reset FORD EXPLORER 2006 4.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: EXPLORER, Model: FORD EXPLORER 2006 4.GPages: 328, PDF Size: 3.59 MB

Page 218 of 328

If the parking brake is fully released, but the brake warning lamp

remains illuminated, the brakes may not be working properly.

See your authorized dealer.

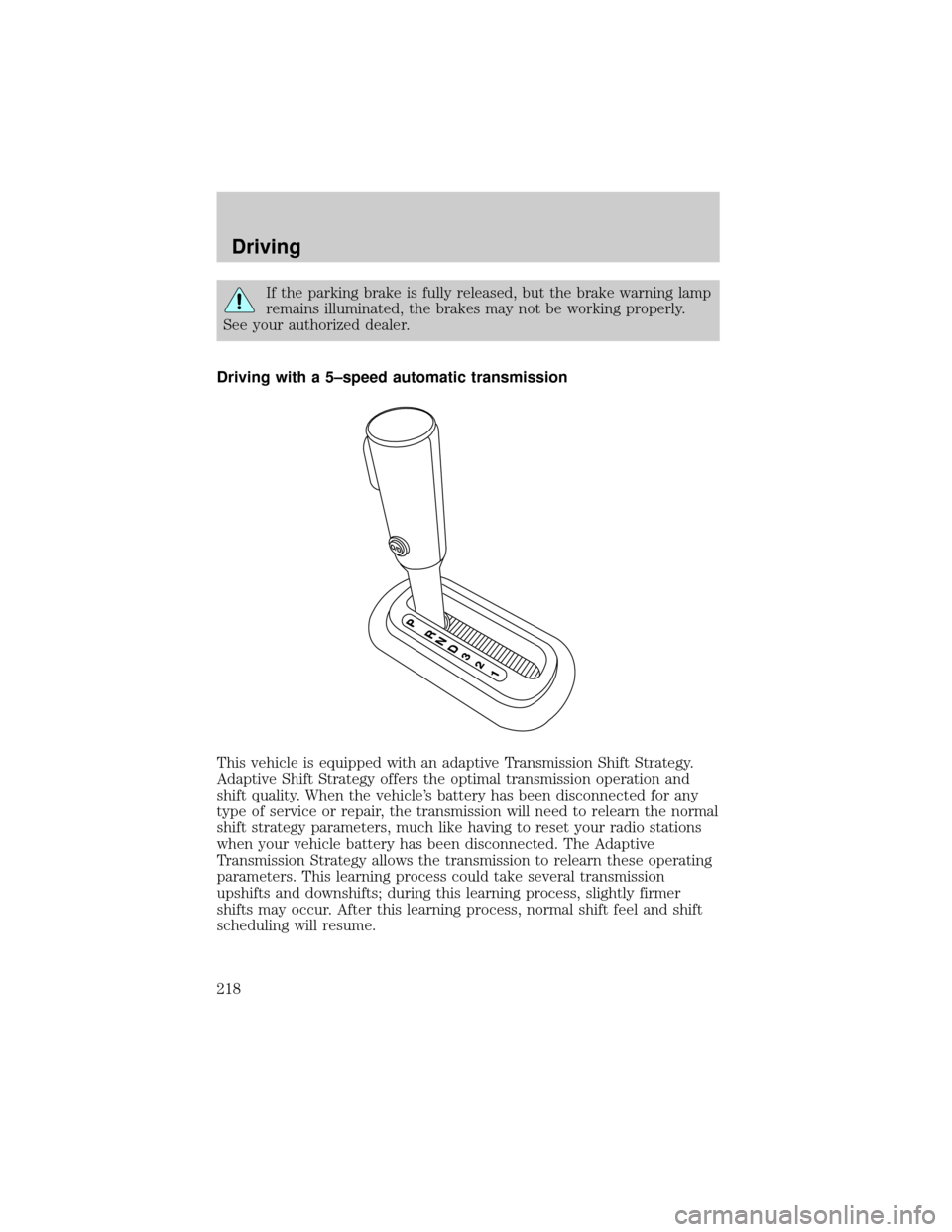

Driving with a 5±speed automatic transmission

This vehicle is equipped with an adaptive Transmission Shift Strategy.

Adaptive Shift Strategy offers the optimal transmission operation and

shift quality. When the vehicle's battery has been disconnected for any

type of service or repair, the transmission will need to relearn the normal

shift strategy parameters, much like having to reset your radio stations

when your vehicle battery has been disconnected. The Adaptive

Transmission Strategy allows the transmission to relearn these operating

parameters. This learning process could take several transmission

upshifts and downshifts; during this learning process, slightly firmer

shifts may occur. After this learning process, normal shift feel and shift

scheduling will resume.

Driving

218

Page 237 of 328

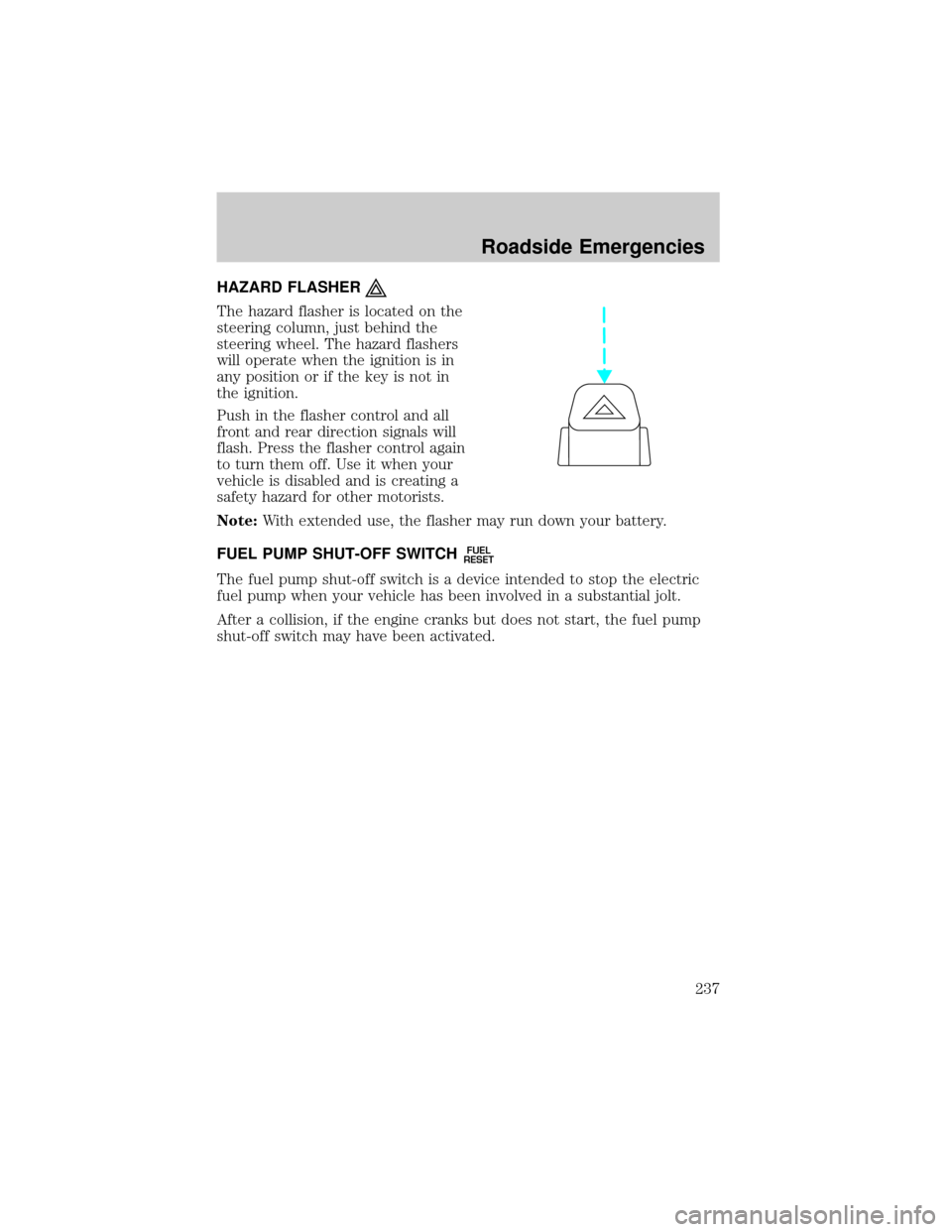

HAZARD FLASHER

The hazard flasher is located on the

steering column, just behind the

steering wheel. The hazard flashers

will operate when the ignition is in

any position or if the key is not in

the ignition.

Push in the flasher control and all

front and rear direction signals will

flash. Press the flasher control again

to turn them off. Use it when your

vehicle is disabled and is creating a

safety hazard for other motorists.

Note:With extended use, the flasher may run down your battery.

FUEL PUMP SHUT-OFF SWITCH

FUEL

RESET

The fuel pump shut-off switch is a device intended to stop the electric

fuel pump when your vehicle has been involved in a substantial jolt.

After a collision, if the engine cranks but does not start, the fuel pump

shut-off switch may have been activated.

Roadside Emergencies

237

Page 238 of 328

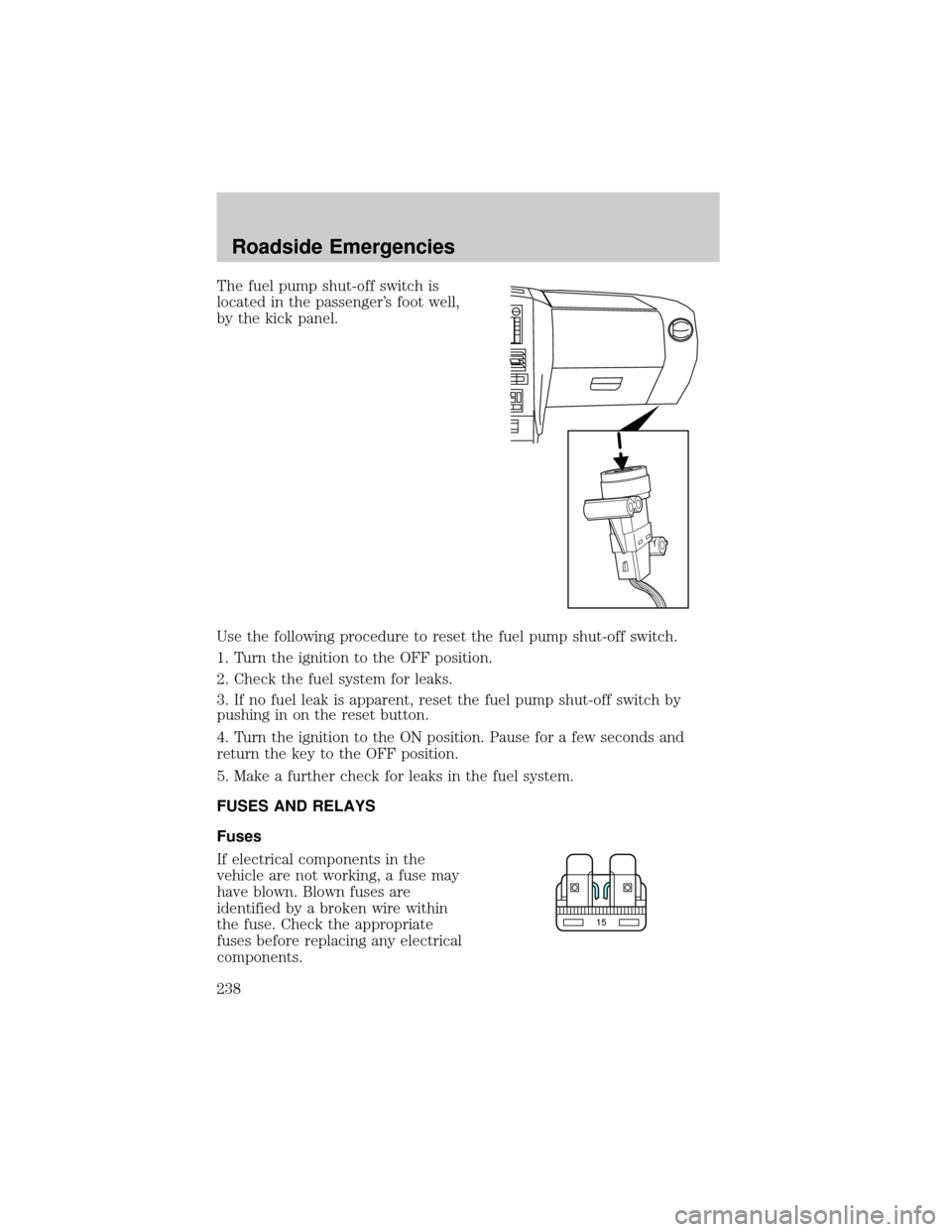

The fuel pump shut-off switch is

located in the passenger's foot well,

by the kick panel.

Use the following procedure to reset the fuel pump shut-off switch.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in on the reset button.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

FUSES AND RELAYS

Fuses

If electrical components in the

vehicle are not working, a fuse may

have blown. Blown fuses are

identified by a broken wire within

the fuse. Check the appropriate

fuses before replacing any electrical

components.

15

Roadside Emergencies

238

Page 288 of 328

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

intervals listed inscheduled maintenance information.The coolant

concentration should be maintained at 50/50 coolant and distilled water,

which equates to a freeze point of -34ÉF (-36ÉC). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014±R1060). The level of coolant

should be maintained at the ªFULL COLDº level in the coolant reservoir.

If the level falls below, add coolant per the instructions in theAdding

engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50±50 mixture of coolant and water provides the following:

²Freeze protection down to -34ÉF (-36ÉC).

²Boiling protection up to 265ÉF (129ÉC).

²Protection against rust and other forms of corrosion.

²Enables calibrated gauges to work properly.

When the engine is cold, check the level of the engine coolant in the

reservoir.

LEAD

RETURN

RECYCLE

Maintenance and Specifications

288

Page 304 of 328

Readiness for Inspection/Maintenance (I/M) testing

In some localities, it may be a legal requirement to pass an I/M test of

the on-board diagnostics system. If your

indicator is on, refer to

the description in theWarning lights and chimessection of the

Instrument Clusterchapter. Your vehicle may not pass the I/M test with

the

indicator on.

If the vehicle's powertrain system or its battery has just been serviced,

the on-board diagnostics system is reset to a ªnot ready for I/M testº

condition. To ready the on-board diagnostics system for I/M testing, a

minimum of 30 minutes of city and highway driving is necessary as

described below:

²First, at least 10 minutes of driving on an expressway or highway.

²Next, at least 20 minutes driving in stop-and-go, city-type traffic with

at least four idle periods.

Allow the vehicle to sit for at least eight hours without starting the

engine. Then, start the engine and complete the above driving cycle. The

engine must warm up to its normal operating temperature. Once started,

do not turn off the engine until the above driving cycle is complete.

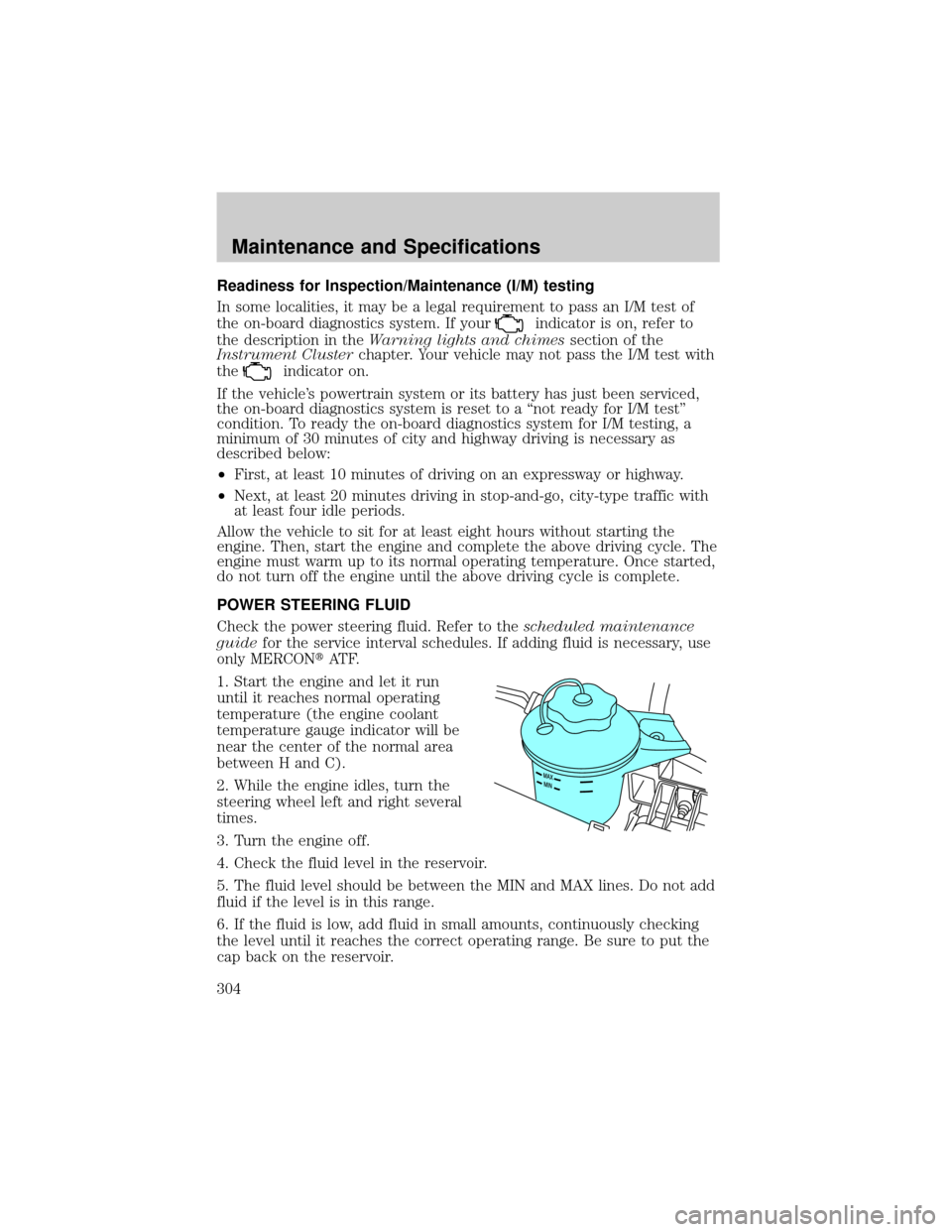

POWER STEERING FLUID

Check the power steering fluid. Refer to thescheduled maintenance

guidefor the service interval schedules. If adding fluid is necessary, use

only MERCONtAT F.

1. Start the engine and let it run

until it reaches normal operating

temperature (the engine coolant

temperature gauge indicator will be

near the center of the normal area

between H and C).

2. While the engine idles, turn the

steering wheel left and right several

times.

3. Turn the engine off.

4. Check the fluid level in the reservoir.

5. The fluid level should be between the MIN and MAX lines. Do not add

fluid if the level is in this range.

6. If the fluid is low, add fluid in small amounts, continuously checking

the level until it reaches the correct operating range. Be sure to put the

cap back on the reservoir.

Maintenance and Specifications

304