FORD F750 2017 13.G Owners Manual

Manufacturer: FORD, Model Year: 2017, Model line: F750, Model: FORD F750 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 321 of 382

To make sure the emissions control

systems operate effectively, you should

have the services listed in the maintenance

schedule performed at the specified time

and mileage intervals. You should avoid

running out of fuel or turning off the ignition

when your vehicle is moving, especially at

high speeds.

Do not make unauthorized modifications

to the engine or vehicle. Modifications

causing increased amounts of unburned

fuel to reach the exhaust system can

significantly increase the temperature of

the engine compartment and the exhaust

system.

Avoid driving your vehicle if it does not

operate properly. If the engine diesels

(more than five seconds of engine run-on

after shut-off), misfires, surges, stalls or

backfires, see an authorized dealer. Be alert

for fluid leakage, odor, smoke, loss of oil

pressure, or charge indicator or over

temperature warning.

Vehicles equipped with a diesel engine

cannot use diesel fuel blended with waste

oil if equipped with a catalytic

converter-muffler. Waste lube oil blending

in fuel plugs the catalytic

converter-muffler, resulting in a significant

loss of engine power.

Noise Emissions Warranty, Prohibited

Tampering Acts and Maintenance

On January 1, 1978, Federal regulations

became effective governing the noise

emissions on trucks over 10000 pounds

(4536 kilograms) GVWR. The following

statements concerning prohibited

tampering acts and maintenance and the

noise warranty are found in the warranty

information, and are applicable to

completed trucks.

Tampering with Noise Control System

Prohibited

Federal law prohibits the following acts or

the causing thereof: (1) The removal or

rendering inoperative, by any person other

than for purposes of maintenance, repair

or replacement, of any device or element

of design incorporated into any new vehicle

for the purpose of noise control prior to its

sale or delivery to the ultimate purchaser

or while it is in use, or (2) the use of the

vehicle after such device or element of

design has been removed or rendered

inoperative by any person.

Among those acts presumed to constitute

tampering are the following acts listed:

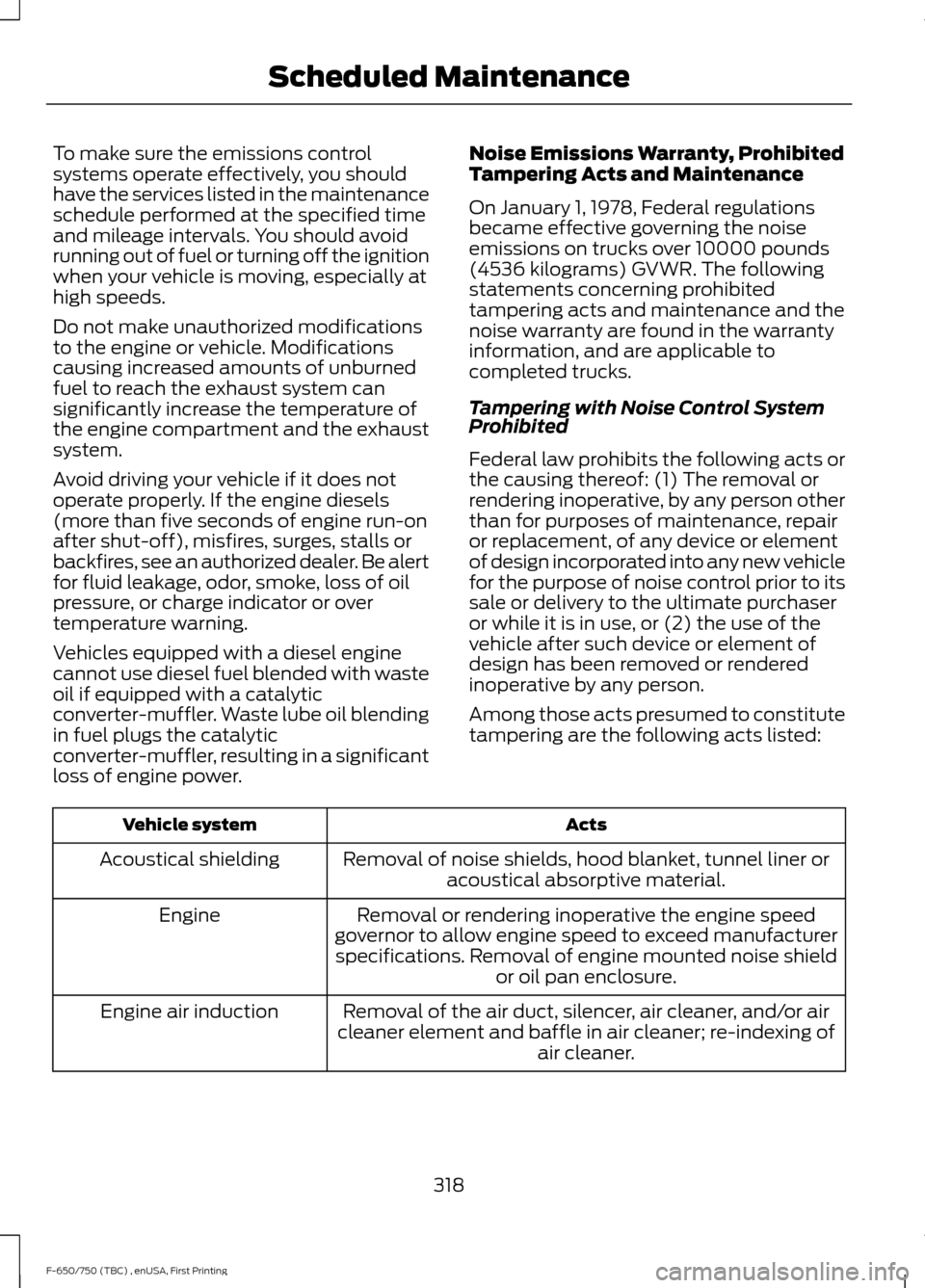

Acts

Vehicle system

Removal of noise shields, hood blanket, tunnel liner oracoustical absorptive material.

Acoustical shielding

Removal or rendering inoperative the engine speed

governor to allow engine speed to exceed manufacturer specifications. Removal of engine mounted noise shield or oil pan enclosure.

Engine

Removal of the air duct, silencer, air cleaner, and/or air

cleaner element and baffle in air cleaner; re-indexing of air cleaner.

Engine air induction

318

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 322 of 382

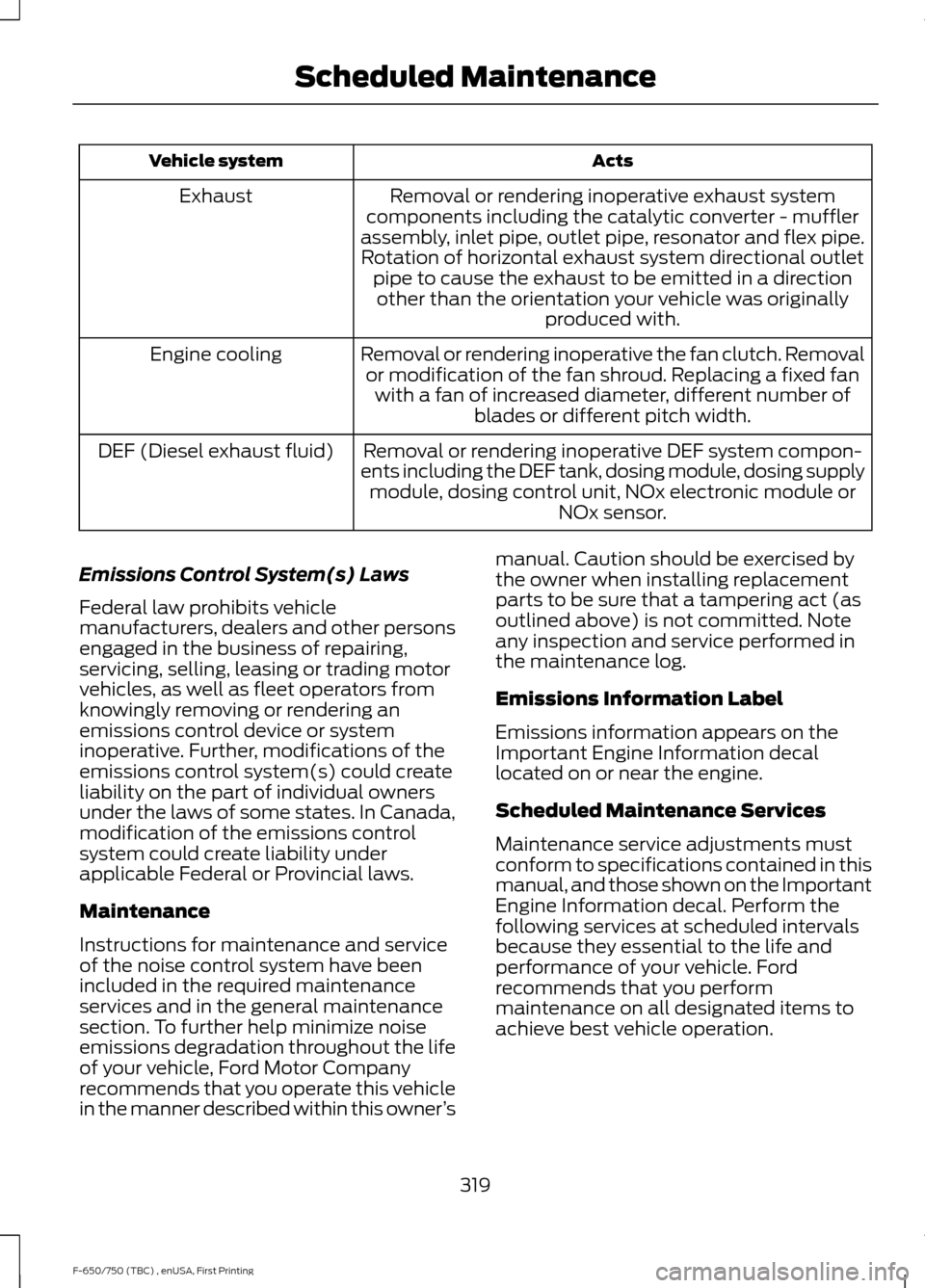

Acts

Vehicle system

Removal or rendering inoperative exhaust system

components including the catalytic converter - muffler

assembly, inlet pipe, outlet pipe, resonator and flex pipe. Rotation of horizontal exhaust system directional outlet pipe to cause the exhaust to be emitted in a directionother than the orientation your vehicle was originally produced with.

Exhaust

Removal or rendering inoperative the fan clutch. Removalor modification of the fan shroud. Replacing a fixed fan with a fan of increased diameter, different number of blades or different pitch width.

Engine cooling

Removal or rendering inoperative DEF system compon-

ents including the DEF tank, dosing module, dosing supply module, dosing control unit, NOx electronic module or NOx sensor.

DEF (Diesel exhaust fluid)

Emissions Control System(s) Laws

Federal law prohibits vehicle

manufacturers, dealers and other persons

engaged in the business of repairing,

servicing, selling, leasing or trading motor

vehicles, as well as fleet operators from

knowingly removing or rendering an

emissions control device or system

inoperative. Further, modifications of the

emissions control system(s) could create

liability on the part of individual owners

under the laws of some states. In Canada,

modification of the emissions control

system could create liability under

applicable Federal or Provincial laws.

Maintenance

Instructions for maintenance and service

of the noise control system have been

included in the required maintenance

services and in the general maintenance

section. To further help minimize noise

emissions degradation throughout the life

of your vehicle, Ford Motor Company

recommends that you operate this vehicle

in the manner described within this owner ’s manual. Caution should be exercised by

the owner when installing replacement

parts to be sure that a tampering act (as

outlined above) is not committed. Note

any inspection and service performed in

the maintenance log.

Emissions Information Label

Emissions information appears on the

Important Engine Information decal

located on or near the engine.

Scheduled Maintenance Services

Maintenance service adjustments must

conform to specifications contained in this

manual, and those shown on the Important

Engine Information decal. Perform the

following services at scheduled intervals

because they essential to the life and

performance of your vehicle. Ford

recommends that you perform

maintenance on all designated items to

achieve best vehicle operation.

319

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 323 of 382

There are three types of maintenance

intervals for general vehicle environments:

On-Highway, City and Severe Service. In

all applications, monitoring miles

(kilometers) and time and when the engine

is due for an oil change determine the

actual interval. When the engine oil change

is required before the truck lubrication

interval, perform the lubrication at the

same time in order to reduce your vehicle

’s

time out of service.

Air Brake Adjustment WARNING

Failure to maintain proper air brake

adjustment can result in reduction

or loss of braking ability.

A qualified service technician, keeping to

the instructions in the service manual,

should perform air brake inspection and

adjustment or repairs.

Cam Brakes - Automatic Slack

Adjusters

WARNING

Do not manually adjust the

automatic slack adjusters to correct

excessive push rod stroke as it may

result in reduced brake effectiveness and

a vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment does

not remedy. Seek service from a qualified

facility for excessive push rod stroke. Inspect standard air brakes equipped with

automatic slack adjusters for proper brake

adjustment as listed in the maintenance

schedule charts.

However, inspect the brakes more

frequently when subjecting them to heavy

use or adverse operating conditions such

as:

•

Frequent brake applications while fully

loaded.

• Operation on hilly or mountainous

terrain.

• Frequent operation on dirt, gravel or

mud.

Some aftermarket brake linings also

require more frequent inspections.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals.

320

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 324 of 382

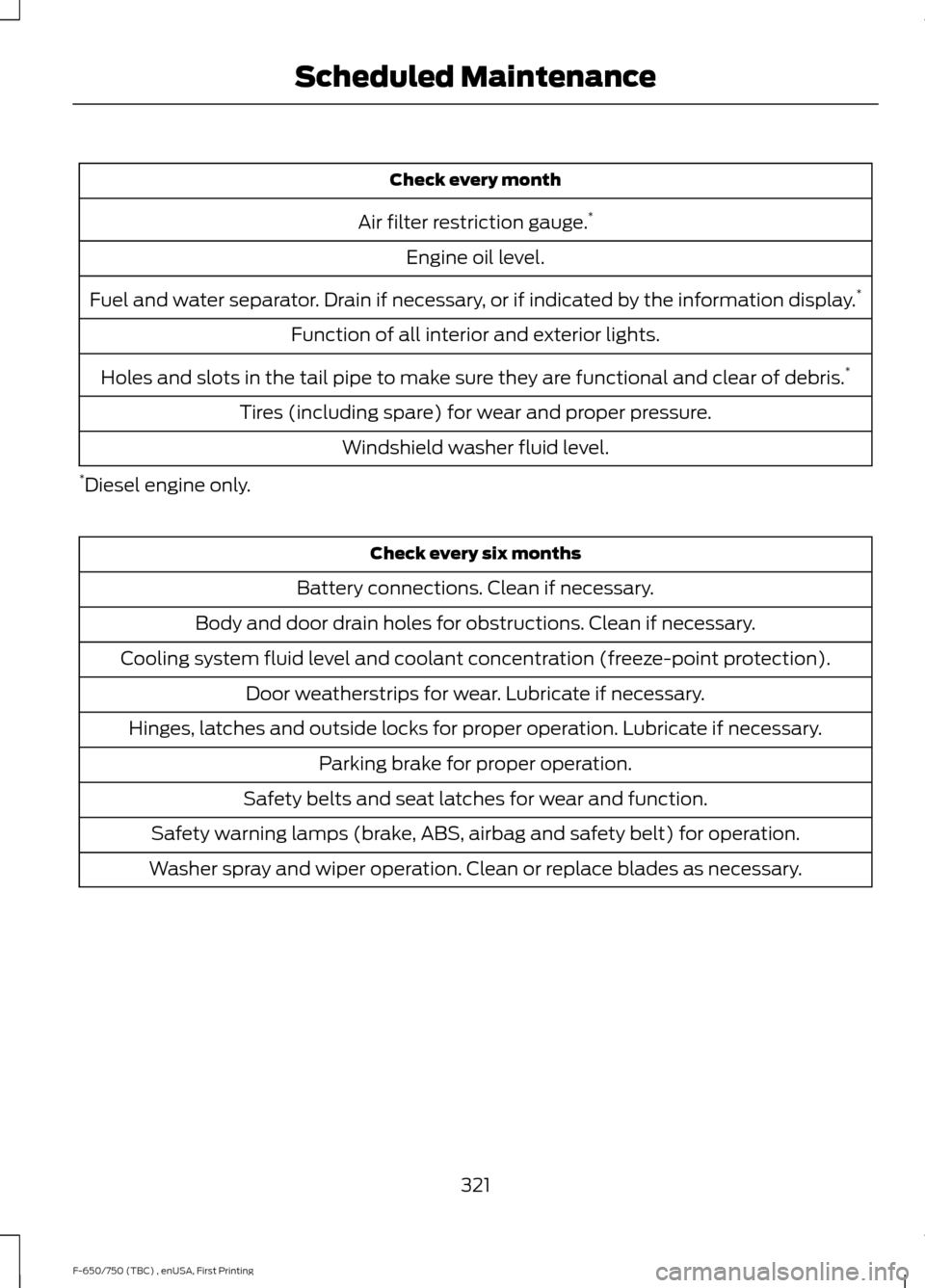

Check every month

Air filter restriction gauge. *

Engine oil level.

Fuel and water separator. Drain if necessary, or if indicated by the information display. *

Function of all interior and exterior lights.

Holes and slots in the tail pipe to make sure they are functional and clear of debris. *

Tires (including spare) for wear and proper pressure. Windshield washer fluid level.

* Diesel engine only. Check every six months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary.

Cooling system fluid level and coolant concentration (freeze-point protection). Door weatherstrips for wear. Lubricate if necessary.

Hinges, latches and outside locks for proper operation. Lubricate if necessary. Parking brake for proper operation.

Safety belts and seat latches for wear and function.

Safety warning lamps (brake, ABS, airbag and safety belt) for operation.

Washer spray and wiper operation. Clean or replace blades as necessary.

321

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 325 of 382

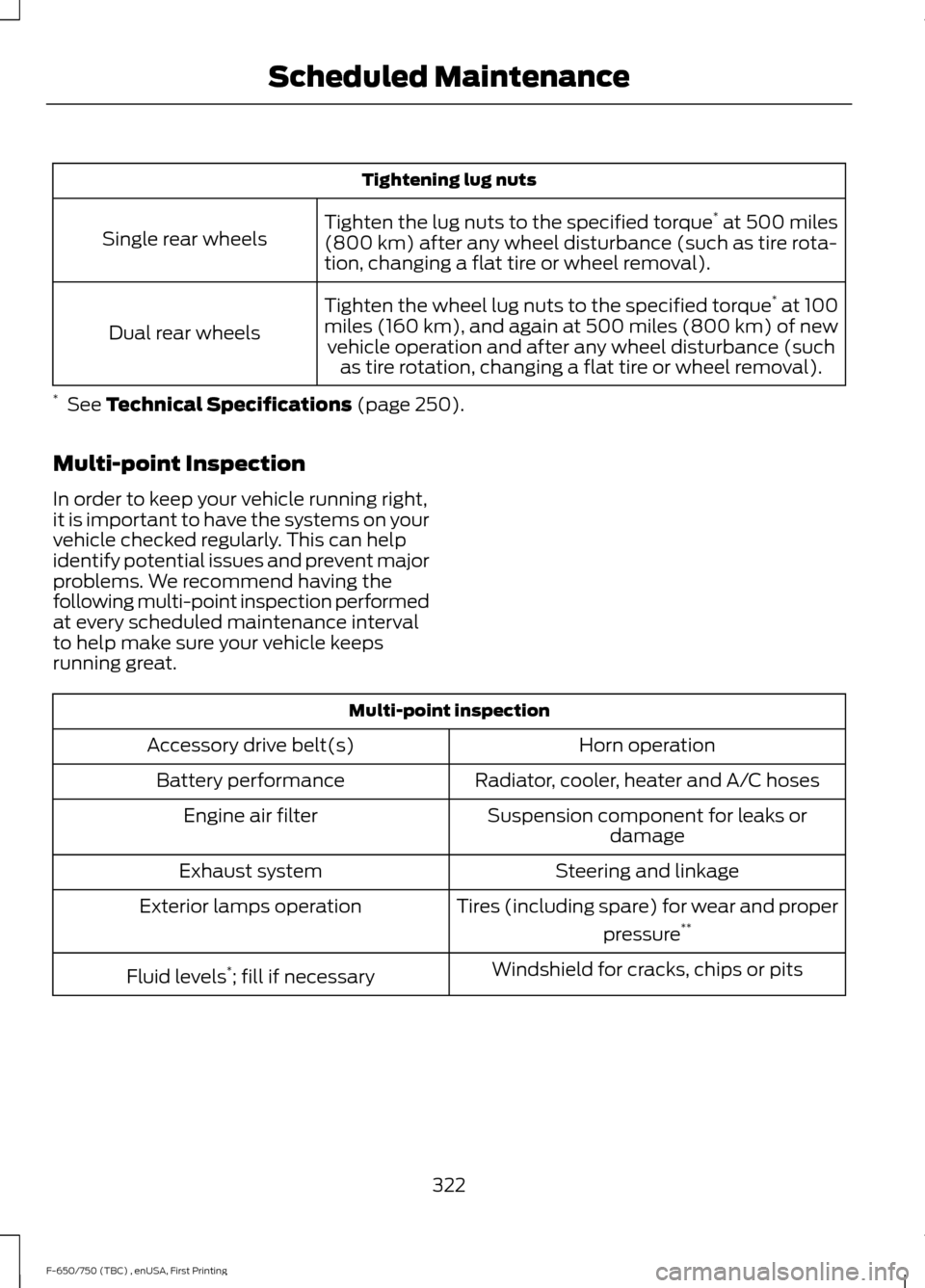

Tightening lug nuts

Tighten the lug nuts to the specified torque *

at 500 miles

(800 km) after any wheel disturbance (such as tire rota-

tion, changing a flat tire or wheel removal).

Single rear wheels

Tighten the wheel lug nuts to the specified torque *

at 100

miles (160 km), and again at 500 miles (800 km) of new vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat tire or wheel removal).

Dual rear wheels

* See Technical Specifications (page 250).

Multi-point Inspection

In order to keep your vehicle running right,

it is important to have the systems on your

vehicle checked regularly. This can help

identify potential issues and prevent major

problems. We recommend having the

following multi-point inspection performed

at every scheduled maintenance interval

to help make sure your vehicle keeps

running great. Multi-point inspection

Horn operation

Accessory drive belt(s)

Radiator, cooler, heater and A/C hoses

Battery performance

Suspension component for leaks ordamage

Engine air filter

Steering and linkage

Exhaust system

Tires (including spare) for wear and properpressure**

Exterior lamps operation

Windshield for cracks, chips or pits

Fluid levels *

; fill if necessary

322

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 326 of 382

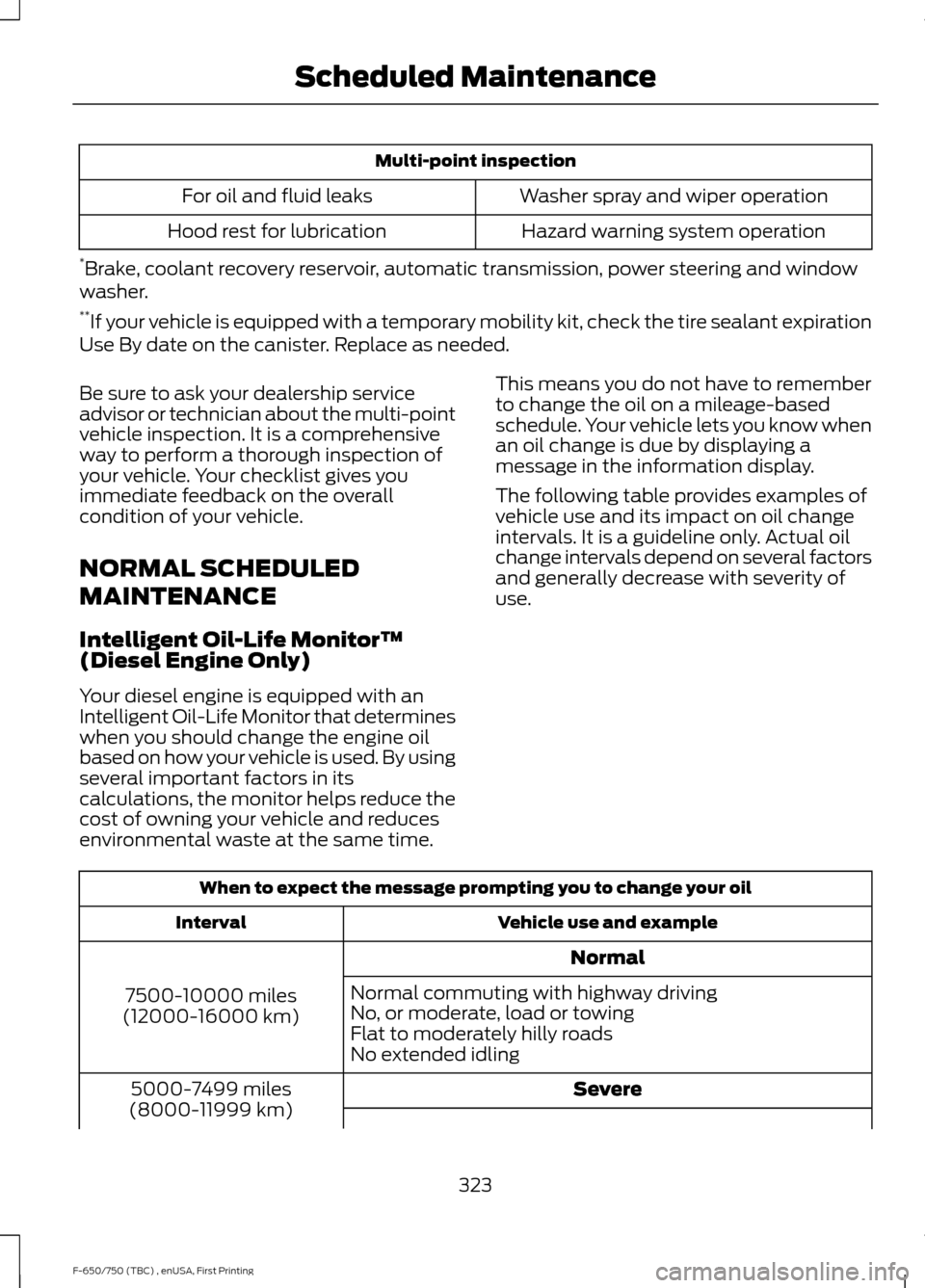

Multi-point inspection

Washer spray and wiper operation

For oil and fluid leaks

Hazard warning system operation

Hood rest for lubrication

* Brake, coolant recovery reservoir, automatic transmission, power steering and window

washer.

** If your vehicle is equipped with a temporary mobility kit, check the tire sealant expiration

Use By date on the canister. Replace as needed.

Be sure to ask your dealership service

advisor or technician about the multi-point

vehicle inspection. It is a comprehensive

way to perform a thorough inspection of

your vehicle. Your checklist gives you

immediate feedback on the overall

condition of your vehicle.

NORMAL SCHEDULED

MAINTENANCE

Intelligent Oil-Life Monitor™

(Diesel Engine Only)

Your diesel engine is equipped with an

Intelligent Oil-Life Monitor that determines

when you should change the engine oil

based on how your vehicle is used. By using

several important factors in its

calculations, the monitor helps reduce the

cost of owning your vehicle and reduces

environmental waste at the same time. This means you do not have to remember

to change the oil on a mileage-based

schedule. Your vehicle lets you know when

an oil change is due by displaying a

message in the information display.

The following table provides examples of

vehicle use and its impact on oil change

intervals. It is a guideline only. Actual oil

change intervals depend on several factors

and generally decrease with severity of

use.

When to expect the message prompting you to change your oil

Vehicle use and example

Interval

Normal

7500-10000 miles

(12000-16000 km) Normal commuting with highway driving

No, or moderate, load or towing

Flat to moderately hilly roads

No extended idling

Severe

5000-7499 miles

(8000-11999 km)

323

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 327 of 382

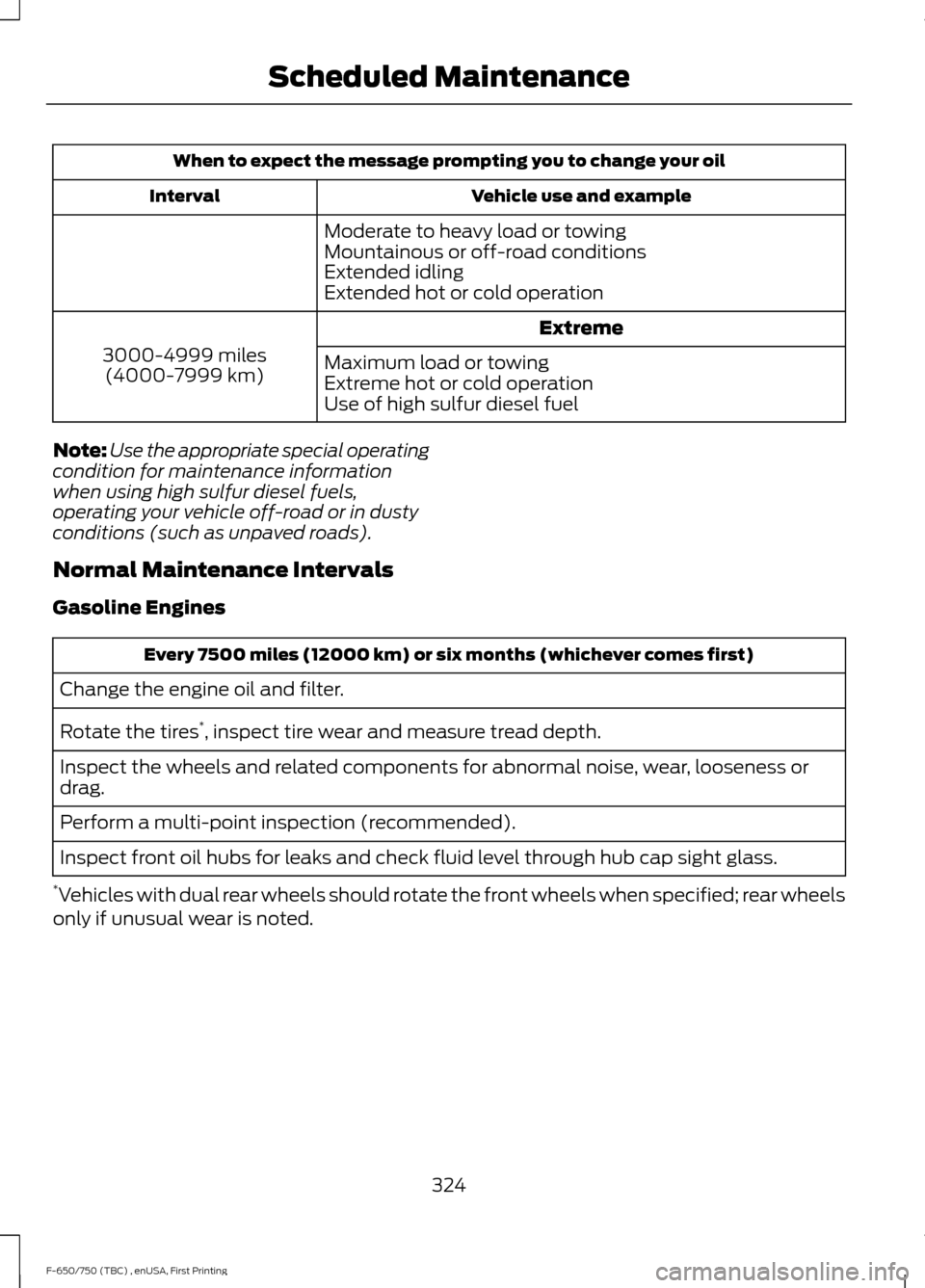

When to expect the message prompting you to change your oil

Vehicle use and example

Interval

Moderate to heavy load or towing

Mountainous or off-road conditions

Extended idling

Extended hot or cold operation Extreme

3000-4999 miles (4000-7999 km) Maximum load or towing

Extreme hot or cold operation

Use of high sulfur diesel fuel

Note: Use the appropriate special operating

condition for maintenance information

when using high sulfur diesel fuels,

operating your vehicle off-road or in dusty

conditions (such as unpaved roads).

Normal Maintenance Intervals

Gasoline Engines Every 7500 miles (12000 km) or six months (whichever comes first)

Change the engine oil and filter.

Rotate the tires *

, inspect tire wear and measure tread depth.

Inspect the wheels and related components for abnormal noise, wear, looseness or

drag.

Perform a multi-point inspection (recommended).

Inspect front oil hubs for leaks and check fluid level through hub cap sight glass.

* Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted.

324

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 328 of 382

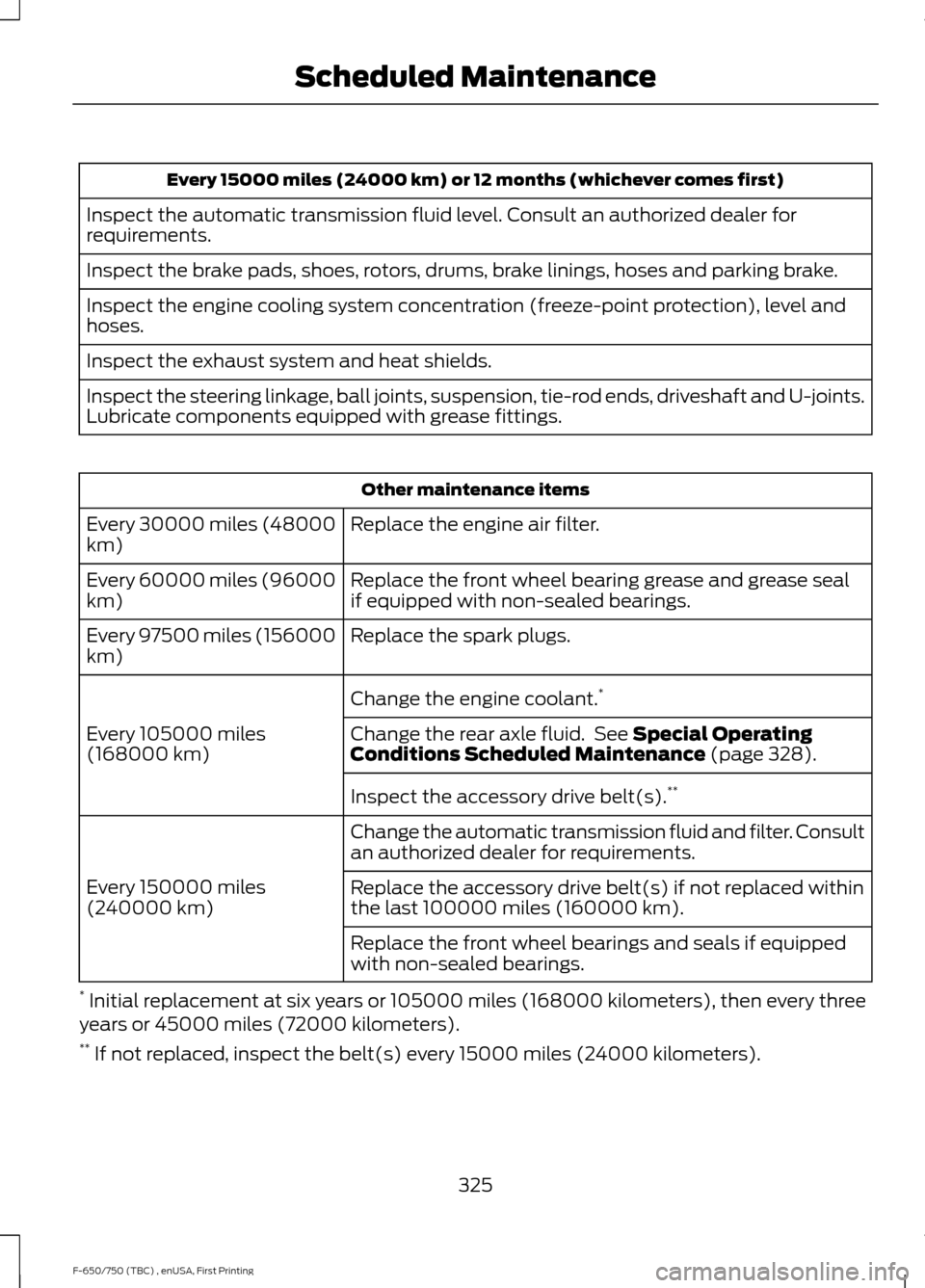

Every 15000 miles (24000 km) or 12 months (whichever comes first)

Inspect the automatic transmission fluid level. Consult an authorized dealer for

requirements.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and parking brake.

Inspect the engine cooling system concentration (freeze-point protection), level and

hoses.

Inspect the exhaust system and heat shields.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and U-joints.

Lubricate components equipped with grease fittings. Other maintenance items

Replace the engine air filter.

Every 30000 miles (48000

km)

Replace the front wheel bearing grease and grease seal

if equipped with non-sealed bearings.

Every 60000 miles (96000

km)

Replace the spark plugs.

Every 97500 miles (156000

km)

Change the engine coolant.*

Every 105000 miles

(168000 km) Change the rear axle fluid. See Special Operating

Conditions Scheduled Maintenance (page 328).

Inspect the accessory drive belt(s). **

Change the automatic transmission fluid and filter. Consult

an authorized dealer for requirements.

Every 150000 miles

(240000 km) Replace the accessory drive belt(s) if not replaced within

the last 100000 miles (160000 km).

Replace the front wheel bearings and seals if equipped

with non-sealed bearings.

* Initial replacement at six years or 105000 miles (168000 kilometers), then every three

years or 45000 miles (72000 kilometers).

** If not replaced, inspect the belt(s) every 15000 miles (24000 kilometers).

325

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 329 of 382

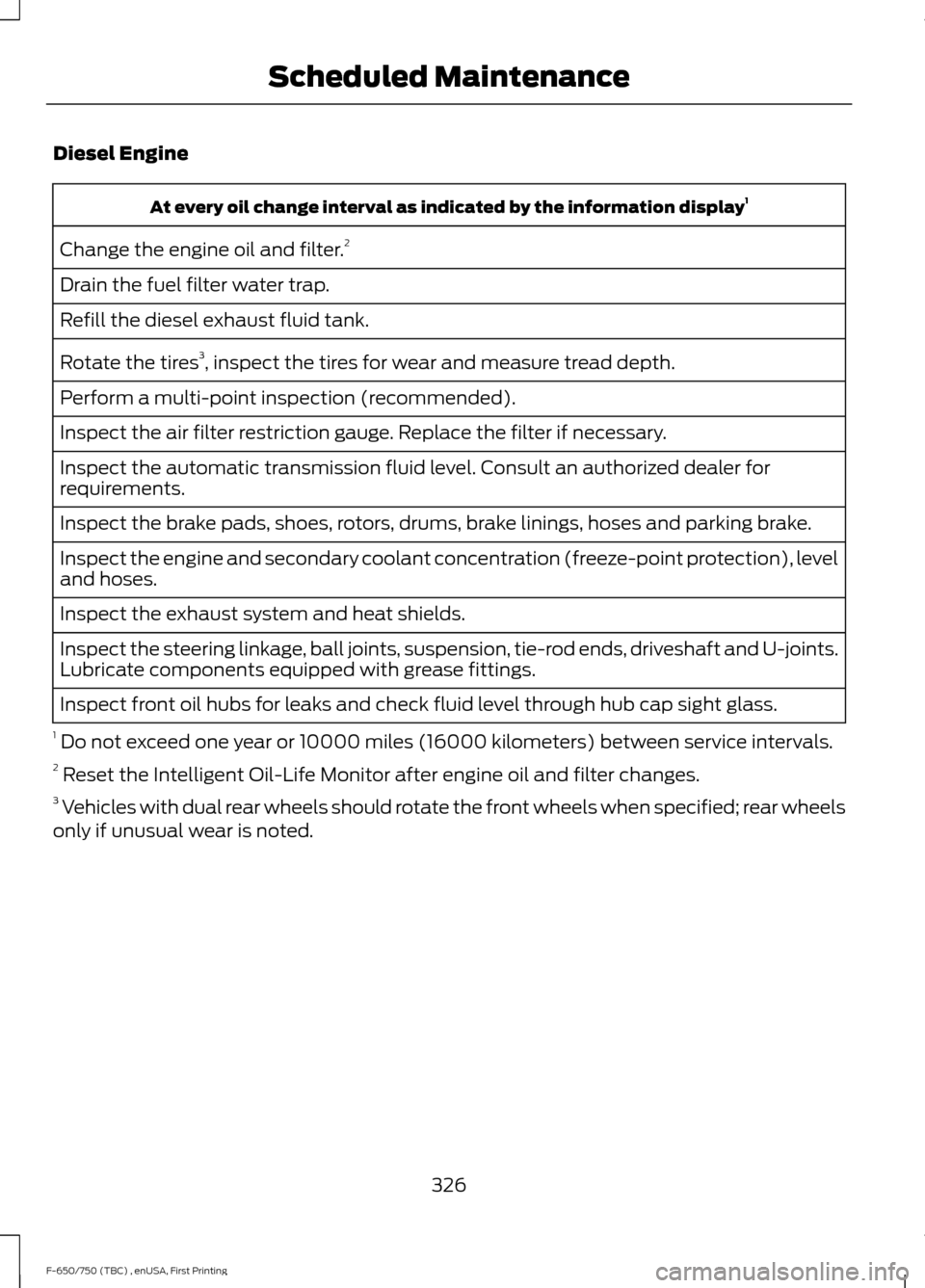

Diesel Engine

At every oil change interval as indicated by the information display

1

Change the engine oil and filter. 2

Drain the fuel filter water trap.

Refill the diesel exhaust fluid tank.

Rotate the tires 3

, inspect the tires for wear and measure tread depth.

Perform a multi-point inspection (recommended).

Inspect the air filter restriction gauge. Replace the filter if necessary.

Inspect the automatic transmission fluid level. Consult an authorized dealer for

requirements.

Inspect the brake pads, shoes, rotors, drums, brake linings, hoses and parking brake.

Inspect the engine and secondary coolant concentration (freeze-point protection), level

and hoses.

Inspect the exhaust system and heat shields.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and U-joints.

Lubricate components equipped with grease fittings.

Inspect front oil hubs for leaks and check fluid level through hub cap sight glass.

1 Do not exceed one year or 10000 miles (16000 kilometers) between service intervals.

2 Reset the Intelligent Oil-Life Monitor after engine oil and filter changes.

3 Vehicles with dual rear wheels should rotate the front wheels when specified; rear wheels

only if unusual wear is noted.

326

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance

Page 330 of 382

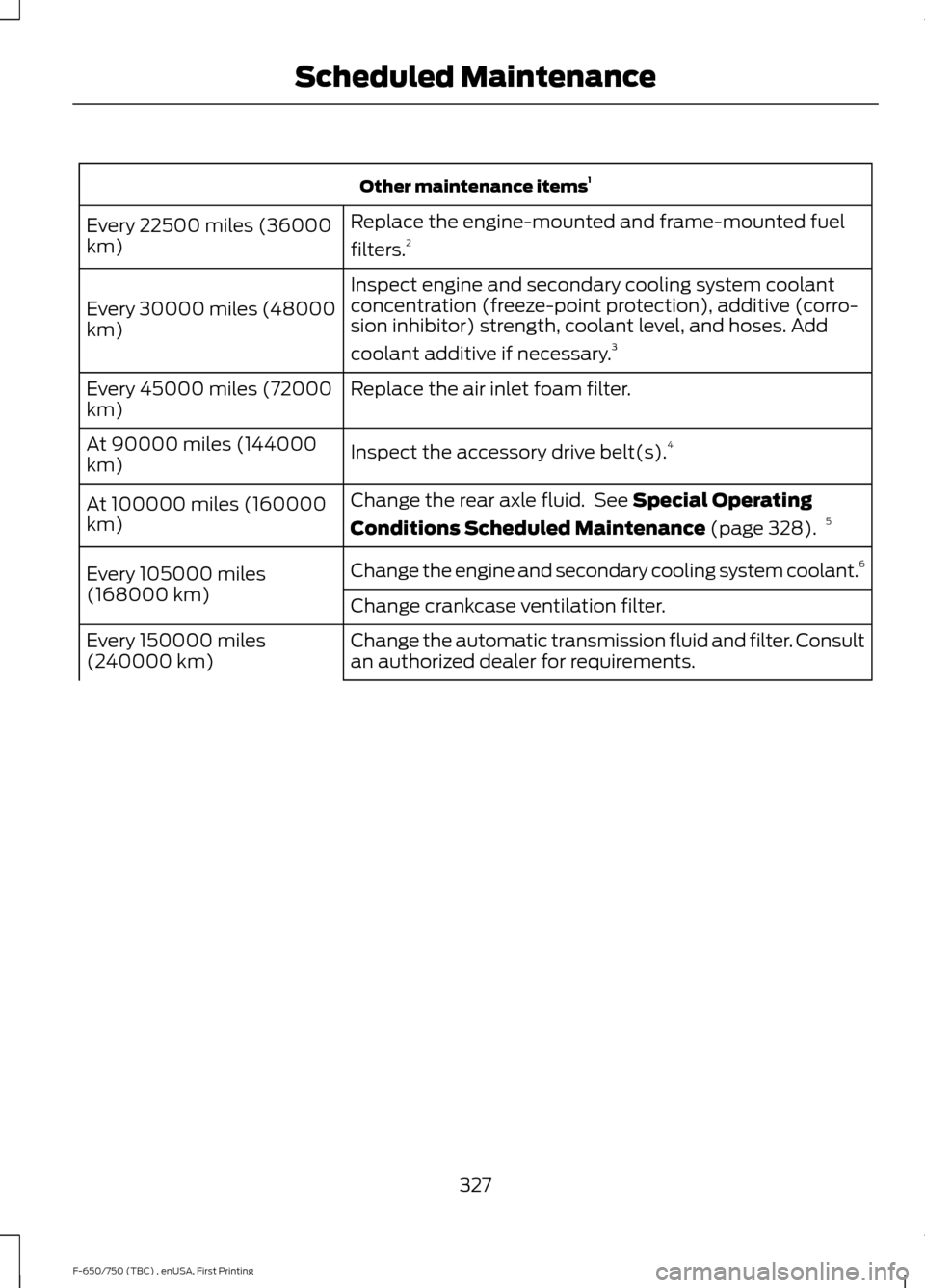

Other maintenance items

1

Replace the engine-mounted and frame-mounted fuel

filters. 2

Every 22500 miles (36000

km)

Inspect engine and secondary cooling system coolant

concentration (freeze-point protection), additive (corro-

sion inhibitor) strength, coolant level, and hoses. Add

coolant additive if necessary.3

Every 30000 miles (48000

km)

Replace the air inlet foam filter.

Every 45000 miles (72000

km)

Inspect the accessory drive belt(s). 4

At 90000 miles (144000

km)

Change the rear axle fluid. See Special Operating

Conditions Scheduled Maintenance

(page 328). 5

At 100000 miles (160000

km)

Change the engine and secondary cooling system coolant. 6

Every 105000 miles

(168000 km) Change crankcase ventilation filter.

Change the automatic transmission fluid and filter. Consult

an authorized dealer for requirements.

Every 150000 miles

(240000 km)

327

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance