light FORD F650 2004 11.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: F650, Model: FORD F650 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 134 of 264

Trailer brakes

Electric brakes and manual, automatic or surge-type trailer brakes are

safe if installed properly and adjusted to the manufacturer’s

specifications. The trailer brakes must meet local and Federal

regulations.

Do not connect a trailer’s hydraulic brake system directly to your

vehicle’s brake system. Your vehicle may not have enough

braking power and your chances of having a collision greatly increase.

Trailer lamps

Trailer lamps are required on most towed vehicles. Your vehicle may be

equipped with one of two possible trailer wiring designs. Make sure all

running lights, brake lights, turn signals and hazard lights are working.

See your dealer or trailer rental agency for proper instructions and

equipment for hooking up trailer lamps.

Driving while you tow

When towing a trailer:

•Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

•Consult your local motor vehicle speed regulations for towing a trailer.

•To eliminate excessive transmission shifting, use a lower gear. This will

also assist in transmission cooling.

•Anticipate stops and brake gradually.

•Do not exceed the GCWR rating or transmission damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

•Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

•Allow more distance for stopping with a trailer attached.

•The trailer tongue weight should be 10–15% of the loaded trailer

weight.

2004 F650/750(f67)

Supplement

USA English(fus)

Driving

134

Page 138 of 264

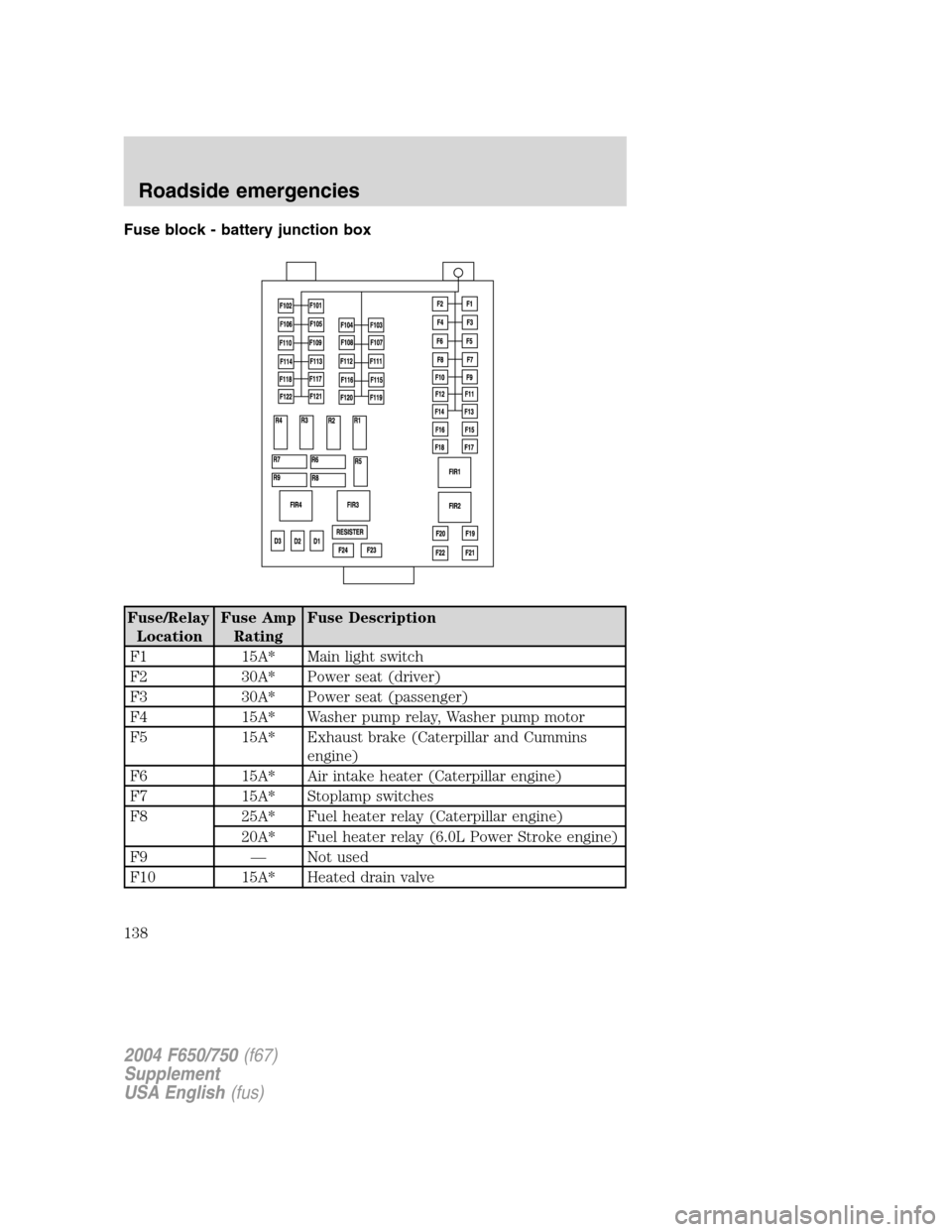

Fuse block - battery junction box

Fuse/Relay

LocationFuse Amp

RatingFuse Description

F1 15A* Main light switch

F2 30A* Power seat (driver)

F3 30A* Power seat (passenger)

F4 15A* Washer pump relay, Washer pump motor

F5 15A* Exhaust brake (Caterpillar and Cummins

engine)

F6 15A* Air intake heater (Caterpillar engine)

F7 15A* Stoplamp switches

F8 25A* Fuel heater relay (Caterpillar engine)

20A* Fuel heater relay (6.0L Power Stroke engine)

F9—Not used

F10 15A* Heated drain valve

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

138

Page 139 of 264

Fuse/Relay

LocationFuse Amp

RatingFuse Description

F11—Not used

F12—Not used

F13 10A* Parking brake

F14—Not used

F15 7.5A* Body builder - trailer adapter stoplamps

F16 5A* WABCO hydraulic ABS

F17—Not used

F18 10A* Fuel transfer pump

F19—Not used

F20 10A* Engine ECM power relay (6.0L Power Stroke

engine)

F21 10A* Control for Hydro-max motor

F22 10A* V8 engine IDM2 logic power

F23—Not used

F24—Not used

F101 30A** Air ABS relay, Hydraulic modulator relay

F102 20A** Ignition switch to customer access

F103 50A** Ignition switch, Central Junction Box (CJB)

fuses 8, 9, 10, 11, 19, 20, 23, 24, 25, 29, 30,

31

F104 20A** Power point

F105 20A** Door lock switches

F106 30A** Main light switch, Multifunction switch, CJB

fuses 16, 26 and 28, Headlamps, DRL relays

F107 50A** CJB fuses 1, 2, 3, 4, 12, 13, 14, 15

F108 40A** Fuel heater relay (Cummins engine)

F109 40A** Power window relay

F110—Not used

F111 30A** Park lamps relay, Park lamps

F112 40A** Blower motor relay, Blower motor

F113 30A** Heated seats

F114 25A** Hydraulic ABS ECU power

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

139

Page 141 of 264

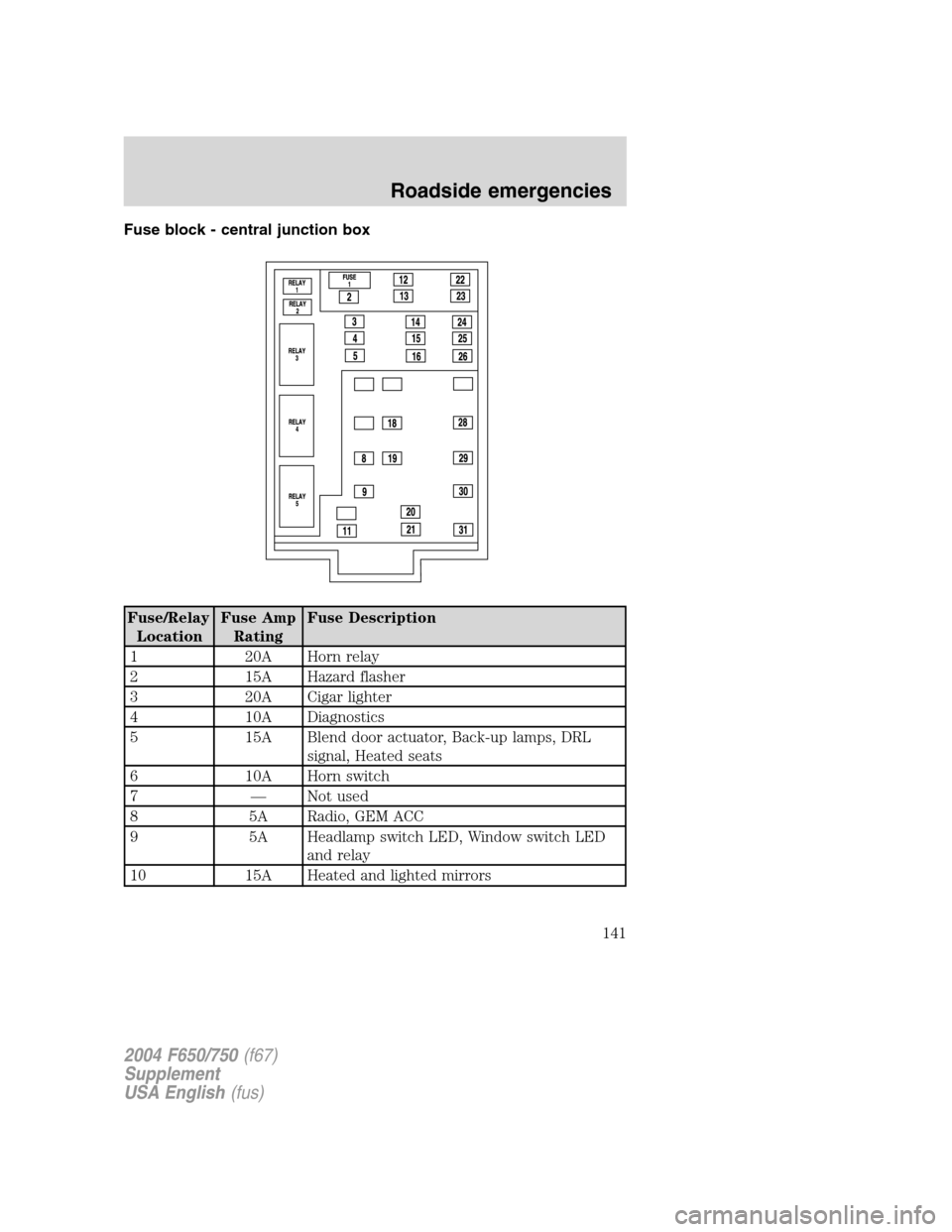

Fuse block - central junction box

Fuse/Relay

LocationFuse Amp

RatingFuse Description

1 20A Horn relay

2 15A Hazard flasher

3 20A Cigar lighter

4 10A Diagnostics

5 15A Blend door actuator, Back-up lamps, DRL

signal, Heated seats

6 10A Horn switch

7—Not used

8 5A Radio, GEM ACC

9 5A Headlamp switch LED, Window switch LED

and relay

10 15A Heated and lighted mirrors

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

141

Page 142 of 264

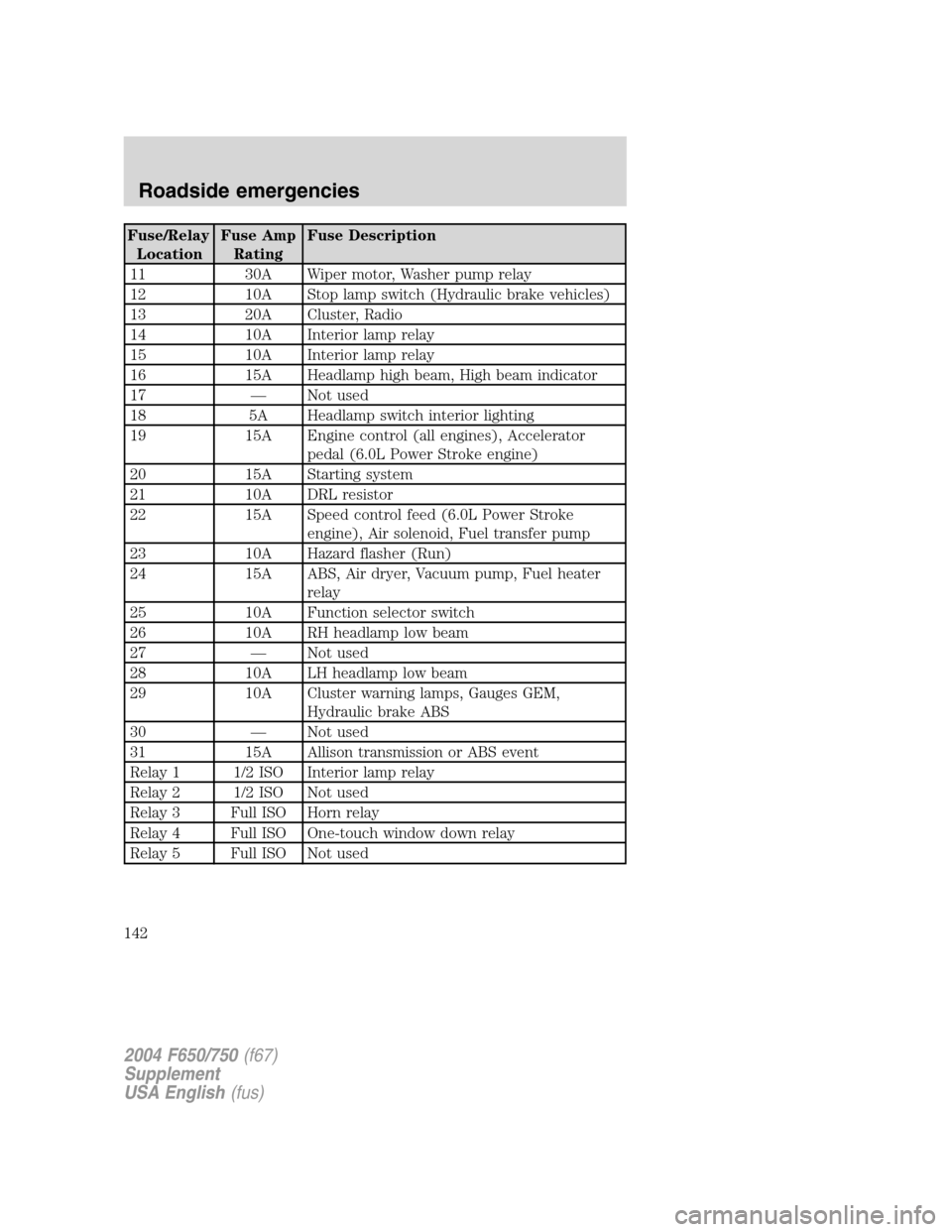

Fuse/Relay

LocationFuse Amp

RatingFuse Description

11 30A Wiper motor, Washer pump relay

12 10A Stop lamp switch (Hydraulic brake vehicles)

13 20A Cluster, Radio

14 10A Interior lamp relay

15 10A Interior lamp relay

16 15A Headlamp high beam, High beam indicator

17—Not used

18 5A Headlamp switch interior lighting

19 15A Engine control (all engines), Accelerator

pedal (6.0L Power Stroke engine)

20 15A Starting system

21 10A DRL resistor

22 15A Speed control feed (6.0L Power Stroke

engine), Air solenoid, Fuel transfer pump

23 10A Hazard flasher (Run)

24 15A ABS, Air dryer, Vacuum pump, Fuel heater

relay

25 10A Function selector switch

26 10A RH headlamp low beam

27—Not used

28 10A LH headlamp low beam

29 10A Cluster warning lamps, Gauges GEM,

Hydraulic brake ABS

30—Not used

31 15A Allison transmission or ABS event

Relay 1 1/2 ISO Interior lamp relay

Relay 2 1/2 ISO Not used

Relay 3 Full ISO Horn relay

Relay 4 Full ISO One-touch window down relay

Relay 5 Full ISO Not used

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

142

Page 143 of 264

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

Jump starting your vehicle

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

143

Page 145 of 264

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

145

Page 148 of 264

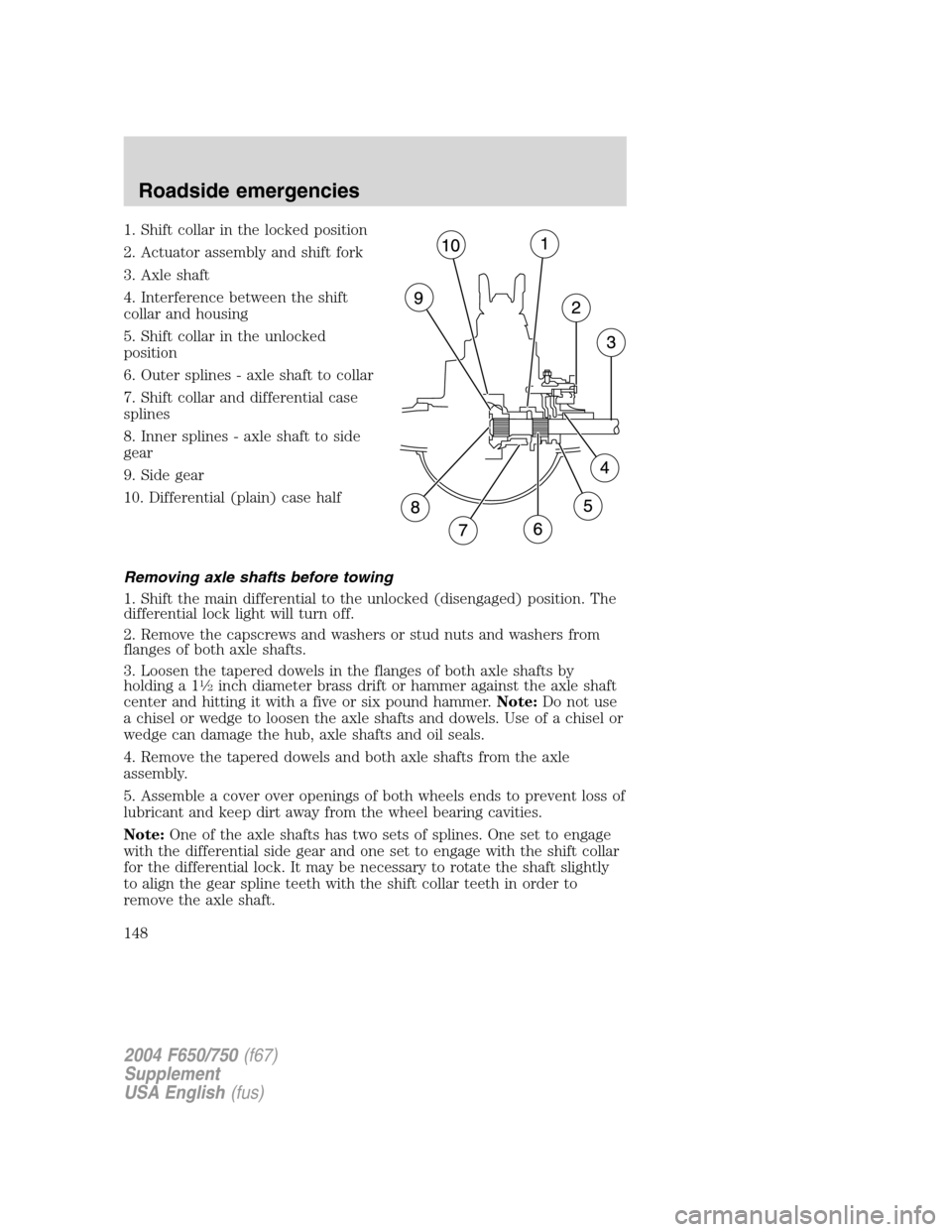

1. Shift collar in the locked position

2. Actuator assembly and shift fork

3. Axle shaft

4. Interference between the shift

collar and housing

5. Shift collar in the unlocked

position

6. Outer splines - axle shaft to collar

7. Shift collar and differential case

splines

8. Inner splines - axle shaft to side

gear

9. Side gear

10. Differential (plain) case half

Removing axle shafts before towing

1. Shift the main differential to the unlocked (disengaged) position. The

differential lock light will turn off.

2. Remove the capscrews and washers or stud nuts and washers from

flanges of both axle shafts.

3. Loosen the tapered dowels in the flanges of both axle shafts by

holding a 1

1⁄2inch diameter brass drift or hammer against the axle shaft

center and hitting it with a five or six pound hammer.Note:Do not use

a chisel or wedge to loosen the axle shafts and dowels. Use of a chisel or

wedge can damage the hub, axle shafts and oil seals.

4. Remove the tapered dowels and both axle shafts from the axle

assembly.

5. Assemble a cover over openings of both wheels ends to prevent loss of

lubricant and keep dirt away from the wheel bearing cavities.

Note:One of the axle shafts has two sets of splines. One set to engage

with the differential side gear and one set to engage with the shift collar

for the differential lock. It may be necessary to rotate the shaft slightly

to align the gear spline teeth with the shift collar teeth in order to

remove the axle shaft.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

148

Page 154 of 264

WASHING THE EXTERIOR

Wash your vehicle regularly with cool or lukewarm water and a neutral

Ph shampoo, such as Motorcraft Detail Wash (ZC-3–A), which is available

from your dealer.

•Never use strong household detergents or soap, such as dish washing

or laundry liquid. These products can discolor and spot painted

surfaces.

•Never wash a vehicle that is“hot to the touch”or during exposure to

strong, direct sunlight.

•Always use a clean sponge or car wash mitt with plenty of water for

best results.

•Dry the vehicle with a chamois or soft terry cloth towel in order to

eliminate water spotting.

•It is especially important to wash the vehicle regularly during the

winter months, as dirt and road salt are difficult to remove and cause

damage to the vehicle.

•Immediately remove items such as gasoline, diesel fuel, bird droppings

and insect deposits because they can cause damage to the vehicle’s

paintwork and trim over time.

•Remove any exterior accessories, such as antennas, before entering a

car wash.

•Suntan lotions and insect repellents can damage any painted

surface; if these substances come in contact with your vehicle,

wash off as soon as possible.

WAXING

Applying a polymer paint sealant to your vehicle every six months will

assist in reducing minor scratches and paint damage.

•Wash the vehicle first.

•Do not use waxes that contain abrasives.

•Do not allow paint sealant to come in contact with any non-body

(low-gloss black) colored trim, such as grained door handles, roof

racks, bumpers, side moldings, mirror housings or the windshield cowl

area. The paint sealant will“gray”or stain the parts over time.

2004 F650/750(f67)

Supplement

USA English(fus)

Cleaning

Cleaning

154

Page 156 of 264

PLASTIC (NON-PAINTED) EXTERIOR PARTS

Use only approved products to clean plastic parts. These products are

available from your dealer.

•For routine cleaning, use Motorcraft Detail Wash (ZC-3–A).

•If tar or grease spots are present, use Ford Extra Strength Tar and

Road Oil Removal (B7A-19520–AA).

INSTRUMENT PANEL AND CLUSTER LENS

Clean the instrument panel with a damp cloth, then dry with a dry cloth.

•Avoid cleaners or polish that increase the gloss of the upper portion of

the instrument panel. The dull finish in this area helps protect the

driver from undesirable windshield reflection.

•Be certain to wash or wipe your hands clean if you have been in

contact with certain products such as insect repellent and suntan

lotion in order to avoid possible damage to the painted surfaces.

INTERIOR TRIM

•Clean the interior trim areas with a damp cloth, then dry by wiping

with a dry, soft, clean cloth.

•Do not use household or glass cleaners as these may damage the

finish.

INTERIOR

For fabric, carpets, cloth seats and safety belts:

•Remove dust and loose dirt with a vacuum cleaner.

•Remove light stains and soil with Ford Extra Strength Upholstery

Cleaner (E8AZ-19523–AA).

•If grease or tar is present on the material, spot-clean the area first

with Motorcraft Spot and Stain Remover (ZC-14).

•Never saturate the seat covers with cleaning solution.

•Do not use household cleaning products or glass cleaners, which can

stain and discolor the fabric and affect the flame retardant abilities of

the seat materials.

Do not use cleaning solvents, bleach or dye on the vehicle’s seat

belts, as these actions may weaken the belt webbing.

2004 F650/750(f67)

Supplement

USA English(fus)

Cleaning

156