check engine FORD F650/750 2021 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: F650/750, Model: FORD F650/750 2021Pages: 390, PDF Size: 5.16 MB

Page 232 of 390

Coolant Change

Change the coolant at specific mileage

intervals as listed in the scheduled

maintenance information. The information

display may display a message to change

coolant at this time. Add prediluted

coolant approved to the correct

specification. See Capacities and

Specifications (page 281).

Engine-driven Cooling Fan (Fan

Clutch)

Your vehicle comes with an engine driven

cooling fan drive, also called a fan clutch.

This fan drive changes the fan speed to

match the vehicle ’s changing cooling air

flow requirements. Fan speed, fan noise

level and fuel consumption all will increase

based on the driving conditions that

include trailer towing, hill climbing, heavy

loads, high speed and high ambient

temperature, individually or in combination.

The fan drive is designed to provide the

minimum fan speed, and resulting

minimum fan noise and fuel consumption

required to meet the ever changing vehicle

cooling air flow requirements. You will hear

the amount of fan noise increasing and

decreasing as the engine power

requirements and vehicle driving conditions

change as you drive. This is to be expected

as being normal to the operation of your

vehicle. High levels of fan noise might also

be heard when your engine is first started,

and should normally decrease after driving

for a short time.

Fail-Safe Cooling

Fail-safe cooling allows you to temporarily

drive your vehicle before any incremental

component damage occurs. The fail-safe

distance depends on ambient

temperature, vehicle load and terrain. How Fail-Safe Cooling Works

If the engine begins to overheat, the

coolant temperature gauge moves toward

the red zone: A warning lamp illuminates and

a message may appear in the

information display.

If the engine reaches a preset

over-temperature condition, the engine

switches to alternating cylinder operation.

Each disabled cylinder acts as an air pump

and cools the engine.

When this occurs, your vehicle still

operates, however:

• Engine power is limited.

• The air conditioning system turns off.

Continued operation increases the engine

temperature, causing the engine to

completely shut down. Your steering and

braking effort increases in this situation.

When the engine temperature cools, you

can re-start the engine. Have your vehicle

checked as soon as possible to minimize

engine damage.

When Fail-Safe Mode Is Activated WARNING:

Fail-safe mode is for

use during emergencies only. Operate

your vehicle in fail-safe mode only as

long as necessary to bring your vehicle

to rest in a safe location and seek

immediate repairs. When in fail-safe

mode, your vehicle will have limited

power, will not be able to maintain

229

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 233 of 390

high-speed operation, and may

completely shut down without warning,

potentially losing engine power, power

steering assist, and power brake assist,

which may increase the possibility of a

crash resulting in serious injury.

WARNING: Do not remove the

coolant reservoir cap when the engine is

on or the cooling system is hot. Wait 10

minutes for the cooling system to cool

down. Cover the coolant reservoir cap

with a thick cloth to prevent the

possibility of scalding and slowly remove

the cap. Failure to follow this instruction

could result in personal injury.

Your vehicle has limited engine power

when in the fail-safe mode, drive your

vehicle with caution. Your vehicle does not

maintain high-speed operation and the

engine may operate poorly.

Remember that the engine is capable of

shutting down to prevent engine damage.

In this situation:

1. Pull off the road as soon as safely possible and switch the engine off.

2. If you are a member of a roadside assistance program, we recommend

that you contact your roadside

assistance service provider.

3. If this is not possible, wait a short period for the engine to cool.

4. Check the coolant level. If the coolant level is at or below the minimum mark,

add prediluted coolant immediately.

5. When the engine temperature cools, you can re-start the engine. Have your

vehicle checked as soon as possible to

minimize engine damage.

Note: Driving your vehicle without repair

increases the chance of engine damage. Engine Coolant Temperature

Management

(If Equipped) WARNING:

To reduce the risk of

crash and injury, be prepared that the

vehicle speed may reduce and the

vehicle may not be able to accelerate

with full power until the coolant

temperature reduces.

If you tow a trailer with your vehicle, the

engine may temporarily reach a higher

temperature during severe operating

conditions, for example ascending a long

or steep grade in high ambient

temperatures.

At this time, you may notice the coolant

temperature gauge moves toward the red

zone and a message may appear in the

information display.

You may notice a reduction in vehicle

speed caused by reduced engine power in

order to manage the engine coolant

temperature. Your vehicle may enter this

mode if certain high-temperature and

high-load conditions take place. The

amount of speed reduction depends on

vehicle loading, grade and ambient

temperature. If this occurs, there is no

need to pull off the road. You can continue

to drive your vehicle.

The air conditioning may turn on and off

during severe operating conditions to

protect the engine from overheating. When

the coolant temperature decreases to the

normal operating temperature, the air

conditioning turns on.

If the coolant temperature gauge moves

fully into the red zone, or if the coolant

temperature warning or service engine

soon messages appear in your information

display, do the following:

230

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 234 of 390

1. Pull off the road as soon as safely

possible and shift the transmission into

park (P).

2. Leave the engine running until the coolant temperature gauge needle

returns to the normal position. After

several minutes, if the temperature

does not drop, follow the remaining

steps.

3. Switch the engine off and wait for it to

cool. Check the coolant level.

4. If the coolant level is at or below the minimum mark, add prediluted coolant

immediately.

5. If the coolant level is normal, restart the engine and continue.

ENGINE COOLANT CHECK -

6.7L DIESEL WARNING: Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury. WARNING:

Do not put coolant in

the windshield washer reservoir. If

sprayed on the windshield, coolant could

make it difficult to see through the

windshield. WARNING:

To reduce the risk of

personal injury, make sure the engine is

cool before unscrewing the coolant

pressure relief cap. The cooling system

is under pressure. Steam and hot liquid

can come out forcefully when you loosen

the cap slightly. WARNING:

Do not add coolant

further than the MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance

(page 319).

Note: Make sure that the coolant level is

between the

MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the

MAX mark.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Adding Coolant WARNING:

Do not add engine

coolant when the engine is hot. Failure

to follow this instruction could result in

personal injury. WARNING:

Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

231

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 235 of 390

Note:

Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See Capacities and

Specifications (page 288). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: Coolants marketed for all makes and

models may not be approved to Ford

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

For vehicles with overflow coolant systems

with a non-pressurized cap on the coolant

recovery system, add coolant to the

coolant recovery reservoir when the engine

is cool. Add prediluted coolant to the

maximum level. For all vehicles which have

a coolant degas system with a pressurized

cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator,

follow these steps to add engine coolant:

1. Turn the engine off and let it cool.

2. Unscrew the cap slowly. Any pressure escapes as you unscrew the cap.

3. Fill the coolant reservoir slowly with prediluted engine coolant to within the

minimum and maximum range on the

engine coolant reservoir. If you

removed the radiator cap in an

overflow system, fill the radiator until the coolant is visible and the radiator

is almost full. If coolant is added to

bring the level within the minimum and

maximum range when the engine is not

cold, the system may remain under

filled.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

Note: If prediluted coolant is not available,

use the approved antifreeze concentrate

diluting it to 50/50 with distilled water. See

Capacities and Specifications

(page 288).

Using water that has not been deionized

may contribute to deposit formation,

corrosion or plugging of the small cooling

system passageways.

If you have to add more than

1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note: During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced.

In case of emergency, you can add a large

amount of water without prediluted

coolant in order to reach a vehicle service

location. On arrival do the following:

1. Drain the cooling system.

2. Chemically clean the cooling system. We recommend Motorcraft Premium

Cooling System Flush.

232

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 236 of 390

3. Refill with prediluted coolant as soon

as possible.

Water alone, without prediluted coolant,

can cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or non-specified

additives to the coolant. These can be

harmful and compromise the corrosion

protection of the coolant.

Engine and Secondary Cooling

System Refill Procedure

The following procedure should be used

when refilling the engine or secondary

cooling systems after it has been drained

or become extremely low:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly turn cap

counterclockwise until pressure begins

to release.

3. Step back when the pressure releases.

4. When you are sure that all the pressure

has been released, use the cloth to turn

the cap counterclockwise and then

remove it.

5. Slowly add prediluted engine coolant to the coolant reservoir until the

coolant level is within the minimum

and maximum range as listed on the

reservoir.

6. Reinstall the pressure relief cap. 7. Start and run the engine at 2000 rpm

for 2 minutes.

8. Shut engine off, and remove the pressure relief cap as previously

outlined.

9. If required, add prediluted engine coolant to the coolant reservoir until

the coolant level is within the minimum

and maximum range as listed on the

reservoir.

10. Engine cooling system: Repeat steps

5 through 9 until the coolant level has

stabilized (is no longer dropping after

each step) and the upper radiator

hose at the radiator is warm to the

touch (indicating that the engine

thermostat is open and coolant is

flowing through the radiator).

11. Check the secondary cooling system.

Repeat steps 1 through 10 until the

coolant level has stabilized (is no

longer dropping after each step) and

the lower passenger side of the

secondary radiator is warm to the

touch (indicating secondary

thermostat is open and coolant is

flowing through the entire system).

12. Check the coolant level in both systems before you drive your vehicle

the next few times.

13. If necessary, add prediluted engine coolant to the coolant reservoirs until

the coolant level is within the

minimum and maximum range as

listed on the reservoir. After any

coolant has been added, check the

coolant concentration.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

233

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 237 of 390

Dispose of used engine coolant in an

appropriate manner. Follow your

community

’s regulations and standards

for recycling and disposing of automotive

fluids.

Severe Climates

If you drive in extremely cold climates:

• It may be necessary to increase the

coolant concentration above 50%.

• A coolant concentration of 60%

provides improved freeze point

protection. Coolant concentrations

above 60% decrease the overheat

protection characteristics of the

coolant and may cause engine

damage.

If you drive in extremely hot climates:

• You can decrease the coolant

concentration to 40%.

• Coolant concentrations below 40%

decrease the freeze and corrosion

protection characteristics of the

coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted engine

coolant for optimum cooling system and

engine protection.

Checking Coolant Corrosion

Inhibitor Additive Strength

At specific mileage intervals as listed in the

scheduled maintenance information

chapter, the coolant corrosion inhibitor

additive should be checked. An information

message may display in the optional

information display at this time. The

purpose of checking is to verify the correct

engine coolant concentration (freeze point

protection) and corrosion inhibitor additive

level (strength) of the coolant for

maximum engine performance and

protection. Three products are available to confirm

the life and health of the coolant, one tool,

a test kit and a coolant inhibitor additive:

234

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 239 of 390

AUTOMATIC TRANSMISSION

FLUID CHECK

The transmission does not consume fluid.

However, check the fluid level if the

transmission is not working properly, for

example if the transmission slips, shifts

slowly or if there are signs of fluid loss.

Replace the transmission fluid and filter

on your vehicle at the specified service

interval. See Scheduled Maintenance

(page 319).

Automatic transmission fluid expands

when warmed. To check the fluid level

consistently and accurately, do the

following:

1. Drive the vehicle until it reaches normal

operating temperature. This may take

up to

20 mi (30 km). Make sure that

the transmission fluid temperature

gauge on the instrument cluster is

within normal operating temperature

196– 215°F (91– 102°C)

before

checking.

2. Make sure that your vehicle is on level ground.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Make sure the parking brake is on. Make

sure the transmission is in park (P) or

neutral (N) and leave the engine

running.

5. Open the hood. See

Opening and

Closing the Hood (page 213).

6. Remove the dipstick and wipe it with a clean, lint-free cloth. See

Under

Hood Overview (page 215).

7. Replace the dipstick and remove it again to check the fluid level. 8. If the fluid level is correct, replace the

dipstick and make sure it is fully seated.

Note: If the fluid level is between the

maximum and minimum marks, the fluid

level is acceptable. Do not add fluid.

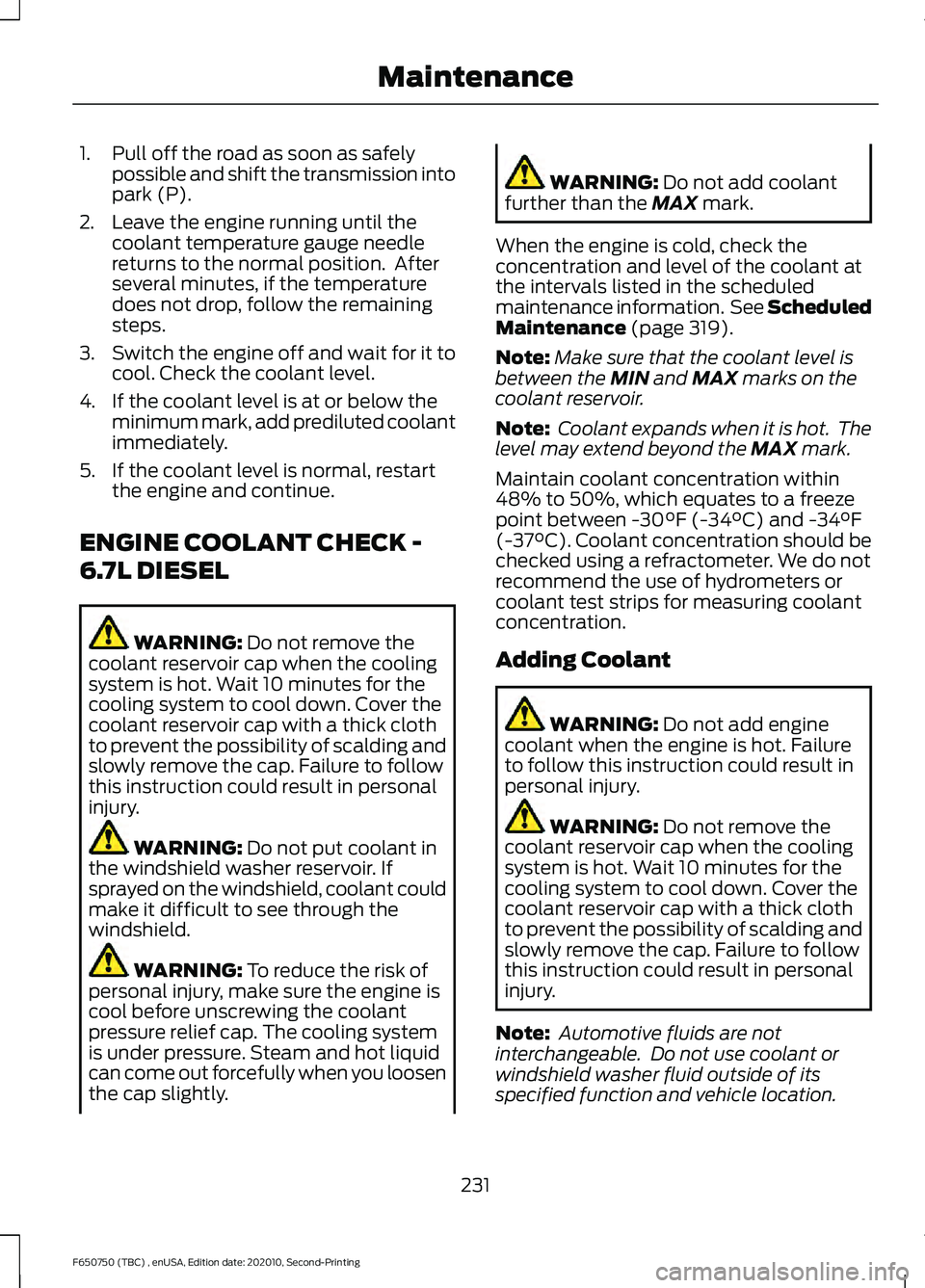

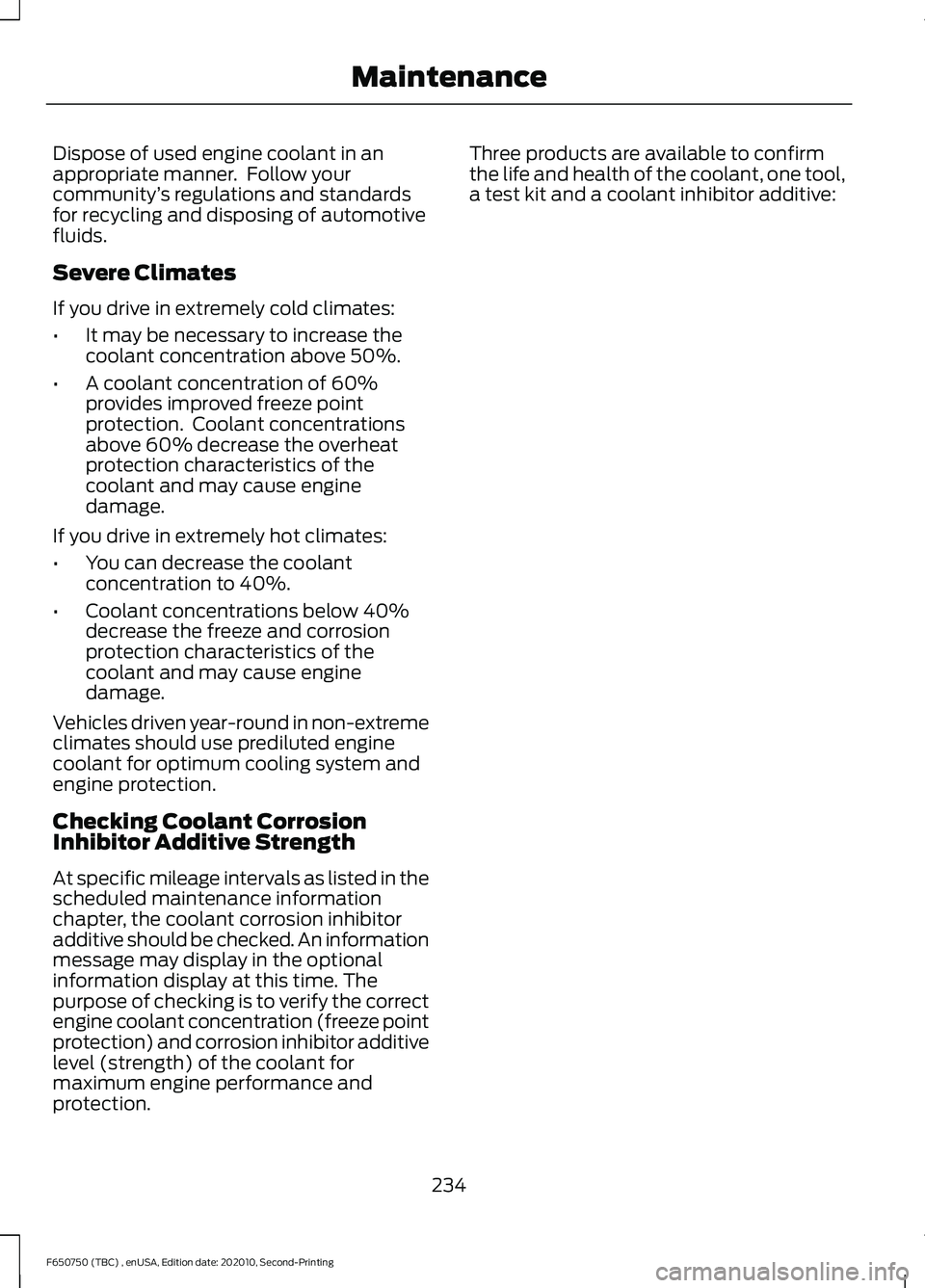

Transmission Fluid Level

Low Fluid Level If the fluid level is at or below the minimum

mark, add fluid immediately. See

Capacities and Specifications

(page

288).

Note: If there is no indication of fluid on the

dipstick, have your vehicle checked

immediately.

Correct Fluid Level Make sure that the fluid level is between

the maximum and minimum marks.

236

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163740 E163742

Page 241 of 390

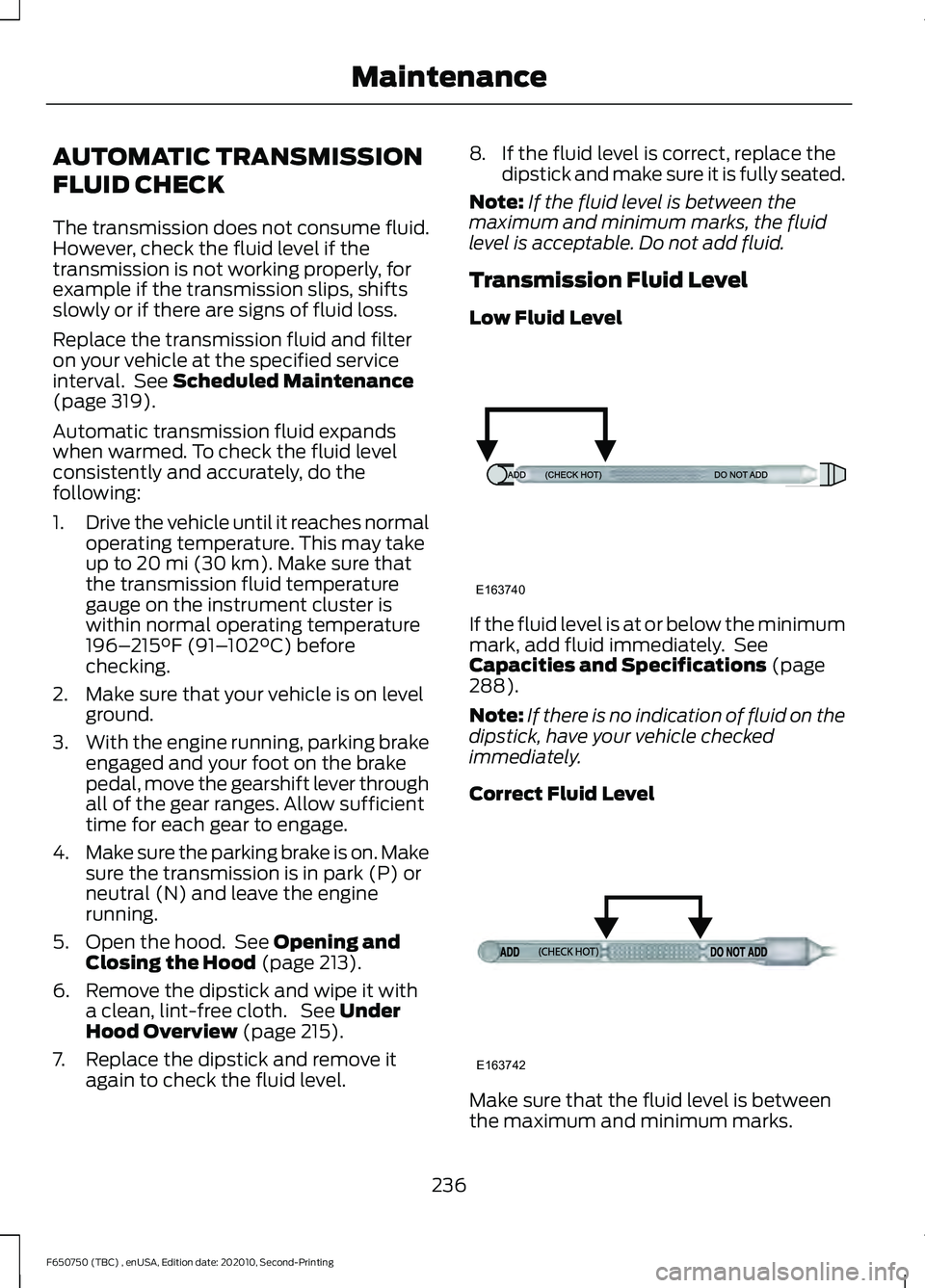

1. Park your vehicle on a level surface.

2. Look at the brake fluid reservoir to see

where the brake fluid level is relative

to the MIN and the MAX marks on the

reservoir.

Note: If the brake fluid level is between the

MIN

and the MAX marks on the reservoir, it

is acceptable.

Note: If the brake fluid level is below the

MIN

mark or above the MAX mark, have

your vehicle checked as soon as possible.

Note: To avoid fluid contamination, the

reservoir cap must remain in place and fully

tight, unless you are adding fluid.

Only use fluid that meets our

specifications. See

Capacities and

Specifications (page 281).

Brake Fluid Service Interval

Brake fluid absorbs water over time which

degrades the effectiveness of the brake

fluid. Change the brake fluid at the

specified intervals to prevent degraded

braking performance. For detailed interval information, see

Scheduled Maintenance in your Owner's

Manual or your local maintenance guide.

POWER STEERING FLUID

CHECK

Check the power steering fluid. See

Scheduled Maintenance

(page 319). If

adding fluid is necessary, use only

MERCON LV ATF

Check the fluid level when it is at ambient

temperature.

1. Check the fluid level in the reservoir. It should be between the MIN and MAX

range. Do not add fluid if the level is

within this range.

2. If the fluid level is low, add fluid to bring

the fluid level up to between the MIN

and MAX range.

3. Switch the engine on.

4. While the engine idles, turn the steering

wheel left and right several times.

5. Switch the engine off.

6. Recheck the fluid level in the reservoir. Do not add fluid if the level is between

the MIN and MAX range.

7. If the fluid is low, add the proper type of fluid in small amounts, continuously

checking the level until it is between

the MIN and MAX range. See

Capacities and Specifications (page

288). Be sure to put the cap back on the

reservoir.

238

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE170684

Page 243 of 390

5. Turn the air conditioning (if equipped)

on and allow the engine to idle for at

least one minute.

6. Release the parking brake. With your foot on the brake pedal and with the

air conditioning on, put the vehicle in

drive (D) and allow the engine to idle

for at least one minute.

•If you do not allow the engine to

relearn its idle trim, the idle quality

of your vehicle may be adversely

affected until the idle trim is

eventually relearned.

7. Drive the vehicle to complete the relearning process

•The vehicle may need to be driven

10 mi (16 km) or more to relearn the

idle and fuel trim strategy along

with the ethanol content for flexible

fuel vehicles.

If the battery has been disconnected or a

new battery has been installed, the clock

and radio settings must be reset once the

battery is reconnected.

Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized standards

for disposal. Call your local authorized

recycling center to find out more about

recycling automotive batteries.

Battery Management System (If

Equipped)

The battery management system (BMS)

monitors battery conditions and takes

actions to extend battery life. If excessive

battery drain is detected, the system may

temporarily disable certain electrical

features to protect the battery. Those

electrical accessories affected include the

rear defrost, heated/cooled seats, climate

control fan, heated steering wheel, audio

and navigation system. A message may be

shown in the information displays to alert the driver that battery protection actions

are active. These messages are only for

notification that an action is taking place,

and not intended to indicate an electrical

problem or that the battery requires

replacement.

Electrical accessory installation

To ensure proper operation of the BMS,

any electrical devices that are added to

the vehicle should not have their ground

connection made directly at the negative

battery post. A connection at the negative

battery post can cause inaccurate

measurements of the battery condition

and potential incorrect system operation.

Note:

Electrical or electronic accessories

added to the vehicle by the dealer or the

owner may adversely affect battery

performance and durability, and may also

affect the performance of other electrical

systems in the vehicle.

When a battery replacement is required,

the battery should only be replaced with

a Ford recommended replacement battery

which matches the electrical requirements

of the vehicle. After battery replacement,

or in some cases after charging the battery

with the external charger, the BMS requires

eight hours of vehicle sleep time (key off

with doors closed) to relearn the new

battery state of charge. Prior to relearning

the state of charge, the BMS may disable

electrical features (to protect the battery)

earlier than normal.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are

properly aimed at the assembly plant. If

your vehicle has been in an accident, the

alignment of your headlamps should be

checked by your authorized dealer.

240

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 251 of 390

Before engine operation, remove any debris

blocking the core.

•

Turbocharger-to-charge air cooler.

• Charge air cooler-to-intake manifold

pipe.

• Mounting bracket.

• Chassis-mounted charge air cooler

core.

Inspect air intake piping:

• Check for accumulation of salt

deposits (where applicable). If present,

disassemble and clean the complete

air intake piping system. If pitting is

evident on the intake piping, use

Motorcraft Silicone Gasket and Sealant

TA-30 to seal joints against leakage.

• Check for loose hoses and clamps.

• Check for ruptured or collapsed hoses.

• Check air cleaner housing for cracks.

EXHAUST SYSTEM

INSPECTION

Note: If your vehicle is equipped with a

catalytic converter or muffler, do not blend

waste oil with diesel fuel. Operate only on

ultra-low sulfur (less than 15 parts per

million sulfur) diesel fuel with a cetane

value of 45 or higher.

If your diesel engine is equipped with a

catalytic converter, it is important to review

the maintenance schedule to make sure

proper functioning of the catalytic

converter. Also, take precautions not to

damage the catalytic converter when

servicing your engine or storing your

vehicle. BRAKE SYSTEM INSPECTION WARNING: Always wear a

respirator approved by the National

Institute of Occupational Studies of

Health (NIOSH) or Mine Safety and

Appliance (MSA) during all brake service

procedures. Wear the respirator from

removal of the wheels through assembly.

Never use compressed air or dry brushing

to clean brake parts or assemblies.

Clean brake parts and assemblies in

open air. During assembly, carefully

place all parts on the floor to avoid

getting dust in the air. Use an industrial

vacuum cleaner with a HEPA filter

system to clean dust from the brake

drums, backing plates and other brake

parts. After using the vacuum, remove

any remaining dust with a rag soaked in

water and wrung until nearly dry.

Never use compressed air or dry

sweeping to clean the work area. Use an

industrial vacuum cleaner with a HEPA

filter system and rags soaked in water

and wrung until nearly dry. Dispose of

used rags with care to avoid getting dust

in the air. Use an approved respirator

when emptying vacuum cleaners and

handling used rags.

Worker clean-up: Wash your hands

before eating, drinking or smoking.

Vacuum your work clothes after use and

then launder them separately, without

shaking them, to prevent fiber dust

getting into the air.

Your vehicle is equipped with

non-asbestos brake linings. However,

exposure to excessive amounts of brake

material (whether asbestos or

non-asbestos, fiberglass, mineral wool,

aramid or carbon) may be a serious health

hazard.

248

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance