fuel cap FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 129 of 454

Back To Article

D - ADJUSTMENTS

1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustm ents

ADJUSTMENTS

ENGINE MECHANICAL

Before beginning any on-vehicle adjustments to fuel or ignition systems, ensure engine mechanical condition is okay.

VALVE CLEARANCE

IGNITION TIMING

CAPRI

1. Place automatic transmission in Park or manual transmission in Neutral. Disconnect and plug hoses attached to vacuum diaphragm

assembly on distributor. Connect tachometer and timing light. Turn off all electrical loads.

2. Start engine, and warm it to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE . Determine initial timing. See IGNITION TIMING table. If base timing is not correct, loosen distributor mounting bolts

and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

3. Increase engine RPM while observing timing light. Verify ignition timing advances. For Turbo models, go to step 5). For non-Turbo

models, continue with step 4).

4. On non-Turbo models, apply 16 in. Hg vacuum to chamber "A". Verify timing advances by 26-30 degrees. Remove vacuum source from

chamber "A". Apply 8 in. Hg vacuum to chamber "B" while observing timing. Verify timing advances by 3-7 degrees. Stop engine, and

remove test equipment.

5. On Turbo models, apply 20 in. Hg vacuum to advance diaphragm. Verify timing advances by 13-17 degrees. Disconnect vacuum source.

Apply 8 psi (.6 kg/cm

2 ) pressure to advance diaphragm. Verify timing retards by 3-7 degrees. Stop engine, and remove test equipment.

FESTIVA

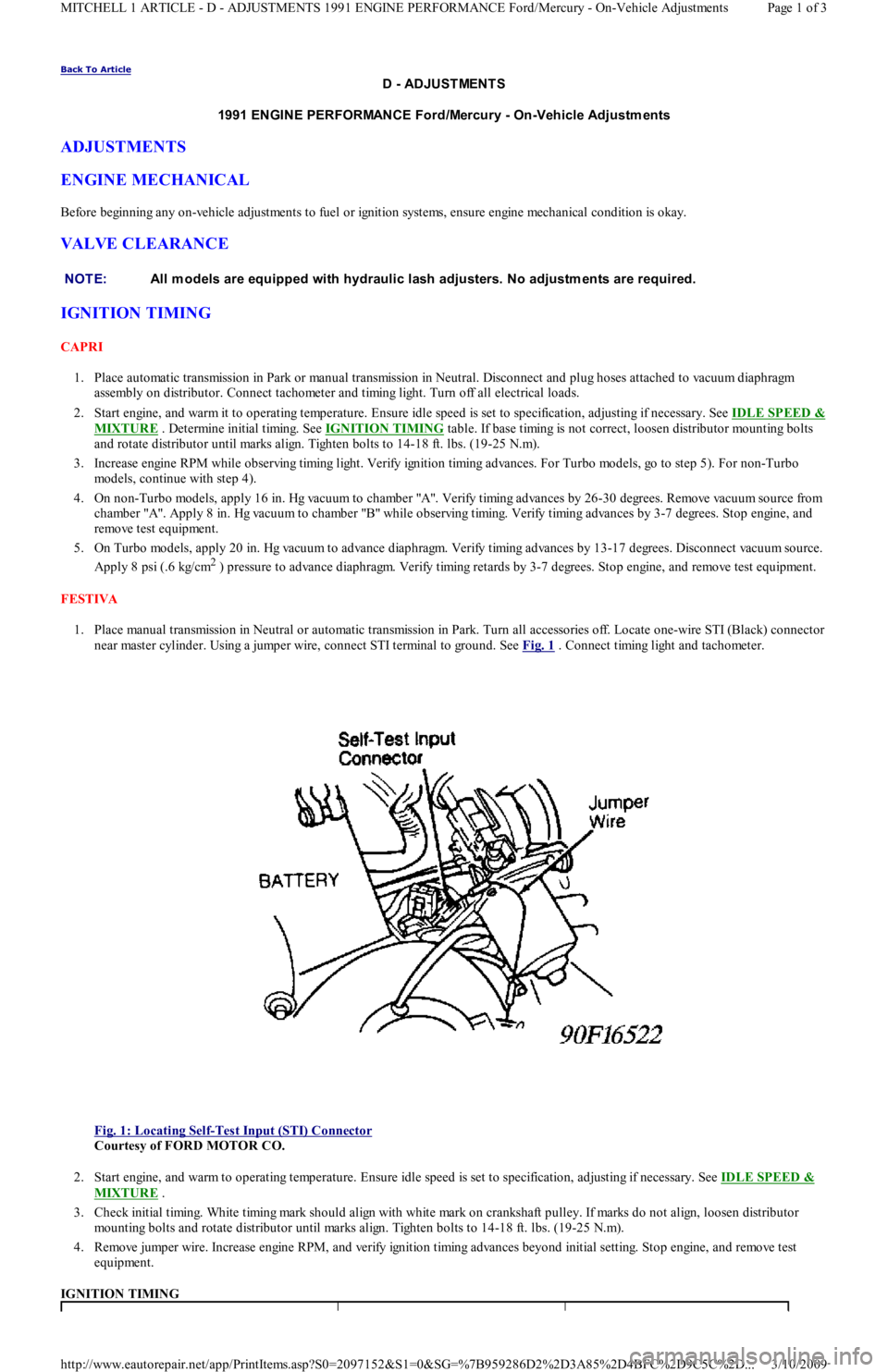

1. Place manual transmission in Neutral or automatic transmission in Park. Turn all accessories off. Locate one-wire STI (Black) connector

near master cylinder. Using a jumper wire, connect STI terminal to ground. See Fig. 1

. Connect timing light and tachometer.

Fig. 1: Locating Self

-Test Input (STI) Connector

Courtesy of FORD MOTOR CO.

2. Start engine, and warm to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE .

3. Check initial timing. White timing mark should align with white mark on crankshaft pulley. If marks do not align, loosen distributor

mounting bolts and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

4. Remove jumper wire. Increase engine RPM, and verify ignition timing advances beyond initial setting. Stop engine, and remove test

equipment.

IGNITION TIMING NOTE:All m odels are equipped with hydraulic lash adjusters. No adjustm ents are required.

Page 1 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 132 of 454

Back To Article

A - ENGINE/VIN ID

1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

APPLICATION

MODEL COVERAGE

VIN DEFINITION

Numbers preceding the explanations in the legend below refer to the sequence of characters as listed on VIN identification label.

SAMPLE VIN

Digit #: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17.

(VIN) K N J P T O 6 H 9 L 6 1 0 0 0 0 0.

VIN Definition

1-3 - Indicates Nation of Origin.

4 - Indicates Restraint System.

5 - Indicates Carline Code.

6-7 - Indicates Body Type.

8 - Indicates Engine Type.

9 - Indicates Check Digit.

10 - Indicates Model Year.

11 - Indicates Assembly Plant.

12-17 - Vehicle Serial Number.

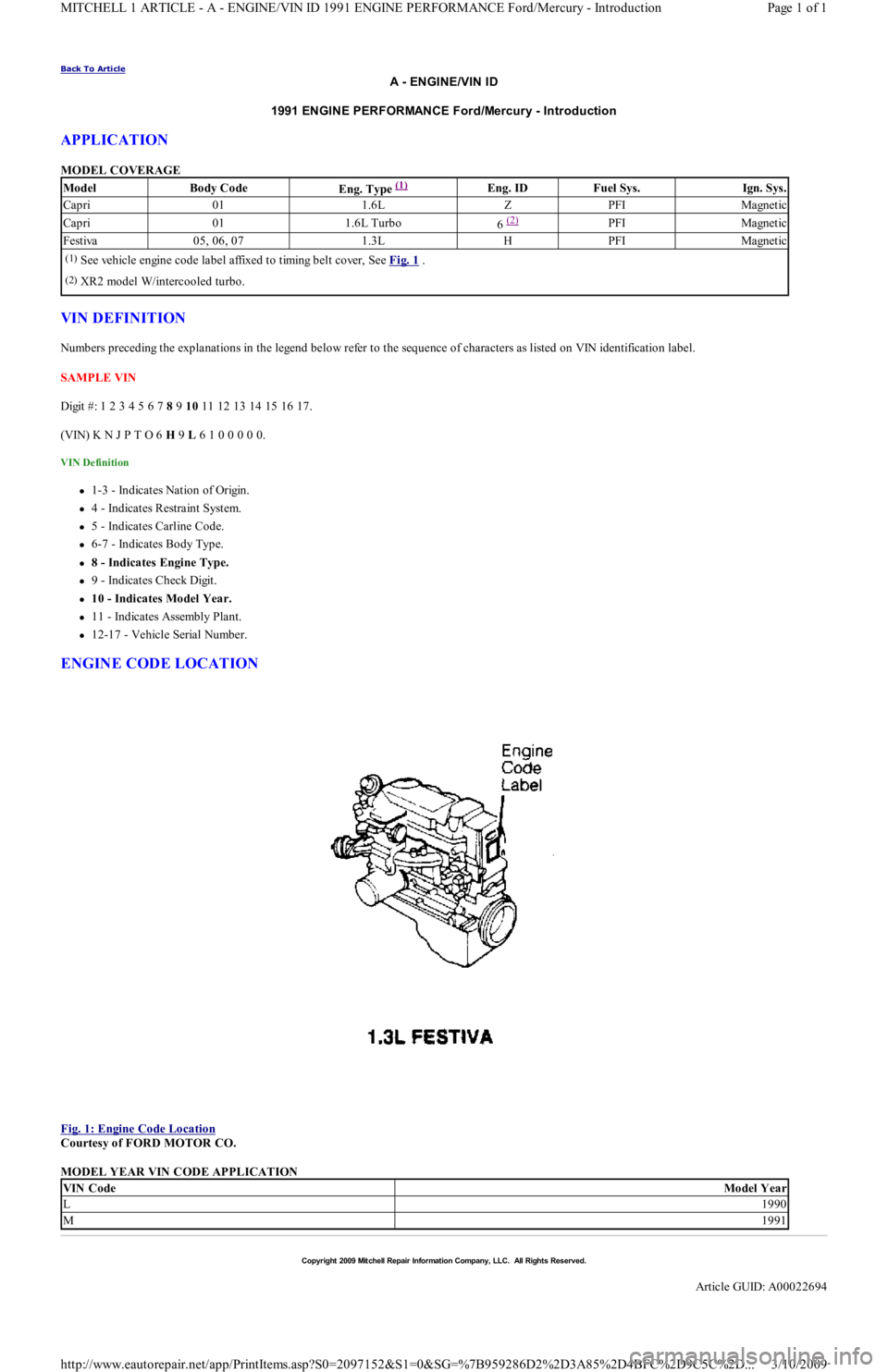

ENGINE CODE LOCATION

Fig. 1: Engine Code Location

Courtesy of FORD MOTOR CO.

MODEL YEAR VIN CODE APPLICATION

ModelBody CodeEng. Type (1) Eng. IDFuel Sys.Ign. Sys.

Capri011.6LZPFIMagnetic

Capri011.6L Turbo6 (2) PFIMagnetic

Festiva05, 06, 071.3LHPFIMagnetic

(1)See vehicle engine code label affixed to timing belt cover, See Fig. 1 .

(2)XR2 model W/intercooled turbo.

VIN CodeModel Year

L1990

M1991

Copyr ight 2009 Mit chell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022694

Page 1 of 1 MITCHELL 1 ARTICLE - A - ENGINE/VIN ID 1991 ENGINE PERFORMANCE Ford/Mercury - Introduction

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 133 of 454

Back To Article

EMISSION CONT ROL APPLICAT IONS

Em ission Applications - Ford Motor Co. - Im ports (1968-97)

EMISSION APPLICATIONS

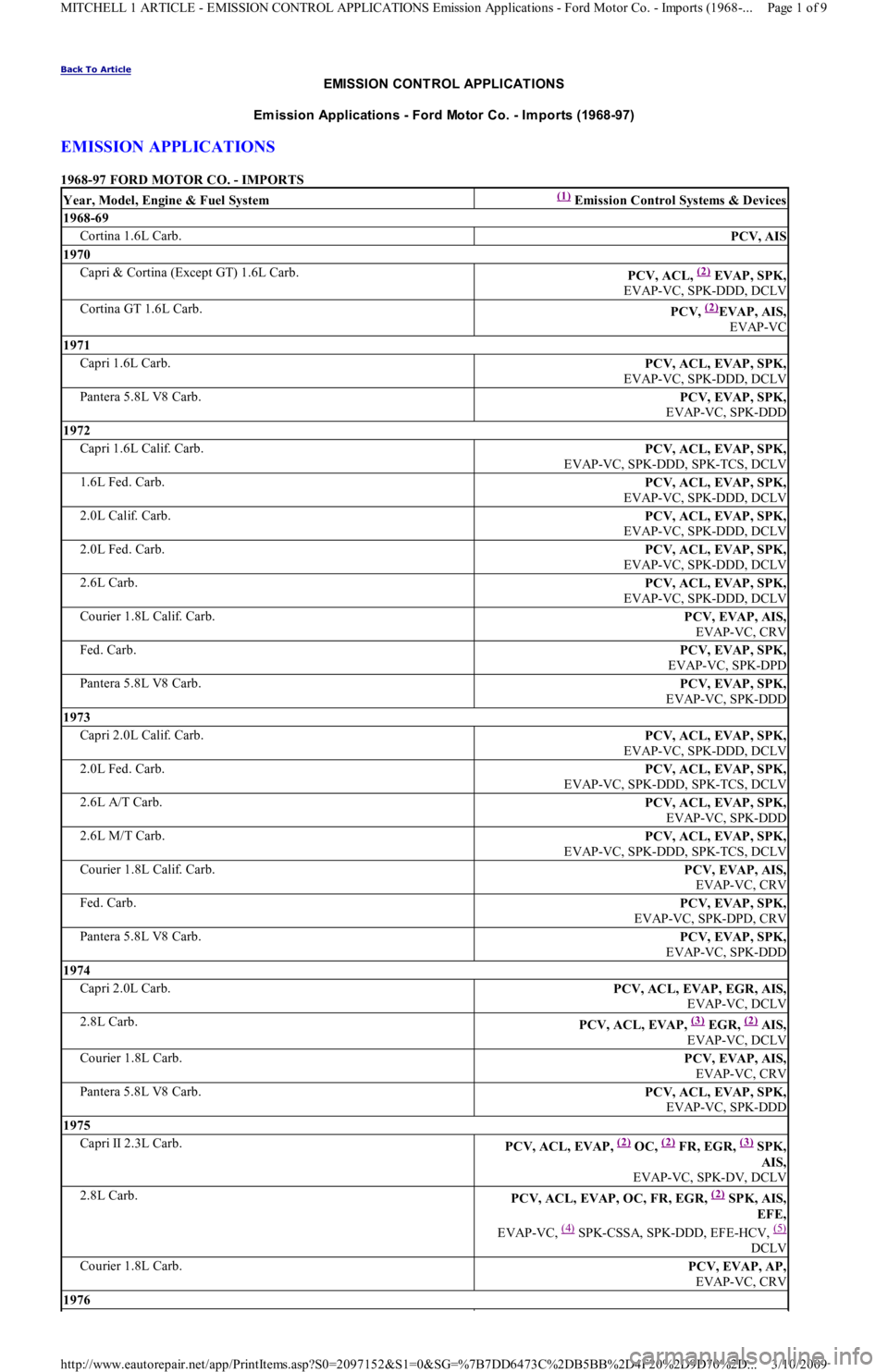

1968-97 FORD MOTOR CO. - IMPORTS

Year, Model, Engine & Fuel System(1) Emission Control Systems & Devices

1968-69

Cortina 1.6L Carb.PCV, AIS

1970

Capri & Cortina (Except GT) 1.6L Carb.PCV, ACL, (2) EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Cortina GT 1.6L Carb.PCV, (2)EVAP, AIS,

EVAP-VC

1971

Capri 1.6L Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1972

Capri 1.6L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

1.6L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.6L Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

Courier 1.8L Calif. Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Fed. Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DPD

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1973

Capri 2.0L Calif. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, DCLV

2.0L Fed. Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

2.6L A/T Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD

2.6L M/T Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD, SPK-TCS, DCLV

Courier 1.8L Calif. Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Fed. Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DPD, CRV

Pantera 5.8L V8 Carb.PCV, EVAP, SPK,

EVAP-VC, SPK-DDD

1974

Capri 2.0L Carb.PCV, ACL, EVAP, EGR, AIS,

EVAP-VC, DCLV

2.8L Carb.PCV, ACL, EVAP, (3) EGR, (2) AIS,

EVAP-VC, DCLV

Courier 1.8L Carb.PCV, EVAP, AIS,

EVAP-VC, CRV

Pantera 5.8L V8 Carb.PCV, ACL, EVAP, SPK,

EVAP-VC, SPK-DDD

1975

Capri II 2.3L Carb.PCV, ACL, EVAP, (2) OC, (2) FR, EGR, (3)SPK,

AIS,

EVAP-VC, SPK-DV, DCLV

2.8L Carb.PCV, ACL, EVAP, OC, FR, EGR, (2)SPK, AIS,

EFE,

EVAP-VC,

(4) SPK-CSSA, SPK-DDD, EFE-HCV, (5)

DCLV

Courier 1.8L Carb.PCV, EVAP, AP,

EVAP-VC, CRV

1976

Page 1 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 147 of 454

ELECTRONIC CONTROL ASSEMBLY (ECA)

REMOVAL & INSTALLATION

Disconnect negative battery cable. On Festiva, from under instrument panel, remove heater duct. On Capri, disengage push-pin retainers by

pulling back on front edges of both center carpet panels. Remove carpet panel retaining screws and panels. Disconnect ECA wire harness

connector. Remove ECA bolts and ECA. To install, reverse removal procedure. On Festiva, ensure mounting clip is inserted into bulkhead

recess.

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

Remove rear seat assembly. With engine running, disconnect fuel pump connector. Run engine until it stalls to relieve fuel line pressure.

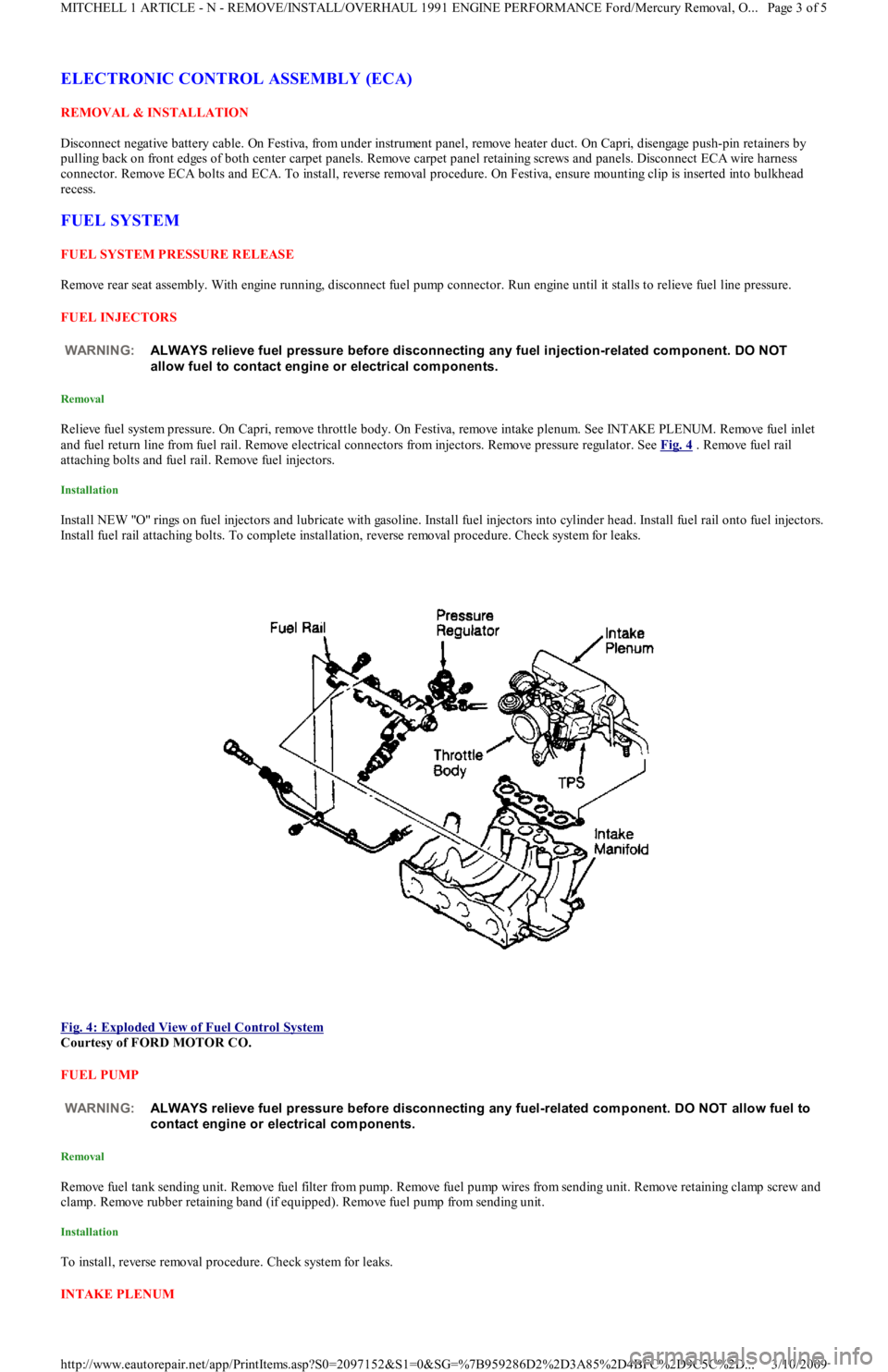

FUEL INJECTORS

Removal

Relieve fuel system pressure. On Capri, remove throttle body. On Festiva, remove intake plenum. See INTAKE PLENUM. Remove fuel inlet

and fuel return line from fuel rail. Remove electrical connectors from injectors. Remove pressure regulator. See Fig. 4

. Remove fuel rail

attaching bolts and fuel rail. Remove fuel injectors.

Installation

Install NEW "O" rings on fuel injectors and lubricate with gasoline. Install fuel injectors into cylinder head. Install fuel rail onto fuel injectors.

Install fuel rail attaching bolts. To complete installation, reverse removal procedure. Check system for leaks.

Fig. 4: Exploded View of Fuel Control System

Courtesy of FORD MOTOR CO.

FUEL PUMP

Removal

Remove fuel tank sending unit. Remove fuel filter from pump. Remove fuel pump wires from sending unit. Remove retaining clamp screw and

clamp. Remove rubber retaining band (if equipped). Remove fuel pump from sending unit.

Installation

To install, reverse removal procedure. Check system for leaks.

INTAKE PLENUM WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection-related com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel-related com ponent. DO NOT allow fuel to

contact engine or electrical com ponents.

Page 3 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 149 of 454

VANE AIRFLOW (VAF) METER

Removal

1. Disconnect negative battery cable. On Capri, disconnect primary and secondary wires from coil. On Festiva, disconnect VAF wire

harness connector. Remove air duct.

2. On Capri, remove retaining bolt and ground wire from air cleaner cover. Remove air cleaner cover bolts and air cleaner cover. From

inside of air cleaner cover, remove VAF meter retaining nuts. On Festiva, remove attaching bolt and 4 nuts. Remove vane airflow met er.

Installation

To install, reverse removal procedure. Position new gasket over VAF mounting studs. Tighten bolts and nuts to specification, see TORQUE

SPECIFICATIONS at end of article.

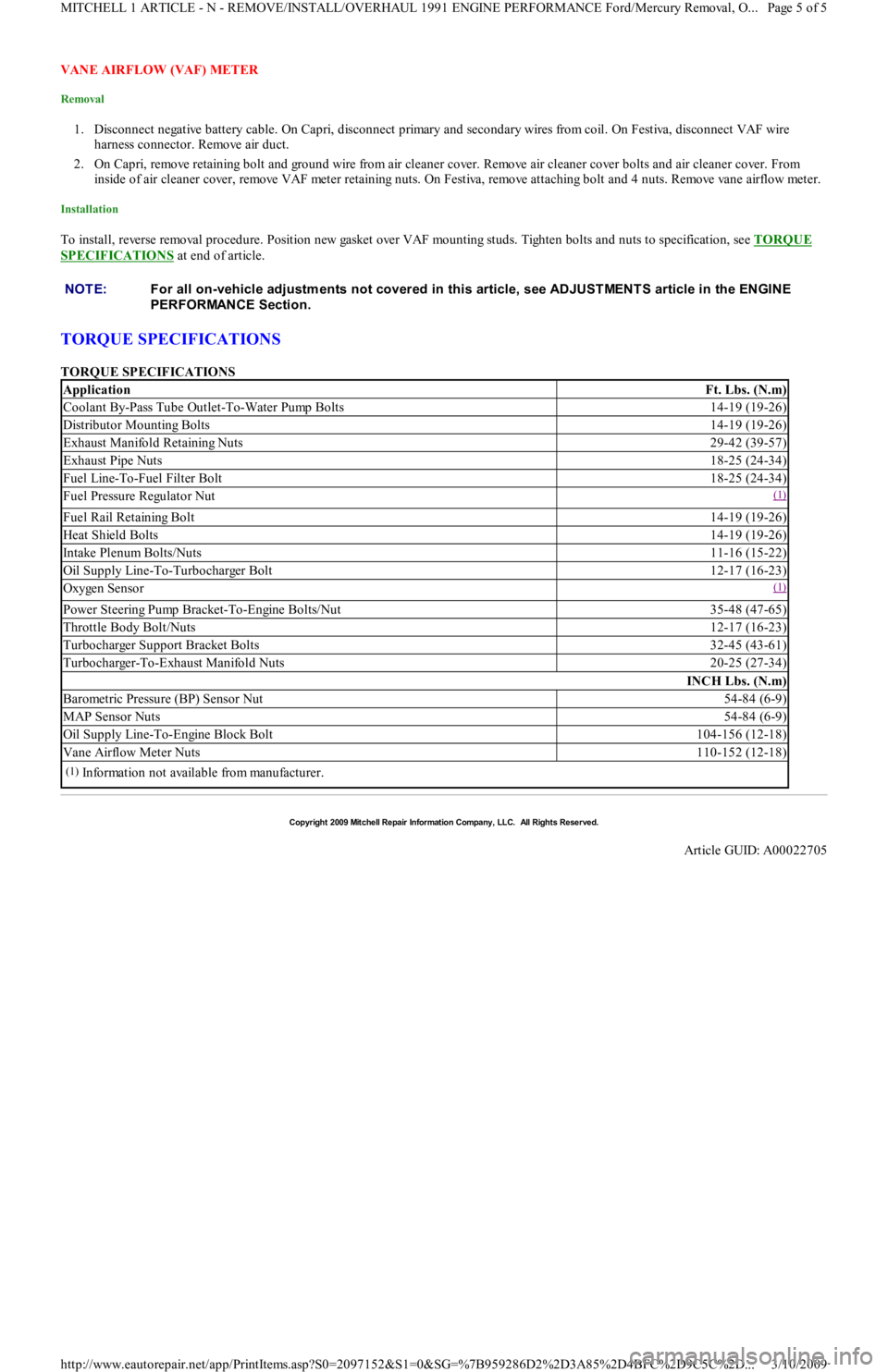

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:For all on-vehicle adjustm ents not covered in this article, see ADJUST MENT S article in the ENGINE

PERFORMANCE Section.

ApplicationFt. Lbs. (N.m)

Coolant By-Pass Tube Outlet-To-Water Pump Bolts14-19 (19-26)

Distributor Mounting Bolts14-19 (19-26)

Exhaust Manifold Retaining Nuts29-42 (39-57)

Exhaust Pipe Nuts18-25 (24-34)

Fuel Line-To-Fuel Filter Bolt18-25 (24-34)

Fuel Pressure Regulator Nut(1)

Fuel Rail Retaining Bolt14-19 (19-26)

Heat Shield Bolts14-19 (19-26)

Intake Plenum Bolts/Nuts11-16 (15-22)

Oil Supply Line-To-Turbocharger Bolt12-17 (16-23)

Oxygen Sensor(1)

Power Steering Pump Bracket-To-Engine Bolts/Nut35-48 (47-65)

Throttle Body Bolt/Nuts12-17 (16-23)

Turbocharger Support Bracket Bolts32-45 (43-61)

Turbocharger-To-Exhaust Manifold Nuts20-25 (27-34)

INCH Lbs. (N.m)

Barometric Pressure (BP) Sensor Nut54-84 (6-9)

MAP Sensor Nuts54-84 (6-9)

Oil Supply Line-To-Engine Block Bolt104-156 (12-18)

Vane Airflow Meter Nuts110-152 (12-18)

(1)Information not available from manufacturer.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022705

Page 5 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 155 of 454

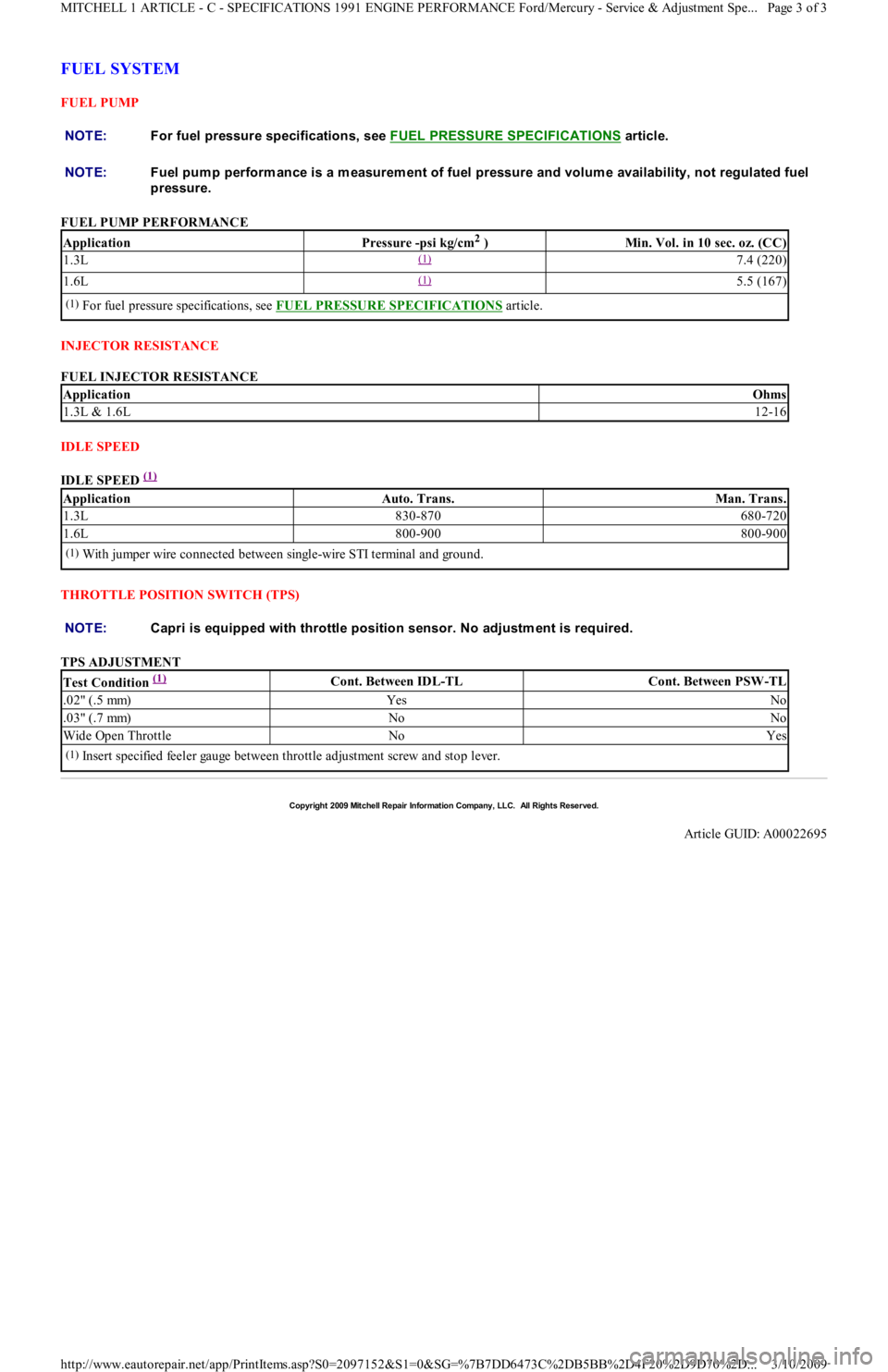

FUEL SYSTEM

FUEL PUMP

FUEL PUMP PERFORMANCE

INJECTOR RESISTANCE

FUEL INJECTOR RESISTANCE

IDLE SPEED

IDLE SPEED

(1)

THROTTLE POSITION SWITCH (TPS)

TPS ADJUSTMENT NOTE:For fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

NOTE:Fuel pum p perform ance is a m easurem ent of fuel pressure and volum e availability, not regulated fuel

pressure.

ApplicationPressure -psi kg/cm2 )Min. Vol. in 10 sec. oz. (CC)

1.3L(1) 7.4 (220)

1.6L(1) 5.5 (167)

(1)For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS article.

ApplicationOhms

1.3L & 1.6L12-16

ApplicationAuto. Trans.Man. Trans.

1.3L830-870680-720

1.6L800-900800-900

(1)With jumper wire connected between single-wire STI terminal and ground.

NOTE:Capri is equipped with throttle position sensor. No adjustm ent is required.

Test Condition (1) Cont. Between IDL-TLCont. Between PSW-TL

.02" (.5 mm)YesNo

.03" (.7 mm)NoNo

Wide Open ThrottleNoYes

(1)Insert specified feeler gauge between throttle adjustment screw and stop lever.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00022695

Page 3 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 156 of 454

Back To Article

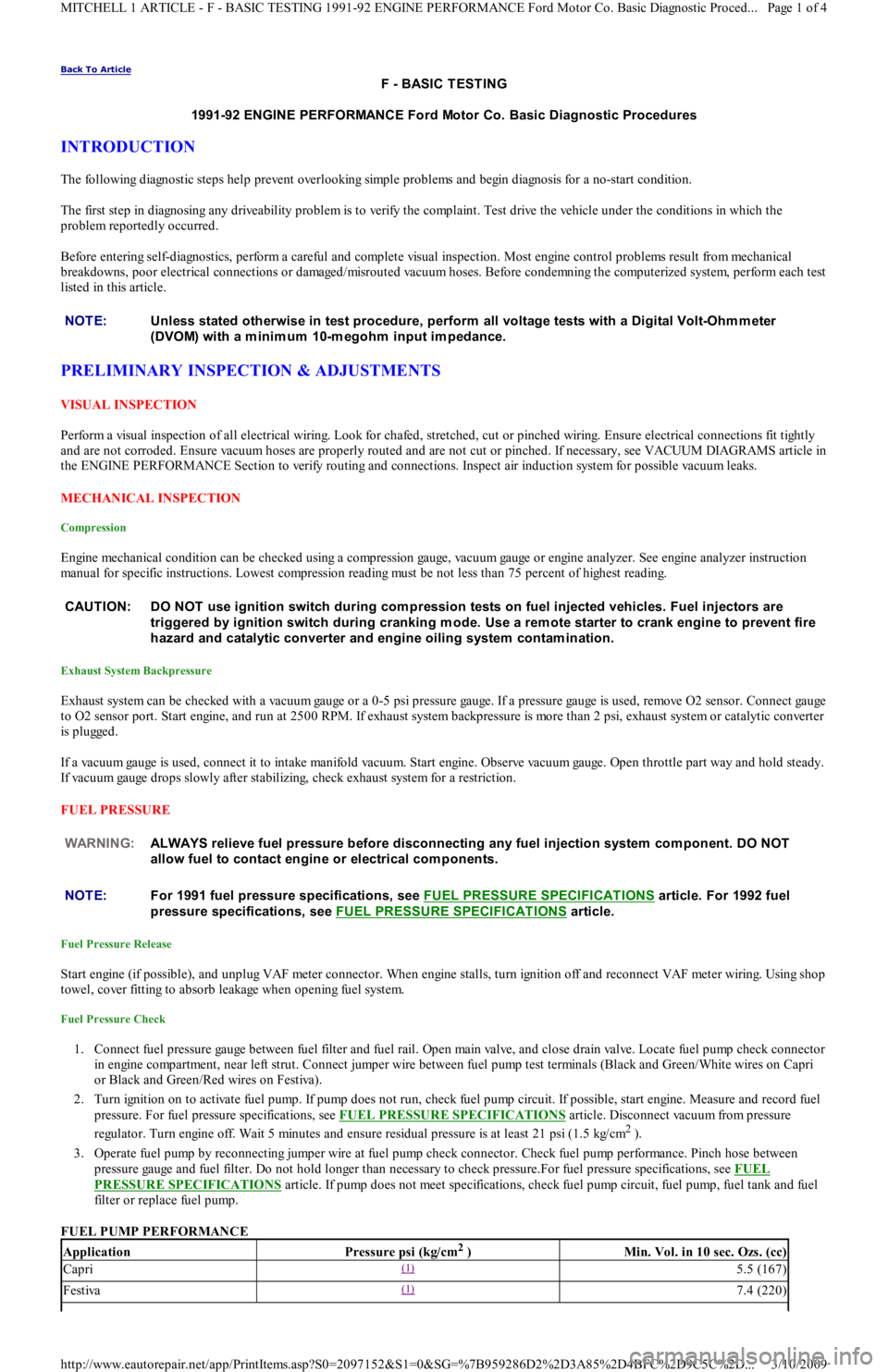

F - BASIC TESTING

1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Procedures

INTRODUCTION

The following diagnostic steps help prevent overlooking simple problems and begin diagnosis for a no-start condition.

The first step in diagnosing any driveability problem is to verify the complaint. Test drive the vehicle under the conditions in which the

problem reportedly occurred.

Before entering self-diagnostics, perform a careful and complete visual inspection. Most engine control problems result from mechanical

breakdowns, poor electrical connections or damaged/misrouted vacuum hoses. Before condemning the computerized system, perform each test

listed in this article.

PRELIMINARY INSPECTION & ADJUSTMENTS

VISUAL INSPECTION

Perform a visual inspection of all electrical wiring. Look for chafed, stretched, cut or pinched wiring. Ensure electrical connections fit tightly

and are not corroded. Ensure vacuum hoses are properly routed and are not cut or pinched. If necessary, see VACUUM DIAGRAMS article in

the ENGINE PERFORMANCE Section to verify routing and connections. Inspect air induction system for possible vacuum leaks.

MECHANICAL INSPECTION

Compression

Engine mechanical condition can be checked using a compression gauge, vacuum gauge or engine analyzer. See engine analyzer instruction

manual for specific instructions. Lowest compression reading must be not less than 75 percent of highest reading.

Exhaust System Backpressure

Exhaust system can be checked with a vacuum gauge or a 0-5 psi pressure gauge. If a pressure gauge is used, remove O2 sensor. Connect gauge

to O2 sensor port. Start engine, and run at 2500 RPM. If exhaust system backpressure is more than 2 psi, exhaust system or catalytic converter

is plugged.

If a vacuum gauge is used, connect it to intake manifold vacuum. Start engine. Observe vacuum gauge. Open throttle part way and hold steady.

If vacuum gauge drops slowly after stabilizing, check exhaust system for a restriction.

FUEL PRESSURE

Fuel Pressure Release

Start engine (if possible), and unplug VAF meter connector. When engine stalls, turn ignition off and reconnect VAF meter wiring. Usin g sh o p

towel, cover fitting to absorb leakage when opening fuel system.

Fuel Pressure Check

1. Connect fuel pressure gauge between fuel filter and fuel rail. Open main valve, and close drain valve. Locate fuel pump check connector

in engine compartment, near left strut. Connect jumper wire between fuel pump test terminals (Black and Green/White wires on Capri

or Black and Green/Red wires on Festiva).

2. Turn ignition on to activate fuel pump. If pump does not run, check fuel pump circuit. If possible, start engine. Measure and record fuel

pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS

article. Disconnect vacuum from pressure

regulator. Turn engine off. Wait 5 minutes and ensure residual pressure is at least 21 psi (1.5 kg/cm

2 ).

3. Operate fuel pump by reconnecting jumper wire at fuel pump check connector. Check fuel pump performance. Pinch hose between

pressure gauge and fuel filter. Do not hold longer than necessary to check pressure.For fuel pressure specifications, see FUEL

PRESSURE SPECIFICATIONS article. If pump does not meet specifications, check fuel pump circuit, fuel pump, fuel tank and fuel

filter or replace fuel pump.

FUEL PUMP PERFORMANCE NOTE:Unless stated otherwise in test procedure, perform all voltage tests with a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

CAUT ION: DO NOT use ignition switch during com pression tests on fuel injected vehicles. Fuel injectors are

triggered by ignition switch during cranking m ode. Use a rem ote starter to crank engine to prevent fire

hazard and catalytic converter and engine oiling system contam ination.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection system com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

NOTE:For 1991 fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article. For 1992 fuel

pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

ApplicationPressure psi (kg/cm2 )Min. Vol. in 10 sec. Ozs. (cc)

Capri(1) 5.5 (167)

Festiva(1) 7.4 (220)

Page 1 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 158 of 454

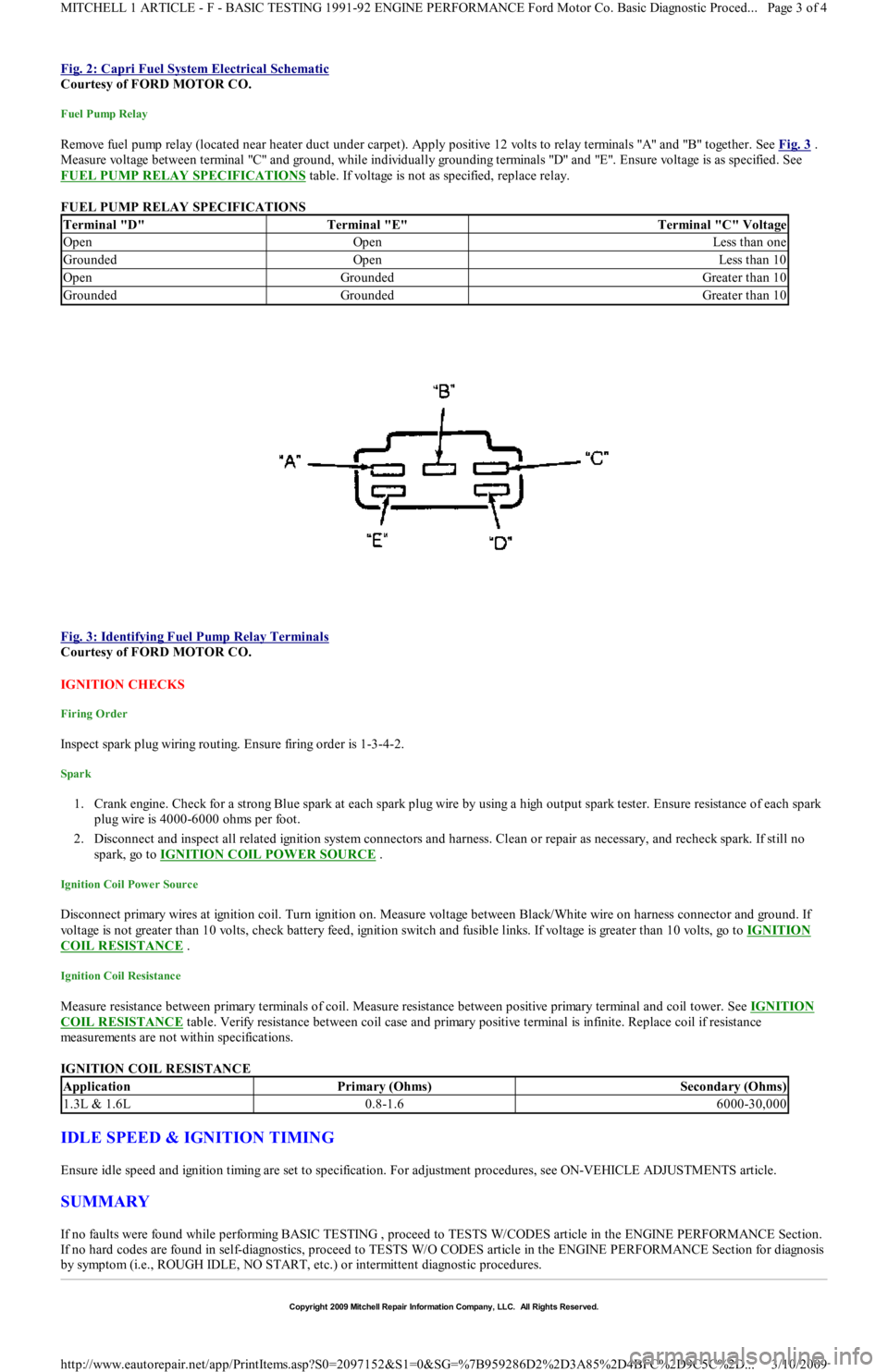

Fig. 2: Capri Fuel System Electrical Schematic

Courtesy of FORD MOTOR CO.

Fuel Pump Relay

Remove fuel pump relay (located near heater duct under carpet). Apply positive 12 volts to relay terminals "A" and "B" together. See Fig. 3 .

Measure voltage between terminal "C" and ground, while individually grounding terminals "D" and "E". Ensure voltage is as specified. See

FUEL PUMP RELAY SPECIFICATIONS

table. If voltage is not as specified, replace relay.

FUEL PUMP RELAY SPECIFICATIONS

Fig. 3: Identifying Fuel Pump Relay Terminals

Courtesy of FORD MOTOR CO.

IGNITION CHECKS

Firing Order

Inspect spark plug wiring routing. Ensure firing order is 1-3-4-2.

Spark

1. Crank engine. Check for a strong Blue spark at each spark plug wire by using a high output spark tester. Ensure resistance of each spark

plug wire is 4000-6000 ohms per foot.

2. Disconnect and inspect all related ignition system connectors and harness. Clean or repair as necessary, and recheck spark. If st il l n o

spark, go to IGNITION COIL POWER SOURCE

.

Ignition Coil Power Source

Disconnect primary wires at ignition coil. Turn ignition on. Measure voltage between Black/White wire on harness connector and ground. If

voltage is not greater than 10 volts, check battery feed, ignition switch and fusible links. If voltage is greater than 10 volts, go to IGNITION

COIL RESISTANCE .

Ignition Coil Resistance

Measure resistance between primary terminals of coil. Measure resistance between positive primary terminal and coil tower. See IGNITION

COIL RESISTANCE table. Verify resistance between coil case and primary positive terminal is infinite. Replace coil if resistance

measurements are not within specifications.

IGNITION COIL RESISTANCE

IDLE SPEED & IGNITION TIMING

Ensure idle speed and ignition timing are set to specification. For adjustment procedures, see ON-VEHICLE ADJUSTMENTS article.

SUMMARY

If no faults were found while performing BASIC TESTING , proceed to TESTS W/CODES article in the ENGINE PERFORMANCE Section.

If no hard codes are found in self-diagnostics, proceed to TESTS W/O CODES article in the ENGINE PERFORMANCE Section for diagnosis

by symptom (i.e., ROUGH IDLE, NO START, etc.) or intermittent diagnostic procedures.

Terminal "D"Terminal "E"Terminal "C" Voltage

OpenOpenLess than one

GroundedOpenLess than 10

OpenGroundedGreater than 10

GroundedGroundedGreater than 10

ApplicationPrimary (Ohms)Secondary (Ohms)

1.3L & 1.6L0.8-1.66000-30,000

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Page 3 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 166 of 454

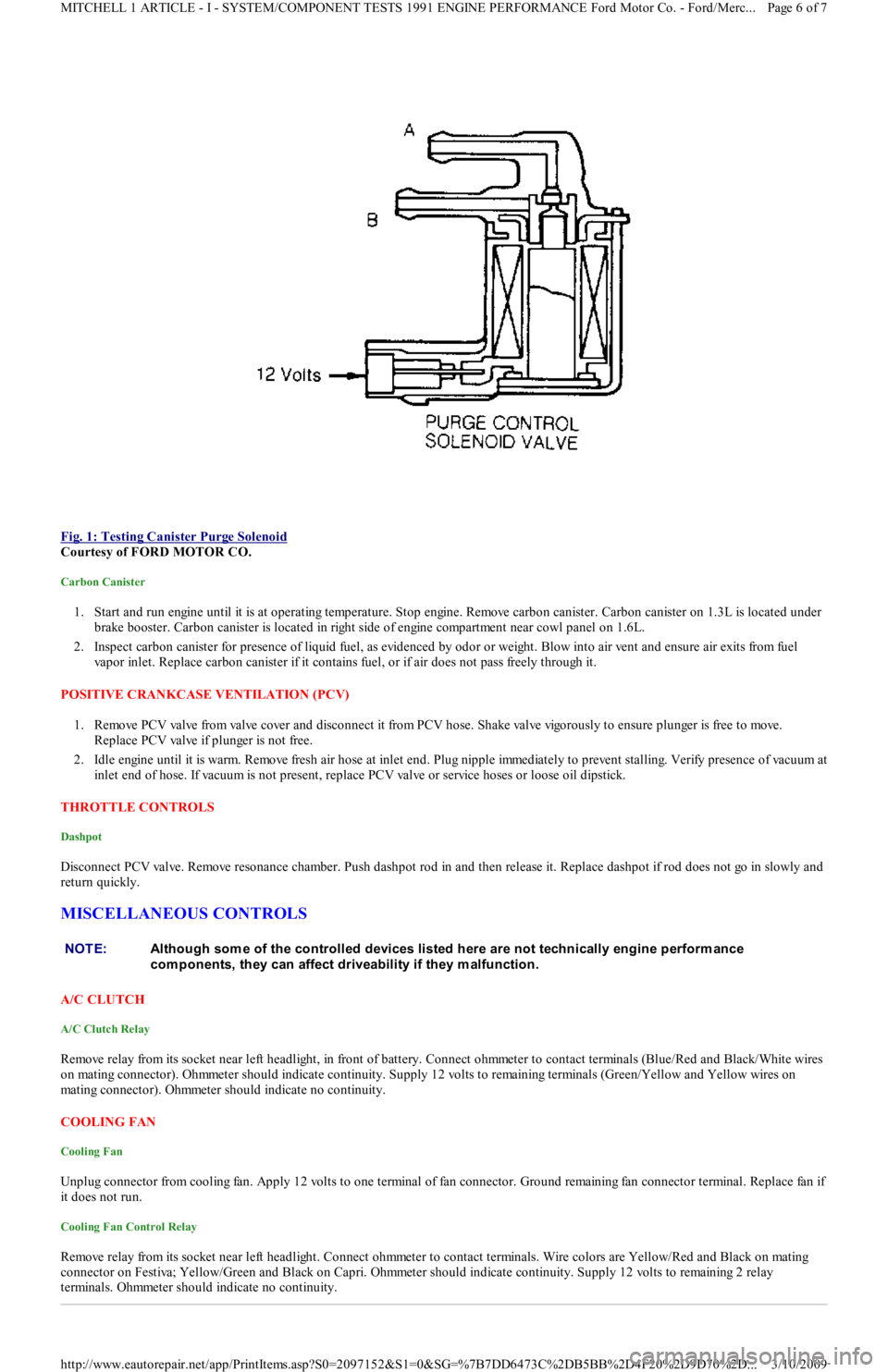

Fig. 1: Testing Canister Purge Solenoid

Courtesy of FORD MOTOR CO.

Carbon Canister

1. Start and run engine until it is at operating temperature. Stop engine. Remove carbon canister. Carbon canister on 1.3L is located under

brake booster. Carbon canister is located in right side of engine compartment near cowl panel on 1.6L.

2. Inspect carbon canister for presence of liquid fuel, as evidenced by odor or weight. Blow into air vent and ensure air exits fro m fu el

vapor inlet. Replace carbon canister if it contains fuel, or if air does not pass freely through it.

POSITIVE CRANKCASE VENTILATION (PCV)

1. Remove PCV valve from valve cover and disconnect it from PCV h o se . S h a ke va l ve vigo r o u sl y t o e n su r e p l u n ge r is fr e e t o mo ve .

Replace PCV valve if plunger is not free.

2. Idle engine until it is warm. Remove fresh air hose at inlet end. Plug nipple immediately to prevent stalling. Verify presence of vacuum at

inlet end of hose. If vacuum is not present, replace PCV valve or service hoses or loose oil dipstick.

THROTTLE CONTROLS

Dashpot

Disconnect PCV valve. Remove resonance chamber. Push dashpot rod in and then release it. Replace dashpot if rod does not go in slowly and

return quickly.

MISCELLANEOUS CONTROLS

A/C CLUTCH

A/C Clutch Relay

Remove relay from its socket near left headlight, in front of battery. Connect ohmmeter to contact terminals (Blue/Red and Black/White wires

on mating connector). Ohmmeter should indicate continuity. Supply 12 volts to remaining terminals (Green/Yellow and Yellow wires on

mating connector). Ohmmeter should indicate no continuity.

COOLING FAN

Cooling Fan

Unplug connector from cooling fan. Apply 12 volts to one terminal of fan connector. Ground remaining fan connector terminal. Replace fan if

it does not run.

Cooling Fan Control Relay

Remove relay from its socket near left headlight. Connect ohmmeter to contact terminals. Wire colors are Yellow/Red and Black on mating

connector on Festiva; Yellow/Green and Black on Capri. Ohmmeter should indicate continuity. Supply 12 volts to remaining 2 relay

terminals. Ohmmeter should indicate no continuity.

NOTE:Although som e of the controlled devices listed here are not technically engine perform ance

com ponents, they can affect driveability if they m alfunction.

Page 6 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 191 of 454

Back To Article

E - T HEORY/OPERAT ION

1991 ENGINE PERFORMANCE Ford/Mercury T heory & Operation

INTRODUCTION

This article covers basic description and operation of engine performance-related systems and components. Read this article before attempting

to diagnose systems with which you are not completely familiar.

COMPUTERIZED ENGINE CONTROLS

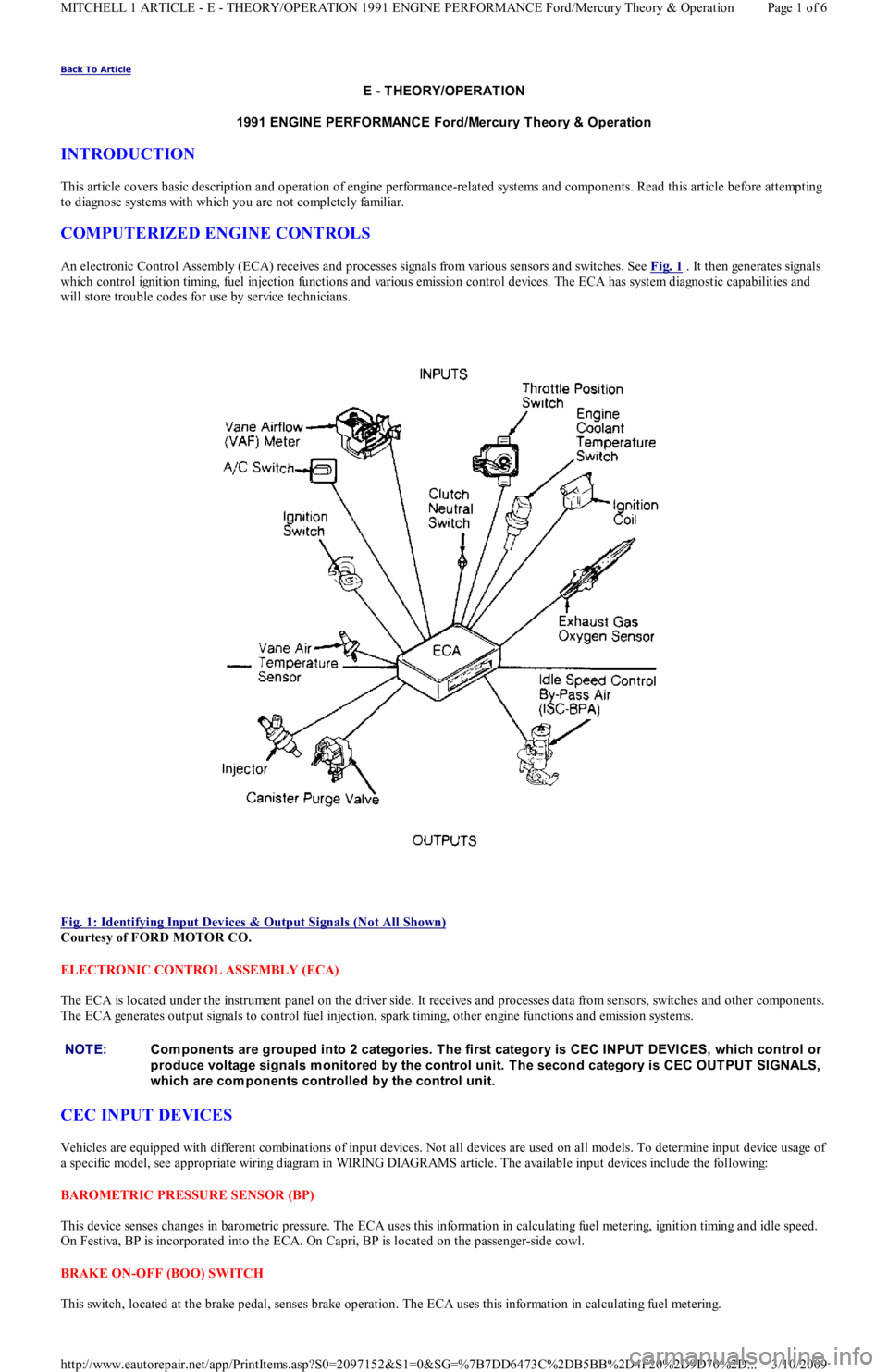

An electronic Control Assembly (ECA) receives and processes signals from various sensors and switches. See Fig. 1 . It then generates signals

which control ignition timing, fuel injection functions and various emission control devices. The ECA has system diagnostic capabilities and

will store trouble codes for use by service technicians.

Fig. 1: Identifying Input Devices & Output Signals (Not All Shown)

Courtesy of FORD MOTOR CO.

ELECTRONIC CONTROL ASSEMBLY (ECA)

The ECA is located under the instrument panel on the driver side. It receives and processes data from sensors, switches and other components.

The ECA generates output signals to control fuel injection, spark timing, other engine functions and emission systems.

CEC INPUT DEVICES

Vehicles are equipped with different combinations of input devices. Not all devices are used on all models. To determine input device usage of

a specific model, see appropriate wiring diagram in WIRING DIAGRAMS article. The available input devices include the following:

BAROMETRIC PRESSURE SENSOR (BP)

This device senses changes in barometric pressure. The ECA uses this information in calculating fuel metering, ignition timing and idle speed.

On Festiva, BP is incorporated into the ECA. On Capri, BP is located on the passenger-side cowl.

BRAKE ON-OFF (BOO) SWITCH

This switch, located at the brake pedal, senses brake operation. The ECA uses this information in calculating fuel metering.

NOTE:Com ponents are grouped into 2 categories. T he first category is CEC INPUT DEVICES, which control or

produce voltage signals m onitored by the control unit. T he second category is CEC OUT PUT SIGNALS,

which are com ponents controlled by the control unit.

Page 1 of 6 MITCHELL 1 ARTICLE - E - THEORY/OPERATION 1991 ENGINE PERFORMANCE Ford/Mercury Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...