light FORD EXPEDITION 2017 3.G Manual PDF

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: EXPEDITION, Model: FORD EXPEDITION 2017 3.GPages: 500, PDF Size: 4.83 MB

Page 222 of 500

•

Avoid using speed control in hilly

terrain.

• Do not rest your foot on the brake

pedal while driving.

• Avoid carrying unnecessary weight.

• Avoid adding particular accessories to

your vehicle (e.g. bug deflectors,

rollbars/light bars, running boards, ski

racks).

• Avoid driving with the wheels out of

alignment.

DRIVING THROUGH WATER WARNING

Do not drive through flowing or deep

water as you may lose control of your

vehicle.

Note:

Driving through standing water can

cause vehicle damage.

Note: Engine damage can occur if water

enters the air filter.

Before driving through standing water,

check the depth. Never drive through water

that is higher than the bottom of the wheel

hubs. When driving through standing water, drive

very slowly and do not stop your vehicle.

Your brake performance and traction may

be limited. After driving through water and

as soon as it is safe to do so:

•

Lightly press the brake pedal to dry the

brakes and to check that they work.

• Check that the horn works.

• Check that the exterior lights work.

• Turn the steering wheel to check that

the steering power assist works.

FLOOR MATS (If Equipped) WARNINGS

Always use floor mats that are

designed to fit the foot well of your

vehicle. Only use floor mats that

leave the pedal area unobstructed. Only

use floor mats that are firmly secured to

retention posts so that they cannot slip out

of position and interfere with the pedals

or impair safe operation of your vehicle in

other ways. Pedals that cannot move freely can

cause loss of vehicle control and

increase the risk of serious personal

injury. Always make sure that the floor

mats are properly attached to the

retention posts in the carpet that are

supplied with your vehicle. Floor mats must

be properly secured to both retention posts

to make sure mats do not shift out of

position. Never place floor mats or any other

covering in the vehicle foot well that

cannot be properly secured to

prevent them from moving and interfering

with the pedals or the ability to control the

vehicle.

219

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Driving HintsE176913

Page 226 of 500

Note:

When you try to restart your vehicle

after a fuel shutoff, the vehicle makes sure

that various systems are safe to restart.

Once your vehicle determines that the

systems are safe, then the vehicle will allow

you to restart.

Note: In the event that your vehicle does

not restart after your third attempt, contact

an authorized dealer.

JUMP STARTING THE VEHICLE WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Use only adequately sized cables

with insulated clamps.

Preparing Your Vehicle

Do not attempt to push-start your

automatic transmission vehicle.

Note:

Attempting to push-start a vehicle

with an automatic transmission may cause

transmission damage.

Note: Use only a 12-volt supply to start your

vehicle. Note:

Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the

two vehicles do not touch.

Connecting the Jumper Cables WARNINGS

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components

as grounding points. Stay clear of moving

parts. To avoid reverse polarity

connections, make sure that you correctly

identify the positive (+) and negative (-)

terminals on both the disabled and booster

vehicles before connecting the cables. Do not attach the end of the positive

cable to the studs or L-shaped eyelet

located above the positive (+)

terminal of your vehicle ’s battery. High

current may flow through and cause

damage to the fuses. Do not connect the end of the

second cable to the negative (-)

terminal of the battery to be jumped.

A spark may cause an explosion of the

gases that surround the battery. Note:

In the illustration, the bottom vehicle

represents the booster vehicle.

223

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Roadside Emergencies

Page 239 of 500

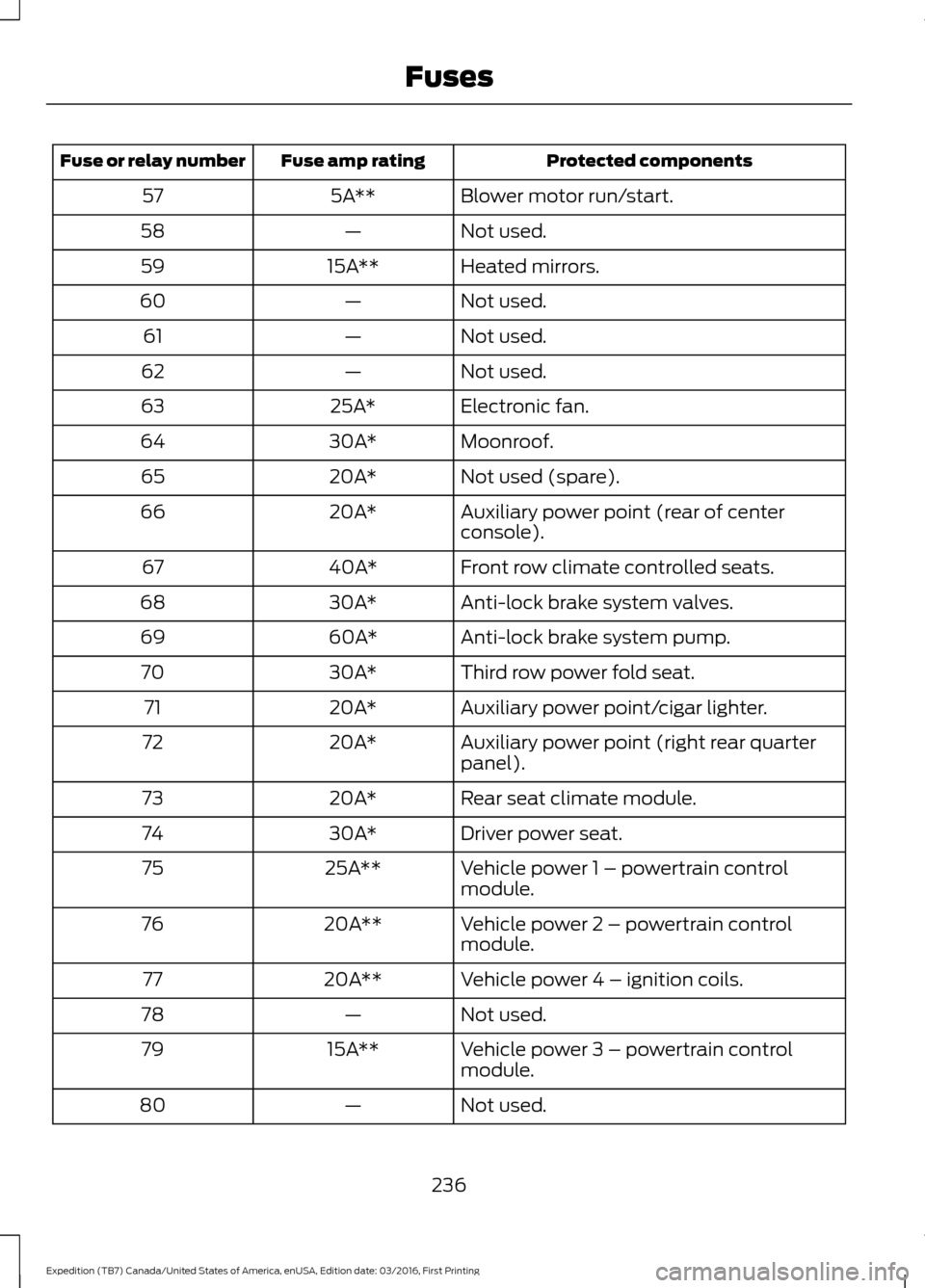

Protected components

Fuse amp rating

Fuse or relay number

Blower motor run/start.

5A**

57

Not used.

—

58

Heated mirrors.

15A**

59

Not used.

—

60

Not used.

—

61

Not used.

—

62

Electronic fan.

25A*

63

Moonroof.

30A*

64

Not used (spare).

20A*

65

Auxiliary power point (rear of center

console).

20A*

66

Front row climate controlled seats.

40A*

67

Anti-lock brake system valves.

30A*

68

Anti-lock brake system pump.

60A*

69

Third row power fold seat.

30A*

70

Auxiliary power point/cigar lighter.

20A*

71

Auxiliary power point (right rear quarter

panel).

20A*

72

Rear seat climate module.

20A*

73

Driver power seat.

30A*

74

Vehicle power 1 – powertrain control

module.

25A**

75

Vehicle power 2 – powertrain control

module.

20A**

76

Vehicle power 4 – ignition coils.

20A**

77

Not used.

—

78

Vehicle power 3 – powertrain control

module.

15A**

79

Not used.

—

80

236

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Fuses

Page 242 of 500

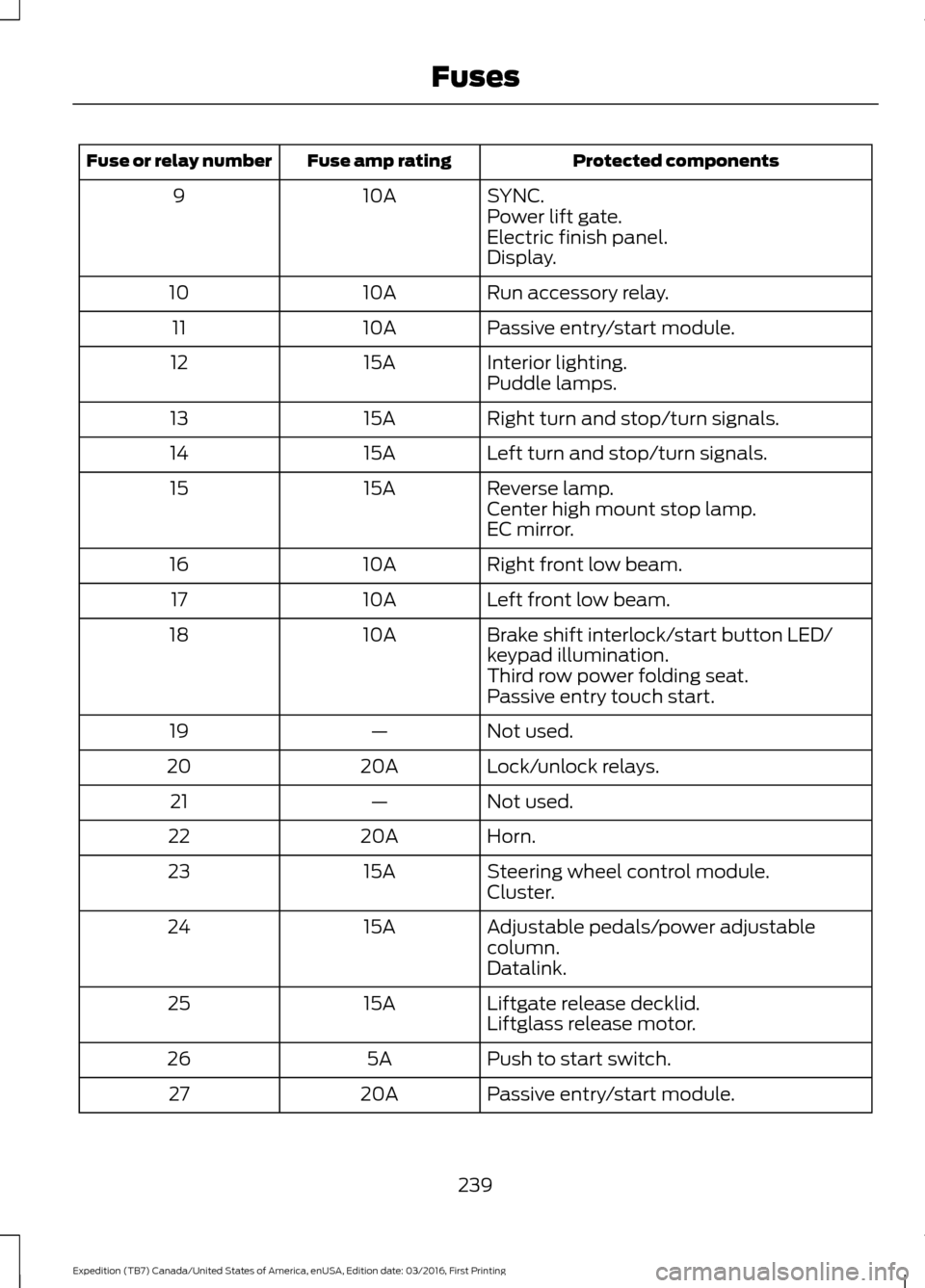

Protected components

Fuse amp rating

Fuse or relay number

SYNC.

10A

9

Power lift gate.

Electric finish panel.

Display.

Run accessory relay.

10A

10

Passive entry/start module.

10A

11

Interior lighting.

15A

12

Puddle lamps.

Right turn and stop/turn signals.

15A

13

Left turn and stop/turn signals.

15A

14

Reverse lamp.

15A

15

Center high mount stop lamp.

EC mirror.

Right front low beam.

10A

16

Left front low beam.

10A

17

Brake shift interlock/start button LED/

keypad illumination.

10A

18

Third row power folding seat.

Passive entry touch start.

Not used.

—

19

Lock/unlock relays.

20A

20

Not used.

—

21

Horn.

20A

22

Steering wheel control module.

15A

23

Cluster.

Adjustable pedals/power adjustable

column.

15A

24

Datalink.

Liftgate release decklid.

15A

25

Liftglass release motor.

Push to start switch.

5A

26

Passive entry/start module.

20A

27

239

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Fuses

Page 250 of 500

Action and description

Message

If the instrument cluster

displays one of the following

messages, repeat the

process.

Not Reset

Reset Cancelled

ENGINE COOLANT CHECK WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, spilling

coolant on hot engine parts can burn you. Do not put engine coolant in the

windshield washer fluid container. If

sprayed on the windshield, engine

coolant could make it difficult to see

through the windshield. To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure. Steam and hot liquid can come

out forcefully when you loosen the cap

slightly. Do not add coolant further than the

MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance

(page 443).

Note: Make sure that the coolant level is

between the

MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the

MAX mark. Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Adding Coolant

WARNING

Never remove the coolant reservoir

cap while the engine is running or hot.

Note:

Automotive fluids are not

interchangeable. Take care not to put

engine coolant in the windshield washer

fluid reservoir or windshield washer fluid in

the engine coolant reservoir.

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See

Capacities and

Specifications (page 304). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: If prediluted coolant is not available,

use the approved concentrated coolant

diluting it to 50/50 with distilled water. See

Capacities and Specifications

(page 304).

Using water that has not been deionised

may contribute to deposit formation,

corrosion and plugging of the small cooling

system passageways.

247

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Maintenance

Page 251 of 500

Note:

Coolants marketed for all makes and

models may not be approved to Ford

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

To top up the coolant level do the

following:

1. Unscrew the cap slowly. Any pressure escapes as you unscrew the cap.

2. Add prediluted coolant approved to the correct specification. See

Capacities and Specifications (page

304).

3. Add enough prediluted coolant to reach the correct level.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the correct level.

If you have to add more than

1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note: During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced. Note:

In case of emergency, you can add a

large amount of water without coolant in

order to reach a vehicle service location.

Water alone, without coolant, can cause

engine damage from corrosion, overheating

or freezing. When you reach a service

location, you must have the cooling system

drained and refilled with prediluted coolant

approved to the correct specification. See

Capacities and Specifications

(page 304).

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of

the coolant.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

Dispose of used engine coolant in an

appropriate manner. Follow your

community's regulations and standards

for recycling and disposing of automotive

fluids.

248

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Maintenance

Page 256 of 500

State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle

’s paint finish, wiper blades or

washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

CHANGING THE 12V BATTERY WARNINGS

Batteries normally produce explosive

gases which can cause personal

injury. Therefore, do not allow

flames, sparks or lighted substances to

come near the battery. When working near

the battery, always shield your face and

protect your eyes. Always provide correct

ventilation. When lifting a plastic-cased battery,

excessive pressure on the end walls

could cause acid to flow through the

vent caps, resulting in personal injury and

damage to the vehicle or battery. Lift the

battery with a battery carrier or with your

hands on opposite corners. WARNINGS

Keep batteries out of reach of

children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or

clothing. Shield your eyes when working

near the battery to protect against possible

splashing of acid solution. In case of acid

contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after

handling. This vehicle may be fitted with more

than one battery. Removing the

battery cables from only one battery

does not disconnect your vehicle electrical

system. Make sure you disconnect the

battery cables from all batteries when

disconnecting power. Failure to do so may

cause serious personal injury or property

damage. Your vehicle is fitted with a Motorcraft

maintenance-free battery which normally

does not require additional water.

When a battery replacement is required,

you must use a recommended

replacement battery that matches the

electrical requirements of the vehicle.

Note:

After cleaning or replacing the

battery, make sure you reinstall the battery

cover or shield.

Note: If you add electrical accessories or

components to the vehicle, it may adversely

affect the low voltage battery performance

and durability. This may also affect the

performance of other electrical systems in

the vehicle.

For longer, trouble-free operation, keep the

top of the battery clean and dry.

253

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing Maintenance

Page 259 of 500

3. Press the wiper blade secondary

locking clip.

4. Remove the wiper blade.

Note: Make sure that the wiper arm does

not spring back against the glass when the

wiper blade is not attached.

5. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place.

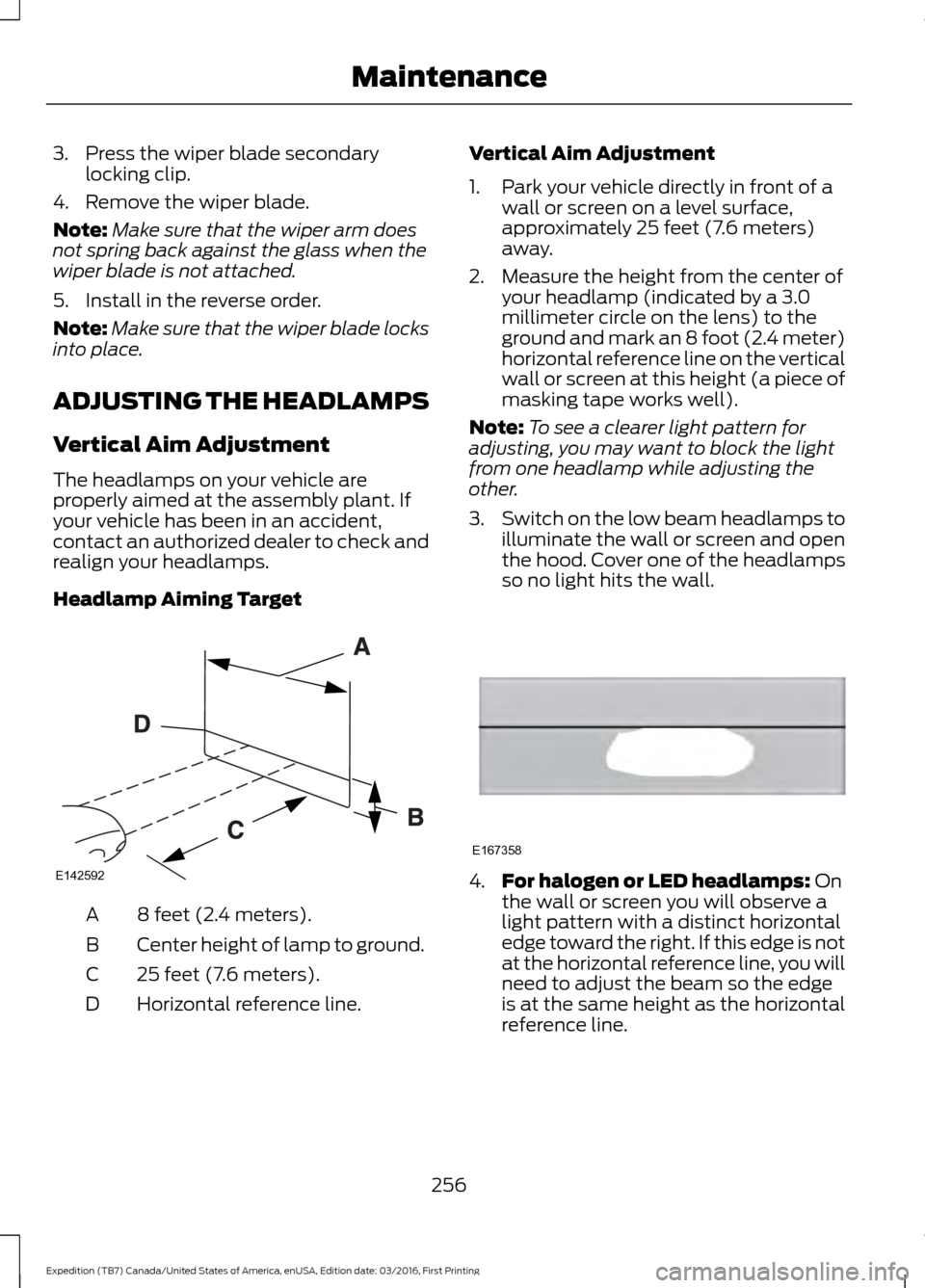

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are

properly aimed at the assembly plant. If

your vehicle has been in an accident,

contact an authorized dealer to check and

realign your headlamps.

Headlamp Aiming Target 8 feet (2.4 meters).

A

Center height of lamp to ground.

B

25 feet (7.6 meters).

C

Horizontal reference line.

D Vertical Aim Adjustment

1. Park your vehicle directly in front of a

wall or screen on a level surface,

approximately 25 feet (7.6 meters)

away.

2. Measure the height from the center of your headlamp (indicated by a 3.0

millimeter circle on the lens) to the

ground and mark an 8 foot (2.4 meter)

horizontal reference line on the vertical

wall or screen at this height (a piece of

masking tape works well).

Note: To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Switch on the low beam headlamps to

illuminate the wall or screen and open

the hood. Cover one of the headlamps

so no light hits the wall. 4.

For halogen or LED headlamps: On

the wall or screen you will observe a

light pattern with a distinct horizontal

edge toward the right. If this edge is not

at the horizontal reference line, you will

need to adjust the beam so the edge

is at the same height as the horizontal

reference line.

256

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing MaintenanceE142592 E167358

Page 263 of 500

LED Rear Lamp, Brake Lamp, Rear

Direction Indicator and Reverse

Lamp Bulbs (If Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

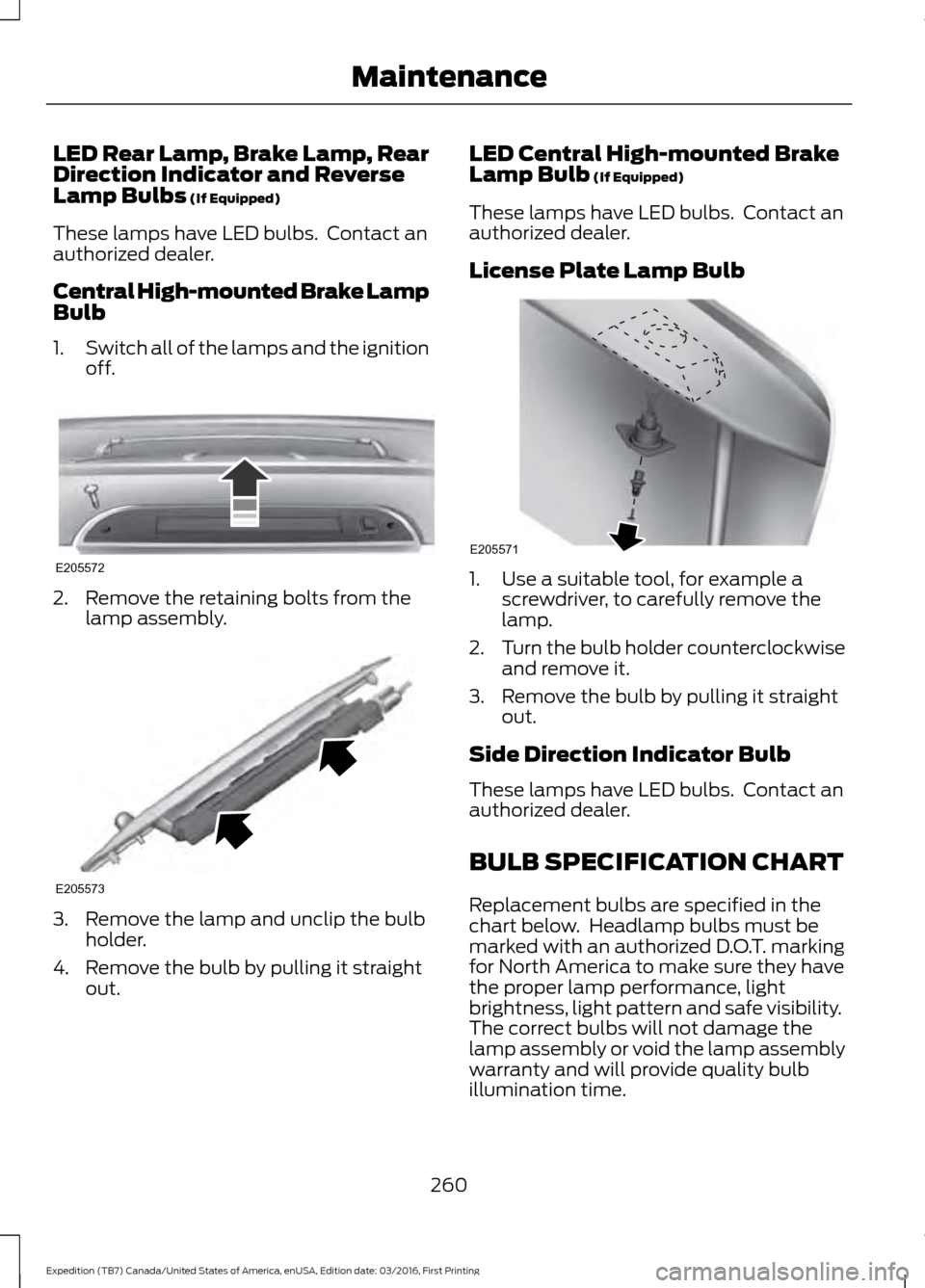

Central High-mounted Brake Lamp

Bulb

1. Switch all of the lamps and the ignition

off. 2. Remove the retaining bolts from the

lamp assembly. 3. Remove the lamp and unclip the bulb

holder.

4. Remove the bulb by pulling it straight out. LED Central High-mounted Brake

Lamp Bulb (If Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

License Plate Lamp Bulb 1. Use a suitable tool, for example a

screwdriver, to carefully remove the

lamp.

2. Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out.

Side Direction Indicator Bulb

These lamps have LED bulbs. Contact an

authorized dealer.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the

chart below. Headlamp bulbs must be

marked with an authorized D.O.T. marking

for North America to make sure they have

the proper lamp performance, light

brightness, light pattern and safe visibility.

The correct bulbs will not damage the

lamp assembly or void the lamp assembly

warranty and will provide quality bulb

illumination time.

260

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing MaintenanceE205572 E205573 E205571

Page 266 of 500

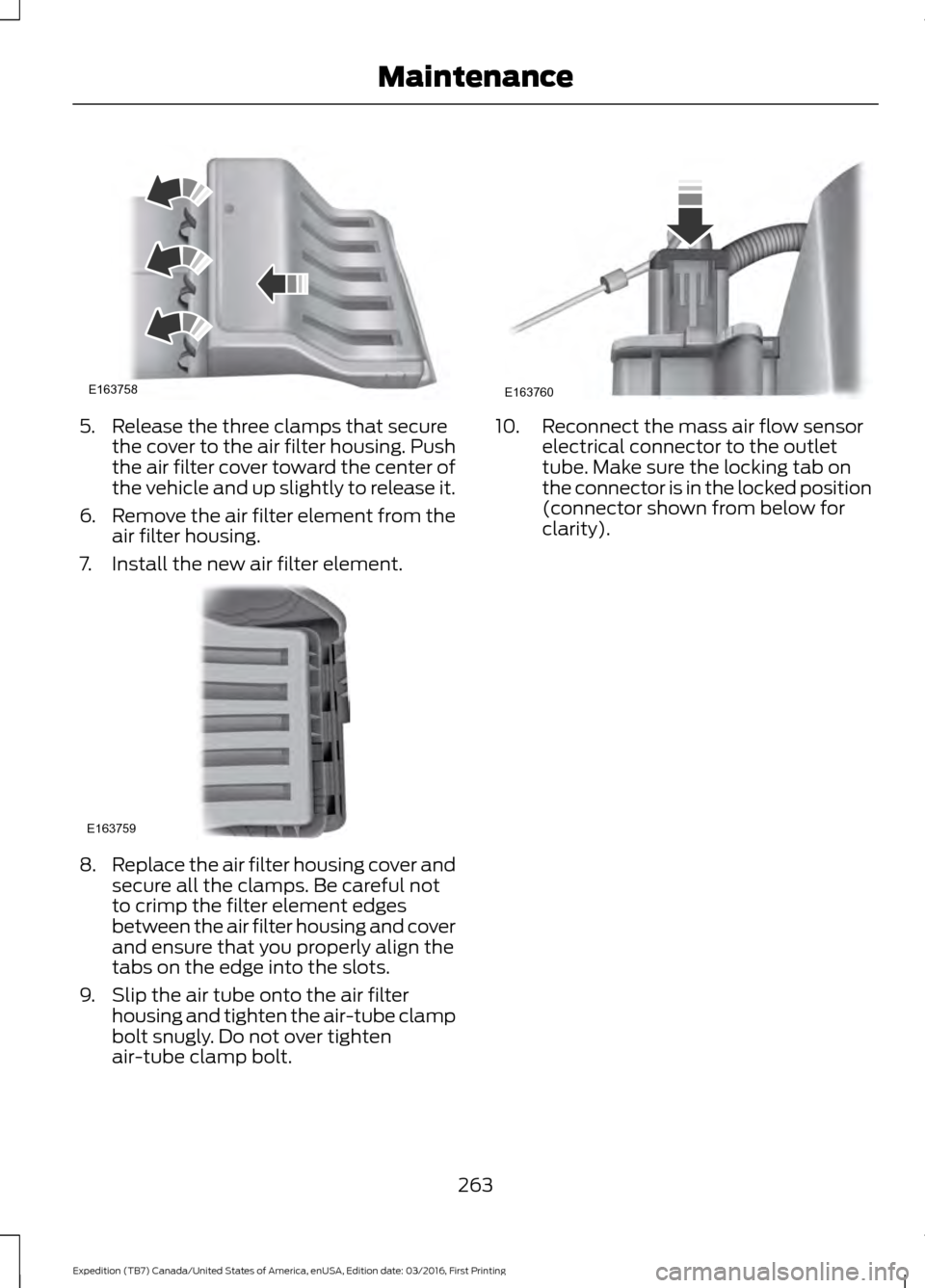

5. Release the three clamps that secure

the cover to the air filter housing. Push

the air filter cover toward the center of

the vehicle and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element. 8.

Replace the air filter housing cover and

secure all the clamps. Be careful not

to crimp the filter element edges

between the air filter housing and cover

and ensure that you properly align the

tabs on the edge into the slots.

9. Slip the air tube onto the air filter housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt. 10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked position

(connector shown from below for

clarity).

263

Expedition (TB7) Canada/United States of America, enUSA, Edition date: 03/2016, First Printing MaintenanceE163758 E163759 E163760