check engine FORD F650 2005 11.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2005, Model line: F650, Model: FORD F650 2005 11.GPages: 272, PDF Size: 1.5 MB

Page 25 of 272

Do not drain water separator while engine is running. Fuel may

ignite if separator is drained while engine is running or vehicle is

moving.

Traction control (if equipped):

Illuminates when the traction

control system is turned off.

Differential lock (if equipped):

Illuminates when the main

differential is locked (engaged).

Turn signal:Illuminates when the

left or right turn signal or the

hazard lights are turned on. If the

indicators stay on or flash faster, check for a burned out bulb.

High beams:Illuminates when the

high beam headlamps are turned on.

Key-in-ignition warning chime:Sounds when the key is left in the

ignition in the OFF/LOCK or ACC position and the driver’s door is

opened.

Headlamps on warning chime:Sounds when the headlamps or parking

lamps are on, the ignition is off (and the key is not in the ignition) and

the driver’s door is opened.

Instrumentation

25

Page 28 of 272

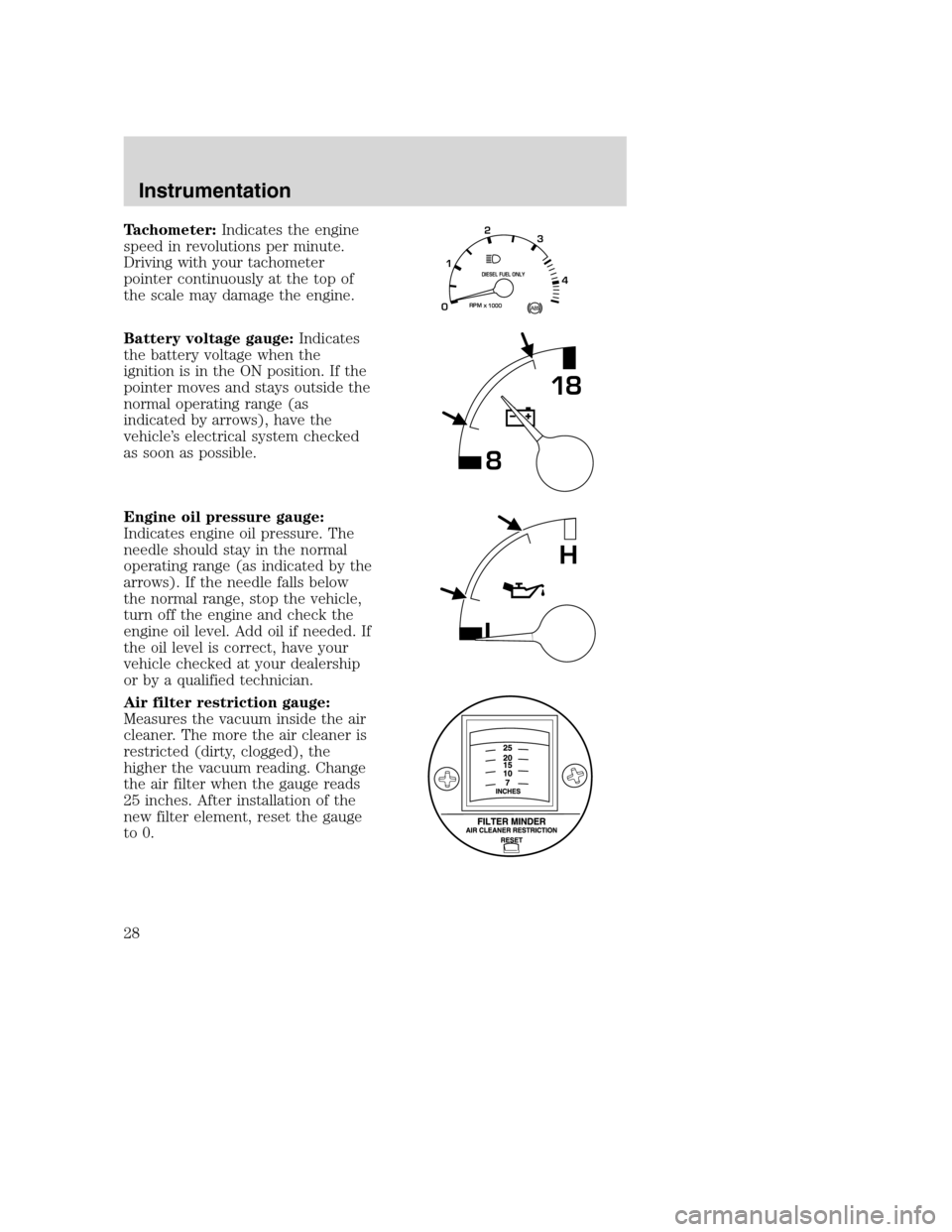

Tachometer:Indicates the engine

speed in revolutions per minute.

Driving with your tachometer

pointer continuously at the top of

the scale may damage the engine.

Battery voltage gauge:Indicates

the battery voltage when the

ignition is in the ON position. If the

pointer moves and stays outside the

normal operating range (as

indicated by arrows), have the

vehicle’s electrical system checked

as soon as possible.

Engine oil pressure gauge:

Indicates engine oil pressure. The

needle should stay in the normal

operating range (as indicated by the

arrows). If the needle falls below

the normal range, stop the vehicle,

turn off the engine and check the

engine oil level. Add oil if needed. If

the oil level is correct, have your

vehicle checked at your dealership

or by a qualified technician.

Air filter restriction gauge:

Measures the vacuum inside the air

cleaner. The more the air cleaner is

restricted (dirty, clogged), the

higher the vacuum reading. Change

the air filter when the gauge reads

25 inches. After installation of the

new filter element, reset the gauge

to 0.

RPM1000

DIESEL FUEL ONLY

X012

3

4

818

L

H

Instrumentation

28

Page 88 of 272

After the engine starts:

•On some engines, the WAIT TO

START light should illuminate

after the engine starts. Allow the

engine to idle about three

minutes or until the engine

coolant temperature gauge begins to rise. Maintain idle speed until the

WAIT TO START light cycles off to indicate the air intake heater has

shut off (approximately six minutes). Operating the engine at higher

speeds will reduce the effectiveness of the air inlet heater.

•Do not increase engine speed

until the oil pressure gauge

indicates normal pressure.

•Ensure engine oil pressure is

indicated on the gauge within 15

seconds after starting.

•Idle the engine for three to five

minutes before operating with a

full load.

•Try to limit engine idle to 10 minutes. Excessive idling reduces fuel

economy.

•When starting a cold engine, increase the engine speed (RPM) slowly

to make sure adequate lubrication is available to the bearings.

Restarting after running out of fuel

The fuel system may need to be purged of air, refer toRunning out of

fuelin theMaintenance and specificationschapter.

Cold weather operation

Do not use volatile starting aids such as ether, propane or

gasoline in the engine air intake system. Glow plugs may ignite

vapors which can cause engine damage or personal injury.

In order to operate the engine in temperatures of 32°F(0°C) or lower,

read the following instructions:

•Make sure that the batteries are of sufficient size and are fully

charged. Check other electrical components to make sure they’re in

optimum condition.

•Use a permanent-type engine coolant solution to protect the engine

against damage from freezing.

WAIT

TO

START

L

H

Driving

88

Page 92 of 272

Backing up

To reduce the risk of the possibility of personal injury while

backing the vehicle, always be sure your vehicle’s path is clear.

Before backing your vehicle, be sure you can do so safely. If anything

behind the cab limits your view, do not rely on mirrors alone to assure

that your intended path is clear. If other people are in the vicinity, have

someone standing well behind your vehicle and outside of your intended

path (visible through an exterior mirror) guide you as you back up.

Although OSHA or some governmental regulations may require the use

of an electrical or mechanical back-up alarm to warn bystanders, such an

alarm does not assure that the intended path is clear. When in doubt, get

out of the vehicle and visually check the intended path is clear; back-up

slowly as to allow others time to move, if necessary.

If an electrical back-up alarm is installed, it should be connected to the

back-up lamp circuit.

Parking your vehicle

Always use the parking brake. When parking on a grade, block the

wheels and turn the front wheels to one side so that if the vehicle rolls,

the front tires will act against the curb to stop the vehicle. The front

wheels will be more effective at stopping a rolling vehicle than the rear

wheels.

When parking your vehicle, do not leave the transmission in

gear; if the key is in the ON position and the vehicle rolls, the

engine could start. Failure to follow these instructions could result in

an unattended vehicle moving, possibly causing personal injury or

property damage.

Driving through water

If driving through deep or standing water is unavoidable, proceed very

slowly especially if the depth is not known. Never drive through water

that is higher than the bottom of the hubs (for trucks) or the bottom of

the wheel rims (for cars). Traction or brake capability may be limited

and your vehicle may stall. Water may also enter your engine’s air intake

and severely damage your engine, drive axles or the transmisison

(through the breather ports).

Once through the water, always dry the brakes by moving your vehicle

slowly while applying light pressure on the brake pedal. Wet brakes do

not stop the vehicle as quickly as dry brakes.

Driving

92

Page 93 of 272

HYDRAULIC BRAKES (IF EQUIPPED)

Your service brakes are self-adjusting. Refer to theGeneral

Maintenance Informationfor scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle’s brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a“metal-to-metal,”“continuous grinding”or

“continuous squeal”sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

If you are driving down a long or steep hill, shift to a lower gear.

Do not apply your brakes continuously, as they may overheat

and become less effective.

Note:Normally, choose the same gear to descend the hill that you would

use to ascend the hill.

IF BRAKES DO NOT GRIP WELL

•If you have been driving through deep water, gently apply the brakes

several times while the vehicle is moving slowly.

•Let the brakes cool if you have been using them excessively, as in

mountain driving or after several fast, high speed stops.

•Check brake adjustment.

•Check brake linings for excessive wear.

Hydraulic brake booster system (Hydromax)

The Hydromax systems receive fluid pressure from the power steering

pump to provide power assist during braking.

The Hydromax booster receives backup pressure from the reserve

system electric pump whenever the fluid in the power steering system is

not flowing. When the engine is OFF, the pump will turn on if the brake

pedal is applied, or if the ignition is turned to the ON position.

The sound of the pump operating may be heard by the driver, but this is

a normal characteristic of the system.

Driving

93

Page 99 of 272

AIR BRAKES (IF EQUIPPED)

Foot service brakes

Air brakes are operated by a

standard dash-mounted foot pedal.

All standard equipment brakes are

designed to be self-adjusting.

Automatic adjustment, when

required, occurs whenever the

brakes are applied and released

during forward or reverse operation.

Know the required stopping

distances for all driving conditions

that may be encountered. For longer brake lining life, take full advantage

of engine braking power when coming to a stop.

Before descending a long or steep hill, shift to a lower gear and avoid

continuous application of the brakes. Normally, choose the same gear to

descend the hill that you would use to ascend the hill.

Do not drive with your foot resting on the brake pedal. This will

result in abnormally high brake temperatures, excessive lining

wear and increased stopping distances.

Continuous application of the brakes will cause the brakes to

overheat, resulting in a temporary loss of braking.

Occasional or intermittent brake squeal or groan may result from

environmental conditions such as cold, hot, wet, snow, salt, mud, etc.

This condition will not affect braking effectiveness. The brakes should be

checked only if squeal occurs continuously with every application.

If brakes do not grip well

•If you have been driving through deep water, gently apply the brakes

several times while the vehicle is moving slowly.

•Let the brakes cool if you have been using them excessively, as in

mountain driving or after several fast, high speed stops.

•Check brake adjustment.

•Check brake linings for excessive wear.

•Check system air pressure.

Driving

99

Page 101 of 272

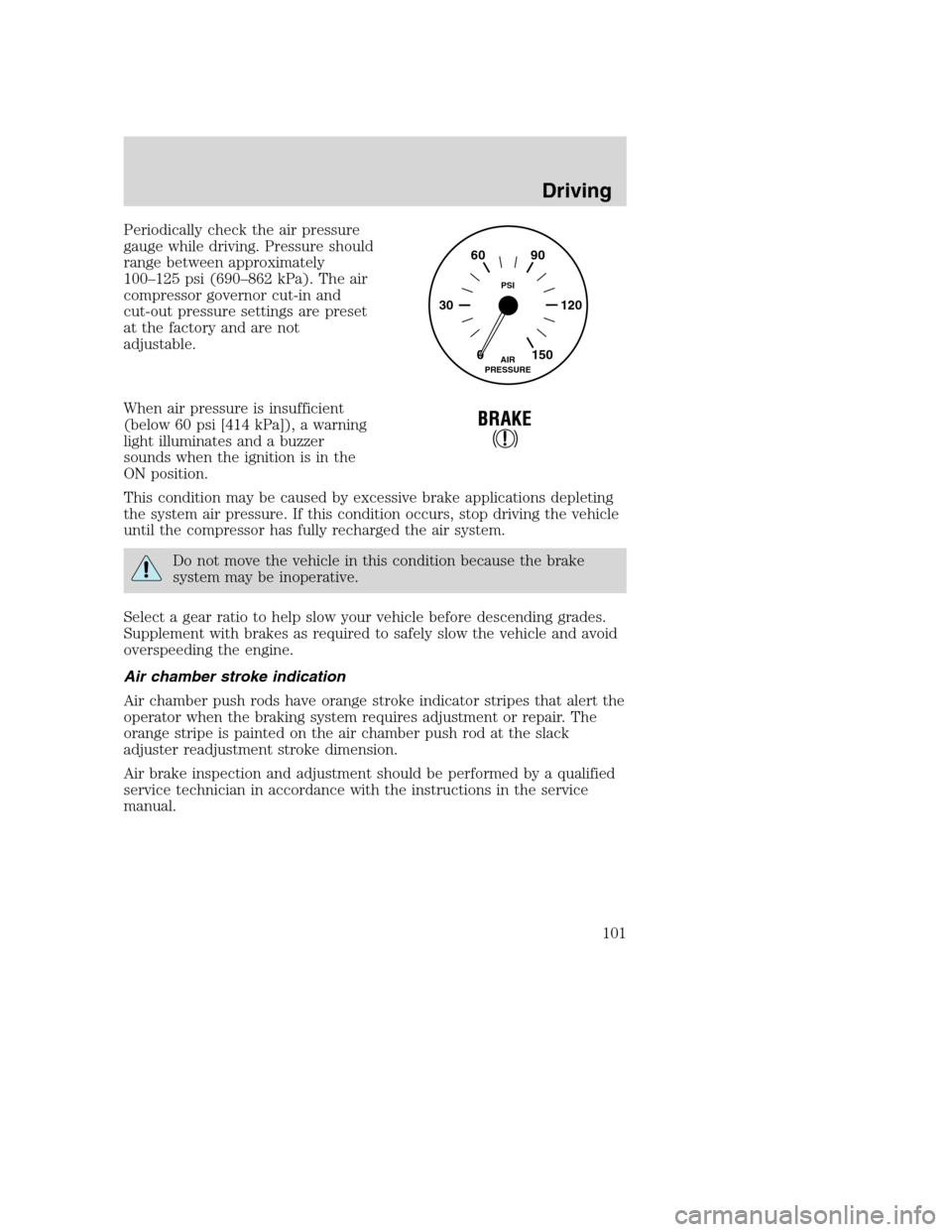

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately

100–125 psi (690–862 kPa). The air

compressor governor cut-in and

cut-out pressure settings are preset

at the factory and are not

adjustable.

When air pressure is insufficient

(below 60 psi [414 kPa]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system.

Do not move the vehicle in this condition because the brake

system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

Air chamber stroke indication

Air chamber push rods have orange stroke indicator stripes that alert the

operator when the braking system requires adjustment or repair. The

orange stripe is painted on the air chamber push rod at the slack

adjuster readjustment stroke dimension.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the service

manual.

0 30 12090 60

150AIR

PRESSUREPSI

Driving

101

Page 136 of 272

When operating empty or lightly loaded, sudden or hard braking

may induce wheel lockup with loss of vehicle control and the

possibility of accident and serious injury, especially on wet or slippery

road surfaces.

TRAILER TOWING

Towing a trailer places an additional load on your vehicle’s engine,

transmission, axle, brakes, tires and suspension. Inspect these

components carefully prior to and after any towing operation.

Your vehicle’s load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

2nd unit bodies are not included in maximum trailer weight ratings. The

weight of the additional“body”must be subtracted from the maximum

trailer weight.

Note:Do not exceed the GVWR or the GAWR specified on the

certification label.

Towing trailers beyond the maximum recommended gross trailer

weight exceeds the limit of the vehicle and could result in

engine damage, transmission damage, structural damage, loss of vehicle

control, vehicle rollover and personal injury.

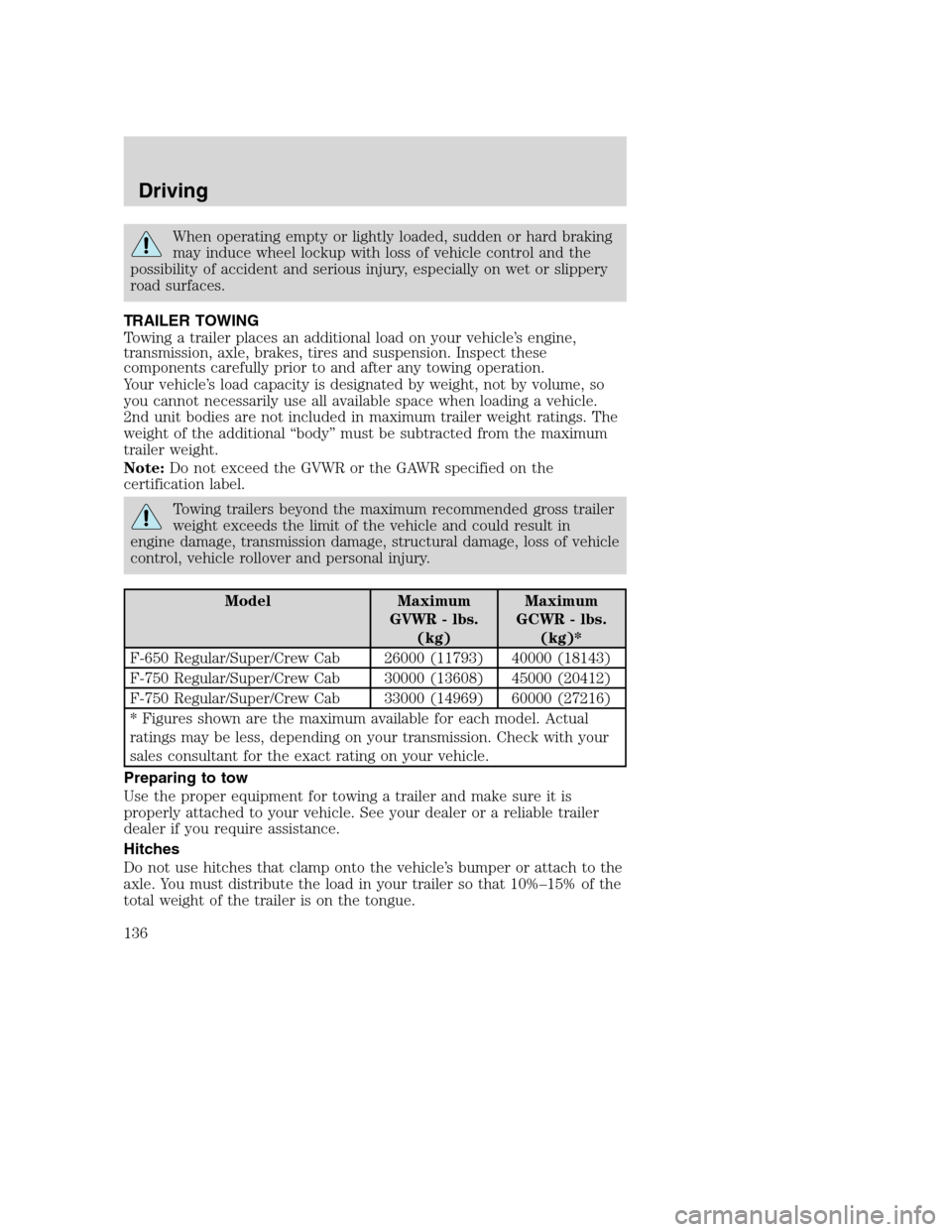

Model Maximum

GVWR - lbs.

(kg)Maximum

GCWR - lbs.

(kg)*

F-650 Regular/Super/Crew Cab 26000 (11793) 40000 (18143)

F-750 Regular/Super/Crew Cab 30000 (13608) 45000 (20412)

F-750 Regular/Super/Crew Cab 33000 (14969) 60000 (27216)

* Figures shown are the maximum available for each model. Actual

ratings may be less, depending on your transmission. Check with your

sales consultant for the exact rating on your vehicle.

Preparing to tow

Use the proper equipment for towing a trailer and make sure it is

properly attached to your vehicle. See your dealer or a reliable trailer

dealer if you require assistance.

Hitches

Do not use hitches that clamp onto the vehicle’s bumper or attach to the

axle. You must distribute the load in your trailer so that 10%–15% of the

total weight of the trailer is on the tongue.

Driving

136

Page 138 of 272

Trailer towing tips

•Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

•Allow more distance for stopping with a trailer attached.

•The trailer tongue weight should be 10–15% of the loaded trailer

weight.

•After you have traveled 50 miles (80 km), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

•To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park)

(if available on your automatic transmission) or N (Neutral) (manual

transmissions and automatic transmissions without a P [Park]

position).

•Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer’s wheels.

Driving

138

Page 150 of 272

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

WRECKER TOWING INSTRUCTIONS

Before moving the towed vehicle, check for adequate road clearance of

vehicle components. It is recommended the towed vehicle be unloaded

prior to being towed to reduce any abnormal load to the vehicle

components resulting from the towing procedures. Before towing, be

sure to fully release the parking brake. The spring-actuated type parking

brake can be reset by recharging the air system with at least 64 psi (441

kPa) of air. If the brake system will not retain air pressure, then the

spring brakes must be released manually. Refer toParking brakein the

Drivingchapter

Note:For towing, make sure the vehicle is securely connected to the

tow vehicle and the tow vehicle parking brakes are applied before

releasing the disabled vehicle’s spring brakes.

+–+–

+–+–

2005 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

150