lock FORD E SERIES 2015 4.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: E SERIES, Model: FORD E SERIES 2015 4.GPages: 360, PDF Size: 3.28 MB

Page 194 of 360

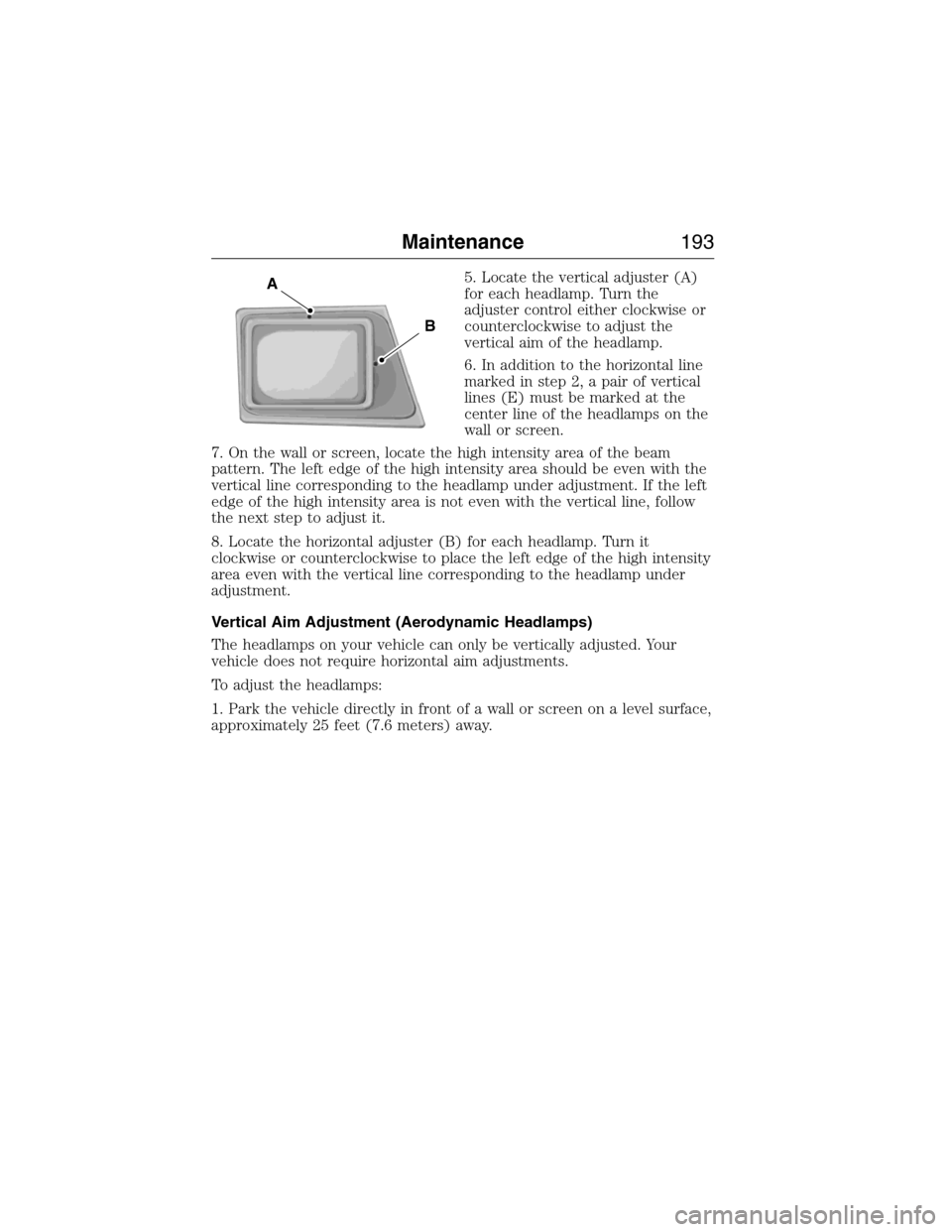

5. Locate the vertical adjuster (A)

for each headlamp. Turn the

adjuster control either clockwise or

counterclockwise to adjust the

vertical aim of the headlamp.

6. In addition to the horizontal line

marked in step 2, a pair of vertical

lines (E) must be marked at the

center line of the headlamps on the

wall or screen.

7. On the wall or screen, locate the high intensity area of the beam

pattern. The left edge of the high intensity area should be even with the

vertical line corresponding to the headlamp under adjustment. If the left

edge of the high intensity area is not even with the vertical line, follow

the next step to adjust it.

8. Locate the horizontal adjuster (B) for each headlamp. Turn it

clockwise or counterclockwise to place the left edge of the high intensity

area even with the vertical line corresponding to the headlamp under

adjustment.

Vertical Aim Adjustment (Aerodynamic Headlamps)

The headlamps on your vehicle can only be vertically adjusted. Your

vehicle does not require horizontal aim adjustments.

To adjust the headlamps:

1. Park the vehicle directly in front of a wall or screen on a level surface,

approximately 25 feet (7.6 meters) away.A

B

Maintenance193

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 195 of 360

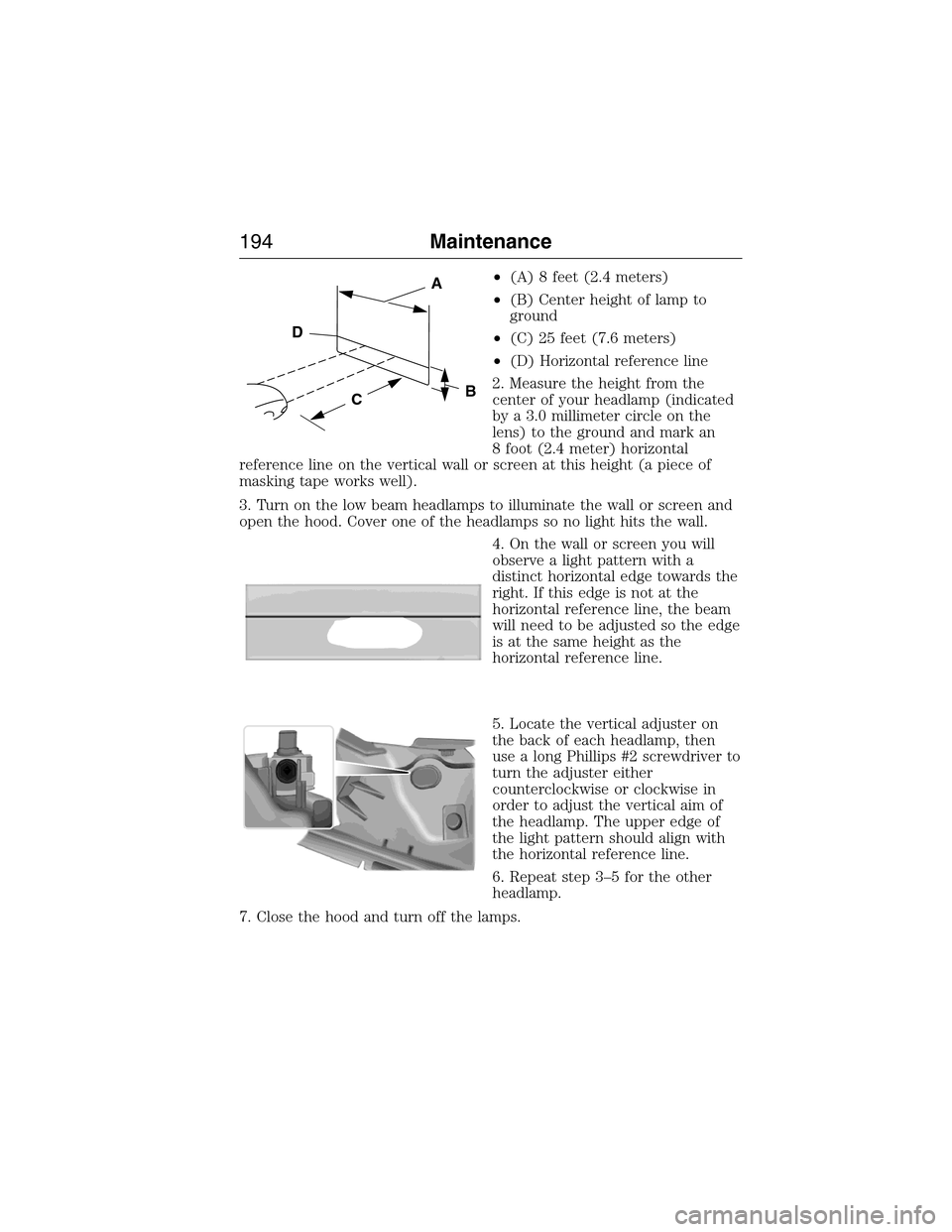

•(A) 8 feet (2.4 meters)

•(B) Center height of lamp to

ground

•(C) 25 feet (7.6 meters)

•(D) Horizontal reference line

2. Measure the height from the

center of your headlamp (indicated

by a 3.0 millimeter circle on the

lens) to the ground and mark an

8 foot (2.4 meter) horizontal

reference line on the vertical wall or screen at this height (a piece of

masking tape works well).

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood. Cover one of the headlamps so no light hits the wall.

4. On the wall or screen you will

observe a light pattern with a

distinct horizontal edge towards the

right. If this edge is not at the

horizontal reference line, the beam

will need to be adjusted so the edge

is at the same height as the

horizontal reference line.

5. Locate the vertical adjuster on

the back of each headlamp, then

use a long Phillips #2 screwdriver to

turn the adjuster either

counterclockwise or clockwise in

order to adjust the vertical aim of

the headlamp. The upper edge of

the light pattern should align with

the horizontal reference line.

6. Repeat step 3–5 for the other

headlamp.

7. Close the hood and turn off the lamps.

C

A

B

D

194Maintenance

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 197 of 360

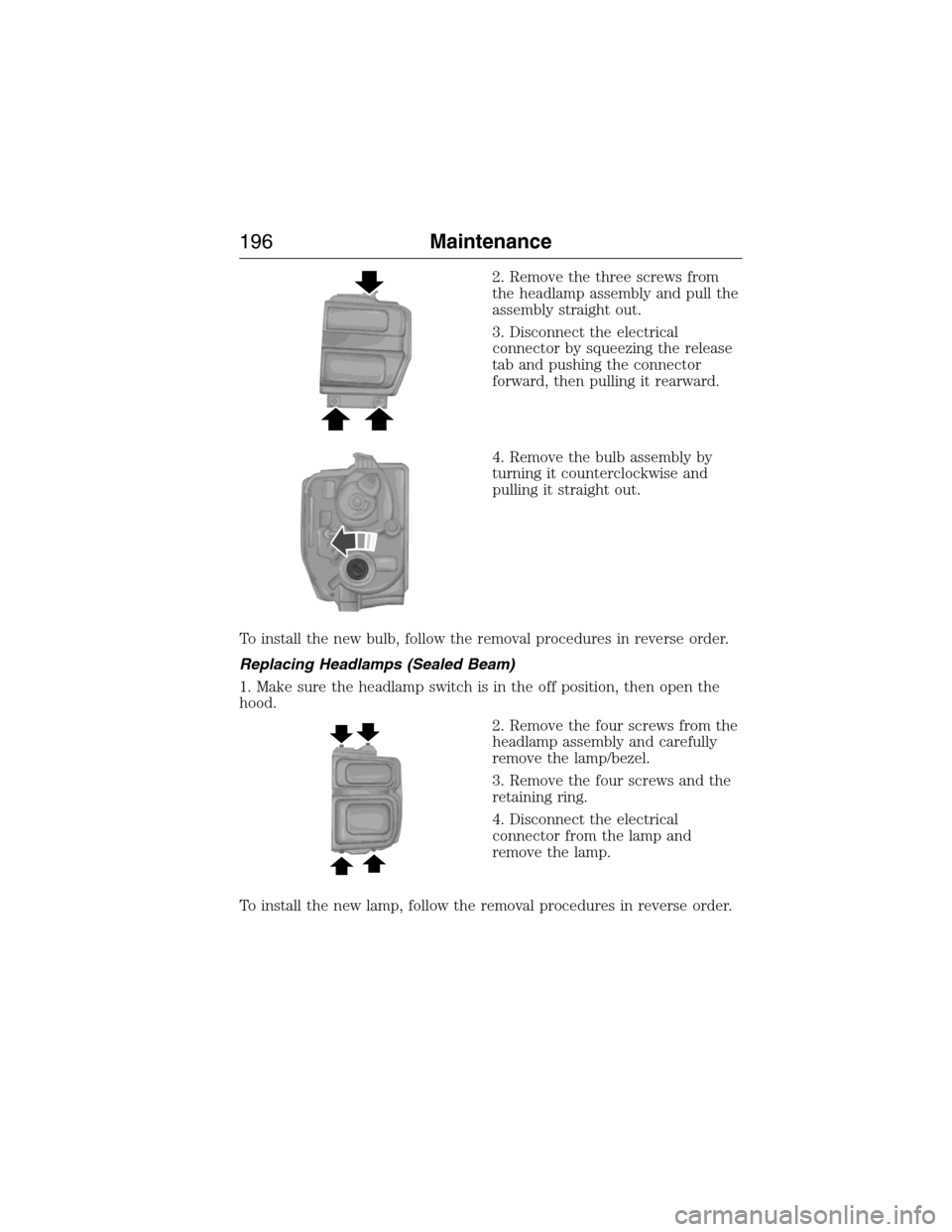

2. Remove the three screws from

the headlamp assembly and pull the

assembly straight out.

3. Disconnect the electrical

connector by squeezing the release

tab and pushing the connector

forward, then pulling it rearward.

4. Remove the bulb assembly by

turning it counterclockwise and

pulling it straight out.

To install the new bulb, follow the removal procedures in reverse order.

Replacing Headlamps (Sealed Beam)

1. Make sure the headlamp switch is in the off position, then open the

hood.

2. Remove the four screws from the

headlamp assembly and carefully

remove the lamp/bezel.

3. Remove the four screws and the

retaining ring.

4. Disconnect the electrical

connector from the lamp and

remove the lamp.

To install the new lamp, follow the removal procedures in reverse order.

196Maintenance

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 198 of 360

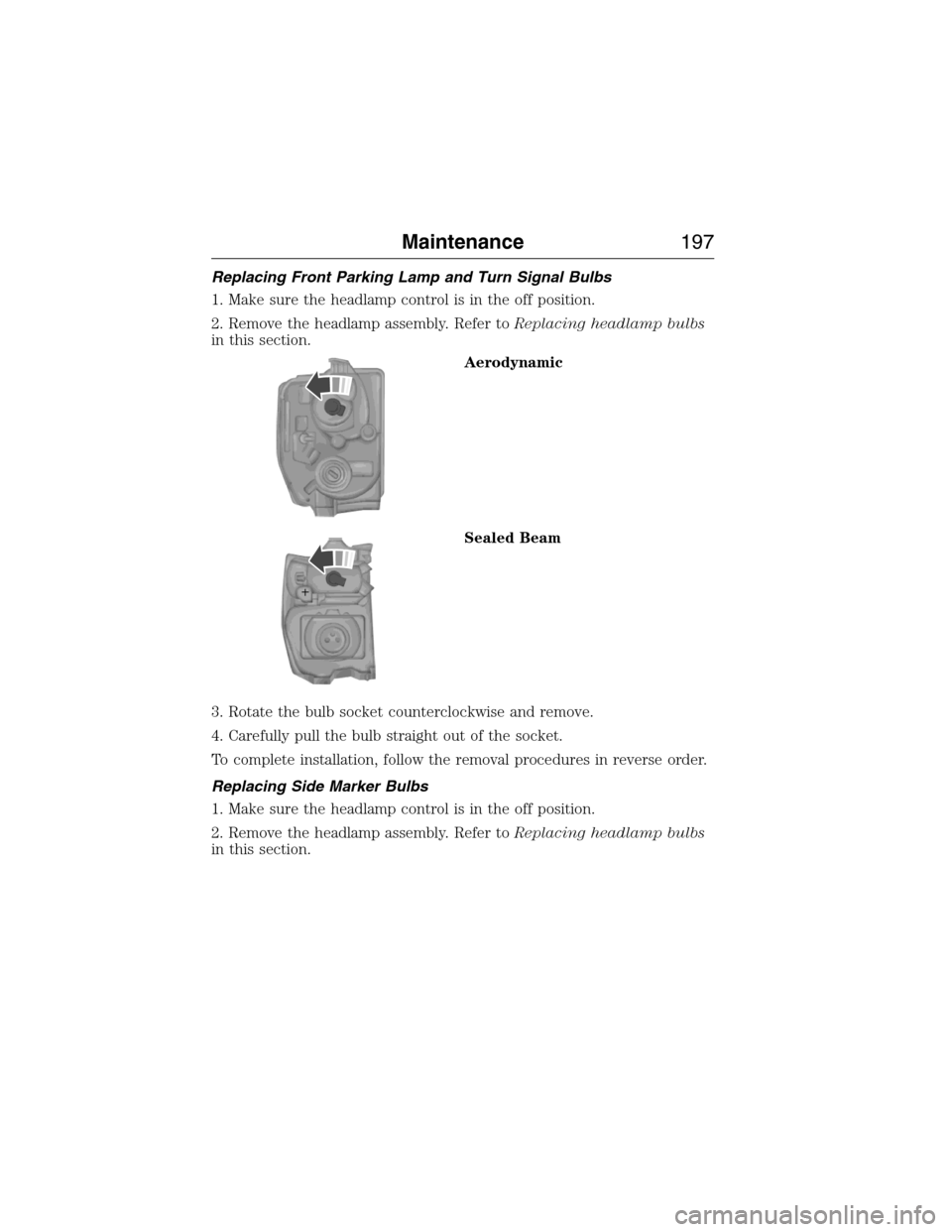

Replacing Front Parking Lamp and Turn Signal Bulbs

1. Make sure the headlamp control is in the off position.

2. Remove the headlamp assembly. Refer toReplacing headlamp bulbs

in this section.

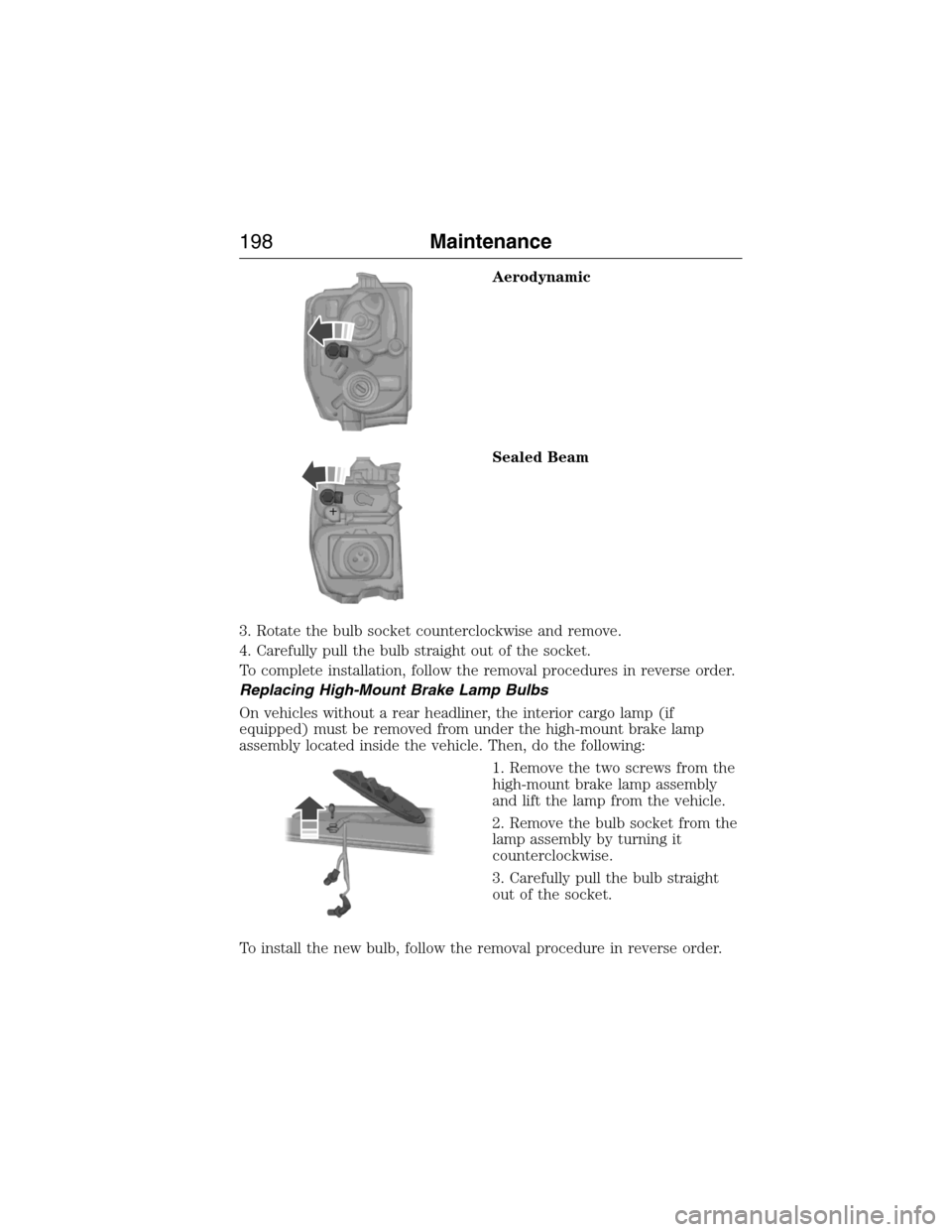

Aerodynamic

Sealed Beam

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pull the bulb straight out of the socket.

To complete installation, follow the removal procedures in reverse order.

Replacing Side Marker Bulbs

1. Make sure the headlamp control is in the off position.

2. Remove the headlamp assembly. Refer toReplacing headlamp bulbs

in this section.

Maintenance197

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 199 of 360

Aerodynamic

Sealed Beam

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pull the bulb straight out of the socket.

To complete installation, follow the removal procedures in reverse order.

Replacing High-Mount Brake Lamp Bulbs

On vehicles without a rear headliner, the interior cargo lamp (if

equipped) must be removed from under the high-mount brake lamp

assembly located inside the vehicle. Then, do the following:

1. Remove the two screws from the

high-mount brake lamp assembly

and lift the lamp from the vehicle.

2. Remove the bulb socket from the

lamp assembly by turning it

counterclockwise.

3. Carefully pull the bulb straight

out of the socket.

To install the new bulb, follow the removal procedure in reverse order.

198Maintenance

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 200 of 360

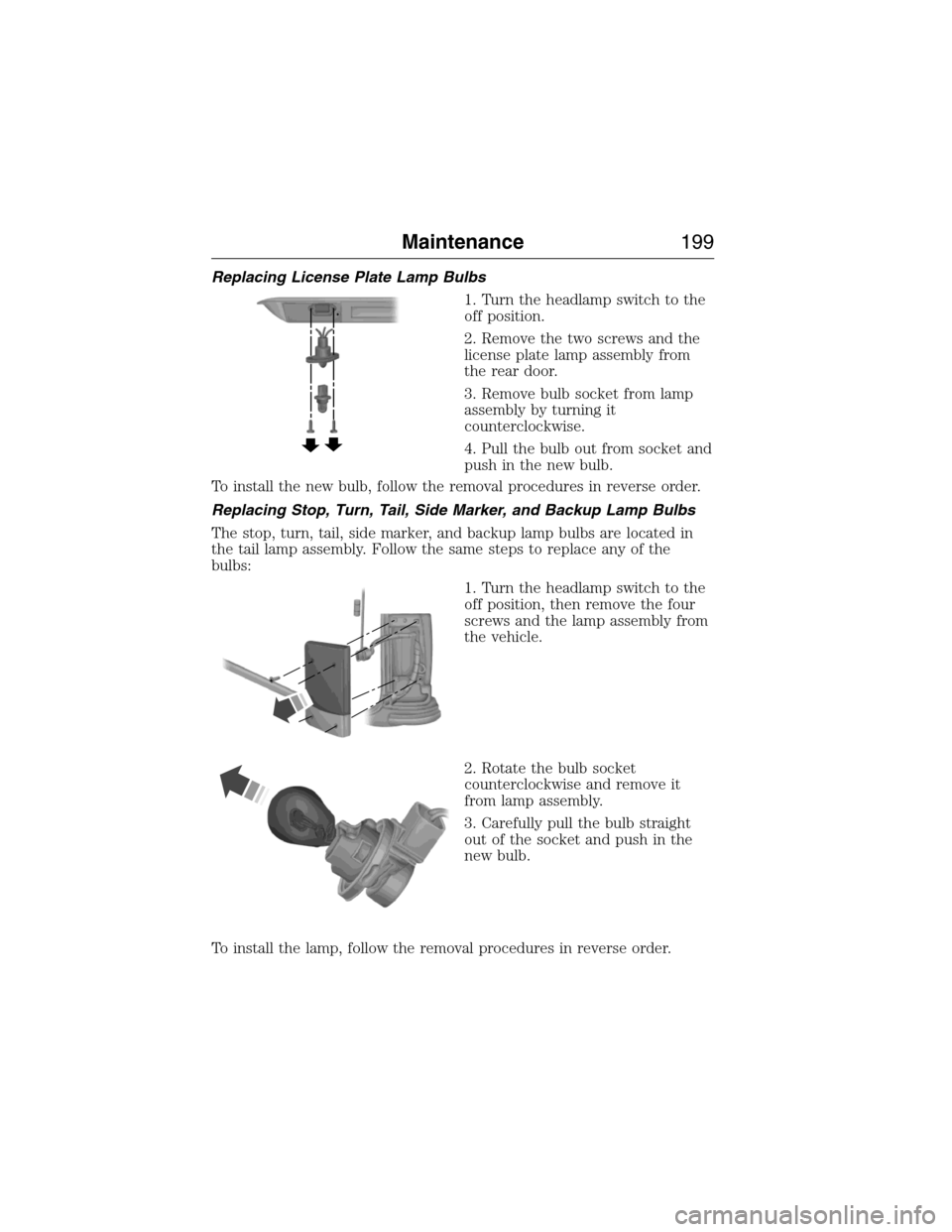

Replacing License Plate Lamp Bulbs

1. Turn the headlamp switch to the

off position.

2. Remove the two screws and the

license plate lamp assembly from

the rear door.

3. Remove bulb socket from lamp

assembly by turning it

counterclockwise.

4. Pull the bulb out from socket and

push in the new bulb.

To install the new bulb, follow the removal procedures in reverse order.

Replacing Stop, Turn, Tail, Side Marker, and Backup Lamp Bulbs

The stop, turn, tail, side marker, and backup lamp bulbs are located in

the tail lamp assembly. Follow the same steps to replace any of the

bulbs:

1. Turn the headlamp switch to the

off position, then remove the four

screws and the lamp assembly from

the vehicle.

2. Rotate the bulb socket

counterclockwise and remove it

from lamp assembly.

3. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

To install the lamp, follow the removal procedures in reverse order.

Maintenance199

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 205 of 360

CLEANING THE ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal.

When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser on all parts that

require cleaning and pressure rinse clean. In Canada, use Motorcraft

Engine Shampoo.

•Never wash or rinse the engine while it is hot or running; water in the

running engine may cause internal damage.

•Never wash or rinse any ignition coil, spark plug wire or spark plug

well, or the area in and around these locations.

•Cover the battery, power distribution box, and air filter assembly to

prevent water damage when cleaning the engine.

CLEANING THE WINDOWS AND WIPER BLADES

The windows and wiper blades should be cleaned regularly. If the wipers

do not wipe properly, substances on the vehicle’s glass or the wiper

blades may cause squeaking or chatter noise from the blades, and

streaking and smearing of the windshield. To clean these items, follow

these tips:

•The windows may be cleaned with a non-abrasive cleaner such as

Motorcraft® Ultra-Clear Spray Glass Cleaner (U.S.) or Motorcraft

Premium Glass Cleaner (Canada).

•The wiper blades can be cleaned with isopropyl (rubbing) alcohol or

Motorcraft Premium Windshield Washer Concentrates in the U.S., or

Motorcraft Premium Quality Windshield Washer Fluid in Canada.

Replace your wiper blades when they appear worn or do not function

properly.

•Do not use abrasive materials, as they may cause scratches.

•Do not use fuel, kerosene, or paint thinner to clean any parts.

204Vehicle Care

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 239 of 360

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. This must be

accomplished within 10 seconds.

If the reset mode has been entered successfully, the horn will sound

once, the system indicator will flash and the message center (if

equipped) will displayTRAIN LEFT FRONT TIRE. If this does not

occur, please try again starting at Step 2.

If after repeated attempts to enter the reset mode, the horn does not

sound, the system indicator does not flash and the message center (if

equipped) does not displayTRAIN LEFT FRONT TIRE, seek service

from your authorized dealer.

5. Train the tire pressure monitoring system sensors in the tires using

the following system reset sequence starting with the left front tire in

the following clockwise order:

•Left front (Driver’s side front tire)

•Right front (Passenger’s side front tire)

•Right rear (Passenger’s side rear tire)

•Left rear (Driver’s side rear tire)

6. Remove the valve cap from the valve stem on the left front tire;

decrease the air pressure until the horn sounds.

Note:The single horn chirp confirms that the sensor identification code

has been learned by the module for this position. If a double horn is

heard, the reset procedure was unsuccessful, and must be repeated.

7. Remove the valve cap from the valve stem on the right front tire;

decrease the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire;

decrease the air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire;

decrease the air pressure until the horn sounds.

Training is complete after the horn sounds for the last tire trained

(driver’s side rear tire), the system indicator stops flashing, and the

message center (if equipped) displays:

TRAINING COMPLETE.

10. Turn the ignition off. If two short horn beeps are heard, the reset

procedure was unsuccessful and must be repeated.

238Wheels and Tires

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 243 of 360

Tire Change Procedure

WARNING:When one of the front wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in park (P) or neutral

(N).

WARNING:To help prevent the vehicle from moving when you

change a tire, be sure to place the transmission in park (P), set

the parking brake and block (in both directions) the wheel that is

diagonally opposite (other side and end of the vehicle) to the tire being

changed.

WARNING:Never get underneath a vehicle that is supported

only by a jack. If the vehicle slips off the jack, you or someone

else could be seriously injured.

WARNING:Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

WARNING:Always use the jack provided as original equipment

with your vehicle. If using a jack other than the one provided as

original equipment with your vehicle, make sure the jack capacity is

adequate for the vehicle weight, including any vehicle cargo or

modifications.

WARNING:Never use wheels or lug nuts different than the

original equipment as this could damage the wheel or mounting

system. This damage could allow the wheels to come off while the

vehicle is being driven.

Note:Passengers should not remain in the vehicle when the vehicle is

being jacked.

1. Park on a level surface, set the parking brake and activate the warning

flashers.

242Wheels and Tires

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)

Page 244 of 360

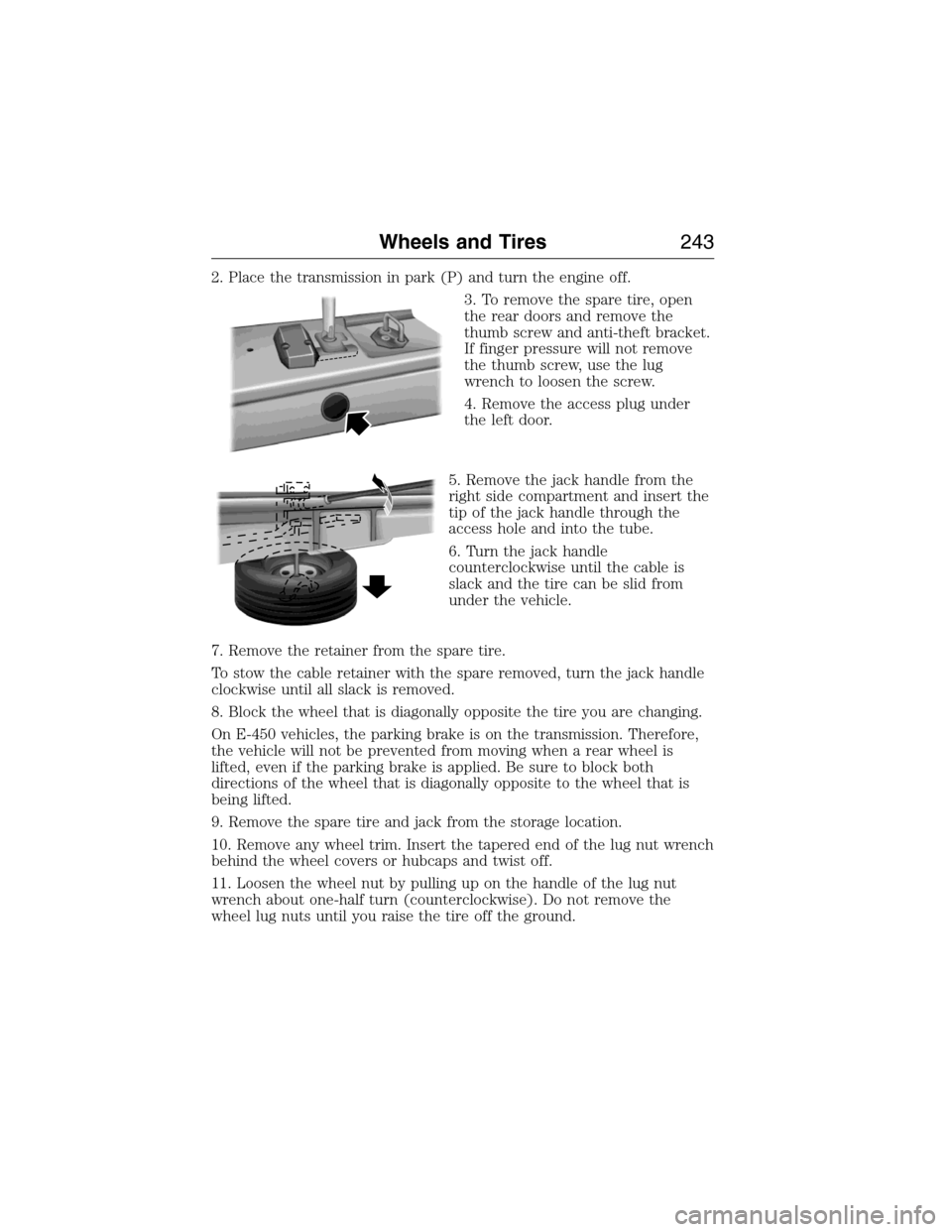

2. Place the transmission in park (P) and turn the engine off.

3. To remove the spare tire, open

the rear doors and remove the

thumb screw and anti-theft bracket.

If finger pressure will not remove

the thumb screw, use the lug

wrench to loosen the screw.

4. Remove the access plug under

the left door.

5. Remove the jack handle from the

right side compartment and insert the

tip of the jack handle through the

access hole and into the tube.

6. Turn the jack handle

counterclockwise until the cable is

slack and the tire can be slid from

under the vehicle.

7. Remove the retainer from the spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

clockwise until all slack is removed.

8. Block the wheel that is diagonally opposite the tire you are changing.

On E-450 vehicles, the parking brake is on the transmission. Therefore,

the vehicle will not be prevented from moving when a rear wheel is

lifted, even if the parking brake is applied. Be sure to block both

directions of the wheel that is diagonally opposite to the wheel that is

being lifted.

9. Remove the spare tire and jack from the storage location.

10. Remove any wheel trim. Insert the tapered end of the lug nut wrench

behind the wheel covers or hubcaps and twist off.

11. Loosen the wheel nut by pulling up on the handle of the lug nut

wrench about one-half turn (counterclockwise). Do not remove the

wheel lug nuts until you raise the tire off the ground.

Wheels and Tires243

2015 Econoline(eco)

Owners Guide gf, 1st Printing, June 2014

USA(fus)