brake FORD F650 2004 11.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: F650, Model: FORD F650 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 142 of 264

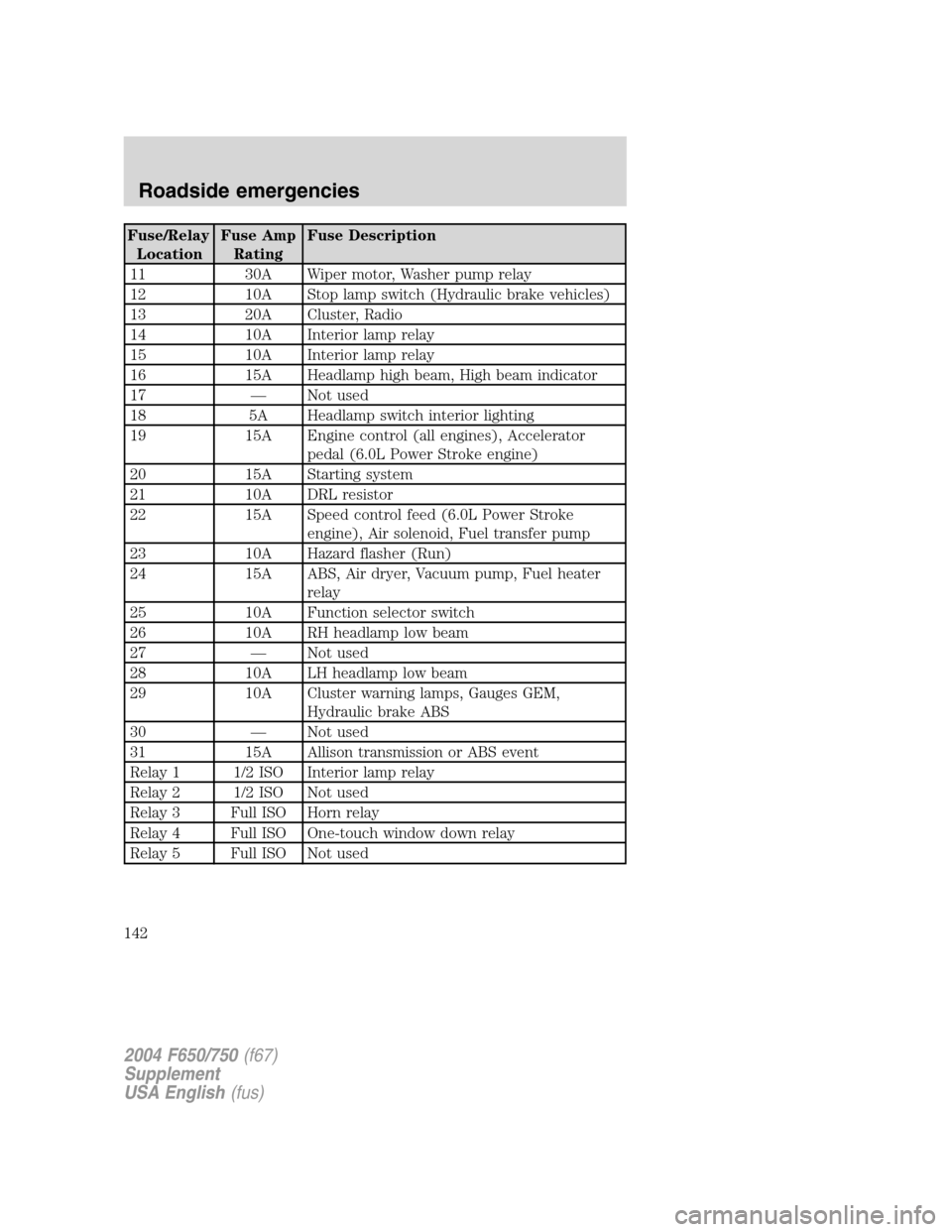

Fuse/Relay

LocationFuse Amp

RatingFuse Description

11 30A Wiper motor, Washer pump relay

12 10A Stop lamp switch (Hydraulic brake vehicles)

13 20A Cluster, Radio

14 10A Interior lamp relay

15 10A Interior lamp relay

16 15A Headlamp high beam, High beam indicator

17—Not used

18 5A Headlamp switch interior lighting

19 15A Engine control (all engines), Accelerator

pedal (6.0L Power Stroke engine)

20 15A Starting system

21 10A DRL resistor

22 15A Speed control feed (6.0L Power Stroke

engine), Air solenoid, Fuel transfer pump

23 10A Hazard flasher (Run)

24 15A ABS, Air dryer, Vacuum pump, Fuel heater

relay

25 10A Function selector switch

26 10A RH headlamp low beam

27—Not used

28 10A LH headlamp low beam

29 10A Cluster warning lamps, Gauges GEM,

Hydraulic brake ABS

30—Not used

31 15A Allison transmission or ABS event

Relay 1 1/2 ISO Interior lamp relay

Relay 2 1/2 ISO Not used

Relay 3 Full ISO Horn relay

Relay 4 Full ISO One-touch window down relay

Relay 5 Full ISO Not used

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

142

Page 146 of 264

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

WRECKER TOWING INSTRUCTIONS

Before moving the towed vehicle, check for adequate road clearance of

vehicle components. It is recommended the towed vehicle be unloaded

prior to being towed to reduce any abnormal load to the vehicle

components resulting from the towing procedures. Before towing, be

sure to fully release the parking brake. The spring-actuated type parking

brake can be reset by recharging the air system with at least 441 kPa (64

psi) of air. If the brake system will not retain air pressure, then the

spring brakes must be released manually. Refer toParking brakein the

Drivingchapter

Note:For towing, make sure the vehicle is securely connected to the

tow vehicle and the tow vehicle parking brakes are applied before

releasing the disabled vehicle’s spring brakes.

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

146

Page 147 of 264

To reduce the risk of personal injury or property damage when

manually releasing the spring brakes, be sure to block the wheels

so the vehicle cannot move once the brakes are released.

Towing the vehicle with the front wheels suspended

When it is necessary to tow a vehicle with the front wheels suspended,

extra precautions must be taken to avoid transmission or differential

damage. Proceed as follows:

•Remove the axle shafts from the axle assembly to prevent the wheels

from driving the differential and the transmission.

•The wheel hub ends must be covered to prevent loss of axle lubricant

and entrance of other contaminants. If the axle shafts are not

removed, removal of the propeller shafts is required.

Note:To avoid transmission damage, vehicles should not be towed even

a short distance without suspending rear wheels or removing the axle

shaft or propeller shaft.

Note:In the event the chassis is equipped with a tandem axle and the

vehicle is to be towed from the front, the forward rear axle may be

raised to clear the road surface and secured to the frame by chains or

U-bolts, allowing only the rear rear axle to contact the road surface. Axle

shafts must be removed from the rear rear axle assembly. The wheel hub

ends must be covered to prevent loss of axle lubricant and entrance of

contaminants. Use extreme care in securing the chains or U-bolts to

avoid possible damage to the brake lines, hoses or other components.

Towing vehicles equipped with a driver-controlled differential lock

Note:If the vehicle must be towed to a service facility with the drive

axle wheels on the ground, it is necessary to remove the axle shafts

before the vehicle is towed.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

147

Page 155 of 264

PAINT CHIPS

Your dealer has touch-up paint and sprays to match your vehicle’s color.

Take your color code (printed on a sticker in the driver’s door jam) to

your dealer to ensure you get the correct color.

•Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

•Always read the instructions before using the products.

ALUMINUM WHEELS AND COVERS

Aluminum wheel rims or covers are coated with a clearcoat paint finish.

In order to maintain their shine:

•Clean with Motorcraft Wheel and Tire Cleaner (ZC-37–A), which is

available from your dealer.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•To remove tar and grease, use Ford Extra Strength Tar and Road Oil

Removal (B7A-19520–AA), available from your dealer.

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

2004 F650/750(f67)

Supplement

USA English(fus)

Cleaning

155

Page 158 of 264

GENERAL SERVICING GUIDELINES AND PRECAUTIONS

As with any machine, care should be taken to avoid being injured when

performing maintenance, repairs or system checks. Improper or

incomplete service could result in the vehicle not working properly

which, in turn, may result in personal injury or damage to the vehicle or

equipment. It is the operator’s responsibility to see that the vehicle

receives proper care and maintenance. If you have any questions about

performing some service, have the service done by a qualified technician.

Servicing guidelines

When servicing your vehicle, always:

•turn off the ignition unless the particular procedure calls for the

engine to be running.

•set the parking brake or chock the wheels.

•use support stands, not a jack, whenever you must be under a raised

vehicle.

•do not smoke.

•wear safety glasses for eye protection.

•operate the engine in a well-ventilated area

•do not work on the brakes or the clutch unless the proper precautions

are taken to avoid inhaling friction material dust.

•do not wear loose-fitting clothing, hanging jewelry, watches or rings.

•avoid contact with hot metal parts. Allow the hot components to cool

before working with, or around them.

Quality service parts are available through your dealer. If dealer parts are

not used, the owner must make sure that the parts that are being used

are equivalent quality to dealer parts.

The use of inferior parts can adversely affect the quality and

reliability of your vehicle which, in turn, can result in property

damage, personal injury or death.

Note:To avoid damage to the vehicle’s electrical components, disconnect

the positive (+) and negative (-) battery cables prior to electric welding.

Attach the welder ground cable as close as possible to the part being

welded. If it is necessary to weld close to an electrical component, it is

recommended that the electronic component be temporarily removed.

Follow the periodic lubrication procedures and regular inspection

intervals as outlined. Have your dealer or service center inspect your

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

Maintenance and specifications

158

Page 159 of 264

vehicle at least once a year. Remember that regular maintenance and

replacement of worn components will usually prevent serious problems

from developing later.

Making modifications to various parts, components and systems

of the vehicle, such as brake and steering systems can adversely

affect the quality, reliability and operation of your vehicle and could

result in property damage, personal injury or death. Such modifications

must be avoided.

The lubrication intervals present a good opportunity to inspect the

vehicle. It is suggested that the various points listed herein be checked

at the lubrication or other recommended intervals.

Failure to properly perform maintenance and servicing

procedures could result in vehicle damage, personal injury or

death.

If the owner/operator of the vehicle is a skilled technician and intends on

performing the vehicle maintenance and service, he is strongly urged to

purchase a service manual.

Take care when performing any maintenance, system check or

service on your vehicle. Some of the materials may also be

hazardous if used, serviced or handled improperly and could result in

property damage, personal injury or death.

Air conditioning system checks

Have your air conditioning system checked each spring. The refrigerant

charge, cleanliness of the condenser-evaporator cores and belt condition

is essential to air conditioning performance.

When the air conditioning system is being used daily, remove the fresh

air filter (if equipped) once each season and check for dirt, lint, etc.

Replace the filter if necessary. Vehicles operating in unusually dusty

conditions may require inspecting and replacing the fresh air filter more

often.

Front axle - general service information

Maintaining the front axle alignment to specifications is very important

and should only be performed by a qualified technician. Toe-in

adjustment is particularly important with radial tires.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

159

Page 160 of 264

Check to make sure that the axle mounting U-bolt nuts, attaching or

mounting bolts and nuts are securely tightened. Regularly check front

axle for damage, binding, worn parts and adequate lubrication.

At regular intervals, or during other scheduled maintenance, (tire

rotation/service, wheel bearing service, alignment, etc.) the kingpins

should be checked for excessive wear. Refer to the service manual for

proper procedures.

Toe-in setting - general inspection

Inspecting steer axle tires in the first 4,800–16,000 service km

(3,000–10,000 service miles) will generally show if tires are wearing

normally.

Rapid outside shoulder wear on both tires indicates too much toe-in.

Rapid inside shoulder wear on both tires indicates too much toe-out. In

P&D-type service, which includes school buses, left-to-right steer tire

tread life differentials up to 40% can be observed depending on routes

and other variables.

Follow the tire manufacturer’s recommended cold inflation pressure for

the tire size, load range (ply rating) and steer axle loading typical for

their operation (each steer axle tire will equal

1⁄2steer axle loading).

Special applications may warrant a setting based on past experience with

the type of tire operating loads and conditions. Radial tires are more

sensitive to toe-in setting than bias ply tires. While not insensitive to

vehicle alignment, fine tuning school bus alignment to line-haul truck

standards will not drastically improve tire tread life.

It is essential that correct toe-in and tire pressure be maintained for

optimum tire wear.

Rear axle - general inspection

Check to make sure that the axle mounting U-bolts, attaching or

mounting bolts and nuts are securely tightened. Refer toU-bolt nut

torque chartin this chapter. Regularly check the rear axle for damaged,

binding or worn parts.

NoSpin Detroit Locker positive locking differential

Vehicle equipped with this type differential have the operator’s manual

supplied with the vehicle. Refer to this manual for maintenance checks.

Brake system - general inspection

Your vehicle is equipped with non-asbestos brake linings. However,

exposure to excessive amounts of brake material (whether asbestos or

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

160

Page 161 of 264

non-asbestos, fiberglass, mineral wool, aramid or carbon) may be a

potentially serious health hazard.

Avoid breathing brake lining fiber dust as it may be extremely

hazardous to your health. Always use of respirator during brake

maintenance.

Note:Persons handling brake linings should follow all precautions listed

below:

1. Always wear a respirator approved by the National Institute of

Occupational Studies of Health (NIOSH) or Mine Safety and Appliance

(MSA) during all brake service procedures. Wear the respirator from

removal of the wheels through assembly.

2.Neveruse compressed air or dry brushing to clean brake parts or

assemblies.

3. Clean brake parts and assemblies in open air. During assembly,

carefully place all parts on the floor to avoid getting dust in the air. Use

an industrial vacuum cleaner with a HEPA filter system to clean dust

from the brake drums, backing plates and other brake parts. After using

the vacuum, remove any remaining dust with a rag soaked in water and

wrung until nearly dry.

4.Neveruse compressed air or dry sweeping to clean the work area.

Use an industrial vacuum cleaner with a HEPA filter system and rags

soaked in water until wrung until nearly dry. Dispose of used rags with

care to avoid getting dust in the air. Use an approved respirator when

emptying vacuum cleaners and handling used rags.

5.Worker clean-up:Wash your hands before eating, drinking or

smoking. Vacuum your work clothes after use and then launder them

separately, without shaking them, to prevent fiber dust getting into the

air.

Air brakes - inspection and adjustment

A regular schedule for periodic cleaning, lubrication, adjustment and

inspection should be established based on the type of vehicle operation.

It is difficult to predetermine an exact maintenance interval (time or

mileage), since vehicles will be used in a wide variety of applications and

conditions. If you are uncertain of the proper schedule and procedures

for your vehicle, contact your dealer.

Periodic checking of push rod travel or brake adjustment is essential for

effective braking. Push rod travel should be checked every service

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

161

Page 162 of 264

interval to determine if adjustment is necessary. Brake chamber push

rods on original equipment chambers now incorporate a stroke indicator

to aid in adjustment checks; an orange paint marker near the base of the

push rod. If the push rod is clean and the brakes require adjustment, the

orange marker can be seen protruding from the chamber when the

brakes are applied.

Slack adjusters should also be checked to ensure proper operation of the

adjuster mechanism at the six-month interval. Push rod travel should be

kept at a minimum without the brakes dragging.

Inspect the brake lining every maintenance interval. When brake lining or

blocks are worn to within 1.6 mm (1/16 in.) of rivets, brake lining must

be replaced. This inspection or adjustment should only be performed by

a qualified technician and must be in accordance with instructions

provided by the service manual.

Do not back off or disconnect the front brakes so that they are less

effective, letting the rear brakes do all the stopping of the vehicle. Do

not overlook the brakes on the trailer, either. Brake condition on the

trailer is just as important as the tractor. Proper brake balance on trucks

and tractor-trailers is essential for effective braking.

Once a year, the entire brake system must be inspected. Check the

following:

•Any rubber as it may deteriorate whenever used. Rubber brake

components should be inspected by a qualified technician and

replaced as necessary. Replacement intervals vary according to the

severity and length of vehicle service.

•Condition of brake drums, brake chambers and slack adjusters.

•System for air leaks.

•Hose or pipes for rust, damage and deterioration.

•Operation of service and parking brakes.

Some parts such as air brake chamber diaphragm, air compressor and air

cleaner should be inspected periodically and replaced if considered

unserviceable.

Air brakes - air dryer

Performance of desiccant or after-cooler type air dryers is dependent on

climatic conditions in which your vehicle is operating. Maintenance

schedules must be establishes for each specific operation.

The use of an air dryer on a vehicle does not eliminate the need to

periodically drain the air reservoirs.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

162

Page 163 of 264

Air brakes - desiccant air dryer

Inspect for moisture in the air system by opening reservoirs, drain cocks

or valves and checking for presence of water. The presence of small

amounts of water due to condensation is normal and should not be

considered as an indication that the dryer is not functioning properly.

The desiccant cartridge should be replaced or rebuilt when it has been

determined that the desiccant is contaminated and does not have

adequate water absorption capacity. The desiccant change interval may

vary; it is generally recommended that the desiccant be replaced every

12 months (yearly). If experience has shown that extended or shortened

life has resulted for a particular installation, then the yearly interval can

be increased or decreased accordingly.

Hydraulic brakes - general inspection and adjustment

A regular schedule for periodic cleaning, lubrication, adjustment and

inspection should be established based on the type of vehicle operation.

It is difficult to predetermine an exact maintenance interval (time or

mileage), since vehicles will be used in a wide variety of applications and

conditions. If you are uncertain of the proper schedule and procedures

for your vehicle, contact your dealer.

Inspect the brake lining every maintenance interval. Establish inspection

intervals that provide for lining replacement before damage to the disc

occurs. Excessive lining wear may expose the backing plate to the disc

causing scoring of the disc faces.

This inspection should be performed by a qualified technician and must

be in accordance with instructions provided by the service manual.

Note:Hydraulic brake system are power assisted. Braking capabilities

will be greatly reduced without engine assist.

Hydraulic brakes - fluid level

Fluid level should be at the bottom edge of the ring on each reservoir fill

port. Do not fill the master cylinder to the top of the reservoir.

Note:If brake fluid requires attention to maintain a proper master

cylinder level, this is an indication of either severe operation (pad wear)

or fluid system leakage. A more frequent and thorough brake inspection

will be required.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

163