FORD F250 SUPER DUTY 2015 Owners Manual

Manufacturer: FORD, Model Year: 2015, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2015Pages: 470, PDF Size: 18.27 MB

Page 291 of 470

11.Set all four tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel (affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver's seating position)or Tire Label located on the B-Pillaror the edge of the driver's door.

CHANGING A ROAD WHEEL

WARNINGS

The use of tire sealants may damageyour tire pressure monitoring systemand should not be used. However, ifyou must use a sealant, the tire pressuremonitoring system sensor and valve stemon the wheel must be replaced by anauthorized dealer.

If the tire pressure monitor sensorbecomes damaged, it will no longerfunction. See Tire PressureMonitoring System (page 282).

Note:If your vehicle is equipped with thetire pressure monitoring system, theindicator light will illuminate when the sparetire is in use. To restore the full function ofthe monitoring system, all road wheelsequipped with tire pressure monitoringsensors must be mounted on the vehicle.

If you get a flat tire while driving, do notapply the brake heavily. Instead, graduallydecrease your speed. Hold the steeringwheel firmly and slowly move to a safeplace on the side of the road.

If your vehicle is equipped with the tirepressure monitoring system, have a flatserviced by an authorized dealer in orderto prevent damage to the system sensors.See Tire Pressure Monitoring System(page 282). Replace the spare tire with aroad tire as soon as possible. Duringrepairing or replacing of the flat tire, havethe authorized dealer inspect the systemsensor for damage.

Dissimilar Spare Wheel and TireAssembly Information

WARNING

Failure to follow these guidelinescould result in an increased risk ofloss of vehicle control, injury or death.

If you have a dissimilar spare wheel andtire, then it is intended for temporary useonly. This means that if you need to use it,you should replace it as soon as possiblewith a road wheel and tire assembly thatis the same size and type as the road tiresand wheels that were originally providedby Ford. If the dissimilar spare tire or wheelis damaged, it should be replaced ratherthan repaired.

A dissimilar spare wheel and tire assemblyis defined as a spare wheel and tireassembly that is different in brand, size orappearance from the road tires and wheelsand can be one of three types:

1.T-type mini-spare: This spare tirebegins with the letter T for tire size andmay have Temporary Use Only molded inthe sidewall.

2.Full-size dissimilar spare with labelon wheel: This spare tire has a label onthe wheel that states: THIS WHEEL ANDTIRE ASSEMBLY FOR TEMPORARY USEONLY

When driving with one of the dissimilarspare tires listed above, do not:

288

Super Duty (), enUSA

Wheels and Tires

Page 292 of 470

•Exceed 50 mph (80 km/h)

•Load the vehicle beyond maximumvehicle load rating listed on the SafetyCompliance Label.

•Tow a trailer.

•Use snow chains on the end of thevehicle with the dissimilar spare tire.

•Use more than one dissimilar spare tireat a time.

•Use commercial car washingequipment.

•Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tireslisted above at any one wheel location canlead to impairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•All-wheel driving capability

3.Full-size dissimilar spare withoutlabel on wheel

When driving with the full-size dissimilarspare wheel and tire assembly, do not:

•Exceed 70 mph (113 km/h).

•Use more than one dissimilar sparewheel and tire assembly at a time.

•Use commercial car washingequipment.

•Use snow chains on the end of thevehicle with the dissimilar spare wheeland tire assembly.

The usage of a full-size dissimilar sparewheel and tire assembly can lead toimpairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•All-wheel driving capability

When driving with the full-size dissimilarspare wheel and tire assembly additionalcaution should be given to:

•Towing a trailer.

•Driving vehicles equipped with acamper body.

•Driving vehicles with a load on thecargo rack.

Drive cautiously when using a full-sizedissimilar spare wheel and tire assemblyand seek service as soon as possible.

Location of the Spare Tire andTools

If your vehicle is equipped with a spare tire,jack and associated tools, see thefollowing table for their locations:

LocationTool

Under the vehicle, just forward of the rearbumperSpare tire (pick-up trucks only)

Regular cab and Crew Cab: Fastened tofloor pan behind rearmost seat onpassenger side

Jack

289

Super Duty (), enUSA

Wheels and Tires

Page 293 of 470

LocationTool

SuperCab: Under rear bench seat onpassenger side

Regular cab: Fastened to floor behind driverseatJack handle, lug wrench, lug wrench exten-sion (only available on dual rear wheelvehicles) and wheel chock (only availableon single rear wheel vehicles equipped witha diesel engine)

SuperCab: Fastened to floor under rear seatCrew Cab: Fastened to floor behind rearseat at driver side

In the glove boxKey and spare tire lock

Removing the Spare Tire (WithSpare Tire Carrier Only)

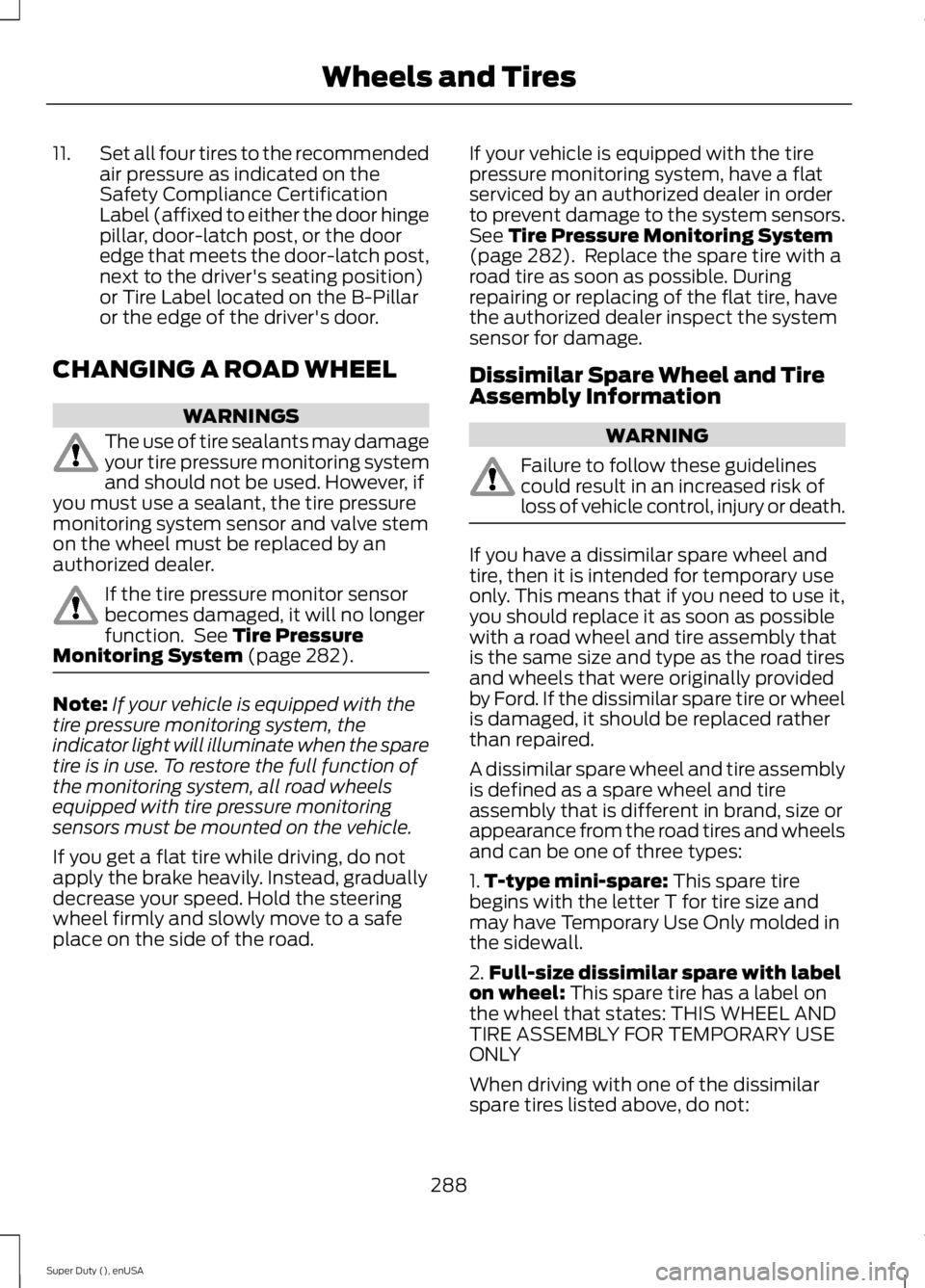

The following tools are required to removethe spare tire:

One handle extension and two typicalextensions. To assemble, align the buttonwith the hole and slide the parts together.

To disconnect, press the button and pullapart.

One wheel nut wrench. Slide over thesquare end of the jack handle.

Note:For vehicles with dual rear wheels,insert the lug wrench extension into the lugwrench to reach the lug nuts.

290

Super Duty (), enUSA

Wheels and TiresE162795 E162796 E162797

Page 294 of 470

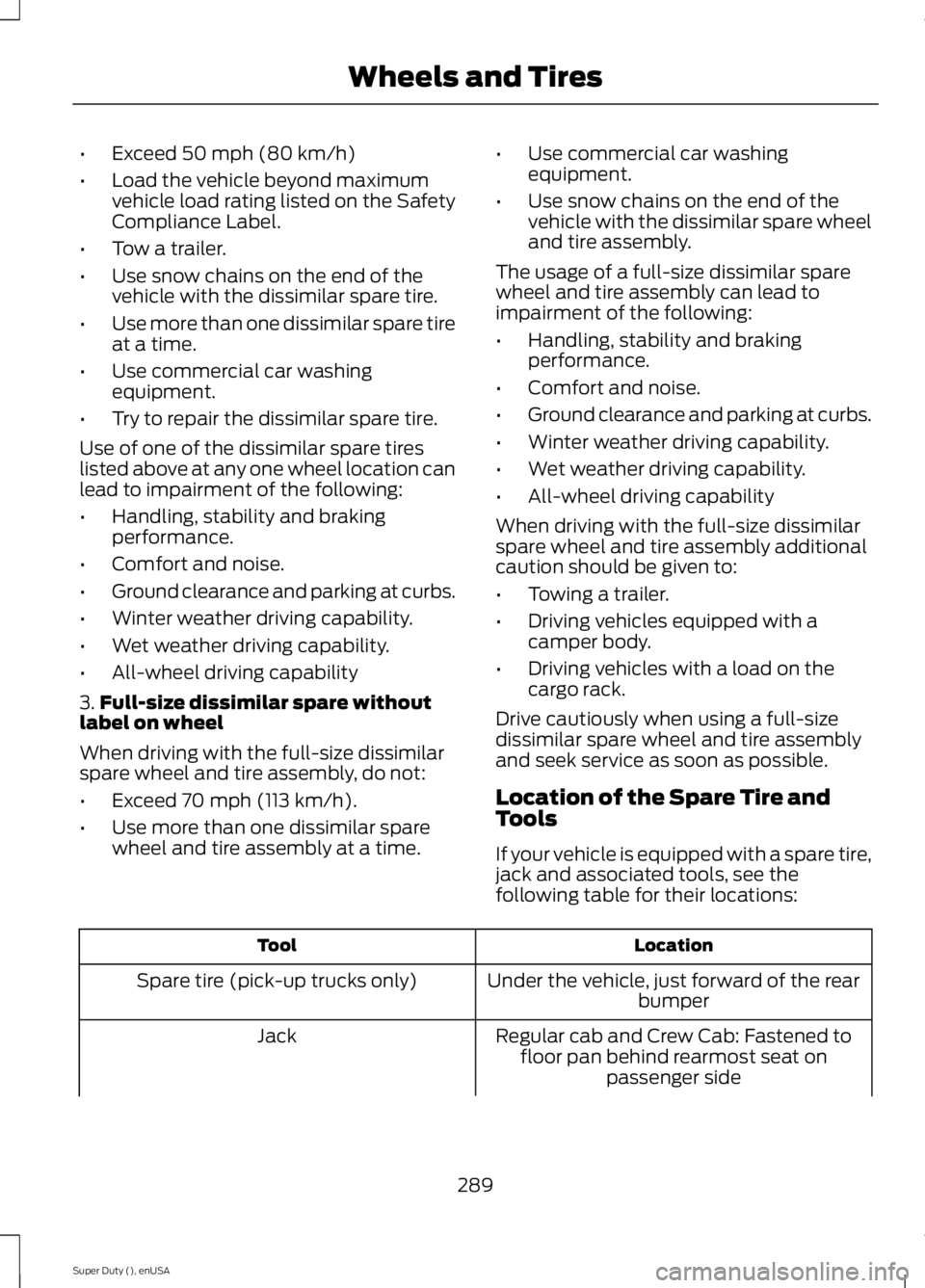

1.Attach the spare tire lock key (A) to thejack handle (B).

2. Fully insert the jack handle (with oneextension) through the bumper holeand into the guide tube. The key andlock will engage with a slight push andcounterclockwise turn. You will feelsome resistance when you turn the jackhandle assembly.

3.Turn the handle counterclockwise andlower the spare tire until you can slidethe tire rearward and the cable is slack.

4.Remove the retainer through the centerof the wheel. If your vehicle is equippedwith a tether, perform the followingsteps.

5.Lift the spare tire on end to access thetether attachment.

6. Use the lug wrench to remove the lugnut from the spare tire tether.

7. If not replacing the spare or flat tire tothe underbody storage area, raise thewheel retainer up into the installedposition.

8. Use the attached fastener strap (onthe spare tire tether) to attach thetether end to the winch retainer priorto raising to the installed position.

Tire Change Procedure

WARNINGS

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

291

Super Duty (), enUSA

Wheels and TiresE162798

AB

AB E162799 E162800

Page 295 of 470

WARNINGS

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

Park on a level surface, set the parkingbrake and activate the hazard flashers.

1.Turn the engine off and block the wheelthat is diagonally opposite of the flattire using the wheel chock.Note: Lockthe manual hub on the wheel if thevehicle is a 4x4.

2. Remove the jack, jack handle, lugwrench and spare tire from thestowage locations.

3.Use the tip of the lug wrench to removeany wheel trim.

4. Loosen each wheel lug nut ½ turncounterclockwise, but do not removethem until the wheel is raised off theground.

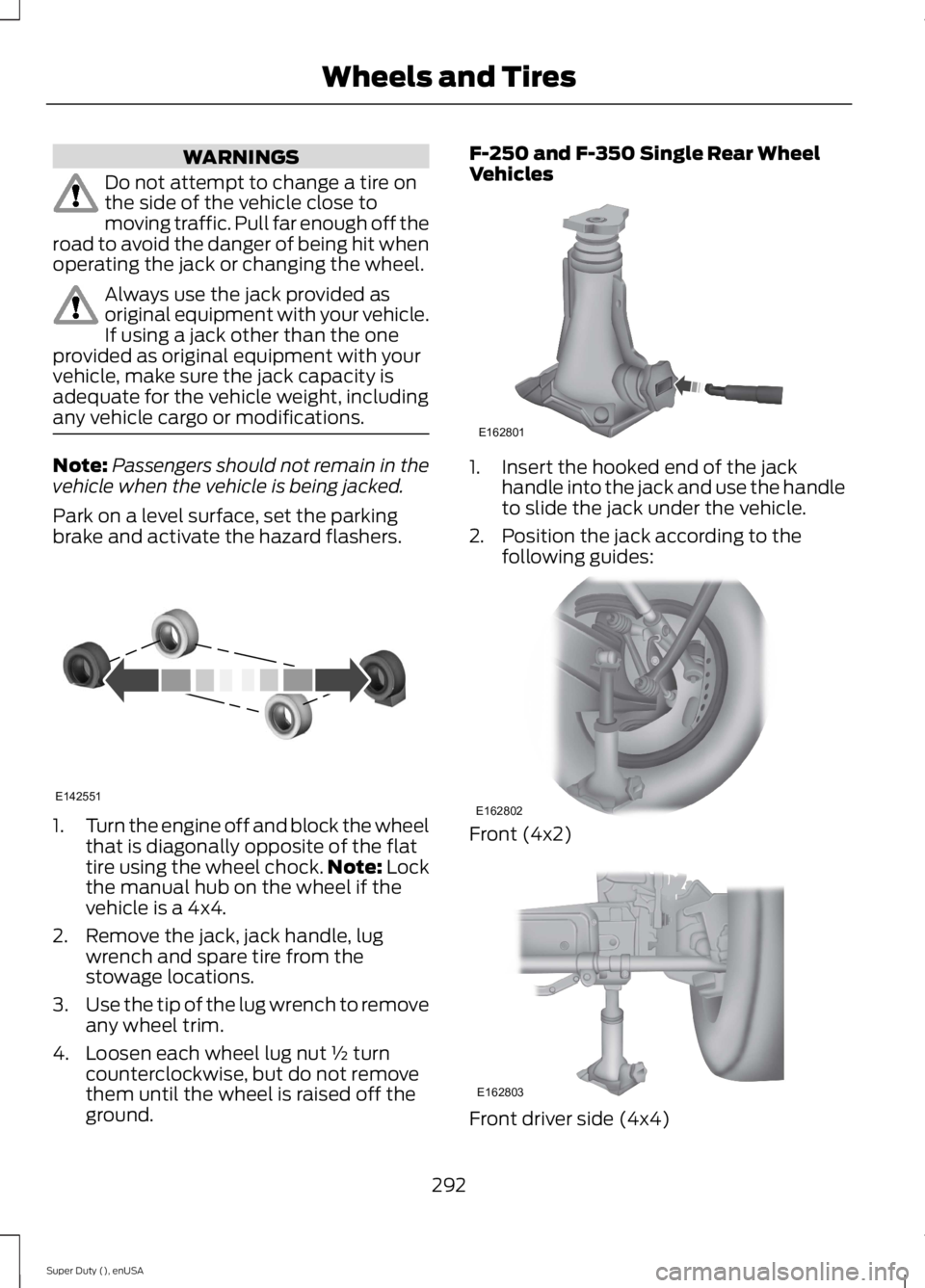

F-250 and F-350 Single Rear WheelVehicles

1. Insert the hooked end of the jackhandle into the jack and use the handleto slide the jack under the vehicle.

2. Position the jack according to thefollowing guides:

Front (4x2)

Front driver side (4x4)

292

Super Duty (), enUSA

Wheels and TiresE142551 E162801 E162802 E162803

Page 296 of 470

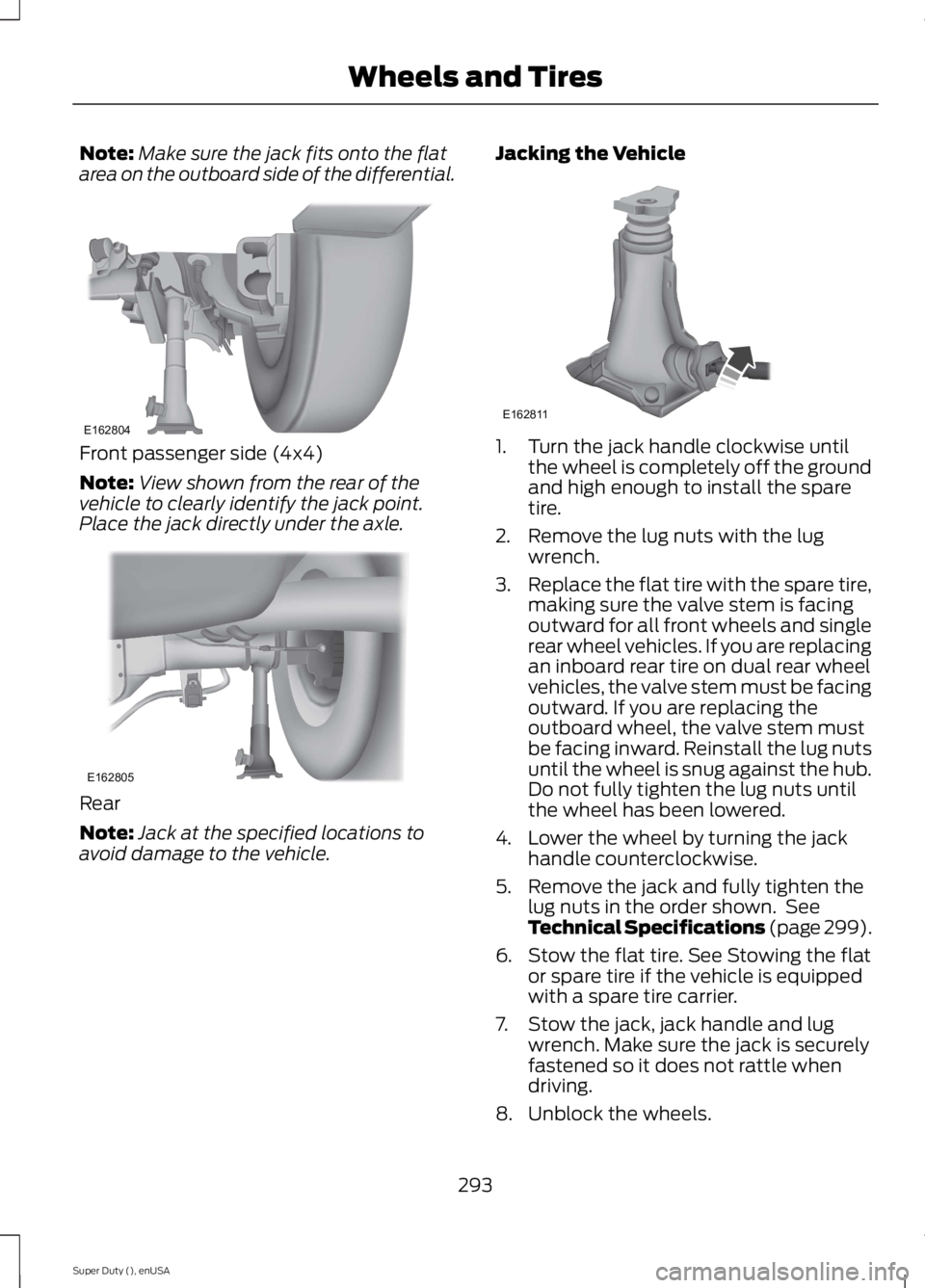

Note:Make sure the jack fits onto the flatarea on the outboard side of the differential.

Front passenger side (4x4)

Note:View shown from the rear of thevehicle to clearly identify the jack point.Place the jack directly under the axle.

Rear

Note:Jack at the specified locations toavoid damage to the vehicle.

Jacking the Vehicle

1. Turn the jack handle clockwise untilthe wheel is completely off the groundand high enough to install the sparetire.

2. Remove the lug nuts with the lugwrench.

3.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward for all front wheels and singlerear wheel vehicles. If you are replacingan inboard rear tire on dual rear wheelvehicles, the valve stem must be facingoutward. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

4. Lower the wheel by turning the jackhandle counterclockwise.

5. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 299).

6. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

7. Stow the jack, jack handle and lugwrench. Make sure the jack is securelyfastened so it does not rattle whendriving.

8. Unblock the wheels.

293

Super Duty (), enUSA

Wheels and TiresE162804 E162805 E162811

Page 297 of 470

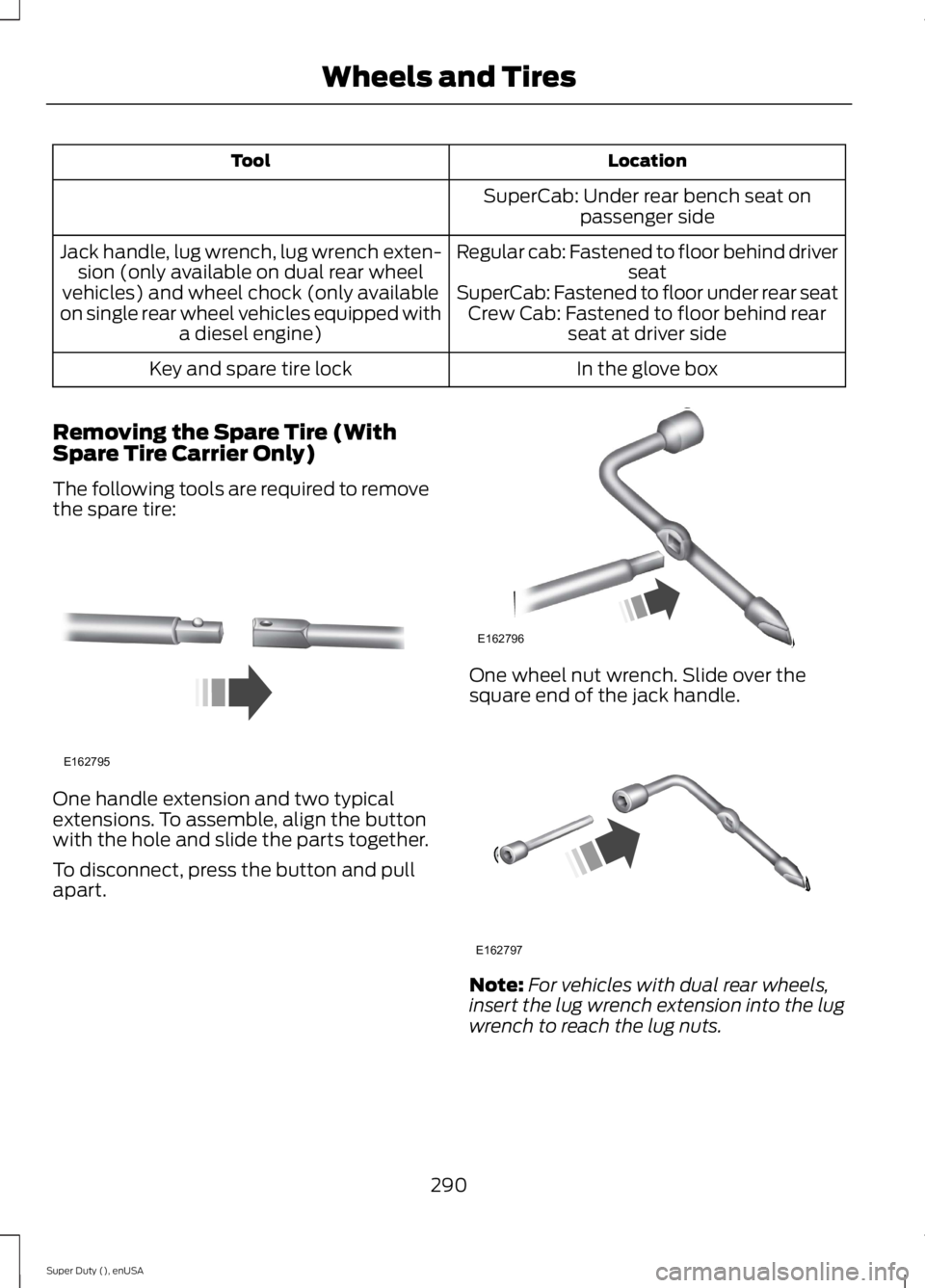

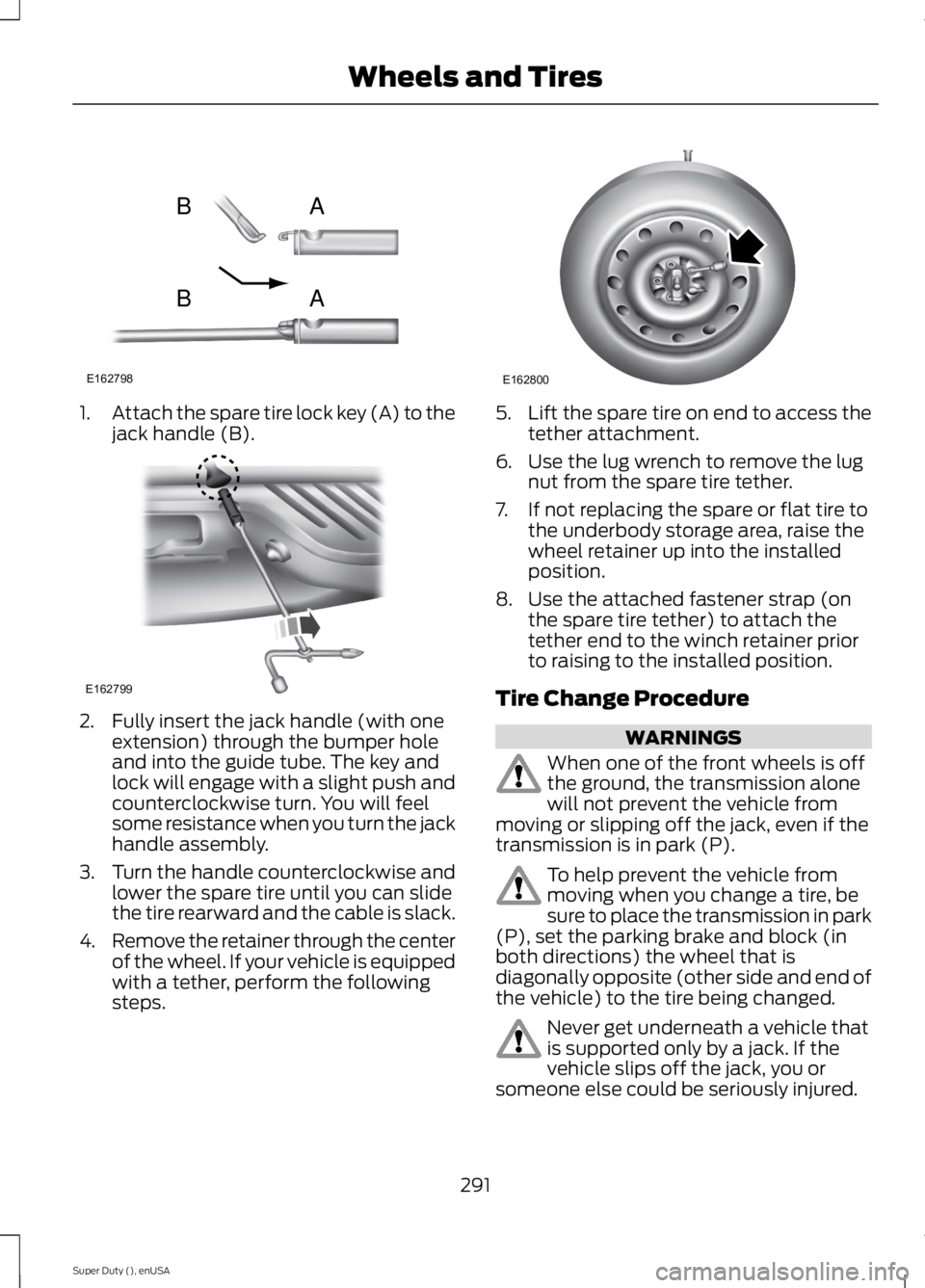

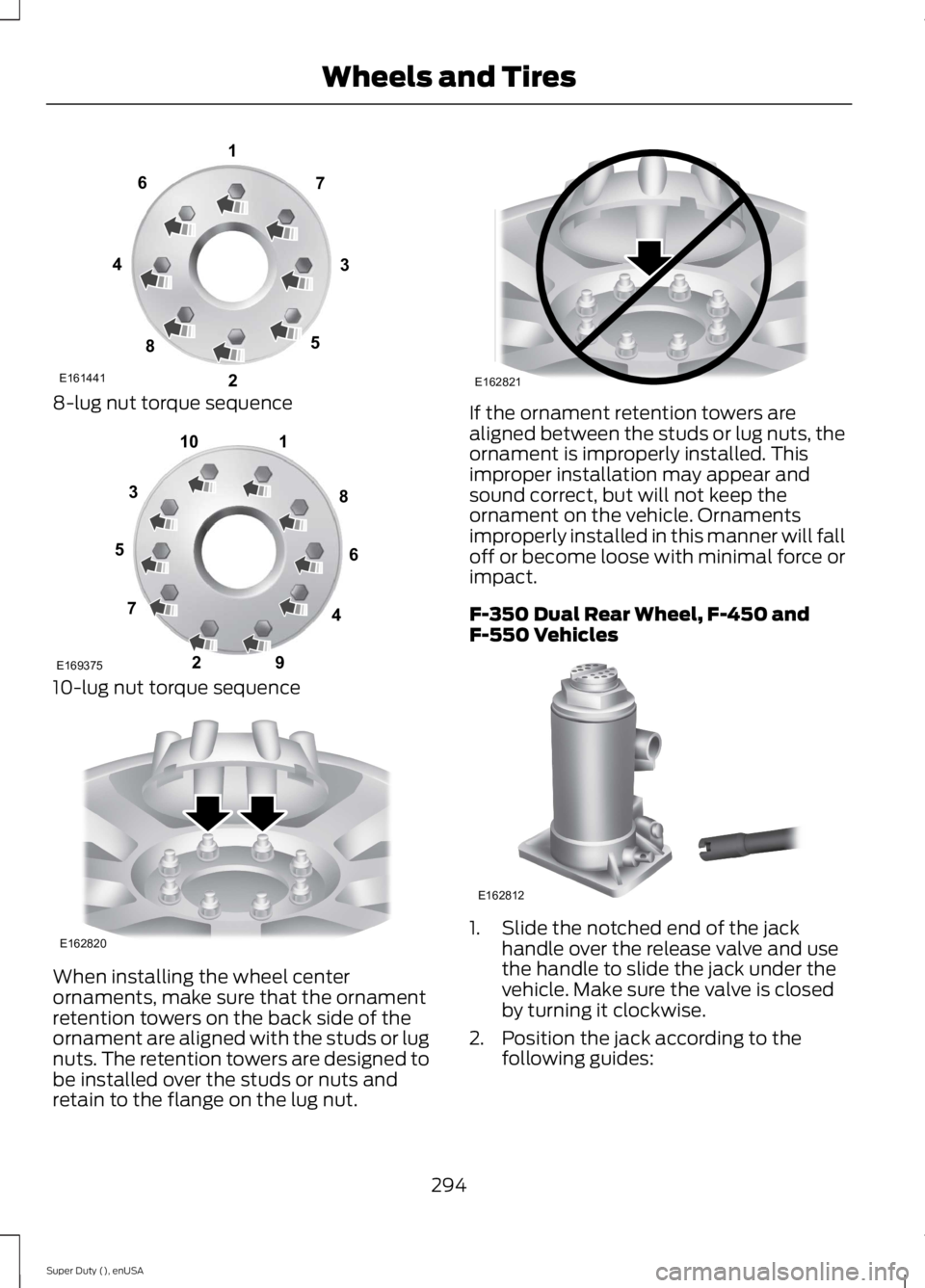

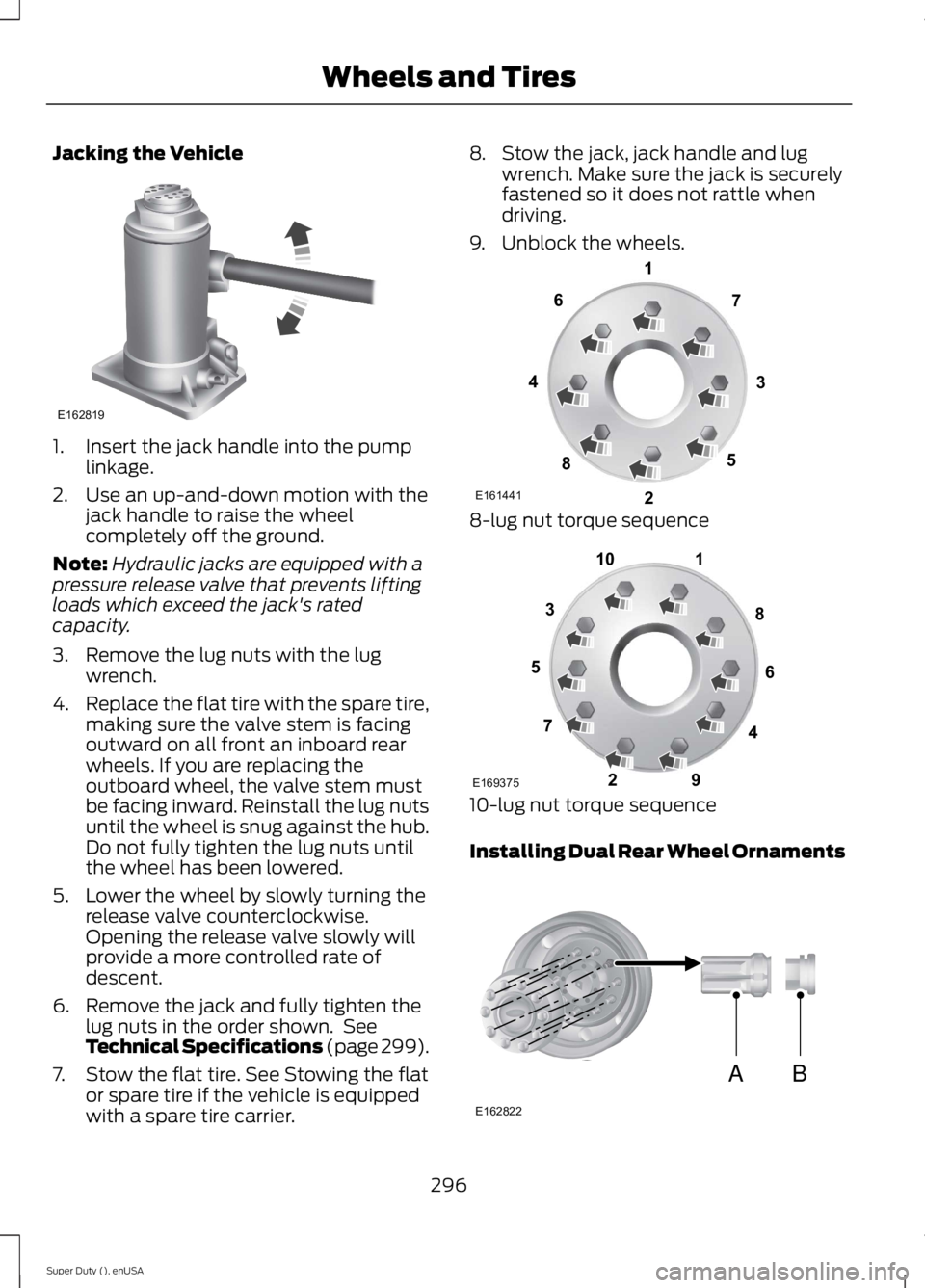

8-lug nut torque sequence

10-lug nut torque sequence

When installing the wheel centerornaments, make sure that the ornamentretention towers on the back side of theornament are aligned with the studs or lugnuts. The retention towers are designed tobe installed over the studs or nuts andretain to the flange on the lug nut.

If the ornament retention towers arealigned between the studs or lug nuts, theornament is improperly installed. Thisimproper installation may appear andsound correct, but will not keep theornament on the vehicle. Ornamentsimproperly installed in this manner will falloff or become loose with minimal force orimpact.

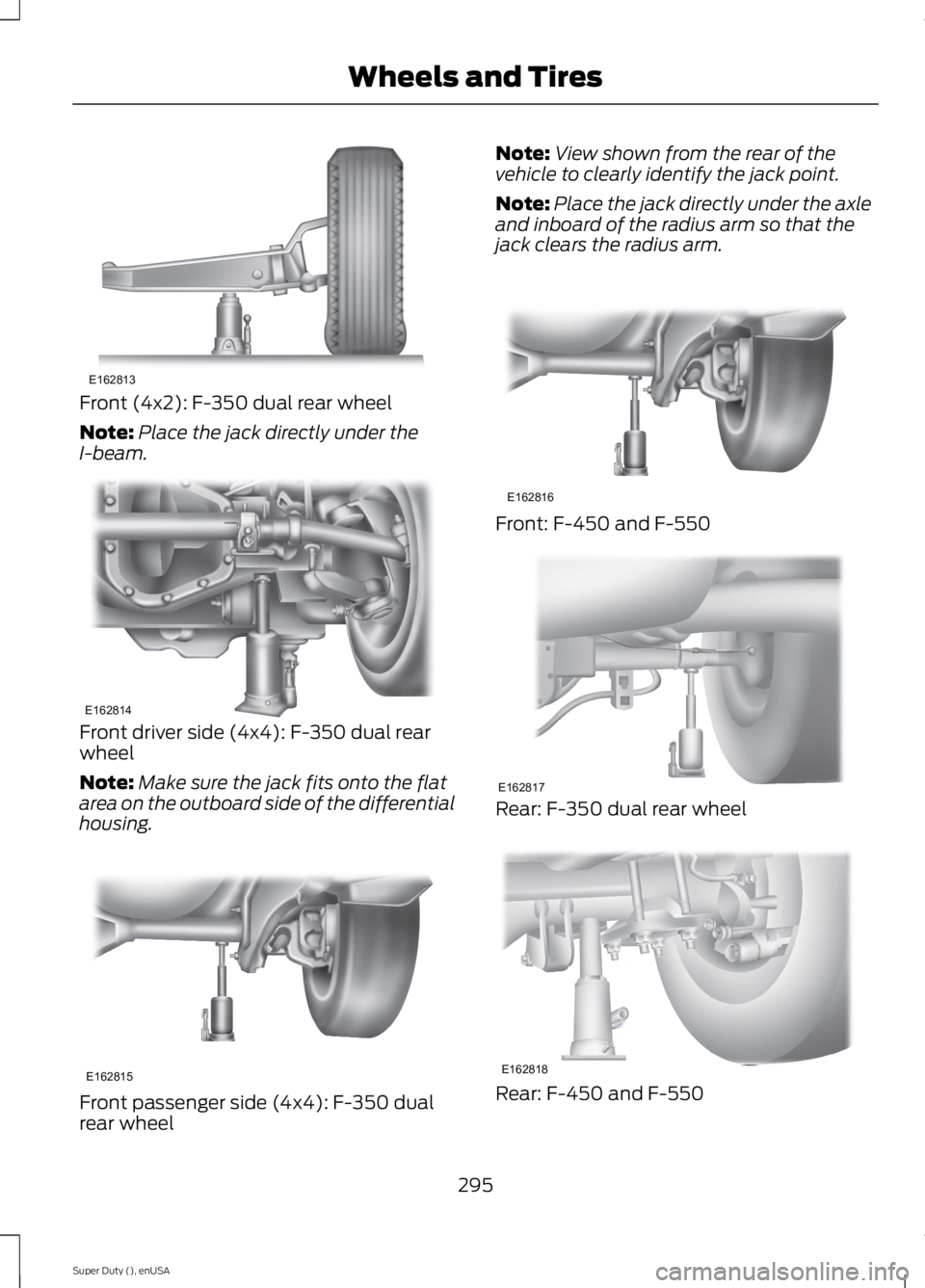

F-350 Dual Rear Wheel, F-450 andF-550 Vehicles

1. Slide the notched end of the jackhandle over the release valve and usethe handle to slide the jack under thevehicle. Make sure the valve is closedby turning it clockwise.

2. Position the jack according to thefollowing guides:

294

Super Duty (), enUSA

Wheels and TiresE161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375 E162820 E162821 E162812

Page 298 of 470

Front (4x2): F-350 dual rear wheel

Note:Place the jack directly under theI-beam.

Front driver side (4x4): F-350 dual rearwheel

Note:Make sure the jack fits onto the flatarea on the outboard side of the differentialhousing.

Front passenger side (4x4): F-350 dualrear wheel

Note:View shown from the rear of thevehicle to clearly identify the jack point.

Note:Place the jack directly under the axleand inboard of the radius arm so that thejack clears the radius arm.

Front: F-450 and F-550

Rear: F-350 dual rear wheel

Rear: F-450 and F-550

295

Super Duty (), enUSA

Wheels and TiresE162813 E162814 E162815 E162816 E162817 E162818

Page 299 of 470

Jacking the Vehicle

1. Insert the jack handle into the pumplinkage.

2. Use an up-and-down motion with thejack handle to raise the wheelcompletely off the ground.

Note:Hydraulic jacks are equipped with apressure release valve that prevents liftingloads which exceed the jack's ratedcapacity.

3. Remove the lug nuts with the lugwrench.

4.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward on all front an inboard rearwheels. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

5. Lower the wheel by slowly turning therelease valve counterclockwise.Opening the release valve slowly willprovide a more controlled rate ofdescent.

6. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 299).

7. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

8. Stow the jack, jack handle and lugwrench. Make sure the jack is securelyfastened so it does not rattle whendriving.

9. Unblock the wheels.

8-lug nut torque sequence

10-lug nut torque sequence

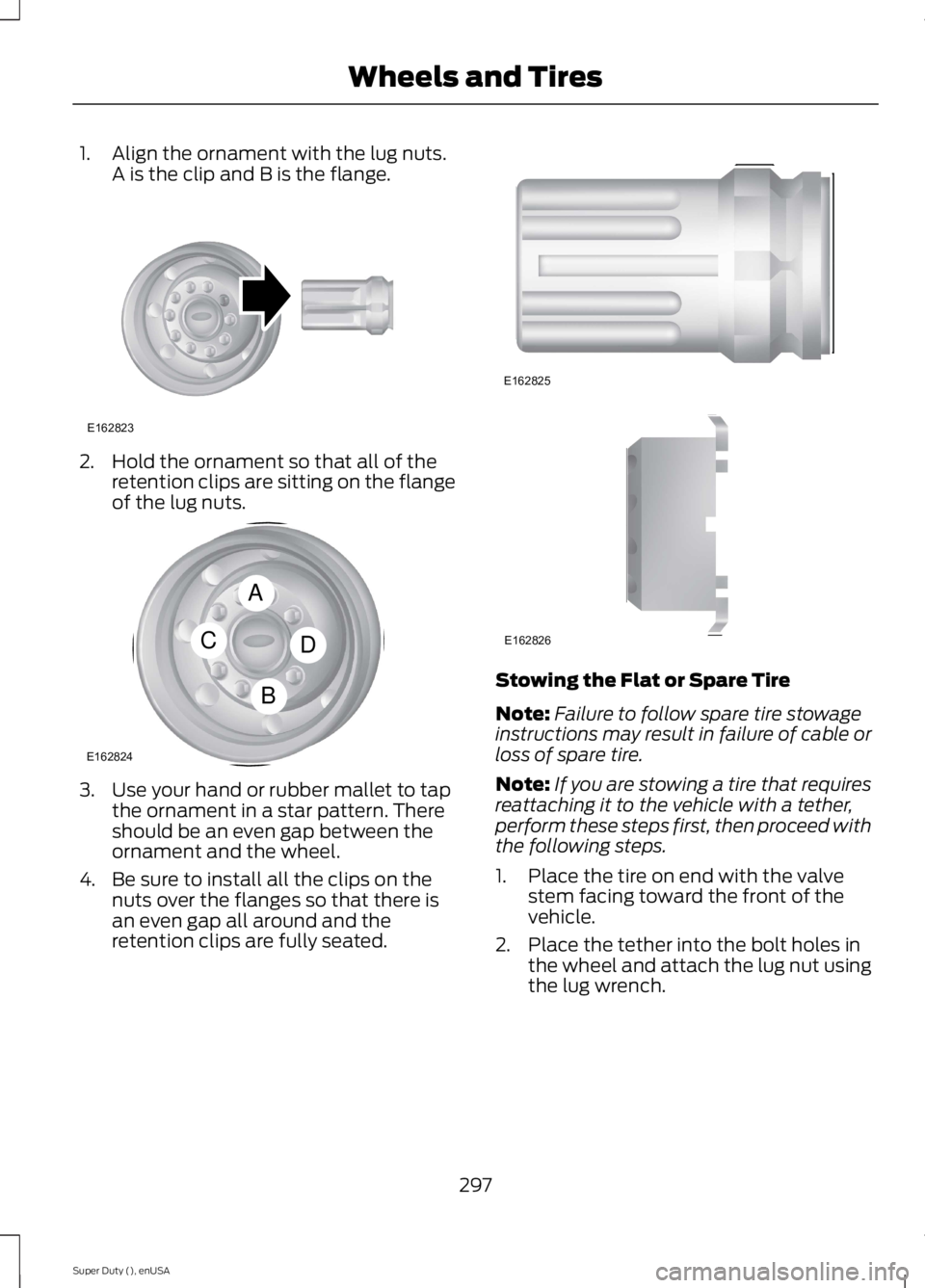

Installing Dual Rear Wheel Ornaments

296

Super Duty (), enUSA

Wheels and TiresE162819 E161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375 AB

E162822

Page 300 of 470

1. Align the ornament with the lug nuts.A is the clip and B is the flange.

2. Hold the ornament so that all of theretention clips are sitting on the flangeof the lug nuts.

3. Use your hand or rubber mallet to tapthe ornament in a star pattern. Thereshould be an even gap between theornament and the wheel.

4. Be sure to install all the clips on thenuts over the flanges so that there isan even gap all around and theretention clips are fully seated.

Stowing the Flat or Spare Tire

Note:Failure to follow spare tire stowageinstructions may result in failure of cable orloss of spare tire.

Note:If you are stowing a tire that requiresreattaching it to the vehicle with a tether,perform these steps first, then proceed withthe following steps.

1. Place the tire on end with the valvestem facing toward the front of thevehicle.

2. Place the tether into the bolt holes inthe wheel and attach the lug nut usingthe lug wrench.

297

Super Duty (), enUSA

Wheels and TiresE162823 A

C

B

D

E162824 E162825 E162826