FORD F150 2004 11.G Owners Manual

Manufacturer: FORD, Model Year: 2004, Model line: F150, Model: FORD F150 2004 11.GPages: 280, PDF Size: 4.13 MB

Page 191 of 280

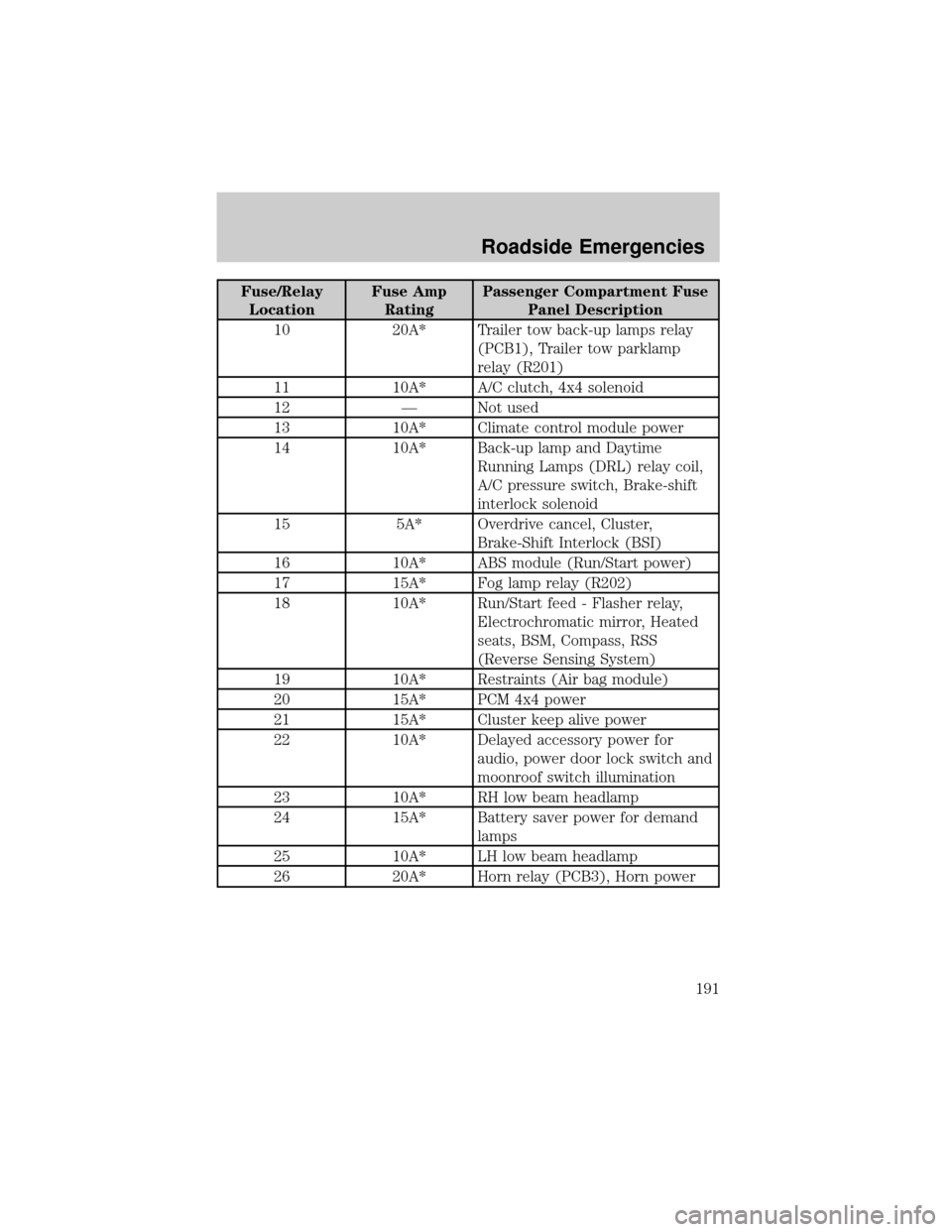

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

10 20A* Trailer tow back-up lamps relay

(PCB1), Trailer tow parklamp

relay (R201)

11 10A* A/C clutch, 4x4 solenoid

12 Ð Not used

13 10A* Climate control module power

14 10A* Back-up lamp and Daytime

Running Lamps (DRL) relay coil,

A/C pressure switch, Brake-shift

interlock solenoid

15 5A* Overdrive cancel, Cluster,

Brake-Shift Interlock (BSI)

16 10A* ABS module (Run/Start power)

17 15A* Fog lamp relay (R202)

18 10A* Run/Start feed - Flasher relay,

Electrochromatic mirror, Heated

seats, BSM, Compass, RSS

(Reverse Sensing System)

19 10A* Restraints (Air bag module)

20 15A* PCM 4x4 power

21 15A* Cluster keep alive power

22 10A* Delayed accessory power for

audio, power door lock switch and

moonroof switch illumination

23 10A* RH low beam headlamp

24 15A* Battery saver power for demand

lamps

25 10A* LH low beam headlamp

26 20A* Horn relay (PCB3), Horn power

Roadside Emergencies

191

Page 192 of 280

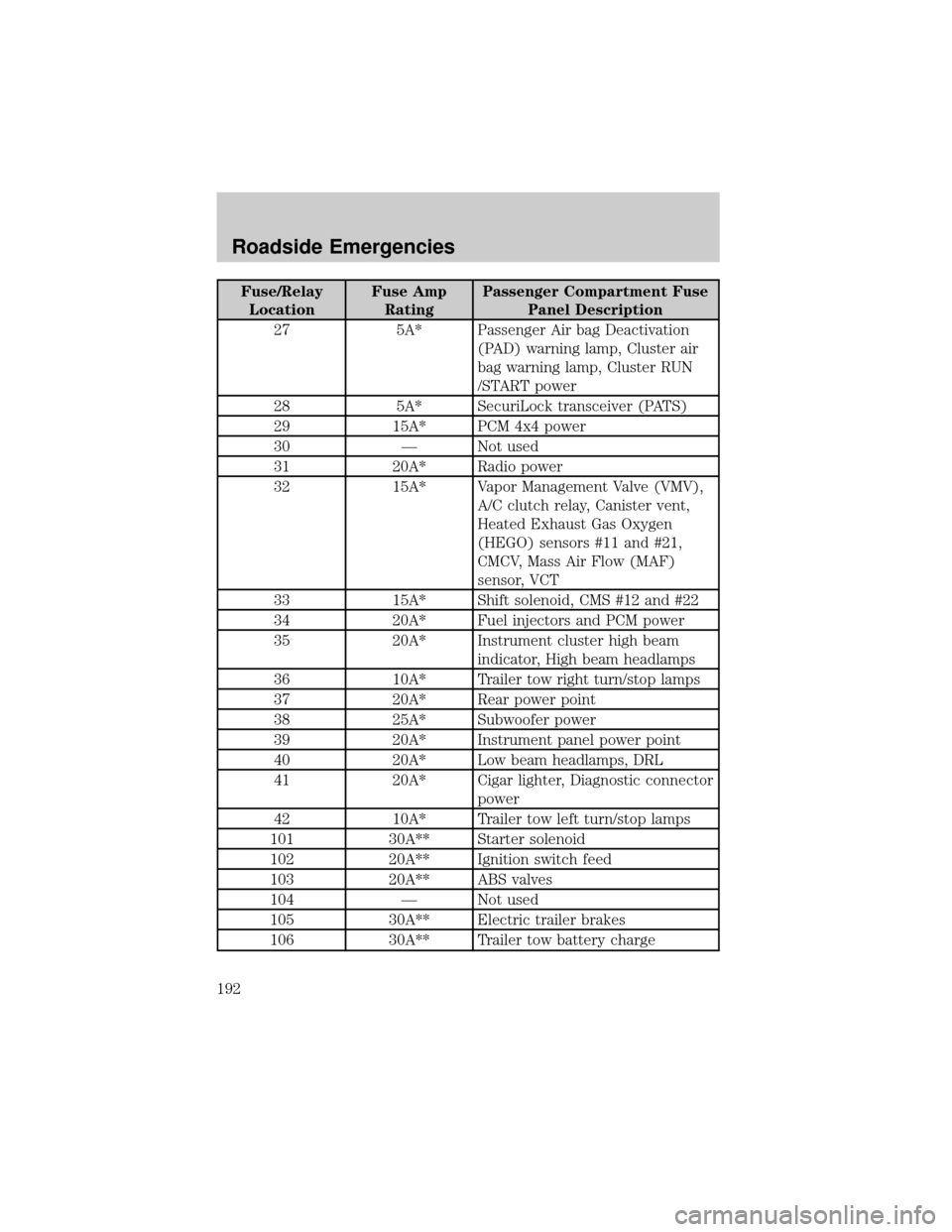

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

27 5A* Passenger Air bag Deactivation

(PAD) warning lamp, Cluster air

bag warning lamp, Cluster RUN

/START power

28 5A* SecuriLock transceiver (PATS)

29 15A* PCM 4x4 power

30 Ð Not used

31 20A* Radio power

32 15A* Vapor Management Valve (VMV),

A/C clutch relay, Canister vent,

Heated Exhaust Gas Oxygen

(HEGO) sensors #11 and #21,

CMCV, Mass Air Flow (MAF)

sensor, VCT

33 15A* Shift solenoid, CMS #12 and #22

34 20A* Fuel injectors and PCM power

35 20A* Instrument cluster high beam

indicator, High beam headlamps

36 10A* Trailer tow right turn/stop lamps

37 20A* Rear power point

38 25A* Subwoofer power

39 20A* Instrument panel power point

40 20A* Low beam headlamps, DRL

41 20A* Cigar lighter, Diagnostic connector

power

42 10A* Trailer tow left turn/stop lamps

101 30A** Starter solenoid

102 20A** Ignition switch feed

103 20A** ABS valves

104 Ð Not used

105 30A** Electric trailer brakes

106 30A** Trailer tow battery charge

Roadside Emergencies

192

Page 193 of 280

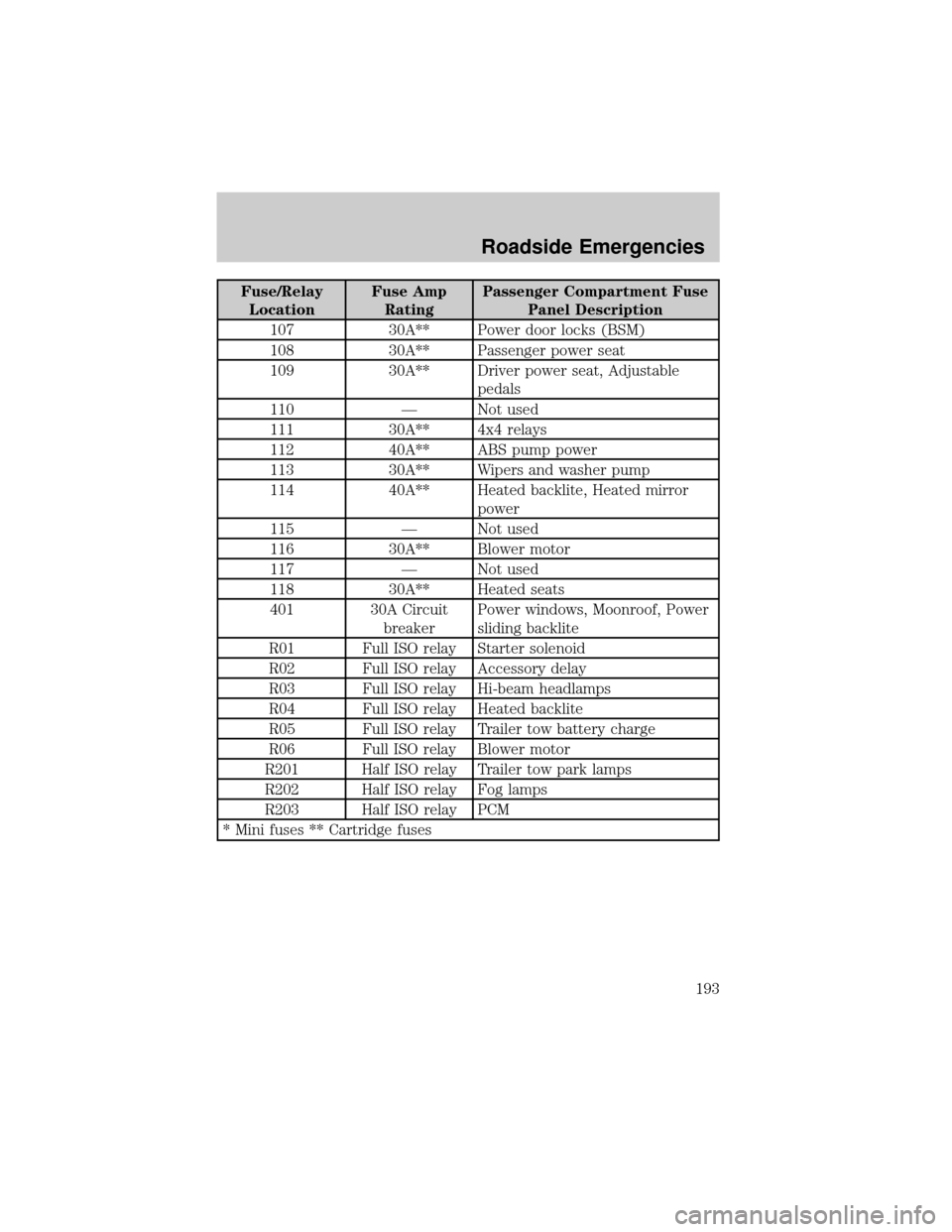

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

107 30A** Power door locks (BSM)

108 30A** Passenger power seat

109 30A** Driver power seat, Adjustable

pedals

110 Ð Not used

111 30A** 4x4 relays

112 40A** ABS pump power

113 30A** Wipers and washer pump

114 40A** Heated backlite, Heated mirror

power

115 Ð Not used

116 30A** Blower motor

117 Ð Not used

118 30A** Heated seats

401 30A Circuit

breakerPower windows, Moonroof, Power

sliding backlite

R01 Full ISO relay Starter solenoid

R02 Full ISO relay Accessory delay

R03 Full ISO relay Hi-beam headlamps

R04 Full ISO relay Heated backlite

R05 Full ISO relay Trailer tow battery charge

R06 Full ISO relay Blower motor

R201 Half ISO relay Trailer tow park lamps

R202 Half ISO relay Fog lamps

R203 Half ISO relay PCM

* Mini fuses ** Cartridge fuses

Roadside Emergencies

193

Page 194 of 280

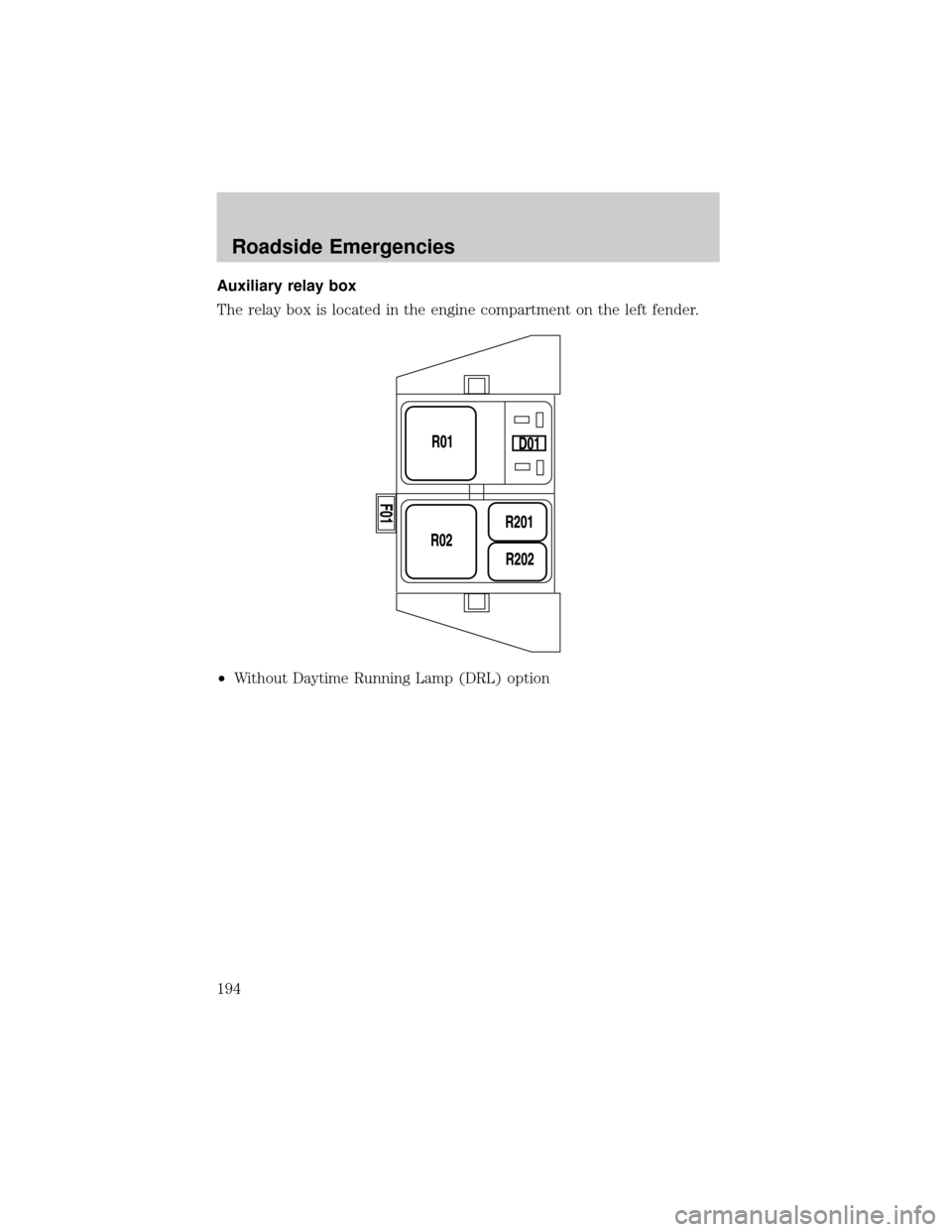

Auxiliary relay box

The relay box is located in the engine compartment on the left fender.

²Without Daytime Running Lamp (DRL) option

Roadside Emergencies

194

Page 195 of 280

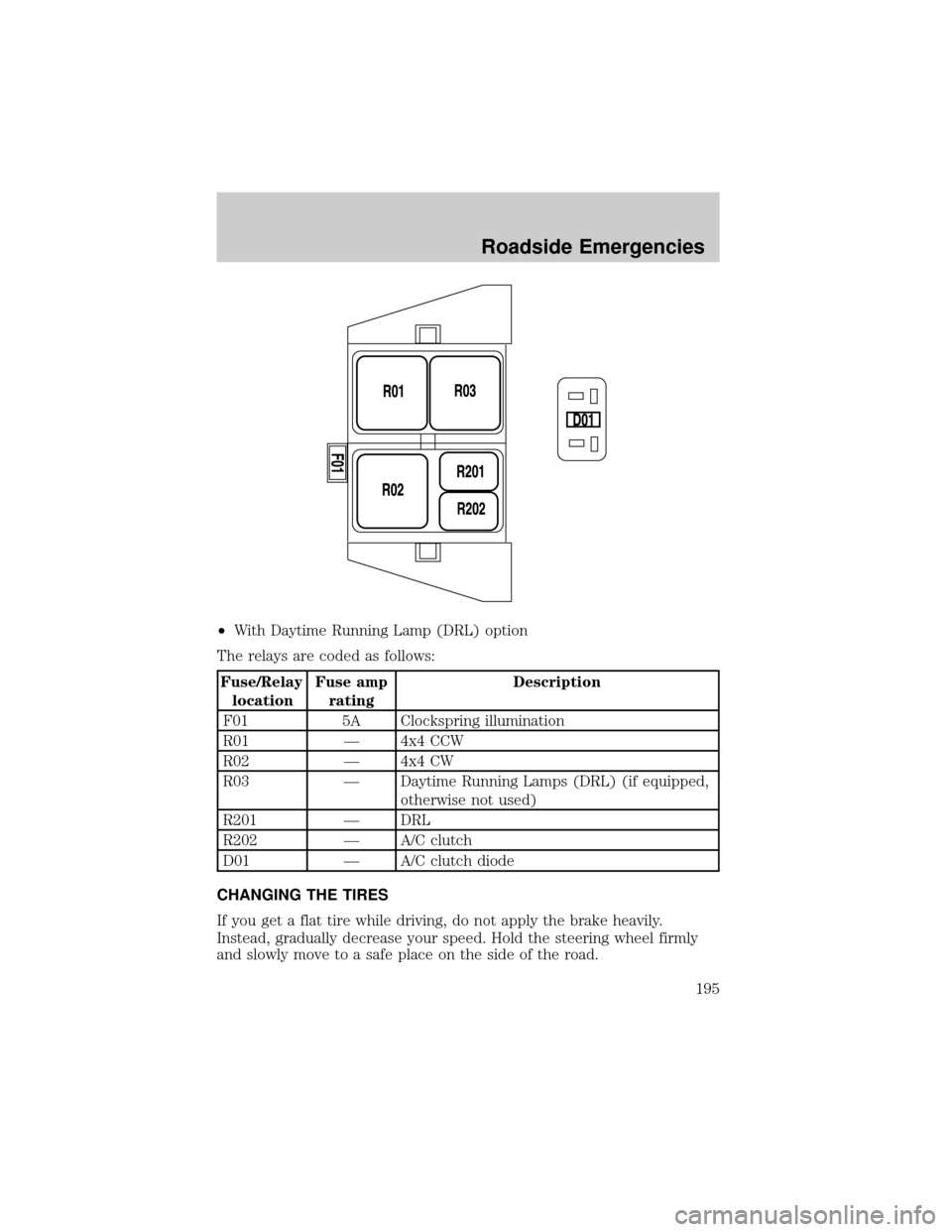

²With Daytime Running Lamp (DRL) option

The relays are coded as follows:

Fuse/Relay

locationFuse amp

ratingDescription

F01 5A Clockspring illumination

R01 Ð 4x4 CCW

R02 Ð 4x4 CW

R03 Ð Daytime Running Lamps (DRL) (if equipped,

otherwise not used)

R201 Ð DRL

R202 Ð A/C clutch

D01 Ð A/C clutch diode

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Roadside Emergencies

195

Page 196 of 280

The use of tire sealants may damage your tires.

Spare tire information

Your vehicle is equipped with a spare tire that may be used as a spare or

a regular tire. The spare tire wheel may not match the road wheel, and is

not equipped with wheel trim. The wheel trim from the wheel/tire may

be used on the spare if the wheels match.

If your vehicle is equipped with 4WD, a spare tire of a different

size than the road tires should not be used. Use of such a tire

could result in damage to driveline components and an increased risk

of loss of vehicle control, vehicle rollover, personal injury or death.

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire Under the vehicle, just forward of

the rear bumper

Jack, jack handle and lug nut

wrenchRegular Cab: Behind the interior

trim on the passenger side of the

cab

SuperCrew and SuperCab: Under

the rear seat on the passenger side

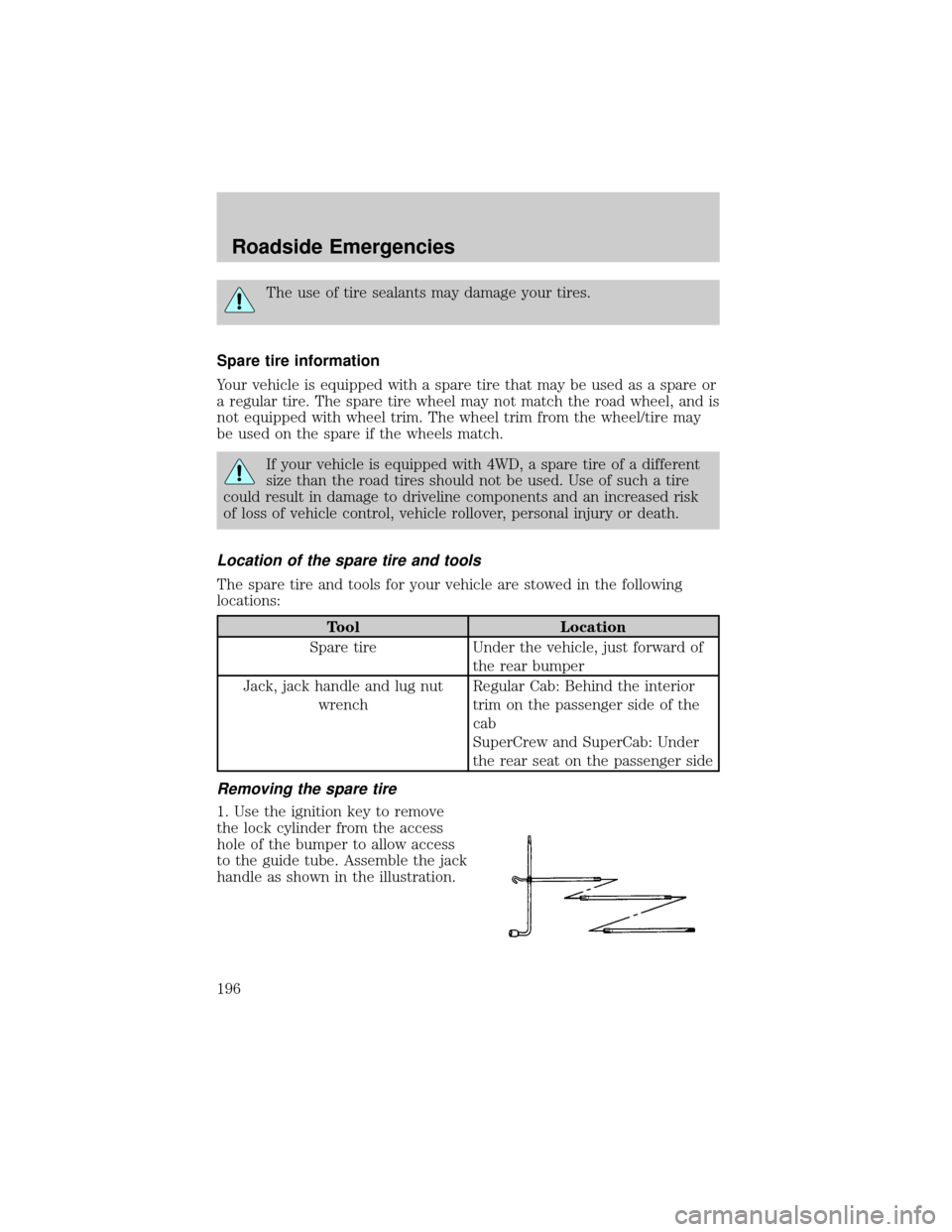

Removing the spare tire

1. Use the ignition key to remove

the lock cylinder from the access

hole of the bumper to allow access

to the guide tube. Assemble the jack

handle as shown in the illustration.

Roadside Emergencies

196

Page 197 of 280

2. Fully insert the jack handle

through the bumper hole and into

the guide tube through the access

hole in the rear bumper.

3. Turn the handle counterclockwise until tire is lowered to the ground,

the tire can be slid rearward and the cable is slightly slack.

4. Slide the retainer through the center of the wheel.

Tire change procedure

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

Refer to the instruction sheet (located with the jack) for detailed tire

change instructions.

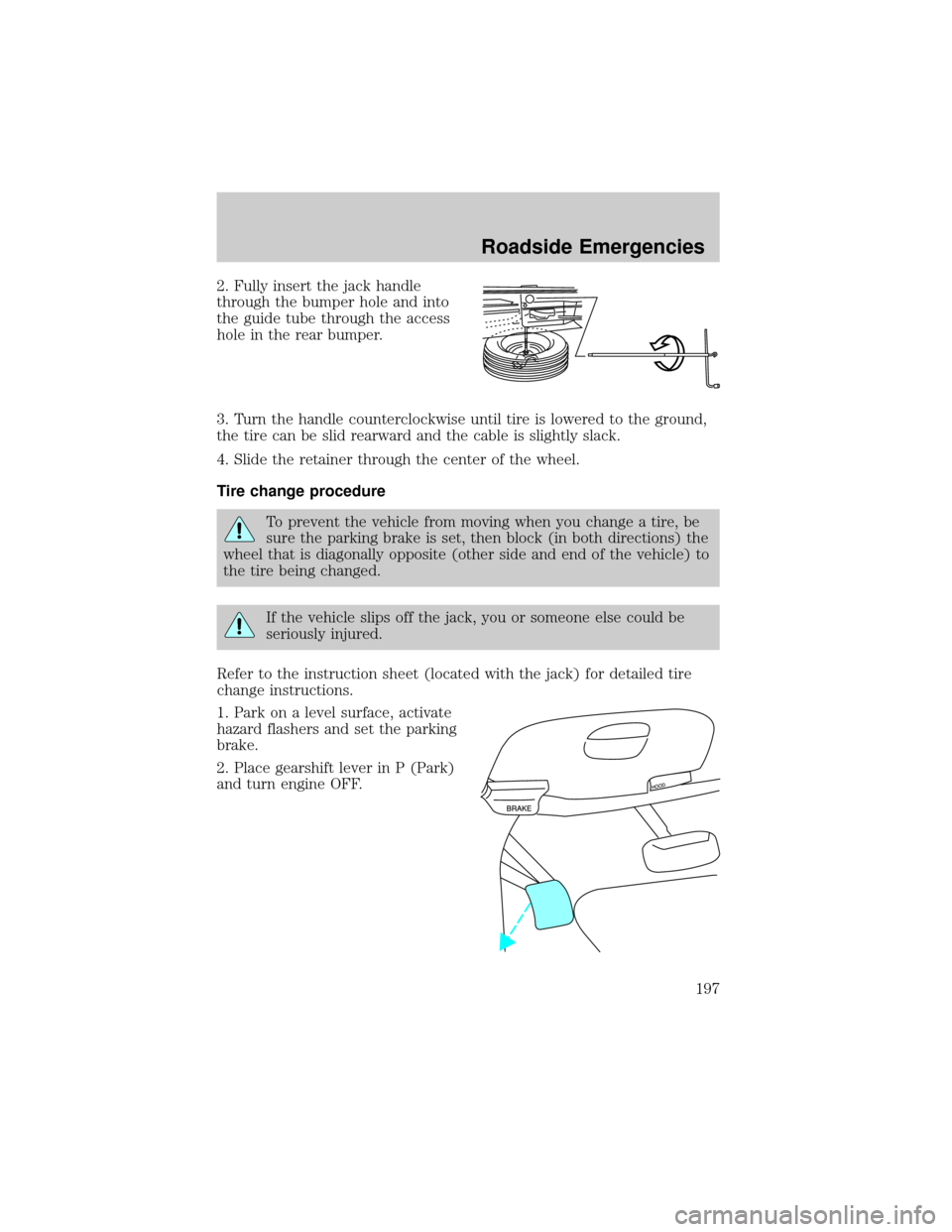

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

2. Place gearshift lever in P (Park)

and turn engine OFF.

Roadside Emergencies

197

Page 198 of 280

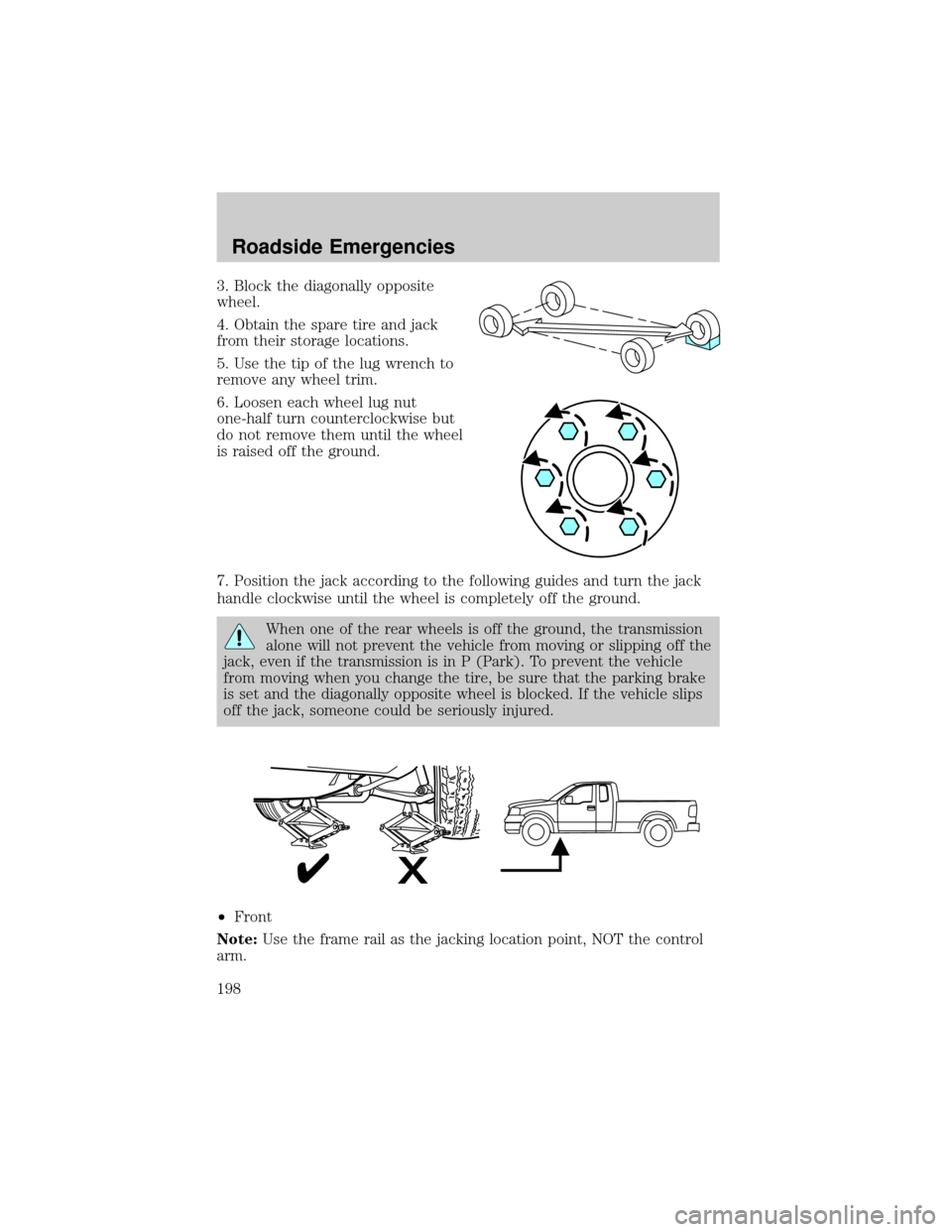

3. Block the diagonally opposite

wheel.

4. Obtain the spare tire and jack

from their storage locations.

5. Use the tip of the lug wrench to

remove any wheel trim.

6. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

7. Position the jack according to the following guides and turn the jack

handle clockwise until the wheel is completely off the ground.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park). To prevent the vehicle

from moving when you change the tire, be sure that the parking brake

is set and the diagonally opposite wheel is blocked. If the vehicle slips

off the jack, someone could be seriously injured.

²Front

Note:Use the frame rail as the jacking location point, NOT the control

arm.

Roadside Emergencies

198

Page 199 of 280

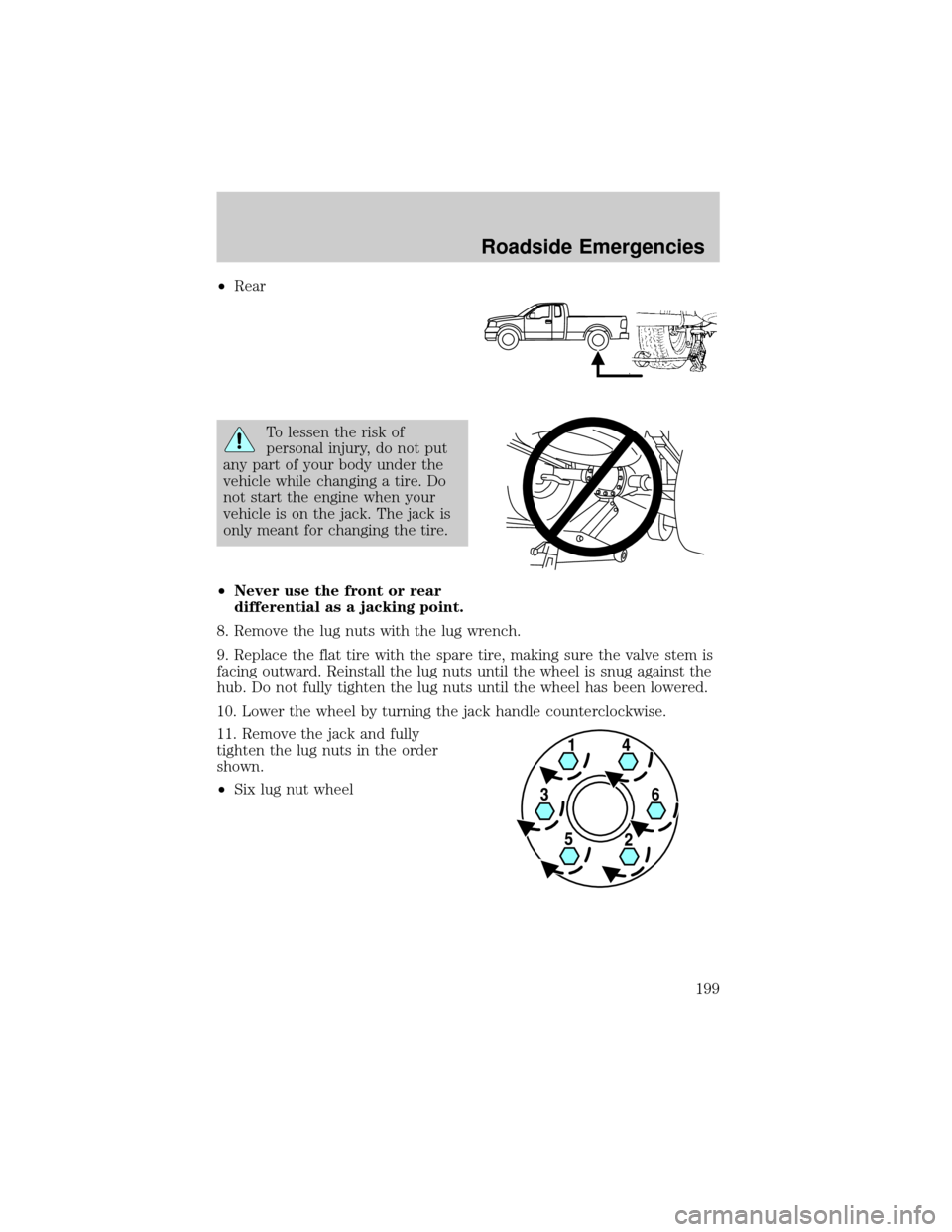

²Rear

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the front or rear

differential as a jacking point.

8. Remove the lug nuts with the lug wrench.

9. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

10. Lower the wheel by turning the jack handle counterclockwise.

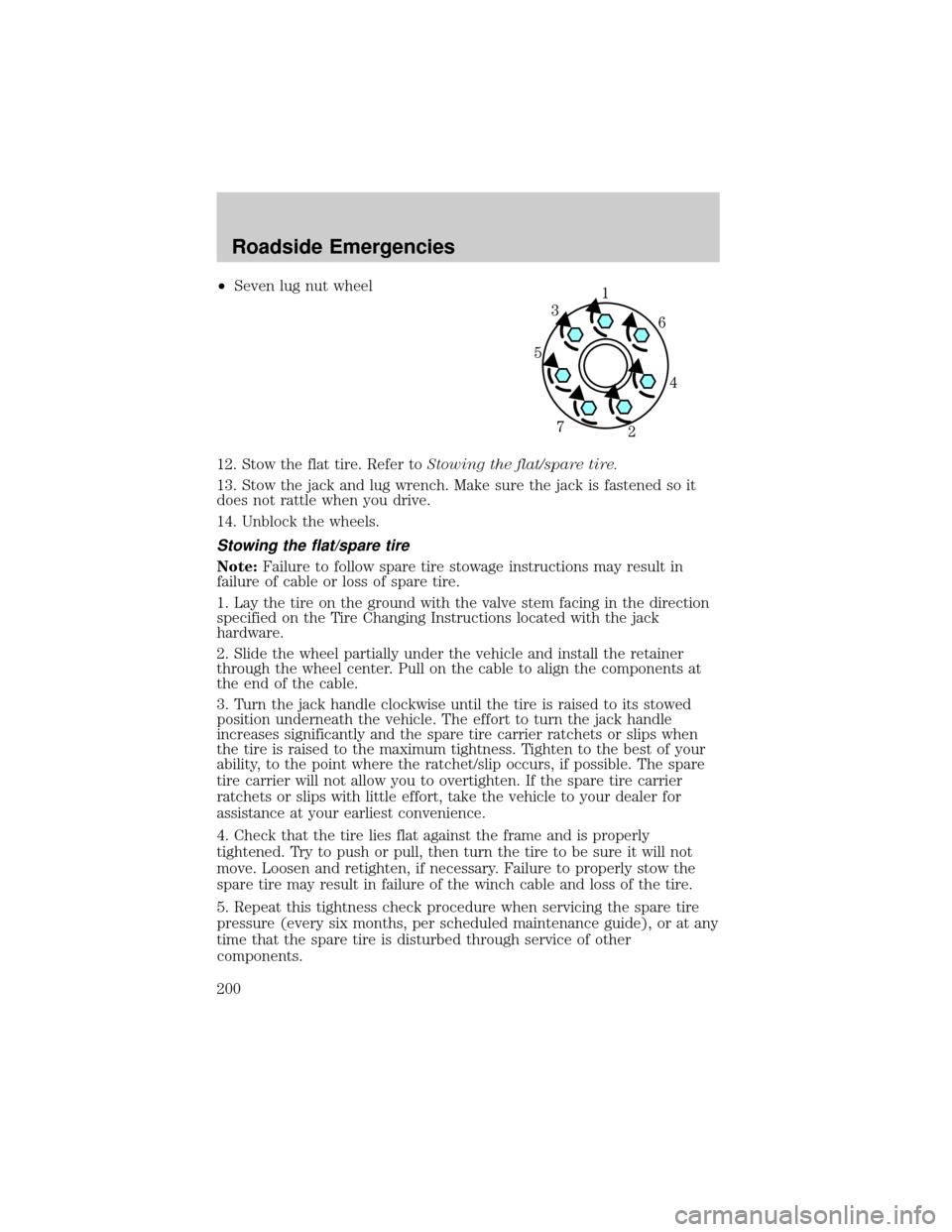

11. Remove the jack and fully

tighten the lug nuts in the order

shown.

²Six lug nut wheel

Roadside Emergencies

199

Page 200 of 280

²Seven lug nut wheel

12. Stow the flat tire. Refer toStowing the flat/spare tire.

13. Stow the jack and lug wrench. Make sure the jack is fastened so it

does not rattle when you drive.

14. Unblock the wheels.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing in the direction

specified on the Tire Changing Instructions located with the jack

hardware.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

Roadside Emergencies

200