check engine light FORD F650/750 2023 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2023, Model line: F650/750, Model: FORD F650/750 2023Pages: 378, PDF Size: 5.65 MB

Page 146 of 378

Vehicles with Automatic Transmission

You cannot turn the system on or off.

When you switch the ignition on, the

system automatically turns on.

AIR BRAKES (IF EQUIPPED)

WARNING: Do not drive or continue

to drive if the low air pressure buzzer is

sounding or the brake warning light is lit.

These warnings indicate that air pressure

is not to normal operating level.

Continued use of the vehicle could result

in loss of braking ability.

WARNING: Avoid repeated light

application of the brake pedal. This

depletes air pressure faster and could

result in loss of braking capability.

WARNING: Do not move the

vehicle when the air pressure is

insufficient because the brake system

may be inoperative.

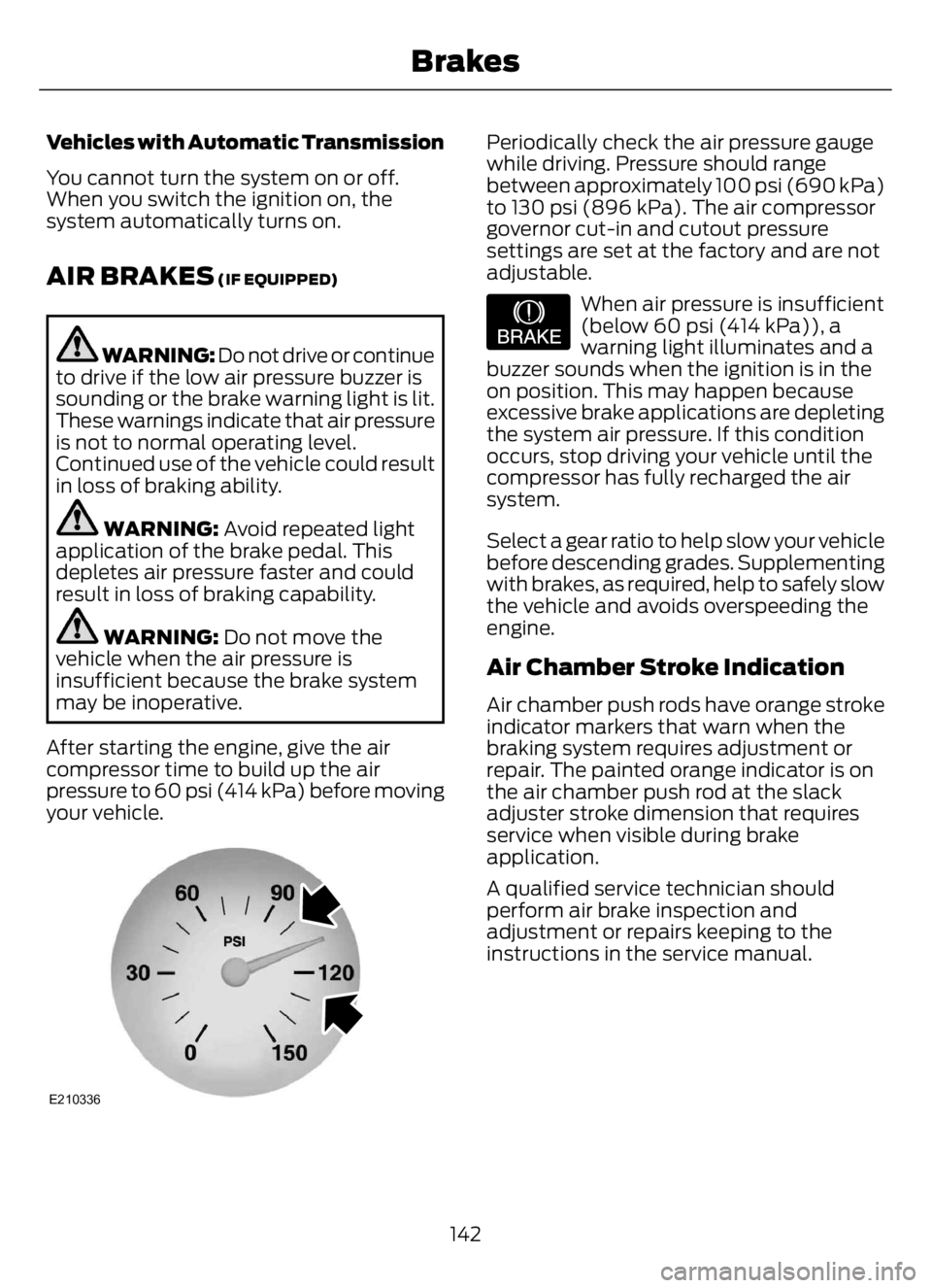

After starting the engine, give the air

compressor time to build up the air

pressure to 60 psi (414 kPa) before moving

your vehicle.

E210336

Periodically check the air pressure gauge

while driving. Pressure should range

between approximately 100 psi (690 kPa)

to 130 psi (896 kPa). The air compressor

governor cut-in and cutout pressure

settings are set at the factory and are not

adjustable.

E206772

When air pressure is insufficient

(below 60 psi (414 kPa)), a

warning light illuminates and a

buzzer sounds when the ignition is in the

on position. This may happen because

excessive brake applications are depleting

the system air pressure. If this condition

occurs, stop driving your vehicle until the

compressor has fully recharged the air

system.

Select a gear ratio to help slow your vehicle

before descending grades. Supplementing

with brakes, as required, help to safely slow

the vehicle and avoids overspeeding the

engine.

Air Chamber Stroke Indication

Air chamber push rods have orange stroke

indicator markers that warn when the

braking system requires adjustment or

repair. The painted orange indicator is on

the air chamber push rod at the slack

adjuster stroke dimension that requires

service when visible during brake

application.

A qualified service technician should

perform air brake inspection and

adjustment or repairs keeping to the

instructions in the service manual.

142

Brakes

Page 153 of 378

PRINCIPLE OF OPERATION

The traction control system helps avoid

drive wheel spin and loss of traction.

If your vehicle begins to slide, the system

applies the brakes to individual wheels

and, when needed, reduces engine power

at the same time. If the wheels spin when

accelerating on slippery or loose surfaces,

the system reduces engine power in order

to increase traction.

Note:The system does not apply the brakes

when vehicle speed is above 25 mph

(40 km/h).

USING TRACTION CONTROL -

VEHICLES WITH: AIR BRAKES

WARNING: Operating your vehicle

with the traction control disabled could

lead to an increased risk of loss of vehicle

control, vehicle rollover, personal injury

and death.

E330660E330660

Press the TCS Off button on the

instrument panel to enable the

mud/snow mode.

This is beneficial when your vehicle is stuck

in snow or on a slippery road surface. This

mode allows wheel spin to dig your vehicle

out and allows you to rock your vehicle.

Press the switch again to select standard

traction control. The system automatically

selects standard traction control at the

next ignition cycle.

System Indicator Light

Note:If the traction control light does not

flash during a traction control event or stays

illuminated, the system is not functioning

properly. Take your vehicle to an authorized

dealer for service.During traction control operation, the

traction control light flashes rapidly and

the engine does not rev-up when you press

further on the accelerator. This is normal

and is no reason for concern.

In mud/snow mode, the TCS OFF light

illuminates on the instrument cluster. If a

traction event occurs in either mode, the

stability and traction control light flashes

rapidly.

USING TRACTION CONTROL -

VEHICLES WITH: HYDRAULIC

BRAKES

WARNING: Operating your vehicle

with the traction control disabled could

lead to an increased risk of loss of vehicle

control, vehicle rollover, personal injury

and death.

The system turns on each time you switch

the ignition on.

E330660E330660

Use the traction control button

on the instrument panel to

switch the system off or on.

If your vehicle is stuck in mud or snow,

switching traction control off is beneficial

as this allows the wheels to spin.

Press the button again to switch the

traction control system on.

System Indicator Light

Note:If the traction control light does not

flash during a traction control event or stays

on, the system is not operating. Have the

system checked as soon as possible.

During a traction control event, the traction

control light rapidly flashes. Pressing

further on the accelerator does not cause

the engine to rev higher. This is normal and

is no reason for concern.

149

Traction Control

Page 184 of 378

ESSENTIAL TOWING CHECKS

See Load limits in the Load Carrying

chapter for load specification terms found

on the tire label and Safety Compliance

label and instructions on calculating your

vehicle's load.

Remember to account for the trailer

tongue weight as part of your vehicle load

when calculating the total vehicle weight.

Hitches

Do not use a hitch that either clamps onto

the bumper or attaches to the axle. You

must distribute the load in your trailer so

that 10-15% of the total weight of the

trailer is on the tongue.

Safety Chains

Note:Do not attach safety chains to the

bumper.

Always connect the safety chains to the

frame or hook retainers of your vehicle

hitch.

To connect the safety chains, cross the

chains under the trailer tongue and allow

enough slack for turning tight corners. Do

not allow the chains to drag on the ground.

Trailer Brakes

WARNING: Do not connect a

trailer's hydraulic brake system directly

to your vehicle's brake system. Your

vehicle may not have enough braking

power and your chances of having a

collision greatly increase.

Electric brakes and manual, automatic or

surge-type trailer brakes are safe if you

install them properly and adjust them to

the manufacturer's specifications. The

trailer brakes must meet local and federal

regulations.The rating for the tow vehicle's braking

system operation is at the gross vehicle

weight rating, not the gross combined

weight rating.

Trailer Lamps

WARNING: Never connect any

trailer lamp wiring to the vehicle's tail

lamp wiring; this may damage the

electrical system resulting in fire. Contact

your authorized dealer as soon as

possible for assistance in proper trailer

tow wiring installation. Additional

electrical equipment may be required.

Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

• Check your hitch, electrical connections

and trailer wheel lug nuts thoroughly

after you have traveled 50 mph

(80 km/h).

• When stopped in congested or heavy

traffic during hot weather, place the

transmission in park (P) or neutral (N)

to aid engine and transmission cooling

and to help air conditioning

performance.

• Turn off the speed control with heavy

loads or in hilly terrain. The speed

control may turn off automatically

when you are towing on long, steep

grades.

180

Towing

Page 185 of 378

• Shift to a lower gear when driving down

a long or steep hill. Do not apply the

brakes continuously, as they may

overheat and become less effective.

• If your transmission is equipped with

the Tow/Haul feature, use this feature

when towing. This provides engine

braking and helps eliminate excessive

transmission shifting for optimum fuel

economy and transmission cooling.

• Allow more distance for stopping with

a trailer attached. Anticipate stops and

brake gradually.

FIFTH WHEEL OPERATION

WARNING: Failure to follow the

fifth wheel manufacturer’s instructions

for hooking and unhooking as well as

sliding the fifth wheel could result in an

accident, personal injury or death.

WARNING: When the tractor and

trailer are parked unattended, the trailer

brake hand control should never be used

to apply the brake, since air may leak

from the system, allowing vehicle

movement, resulting in possible property

damage, personal injury or death.

Before hook-up, make sure:

• The fifth wheel jaws are fully open.

• The fifth wheel is fully tilted back to

prevent body damage when the tractor

is backed under a trailer.

• You block the trailer wheels and adjust

and apply the trailer spring brakes.

Never chase a trailer.

• The brake hoses and light cords are

clear of the fifth wheel.

Hook-up

1. Back the tractor squarely under the

trailer, engaging the fifth-wheel jaws

on the kingpin. Always back up slowly;

make sure the trailer is neither too high

nor too low. Avoid backing under the

trailer from an angle.

2. Connect the service and emergency

brake hoses and trailer light connector.

3. Inspect the jaws of the fifth wheel to

be sure they have fully closed on the

trailer kingpin and the trailer plate is

resting securely on the fifth wheel.

4. Make sure the coupler release lever is

in the locked position.

5. Charge the trailer brake system. Set

the trailer brakes, with either the hand

valve or tractor protection valve. Pull

against the trailer for an extra check of

proper hook-up. Do not pull hard

enough to damage or strain the

equipment.

6. Set the tractor parking brakes and fully

raise the trailer landing gear.

7. Check the operation of all trailer lights

and correct any lights that may be

faulty.

Un-hook

1. Try to keep the tractor and trailer in a

straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making

sure it is on solid, level ground. The

weight of the trailer is to be on the

landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light

cords. Be sure hoses and cords are

clear.

6. Pull coupler release lever to disengage

the fifth wheel jaws.

181

Towing

Page 191 of 378

Avoid driving too fast during the first

1,000 mi (1,600 km). Vary your speed

frequently and change up through the

gears early. Do not labor the engine.

Drive your new vehicle at least 1,000 mi

(1,600 km) before towing a trailer. Make

sure you use the specified engine oil. See

Engine Oil Capacity and Specification

(page 292).

Do not add friction modifier compounds

or special break-in oils during the first few

thousand miles (kilometers) of operation.

These additives may prevent piston ring

seating.

DRIVING THROUGH WATER

WARNING: Do not drive through

flowing or deep water as you may lose

control of your vehicle.

Note:Driving through standing water can

cause vehicle damage.

Note:Engine damage can occur if water

enters the air filter.

Before driving through standing water,

check the depth. Never drive through water

that is higher than the bottom of the wheel

hubs.

E176913E176913

When driving through standing water, drive

very slowly and do not stop your vehicle.

Your brake performance and traction may

be limited. After driving through water and

as soon as it is safe to do so:

• Lightly press the brake pedal to dry the

brakes and to check that they work.

• Check that the horn works.

• Check that the exterior lights work.

• Turn the steering wheel to check that

the steering power assist works.

Operation in Standing Water

Ingestion of water into the diesel engine

can result in immediate and severe

damage to the engine. If driving through

water, slow down to avoid splashing water

into the intake. If the engine stalls, and you

suspect ingestion of water into the engine,

do not try to restart the engine. Consult

your dealer for service immediately.

Your fuel tank vents to the atmosphere by

valves on top of the tank and through the

fuel cap. If water reaches the top of the

tank, the valves may pull water into the

fuel tank. Water in the fuel can cause

performance issues and damage the fuel

injection system.

187

Driving Hints

Page 216 of 378

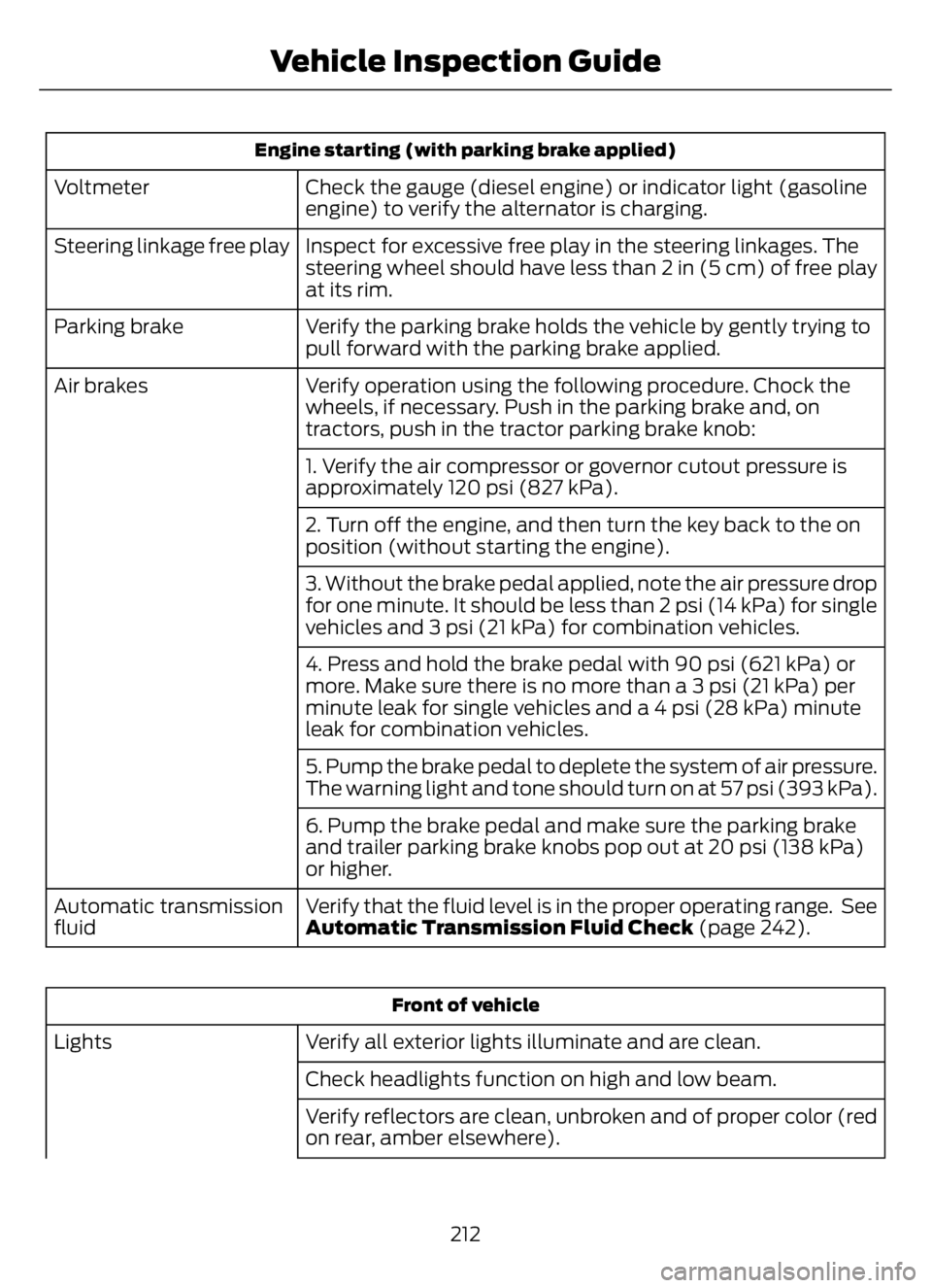

Engine starting (with parking brake applied)

Check the gauge (diesel engine) or indicator light (gasoline

engine) to verify the alternator is charging. Voltmeter

Inspect for excessive free play in the steering linkages. The

steering wheel should have less than 2 in (5 cm) of free play

at its rim. Steering linkage free play

Verify the parking brake holds the vehicle by gently trying to

pull forward with the parking brake applied. Parking brake

Verify operation using the following procedure. Chock the

wheels, if necessary. Push in the parking brake and, on

tractors, push in the tractor parking brake knob: Air brakes

1. Verify the air compressor or governor cutout pressure is

approximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key back to the on

position (without starting the engine).

3. Without the brake pedal applied, note the air pressure drop

for one minute. It should be less than 2 psi (14 kPa) for single

vehicles and 3 psi (21 kPa) for combination vehicles.

4. Press and hold the brake pedal with 90 psi (621 kPa) or

more. Make sure there is no more than a 3 psi (21 kPa) per

minute leak for single vehicles and a 4 psi (28 kPa) minute

leak for combination vehicles.

5. Pump the brake pedal to deplete the system of air pressure.

The warning light and tone should turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the parking brake

and trailer parking brake knobs pop out at 20 psi (138 kPa)

or higher.

Verify that the fluid level is in the proper operating range. See

Automatic Transmission Fluid Check (page 242). Automatic transmission

fluid

Front of vehicle

Verify all exterior lights illuminate and are clean. Lights

Check headlights function on high and low beam.

Verify reflectors are clean, unbroken and of proper color (red

on rear, amber elsewhere).

212

Vehicle Inspection Guide

Page 221 of 378

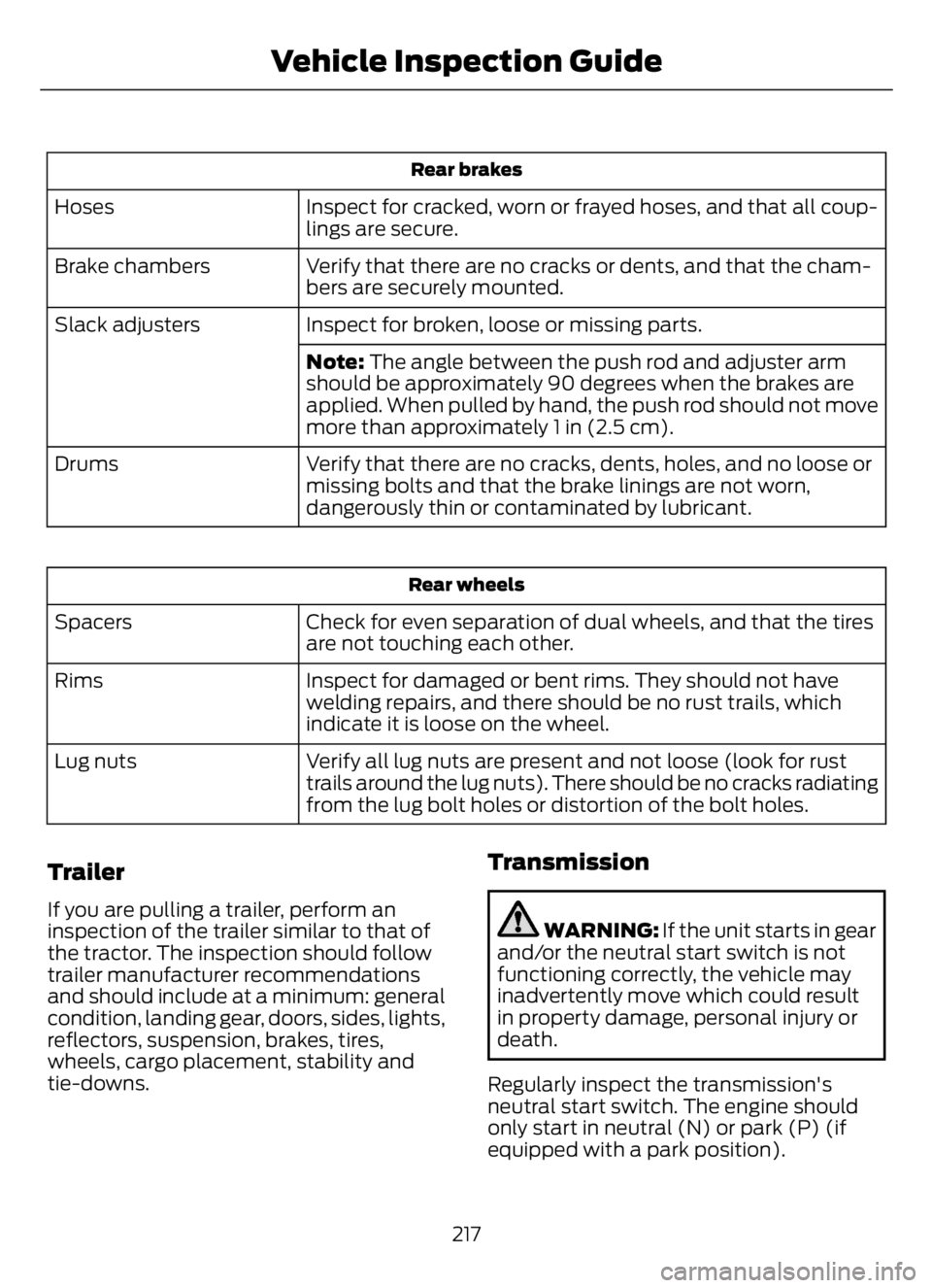

Rear brakes

Inspect for cracked, worn or frayed hoses, and that all coup-

lings are secure. Hoses

Verify that there are no cracks or dents, and that the cham-

bers are securely mounted. Brake chambers

Inspect for broken, loose or missing parts. Slack adjusters

Note: The angle between the push rod and adjuster arm

should be approximately 90 degrees when the brakes are

applied. When pulled by hand, the push rod should not move

more than approximately 1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose or

missing bolts and that the brake linings are not worn,

dangerously thin or contaminated by lubricant. Drums

Rear wheels

Check for even separation of dual wheels, and that the tires

are not touching each other. Spacers

Inspect for damaged or bent rims. They should not have

welding repairs, and there should be no rust trails, which

indicate it is loose on the wheel. Rims

Verify all lug nuts are present and not loose (look for rust

trails around the lug nuts). There should be no cracks radiating

from the lug bolt holes or distortion of the bolt holes. Lug nuts

Trailer

If you are pulling a trailer, perform an

inspection of the trailer similar to that of

the tractor. The inspection should follow

trailer manufacturer recommendations

and should include at a minimum: general

condition, landing gear, doors, sides, lights,

reflectors, suspension, brakes, tires,

wheels, cargo placement, stability and

tie-downs.

Transmission

WARNING: If the unit starts in gear

and/or the neutral start switch is not

functioning correctly, the vehicle may

inadvertently move which could result

in property damage, personal injury or

death.

Regularly inspect the transmission's

neutral start switch. The engine should

only start in neutral (N) or park (P) (if

equipped with a park position).

217

Vehicle Inspection Guide

Page 237 of 378

3. Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the

drain valve and then remove the

container from under your vehicle.

5. Restart the engine. If the Water in Fuel

Drain Filter message and light

continues to illuminate, have the fuel

system checked and repaired.

ENGINE COOLANT CHECK -

6.7L DIESEL

WARNING: Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury.

WARNING: Do not put coolant in

the windshield washer reservoir. If

sprayed on the windshield, coolant could

make it difficult to see through the

windshield.

WARNING: To reduce the risk of

personal injury, make sure the engine is

cool before unscrewing the coolant

pressure relief cap. The cooling system

is under pressure. Steam and hot liquid

can come out forcefully when you loosen

the cap slightly.

WARNING: Do not add coolant

further than the MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance (page 319).

Note:Make sure that the coolant level is

between the MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.

Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Coolant concentration should be

checked using a refractometer. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Adding Coolant

WARNING: Do not add engine

coolant when the engine is hot. Failure

to follow this instruction could result in

personal injury.

WARNING: Do not remove the

coolant reservoir cap when the cooling

system is hot. Wait 10 minutes for the

cooling system to cool down. Cover the

coolant reservoir cap with a thick cloth

to prevent the possibility of scalding and

slowly remove the cap. Failure to follow

this instruction could result in personal

injury.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

233

Maintenance

Page 238 of 378

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See Cooling System Capacity

and Specification (page 297). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: Coolants marketed for all makes and

models may not be approved to Ford

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

For vehicles with overflow coolant systems

with a non-pressurized cap on the coolant

recovery system, add coolant to the

coolant recovery reservoir when the engine

is cool. Add prediluted coolant to the

maximum level. For all vehicles which have

a coolant degas system with a pressurized

cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator,

follow these steps to add engine coolant:

1. Turn the engine off and let it cool.

2. Unscrew the cap slowly. Any pressure

escapes as you unscrew the cap.

3. Fill the coolant reservoir slowly with

prediluted engine coolant to within the

minimum and maximum range on the

engine coolant reservoir. If you

removed the radiator cap in an

overflow system, fill the radiator untilthe coolant is visible and the radiator

is almost full. If coolant is added to

bring the level within the minimum and

maximum range when the engine is not

cold, the system may remain under

filled.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant

reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

Note:If prediluted coolant is not available,

use the approved antifreeze concentrate

diluting it to 50/50 with distilled water. See

Cooling System Capacity and

Specification (page 297). Using water that

has not been deionized may contribute to

deposit formation, corrosion or plugging of

the small cooling system passageways.

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note:During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced.

In case of emergency, you can add a large

amount of water without prediluted

coolant in order to reach a vehicle service

location. On arrival do the following:

1. Drain the cooling system.

2. Chemically clean the cooling system.

We recommend Motorcraft Premium

Cooling System Flush.

234

Maintenance

Page 242 of 378

ENGINE COOLANT CHECK -

7.3L

WARNING: Do not remove the

coolant reservoir cap when the engine is

on or the cooling system is hot. Wait 10

minutes for the cooling system to cool

down. Cover the coolant reservoir cap

with a thick cloth to prevent the

possibility of scalding and slowly remove

the cap. Failure to follow this instruction

could result in personal injury.

WARNING: Do not put coolant in

the windshield washer reservoir. If

sprayed on the windshield, coolant could

make it difficult to see through the

windshield.

WARNING: To reduce the risk of

personal injury, make sure the engine is

cool before unscrewing the coolant

pressure relief cap. The cooling system

is under pressure. Steam and hot liquid

can come out forcefully when you loosen

the cap slightly.

WARNING: Do not add coolant

further than the MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance (page 319).

Note:Make sure that the coolant level is

between the MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the MAX mark.Maintain coolant concentration within

48% to 50%, which equates to a freeze

point between -30°F (-34°C) and -34°F

(-37°C). Check the coolant concentration

using a refractometer. We do not

recommend the use of hydrometers or

coolant test strips for measuring coolant

concentration.

Adding Coolant

WARNING: Do not add engine

coolant when the engine is on or the

cooling system is hot. Failure to follow

this instruction could result in personal

injury.

WARNING: Do not remove the

coolant reservoir cap when the engine is

on or the cooling system is hot. Wait 10

minutes for the cooling system to cool

down. Cover the coolant reservoir cap

with a thick cloth to prevent the

possibility of scalding and slowly remove

the cap. Failure to follow this instruction

could result in personal injury.

Note: Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

238

Maintenance