clock FORD F150 2015 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: F150, Model: FORD F150 2015 13.GPages: 549, PDF Size: 5.97 MB

Page 39 of 549

Left-Hand Side

Turn counterclockwise to lock and

clockwise to unlock.

Right-Hand Side

Turn clockwise to lock and

counterclockwise to unlock.

36

F-150 (), enUSA, First Printing Child Safety

Page 248 of 549

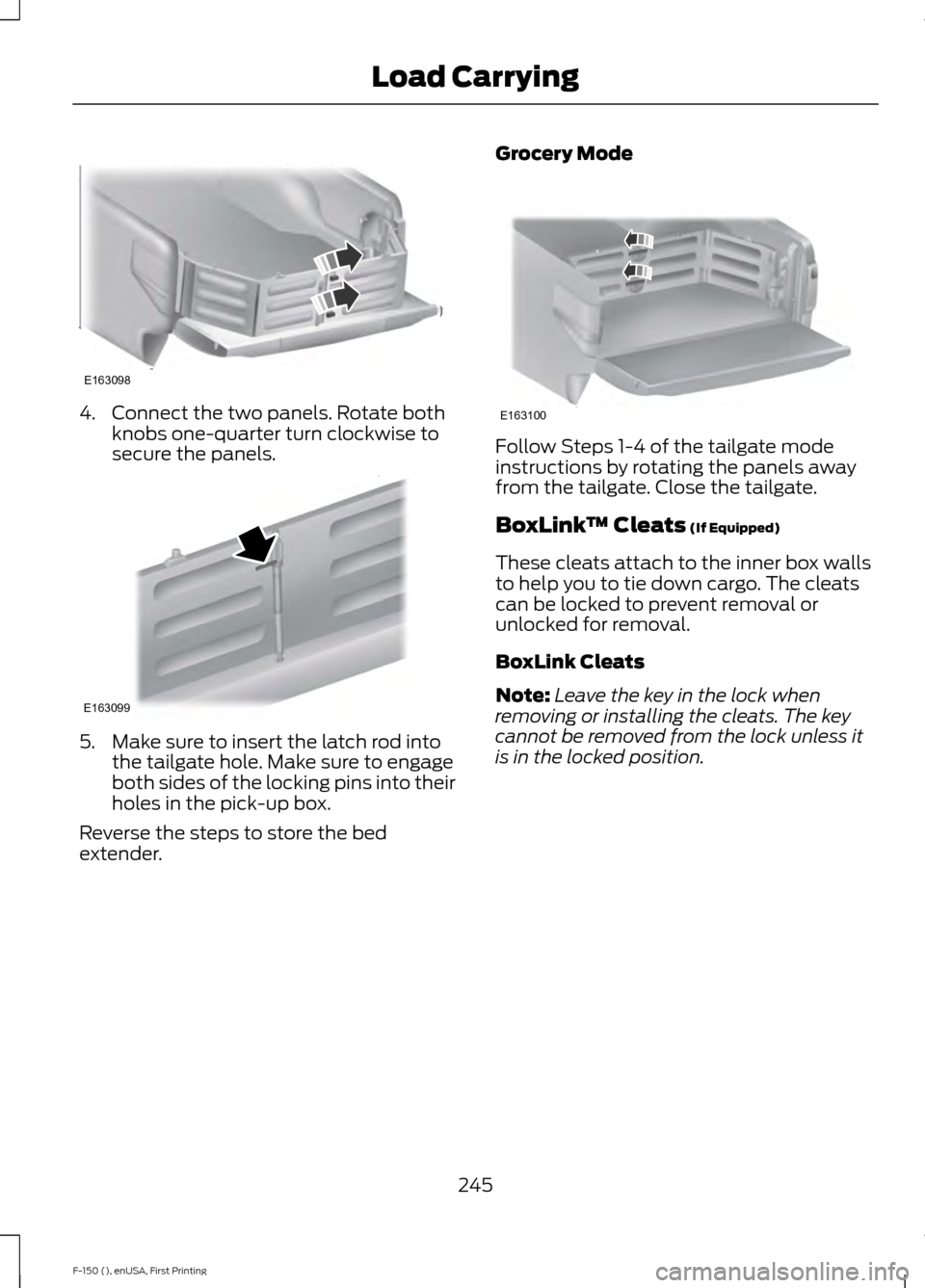

4. Connect the two panels. Rotate both

knobs one-quarter turn clockwise to

secure the panels. 5. Make sure to insert the latch rod into

the tailgate hole. Make sure to engage

both sides of the locking pins into their

holes in the pick-up box.

Reverse the steps to store the bed

extender. Grocery Mode Follow Steps 1-4 of the tailgate mode

instructions by rotating the panels away

from the tailgate. Close the tailgate.

BoxLink

™ Cleats (If Equipped)

These cleats attach to the inner box walls

to help you to tie down cargo. The cleats

can be locked to prevent removal or

unlocked for removal.

BoxLink Cleats

Note: Leave the key in the lock when

removing or installing the cleats. The key

cannot be removed from the lock unless it

is in the locked position.

245

F-150 (), enUSA, First Printing Load CarryingE163098 E163099 E163100

Page 249 of 549

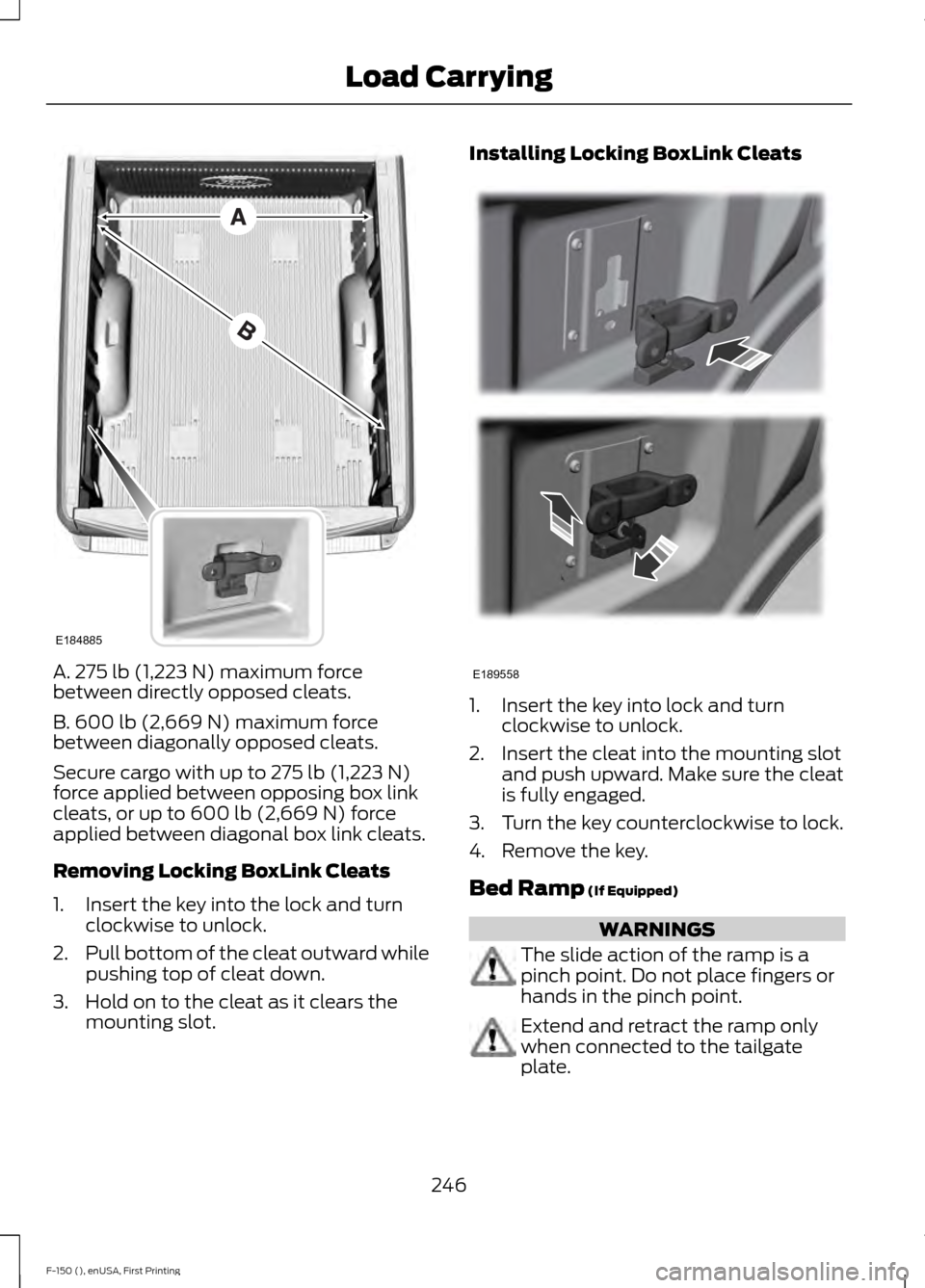

A. 275 lb (1,223 N) maximum force

between directly opposed cleats.

B. 600 lb (2,669 N)

maximum force

between diagonally opposed cleats.

Secure cargo with up to

275 lb (1,223 N)

force applied between opposing box link

cleats, or up to

600 lb (2,669 N) force

applied between diagonal box link cleats.

Removing Locking BoxLink Cleats

1. Insert the key into the lock and turn clockwise to unlock.

2. Pull bottom of the cleat outward while

pushing top of cleat down.

3. Hold on to the cleat as it clears the mounting slot. Installing Locking BoxLink Cleats

1. Insert the key into lock and turn

clockwise to unlock.

2. Insert the cleat into the mounting slot and push upward. Make sure the cleat

is fully engaged.

3. Turn the key counterclockwise to lock.

4. Remove the key.

Bed Ramp

(If Equipped) WARNINGS

The slide action of the ramp is a

pinch point. Do not place fingers or

hands in the pinch point.

Extend and retract the ramp only

when connected to the tailgate

plate.

246

F-150 (), enUSA, First Printing Load CarryingE184885 E189558

Page 306 of 549

Only use oils certified for gasoline engines

by the American Petroleum Institute (API).

An oil with this trademark symbol

conforms to the current engine and

emission system protection standards and

fuel economy requirements of the

International Lubricants Specification

Advisory Council (ILSAC), comprised of

U.S. and Japanese automobile

manufacturers.

1. Check the engine oil level.

2. If the engine oil level is not within the

normal range, add engine oil that

meets Ford specifications. See

Capacities and Specifications (page

359

).

3. Remove the engine oil filler cap and use a funnel to pour the engine oil into

the opening.

4. Wipe off any spilled oil.

5. Recheck the engine oil level. Make sure

the oil level is not above the normal

operating range on the engine oil level

dipstick.

6. Install the engine oil level dipstick and ensure it is fully seated.

7. Fully install the engine oil filler cap by turning the filler cap clockwise until

three clicks are heard or until the cap

is fully seated.

ENGINE COOLANT CHECK WARNINGS

Do not add engine coolant when the

engine is hot. Steam and scalding

liquids released from a hot cooling

system can burn you badly. Also, spilling

coolant on hot engine parts can burn you. Do not put engine coolant in the

windshield washer fluid container. If

sprayed on the windshield, engine

coolant could make it difficult to see

through the windshield. WARNINGS

To reduce the risk of personal injury,

make sure the engine is cool before

unscrewing the coolant pressure

relief cap. The cooling system is under

pressure. Steam and hot liquid can come

out forcefully when you loosen the cap

slightly. Do not add coolant further than the

MAX mark.

Checking the Engine Coolant

When the engine is cold, check the

concentration and level of the engine

coolant at the intervals listed in the

scheduled maintenance information.

See

Scheduled Maintenance (page 518).

Note: Make sure that the coolant level is

between the MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.

Note: If the level is at the MIN mark, below

the MIN mark, or empty, add coolant

immediately.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C).

Note: For best results, coolant

concentration should be tested with a

refractometer such as Robinair Coolant and

Battery Refractometer 75240. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentrations.

Note: Automotive fluids are not

interchangeable. Do not use engine coolant,

antifreeze or windshield washer fluid outside

of its specified function and vehicle location.

303

F-150 (), enUSA, First Printing Maintenance

Page 312 of 549

Note:

If your battery has a cover/shield,

make sure it is reinstalled after the battery

has been cleaned or replaced.

Note: Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after handling.

Note: Electrical or electronic accessories

or components added to your vehicle by the

dealer or the owner may adversely affect

battery performance and durability.

Your vehicle is equipped with a Motorcraft

maintenance-free battery which normally

does not require additional water during

its life of service.

For longer, trouble-free operation, keep the

top of the battery clean and dry. Also,

make certain the battery cables are always

tightly fastened to the battery terminals.

If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

It is recommended that the negative

battery cable terminal be disconnected

from the battery if you plan to store your

vehicle for an extended period of time.

Because your vehicle ’s engine is

electronically controlled by a computer,

some control conditions are maintained

by power from the battery. When the

battery is disconnected or a new battery

is installed, the engine must relearn its idle

and fuel trim strategy for optimum

driveability and performance. Flexible fuel

vehicles (FFV) must also relearn the

ethanol content of the fuel for optimum

driveability and performance. To begin this

process:

1. With your vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P(Park), turn off all

accessories. 3. Start the engine. Run the engine until

it reaches normal operating

temperature.

4. Allow the engine to idle for at least one

minute.

5. Turn the air conditioning on and allow the engine to idle for at least one

minute.

6. Release the parking brake. With your foot on the brake pedal and with the

air conditioning on, put your vehicle in

D

(Drive) and allow the engine to idle

for at least one minute.

• If you do not allow the engine to

relearn its idle trim, the idle quality

of your vehicle may be adversely

affected until the idle trim is

eventually relearned.

7. Drive your vehicle to complete the relearning process

•Your vehicle may need to be driven

10 miles (16 kilometers) or more to

relearn the idle and fuel trim

strategy along with the ethanol

content for flexible fuel vehicles.

• For flexible fuel vehicles, if you are

operating on E85, you may

experience poor starts or an

inability to start the engine and

driveability problems until the fuel

trim and ethanol content have been

relearned.

If the battery has been disconnected or a

new battery has been installed, the clock

and radio settings must be reset once the

battery is reconnected.

Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized standards

for disposal. Call your local authorized

recycling center to find out more about

recycling automotive batteries.

309

F-150 (), enUSA, First Printing Maintenance

Page 315 of 549

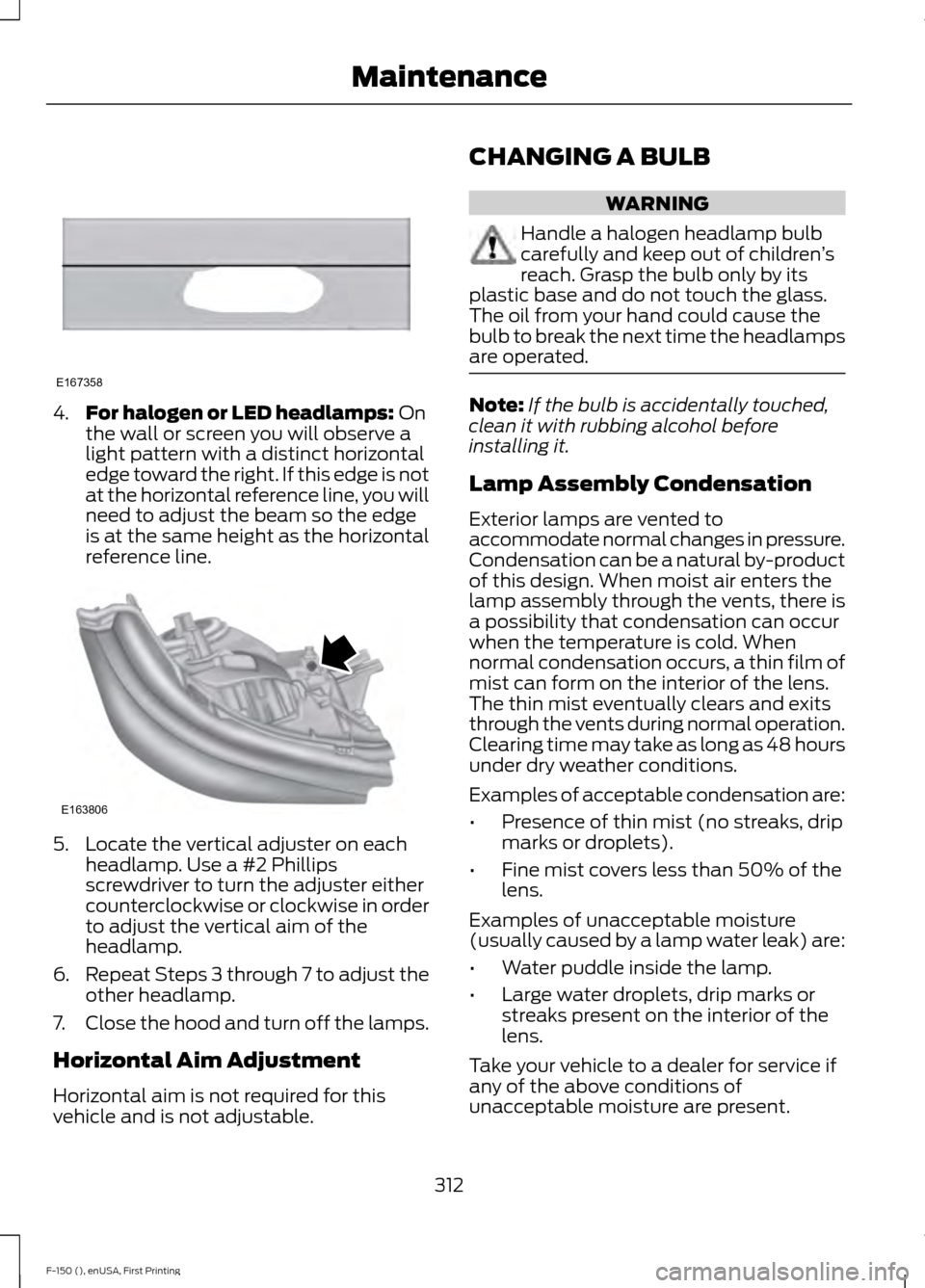

4.

For halogen or LED headlamps: On

the wall or screen you will observe a

light pattern with a distinct horizontal

edge toward the right. If this edge is not

at the horizontal reference line, you will

need to adjust the beam so the edge

is at the same height as the horizontal

reference line. 5. Locate the vertical adjuster on each

headlamp. Use a #2 Phillips

screwdriver to turn the adjuster either

counterclockwise or clockwise in order

to adjust the vertical aim of the

headlamp.

6. Repeat Steps 3 through 7 to adjust the

other headlamp.

7. Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for this

vehicle and is not adjustable. CHANGING A BULB WARNING

Handle a halogen headlamp bulb

carefully and keep out of children

’s

reach. Grasp the bulb only by its

plastic base and do not touch the glass.

The oil from your hand could cause the

bulb to break the next time the headlamps

are operated. Note:

If the bulb is accidentally touched,

clean it with rubbing alcohol before

installing it.

Lamp Assembly Condensation

Exterior lamps are vented to

accommodate normal changes in pressure.

Condensation can be a natural by-product

of this design. When moist air enters the

lamp assembly through the vents, there is

a possibility that condensation can occur

when the temperature is cold. When

normal condensation occurs, a thin film of

mist can form on the interior of the lens.

The thin mist eventually clears and exits

through the vents during normal operation.

Clearing time may take as long as 48 hours

under dry weather conditions.

Examples of acceptable condensation are:

• Presence of thin mist (no streaks, drip

marks or droplets).

• Fine mist covers less than 50% of the

lens.

Examples of unacceptable moisture

(usually caused by a lamp water leak) are:

• Water puddle inside the lamp.

• Large water droplets, drip marks or

streaks present on the interior of the

lens.

Take your vehicle to a dealer for service if

any of the above conditions of

unacceptable moisture are present.

312

F-150 (), enUSA, First Printing MaintenanceE167358 E163806

Page 317 of 549

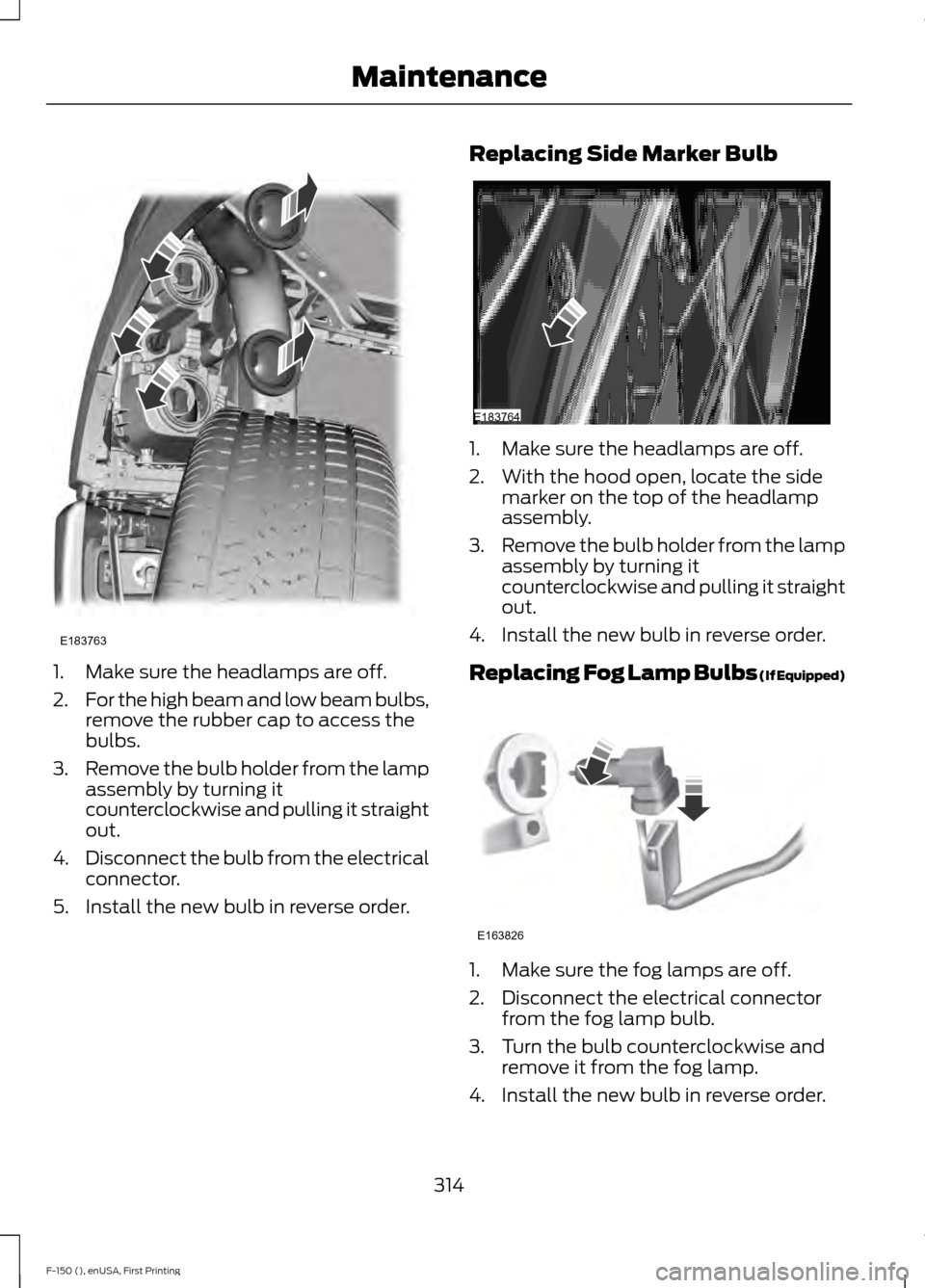

1. Make sure the headlamps are off.

2.

For the high beam and low beam bulbs,

remove the rubber cap to access the

bulbs.

3. Remove the bulb holder from the lamp

assembly by turning it

counterclockwise and pulling it straight

out.

4. Disconnect the bulb from the electrical

connector.

5. Install the new bulb in reverse order. Replacing Side Marker Bulb 1. Make sure the headlamps are off.

2. With the hood open, locate the side

marker on the top of the headlamp

assembly.

3. Remove the bulb holder from the lamp

assembly by turning it

counterclockwise and pulling it straight

out.

4. Install the new bulb in reverse order.

Replacing Fog Lamp Bulbs (If Equipped) 1. Make sure the fog lamps are off.

2. Disconnect the electrical connector

from the fog lamp bulb.

3. Turn the bulb counterclockwise and remove it from the fog lamp.

4. Install the new bulb in reverse order.

314

F-150 (), enUSA, First Printing MaintenanceE183763 E183764 E163826

Page 318 of 549

Replacing LED Headlamp Bulbs (If

Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

Replacing LED Direction Indicator

and Side Marker Bulbs

(If Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

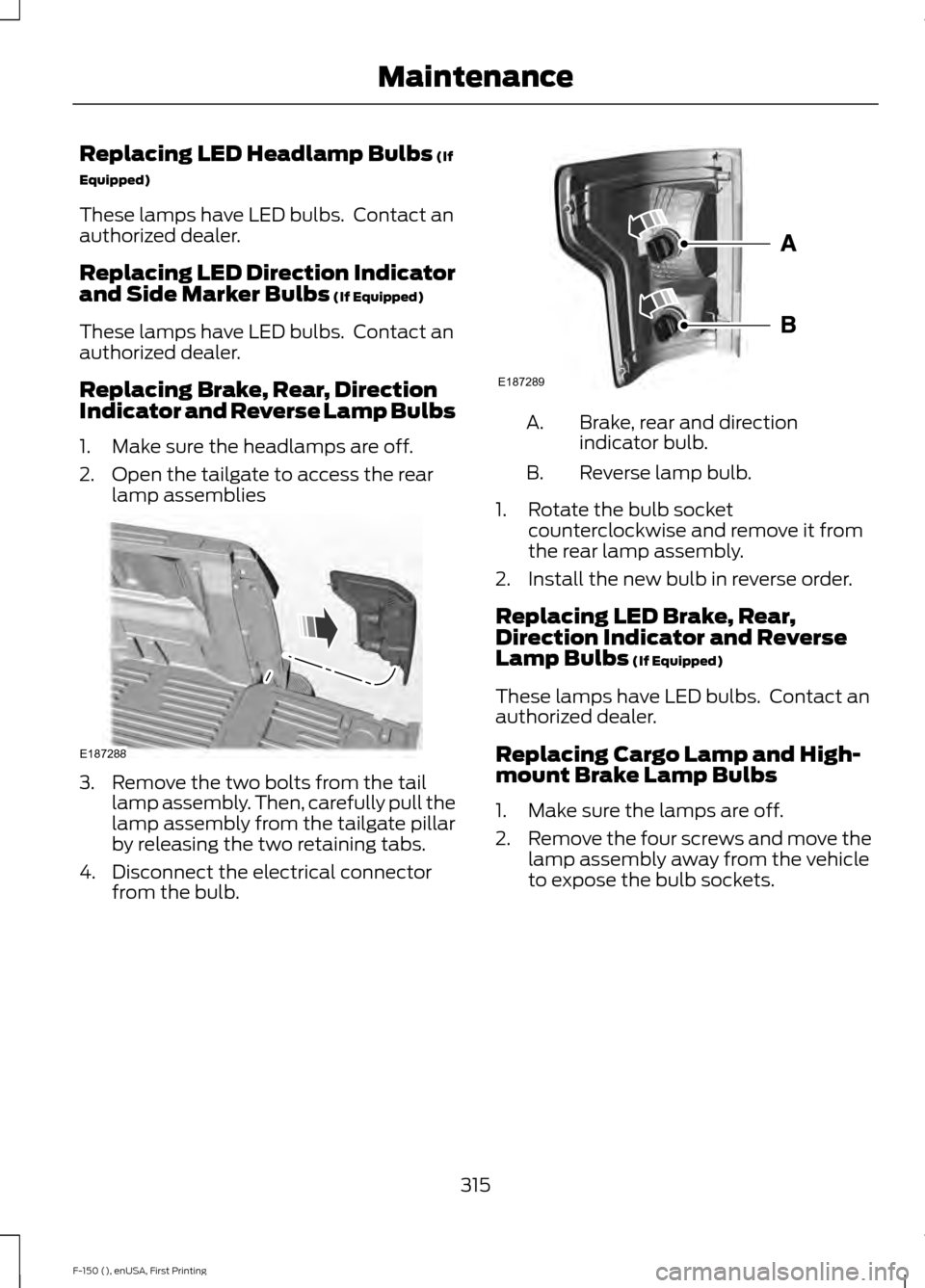

Replacing Brake, Rear, Direction

Indicator and Reverse Lamp Bulbs

1. Make sure the headlamps are off.

2. Open the tailgate to access the rear lamp assemblies 3. Remove the two bolts from the tail

lamp assembly. Then, carefully pull the

lamp assembly from the tailgate pillar

by releasing the two retaining tabs.

4. Disconnect the electrical connector from the bulb. Brake, rear and direction

indicator bulb.

A.

Reverse lamp bulb.

B.

1. Rotate the bulb socket counterclockwise and remove it from

the rear lamp assembly.

2. Install the new bulb in reverse order.

Replacing LED Brake, Rear,

Direction Indicator and Reverse

Lamp Bulbs

(If Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

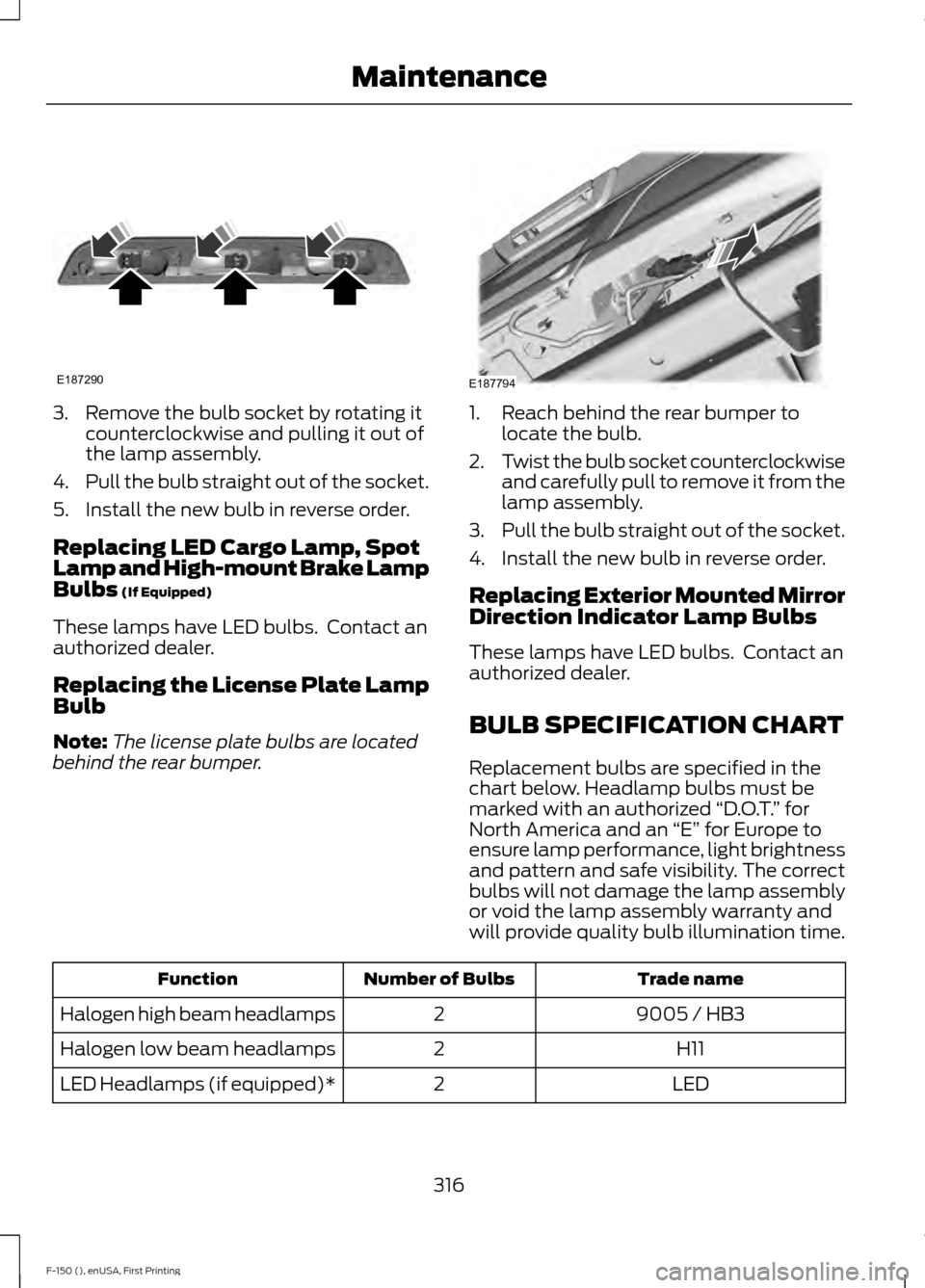

Replacing Cargo Lamp and High-

mount Brake Lamp Bulbs

1. Make sure the lamps are off.

2. Remove the four screws and move the

lamp assembly away from the vehicle

to expose the bulb sockets.

315

F-150 (), enUSA, First Printing MaintenanceE187288 E187289

Page 319 of 549

3. Remove the bulb socket by rotating it

counterclockwise and pulling it out of

the lamp assembly.

4. Pull the bulb straight out of the socket.

5. Install the new bulb in reverse order.

Replacing LED Cargo Lamp, Spot

Lamp and High-mount Brake Lamp

Bulbs (If Equipped)

These lamps have LED bulbs. Contact an

authorized dealer.

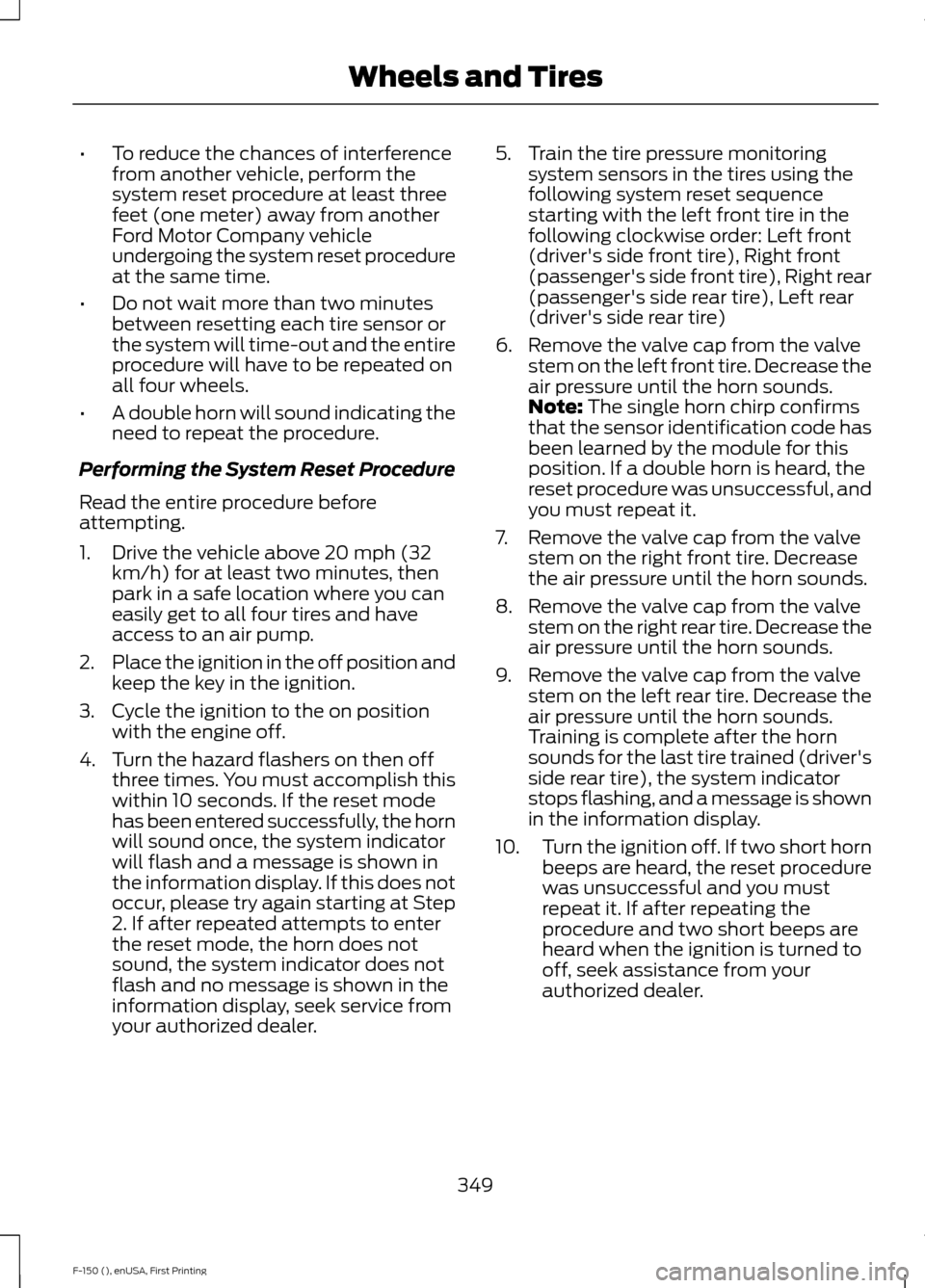

Replacing the License Plate Lamp

Bulb

Note: The license plate bulbs are located

behind the rear bumper. 1. Reach behind the rear bumper to

locate the bulb.

2. Twist the bulb socket counterclockwise

and carefully pull to remove it from the

lamp assembly.

3. Pull the bulb straight out of the socket.

4. Install the new bulb in reverse order.

Replacing Exterior Mounted Mirror

Direction Indicator Lamp Bulbs

These lamps have LED bulbs. Contact an

authorized dealer.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the

chart below. Headlamp bulbs must be

marked with an authorized “D.O.T.” for

North America and an “E” for Europe to

ensure lamp performance, light brightness

and pattern and safe visibility. The correct

bulbs will not damage the lamp assembly

or void the lamp assembly warranty and

will provide quality bulb illumination time. Trade name

Number of Bulbs

Function

9005 / HB3

2

Halogen high beam headlamps

H11

2

Halogen low beam headlamps

LED

2

LED Headlamps (if equipped)*

316

F-150 (), enUSA, First Printing MaintenanceE187290 E187794

Page 352 of 549

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least three

feet (one meter) away from another

Ford Motor Company vehicle

undergoing the system reset procedure

at the same time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system will time-out and the entire

procedure will have to be repeated on

all four wheels.

• A double horn will sound indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then

park in a safe location where you can

easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If the reset mode

has been entered successfully, the horn

will sound once, the system indicator

will flash and a message is shown in

the information display. If this does not

occur, please try again starting at Step

2. If after repeated attempts to enter

the reset mode, the horn does not

sound, the system indicator does not

flash and no message is shown in the

information display, seek service from

your authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front

(driver's side front tire), Right front

(passenger's side front tire), Right rear

(passenger's side rear tire), Left rear

(driver's side rear tire)

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn chirp confirms

that the sensor identification code has

been learned by the module for this

position. If a double horn is heard, the

reset procedure was unsuccessful, and

you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained (driver's

side rear tire), the system indicator

stops flashing, and a message is shown

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

349

F-150 (), enUSA, First Printing Wheels and Tires