FORD F650/750 2019 Owners Manual

Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 211 of 387

CHANGING THE 12V BATTERY

WARNING: This vehicle may be

equipped with more than one battery,

removal of cable from only one battery

does not disconnect the vehicle

electrical system. Be sure to disconnect

cables from all batteries when

disconnecting power. Failure to do so

may cause serious personal injury or

property damage. WARNING:

Batteries normally

produce explosive gases which can

cause personal injury. Therefore, do not

allow flames, sparks or lighted

substances to come near the battery.

When working near the battery, always

shield your face and protect your eyes.

Always provide proper ventilation. WARNING:

When lifting a

plastic-cased battery, excessive pressure

on the end walls could cause acid to flow

through the vent caps, resulting in

personal injury and damage to the

vehicle or battery. Lift the battery with a

battery carrier or with your hands on

opposite corners. WARNING:

Keep batteries out of

reach of children. Batteries contain

sulfuric acid. Avoid contact with skin,

eyes or clothing. Shield your eyes when

working near the battery to protect

against possible splashing of acid

solution. In case of acid contact with skin

or eyes, flush immediately with water for

a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed,

call a physician immediately.

Note: If your battery has a cover/shield,

make sure it is reinstalled after the battery

has been cleaned or replaced. Note:

Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after handling.

Note: Electrical or electronic accessories

or components added to the vehicle by the

dealer or the owner may adversely affect

battery performance and durability.

Your vehicle is equipped with a Motorcraft

maintenance-free battery which normally

does not require additional water during

its life of service.

For longer, trouble-free operation, keep the

top of the battery clean and dry. Also,

make certain the battery cables are always

tightly fastened to the battery terminals.

If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

It is recommended that the negative

battery cable terminal be disconnected

from the battery if you plan to store your

vehicle for an extended period of time.

Because your vehicle ’s engine is

electronically controlled by a computer,

some control conditions are maintained

by power from the battery. When the

battery is disconnected or a new battery

is installed, the engine must relearn its idle

and fuel trim strategy for optimum

driveability and performance. To begin this

process

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in park (P) or neutral (N) and turn off all accessories.

3. Start the engine. Run the engine until it reaches normal operating

temperature.

4. Allow the engine to idle for at least one

minute.

208

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Maintenance

Page 212 of 387

5. Turn the air conditioning (if equipped)

on and allow the engine to idle for at

least one minute.

6. Release the parking brake. With your foot on the brake pedal and with the

air conditioning on, put the vehicle in

drive (D) and allow the engine to idle

for at least one minute.

•If you do not allow the engine to

relearn its idle trim, the idle quality

of your vehicle may be adversely

affected until the idle trim is

eventually relearned.

7. Drive the vehicle to complete the relearning process

•The vehicle may need to be driven

10 mi (16 km) or more to relearn the

idle and fuel trim strategy along

with the ethanol content for flexible

fuel vehicles.

If the battery has been disconnected or a

new battery has been installed, the clock

and radio settings must be reset once the

battery is reconnected.

Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized standards

for disposal. Call your local authorized

recycling center to find out more about

recycling automotive batteries.

Battery Management System (If

Equipped)

The battery management system (BMS)

monitors battery conditions and takes

actions to extend battery life. If excessive

battery drain is detected, the system may

temporarily disable certain electrical

features to protect the battery. Those

electrical accessories affected include the

rear defrost, heated/cooled seats, climate

control fan, heated steering wheel, audio

and navigation system. A message may be

shown in the information displays to alert the driver that battery protection actions

are active. These messages are only for

notification that an action is taking place,

and not intended to indicate an electrical

problem or that the battery requires

replacement.

Electrical accessory installation

To ensure proper operation of the BMS,

any electrical devices that are added to

the vehicle should not have their ground

connection made directly at the negative

battery post. A connection at the negative

battery post can cause inaccurate

measurements of the battery condition

and potential incorrect system operation.

Note:

Electrical or electronic accessories

added to the vehicle by the dealer or the

owner may adversely affect battery

performance and durability, and may also

affect the performance of other electrical

systems in the vehicle.

When a battery replacement is required,

the battery should only be replaced with

a Ford recommended replacement battery

which matches the electrical requirements

of the vehicle. After battery replacement,

or in some cases after charging the battery

with the external charger, the BMS requires

eight hours of vehicle sleep time (key off

with doors closed) to relearn the new

battery state of charge. Prior to relearning

the state of charge, the BMS may disable

electrical features (to protect the battery)

earlier than normal.

209

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Maintenance

Page 213 of 387

CHECKING THE WIPER

BLADES

Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid

or water applied with a soft sponge or

cloth.

CHANGING THE WIPER

BLADES

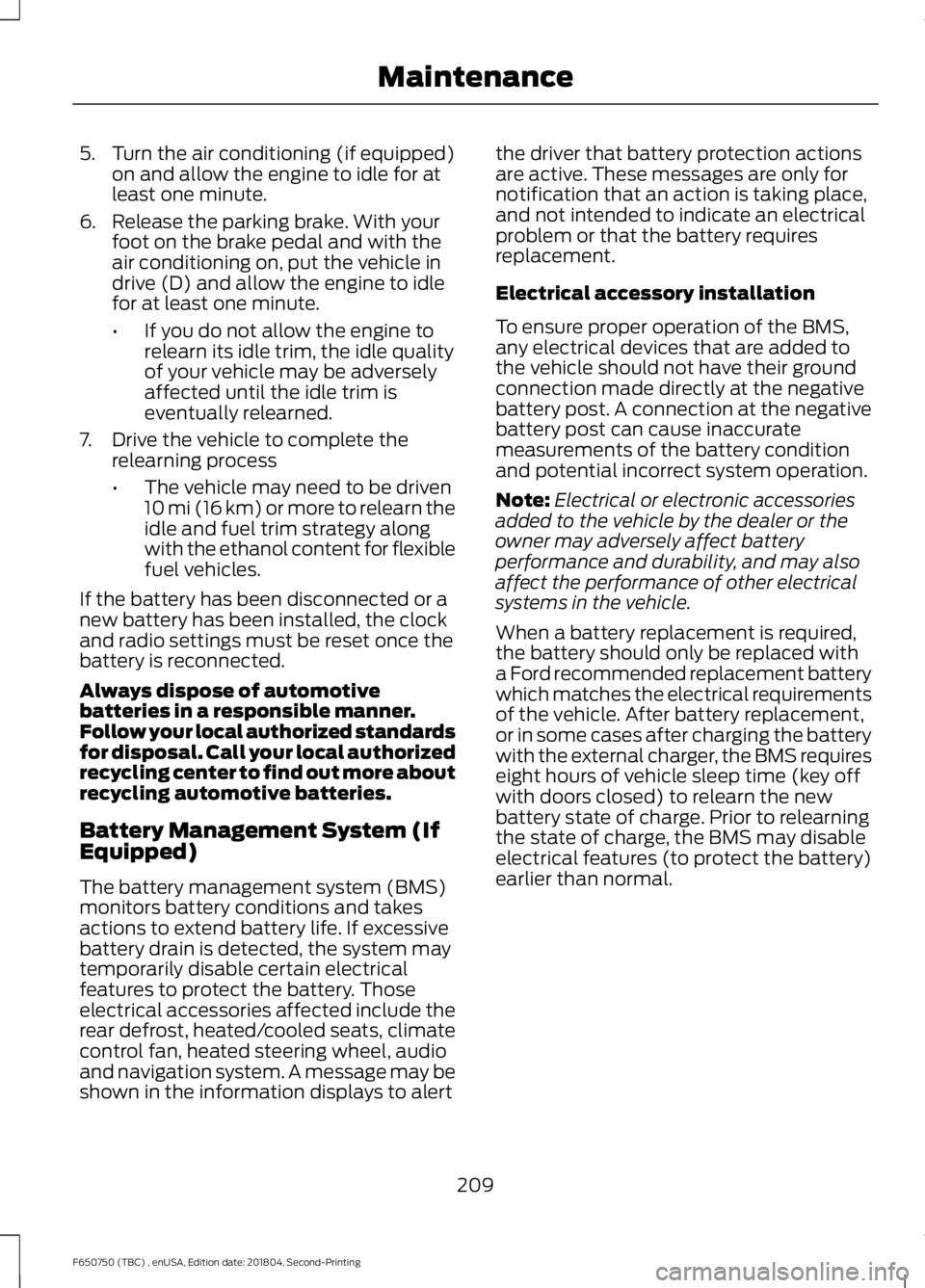

You can manually move the wiper arms

when the ignition is off. This allows for ease

of blade replacement and cleaning under

the blades.

1. Pull the wiper blade and arm away

from the glass. 2. Release the wiper blade lock (A) and

separate the wiper blade from the

wiper arm.

3. Install in the reverse order.

Note: Make sure that the wiper blade locks

into place. Lower the wiper arm and blade

back on the windshield. The wiper arms will

automatically return to their normal position

when you turn the ignition on.

• Replace wiper blades at least once per

year for optimum performance.

• You can improve poor wiper quality by

cleaning the wiper blades and the

windshield.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are

properly aimed at the assembly plant. If

your vehicle has been in an accident, the

alignment of your headlamps should be

checked by your authorized dealer.

210

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE142463 E165804 A

E165794

Page 214 of 387

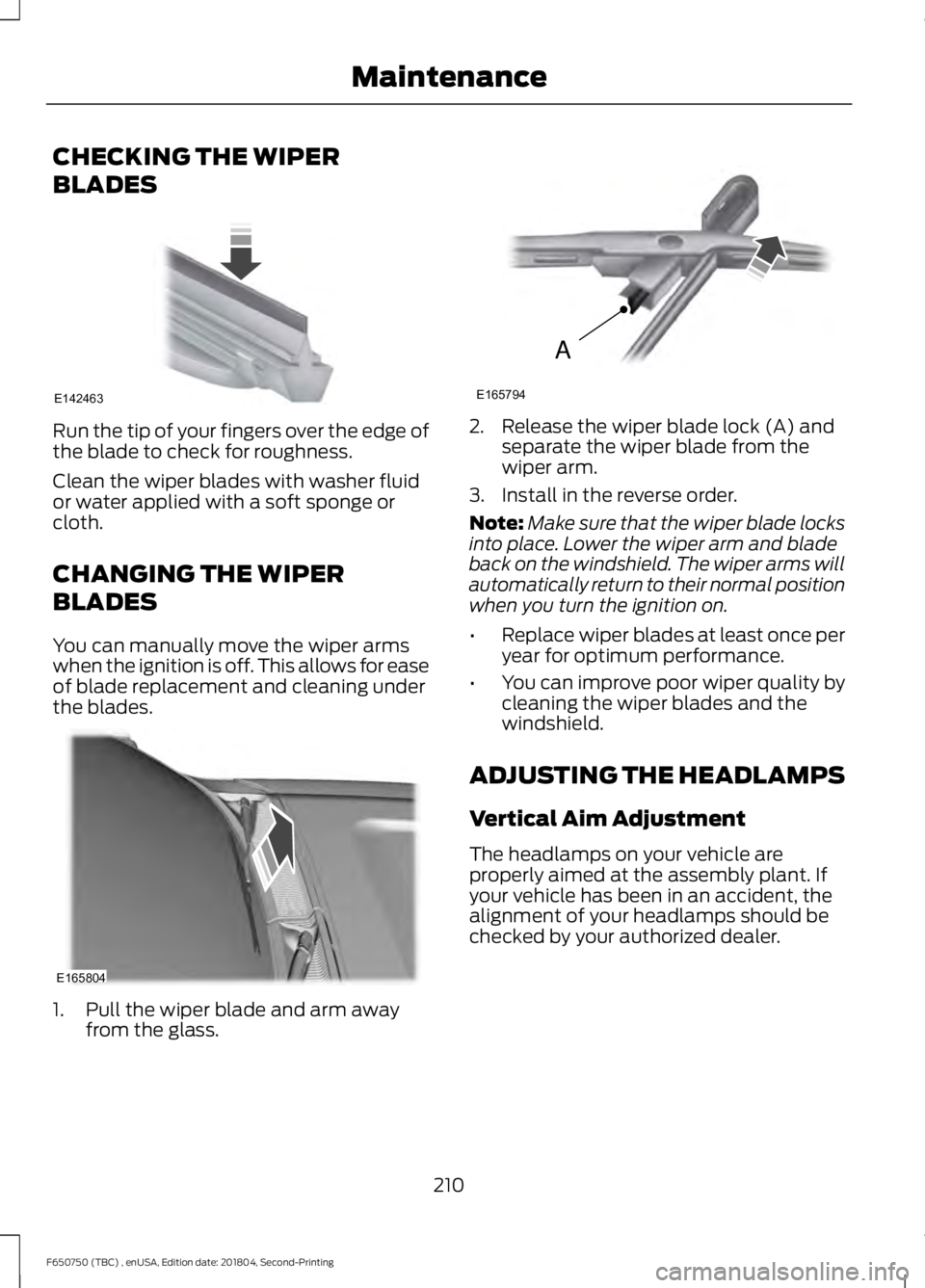

Headlamp Aiming Target

8 feet (2.4 meters)

A

Center height of lamp to ground

B

25 feet (7.6 meters)

C

Horizontal reference line

D

Vertical Aim Adjustment Procedure

1. Park the vehicle directly in front of a wall or screen on a level surface,

approximately 25 ft (7.6 m) away.

2. Measure the height of the headlamp bulb center from the ground and mark

an

8 ft (2.4 m) horizontal reference line

on the vertical wall or screen at this

height.

Note: To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Turn on the low beam headlamps to illuminate the wall or screen and open

the hood. 4. On the wall or screen you will observe

a flat zone of high intensity light

located at the top of the right hand

portion of the beam pattern. If the top

edge of the high intensity light zone is

not at the horizontal reference line, the

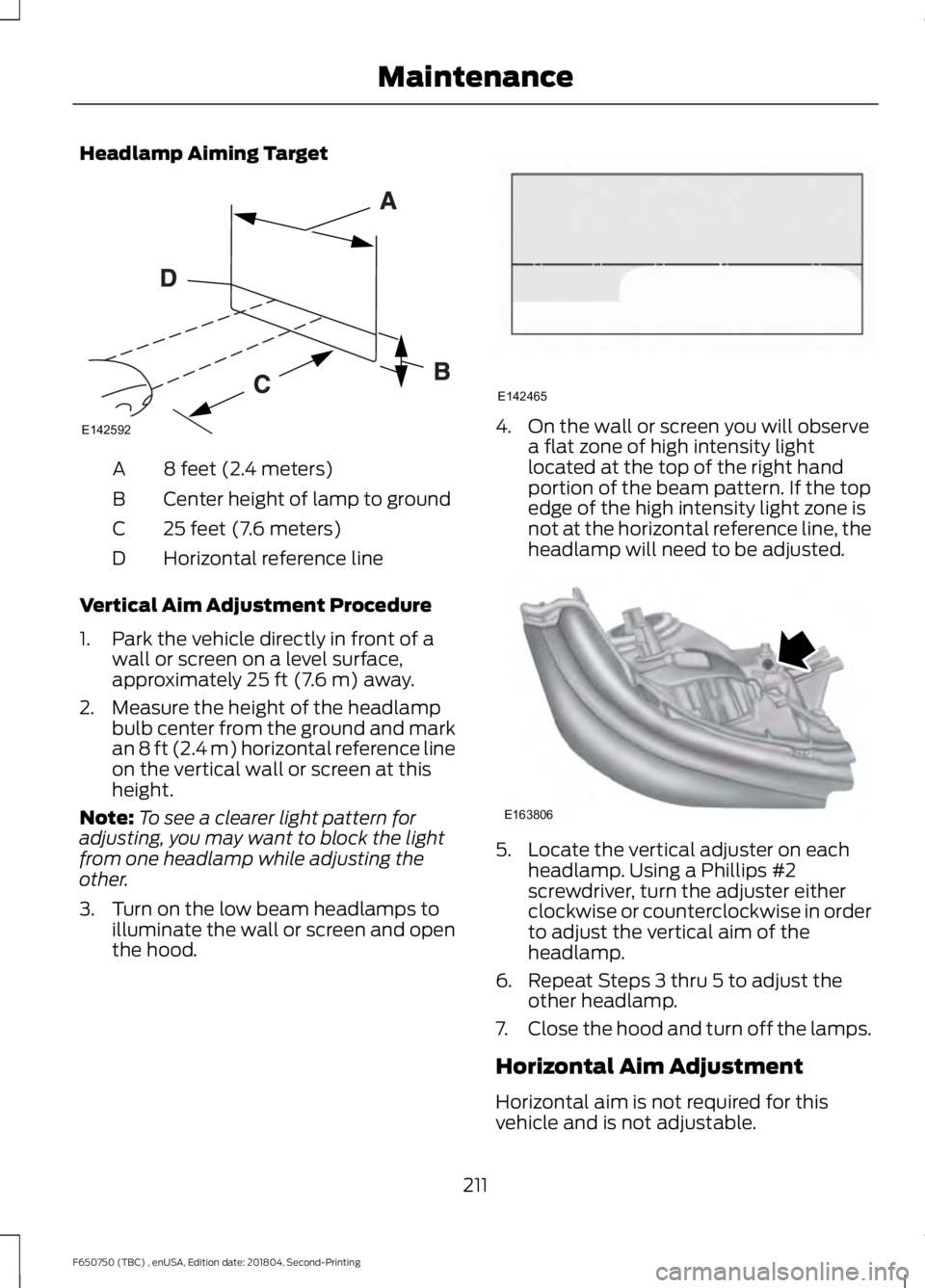

headlamp will need to be adjusted. 5. Locate the vertical adjuster on each

headlamp. Using a Phillips #2

screwdriver, turn the adjuster either

clockwise or counterclockwise in order

to adjust the vertical aim of the

headlamp.

6. Repeat Steps 3 thru 5 to adjust the other headlamp.

7. Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for this

vehicle and is not adjustable.

211

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE142592 E142465 E163806

Page 215 of 387

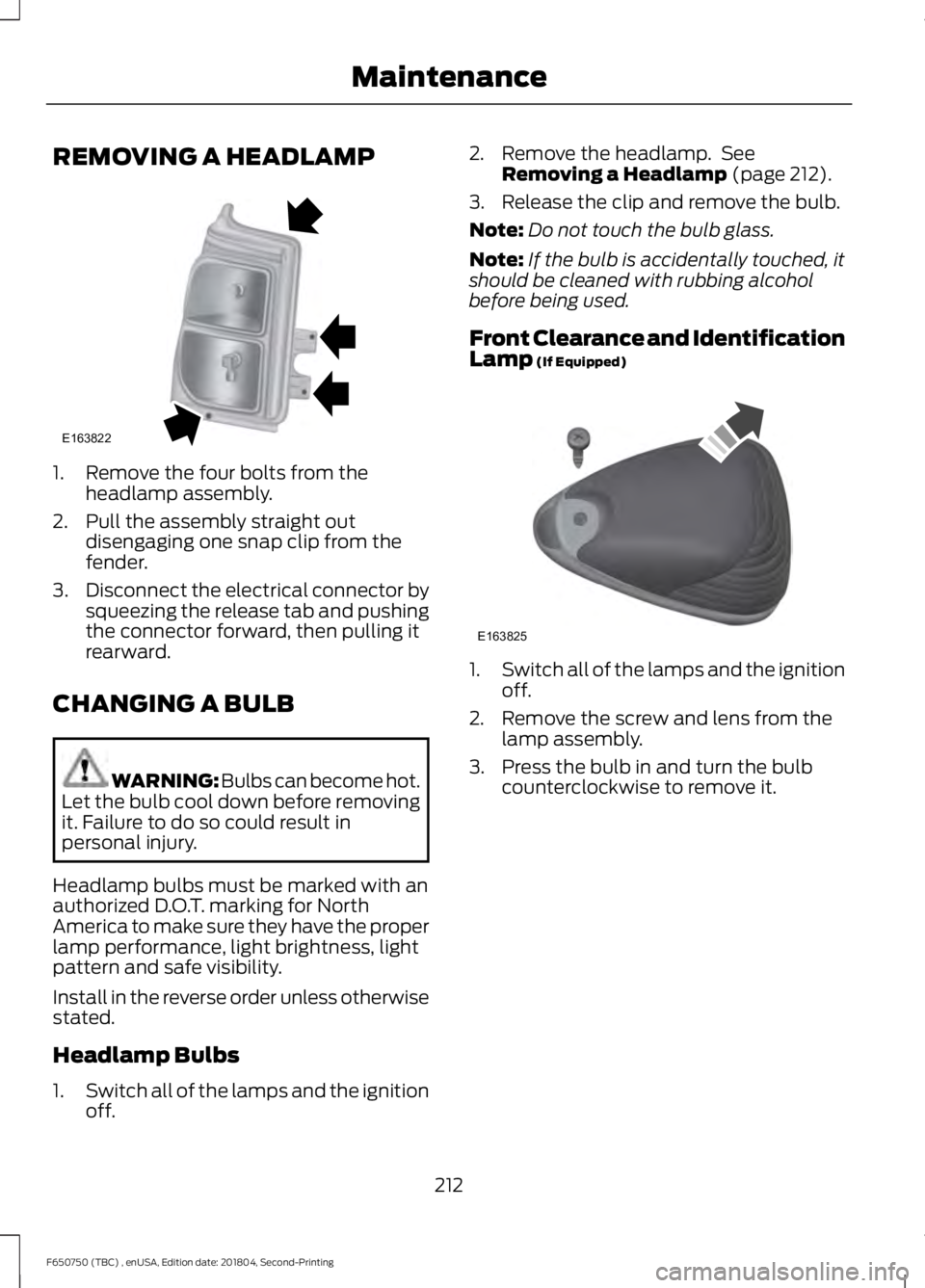

REMOVING A HEADLAMP

1. Remove the four bolts from the

headlamp assembly.

2. Pull the assembly straight out disengaging one snap clip from the

fender.

3. Disconnect the electrical connector by

squeezing the release tab and pushing

the connector forward, then pulling it

rearward.

CHANGING A BULB WARNING: Bulbs can become hot.

Let the bulb cool down before removing

it. Failure to do so could result in

personal injury.

Headlamp bulbs must be marked with an

authorized D.O.T. marking for North

America to make sure they have the proper

lamp performance, light brightness, light

pattern and safe visibility.

Install in the reverse order unless otherwise

stated.

Headlamp Bulbs

1. Switch all of the lamps and the ignition

off. 2. Remove the headlamp. See

Removing a Headlamp (page 212).

3. Release the clip and remove the bulb.

Note: Do not touch the bulb glass.

Note: If the bulb is accidentally touched, it

should be cleaned with rubbing alcohol

before being used.

Front Clearance and Identification

Lamp

(If Equipped) 1.

Switch all of the lamps and the ignition

off.

2. Remove the screw and lens from the lamp assembly.

3. Press the bulb in and turn the bulb counterclockwise to remove it.

212

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163822 E163825

Page 216 of 387

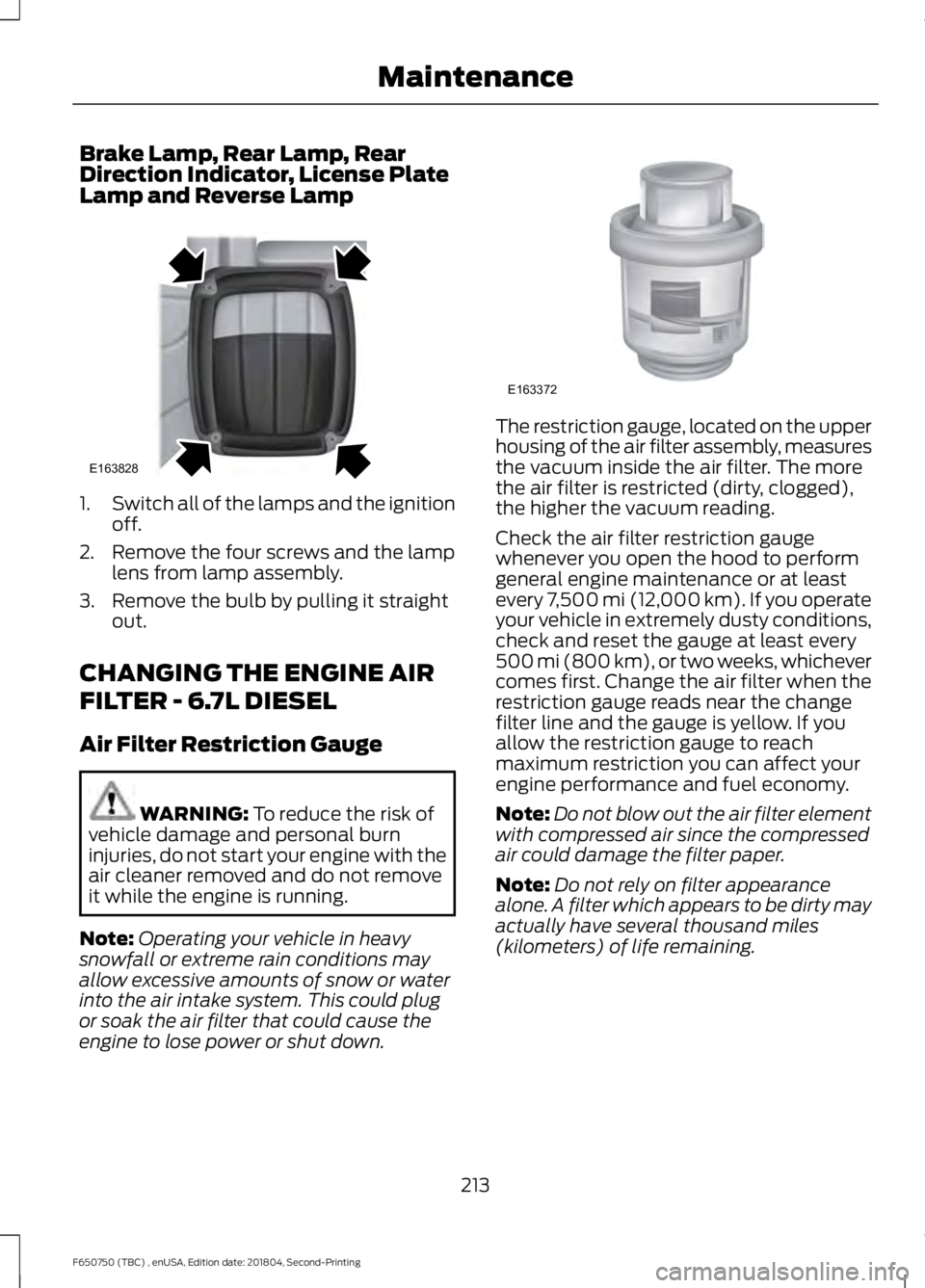

Brake Lamp, Rear Lamp, Rear

Direction Indicator, License Plate

Lamp and Reverse Lamp

1.

Switch all of the lamps and the ignition

off.

2. Remove the four screws and the lamp lens from lamp assembly.

3. Remove the bulb by pulling it straight out.

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge WARNING: To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running.

Note: Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

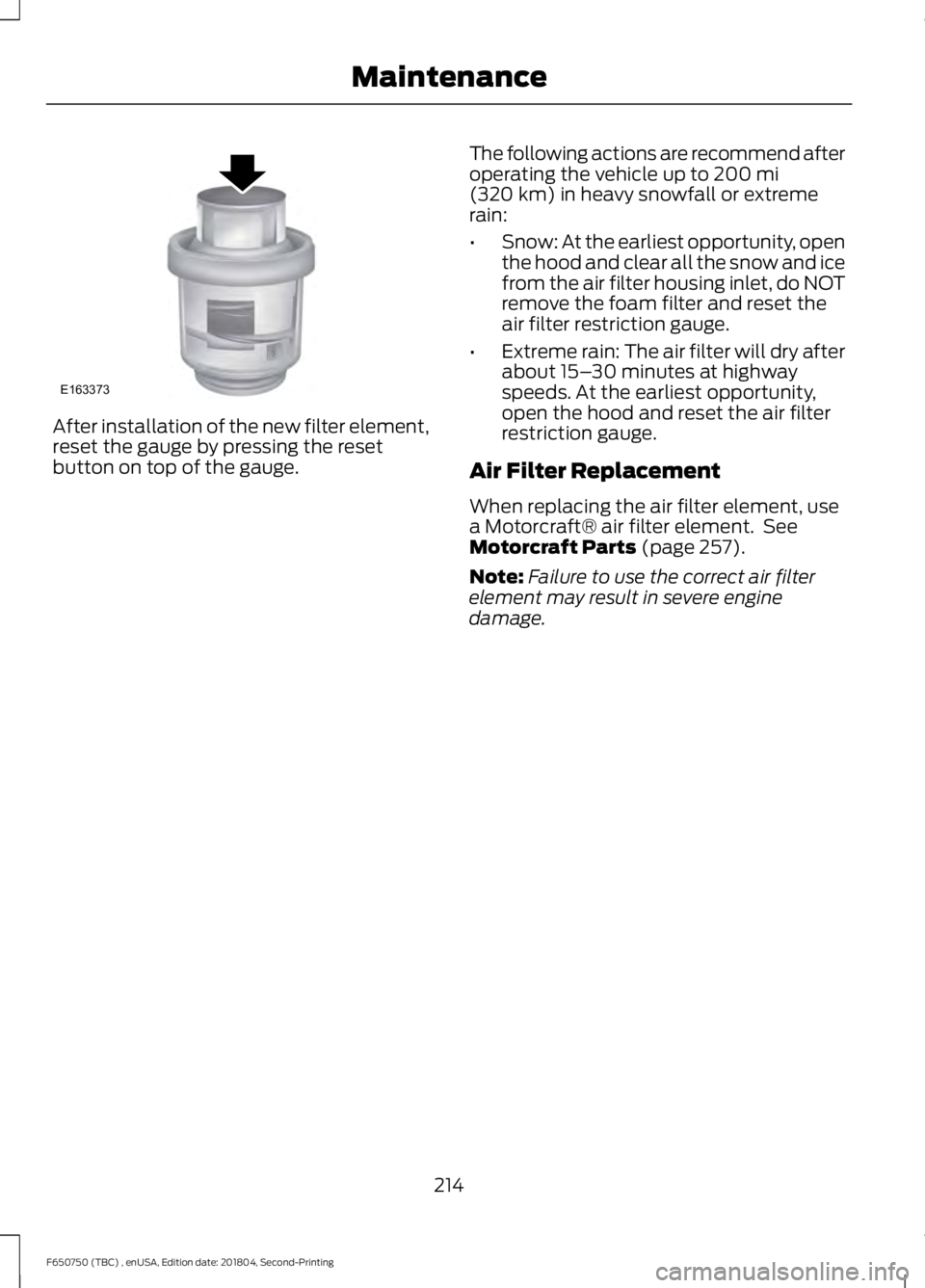

engine to lose power or shut down. The restriction gauge, located on the upper

housing of the air filter assembly, measures

the vacuum inside the air filter. The more

the air filter is restricted (dirty, clogged),

the higher the vacuum reading.

Check the air filter restriction gauge

whenever you open the hood to perform

general engine maintenance or at least

every 7,500 mi (12,000 km). If you operate

your vehicle in extremely dusty conditions,

check and reset the gauge at least every

500 mi (800 km), or two weeks, whichever

comes first. Change the air filter when the

restriction gauge reads near the change

filter line and the gauge is yellow. If you

allow the restriction gauge to reach

maximum restriction you can affect your

engine performance and fuel economy.

Note:

Do not blow out the air filter element

with compressed air since the compressed

air could damage the filter paper.

Note: Do not rely on filter appearance

alone. A filter which appears to be dirty may

actually have several thousand miles

(kilometers) of life remaining.

213

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163828 E163372

Page 217 of 387

After installation of the new filter element,

reset the gauge by pressing the reset

button on top of the gauge.

The following actions are recommend after

operating the vehicle up to 200 mi

(320 km) in heavy snowfall or extreme

rain:

• Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet, do NOT

remove the foam filter and reset the

air filter restriction gauge.

• Extreme rain: The air filter will dry after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

Air Filter Replacement

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts

(page 257).

Note: Failure to use the correct air filter

element may result in severe engine

damage.

214

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163373

Page 218 of 387

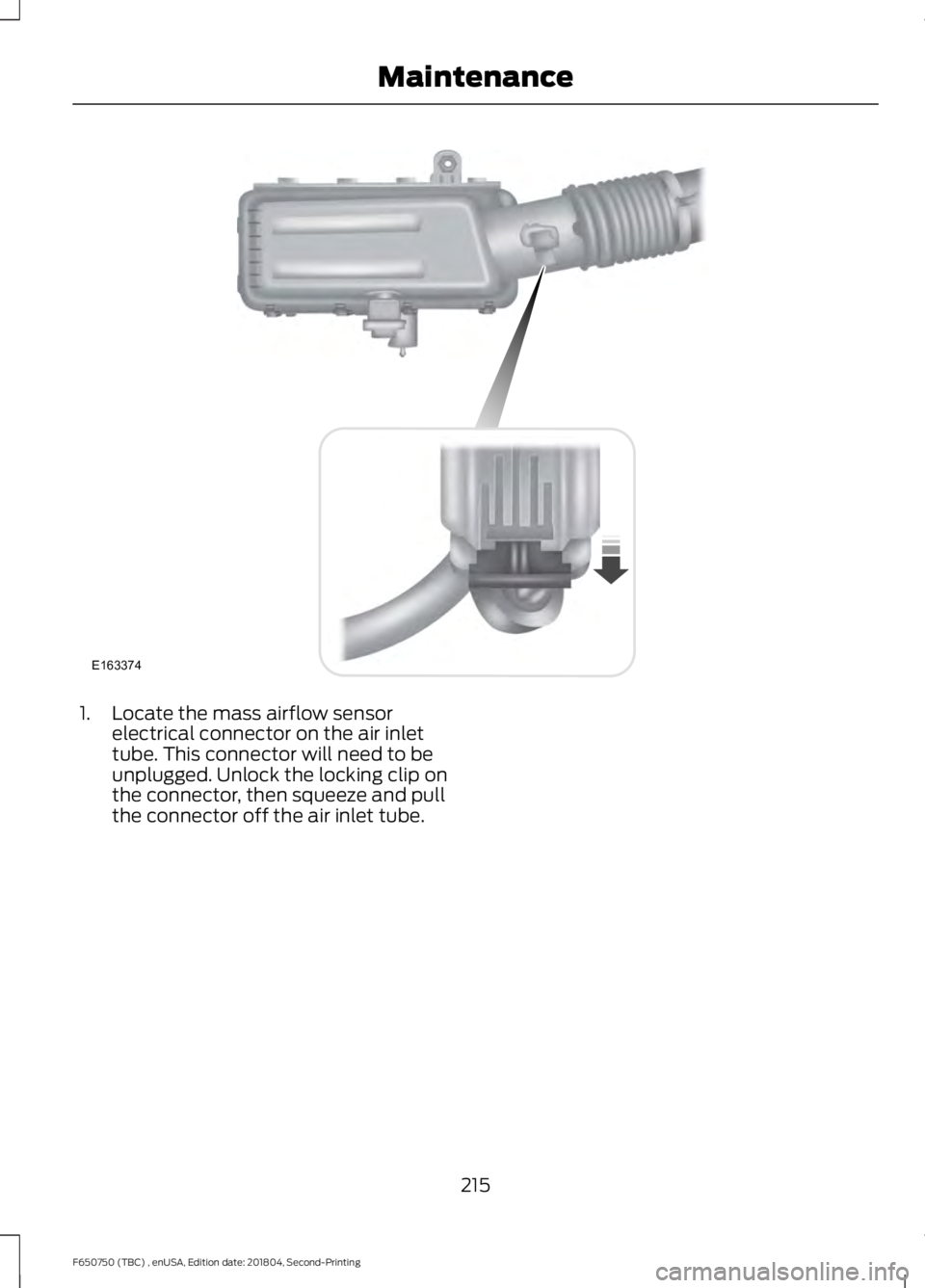

1. Locate the mass airflow sensor

electrical connector on the air inlet

tube. This connector will need to be

unplugged. Unlock the locking clip on

the connector, then squeeze and pull

the connector off the air inlet tube.

215

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE163374

Page 219 of 387

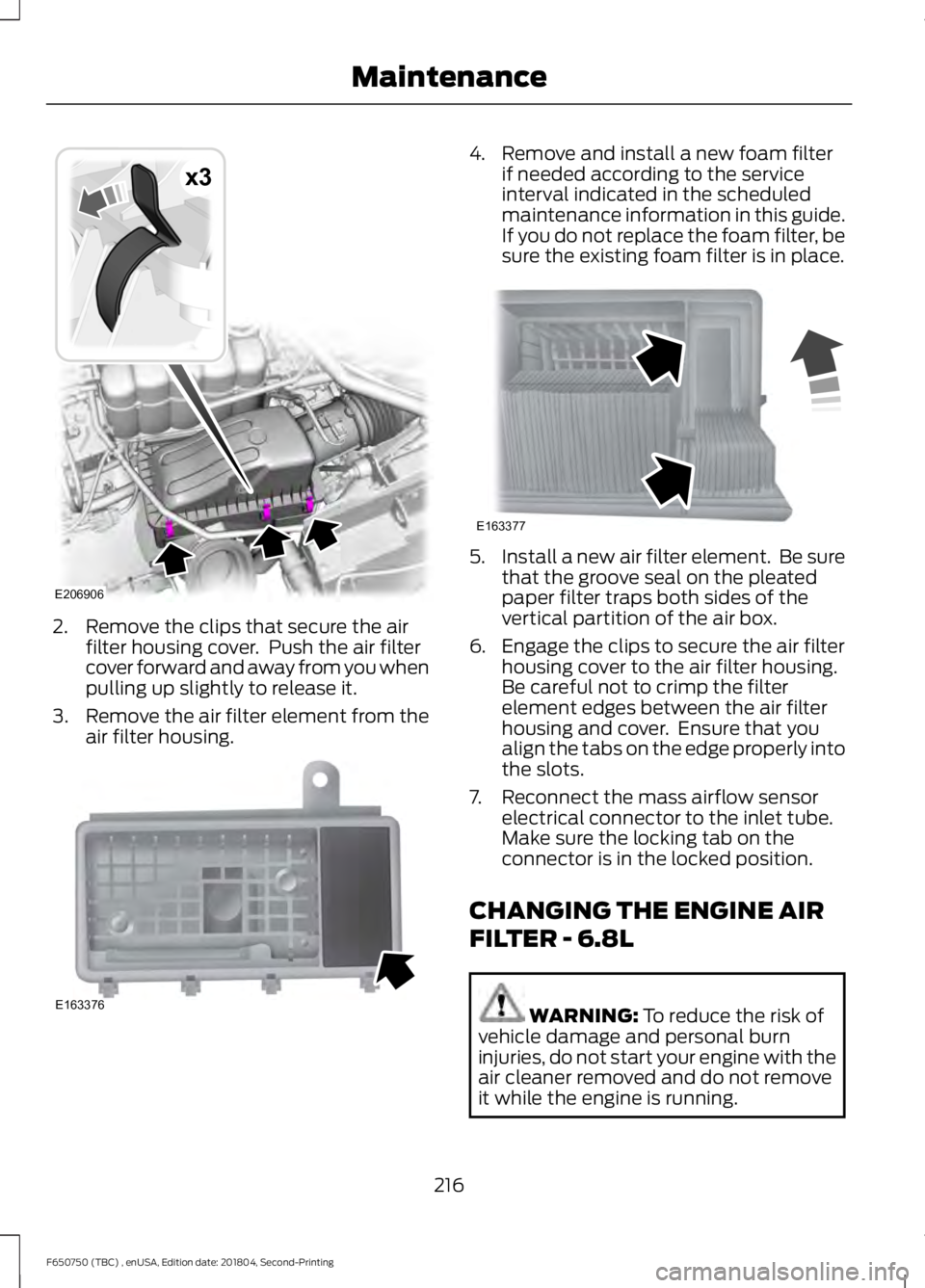

2. Remove the clips that secure the air

filter housing cover. Push the air filter

cover forward and away from you when

pulling up slightly to release it.

3. Remove the air filter element from the

air filter housing. 4. Remove and install a new foam filter

if needed according to the service

interval indicated in the scheduled

maintenance information in this guide.

If you do not replace the foam filter, be

sure the existing foam filter is in place. 5.

Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box.

6. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

7. Reconnect the mass airflow sensor electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position.

CHANGING THE ENGINE AIR

FILTER - 6.8L WARNING: To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running.

216

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE206906

x3 E163376 E163377

Page 220 of 387

Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down.

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 258).

Note: Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

Change the air filter element at the correct

interval. See

Scheduled Maintenance

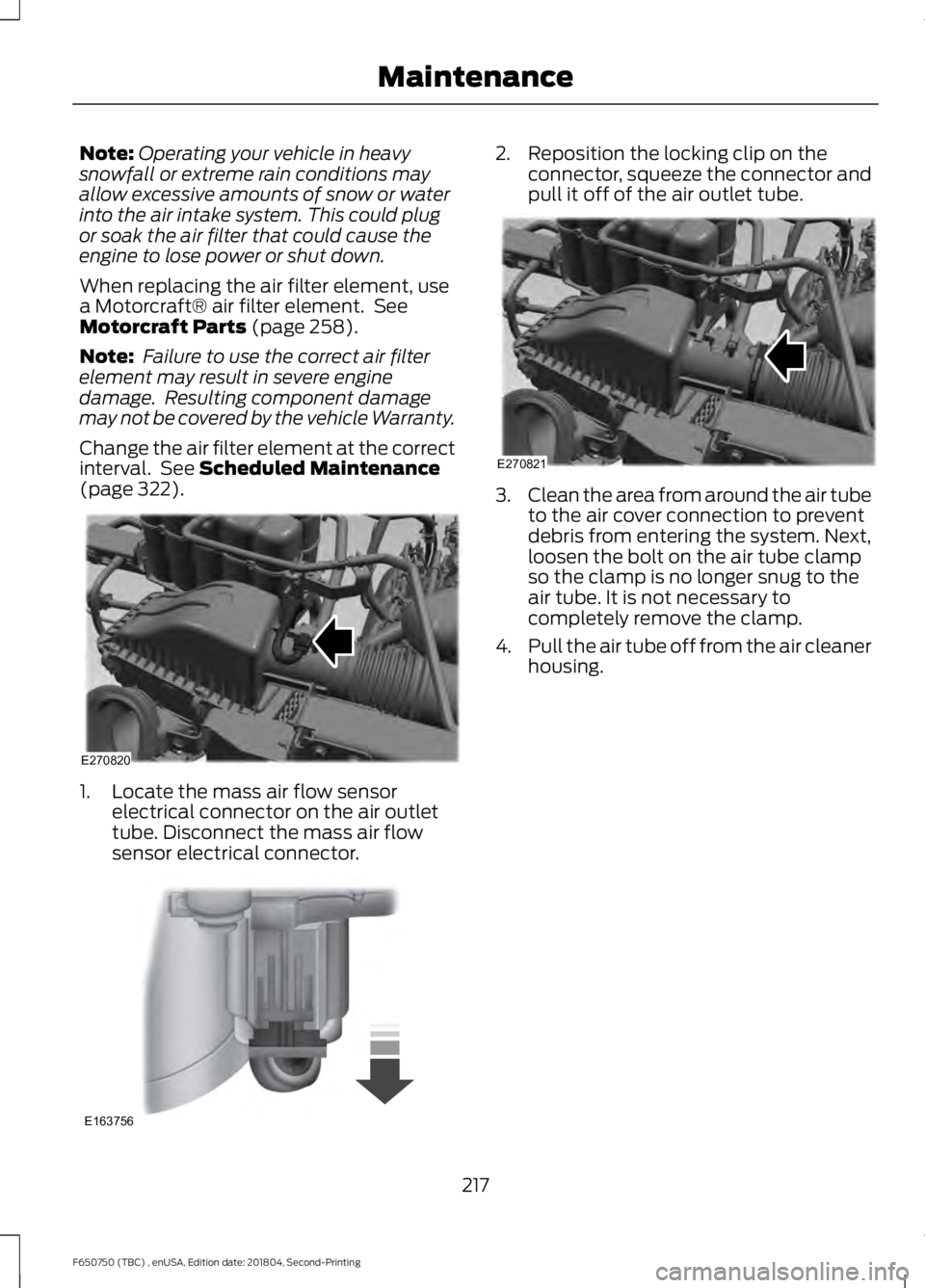

(page 322). 1. Locate the mass air flow sensor

electrical connector on the air outlet

tube. Disconnect the mass air flow

sensor electrical connector. 2. Reposition the locking clip on the

connector, squeeze the connector and

pull it off of the air outlet tube. 3.

Clean the area from around the air tube

to the air cover connection to prevent

debris from entering the system. Next,

loosen the bolt on the air tube clamp

so the clamp is no longer snug to the

air tube. It is not necessary to

completely remove the clamp.

4. Pull the air tube off from the air cleaner

housing.

217

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE270820 E163756 E270821