ignition FORD E SERIES 2023 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: E SERIES, Model: FORD E SERIES 2023Pages: 292, PDF Size: 6.81 MB

Page 140 of 292

TOWING THE VEHICLE ON

FOUR WHEELS

Emergency Towing

WARNING: If your vehicle has asteering wheel lock make sure theignition is in the accessory or on positionwhen being towed.

You can flat-tow (all wheels on theground, regardless of the powertrain ortransmission configuration) your disabledvehicle (without access to wheel dolliesor vehicle transport trailer) under thefollowing conditions:

•Your vehicle is facing forward so youtow it in a forward direction.

•You shift into neutral (N). If you cannotshift into neutral (N), you may need tooverride the transmission. SeeTransmission (page 96).

•Maximum speed is 35 mph (56 km/h).

•Maximum distance is 50 mi (80 km).

Recreational Towing

Note: Put your climate control system inrecirculated air mode to prevent exhaustfumes from entering the vehicle. SeeClimate Control (page 74).

Follow these guidelines if you have a needfor recreational vehicle towing. An exampleof recreational towing would be towingyour vehicle behind a motorhome. Theseguidelines are to make sure you do notdamage the transmission during towing.

Do not tow your vehicle with any wheelson the ground, as vehicle or transmissiondamage may occur. It is recommended totow your vehicle with all four wheels offthe ground, for example when using avehicle transport trailer. Otherwise, youcannot tow your vehicle.

137

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingTowing

Page 159 of 292

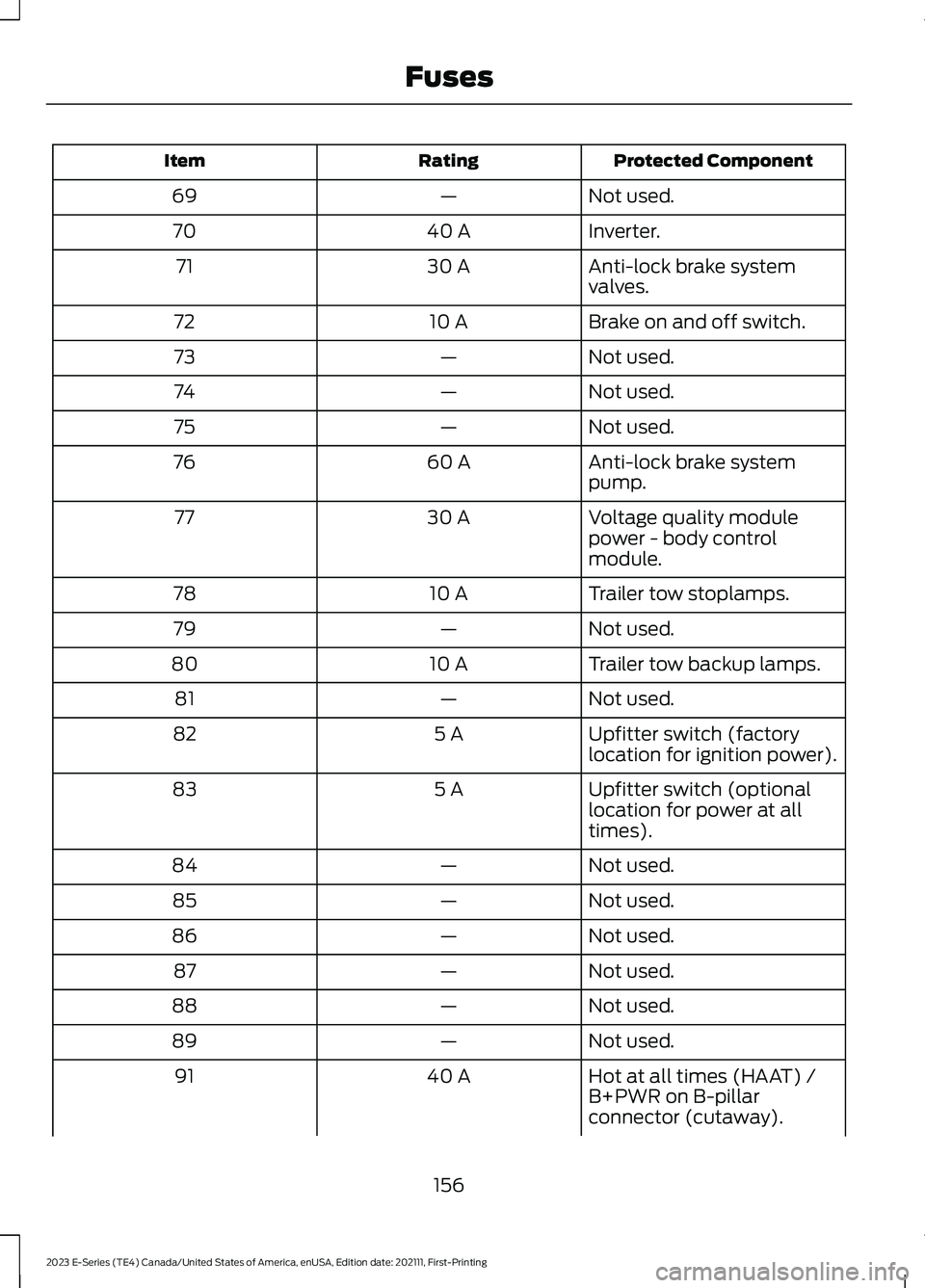

Protected ComponentRatingItem

Not used.—69

Inverter.40 A70

Anti-lock brake systemvalves.30 A71

Brake on and off switch.10 A72

Not used.—73

Not used.—74

Not used.—75

Anti-lock brake systempump.60 A76

Voltage quality modulepower - body controlmodule.

30 A77

Trailer tow stoplamps.10 A78

Not used.—79

Trailer tow backup lamps.10 A80

Not used.—81

Upfitter switch (factorylocation for ignition power).5 A82

Upfitter switch (optionallocation for power at alltimes).

5 A83

Not used.—84

Not used.—85

Not used.—86

Not used.—87

Not used.—88

Not used.—89

Hot at all times (HAAT) /B+PWR on B-pillarconnector (cutaway).

40 A91

156

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingFuses

Page 162 of 292

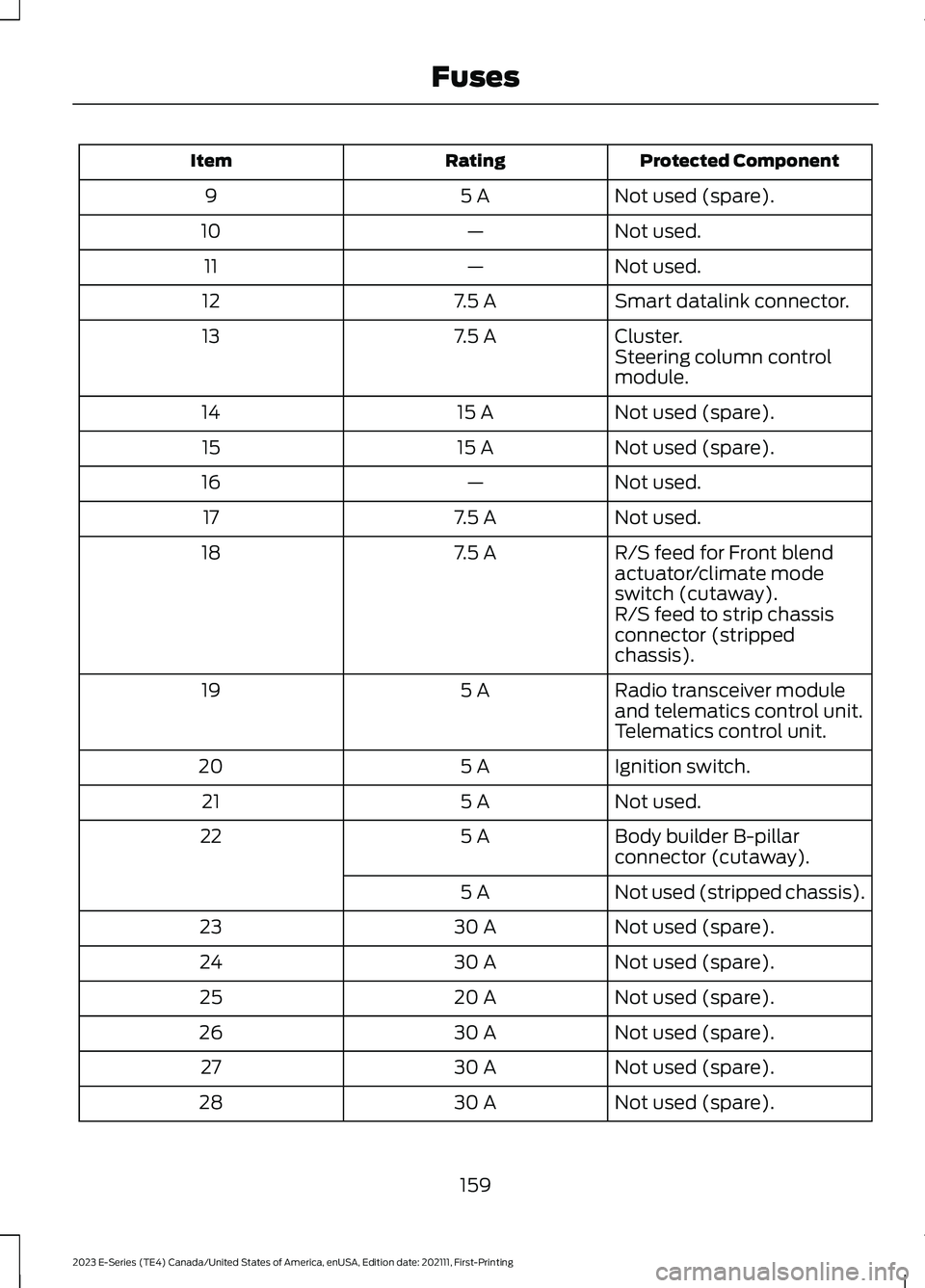

Protected ComponentRatingItem

Not used (spare).5 A9

Not used.—10

Not used.—11

Smart datalink connector.7.5 A12

Cluster.7.5 A13Steering column controlmodule.

Not used (spare).15 A14

Not used (spare).15 A15

Not used.—16

Not used.7.5 A17

R/S feed for Front blendactuator/climate modeswitch (cutaway).

7.5 A18

R/S feed to strip chassisconnector (strippedchassis).

Radio transceiver moduleand telematics control unit.5 A19

Telematics control unit.

Ignition switch.5 A20

Not used.5 A21

Body builder B-pillarconnector (cutaway).5 A22

Not used (stripped chassis).5 A

Not used (spare).30 A23

Not used (spare).30 A24

Not used (spare).20 A25

Not used (spare).30 A26

Not used (spare).30 A27

Not used (spare).30 A28

159

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingFuses

Page 167 of 292

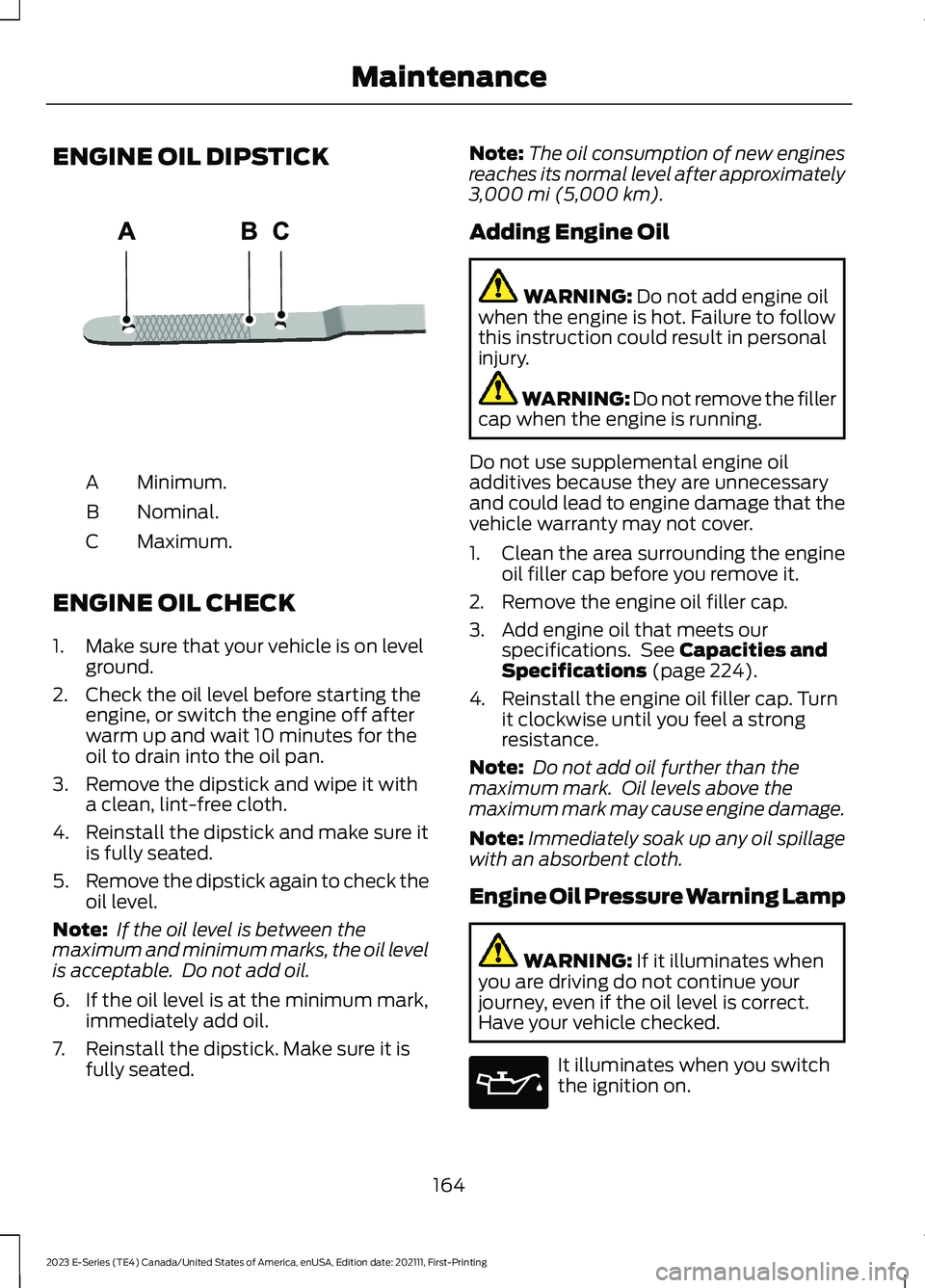

ENGINE OIL DIPSTICK

Minimum.A

Nominal.B

Maximum.C

ENGINE OIL CHECK

1.Make sure that your vehicle is on levelground.

2.Check the oil level before starting theengine, or switch the engine off afterwarm up and wait 10 minutes for theoil to drain into the oil pan.

3.Remove the dipstick and wipe it witha clean, lint-free cloth.

4.Reinstall the dipstick and make sure itis fully seated.

5.Remove the dipstick again to check theoil level.

Note: If the oil level is between themaximum and minimum marks, the oil levelis acceptable. Do not add oil.

6.If the oil level is at the minimum mark,immediately add oil.

7.Reinstall the dipstick. Make sure it isfully seated.

Note:The oil consumption of new enginesreaches its normal level after approximately3,000 mi (5,000 km).

Adding Engine Oil

WARNING: Do not add engine oilwhen the engine is hot. Failure to followthis instruction could result in personalinjury.

WARNING: Do not remove the fillercap when the engine is running.

Do not use supplemental engine oiladditives because they are unnecessaryand could lead to engine damage that thevehicle warranty may not cover.

1.Clean the area surrounding the engineoil filler cap before you remove it.

2.Remove the engine oil filler cap.

3.Add engine oil that meets ourspecifications. See Capacities andSpecifications (page 224).

4.Reinstall the engine oil filler cap. Turnit clockwise until you feel a strongresistance.

Note: Do not add oil further than themaximum mark. Oil levels above themaximum mark may cause engine damage.

Note:Immediately soak up any oil spillagewith an absorbent cloth.

Engine Oil Pressure Warning Lamp

WARNING: If it illuminates whenyou are driving do not continue yourjourney, even if the oil level is correct.Have your vehicle checked.

It illuminates when you switchthe ignition on.

164

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingMaintenanceE250320

Page 180 of 292

5.Locate the vertical adjuster on eachheadlamp. Using a Phillips #2screwdriver, turn the adjuster eitherclockwise or counterclockwise in orderto adjust the vertical aim of theheadlamp.

6.Repeat steps 3 through 5 to adjust theother headlamp.

7.Close the hood and switch off thelamps.

WASHER FLUID CHECK

WARNING: If you operate yourvehicle in temperatures below 40°F(5°C), use washer fluid with antifreezeprotection. Failure to use washer fluidwith antifreeze protection in coldweather could result in impairedwindshield vision and increase the riskof injury or accident.

Add fluid to fill the reservoir if the level islow. Only use a washer fluid that meetsFord specifications. See Capacities andSpecifications (page 224).

State or local regulations on volatileorganic compounds may restrict the useof methanol, a common windshield washerantifreeze additive. Washer fluidscontaining non-methanol antifreezeagents should be used only if they providecold weather protection without damagingthe vehicle’s paint finish, wiper blades orwasher system.

FUEL FILTER

Your vehicle is equipped with a lifetimefuel filter that is integrated with the fueltank. Regular maintenance or replacementis not needed.

CHECKING THE WIPER

BLADES

Run the tip of your fingers over the edge ofthe blade to check for roughness.

Clean the wiper blades with washer fluidor water applied with a soft sponge orcloth.

CHANGING THE WIPER

BLADES

You can manually move the wiper armswhen the ignition is off. This allows for easeof blade replacement and cleaning underthe blades.

177

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingMaintenanceE163806 E142463

Page 181 of 292

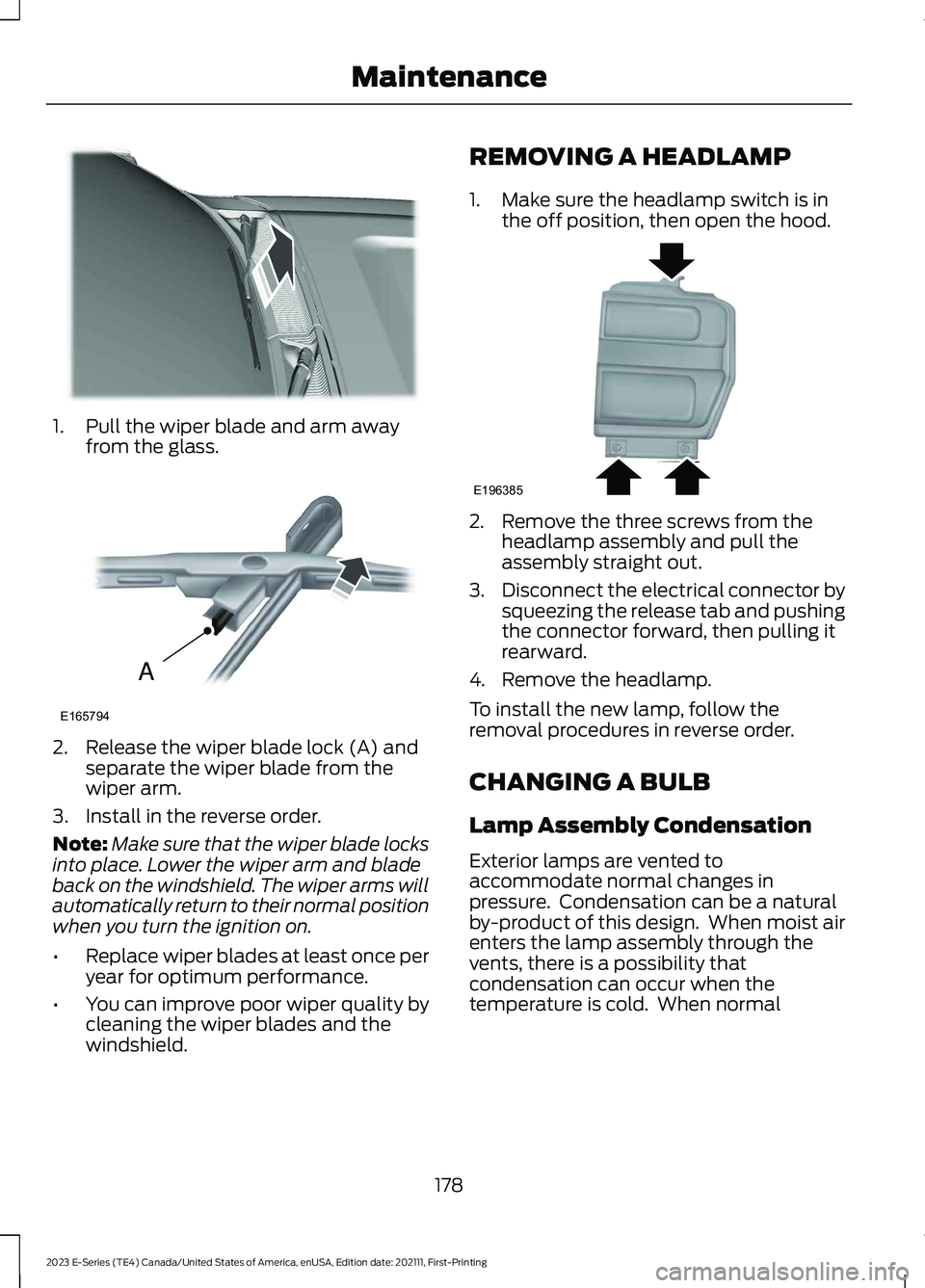

1.Pull the wiper blade and arm awayfrom the glass.

2.Release the wiper blade lock (A) andseparate the wiper blade from thewiper arm.

3.Install in the reverse order.

Note:Make sure that the wiper blade locksinto place. Lower the wiper arm and bladeback on the windshield. The wiper arms willautomatically return to their normal positionwhen you turn the ignition on.

•Replace wiper blades at least once peryear for optimum performance.

•You can improve poor wiper quality bycleaning the wiper blades and thewindshield.

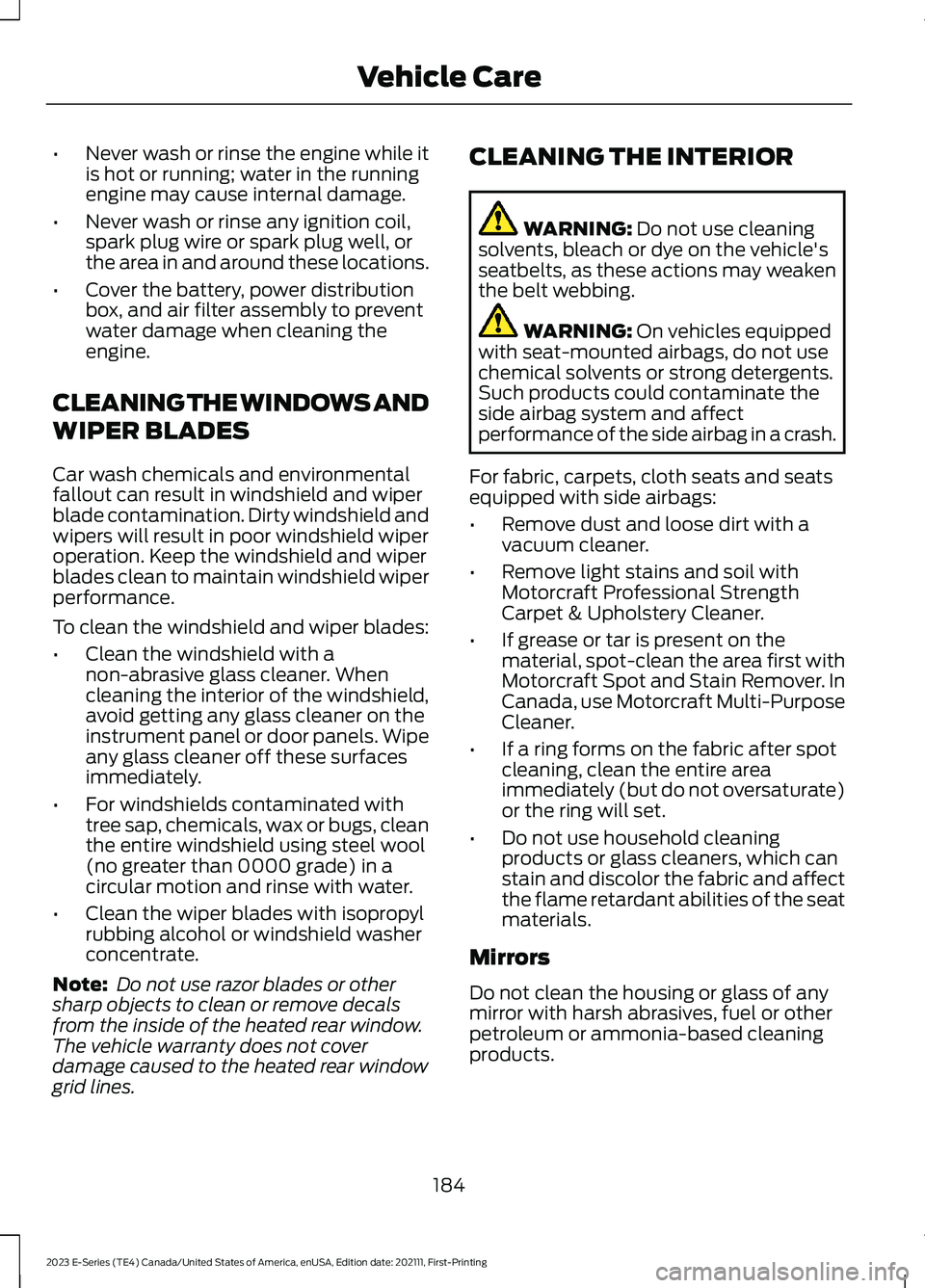

REMOVING A HEADLAMP

1.Make sure the headlamp switch is inthe off position, then open the hood.

2.Remove the three screws from theheadlamp assembly and pull theassembly straight out.

3.Disconnect the electrical connector bysqueezing the release tab and pushingthe connector forward, then pulling itrearward.

4.Remove the headlamp.

To install the new lamp, follow theremoval procedures in reverse order.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented toaccommodate normal changes inpressure. Condensation can be a naturalby-product of this design. When moist airenters the lamp assembly through thevents, there is a possibility thatcondensation can occur when thetemperature is cold. When normal

178

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingMaintenanceE165804 AE165794 E196385

Page 187 of 292

•Never wash or rinse the engine while itis hot or running; water in the runningengine may cause internal damage.

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, orthe area in and around these locations.

•Cover the battery, power distributionbox, and air filter assembly to preventwater damage when cleaning theengine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

To clean the windshield and wiper blades:

•Clean the windshield with anon-abrasive glass cleaner. Whencleaning the interior of the windshield,avoid getting any glass cleaner on theinstrument panel or door panels. Wipeany glass cleaner off these surfacesimmediately.

•For windshields contaminated withtree sap, chemicals, wax or bugs, cleanthe entire windshield using steel wool(no greater than 0000 grade) in acircular motion and rinse with water.

•Clean the wiper blades with isopropylrubbing alcohol or windshield washerconcentrate.

Note: Do not use razor blades or othersharp objects to clean or remove decalsfrom the inside of the heated rear window.The vehicle warranty does not coverdamage caused to the heated rear windowgrid lines.

CLEANING THE INTERIOR

WARNING: Do not use cleaningsolvents, bleach or dye on the vehicle'sseatbelts, as these actions may weakenthe belt webbing.

WARNING: On vehicles equippedwith seat-mounted airbags, do not usechemical solvents or strong detergents.Such products could contaminate theside airbag system and affectperformance of the side airbag in a crash.

For fabric, carpets, cloth seats and seatsequipped with side airbags:

•Remove dust and loose dirt with avacuum cleaner.

•Remove light stains and soil withMotorcraft Professional StrengthCarpet & Upholstery Cleaner.

•If grease or tar is present on thematerial, spot-clean the area first withMotorcraft Spot and Stain Remover. InCanada, use Motorcraft Multi-PurposeCleaner.

•If a ring forms on the fabric after spotcleaning, clean the entire areaimmediately (but do not oversaturate)or the ring will set.

•Do not use household cleaningproducts or glass cleaners, which canstain and discolor the fabric and affectthe flame retardant abilities of the seatmaterials.

Mirrors

Do not clean the housing or glass of anymirror with harsh abrasives, fuel or otherpetroleum or ammonia-based cleaningproducts.

184

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingVehicle Care

Page 216 of 292

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least 3 ft(1 m) away from another vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system can time-out and you haveto repeat the entire procedure on allfour wheels.

•A double horn sounds indicating theneed to repeat the procedure.

Performing the System Reset Procedure- Single Rear Wheel

Read the entire procedure beforeattempting.

1.Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3.Cycle the ignition to the on positionwith the engine off.

4.Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If you successfullyenter the reset mode, the horn soundsonce, the system indicator flashes anda message shows in the informationdisplay. If this does not occur, pleasetry again starting at step 2. If afterrepeated attempts to enter the resetmode, the horn does not sound, thesystem indicator does not flash and nomessage shows in the informationdisplay, have the system checked assoon as possible.

5.Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front -driver side front tire, Right front -passenger side front tire, Right rear -passenger side rear tire, Left rear -driver side rear tire.

6.Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn tone confirms thatthe sensor identification code has beenlearned by the module for this position. Ifyou hear a double horn, the reset procedurewas unsuccessful, and you must repeat it.

7.Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8.Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9.Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained, driverside rear tire, the system indicatorstops flashing, and a message showsin the information display.

10.Turn the ignition off. If you hear twoshort tones, the reset procedure wasunsuccessful and you must repeat it.If you hear two short beeps when theignition is off after repeating theprocedure, have the system checkedas soon as possible

213

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingWheels and Tires

Page 217 of 292

11.Set all four tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel, affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver seating position orTire Label located on the B-Pillar orthe edge of the driver door.

Performing the System Reset Procedure- Dual Rear Wheel

For further information seeUnderstanding Your Tire PressureMonitoring System and refer to DualRear Wheel, earlier in this section.

Read the entire procedure beforeattempting.

1.Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all six tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3.Cycle the ignition to the on positionwith the engine off.

4.Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If you successfullyenter the reset mode, the horn soundsonce, the system indicator flashes anda message shows in the informationdisplay. If this does not occur, pleasetry again starting at step 2. If afterrepeated attempts to enter the resetmode, the horn does not sound, thesystem indicator does not flash and nomessage shows in the informationdisplay, seek service from yourauthorized dealer.

5.Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing order: Left front - driver sidefront tire, Right front - passenger sidefront tire, Right outer rear -passengerside rear outer tire, Right inner rear -passenger side rear inner tire, Left outerrear - driver side rear outer tire, Leftinner rear - driver side rear inner tire.

6.Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn chirp confirms thatthe sensor identification code has beenlearned by the module for this position. If adouble horn is heard, the reset procedurewas unsuccessful, and you must repeat it.

7.Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8.Remove the valve cap from the valvestem on the right outer rear tire.Decrease the air pressure until the hornsounds.

9.Remove the valve cap from the valvestem on the right inner rear tire.Decrease the air pressure until the hornsounds.

10.Remove the valve cap from the valvestem on the left outer rear tire.Decrease the air pressure until thehorn sounds.

11.Remove the valve cap from the valvestem on the left inner rear tire.Decrease the air pressure until thehorn sounds. Training is completeafter the horn sounds for the last tiretrained, the system indicator stopsflashing, and a message is shown inthe information display.

214

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingWheels and Tires

Page 218 of 292

12.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

13.Set all six tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel, affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver seating position orTire Label located on the B-Pillar orthe edge of the driver door.

CHANGING A ROAD WHEEL

WARNING: To determine therequired pressure(s) for your vehicle, seethe Safety Compliance CertificationLabel (on the door hinge pillar,door-latch post or the door edge thatmeets the door-latch post, next to thedriver seat) or the Tire Label on theB-Pillar or the edge of the driver door.

Note:You should only use tire sealants inroadside emergencies as they may causedamage to the tire pressure monitoringsystem sensor.

Note:The tire pressure monitoring systemindicator light illuminates when the sparetire is in use. To restore the full function ofthe monitoring system, all road wheelsequipped with tire pressure monitoringsensors must be mounted on the vehicle.

Note:Do not use wheels or lug nutsdifferent than the original equipment, as thismay damage the wheel or mounting system.

If you get a flat tire when driving, do notapply the brake heavily. Instead, graduallydecrease your speed. Hold the steeringwheel firmly and slowly move to a safeplace on the side of the road.

Have a flat serviced by an authorizeddealer to prevent damage to the tirepressure monitoring system sensors. SeeTire Pressure Monitoring System (page209). Replace the spare tire with a road tireas soon as possible. During repairing orreplacing of the flat tire, have theauthorized dealer inspect the tire pressuremonitoring system sensor for damage.

Dissimilar Spare Wheel and TireAssembly Information

WARNING: Failure to follow theseguidelines could result in an increasedrisk of loss of vehicle control, injury ordeath.

If you have a dissimilar spare wheel andtire, then it is intended for temporary useonly. This means that if you need to use it,you should replace it as soon as possiblewith a road wheel and tire assembly thatis the same size and type as the road tiresand wheels that were originally providedby Ford. If the dissimilar spare tire or wheelis damaged, it should be replaced ratherthan repaired.

A dissimilar spare wheel and tire assemblyis defined as a spare wheel and tireassembly that is different in brand, size orappearance from the road tires and wheelsand can be one of three types:

1.T-type mini-spare: This spare tirebegins with the letter T for tire size andmay have Temporary Use Only molded inthe sidewall.

215

2023 E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202111, First-PrintingWheels and Tires