FORD F650 2007 11.G Owners Manual

Manufacturer: FORD, Model Year: 2007, Model line: F650, Model: FORD F650 2007 11.GPages: 280, PDF Size: 1.93 MB

Page 121 of 280

When disconnecting the trailer:

•Lower the landing gear, then press the lower portion of the switch.

• Disconnect the brake hoses, trailer-side and rear light connectors,

then pull the release lever on the fifth wheel.

The upper portion of the switch must be pressed before operating with a

trailer or operating in the bobtail mode.

Suspension conversions

It is not recommended, or approved, that suspension conversions be

performed. However, it is understood that, on occasion, aftermarket add-on

suspensions are installed by others on the truck chassis which allow

operator control for weight transfer from other axles (i.e., air lift axles).

When operating a loaded vehicle, the driver must keep all

adjustable axles on the ground at all times, supporting their

share of the vehicle’s load. Failure to do so can overload other axles,

tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

AUTOMATIC TRANSMISSION OPERATION (IF EQUIPPED)

Main transmission, auxiliary transmission, transfer case and power take-off

(PTO) control shift patterns can be found on a placard or decal on the

driver’s sun visor, on the instrument panel or on the shift control itself.

The main transmission control is used to select the various gear ratios or

speeds of the transmission. Selecting D (Direct Drive), does not change

the transmission gear ratio, but is used where the gear ratios in the main

transmission are adequate to handle the vehicle operation.

If the transmission fails to shift properly, check the inline 10A fuse

located in the battery cables above the battery.

Hold the brake pedal down while you move the gearshift lever

between positions. If you don’t hold the brake pedal down, your

vehicle may move unexpectedly and cause property damage, personal

injury or death.

Allison 2200 automatic transmission with park pawl feature

Note: For Allison automatic transmission-equipped vehicles, also refer to

the separate Allison Transmission Operator’s Manual.

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

121

Page 122 of 280

A parking pawl effectively grounds the transmission’s output shaft

preventing rotation of the driveline. If the vehicle is stationary, selecting

the P (Park) position places the transmission in neutral and engages the

parking pawl (always use the parking brake, also).

Note:If the P (Park) position is selected when the vehicle is in motion,

the parking pawl mechanism will ratchet and NOThold the truck.

Always set the parking brake fully. Do not use the gearshift in

place of the parking brake.

To avoid sudden, unexpected vehicle movement and

possible personal injury or death:

1. Bring the vehicle to a complete stop.

2. Shift the transmission into P (Park). Slowly lift your foot from the

brake pedal to engage the transmission parking pawl mechanism.

3. Apply the parking brake and make sure it is holding properly. Do not

rely solely on the parking mechanism of the transmission.)

4. Turn the engine off when you leave the vehicle. Never leave the

vehicle unattended when the engine is running.

Allison 2500 automatic transmission

This transmission is available with a column-mounted gearshift lever. The

gear positions are displayed on the RNDL in the instrument cluster.

To avoid sudden, unexpected vehicle movement and

possible personal injury or death:

1. Bring the vehicle to a complete stop.

2. Shift the transmission into N (Neutral).

3. Apply the parking brake and make sure it is holding properly.

4. Turn the engine off when you leave the vehicle. Never leave the

vehicle unattended when the engine is running.

Allison 3000 Series automatic transmission

Two modes are available for the Allison 3000 Series: Performance and

Economy. Performance mode will give you the best all-around

transmission operation; Economy provides operation at lower engine

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

122

Page 123 of 280

RPM while maintaining adequate performance. The transmission will

automatically default to Performance mode when you start the engine.

Pressing MODE on the shifter will activate the Economy mode; this will

also illuminate the Mode ON lamp.

If the engine speed is above idle when a gear is selected using the

shifter, the vehicle will not move. To move the vehicle, the shifter must

be moved to re-select a gear after the engine speed returns to idle.

Note:For more information regarding the Allison 3000 Series, refer to

the separate Allison 3000 Series Operator’s Manual.

Torque lock

If your vehicle is parked on an incline and P (Park) is not properly

engaged (The parking brake is not applied before the transmission is

shifted into P [Park]), the weight of the vehicle may generate an

excessive amount of torque on the park pawl. In this situation, it may be

difficult to shift the transmission out of P (Park). Hold the brake pedal

down while shifting out of P (Park), then release the parking brake.

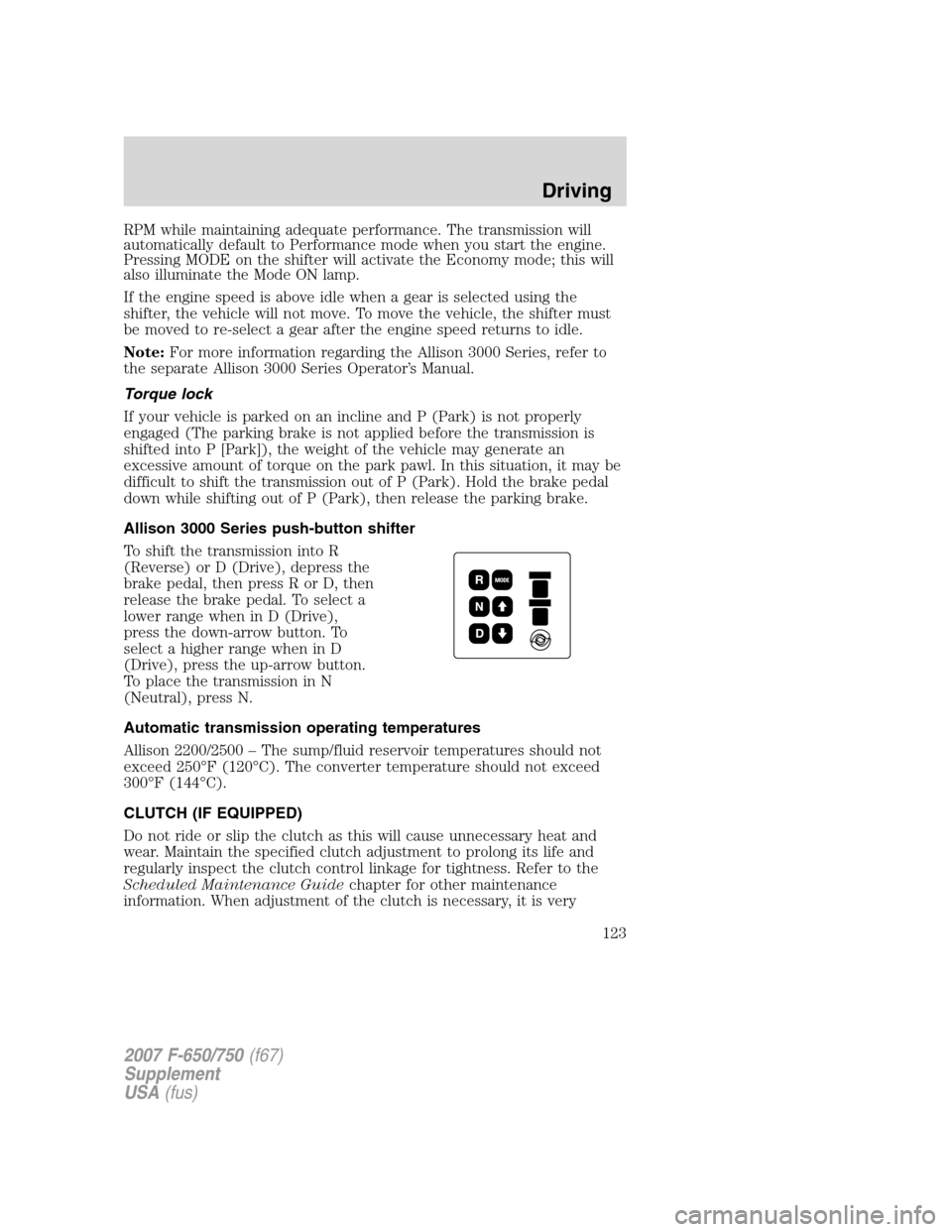

Allison 3000 Series push-button shifter

To shift the transmission into R

(Reverse) or D (Drive), depress the

brake pedal, then press R or D, then

release the brake pedal. To select a

lower range when in D (Drive),

press the down-arrow button. To

select a higher range when in D

(Drive), press the up-arrow button.

To place the transmission in N

(Neutral), press N.

Automatic transmission operating temperatures

Allison 2200/2500 – The sump/fluid reservoir temperatures should not

exceed 250°F (120°C). The converter temperature should not exceed

300°F (144°C).

CLUTCH (IF EQUIPPED)

Do not ride or slip the clutch as this will cause unnecessary heat and

wear. Maintain the specified clutch adjustment to prolong its life and

regularly inspect the clutch control linkage for tightness. Refer to the

Scheduled Maintenance Guide chapter for other maintenance

information. When adjustment of the clutch is necessary, it is very

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

123

Page 124 of 280

important that the work be performed properly or early clutch failure

may result and a costly clutch overhaul may become necessary. Clutch

work should only be performed by a qualified technician.

Engaging the clutch

•Always start in the proper gear. An empty vehicle can start in a

higher gear than a fully loaded vehicle. Starting in too high a gear can

cause clutch slippage and excessive heat and wear on the clutch. A

gear that will start the vehicle moving at idle speed is the correct gear.

If the engine has to be revved to get the vehicle going, the gear

selection is too high.

• Do not shift until the vehicle has reached the proper speed.

Upshifting before the vehicle has reached the proper speed can cause

clutch slippage and excessive heat and wear on the clutch.

• Never hold a vehicle on a grade with the clutch. This will cause

the clutch to slip and can actually burn up the clutch.

• Never coast with the clutch disengaged. The high RPM

(sometimes over 10,000), can actually burst the facing material of the

clutch.

• Never engage the clutch while coasting. Re-engaging the clutch

after coasting may not only cause a great shock to the clutch, but the

whole drivetrain. Internal engine damage and/or clutch and flywheel

failure can result from this.

If your vehicle’s transmission is equipped with a ceramic clutch, you

must start the vehicle moving in first gear and engage the clutch before

pressing the accelerator at idle. Also, don’t try to slip the clutch by

raising engine RPM and riding or feathering the clutch pedal since the

vehicle will experience erratic engagement. Erratic engagement can

cause the engine stalling and potential serious damage to the vehicle’s

driveline components.

Clutch brake (vehicles equipped with a non-synchronized

transmission) - Vehicle stationary

A clutch brake is used to stop the transmission input shaft rotation so

that the initial 1 (First) or R (Reverse) gear selection can be

accomplished when the vehicle is stationary and the engine is running at

idle speed. Clutch brake application occurs in the last inch (25 mm) of

clutch pedal travel.

When using the clutch brake, fully depress the clutch pedal and shift the

transmission into 1 (First) or R (Reverse). If the transmission won’t go

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

124

Page 125 of 280

into one of these gears, slowly release the clutch pedal while applying

light pressure on the transmission shift lever until it shifts into gear.

Note:After engagement of 1 (First) gear, do notuse the clutch brake

for upshifting or downshifting. If you do, clutch brake life will shorten

and gear selection shift efforts may increase.

Double-clutch procedures - vehicles equipped with a

non-synchronized transmission

In order to properly upshift or downshift, perform the following steps:

1. Depress the clutch pedal to disengage the clutch.

2. Shift the transmission into neutral.

3. Release the clutch pedal.

If upshifting , wait until the engine speed matches the transmission

speed of the gear you are selecting.

If downshifting, accelerate the engine until the engine speed matches

the input speed of the gear you are selecting. Depress the clutch pedal

immediately and shift into the desired gear, then release the clutch

pedal.

MANUAL TRANSMISSION OPERATION (IF EQUIPPED)

Note: Continued use of a damaged or worn clutch, prolonged clutch

slippage or downshifting at excessive speeds can result in a failure of the

engine, transmission or clutch components.

Note: To avoid premature clutch wear and failure, do not drive with

your foot resting on the clutch pedal or use it to hold the vehicle at a

standstill on an upgrade as when waiting for a traffic light.

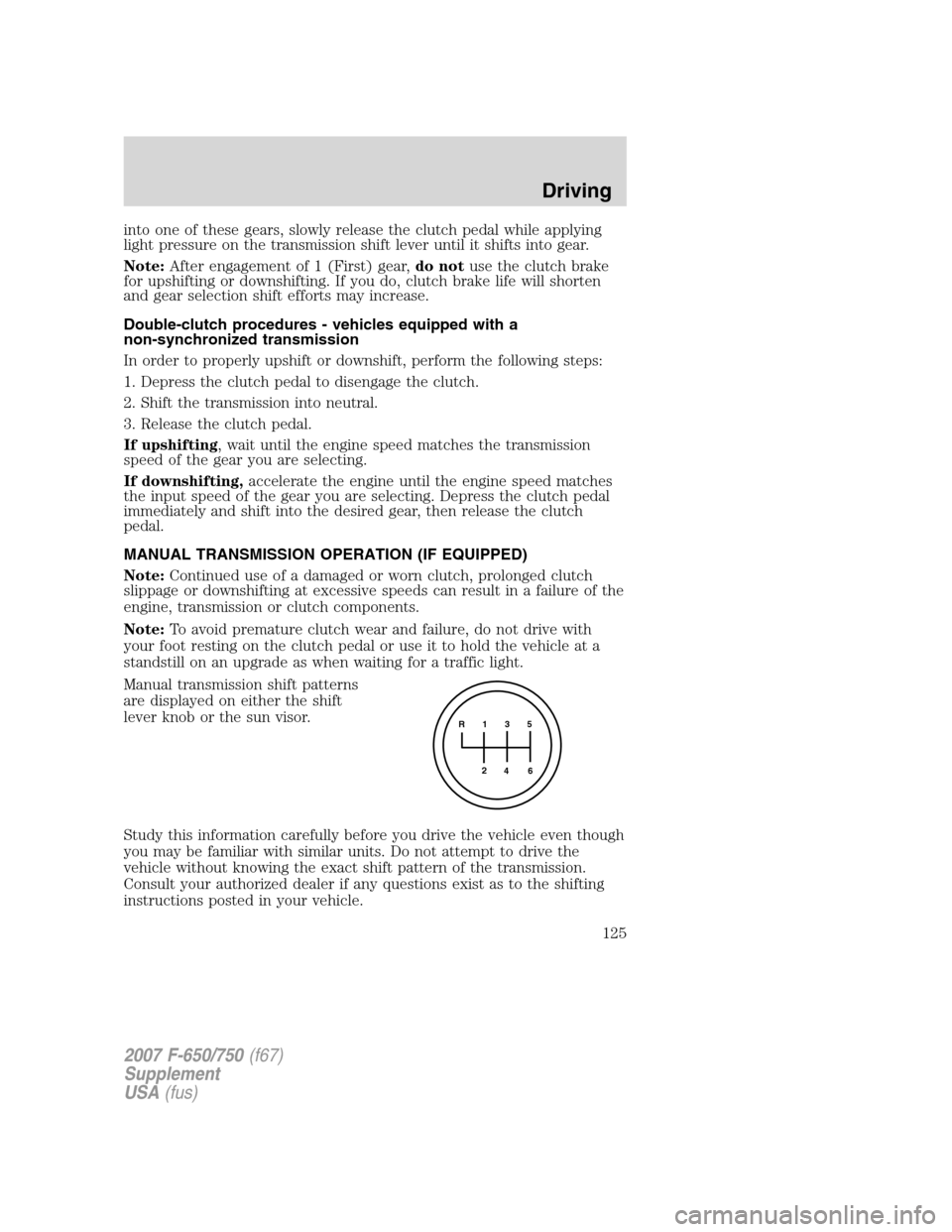

Manual transmission shift patterns

are displayed on either the shift

lever knob or the sun visor.

Study this information carefully before you drive the vehicle even though

you may be familiar with similar units. Do not attempt to drive the

vehicle without knowing the exact shift pattern of the transmission.

Consult your authorized dealer if any questions exist as to the shifting

instructions posted in your vehicle.

R 1 3 5

4

6

2

2007 F-650/750

(f67)

Supplement

USA (fus)

Driving

125

Page 126 of 280

Do not coast the vehicle with the clutch pedal depressed or with

the transmission in neutral. This practice could result in loss of

vehicle control.

Driving hints

The following driving hints are provided as a brief, general guide in

operating the different manual transmissions used in your vehicle.

• When shifting into 1 (First) or R (Reverse) with vehicle standing still,

quickly release and depress the clutch pedal (if necessary to complete

gear engagement).

• Always use the lowest (or most appropriate) gear to start the vehicle.

• Always use a gear ratio low enough to allow the engine to operate

above the minimum engine operation speed range.

• Do not lug the engine.

• Do not slam or jerk the gearshift lever into gear.

• When more power is required, shift to a lower gear and accelerate the

engine near the governed speed.

Shifting with a synchronized transmission

With the clutch pedal depressed, use 2 (Second) gear synchronizer to

stop the clutch disc rotation; this allows smooth engagement of 1 (First)

or R (Reverse) To complete the gear engagement, it may be necessary to

apply light pressure to the gearshift lever during initial engagement of

the clutch. It takes a second or two to match gear speeds; steady

pressure on the gearshift lever will help the synchronizer perform its job

more quickly. If the gearshift lever is forced into position, this action

defeats the purpose of the synchronizer by causing gear clash.

Shifting with a non-synchronized transmission

Refer to Clutch brake andDouble clutch procedures in theClutch

section of this chapter.

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

126

Page 127 of 280

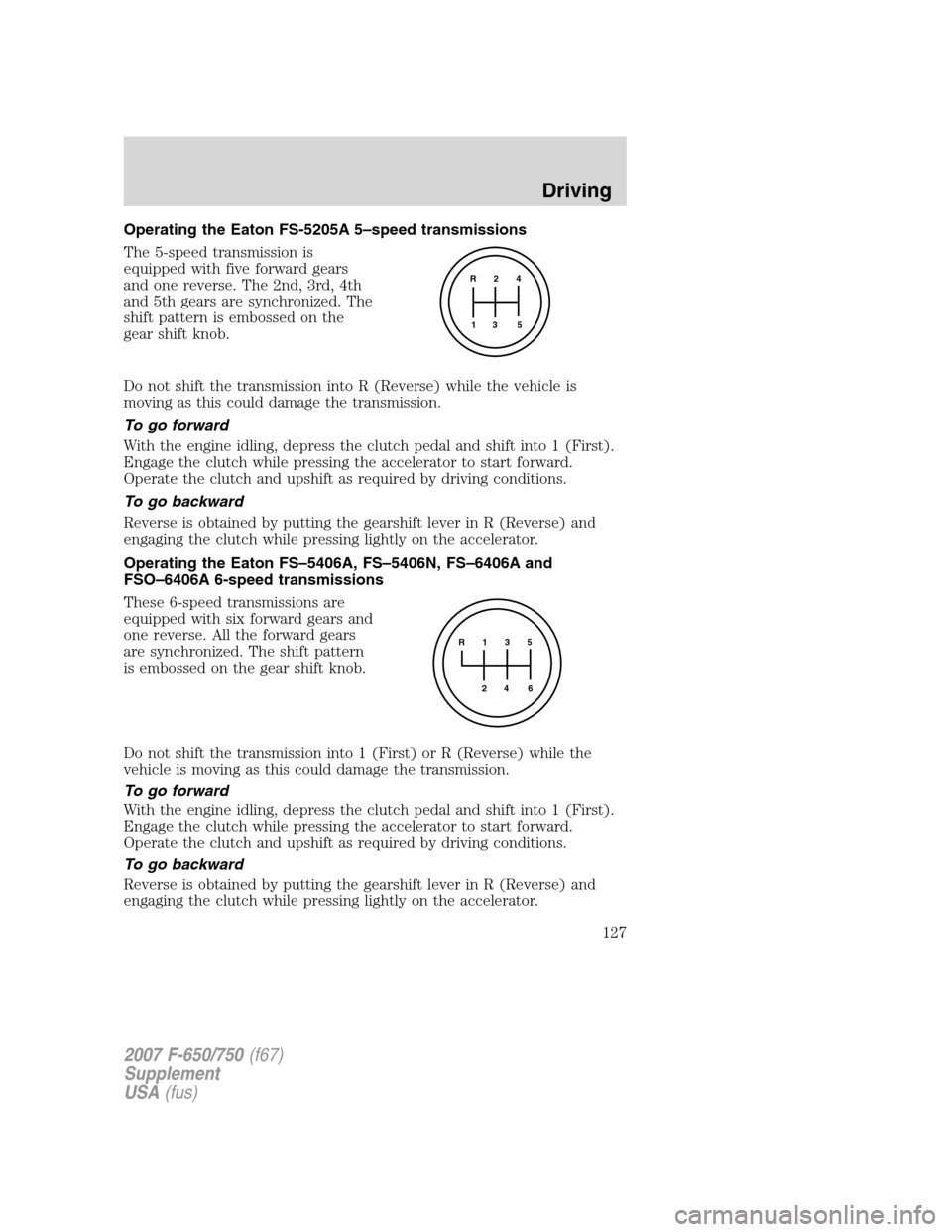

Operating the Eaton FS-5205A 5–speed transmissions

The 5-speed transmission is

equipped with five forward gears

and one reverse. The 2nd, 3rd, 4th

and 5th gears are synchronized. The

shift pattern is embossed on the

gear shift knob.

Do not shift the transmission into R (Reverse) while the vehicle is

moving as this could damage the transmission.

To go forward

With the engine idling, depress the clutch pedal and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

Operating the Eaton FS–5406A, FS–5406N, FS–6406A and

FSO–6406A 6-speed transmissions

These 6-speed transmissions are

equipped with six forward gears and

one reverse. All the forward gears

are synchronized. The shift pattern

is embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, depress the clutch pedal and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

R 2 4 3 5 1

R 1 3 5

4

6

2

2007 F-650/750

(f67)

Supplement

USA (fus)

Driving

127

Page 128 of 280

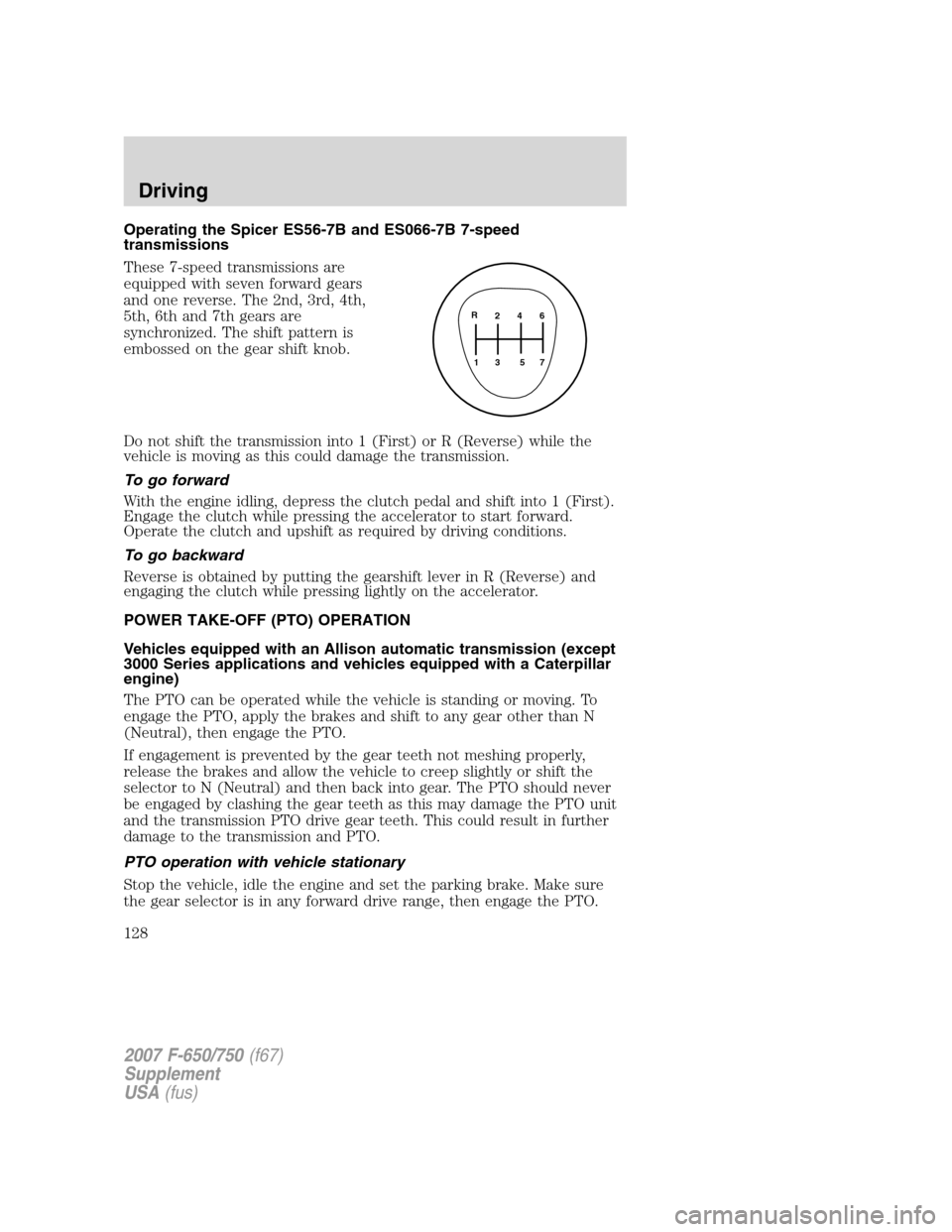

Operating the Spicer ES56-7B and ES066-7B 7-speed

transmissions

These 7-speed transmissions are

equipped with seven forward gears

and one reverse. The 2nd, 3rd, 4th,

5th, 6th and 7th gears are

synchronized. The shift pattern is

embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, depress the clutch pedal and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

POWER TAKE-OFF (PTO) OPERATION

Vehicles equipped with an Allison automatic transmission (except

3000 Series applications and vehicles equipped with a Caterpillar

engine)

The PTO can be operated while the vehicle is standing or moving. To

engage the PTO, apply the brakes and shift to any gear other than N

(Neutral), then engage the PTO.

If engagement is prevented by the gear teeth not meshing properly,

release the brakes and allow the vehicle to creep slightly or shift the

selector to N (Neutral) and then back into gear. The PTO should never

be engaged by clashing the gear teeth as this may damage the PTO unit

and the transmission PTO drive gear teeth. This could result in further

damage to the transmission and PTO.

PTO operation with vehicle stationary

Stop the vehicle, idle the engine and set the parking brake. Make sure

the gear selector is in any forward drive range, then engage the PTO.

2 4 6 3 5 7 1

R

2007 F-650/750

(f67)

Supplement

USA (fus)

Driving

128

Page 129 of 280

After the PTO is engaged, move the range selector to N (Neutral).

Increase the engine speed until the desired power take-off operation

speed is obtained. To disengage the PTO after operation with the vehicle

standing, release the throttle, allow the drive equipment to come to a

stop, and then disengage the PTO.

When the PTO is operated with the vehicle stationary, the

transmission must be placed in N (Neutral) with the parking

brake set. If the transmission is not in N (Neutral) and is equipped

with a remote throttle control, an increase in engine speed can

overpower the parking brake and cause the vehicle to move, possibly

resulting in personal injury and/or property damage.

PTO operation while vehicle is moving

After the PTO is engaged for driven vehicle operation, shift to the

desired range and drive the vehicle. The speed of the PTO, during this

period of operation, will always maintain direct relation to vehicle speed.

PTO speed will decrease in relation to vehicle (transmission output)

speed as shifts to a higher gear occur. When operating the PTO while the

vehicle is moving, the PTO may be disengaged whenever it is no longer

required. When there is no load on the PTO gear, it can be pulled out of

engagement.

Vehicles equipped with an Allison 3000 Series automatic

transmission

The PTO drive gear is engine driven and provides direct engine power.

The PTO can be operated when the vehicle is either stationary or moving.

The PTO gear is in constant mesh with the drive gear in the torque

converter housing. A friction clutch or constant drive is used to transmit

power to the PTO.

Vehicles equipped with a Caterpillar engine

The PTO will only operate if the transmission is in N (Neutral). This

feature can be overridden by a special service tool; see your dealer or

service representative for more information.

Vehicles equipped with a manual transmission

Transmission-mounted PTO units are available for local installation on

your vehicle. See your Body Builder’s Layout Book for restrictions on

use and installation of PTO units.

To engage the PTO unit, stop the vehicle and place the transmission in N

(Neutral). Depress the clutch and allow the gears to stop rotating, then

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

129

Page 130 of 280

engage the PTO unit. The PTO can also be selected with the

transmission in gear as long as the clutch is depressed.

When operating the PTO with the vehicle stationary, first set the parking

brake (chock the wheels if the vehicle is on a hill or another uneven

surface).

REAR AXLE INFORMATION

Axle operating temperature normally will not exceed 100°F (38°C). If

the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation will increase and shorten the life of the lubricant

and seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Gross axle weight

Your truck has gross axle weight, gross vehicle weight and gross

combination weight ratings. Do not exceed these ratings.

Exceeding these ratings by overloading can cause component

failure resulting in property damage, personal injury or death.

Rear axles with locking or limited-slip differentials

If your vehicle is equipped with a locking or limited-slip differential, note

the following:

• Power will be transmitted to the opposite wheel should one of the

wheels begin to slip.

• Both wheels must be raised off the ground should it be necessary to

operate one wheel with the vehicle stationary.

If both wheels are not raised off the ground, the one wheel that

is not raised may pull the vehicle off its support, possibly

resulting in personal injury

Driver-controlled differential lock

To prevent the vehicle from moving when servicing the wheels, tires or

brakes, turn the engine off and raise all drive wheels of the locker

differential axle. Axles equipped with NoSPIN Detroit Locker differentials

deliver power to both wheels even when only one wheel is on the ground.

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

130