lsllt"s (e) (lielL',1ro IWO ball-/)cmiIJYs ,lrId olle ,01lcI hCMiny (d) Wile" ,cnewi"y Ihc IIL'cr/lL' ,01lcI /)(1,1/ill[lS ill I!lc I,Jyslml/, (ISO wllels 25 75 111111 (1 OTt! ill) fony. IIlhc Oligin,ll ,ollers W{!lC 33 111/11 (T 299 ill) lony, two exll,l space's will be requi,ed

(Fiy 623)

15 Gcarbox (5'SI}Cc(l) -rC

Fit the \juidc to the leve r 3 Posit ion the reverse idler \Je~r in the m~in cDsill\j with the Ion,) shoulder facing the reill and en{lllued with thc ,eiDy Icver. Slide ill thc Idler shalt lInci t

)me from t he SMne l"JilCk It more than one pDck is purchased, do not ,ni x lho needlc rol lers from sepilrate p~cks. 5 Insert the layshJlI in the gear cluster unlil the front of Ihe shah is flush With the frunt \Ie~r on lhe cluster.

1221 3 r(I/41h syl1chro unit

Fig 6.23 Layshaft necdle roll.)/ he

G Loc,.tc the lilyshah iln!! gCilr ell/stP' III tho hOllom of the .11il;n

caslnu_ 7 Pos.1I0n ,. n(.'w \Jaskot on the Ill;nll (;;05"'11. Ihen hi the mllinshah ilnt! inlCrll1ed"l\C houslIlg. and IClllpor;I"ly secu.e w,th twO bolts. 8 Fit the mll"t Shilh needte roller heilrrn\J to the end 01 lhe mainshJlt

or In the centle 01 lho input Shilh (photo).

.....

,

~

; , .. '-; . '. ~, .

,

15.8 Input sh

i 1 ,1

I

procarmanuals.com

Page 121 of 205

)20 Chapter 6 M anual gearbox and automatic transmissio n

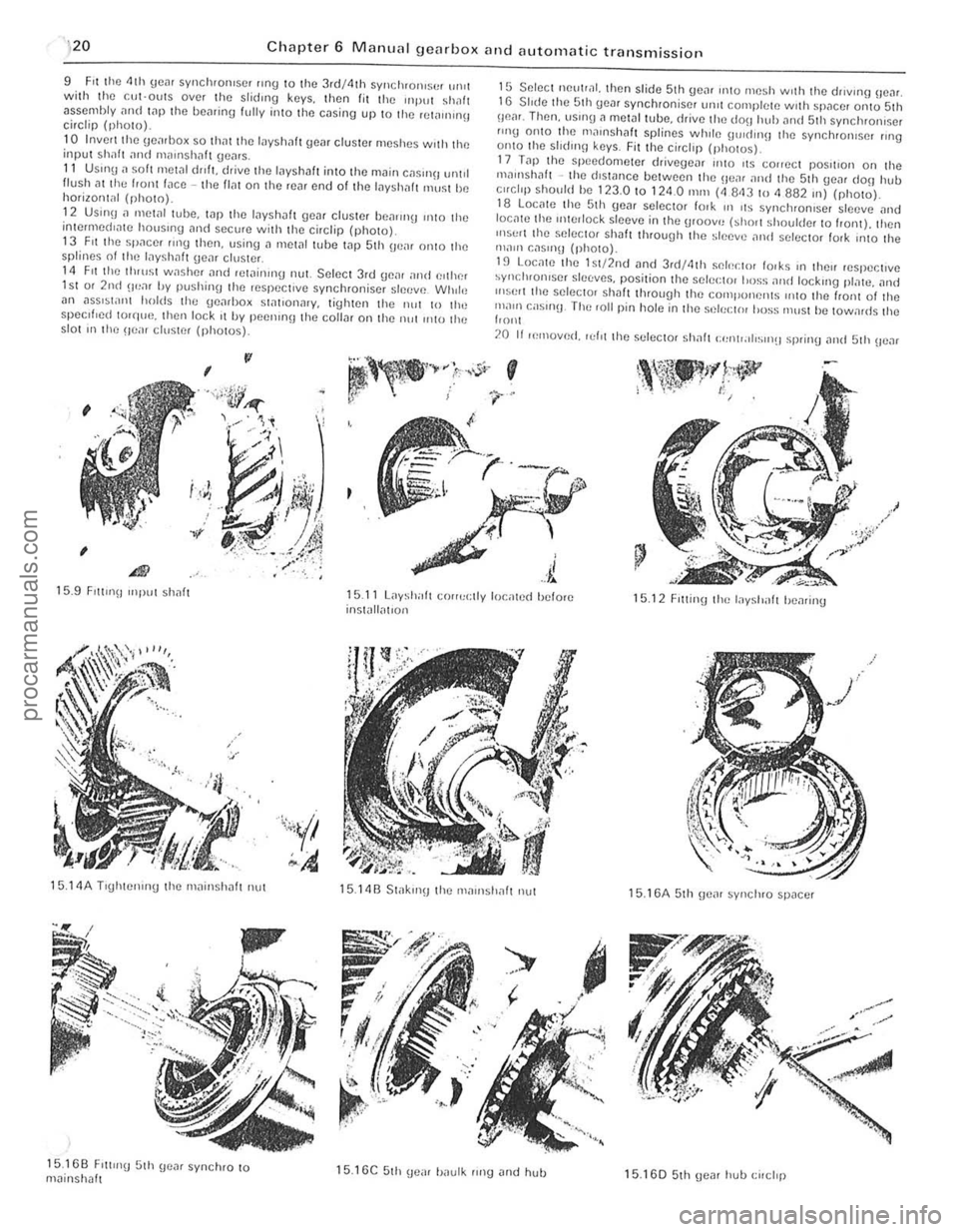

9 F it the 4th gCill syncluolliser "n9 to the 3rd/4lh sym;luOI"s(1f 'HUI with lhe c:ul-outs over the slidlllg k(lYs. then fit the UlPUl shalt asscnlhly i]n(l lilP the bearing fully into tho casing up 10 the rclo1llunu circtip (photo).

10 Invert Ihe \jCo1rilox so Ihil! the l

12 Us;n!).1 mel,lilllbe. lilfl the Inyshaf gear cluster be,IIPI'!J 11110 the inlcrmcd'

15 Seleci neulrnl. then slide 5th ge", IlItO mesh WIth the driVing Be",. 16 Slide the 51h gem synchroniser unll complete with sp"ce[ Onto 51h Oll"r. Then. usrng.l metal tube, drive Ihe dO\1 huh "lid 51h synchronlser flng OnlO Ihe 1ll",nsh,,11 splines whIle UlOld"l!) the synchronIse! 111111 onto Ihe shdlll[J keys. Fit the circhp (pholUs).

17

T"p Ihe sp eedometer drivegeilr "HO ItS COrreCI poslilon on Ihe mollllsh"ft -the dlsWllce belwoon Ihe HeM 'Illd the 5th gO,l[ dOll hub c"cllp should be 123.0 to 1 24 .0 111m (4 843 10 <1 882 Ill) (nhoto). lB Loc"le Ihc 5th He", selector fOlk In liS syn ch ronlSN sleeve "nd loc"le Ihe Interlock sleeve in Ihe uroov", hhol! Shollider 10 front). then InSurt the seleClor sh~1t through the sleeve ,1nd SeleCIOr fOlk InlO the "'aOll r.,lsll1\J (photo).

19 LocnlC the lSI/2nd "nd 3rd/4th Sf)I'~rIOr IOlks 1(1 Ihell respecllve ~Yllcillonlser sleeves. posilion the selectOl !ross

20 If If!rnoverl. 'ef'l Ihe seleCIOr sh,,11 (:"nlr,, 11~1I1!1 sprinU ",ui 51h \Ie",

.' /

15.9 FI1l1I1\1 Inpul shnl1 15.11 L;,ysh;r!t corruc tly located hefore inst,111,11101l 15.12 F,ltintllile Inysllilft hearing

15. 14A Tlghtelllng thc rn"insha fl nut

15.16B F'lllI'\) 5th genr synchlO to m~inshalt

15.148 Slak,n\1 the rH.lloslrall nul

15.16C 5th \le,,, haulk flng Jod hull

15.16A 5th gem synchro spacer

15. 160 51h gear hub {:ilchp

procarmanuals.com

Page 122 of 205

) Chapter 6 Manual gearbox and automatic transmissio n

121

"

i

...,

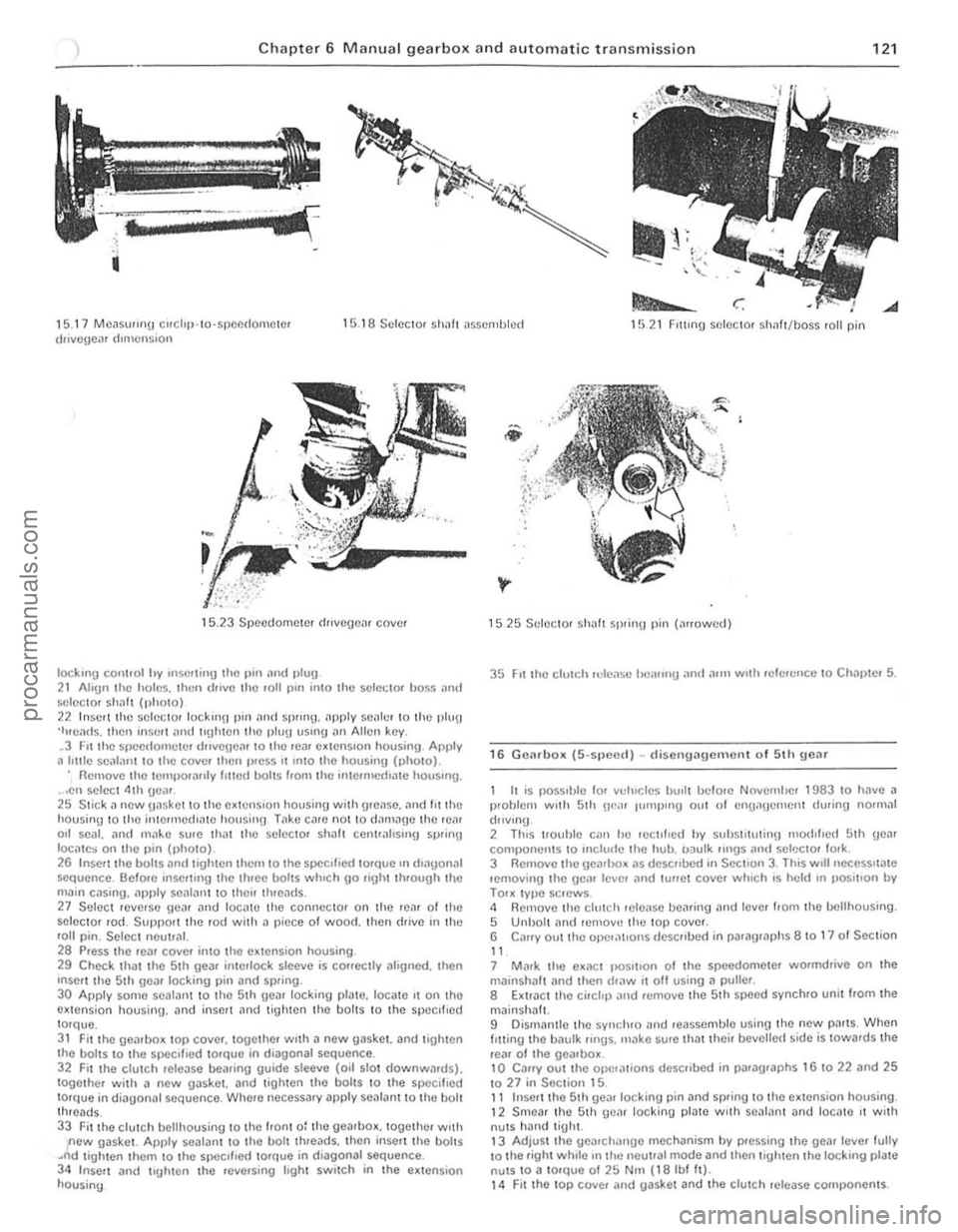

1 5. 17 MC~Sll"nu corchp· 10·SPCI1(lOIllClcr drivcgc,l' dImension 1 5 .1 8 Sc lcCl0f Sholl! t1sscmlJ lcct 1521 FIlling selector sh1lft/boss fall pin

15.23 Speedome ter dJlvcgcn, cove.

IOCkmg cOI1l,ol hy Inserl;"y the 1)111 ;lnd 1>lu9 2 1 Ahgn the holes. then (lillie Ihe roll pin il1lo the sc lcCIOf boss ;111\1 SI~ICC1Of s h

main c .. sing ... pply se

29 Check that the 5th gea. interlock slceve is corrcctly .11ognoo. then 'nscrt thc Sth geil' locking pin and spring.

30 Appl y some scalallt to the 5th geilr locking plate. 10Cilte It on thO extensio n housing. an d inselt nnd t igh ten th e bolts to I h e specIfIed torque. 31 Fit the Ueilrbo~ top covcr. together WIth a new gas\(et. and lighten

the boilS to t he sf1eclf.ed tOfQue in diagonal sequence. 32 F u the clulC h relCilSe bearing guide sleeve (oil slot dow nwllfd s). together with a new gilsket. and lighlen th o boi lS to the specillt~d torque in d;ilgon;11 sequence. Where neceSS;1ry apply seal,.nt to the bolt threads_ 33 Fitthe clutch bell housing to the Iron t 0: the gearhox. together woth new gaske t. Apply sealant to the bolt threads. thcn inse n the boilS .~d tigh ten them to Ihe SIXlcllled 10rQue in diagonal sequence. 34 Inscrt and trgh le n the .ev(usinl.l Ioght switch in Ihe ex tensio n housing

1525 Selec tor sh aft spring pin (arrowed)

35 FIt the clutch reLease l"l'lIIng and a.1Il wuh .efercnce 10 Chnl)\ el 5.

16 G e(lr box (5-spee{l) -d isellg i:lgem enl of 5th gear

I I

is possI ble 'or vducles hu,l t bclo.e NovcmiJer 1983 to have i:l p.oblem WIth 5th ne". Illillplllg Ollt of cnuanClllcn t during normal

(hlv lnu

2 ThiS 1I0uhle Cilll he rcc tl',cd hy suhstitutinu nlod,hc

3 Rem ove Ihe gearbo_ "s de$("bed in SectIon 3. This wrll nCCCSSlla te lemov ing the ge(l' Icvcr "nd lu"C I cove. whIch is held In ,)OSltlo n by TOOK typc sClews . 4 Removo the clutch Hlleilse bearing and tevcl 110m the bclthousing . 5 Unbolt ami lemovc the lOP covel. 6 C"ory out the opel,1t'0"S dcsc llbed in par "graphs 8 10 1" 01 Seclion

" 7 M"r\( Ihe ex.1Ct IIOS""o n of t he speedometcl wormdrive on the milinshil lt (lnd then draw it off using a pulter .

8 Extr"ct the ci. et,p "nd H)move the 5 th sp(lcd sync hro unil/rom Ihe

mJinsh"lt. 9 Dismanlle the synr.hro "nd reasscmble using the new p" rts, When I Itting t he b"ulk lings. m"ko sure that theil bevelle( 1 side is tOwa.ds the

re,,' o f Iho ge",box. 10 Caffy out the ope,,,,,ons desCfibed in jh"lfilgraphs 16 to 22 and 25 1027 in Section 15. 11 Inser t the 5 th ge

procarmanuals.com

Page 126 of 205

Chapter 6 Manual gearbox and automatic transmission 125

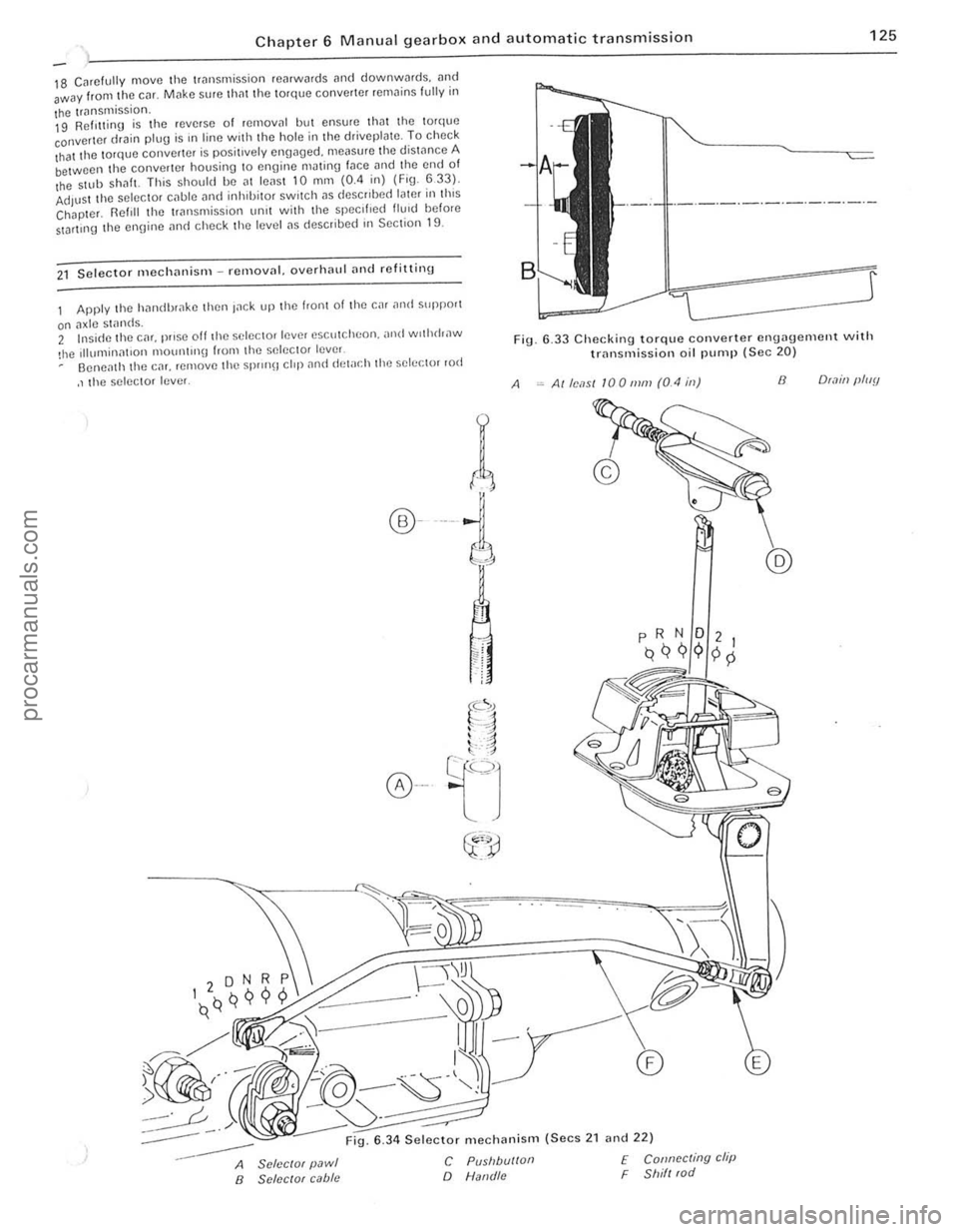

18 Carefully ~ove the lrilnsmission reilrwards ilnd downwmds, and

away from the car. Make sur e that lhe torque conver ter rema ins fully in

the transmission. 19 Refilling is the reverse of remova l but ensure that the torque converter drain plug is In line wIth the hole in the driveplate . To check

that the torque converter is positively engaged. measure the distance A between the converter housing to engine mJting fJce and the end of the $llIb ShilfL This should be al leilsl 10 mm (0.4 in) (Fig. 633). Adjust the selector cilble i1nd inhlbilOr switch i1S deSCribed later ill this Chapter. Reftll the 1riln smission unit with lhe specified flu,d before StDrlll1g the ennine i1nd check lhe level i1S describe(f in Section 19.

21 Selecto r mechililism -removnl. overhnlll ilud refitting

Apply the hnndbr,lke then Inek up the front of the car ilntl suppo'1

on ilxle stands. 2 Insi(fe the cm. prose off th e selector lever escutcheon. ,md wothrhaw

!he Illumillnt,on 1ll0U1l1l1l\J from the selec tor lever Oeneilth the CM. remove the Spr

r(

®---i

A

6 .33 Checking torque converter engagement with trnnsmission oil pump (Sec 20)

Alle,1S1 100111111 (0.4 ill) 8 O(.1ill (lluy

:-----

--

6 .34 Selector mechanism (Secs 2 1 and 22)

A SclcclOf pawl B SClccrof cabie

C Pusllbu/loll

o Natld/c

f Connccting clip F Shill (od

.'

. 1 , ;

I

procarmanuals.com

Page 128 of 205

Chapter 6 Manual gearbox and automatic transmissio n 127

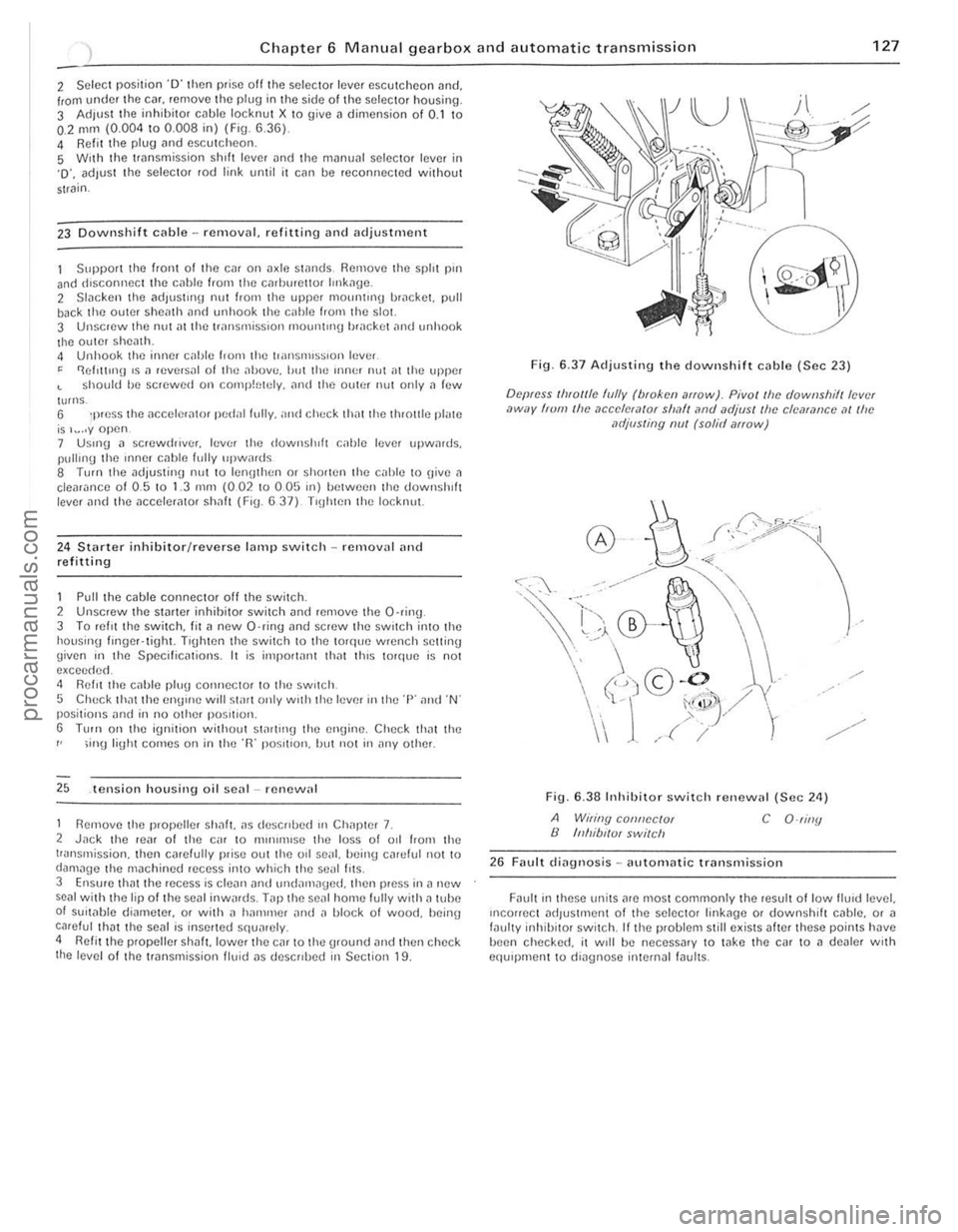

2 Select position O' th en pri$e off the selector level escutcheon nnd. Irom under th e cnr. re move the plug in the side 01 the selector housing. 3 Adjust the inhibito r cnble locknut X to giv e a dimension of 0.1 to 0.2 mm (0.004 to 0 .008 in) (Fig. 6 .36). 4 Refit the plug nnd escutcheon. S With the trnn smission shih lever and the mnnunl selector lever in '0'. ndJust th e selector rod link until it cnll be reconnected without strain .

23 Downshift cable -removal. refitting and adjustment

Support till! front o f th e cm on Jxle Sl

24

S lnrter inhibitor/reverse Inml) switch -removal and re fitting

1 Pull the cable connector off the switch" 2 Unscrew the slnrter inhihitor swilch and remove the a"int[ 3 To rel'llhe swilCh. fil a new a·ring nnd screw the switch into lhe housing longer. tight. T'gh ten Ihe switch 10 the lorque wrench settin g

given ,n the Specilicntions. I t is imporlnl11 ,hn t thiS torque is not excee dud, 4 Ro::I't the cnhle plug conn ector to the sw,tch,

5 Chuc k th,ll th e en!J"'c will st",t only w,th the lever '" the '1" and "N' posilions and in no other POSlt'on. S TlIIn 0 " the ignition without startll1g th e engine, Check IhM the

r ' ;inU light comes 0 11 in th e "R" po~rtlon, but not in any other.

25 .tension housing o il senl-renew,,1

1 Remove the propeller shnl!. ns do::scrrhed III Chi,pter 7.

2 Jnck t he r enr of Ihe c,u to [1Hn",HSe the loss of 011 from the

transmission . then carefully pr ise out the od seill. being cJrtJIut not to (JamJ,Je the machined recess into which the sc,rI I,ts, 3 E'lslIfe that the recess is cle

6.37 Adjusting the downshift cable (Sec 23)

Depress Ihlollle hJlly (bloken arIOw). Pivol/he downshilllev,·( ,)wuy frum Ihe ,1ccelef,1{Qr sllMI lind UdjllS! Ih e clcarance at Ihe MljllSling nul (solid arrow)

~r:;0/,/5.;~··ll ~

Fig. 6,38 Inhibito r switc h renewal (Sec 24)

A Wiling connector B Inhibl/Ul swilch C O-riny

26 Fault dingl10sis -nutornatic Ir

"."

" , .

, ,

J

,

procarmanuals.com

Page 129 of 205

)

Chapter 7 Propeller shaft

Contents

Cenl,C be"wl(J rCl1<,w,,1 !':HlII d'''!I(lOSIS 1',01'"11,,, Shill, Gel,..,,;!1 li('SCIIIIIIO"

Specifications

Type

Torque wrench settings C{:II(,,, I,/!,,, ,,,! )

(',op"lll:r shall (" "',II i,xlc I I,moO]

Cello!',,1 duscriptioll

3 , ..

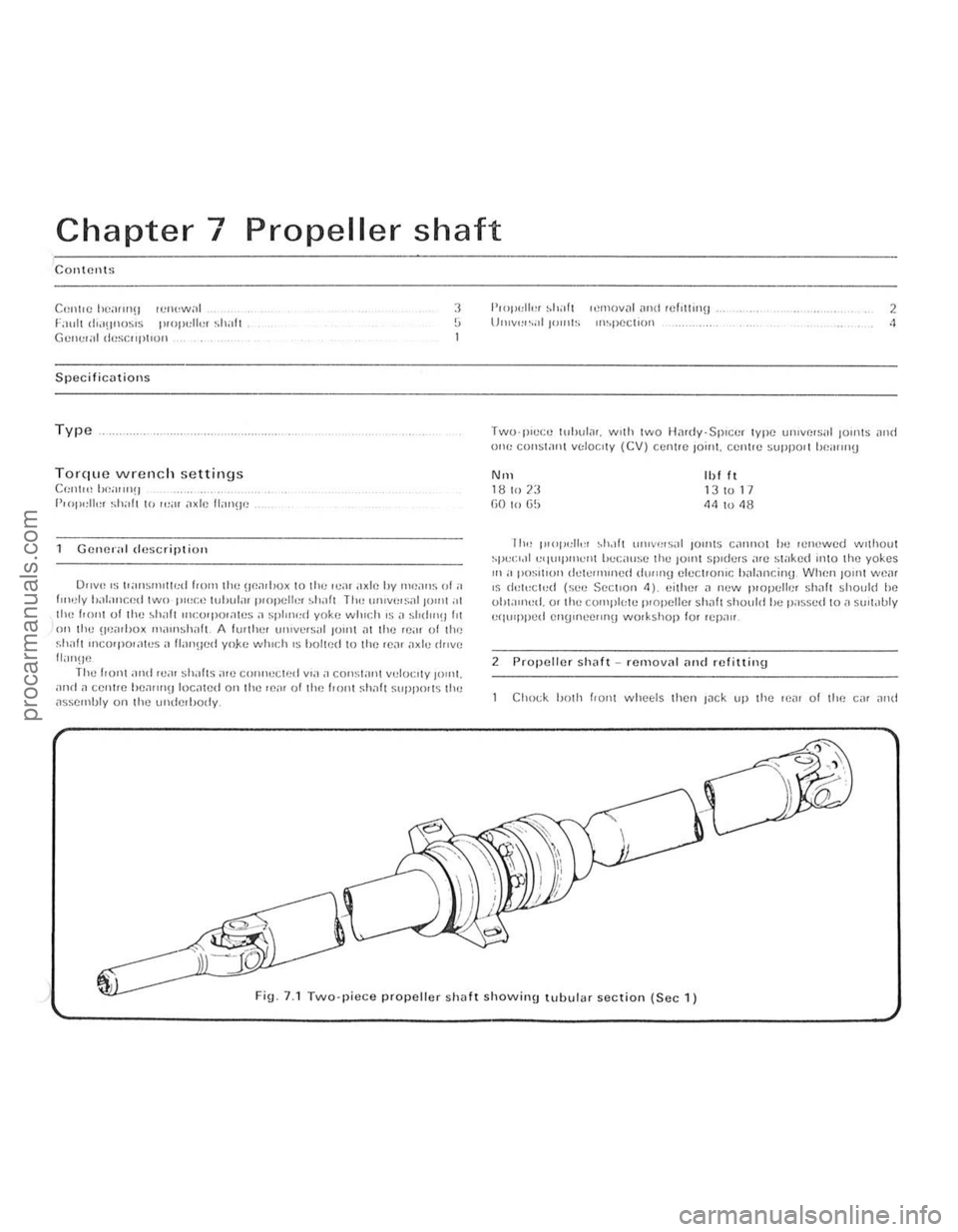

o"V() IS lI"Il~""w,d 110m III!: HP.;uh<)x 10 thCIVill ,"xlc hy mpdns "r " r",,!ly 1)"I,lIlted two 1''',Co) tuhul;1I p,opcli.:r ~hafl The u 'Hv""Si,1 JOlin ;" 1he 1'0111 of tile ,hilh IIH:()rpOI,lICS;) sphno"r yoke winch IS,' ~hd"'!II'1 Oil Iliu \lUilllJu x "''''''SIHlft A (w Illel lIIuvcrs"r lUll)! ,11 11'0 leill uf the f.Il,1f1 IIl(;orpOr;\I(!s iI [lill1lter! yoke which IS holled to the Ie", ,1xle drive !lilll\IC The honl ,111<1 "."" sh"hs illU cOIll"'cl(,d vIa a COI1~1

!'wpldlc, ~h;!h ,ctl1()v;)1 ,md rcf,UIIlU l)n,v,,,,,,II'''''IS '""pectln!) 2 .,

TWO'IHCCll tl1l>\lI., •. w llh lwo HMdy,Splcer type uillvelsitl 10lols an d 01'(' COIISWII1 V"loc,ly (CV) ccnl.e 10"'1. CC"lIC SUppO' 1 IUI;II">!)

NIIl 1 B 10 23 (;0 hI tj~

'1)111 13 10 17 114 10 48

II", 1110) ",11." ,hol!1 ,,,uv,,,s;r ) )OUlls C;IP"lOl hc ICllewed wllhoul ,purloll "'l"'Pllh:ll1 hcciI",e Ihe )01111 s pldels ;IIC sl"ke(1 11110 Ihe yokes ,n i> I'OSl1l011 dUWln)lnud dUlln9 elccl ,olHC h;>l;lI1cin\j When 101111 we;u IS dd,'Cit,d (seu SectIon 11). "ilher .1 new IHopelh;. sh~1t should he ohl;"""d. 01 lilt) cOlllpl{,tc plopelle. shah shQuld he p;rss~d to;> SIIII.IUly

equI pped el1!).necIIt>\j wOlkshop lor I~pn"

2 Propeller sh

ig. 7. 1 Two-piece propeller shaft showing tubular section (Sec 1)

procarmanuals.com