brake FORD F650 2004 11.G Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: F650, Model: FORD F650 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 198 of 264

PROPELLER SHAFT

At the regular lubrication interval, check the universal joints for any

evidence of wear or looseness. Should propeller shaft vibrations occur,

stop the vehicle immediately to avoid possible hazardous consequences

or damage to other components.

REAR AXLE LUBRICANT

Refer to your general maintenance information section for rear axle

lubricant level checks and lubricant change intervals.

Your rear axle may be filled with an optional synthetic lubricant which

allows the use of extended service intervals. A tag on the filler plug will

identify the use of the synthetic lubricant.

Use only a lubricant that meets manufacturer specifications (refer to

Lubricant specificationsin this chapter).

Use of a non-approved rear axle lubricant may cause internal axle

component damage.

Check your rear axle lubricant level using the following procedure:

1. Park the vehicle on level ground.

2. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission) and turn the engine off.

3. Clean any dirt from around the rear axle filler plug.

4. Remove the filler plug and inspect the lubricant level.

5. The lubricant level should be up to the bottom of the filler plug

opening.

6. If necessary, add enough lubricant through the filler plug opening so

that the lubricant level is at the bottom of the opening.

7. Clean and install the filler plug securely.

Drain and refill your rear axle lubricant using the following procedure:

1. Drain the rear axle while the lubricant is warm.

2. Park the vehicle on level ground.

3. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission) and turn the engine off.

4. Clean any dirt from around the rear axle filler and drain plugs.

5. Remove the filler and drain plugs and drain the lubricant into a

suitable container. Dispose all used automotive fluids in a responsible

manner following your local authorized standards.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

198

Page 201 of 264

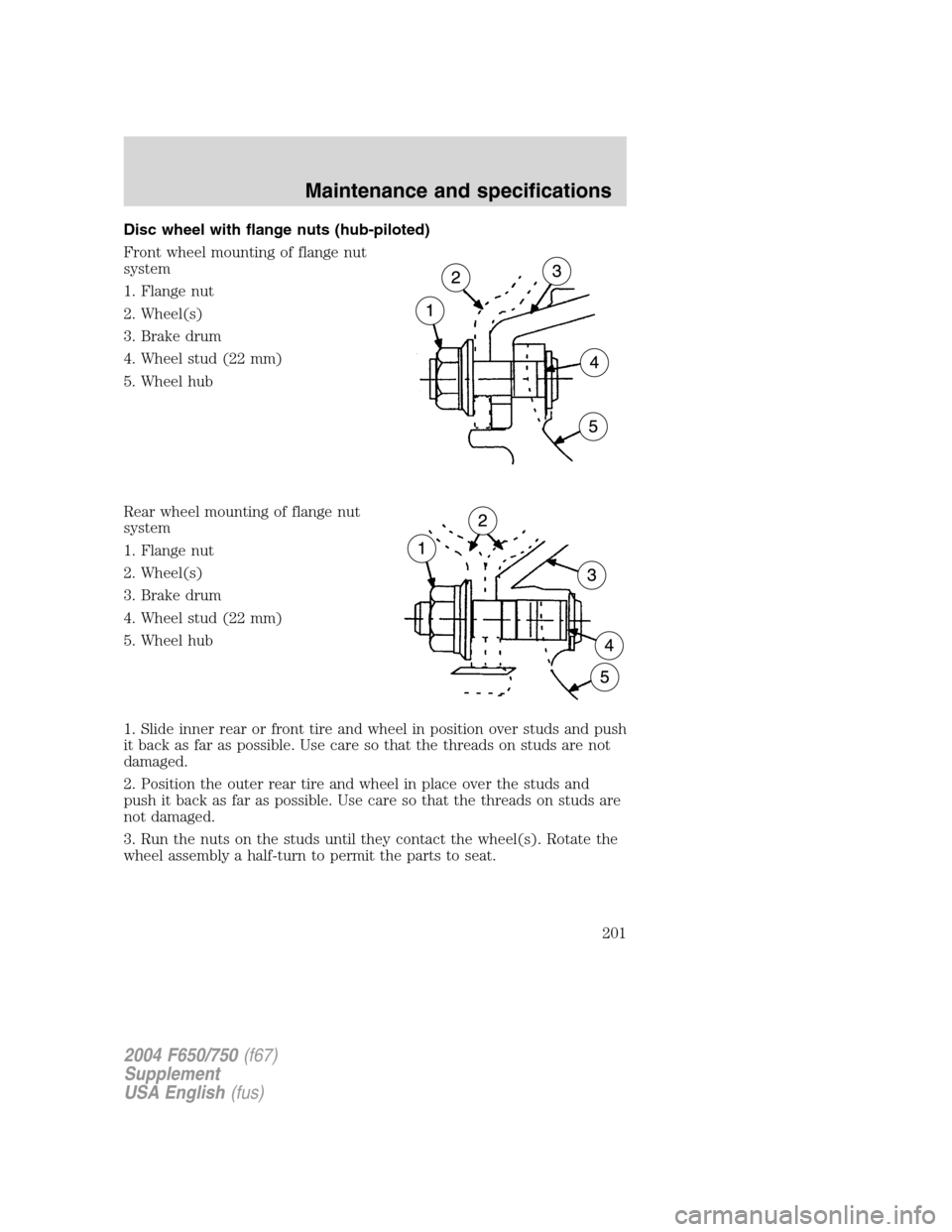

Disc wheel with flange nuts (hub-piloted)

Front wheel mounting of flange nut

system

1. Flange nut

2. Wheel(s)

3. Brake drum

4. Wheel stud (22 mm)

5. Wheel hub

Rear wheel mounting of flange nut

system

1. Flange nut

2. Wheel(s)

3. Brake drum

4. Wheel stud (22 mm)

5. Wheel hub

1. Slide inner rear or front tire and wheel in position over studs and push

it back as far as possible. Use care so that the threads on studs are not

damaged.

2. Position the outer rear tire and wheel in place over the studs and

push it back as far as possible. Use care so that the threads on studs are

not damaged.

3. Run the nuts on the studs until they contact the wheel(s). Rotate the

wheel assembly a half-turn to permit the parts to seat.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

201

Page 202 of 264

4. Draw up the nuts alternately following the crisscross sequence

illustrated underInstallation, tightening and alignment. Do not fully

tighten the nuts. This will allow uniform seating of the nuts and assure

even face-to-face contact of the wheel and hub.

5. Continue tightening the nuts to the torque specifications in the torque

chart using the same crisscross sequence shown.

6. After operating the vehicle approximately 80 km (50 miles), check the

nuts for tightness. Some natural seating of parts may be encountered

and the torque on the nuts will drop. Retighten all nuts to specifications.

Once a week, inspect and retighten the wheel stud nuts.

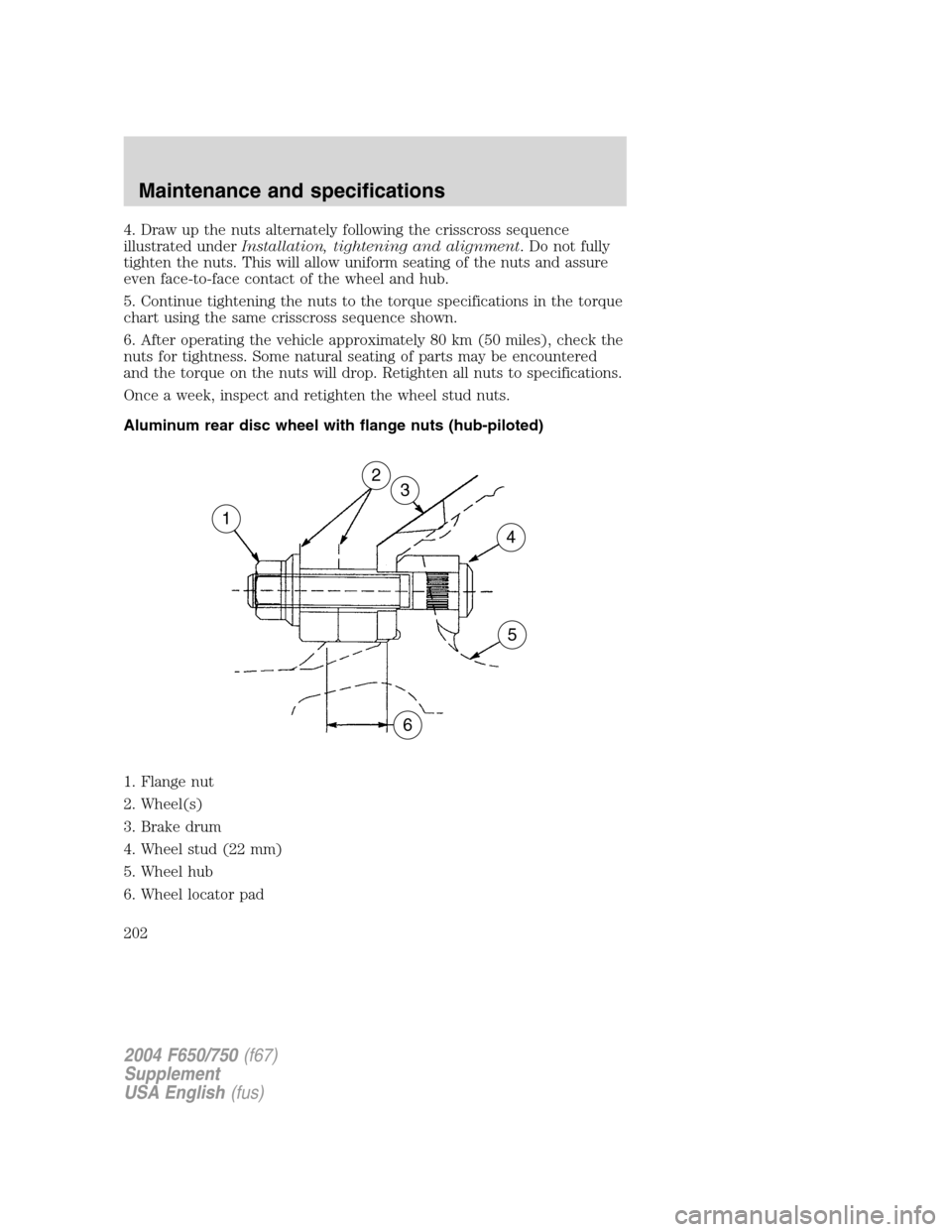

Aluminum rear disc wheel with flange nuts (hub-piloted)

1. Flange nut

2. Wheel(s)

3. Brake drum

4. Wheel stud (22 mm)

5. Wheel hub

6. Wheel locator pad

1

6

5

4

32

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

202

Page 203 of 264

Prior to re-installing rear aluminum hub-piloted wheels, clean each wheel

locator pad on the hub from all dirt, rust and foreign material. Apply a

light coat of chassis grease, never-seize or disc brake corrosion control

grease, only to the wheel locator pad.

When installing the tire and rim assembly on disc-brake equipped axles,

make sure the tire valve stem clears the brake caliper. The use of a tire

manufacturer’s stem forming tool is the only acceptable method of

obtaining clearance when necessary.

Note:Always observe the following instructions:

•Always loosen rim clamps before complete removal of nut from stud

(cast spoke wheels). With loosened nuts on stud, strike clamps with a

heavy hammer and be sure each clamp is loose.

•Always deflate tires completely before removing locks or side rings.

•Always inflate tires in a safety cage.

•Never mix rim side rings or lock rings of different types,

manufacturers or sizes.

•Never use cracked, bent or badly rusted parts.

•Never re-inflate flat tires on-vehicle; use the spare tire.

•Never add air until each side ring or lock ring is fully seated.

•Never hammer side ring or lock ring on a partially- or fully-inflated

tire.

Failure to follow these instructions could result in property

damage, personal injury or death

Proper torque

It is important to tighten and maintain wheel and rim mounting nuts to

the proper torque. Loose nuts or over-tightened nuts can lead to

premature wear and possible failure of the wheel and/or mounting

hardware.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

203

Page 216 of 264

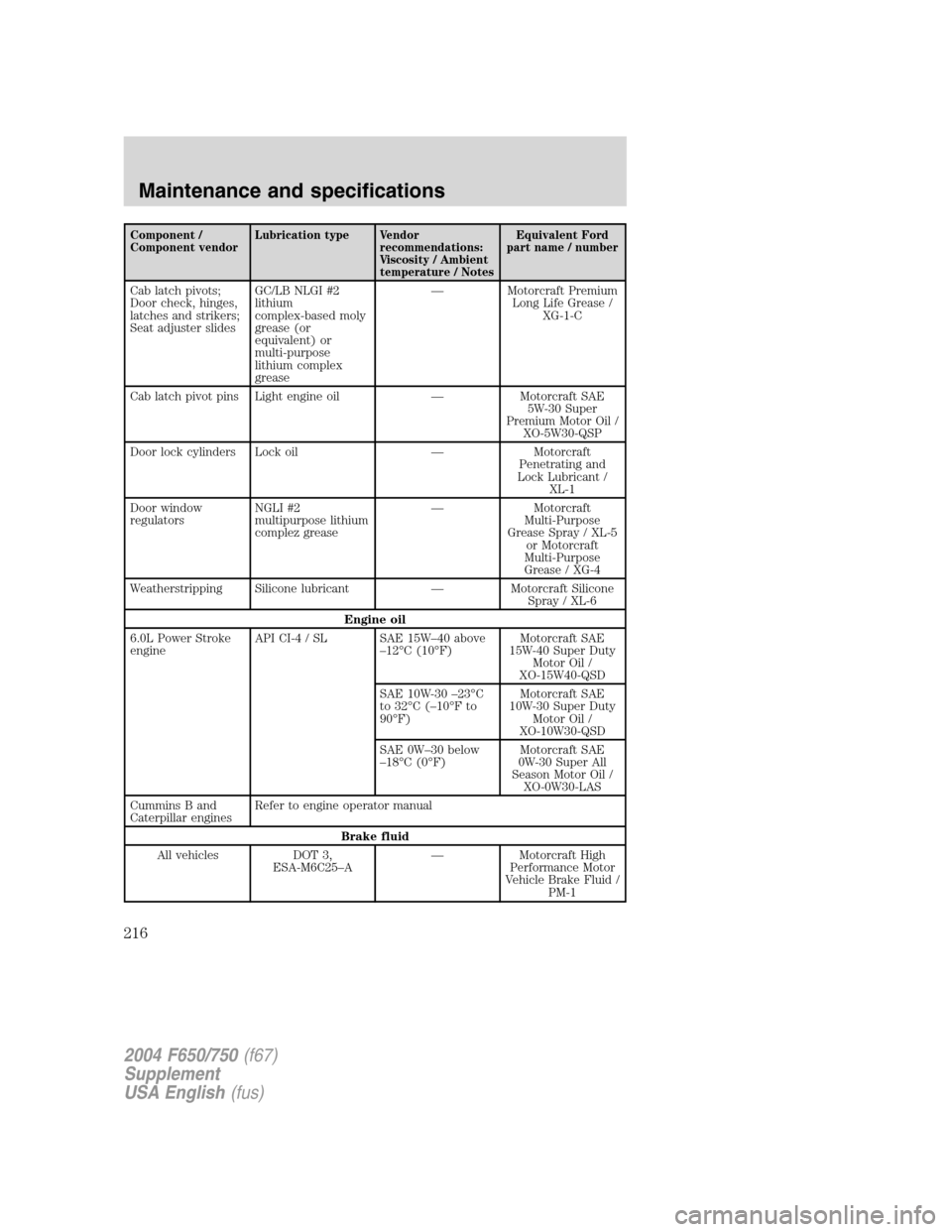

Component /

Component vendorLubrication type Vendor

recommendations:

Viscosity / Ambient

temperature / NotesEquivalent Ford

part name / number

Cab latch pivots;

Door check, hinges,

latches and strikers;

Seat adjuster slidesGC/LB NLGI #2

lithium

complex-based moly

grease (or

equivalent) or

multi-purpose

lithium complex

grease—Motorcraft Premium

Long Life Grease /

XG-1-C

Cab latch pivot pins Light engine oil—Motorcraft SAE

5W-30 Super

Premium Motor Oil /

XO-5W30-QSP

Door lock cylinders Lock oil—Motorcraft

Penetrating and

Lock Lubricant /

XL-1

Door window

regulatorsNGLI #2

multipurpose lithium

complez grease—Motorcraft

Multi-Purpose

Grease Spray / XL-5

or Motorcraft

Multi-Purpose

Grease / XG-4

Weatherstripping Silicone lubricant—Motorcraft Silicone

Spray / XL-6

Engine oil

6.0L Power Stroke

engineAPI CI-4 / SL SAE 15W–40 above

–12°C (10°F)Motorcraft SAE

15W-40 Super Duty

Motor Oil /

XO-15W40-QSD

SAE 10W-30–23°C

to 32°C(–10°Fto

90°F)Motorcraft SAE

10W-30 Super Duty

Motor Oil /

XO-10W30-QSD

SAE 0W–30 below

–18°C(0°F)Motorcraft SAE

0W-30 Super All

Season Motor Oil /

XO-0W30-LAS

Cummins B and

Caterpillar enginesRefer to engine operator manual

Brake fluid

All vehicles DOT 3,

ESA-M6C25–A—Motorcraft High

Performance Motor

Vehicle Brake Fluid /

PM-1

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

216

Page 227 of 264

AIR BRAKE ADJUSTMENT

Failure to maintain proper air brake adjustment can result in

reduction or loss of braking ability.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the Ford Truck

Service Manual.

Cam brakes - automatic slack adjusters

Inspect standard air brakes equipped with automatic slack adjusters for

proper brake adjustment every four months or 32,000 km (20,000 miles)

whichever occurs first.

However, more frequent inspection is required if your vehicle’s brakes

are subjected to heavy use or adverse operating conditions such as:

•Frequent brake applications while fully loaded.

•Operation on hilly or mountainous terrain.

•Frequent operation on dirt, gravel or mud.

Some aftermarket brake linings also require more frequent inspections.

2004 F650/750(f67)

Supplement

USA English(fus)

General maintenance information

227

Page 229 of 264

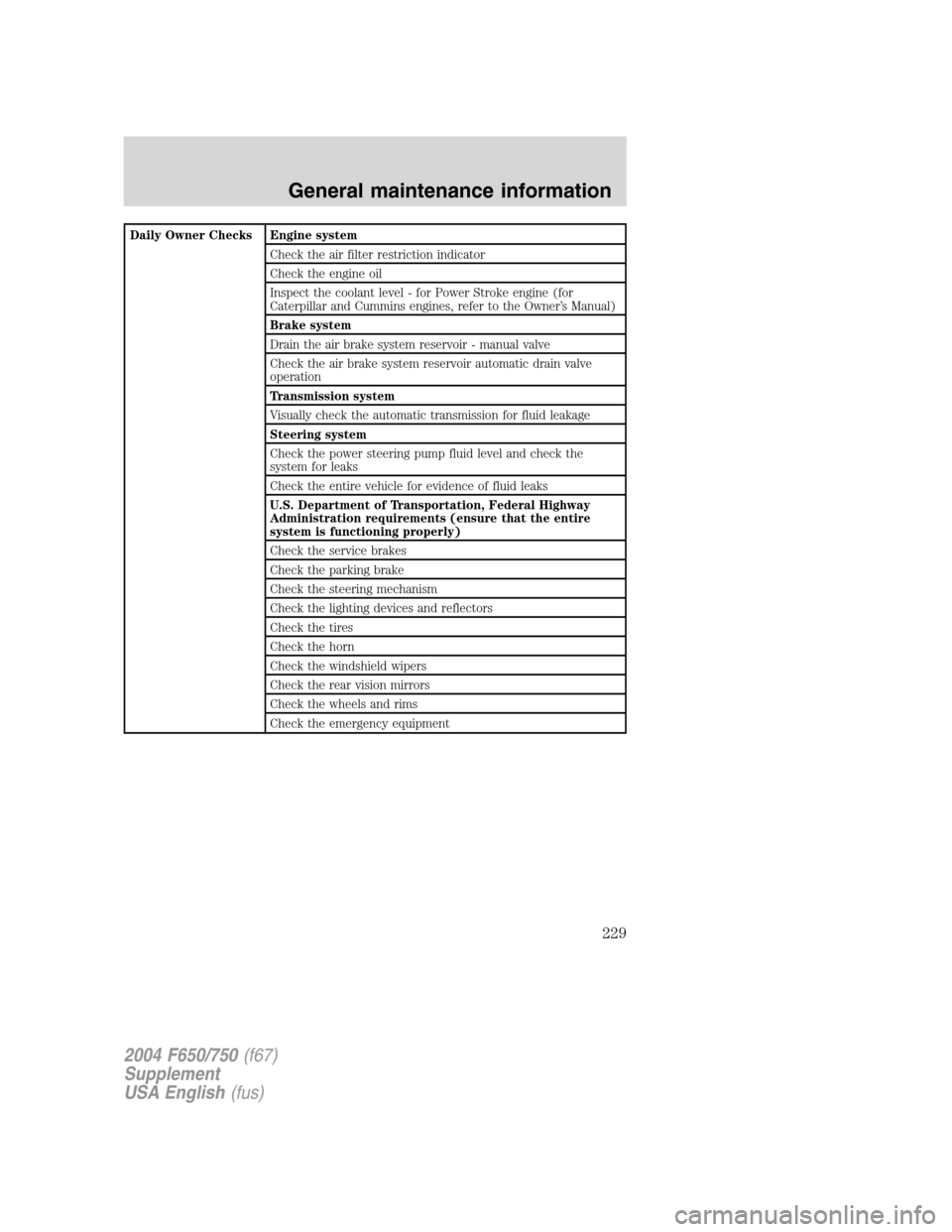

Daily Owner Checks Engine system

Check the air filter restriction indicator

Check the engine oil

Inspect the coolant level - for Power Stroke engine (for

Caterpillar and Cummins engines, refer to the Owner’s Manual)

Brake system

Drain the air brake system reservoir - manual valve

Check the air brake system reservoir automatic drain valve

operation

Transmission system

Visually check the automatic transmission for fluid leakage

Steering system

Check the power steering pump fluid level and check the

system for leaks

Check the entire vehicle for evidence of fluid leaks

U.S. Department of Transportation, Federal Highway

Administration requirements (ensure that the entire

system is functioning properly)

Check the service brakes

Check the parking brake

Check the steering mechanism

Check the lighting devices and reflectors

Check the tires

Check the horn

Check the windshield wipers

Check the rear vision mirrors

Check the wheels and rims

Check the emergency equipment

2004 F650/750(f67)

Supplement

USA English(fus)

General maintenance information

229

Page 230 of 264

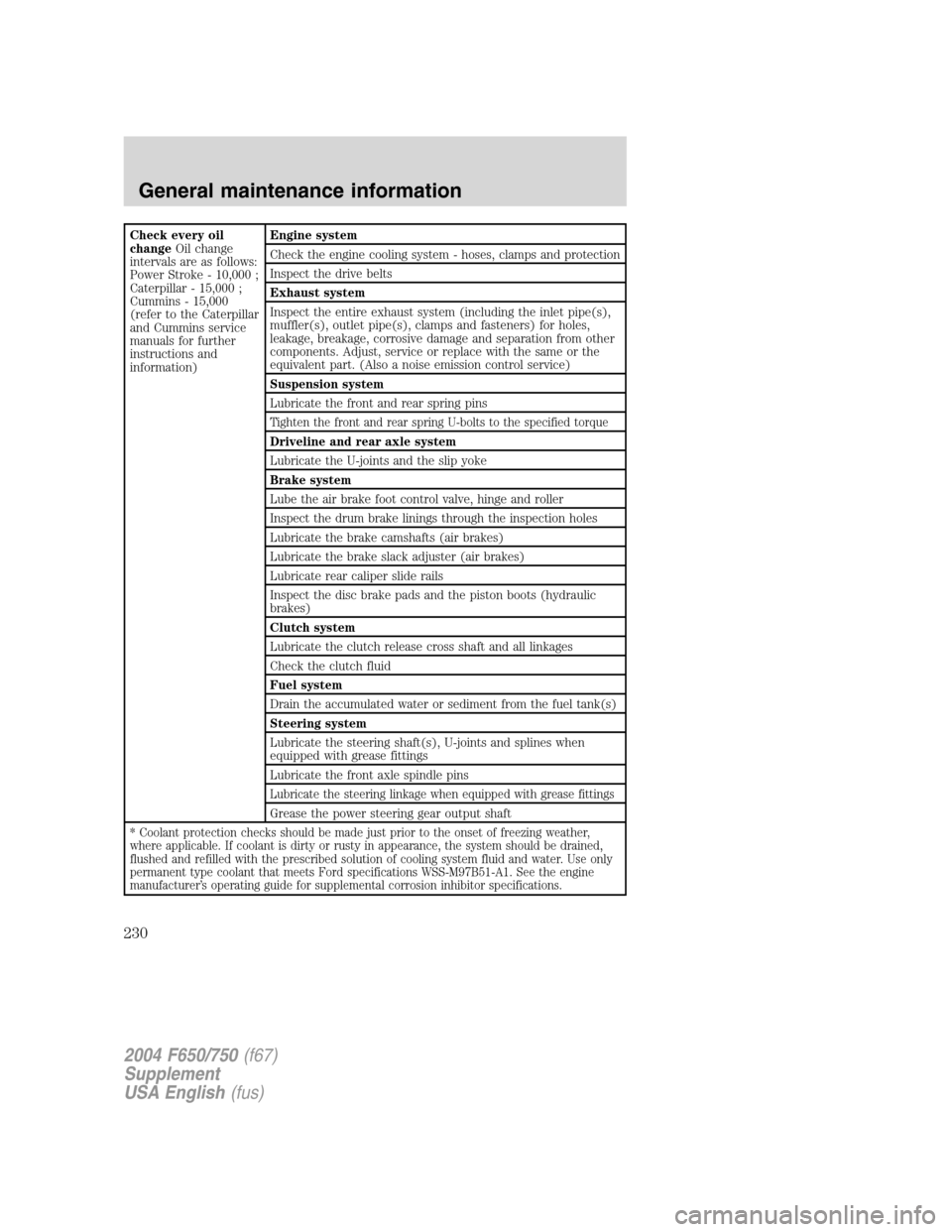

Check every oil

changeOil change

intervals are as follows:

Power Stroke - 10,000 ;

Caterpillar - 15,000 ;

Cummins - 15,000

(refer to the Caterpillar

and Cummins service

manuals for further

instructions and

information)Engine system

Check the engine cooling system - hoses, clamps and protection

Inspect the drive belts

Exhaust system

Inspect the entire exhaust system (including the inlet pipe(s),

muffler(s), outlet pipe(s), clamps and fasteners) for holes,

leakage, breakage, corrosive damage and separation from other

components. Adjust, service or replace with the same or the

equivalent part. (Also a noise emission control service)

Suspension system

Lubricate the front and rear spring pins

Tighten the front and rear spring U-bolts to the specified torque

Driveline and rear axle system

Lubricate the U-joints and the slip yoke

Brake system

Lube the air brake foot control valve, hinge and roller

Inspect the drum brake linings through the inspection holes

Lubricate the brake camshafts (air brakes)

Lubricate the brake slack adjuster (air brakes)

Lubricate rear caliper slide rails

Inspect the disc brake pads and the piston boots (hydraulic

brakes)

Clutch system

Lubricate the clutch release cross shaft and all linkages

Check the clutch fluid

Fuel system

Drain the accumulated water or sediment from the fuel tank(s)

Steering system

Lubricate the steering shaft(s), U-joints and splines when

equipped with grease fittings

Lubricate the front axle spindle pins

Lubricate the steering linkage when equipped with grease fittings

Grease the power steering gear output shaft

* Coolant protection checks should be made just prior to the onset of freezing weather,

where applicable. If coolant is dirty or rusty in appearance, the system should be drained,

flushed and refilled with the prescribed solution of cooling system fluid and water. Use only

permanent type coolant that meets Ford specifications WSS-M97B51-A1. See the engine

manufacturer’s operating guide for supplemental corrosion inhibitor specifications.

2004 F650/750(f67)

Supplement

USA English(fus)

General maintenance information

230

Page 232 of 264

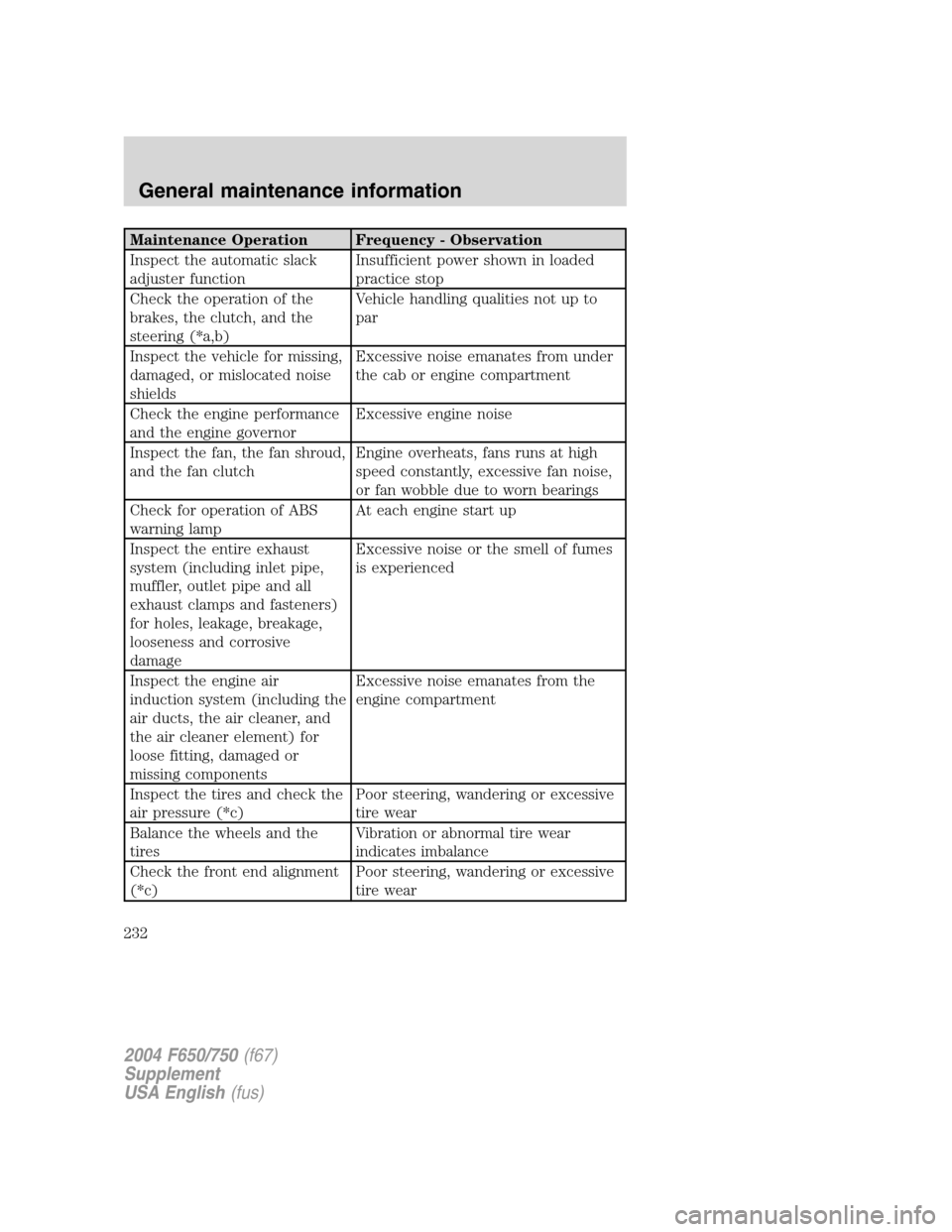

Maintenance Operation Frequency - Observation

Inspect the automatic slack

adjuster functionInsufficient power shown in loaded

practice stop

Check the operation of the

brakes, the clutch, and the

steering (*a,b)Vehicle handling qualities not up to

par

Inspect the vehicle for missing,

damaged, or mislocated noise

shieldsExcessive noise emanates from under

the cab or engine compartment

Check the engine performance

and the engine governorExcessive engine noise

Inspect the fan, the fan shroud,

and the fan clutchEngine overheats, fans runs at high

speed constantly, excessive fan noise,

or fan wobble due to worn bearings

Check for operation of ABS

warning lampAt each engine start up

Inspect the entire exhaust

system (including inlet pipe,

muffler, outlet pipe and all

exhaust clamps and fasteners)

for holes, leakage, breakage,

looseness and corrosive

damageExcessive noise or the smell of fumes

is experienced

Inspect the engine air

induction system (including the

air ducts, the air cleaner, and

the air cleaner element) for

loose fitting, damaged or

missing componentsExcessive noise emanates from the

engine compartment

Inspect the tires and check the

air pressure (*c)Poor steering, wandering or excessive

tire wear

Balance the wheels and the

tiresVibration or abnormal tire wear

indicates imbalance

Check the front end alignment

(*c)Poor steering, wandering or excessive

tire wear

2004 F650/750(f67)

Supplement

USA English(fus)

General maintenance information

232

Page 233 of 264

Maintenance Operation Frequency - Observation

Check the transmission and

engine mountings (*b)Hard shifting or excessive vibration

Check and adjust transmission

controls (*b)High effort to shift or noisy

transmission

Check fuel pump pressure Insufficient full-throttle power or

backfiring

Clean radiator cap seal. Clean

and inspect the cap surface on

the radiatorWhen the cap does not hold pressure

Check the battery terminals for

corrosionWhenever electrical power supply has

diminished

Tighten the wheel mounting

nuts to the specified torque.

Refer toServicing your

wheels and tiresRequired initially at 800 and 1,600 km

(500 and 1,000 miles). Perform again

at 800 and 1,600 km (500 and 1,000

mile) intervals after each tire

removal/replacement.

*a During maintenance and repair, protect the fuel tube and the hose

assemblies, the power steering lines, and the brake lines from the

external heat, the acids and the abrasion that could damage the lines.

*b Check for (free) linkage action and ensure that (return) spring

force is adequate to maintain pedal free play.

*c Adjust, repair or replace as required with the same or equivalent

parts.

2004 F650/750(f67)

Supplement

USA English(fus)

General maintenance information

233