fuel cap FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 2 of 454

Back To Article

INST RUMENT PANEL

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Switches & Instrum ent Panels - Standard

DESCRIPTION & OPERATION

Instrument panel on Capri contains a speedometer, tachometer, fuel, water temperature, oil pressure and voltmeter gauges. A boost gauge is

incorporated into the tachometer on turbo models. Instrument panel is equipped with indicator/warning lights for charging system, air b ag,

manual shift, seat belt, turn signals, high beam and brakes. A CHECK ENGINE light, located on instrument panel, illuminates if a

computerized engine control fault occurs with engine running.

Instrument panel on Festiva contains a speedometer, fuel and water temperature gauges. Instrument panel is equipped with indicator/warning

lights for charging system, oil pressure, seat belt, rear defogger, turn signals, high beam and brakes. A CHECK ENGINE light, located on

instrument panel, illuminates if a computerized engine control fault occurs with engine running.

TROUBLE SHOOTING

FUEL GAUGE

Fuel Gauge Always Reads Empty

If fuel gauge always reads empty, check these items:

Check fuel gauge for open or damaged wires.

Check for open ground at fuel gauge sending unit.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel instrument panel.

Check for fuel tank float full of fuel (sunk).

Fuel Gauge Always Reads Full

If fuel gauge always reads full, check these items:

Check for fuel gauge Yellow wire shorted to ground.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Fuel Gauge Inaccurate

If fuel gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective fuel sending unit.

Check for defective instrument panel voltage regulator (Festiva).

TEMPERATURE GAUGE

Temperature Gauge Always Reads Cold

If temperature gauge always reads cold, check these items:

Check temperature gauge for open wire.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel to instrument panel.

Temperature Gauge Always Reads Hot

CAUT ION: On m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag system

is powered directly from the battery and back-up power supply. Before any repairs are perform ed,

disconnect and shield battery ground cable. Disconnect the back-up power supply BEFORE servicing

ANY air bag com ponent. Use caution when working near steering colum n. Air bag could accidentally

deploy at any tim e.

NOTE:Ensure continuity exists between chassis ground and Black wire of instrum ent panel connector,

especially if fault exists in m ultiple gauge circuits. See appropriate chassis wiring diagram in the

WIRING DIAGRAMS Section.

Page 1 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 4 of 454

Turbo Boost Gauge Always Reads High

If turbo boost gauge always reads high, check these items:

Check for damaged White/Black signal wire.

Check for defective boost sensing unit.

Check for defective boost gauge.

Turbo Boost Gauge Inaccurate

If turbo boost gauge is inaccurate, check these items:

Check for loose or corroded connections.

Check for defective boost sensing unit.

Check for defective boost gauge.

TESTING

FUEL GAUGE SENDING UNIT

Capri

Remove rear seat cushion. Disconnect fuel pump/fuel gauge sending unit electrical connector at access cover. Turn ignition on. Fuel gauge

should read empty. Using a jumper wire, connect Yellow fuel gauge wire of vehicle harness connector to ground. Fuel gauge should read full.

If fuel gauge operates as specified, replace fuel gauge sending unit.

Festiva

Remove fuel gauge sending unit from tank. See FUEL SENDING UNIT under REMOVAL & INSTALLATION. Connect an ohmmeter and

check sending unit resistance as indicated in FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

table. Replace sending unit if

resistance is drastically different than specification.

FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

OIL PRESSURE GAUGE (CAPRI)

1. Remove electrical connector from oil pressure sending unit located on right side of engine block. Turn ignition switch on. Oil pressure

gauge should read low. Install a jumper wire between Yellow/Red wire of oil pressure sending unit vehicle harness connector and

ground. Oil pressure gauge should read high.

2. If oil pressure gauge operates as specified, replace sending unit. If gauge does not operate as specified, check instrument panel power

and ground circuits.

OIL PRESSURE WARNING LIGHT (FESTIVA)

Light Stays On With Engine Running

1. Turn ignition on (DO NOT start engine). Disconnect Yellow/Red wire from oil pressure switch connector. Light should go off.

2. If light stays on, repair short in Yellow/Red wire between oil indicator light and oil pressure switch. Reconnect wire to switch. Light

should be on with ignition on. If light does not go off when engine is started, check switch or engine for low oil pressure.

Oil Light Will Not Go On With Ignition On

1. Ground Yellow/Red wire at instrument panel connector. If light goes on, repair Yellow/Red wire between oil pressure switch and

indicator light or replace defective oil pressure switch.

2. If light does not illuminate, check bulb or check instrument panel ground circuit.

TEMPERATURE GAUGE (CAPRI)

1. Remove electrical connector from temperature sending unit located at front of cylinder head. Connect one lead of Gauge System Tester

(021-00055) to connector and other tester lead to ground. Set tester to 18 ohms, turn ignition switch on and observe temperature gauge.

Gauge should read 250°F.

2. Turn tester to 60 ohms. Gauge should read 175°F. Turn tester to 223 ohms. Gauge should read 100°F. If all readings are within twice

the needle width of correct reading, gauge is functioning properly. If readings are not as specified, replace gauge.

TEMPERATURE GAUGE (FESTIVA)

See TROUBLE SHOOTING for possible service areas.

TEMPERATURE SENDING UNIT (CAPRI)

Remove sending unit from engine and place in container of water. Heat water to 176°F (80°C). Measure resistance between sending unit

connector and case. Resistance should be 49.3-57.7 ohms. If resistance is not as specified, replace sending unit. NOTE:Inspect fuel tank for distortion or dam age. If distorted or dam aged, repair or replace tank before testing.

Float PositionOhms

Full Position (Up)Approximately 7

Half-Full Position (Middle)Approximately 33

Empty Position (Down)Approximately 95

Page 3 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 5 of 454

TURBO BOOST GAUGE & SENSOR (CAPRI)

1. Disconnect 3-pin boost sensor electrical connected located on right side of firewall. Turn ignition on. Measure voltage between

Yellow/Green and Black wires. Voltage should be greater than 10 volts. Turn ignition off. If voltage is greater than 10 volts, go t o n e xt

step. If voltage is 10 volts or less, repair Yellow/Green or Black wires as necessary.

2. Remove instrument panel. See INSTRUMENT PANEL

under REMOVAL & INSTALLATION. Disconnect instrument panel 8-pin

connector. With boost sensor disconnected, measure resistance through White/Black between instrument panel and boost sensor harness

connector. If resistance is less than 5 ohms, go to next step. If resistance is 5 ohms or more, repair or replace White/Black wire.

3. With 8-pin instrument panel connector disconnected, ground White/Black at boost gauge. Boost gauge should read low. Apply 12 vo l t s

to White/Black wire at boost gauge. Boost gauge should read high. If boost gauge operates as specified, go to next step. If boost gauge

does not operate as specified, replace boost gauge.

4. Reconnect instrument panel connectors (if removed). With ignition on and boost sensor disconnected, install jumper wire between

Yellow/Green and White/Black wires of boost sensor vehicle harness connector. Boost gauge should read high. If boost gauge reads

high, replace boost sensor. If boost gauge does not read high, go to TROUBLE SHOOTING

for other possible causes.

REMOVAL & INSTALLATION

INSTRUMENT PANEL

Removal & Installation (Capri)

1. Disconnect negative battery cable. Pull storage compartment from heater/radio bezel. Pull outward and remove trim covers located on

both sides of steering column. Remove retaining screws and carefully pull instrument panel bezel partially away from dash. Disconnect

electrical connectors from clock and switches in bezel. Remove instrument panel bezel.

2. Disconnect speedometer cable from transaxle. Remove instrument panel retaining screws and slide instrument panel outward. Press lock

tab and release speedometer cable from instrument panel. Remove electrical connectors from rear of instrument panel. Remove

instrument panel. To install instrument panel, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove upper and lower steering column covers. Remove screws from panel bezel and remove bezel.

Disconnect rear wiper switch and rear defogger switch wiring harness connectors (if equipped).

2. Remove instrument panel-to-dash screws. Pull panel from dash. Reach behind panel and release speedometer drive cable lock tab. Lift

lock tabs and disconnect 2 electrical connectors from rear of panel. Remove panel. To install instrument panel, reverse removal

procedure.

INDICATOR LIGHTS

Removal & Installation

Remove instrument panel for access to indicator light bulbs. See INSTRUMENT PANEL under REMOVAL & INSTALLATION. To remove

bulb, rotate bulb counterclockwise to disengage locking tabs. When tabs release, pull bulb from printed circuit board. To install bulb, reverse

removal procedure. Install instrument panel and test lights.

SPEEDOMETER R & I

Removal & Installation (Capri)

R e mo ve n e ga t ive b a t t e r y c a b l e . R e mo ve in st r u me n t p a n e l . S e e INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble

instrument panel and remove speedometer/tachometer/boost gauge assembly from instrument panel. To install, apply a 3/16" (4.6 mm) b al l o f

Silicone Damping Grease (D7AZ-19A331-A) into drive hole of speedometer head. Reverse removal procedure to complete installation.

Removal & Installation (Festiva)

R e mo ve n e ga t ive b a t t e r y c a b l e . R e mo ve in st r u me n t p a n e l . S e e INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble

instrument panel and remove speedometer head assembly from instrument panel. Speedometer is a separate module and can be removed

independently from gauges. To install, reverse removal procedure.

SPEED SENSOR

On vehicles equipped with speed control, a speed sensor is mounted in speedometer head assembly. If replacement is necessary, speedometer

head assembly must be replaced. See SPEEDOMETER R & I

under REMOVAL & INSTALLATION.

FUEL GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove fuel gauge.

To install gauge, reverse removal procedure. On Capri, the fuel/volt gauge must be replaced as an assembly.

FUEL SENDING UNIT

Removal & Installation

1. For Festiva, remove rear seat. For Capri, remove rear seat cushion. On Festiva, remove carpet hold-down pins and lift carpet for access

to sending unit access plate. On all models, remove access plate screws. NOTE:Federal law requires that a label stating the odom eter has been repaired or replaced be affixed to any

vehicle that has its odom eter repaired, replaced or set to zero.

Page 4 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 6 of 454

2. Lift access plate and disconnect sending unit wiring. To relieve fuel pressure, start engine and run it until engine stalls. Turn ignition off.

Disconnect and plug fuel lines at sending unit. Remove sending u n it a t t a c h in g sc r e ws. R e mo ve se n d in g u n it . To in st a l l , r e ve r se removal

procedure.

TACHOMETER

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove tachometer.

To install tachometer, reverse removal procedure. On Capri, the tachometer/speedometer/boost gauge assembly must be replaced as an

assembly.

TEMPERATURE GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove temperature

gauge. To install gauge, reverse removal procedure. On Capri, the temperature/oil pressure gauge assembly must be replaced as an assembly.

TEMPERATURE SENDING UNIT

Removal

Disconnect sending unit wire, located on side of block below thermostat housing (Festiva) or cylinder head (Capri). Remove radiator cap to

relieve cooling system pressure. Position drain pan below sending unit. Remove temperature sending unit.

Installation

To install, apply Pipe Sealant With Teflon (D8AZ-19554-A) to threads of sending unit. Reverse removal procedure to complete installation.

Fill cooling system to proper level. Start engine and check for coolant leaks at sending unit.

WIRING DIAGRAMS

CAUT ION: T achom eter is calibrated at factory. Rough handling could disturb calibration.

NOTE:Refer to the appropriate WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028301

Page 5 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 51 of 454

CATALYTIC CONVERTER

Continued operation of vehicle with a severe malfunction could cause converter to overheat, resulting in possible damage to converter and

ve h ic l e .

Any modification to the exhaust system on turbo models, which reduces exhaust backpressure, will lead to lean fuel mixtures and excessive

spark advance. This could cause serious engine damage.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

ENGINE OIL

FUEL PUMP SHUTOFF SWITCH

This switch stops flow of fuel to engine after a collision. The impact does not have to be great for switch to be triggered. Switch must be reset

after collision. Switch is located under left rear speaker in luggage compartment. Press button to reset switch.

FUEL SYSTEM SERVICE

HALOGEN BULBS

PASSIVE RESTRAINTS

RADIATOR CAP

RADIATOR FAN WARNING:Many solid state electrical com ponents can be dam aged by static electricity (ESD). Som e will display a

warning label, but m any will not. Discharge personal static electricity by touching a m etal ground point

on the vehicle prior to servicing any ESD sensitive com ponent.

CAUT ION: Never use non-detergent or straight m ineral oil.

WARNING:Relieve fuel system pressure prior to servicing any fuel system com ponent (fuel injection m odels).

WARNING:Halogen bulbs contain pressurized gas which m ay explode if overheated. DO NOT touch glass portion

of bulb with bare hands. Eye protection should be worn when handling or working around halogen

bulbs.

CAUT ION: Before operating vehicle, securely fasten passive shoulder restraints to the em ergency release buckles.

T he buckle fits in only one way. Ensure to position it properly.

CAUT ION: Always disconnect the fan m otor when working near the radiator fan. T he fan is tem perature controlled

and could start at any tim e even when the ignition key is in the OFF position. DO NOT loosen or rem ove

radiator cap when cooling system is hot.

WARNING:Keep hands away from radiator fan. Fan is controlled by a therm ostatic switch which m ay com e on or

run for up to 15 m inutes even after engine is turned off.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00058075

Page 3 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 86 of 454

Back To Article

ENGINE COOLING FAN

1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

DESCRIPTION

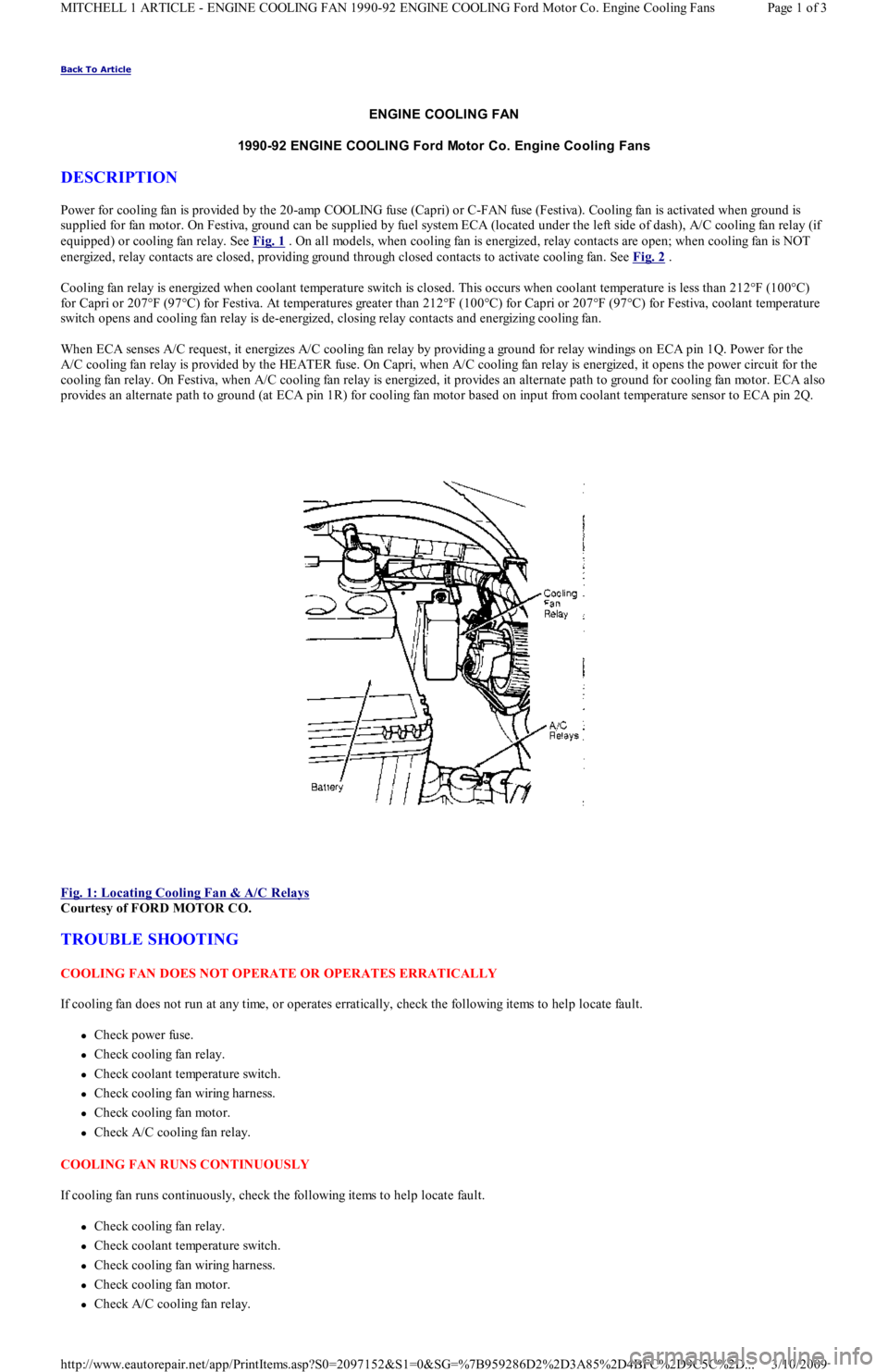

Power for cooling fan is provided by the 20-amp COOLING fuse (Capri) or C-FAN fuse (Festiva). Cooling fan is activated when ground is

supplied for fan motor. On Festiva, ground can be supplied by fuel system ECA (located under the left side of dash), A/C cooling fan relay (if

equipped) or cooling fan relay. See Fig. 1

. On all models, when cooling fan is energized, relay contacts are open; when cooling fan is NOT

energized, relay contacts are closed, providing ground through closed contacts to activate cooling fan. See Fig. 2

.

Cooling fan relay is energized when coolant temperature switch is closed. This occurs when coolant temperature is less than 212°F (1 00 °C)

for Capri or 207°F (97°C) for Festiva. At temperatures greater than 212°F (100°C) for Capri or 207°F (97°C) for Festiva, coolant temperature

switch opens and cooling fan relay is de-energized, closing relay contacts and energizing cooling fan.

When ECA senses A/C request, it energizes A/C cooling fan relay by providing a ground for relay windings on ECA pin 1Q. Power for the

A/C cooling fan relay is provided by the HEATER fuse. On Capri, when A/C cooling fan relay is energized, it opens the power circuit for the

cooling fan relay. On Festiva, when A/C cooling fan relay is energized, it provides an alternate path to ground for cooling fan mo t o r. E CA al so

provides an alternate path to ground (at ECA pin 1R) for cooling fan motor based on input from coolant temperature sensor to ECA pin 2Q.

Fig. 1: Locating Cooling Fan & A/C Relays

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

COOLING FAN DOES NOT OPERATE OR OPERATES ERRATICALLY

If cooling fan does not run at any time, or operates erratically, check the following items to help locate fault.

Check power fuse.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

COOLING FAN RUNS CONTINUOUSLY

If cooling fan runs continuously, check the following items to help locate fault.

Check cooling fan relay.

Check coolant temperature switch.

Check cooling fan wiring harness.

Check cooling fan motor.

Check A/C cooling fan relay.

Page 1 of 3 MITCHELL 1 ARTICLE - ENGINE COOLING FAN 1990-92 ENGINE COOLING Ford Motor Co. Engine Cooling Fans

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 101 of 454

Back To Article

ENGINE OVERHAUL

1991-92 FORD MOT OR CO. ENGINES 1.3L & 1.6L 4-Cylinder

ENGINE IDENTIFICATION

Engine can be identified by Vehicle Identification Number (VIN) on metal tab attached to instrument panel. Tab is close to windshield on

driver's side and is visible through windshield. VIN has 17 characters. The 8th character identifies engine.

ENGINE IDENTIFICATION CODES

ADJUSTMENTS

VALVE ARRANGEMENT

Firewall Side

In t ake val ves.

Radiator Side

Exhaust valves.

VALVE CLEARANCE ADJUSTMENT

Hydraulic lifters are used. Adjustment is NOT possible nor necessary.

REMOVAL & INSTALLATION

FUEL PRESSURE RELEASE

Remove rear seat. Remove fuel pump access panel. Disconnect fuel pump electrical connector. Start engine and allow to idle until engine dies.

ENGINE

Removal (1.3L)

1. Remove battery and battery tray. Index hood-to-hinge and remove hood. Drain coolant. Drain engine oil and transaxle fluid. Disconnect

vane airflow meter connector, vane airflow meter and hose.

2. Remove oil dipstick, cooling fan and radiator assembly. Disconnect accelerator cable from mounting bracket and throttle lever.

Disconnect speedometer cable at transaxle. Mark and disconnect fuel lines at fuel pump. Plug fuel lines. Remove heater hoses. Remove

brake booster vacuum hose. Disconnect transaxle vacuum hose.

3. Remove charcoal canister hoses from engine. Disconnect engine wiring harness. Remove alternator and brackets. Remove engine ground

strap. Raise vehicle and remove catalytic converter.

4. Disconnect A/C compressor without removing hoses, and set compressor aside. Disconnect distributor wiring at coil. On automatic

transaxle models, remove shift lever-to-manual shaft assembly nut. Remove shift cable from transaxle. Loosen front wheel bolts. Raise

vehicle and remove wheel assemblies.

5. Remove stabilizer mounting nuts and brackets. Remove lower arm clamp bolts and nuts. Pull lower arms downward, separating lower

arms from knuckles. Separate halfshafts and install Differential Plugs (T87C-7025-C) between differential side gears. See FWD AXLE

SHAFTS article in DRIVE AXLES Section.

6. On manual transaxle vehicles, disconnect clutch control cable and shift control cable rod. Remove stabilizer bar from transaxle. Remove

catalytic converter inlet pipe. Support engine assembly with hoist. Remove rear crossmember mount bolts. Remove front and rear engine

mount nuts.

7. Remove crossmember. Lower vehicle and attach engine lift hooks. Remove right engine mount bolt. Remove engine/transaxle assembly.

Remove gusset plates. Remove starter and flywheel cover. Remove torque converter bolts on automatic transaxle. Remove engine-to-

transaxle bolts. Separate transaxle from engine.

Installation (1.3L)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position in vehicle. Support engine

in chassis and install engine mount bolts. Raise vehicle and install front engine mount nut. Tighten nuts to specification. See TORQUE

SPECIFICATIONS table at end of article.

2. Position crossmember onto mounts and chassis. Tighten rear nut. Install mount-to-crossmember nuts and tighten. Remove differential

plugs and install halfshafts. To complete installation, reverse removal procedure. Tighten all bolts/nuts to specifications. Fill all fluid NOTE:For engine repair procedures not covered in this article, see ENGINE OVERHAUL PROCEDURES

-

GENERAL INFORMATION

article in the GENERAL INFORMAT ION section.

ApplicationVIN Code

Festiva

1.3L SOHC PFIH

Capri

1.6L DOHC PFIZ

1.6L DOHC PFI TURBO6

NOTE:When rem oving engine m ounts, m ark and note location and position to ensure proper installation.

Engine and transaxle are rem oved as an assem bly.

Page 1 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 104 of 454

1. Position new gasket on exhaust manifold, and install turbocharger onto studs. Install 4 retaining nuts and tighten to specification. See

TORQUE SPECIFICATIONS

table at end of article.

2. Remove oil supply line from turbocharger. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first .

Carefully position turbocharger assembly in engine compartment and slide exhaust manifold on studs. Position heater tube bracket onto

exhaust stud. Install 11 retaining nuts onto exhaust manifold and tighten to specification. See TORQUE SPECIFICATIONS

table at

end of article. Tighten heater tube clamp bolt securely.

3. Raise vehicle. Position new gasket and install 2 retaining bolts on heater tube outlet. Install 2 retaining bolts into turbocharger support

bracket and tighten bolts to specification.

4. Connect coolant return hose. Connect oil return hose and secure with clamp. Position exhaust pipe onto turbocharger, and start nuts

and washers. Install 2 retaining bolts on exhaust hanger at engine. Slide on 2 rubber exhaust hangers at catalytic converter. Tighten

exhaust pipe retaining nuts to specification. Lower vehicle.

5. Install retaining bolt and brass washers on oil supply line, carefully position oil line into vehicle and hand-start bolt into engine block.

Connect and finger tighten oil line to turbocharger. Tighten oil line bolt and oil supply line on turbocharger to specification.

6. Connect coolant supply hose. Position air cleaner duct tube on turbocharger and tighten clamp. Install 2 screws retaining air cleaner

duct tube. Position power steering pump bracket on engine, and install 2 retaining bolts and one retaining nut. Tighten to specification.

Position power steering pump on mounting bracket, and install though bolt and adjuster. Connect lower radiator hose. Install power

steering belt. Position upper heat shield and install 2 retaining bolts finger tight.

7. Position lower heat shield and install three retaining bolts finger tight. Tighten all heat shield bolts to specification. Connect O2 sensor

and install connector into its retaining clip. See TORQUE SPECIFICATIONS

table at end of article. Position intercooler hose on

turbocharger and secure with clamp. Install throttle body air intake tube. Connect negative battery cable. Refill cooling system.

CYLINDER HEAD

Removal (1.3L)

1. Disconnect battery ground cable. Mark and disconnect fuel lines at fuel pump. Remove accessory belts, water pump pulley, crankshaft

pulley, timing belt covers, timing belt tensioner, timing belt, valve cover and exhaust and intake manifolds. Drain cooling system.

2. Mark and remove electrical connectors and vacuum hoses. Remove spark plug wires from spark plugs, and remove spark plugs. Remove

distributor cap. Disconnect vacuum hoses and distributor wiring.

3. Index distributor-to-mount position and remove hold-down bolt. Remove distributor assembly. Remove engine ground strap. Remove

front and rear engine lifting hooks. Remove upper radiator hose, by-pass hose and bracket.

4. Remove bolts retaining rocker arm shaft. Remove rocker arm assemblies. Remove cylinder head bolts. Remove head and gasket.

Inspection (1.3L)

1. Thoroughly clean and check gasket mating surface of cylinder head and block. Check cylinder for cracks, nicks, burrs or damage. Using

a straightedge and feeler gauge, check warpage over entire gasket area. Ensure cylinder head and/or block warpage does not

exceed .006" (.15 mm).

2. If warpage exceeds .006" (.15 mm), machine cylinder head and/or block gasket surface. Maximum machining allowed is .008" (.20 mm).

If more machining is required, replace block and/or cylinder head.

Installation (1.3L)

1. Place new head gasket properly on block. Carefully place cylinder head in position on block. Install head bolts. Tighten bolts in

sequence and in 2 steps. See Fig. 1

.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching springs. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. To complete installation, reverse removal procedure. Tighten all bolts/nuts to

specification. Fill all fluids to proper levels. NOTE:T urbocharger-to-exhaust m anifold m ounting nuts are of special quality. Ensure correct nuts are

used.

NOTE:Ensure one brass washer is positioned on each side of oil line fitting.

NOTE:Feed O2 sensor wire through upper heat shield. Install wire retainer under LH bolt.

NOTE:If turbocharger was replaced: Disconnect ignition coil, crank engine for 20 seconds, connect ignition

coil, start engine and run at idle for 30 seconds and check for leaks.

NOTE:If original tim ing belt is being reused, m ark direction of rotation for installation reference.

Page 4 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 116 of 454

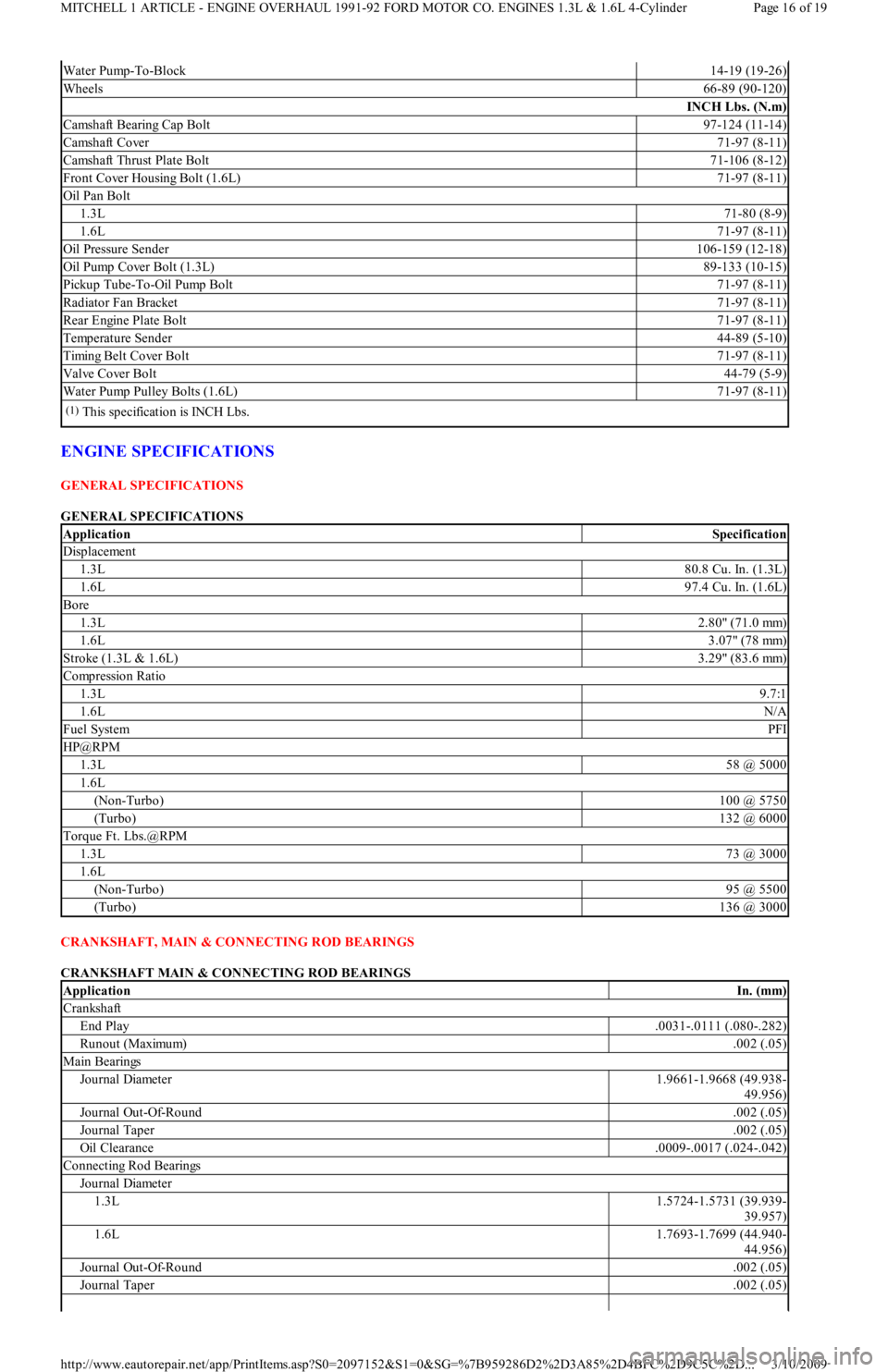

ENGINE SPECIFICATIONS

GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS

CRANKSHAFT MAIN & CONNECTING ROD BEARINGS

Water Pump-To-Block14-19 (19-26)

Wheels66-89 (90-120)

INCH Lbs. (N.m)

Camshaft Bearing Cap Bolt97-124 (11-14)

Camshaft Cover71-97 (8-11)

Camshaft Thrust Plate Bolt71-106 (8-12)

Front Cover Housing Bolt (1.6L)71-97 (8-11)

Oil Pan Bolt

1.3L71-80 (8-9)

1.6L71-97 (8-11)

Oil Pressure Sender106-159 (12-18)

Oil Pump Cover Bolt (1.3L)89-133 (10-15)

Pickup Tube-To-Oil Pump Bolt71-97 (8-11)

Radiator Fan Bracket71-97 (8-11)

Rear Engine Plate Bolt71-97 (8-11)

Temperature Sender44-89 (5-10)

Timing Belt Cover Bolt71-97 (8-11)

Valve Cover Bolt44-79 (5-9)

Water Pump Pulley Bolts (1.6L)71-97 (8-11)

(1)This specification is INCH Lbs.

ApplicationSpecification

Displacement

1.3L80.8 Cu. In. (1.3L)

1.6L97.4 Cu. In. (1.6L)

Bore

1.3L2.80" (71.0 mm)

1.6L3.07" (78 mm)

Stroke (1.3L & 1.6L)3.29" (83.6 mm)

Compression Ratio

1.3L9.7:1

1.6LN/A

Fuel SystemPFI

HP@RPM

1.3L58 @ 5000

1.6L

(Non-Turbo)100 @ 5750

(Turbo)132 @ 6000

Torque Ft. Lbs.@RPM

1.3L73 @ 3000

1.6L

(Non-Turbo)95 @ 5500

(Turbo)136 @ 3000

ApplicationIn. (mm)

Crankshaft

End Play.0031-.0111 (.080-.282)

Runout (Maximum).002 (.05)

Main Bearings

Journal Diameter1.9661-1.9668 (49.938-

49.956)

Journal Out-Of-Round.002 (.05)

Journal Taper.002 (.05)

Oil Clearance.0009-.0017 (.024-.042)

Connecting Rod Bearings

Journal Diameter

1.3L1.5724-1.5731 (39.939-

39.957)

1.6L1.7693-1.7699 (44.940-

44.956)

Journal Out-Of-Round.002 (.05)

Journal Taper.002 (.05)

Page 16 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...