oil FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 421 of 454

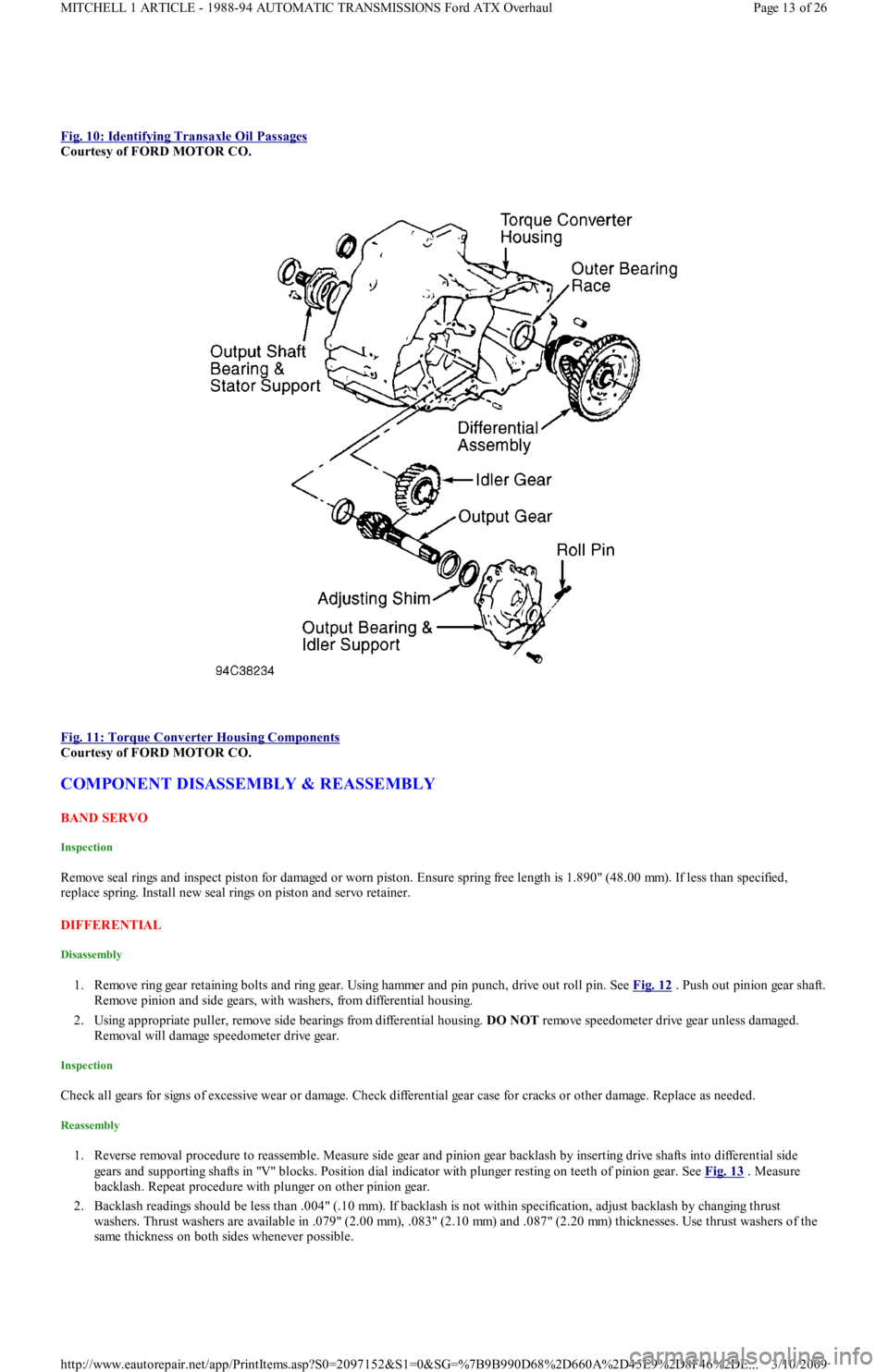

Fig. 10: Identifying Transaxle Oil Passages

Courtesy of FORD MOTOR CO.

Fig. 11: Torque Converter Housing Components

Courtesy of FORD MOTOR CO.

COMPONENT DISASSEMBLY & REASSEMBLY

BAND SERVO

Inspection

Remove seal rings and inspect piston for damaged or worn piston. Ensure spring free length is 1.890" (48.00 mm). If less than specified,

replace spring. Install new seal rings on piston and servo retainer.

DIFFERENTIAL

Disassembly

1. Remove ring gear retaining bolts and ring gear. Using hammer and pin punch, drive out roll pin. See Fig. 12. Push out pinion gear shaft.

Remove pinion and side gears, with washers, from differential housing.

2. Using appropriate puller, remove side bearings from differential housing. DO NOT remove speedometer drive gear unless damaged.

Removal will damage speedometer drive gear.

Inspection

Check all gears for signs of excessive wear or damage. Check differential gear case for cracks or other damage. Replace as needed.

Reassembly

1. Reverse removal procedure to reassemble. Measure side gear and pinion gear backlash by inserting drive shafts into differential side

gears and supporting shafts in "V" blocks. Position dial indicator with plunger resting on teeth of pinion gear. See Fig. 13

. Measure

backlash. Repeat procedure with plunger on other pinion gear.

2. Backlash readings should be less than .004" (.10 mm). If backlash is not within specification, adjust backlash by changing thrust

washers. Thrust washers are available in .079" (2.00 mm), .083" (2.10 mm) and .087" (2.20 mm) thicknesses. Use thrust washers of t h e

same thickness on both sides whenever possible.

Page 13 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 423 of 454

Fig. 14: Exploded View Of Drum Hub Assembly

Courtesy of FORD MOTOR CO.

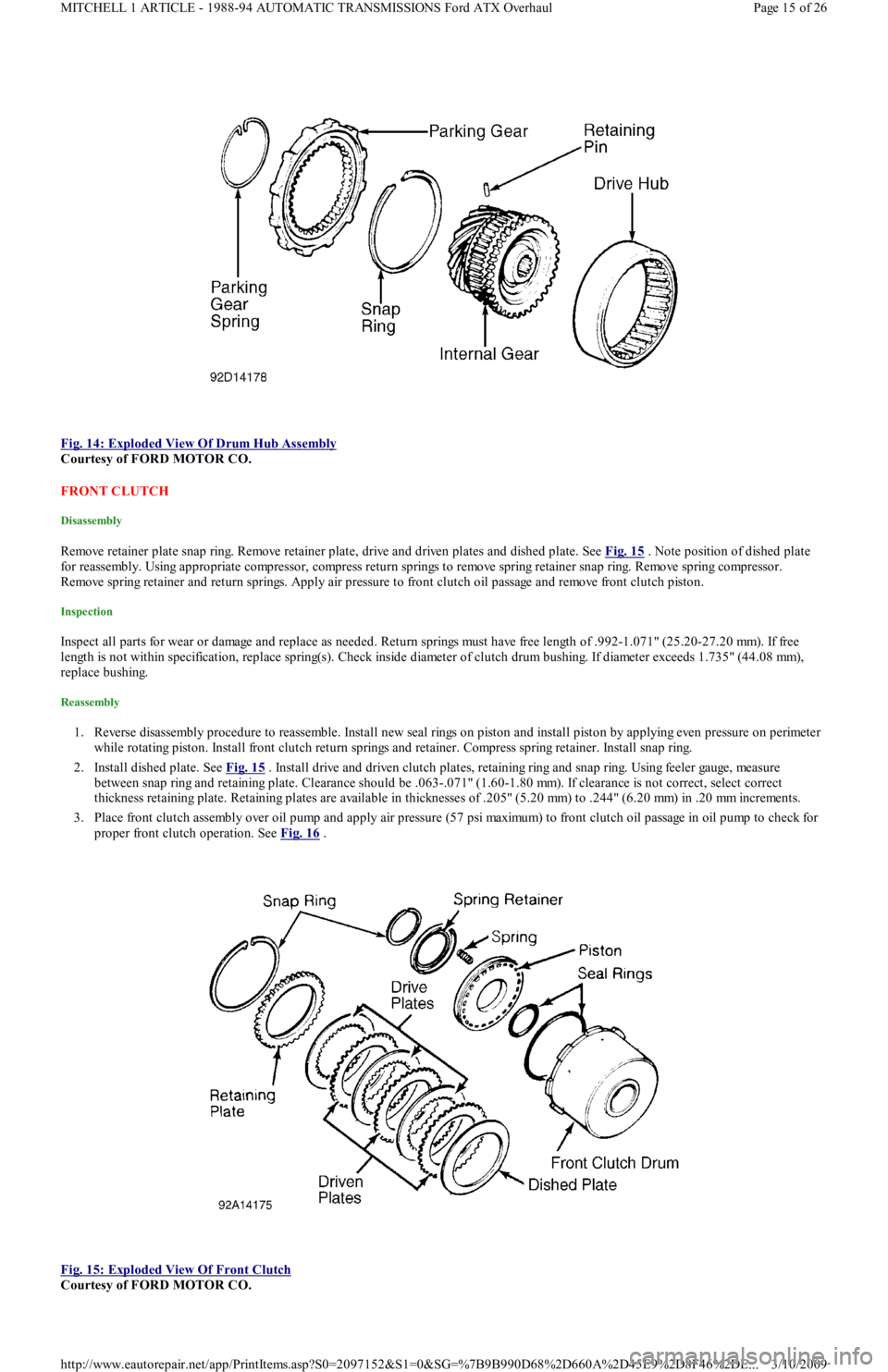

FRONT CLUTCH

Disassembly

Remove retainer plate snap ring. Remove retainer plate, drive and driven plates and dished plate. See Fig. 15 . Note position of dished plate

for reassembly. Using appropriate compressor, compress return springs to remove spring retainer snap ring. Remove spring compressor.

Remove spring retainer and return springs. Apply air pressure to front clutch oil passage and remove front clutch piston.

Inspection

Inspect all parts for wear or damage and replace as needed. Return springs must have free length of .992-1.071" (25.20-27.20 mm). If free

length is not within specification, replace spring(s). Check inside diameter of clutch drum bushing. If diameter exceeds 1.735" (44.08 mm),

replace bushing.

Reassembly

1. Reverse disassembly procedure to reassemble. Install new seal rings on piston and install piston by applying even pressure on perimeter

while rotating piston. Install front clutch return springs and retainer. Compress spring retainer. Install snap ring.

2. Install dished plate. See Fig. 15

. Install drive and driven clutch plates, retaining ring and snap ring. Using feeler gauge, measure

between snap ring and retaining plate. Clearance should be .063-.071" (1.60-1.80 mm). If clearance is not correct, select correct

thickness retaining plate. Retaining plates are available in thicknesses of .205" (5.20 mm) to .244" (6.20 mm) in .20 mm increments.

3. Place front clutch assembly over oil pump and apply air pressure (57 psi maximum) to front clutch oil passage in oil pump to check for

proper front clutch operation. See Fig. 16

.

Fig. 15: Exploded View Of Front Clutch

Courtesy of FORD MOTOR CO.

Page 15 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 424 of 454

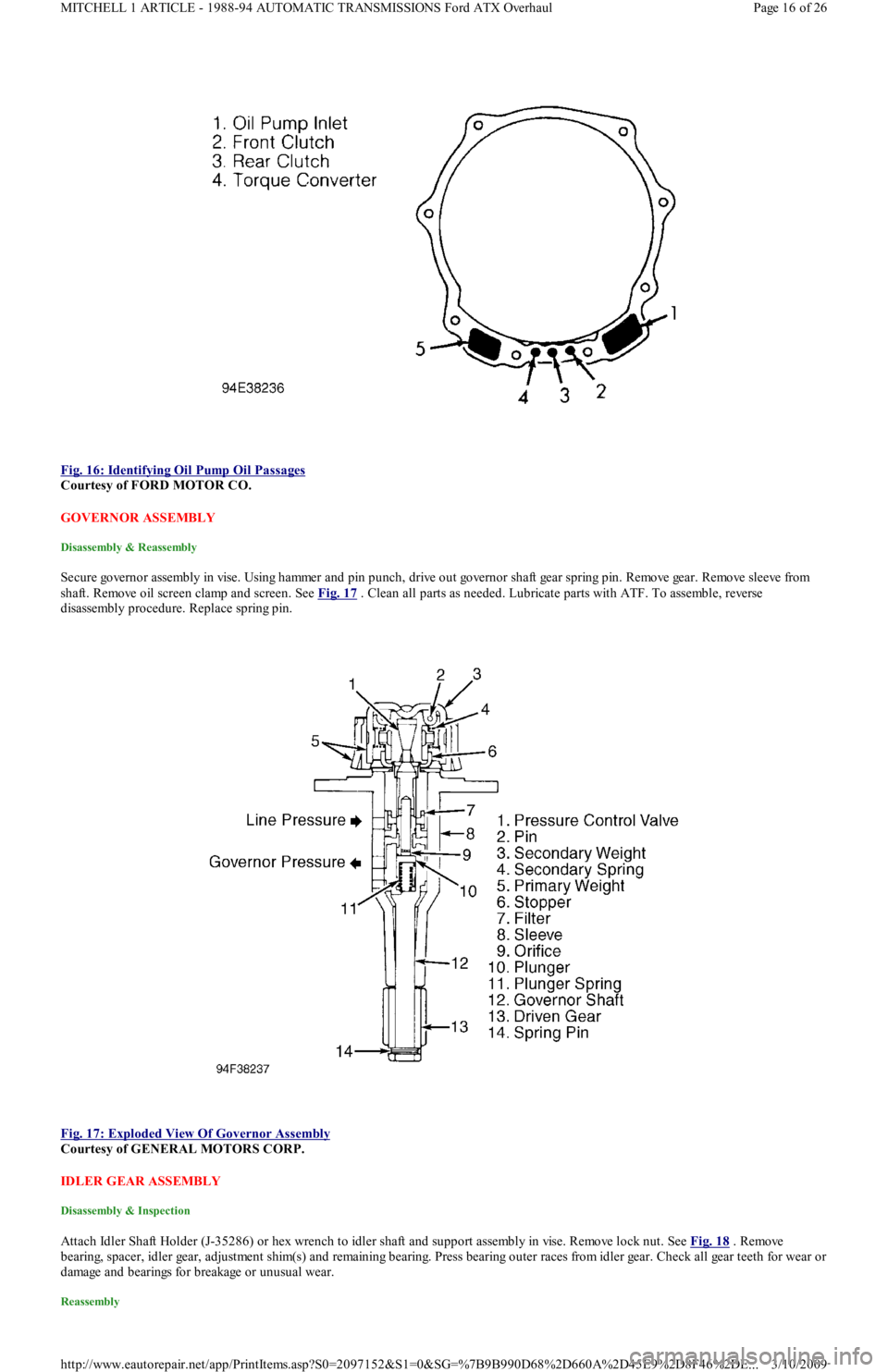

Fig. 16: Identifying Oil Pump Oil Passages

Courtesy of FORD MOTOR CO.

GOVERNOR ASSEMBLY

Disassembly & Reassembly

S e c u r e go ve r n o r a sse mb l y in vise . Usin g h a mme r a n d p in p u n c h , d r ive o u t go ve r n o r sh a ft ge a r sp r in g p in . R e mo ve ge a r . R e mo ve sl eeve from

shaft. Remove oil screen clamp and screen. See Fig. 17

. Clean all parts as needed. Lubricate parts with ATF. To assemble, reverse

disassembly procedure. Replace spring pin.

Fig. 17: Exploded View Of Governor Assembly

Courtesy of GENERAL MOTORS CORP.

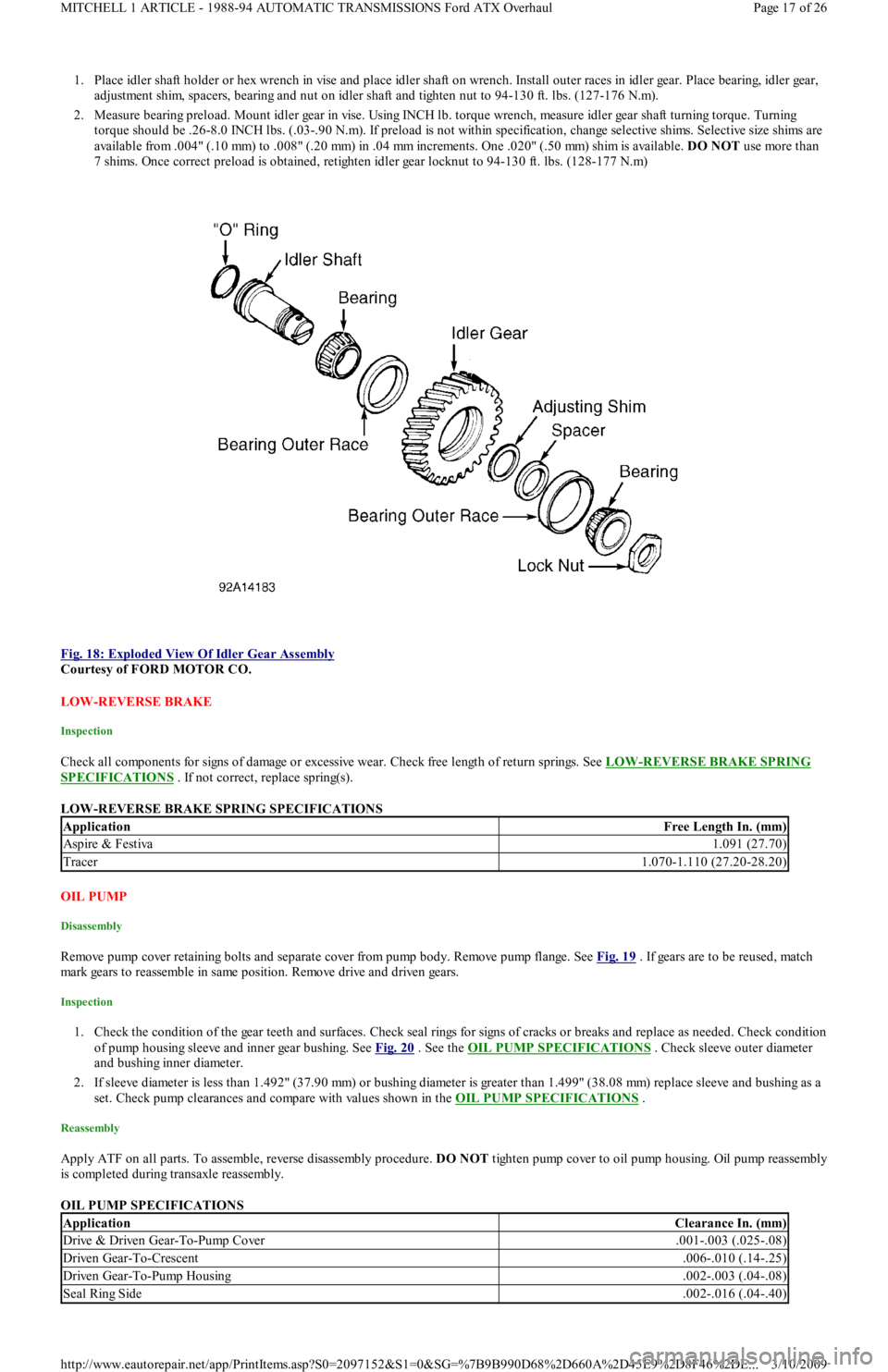

IDLER GEAR ASSEMBLY

Disassembly & Inspection

Attach Idler Shaft Holder (J-35286) or hex wrench to idler shaft and support assembly in vise. Remove lock nut. See Fig. 18 . Remove

bearing, spacer, idler gear, adjustment shim(s) and remaining bearing. Press bearing outer races from idler gear. Check all gear teeth for wear or

damage and bearings for breakage or unusual wear.

Reassembly

Page 16 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 425 of 454

1. Place idler shaft holder or hex wrench in vise and place idler shaft on wrench. Install outer races in idler gear. Place bearing, idler gear,

adjustment shim, spacers, bearing and nut on idler shaft and tighten nut to 94-130 ft. lbs. (127-176 N.m).

2. Measure bearing preload. Mount idler gear in vise. Using INCH lb. torque wrench, measure idler gear shaft turning torque. Turning

torque should be .26-8.0 INCH lbs. (.03-.90 N.m). If preload is not within specification, change selective shims. Selective size shims are

available from .004" (.10 mm) to .008" (.20 mm) in .04 mm increments. One .020" (.50 mm) shim is available. DO NOT use more than

7 shims. Once correct preload is obtained, retighten idler gear locknut to 94-130 ft. lbs. (128-177 N.m)

Fig. 18: Exploded View Of Idler Gear Assembly

Courtesy of FORD MOTOR CO.

LOW-REVERSE BRAKE

Inspection

Check all components for signs of damage or excessive wear. Check free length of return springs. See LOW-REVERSE BRAKE SPRING

SPECIFICATIONS . If not correct, replace spring(s).

LOW-REVERSE BRAKE SPRING SPECIFICATIONS

OIL PUMP

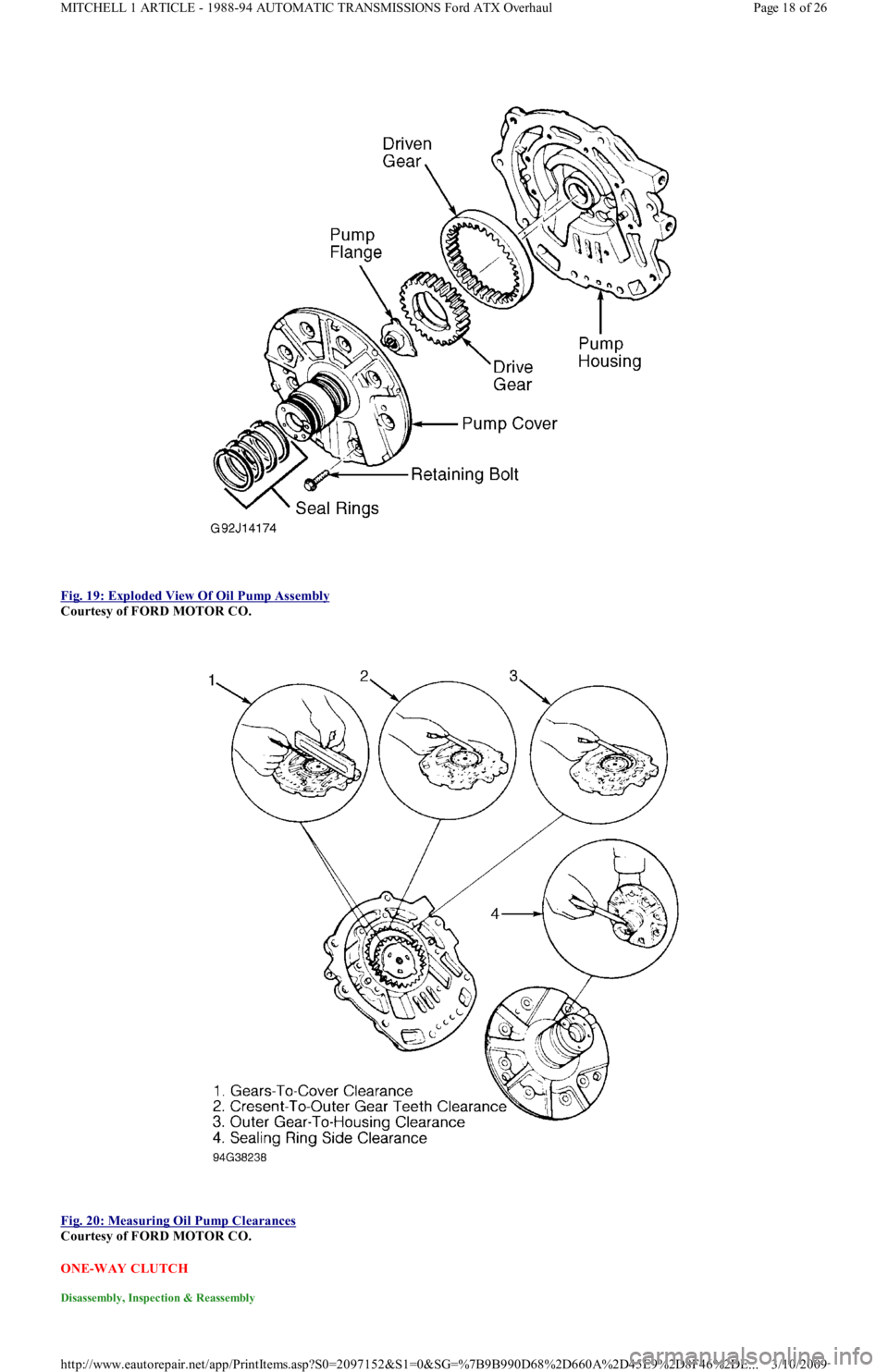

Disassembly

Remove pump cover retaining bolts and separate cover from pump body. Remove pump flange. See Fig. 19 . If gears are to be reused, match

mark gears to reassemble in same position. Remove drive and driven gears.

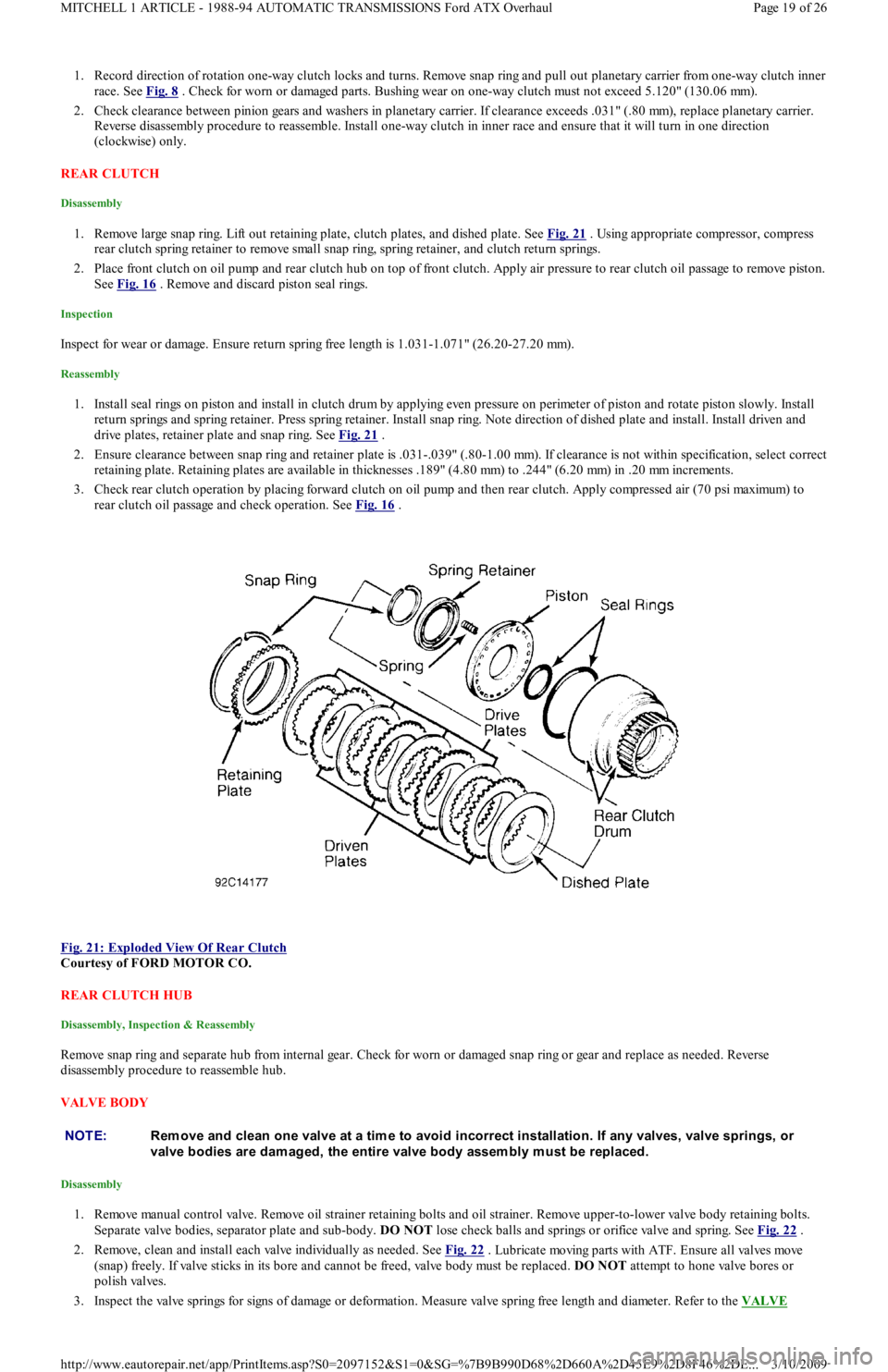

Inspection

1. Check the condition of the gear teeth and surfaces. Check seal rings for signs of cracks or breaks and replace as needed. Check condition

of pump housing sleeve and inner gear bushing. See Fig. 20

. See the OIL PUMP SPECIFICATIONS . Check sleeve outer diameter

and bushing inner diameter.

2. If sleeve diameter is less than 1.492" (37.90 mm) or bushing diameter is greater than 1.499" (38.08 mm) replace sleeve and bushing as a

set. Check pump clearances and compare with values shown in the OIL PUMP SPECIFICATIONS

.

Reassembly

Apply ATF on all parts. To assemble, reverse disassembly procedure. DO NOTtighten pump cover to oil pump housing. Oil pump reassembly

is completed during transaxle reassembly.

OIL PUMP SPECIFICATIONS

ApplicationFree Length In. (mm)

Aspire & Festiva1.091 (27.70)

Tracer1.070-1.110 (27.20-28.20)

ApplicationClearance In. (mm)

Drive & Driven Gear-To-Pump Cover.001-.003 (.025-.08)

Driven Gear-To-Crescent.006-.010 (.14-.25)

Driven Gear-To-Pump Housing.002-.003 (.04-.08)

Seal Ring Side.002-.016 (.04-.40)

Page 17 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 426 of 454

Fig. 19: Exploded View Of Oil Pump Assembly

Courtesy of FORD MOTOR CO.

Fig. 20: Measuring Oil Pump Clearances

Courtesy of FORD MOTOR CO.

ONE-WAY CLUTCH

Disassembly, Inspection & Reassembly

Page 18 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 427 of 454

1. Record direction of rotation one-way clutch locks and turns. Remove snap ring and pull out planetary carrier from one-way clutch inner

race. See Fig. 8

. Check for worn or damaged parts. Bushing wear on one-way clutch must not exceed 5.120" (130.06 mm).

2. Check clearance between pinion gears and washers in planetary carrier. If clearance exceeds .031" (.80 mm), replace planetary carrier.

Reverse disassembly procedure to reassemble. Install one-way clutch in inner race and ensure that it will turn in one direction

(clockwise) only.

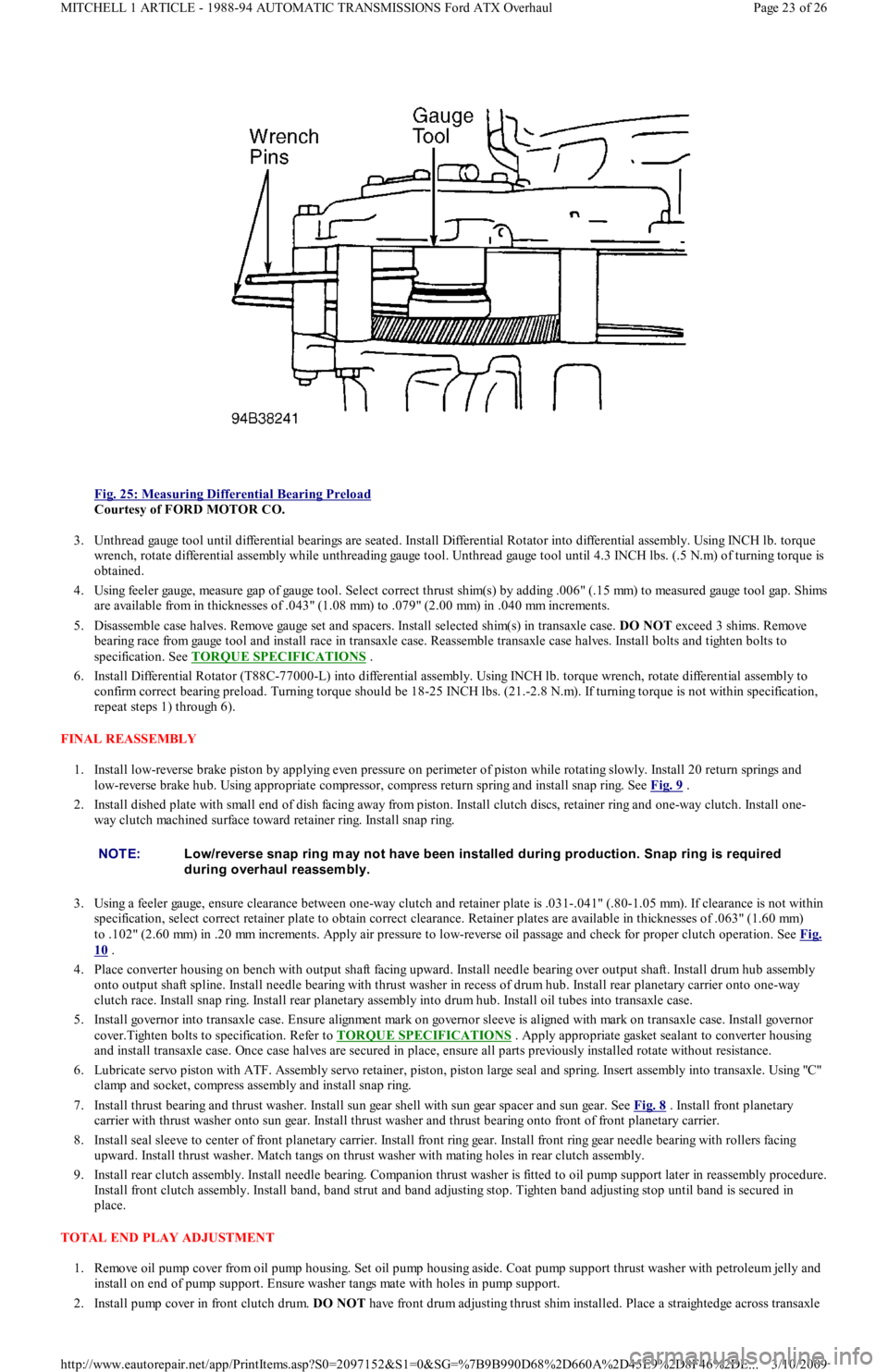

REAR CLUTCH

Disassembly

1. Remove large snap ring. Lift out retaining plate, clutch plates, and dished plate. See Fig. 21 . Using appropriate compressor, compress

rear clutch spring retainer to remove small snap ring, spring retainer, and clutch return springs.

2. Place front clutch on oil pump and rear clutch hub on top of front clutch. Apply air pressure to rear clutch oil passage to remove piston.

See Fig. 16

. Remove and discard piston seal rings.

Inspection

Inspect for wear or damage. Ensure return spring free length is 1.031-1.071" (26.20-27.20 mm).

Reassembly

1. Install seal rings on piston and install in clutch drum by applying even pressure on perimeter of piston and rotate piston slowly. Install

return springs and spring retainer. Press spring retainer. Install snap ring. Note direction of dished plate and install. Install driven and

drive plates, retainer plate and snap ring. See Fig. 21

.

2. Ensure clearance between snap ring and retainer plate is .031-.039" (.80-1.00 mm). If clearance is not within specification, select correct

retaining plate. Retaining plates are available in thicknesses .189" (4.80 mm) to .244" (6.20 mm) in .20 mm increments.

3. Check rear clutch operation by placing forward clutch on oil pump and then rear clutch. Apply compressed air (70 psi maximum) to

rear clutch oil passage and check operation. See Fig. 16

.

Fig. 21: Exploded View Of Rear Clutch

Courtesy of FORD MOTOR CO.

REAR CLUTCH HUB

Disassembly, Inspection & Reassembly

Remove snap ring and separate hub from internal gear. Check for worn or damaged snap ring or gear and replace as needed. Reverse

disassembly procedure to reassemble hub.

VALVE BODY

Disassembly

1. Remove manual control valve. Remove oil strainer retaining bolts and oil strainer. Remove upper-to-lower valve body retaining bolts.

Separate valve bodies, separator plate and sub-body. DO NOT lose check balls and springs or orifice valve and spring. See Fig. 22

.

2. Remove, clean and install each valve individually as needed. See Fig. 22

. Lubricate moving parts with ATF. Ensure all valves move

(snap) freely. If valve sticks in its bore and cannot be freed, valve body must be replaced. DO NOT attempt to hone valve bores or

polish valves.

3. Inspect the valve springs for signs of damage or deformation. Measure valve spring free length and diameter. Refer to the VALVE

NOTE:Rem ove and clean one valve at a tim e to avoid incorrect installation. If any valves, valve springs, or

valve bodies are dam aged, the entire valve body assem bly m ust be replaced.

Page 19 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 431 of 454

Fig. 25: Measuring Differential Bearing Preload

Courtesy of FORD MOTOR CO.

3. Unthread gauge tool until differential bearings are seated. Install Differential Rotator into differential assembly. Using INCH lb. torque

wrench, rotate differential assembly while unthreading gauge tool. Unthread gauge tool until 4.3 INCH lbs. (.5 N.m) of turning torque is

obtained.

4. Using feeler gauge, measure gap of gauge tool. Select correct thrust shim(s) by adding .006" (.15 mm) to measured gauge tool ga p . S h ims

are available from in thicknesses of .043" (1.08 mm) to .079" (2.00 mm) in .040 mm increments.

5. Disassemble case halves. Remove gauge set and spacers. Install selected shim(s) in transaxle case. DO NOT exceed 3 shims. Remove

bearing race from gauge tool and install race in transaxle case. Reassemble transaxle case halves. Install bolts and tighten bolts to

specification. See TORQUE SPECIFICATIONS

.

6. Install Differential Rotator (T88C-77000-L) into differential assembly. Using INCH lb. torque wrench, rotate differential assembly to

confirm correct bearing preload. Turning torque should be 18-25 INCH lbs. (21.-2.8 N.m). If turning torque is not within specification,

repeat steps 1) through 6).

FINAL REASSEMBLY

1. Install low-reverse brake piston by applying even pressure on perimeter of piston while rotating slowly. Install 20 return springs and

low-reverse brake hub. Using appropriate compressor, compress return spring and install snap ring. See Fig. 9

.

2. Install dished plate with small end of dish facing away from piston. Install clutch discs, retainer ring and one-way clutch. Install one-

way clutch machined surface toward retainer ring. Install snap ring.

3. Using a feeler gauge, ensure clearance between one-way clutch and retainer plate is .031-.041" (.80-1.05 mm). If clearance is not within

specification, select correct retainer plate to obtain correct clearance. Retainer plates are available in thicknesses of .063" (1.60 mm)

to .102" (2.60 mm) in .20 mm increments. Apply air pressure to low-reverse oil passage and check for proper clutch operation. See Fig.

10 .

4. Place converter housing on bench with output shaft facing upward. Install needle bearing over output shaft. Install drum hub assembly

onto output shaft spline. Install needle bearing with thrust washer in recess of drum hub. Install rear planetary carrier onto one-way

clutch race. Install snap ring. Install rear planetary assembly into drum hub. Install oil tubes into transaxle case.

5. Install governor into transaxle case. Ensure alignment mark on governor sleeve is aligned with mark on transaxle case. Install go ve r n o r

cover.Tighten bolts to specification. Refer to TORQUE SPECIFICATIONS

. Apply appropriate gasket sealant to converter housing

and install transaxle case. Once case halves are secured in place, ensure all parts previously installed rotate without resistance.

6. Lubricate servo piston with ATF. Assembly servo retainer, piston, piston large seal and spring. Insert assembly into transaxle. Usin g "C"

clamp and socket, compress assembly and install snap ring.

7. Install thrust bearing and thrust washer. Install sun gear shell with sun gear spacer and sun gear. See Fig. 8

. Install front planetary

carrier with thrust washer onto sun gear. Install thrust washer and thrust bearing onto front of front planetary carrier.

8. Install seal sleeve to center of front planetary carrier. Install front ring gear. Install front ring gear needle bearing with rollers facing

upward. Install thrust washer. Match tangs on thrust washer with mating holes in rear clutch assembly.

9. Install rear clutch assembly. Install needle bearing. Companion thrust washer is fitted to oil pump support later in reassembly procedure.

Install front clutch assembly. Install band, band strut and band adjusting stop. Tighten band adjusting stop until band is secured in

place.

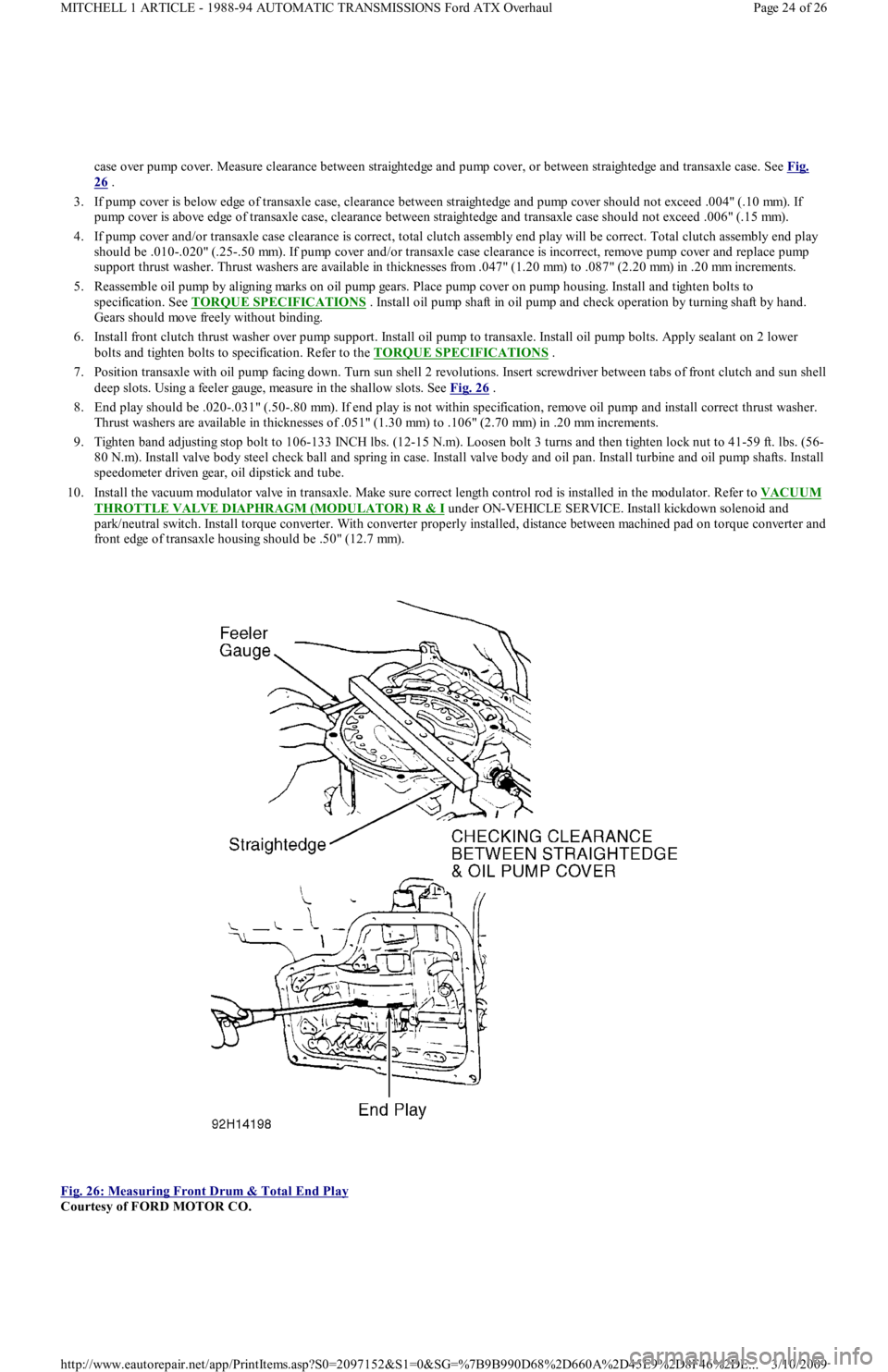

TOTAL END PLAY ADJUSTMENT

1. Remove oil pump cover from oil pump housing. Set oil pump housing aside. Coat pump support thrust washer with petroleum jelly and

install on end of pump support. Ensure washer tangs mate with holes in pump support.

2. Install pump cover in front clutch drum. DO NOT have front drum adjusting thrust shim installed. Place a straightedge across transaxle

NOTE:Low/reverse snap ring m ay not have been installed during production. Snap ring is required

during overhaul reassem bly.

Page 23 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 432 of 454

case over pump cover. Measure clearance between straightedge and pump cover, or between straightedge and transaxle case. See Fig.

26 .

3. If pump cover is below edge of transaxle case, clearance between straightedge and pump cover should not exceed .004" (.10 mm). If

pump cover is above edge of transaxle case, clearance between straightedge and transaxle case should not exceed .006" (.15 mm).

4. If pump cover and/or transaxle case clearance is correct, total clutch assembly end play will be correct. Total clutch assembly end play

should be .010-.020" (.25-.50 mm). If pump cover and/or transaxle case clearance is incorrect, remove pump cover and replace pump

support thrust washer. Thrust washers are available in thicknesses from .047" (1.20 mm) to .087" (2.20 mm) in .20 mm increments.

5. Reassemble oil pump by aligning marks on oil pump gears. Place pump cover on pump housing. Install and tighten bolts to

specification. See TORQUE SPECIFICATIONS

. Install oil pump shaft in oil pump and check operation by turning shaft by hand.

Gears should move freely without binding.

6. Install front clutch thrust washer over pump support. Install oil pump to transaxle. Install oil pump bolts. Apply sealant on 2 lower

bolts and tighten bolts to specification. Refer to the TORQUE SPECIFICATIONS

.

7. Position transaxle with oil pump facing down. Turn sun shell 2 revolutions. Insert screwdriver between tabs of front clutch and sun shell

deep slots. Using a feeler gauge, measure in the shallow slots. See Fig. 26

.

8. End play should be .020-.031" (.50-.80 mm). If end play is not within specification, remove oil pump and install correct thrust washer.

Thrust washers are available in thicknesses of .051" (1.30 mm) to .106" (2.70 mm) in .20 mm increments.

9. Tighten band adjusting stop bolt to 106-133 INCH lbs. (12-15 N.m). Loosen bolt 3 turns and then tighten lock nut to 41-59 ft. lbs. (56-

80 N.m). Install valve body steel check ball and spring in case. Install valve body and oil pan. Install turbine and oil pump sh aft s. In st al l

speedometer driven gear, oil dipstick and tube.

10. Install the vacuum modulator valve in transaxle. Make sure correct length control rod is installed in the modulator. Refer to VACUUM

THROTTLE VALVE DIAPHRAGM (MODULATOR) R & I under ON-VEHICLE SERVICE. Install kickdown solenoid and

park/neutral switch. Install torque converter. With converter properly installed, distance between machined pad on torque converter and

front edge of transaxle housing should be .50" (12.7 mm).

Fig. 26: Measuring Front Drum & Total End Play

Courtesy of FORD MOTOR CO.

Page 24 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 433 of 454

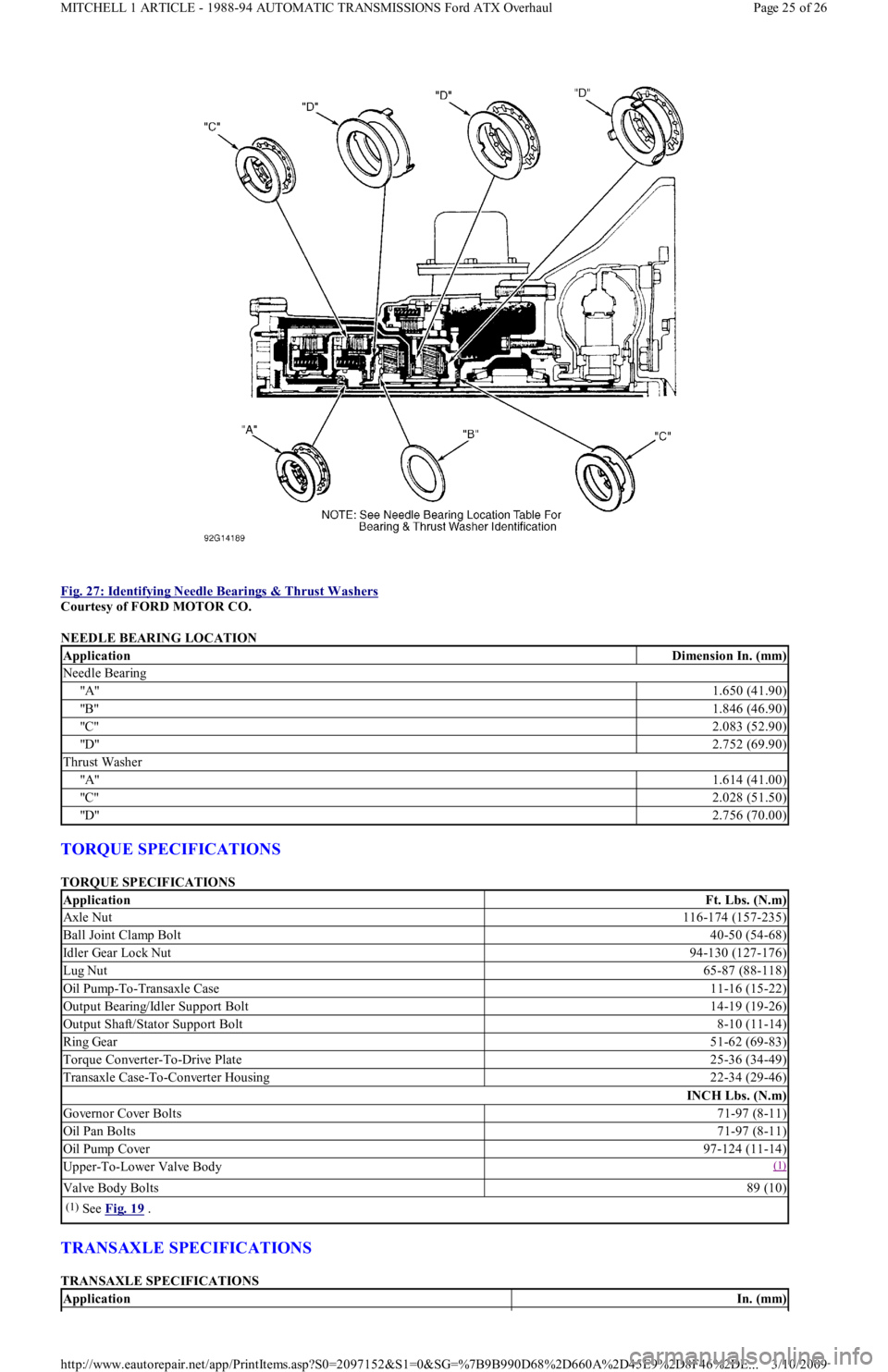

Fig. 27: Identifying Needle Bearings & Thrust Washers

Courtesy of FORD MOTOR CO.

NEEDLE BEARING LOCATION

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

TRANSAXLE SPECIFICATIONS

TRANSAXLE SPECIFICATIONS

ApplicationDimension In. (mm)

Needle Bearing

"A"1.650 (41.90)

"B"1.846 (46.90)

"C"2.083 (52.90)

"D"2.752 (69.90)

Thrust Washer

"A"1.614 (41.00)

"C"2.028 (51.50)

"D"2.756 (70.00)

ApplicationFt. Lbs. (N.m)

Axle Nut116-174 (157-235)

Ball Joint Clamp Bolt40-50 (54-68)

Idler Gear Lock Nut94-130 (127-176)

Lug Nut65-87 (88-118)

Oil Pump-To-Transaxle Case11-16 (15-22)

Output Bearing/Idler Support Bolt14-19 (19-26)

Output Shaft/Stator Support Bolt8-10 (11-14)

Ring Gear51-62 (69-83)

Torque Converter-To-Drive Plate25-36 (34-49)

Transaxle Case-To-Converter Housing22-34 (29-46)

INCH Lbs. (N.m)

Go ve r n o r C o ve r B o l t s71-97 (8-11)

Oil Pan Bolts71-97 (8-11)

Oil Pump Cover97-124 (11-14)

Upper-To-Lower Valve Body(1)

Valve Body Bolts89 (10)

(1)See Fig. 19 .

ApplicationIn. (mm)

Page 25 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 434 of 454

Differential Backlash.004 (.01)

Front Clutch Drum Bushing Diameter1.735 (44.08)

Front Clutch Pack Clearance.063-.071 (1.6-1.8)

Front Drum End Play.020-.031 (.5-.8)

Front Planetary Pinion Clearance.031 (.8)

Low/Reverse Clutch Pack Clearance.032-.041 (.8-1.05)

Oil Pump Gear Clearance.010 (.25)

Oil Pump Sealing Ring Clearance.016 (.40)

Outer Gear-To-Housing Clearance (1) .10 (.25)

Output Gear End Play.003 (.08)

Rear Clutch Pack Clearance.031-.039 (.8-1.0)

Rear Planetary Pinion Clearance.031 (.8)

(1)Oil pump outer gear.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00025375

Page 26 of 26 MITCHELL 1 ARTICLE - 1988-94 AUTOMATIC TRANSMISSIONS Ford ATX Overhaul

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...