suspension FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 247 of 454

SUSPENSION TROUBLE SHOOTING

BASIC SUSPENSION TROUBLE SHOOTING CHART

article

Shroud or housing looseTighten holding screws

Lock plate retaining ring not seatedSee STEERING COLUMN

article

Loose sight shieldTighten holding screws

High Steering Shaft Effort

Co l u mn assemb l y misal ign edSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Tight steering universal jointSee STEERING COLUMN

article

High Shift Effort

Column is out of alignmentSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Seals or bearings not lubricatedSee STEERING COLUMNS

article

Mounting bracket screws too longReplace with new shorter

screws

Burrs on shift tubeRemove burrs or replace tube

Lower bowl bearing assembled wrongSee STEERING COLUMN

article

Shift tube bent or brokenReplace as necessary

Improper adjustment of shift leversSee STEERING COLUMN

article

Improper Trans. Shifting

Sheared shift tube jointReplace as necessary

Sheared lower shaft leverReplace as necessary

Improper shift lever adjustmentSee STEERING COLUMN

article

Improper gate plate adjustmentSee STEERING COLUMN

article

Excess Play in Column

Instrument panel bracket bolts looseTighten bolts and check

bracket

Broken weld nut on jacketSee STEERING COLUMN

article

Instrument bracket capsule shearedSee STEERING COLUMN

article

Column bracket/jacket bolts looseTighten bolts and check

bracket

Steering Locks in Gear

Release lever mechanismSee STEERING COLUMN

article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Front End Noise

Loose or worn wheelSee Wheel Bearing

Adjustment in SUSPENSION

Worn shocks or shock mountingsReplace struts or strut

mo u n t in gs

Worn struts or strut mountingsReplace struts or strut

mo u n t in gs

Loose or worn lower control armSee SUSPENSION

Loose steering gear-to-frame boltsSee STEERING

Worn control arm bushingsSee SUSPENSION

Ball joints not lubricatedLubricate ball joints & see

Ball Joint Checking in

SUSPENSION

Front Wheel Shake, Shimmy, or Vibration

Tires or wheels out of balanceCheck tire balance

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Drive shaft unbalancedCheck drive shaft balance

Loose or worn wheel bearingsSee WHEEL ALIGNMENT

Loose or worn tie rod endsSee SUSPENSION

Page 34 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 248 of 454

WHEEL ALIGNMENT TROUBLE SHOOTING

BASIC WHEEL ALIGNMENT TROUBLE SHOOTING CHART

Worn upper ball jointsSee Ball Joint Checking in

SUSPENSION

Worn shock absorbersReplace shock absorbers

Worn strut bushingsReplace strut bushings

Car Pulls to One Side

Mismatched or uneven tiresCheck tire condition

Broken or sagging springsSee SUSPENSION

Loose or worn strut bushingsSee SUSPENSION

Improper wheel alignmentSee WHEEL ALIGNMENT

Improper rear axle alignmentCheck rear axle alignment

Power steering gear unbalancedSee STEERING

Front brakes draggingSee BRAKES

Abnormal Tire Wear

Unbalanced tiresCheck tire balance & rotation

Sagging or broken springsSee SUSPENSION

Incorrect front end alignmentSee WHEEL ALIGNMENT

Faulty shock absorbersReplace chock absorbers

Scuffed Tires

Toe-In incorrectSee WHEEL ALIGNMENT

Suspension arm bent or twistedSee appropriate

SUSPENSION article

Springs Bottom or Sag

Bent or broken springsSee SUSPENSION

Leaking or worn shock absorbersReplace shock absorbers

Frame misalignmentCheck frame for damage

Spring Noises

Lo o se "U" Bo l t sSee SUSPENSION

Loose or worn bushingsSee SUSPENSION

Worn or missing interlinersSee SUSPENSION

Shock Absorber Noise

Loose shock mountingsCheck & tighten mountings

Worn bushingsReplace bushings

Air in systemBleed air from system

Undercoating on shocksRemove undercoating

Car Leans or Sways on Corners

Loose stabilizer barSee SUSPENSION

Faulty shocks or mountingsReplace shocks or mountings

Broken or sagging springsSee SUSPENSION

Shock Absorbers Leaking

Worn seals or reservoir tube crimpedSee SUSPENSION

Broken Springs

Lo o se "U" b o l t sSee SUSPENSION

Inoperative shock absorbersReplace shock absorbers

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Premature Tire Wear

Improper tire inflationCheck tire pressure

Front alignment out of toleranceSee ALIGNMENT SPECS in

WHEEL ALIGNMENT

section

Suspension components wornSee SUSPENSION section

Steering system components wornSee STEERING section

Improper standing heightSee WHEEL ALIGNMENT

Uneven or sagging springsSee SUSPENSION section

Bent wheelSee WHEEL ALIGNMENT

Improper torsion bar adjustmentSee SUSPENSION section

Loose or worn wheel bearingsSee WHEEL BEARING ADJ.

in SUSPENSION section

Worn or defective shockReplace shock absorbers

Tires out of balanceCheck tire balance

Pulls to One Side

Improper tire inflationCheck tire pressure

Brake draggingSee BRAKE section

Page 35 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 249 of 454

Mismatched tiresSee WHEEL ALIGNMENT

Broken or sagging springSee SUSPENSION section

Broken torsion barSee SUSPENSION section

Power steering valve not centeredSee STEERING section

Front alignment out of toleranceSee WHEEL ALIGNMENT

section

Defective wheel bearingSee WHEEL BEARINGS in

SUSPENSION section

Uneven sway bar linksSee SUSPENSION section

Frame bentCheck for frame damage

Steering system bushing wornSee STEERING section

Hard Steering

Idler arm bushing too tightSee STEERING LINKAGE in

STEERING section

Ball joint tight or seizedSee SUSPENSION section

Steering linkage too tightSee STEERING LINKAGE in

STEERING section

Power steering fluid lowAdd proper amount of fluid

Power steering drive belt looseSee STEERING section

Power steering pump defectiveSee STEERING section

Steering gear out of adjustmentSee STEERING section

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Damaged steering gearSee STEERING section

Damaged suspensionSee SUSPENSION section

Bent steering knuckle or supportsSee SUSPENSION section

Vehicle "Wanders"

Strut rod or control arm bushing wornSee SUSPENSION section

Loose or worn wheel bearingsSee WHEEL BEARINGS in

SUSPENSION section

Improper tire inflationCheck tire pressure

Stabilizer bar missing or defectiveSee SUSPENSION section

Wheel alignment out of toleranceSee Adjustment in WHEEL

ALIGNMENT section

Broken springSee SUSPENSION section

Defective shock absorberReplace shock absorbers

Worn steering & suspension componentsSee SUSPENSION section

Front End Shimmy

Tire out of balance/roundCheck tire balance

Excessive wheel runoutSee WHEEL ALIGNMENT

Insufficient or improper casterSee WHEEL ALIGNMENT

section

Worn suspension or steering componentsSee SUSPENSION section

Defective shock absorbersReplace shock absorber

Wheel bearings worn or looseSee WHEEL BEARING ADJ.

in SUSPENSION section

Power steering reaction Bracket looseSee STEERING section

Steering gear box (rack) mounting looseSee STEERING section

Steering gear adjustment looseSee STEERING section

Worn spherical jointsSee SUSPENSION section

Toe-In Not Adjustable

Lower control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Camber Not Adjustable

Control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Hub & bearing not seated properlySee SUSPENSION section

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00027342

Page 36 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 301 of 454

Back To Article

GENERAL INFORMATION

Wheel Alignm ent T heory & Operation

* PLEASE READ THIS FIRST *

PRE-ALIGNMENT INSTRUCTIONS

GENERAL ALIGNMENT CHECKS

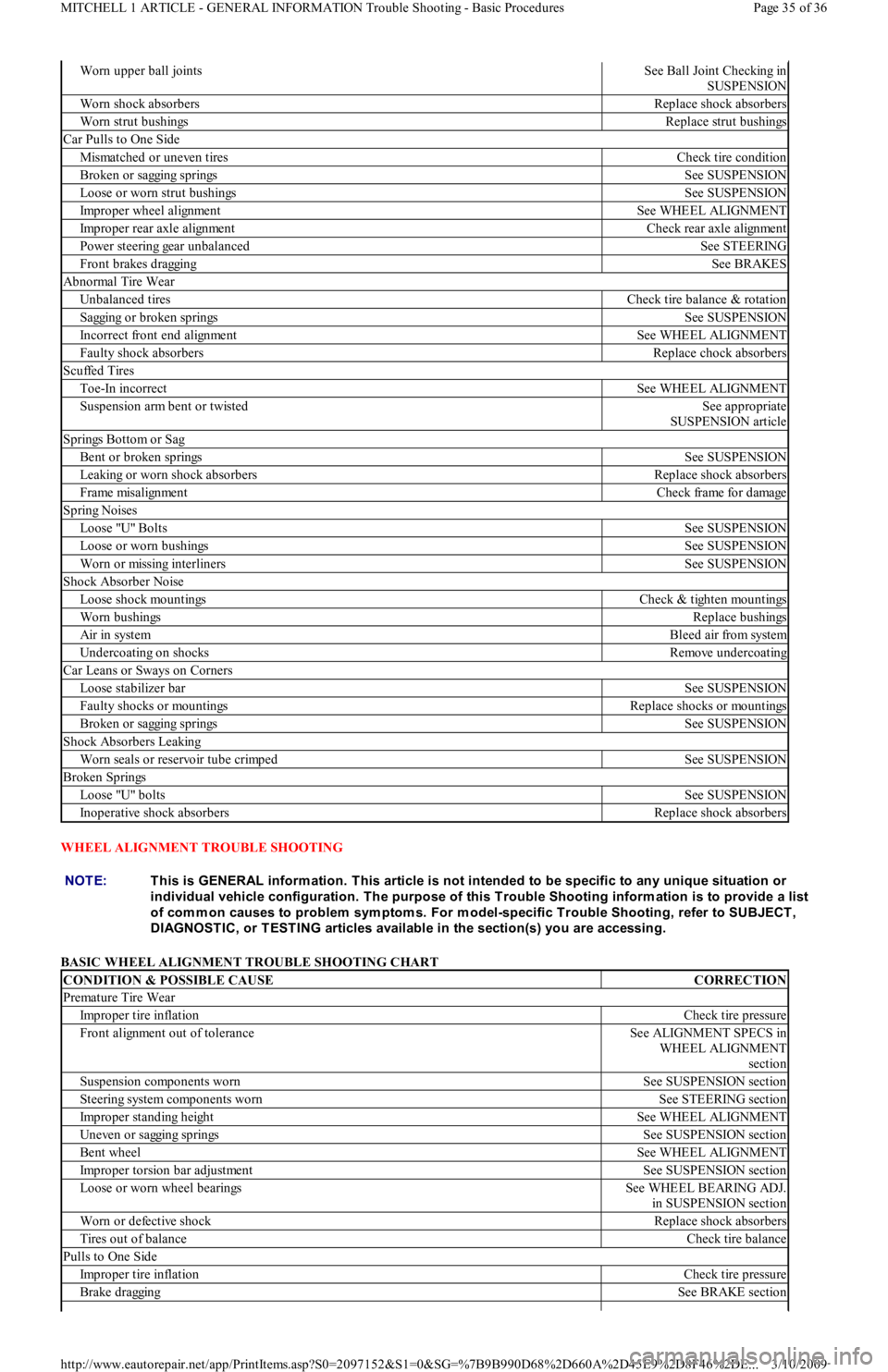

Before adjusting wheel alignment, check the following:

Each axle uses tires of same construction and tread style, equal in tread wear and overall diameter. Verify that radial and axial runout is

not excessive. Inflation should be at manufacturer's specifications.

Steering linkage and suspension must not have excessive play. Check for wear in tie rod ends and ball joints. Springs must not be

sagging. Control arm and strut rod bushings must not have excessive play. See Fig. 1

.

Fig. 1: Checking Steering Linkage

Vehicle must be on level floor with full fuel tank, no passenger load, spare tire in place and no load in trunk. Bounce front and rear end

of vehicle several times. Confirm vehicle is at normal riding height.

Steering wheel must be centered with wheels in straight ahead position. If required, shorten one tie rod adjusting sleeve and lengthen

opposite sleeve (equal amount of turns). See Fig. 2

.

Wheel bearings should have the correct preload and lug nuts must be tightened to manufacturer's specifications. Adjust camber, caster

and toe-in using this sequence. Follow instructions of the alignment equipment manufacturer. NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

CAUT ION: DO NOT attem pt to correct alignm ent by straightening parts. Dam aged parts MUST be replaced.

Page 1 of 4 MITCHELL 1 ARTICLE - GENERAL INFORMATION Wheel Alignment Theory & Operation

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 391 of 454

Back To Article

SUSPENSION - FRONT

1991-92 SUSPENSION Front

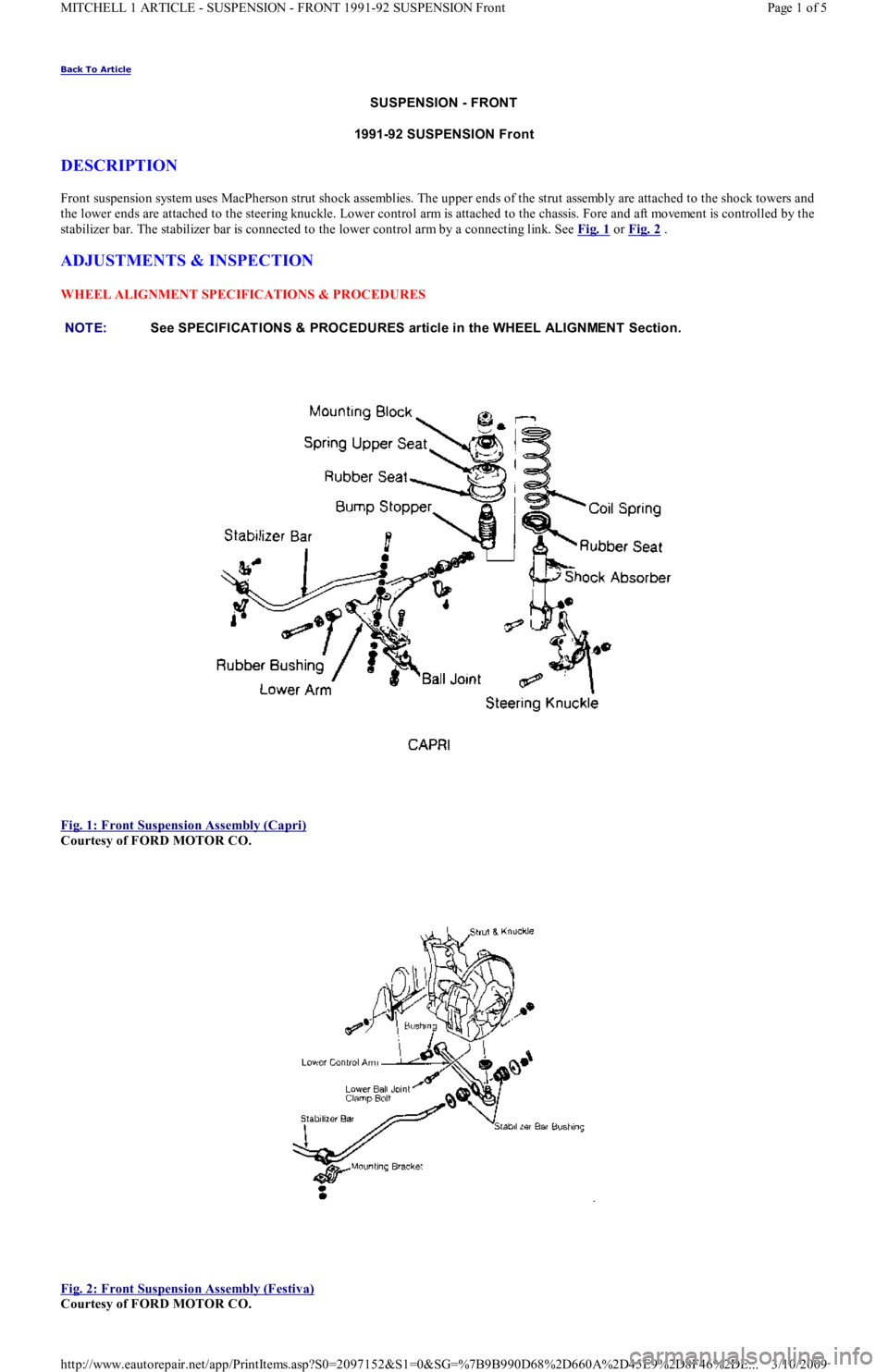

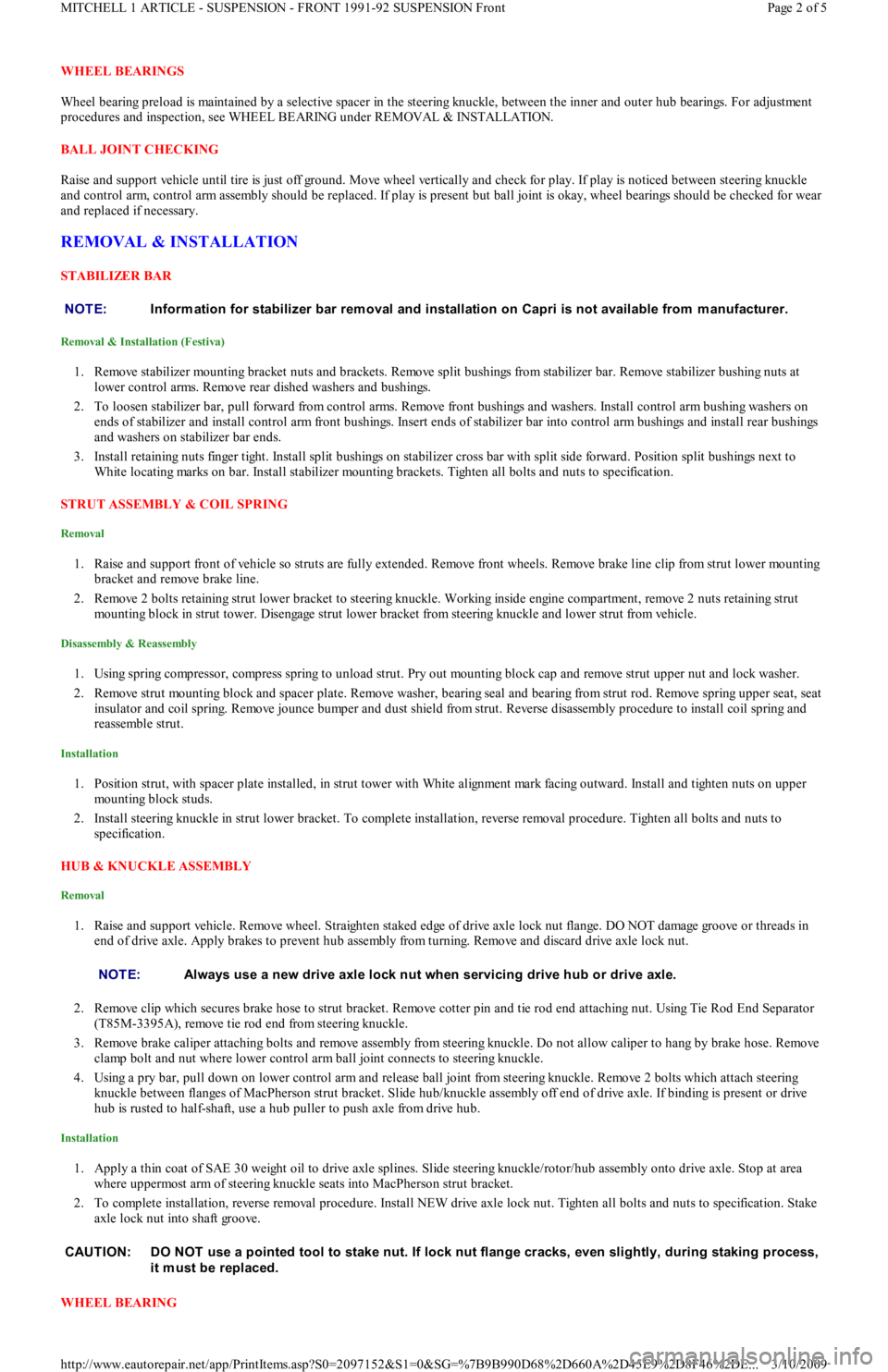

DESCRIPTION

Front suspension system uses MacPherson strut shock assemblies. The upper ends of the strut assembly are attached to the shock towers and

the lower ends are attached to the steering knuckle. Lower control arm is attached to the chassis. Fore and aft movement is controlled by the

stabilizer bar. The stabilizer bar is connected to the lower control arm by a connecting link. See Fig. 1

or Fig. 2 .

ADJUSTMENTS & INSPECTION

WHEEL ALIGNMENT SPECIFICATIONS & PROCEDURES

Fig. 1: Front Suspension Assembly (Capri)

Courtesy of FORD MOTOR CO.

Fig. 2: Front Suspension Assembly (Festiva)

Courtesy of FORD MOTOR CO. NOTE:See SPECIFICAT IONS & PROCEDURES article in the WHEEL ALIGNMENT Section.

Page 1 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 392 of 454

WHEEL BEARINGS

Wheel bearing preload is maintained by a selective spacer in the steering knuckle, between the inner and outer hub bearings. For adjustment

procedures and inspection, see WHEEL BEARING under REMOVAL & INSTALLATION.

BALL JOINT CHECKING

Raise and support vehicle until tire is just off ground. Move wheel vertically and check for play. If play is noticed between steering knuckle

and control arm, control arm assembly should be replaced. If play is present but ball joint is okay, wheel bearings should be checked for wear

and replaced if necessary.

REMOVAL & INSTALLATION

STABILIZER BAR

Removal & Installation (Festiva)

1. Remove stabilizer mounting bracket nuts and brackets. Remove split bushings from stabilizer bar. Remove stabilizer bushing nuts at

lower control arms. Remove rear dished washers and bushings.

2. To loosen stabilizer bar, pull forward from control arms. Remove front bushings and washers. Install control arm bushing washers on

ends of stabilizer and install control arm front bushings. Insert ends of stabilizer bar into control arm bushings and install rear bushings

and washers on stabilizer bar ends.

3. Install retaining nuts finger tight. Install split bushings on stabilizer cross bar with split side forward. Position split bushings next to

White locating marks on bar. Install stabilizer mounting brackets. Tighten all bolts and nuts to specification.

STRUT ASSEMBLY & COIL SPRING

Removal

1. Raise and support front of vehicle so struts are fully extended. Remove front wheels. Remove brake line clip from strut lower mounting

bracket and remove brake line.

2. Remove 2 bolts retaining strut lower bracket to steering knuckle. Working inside engine compartment, remove 2 nuts retaining strut

mounting block in strut tower. Disengage strut lower bracket from steering knuckle and lower strut from vehicle.

Disassembly & Reassembly

1. Using spring compressor, compress spring to unload strut. Pry out mounting block cap and remove strut upper nut and lock washer.

2. Remove strut mounting block and spacer plate. Remove washer, bearing seal and bearing from strut rod. Remove spring upper seat, seat

insulator and coil spring. Remove jounce bumper and dust shield from strut. Reverse disassembly procedure to install coil spring a n d

reassemble strut.

Installation

1. Position strut, with spacer plate installed, in strut tower with White alignment mark facing outward. Install and tighten nuts on upper

mounting block studs.

2. Install steering knuckle in strut lower bracket. To complete installation, reverse removal procedure. Tighten all bolts and nuts to

specification.

HUB & KNUCKLE ASSEMBLY

Removal

1. Raise and support vehicle. Remove wheel. Straighten staked edge of drive axle lock nut flange. DO NOT damage groove or threads in

end of drive axle. Apply brakes to prevent hub assembly from turning. Remove and discard drive axle lock nut.

2. Remove clip which secures brake hose to strut bracket. Remove cotter pin and tie rod end attaching nut. Using Tie Rod End Separator

(T85M-3395A), remove tie rod end from steering knuckle.

3. Remove brake caliper attaching bolts and remove assembly from steering knuckle. Do not allow caliper to hang by brake hose. Remove

clamp bolt and nut where lower control arm ball joint connects to steering knuckle.

4. Using a pry bar, pull down on lower control arm and release ball joint from steering knuckle. Remove 2 bolts which attach steering

knuckle between flanges of MacPherson strut bracket. Slide hub/knuckle assembly off end of drive axle. If binding is present or drive

hub is rusted to half-shaft, use a hub puller to push axle from drive hub.

Installation

1. Apply a thin coat of SAE 30 weight oil to drive axle splines. Slide steering knuckle/rotor/hub assembly onto drive axle. Stop at area

where uppermost arm of steering knuckle seats into MacPherson strut bracket.

2. To complete installation, reverse removal procedure. Install NEW drive axle lock nut. Tighten all bolts and nuts to specification. Stake

axle lock nut into shaft groove.

WHEEL BEARING NOTE:Inform ation for stabilizer bar rem oval and installation on Capri is not available from m anufacturer.

NOTE:Always use a new drive axle lock nut when servicing drive hub or drive axle.

CAUT ION: DO NOT use a pointed tool to stake nut. If lock nut flange cracks, even slightly, during staking process,

it m ust be replaced.

Page 2 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 393 of 454

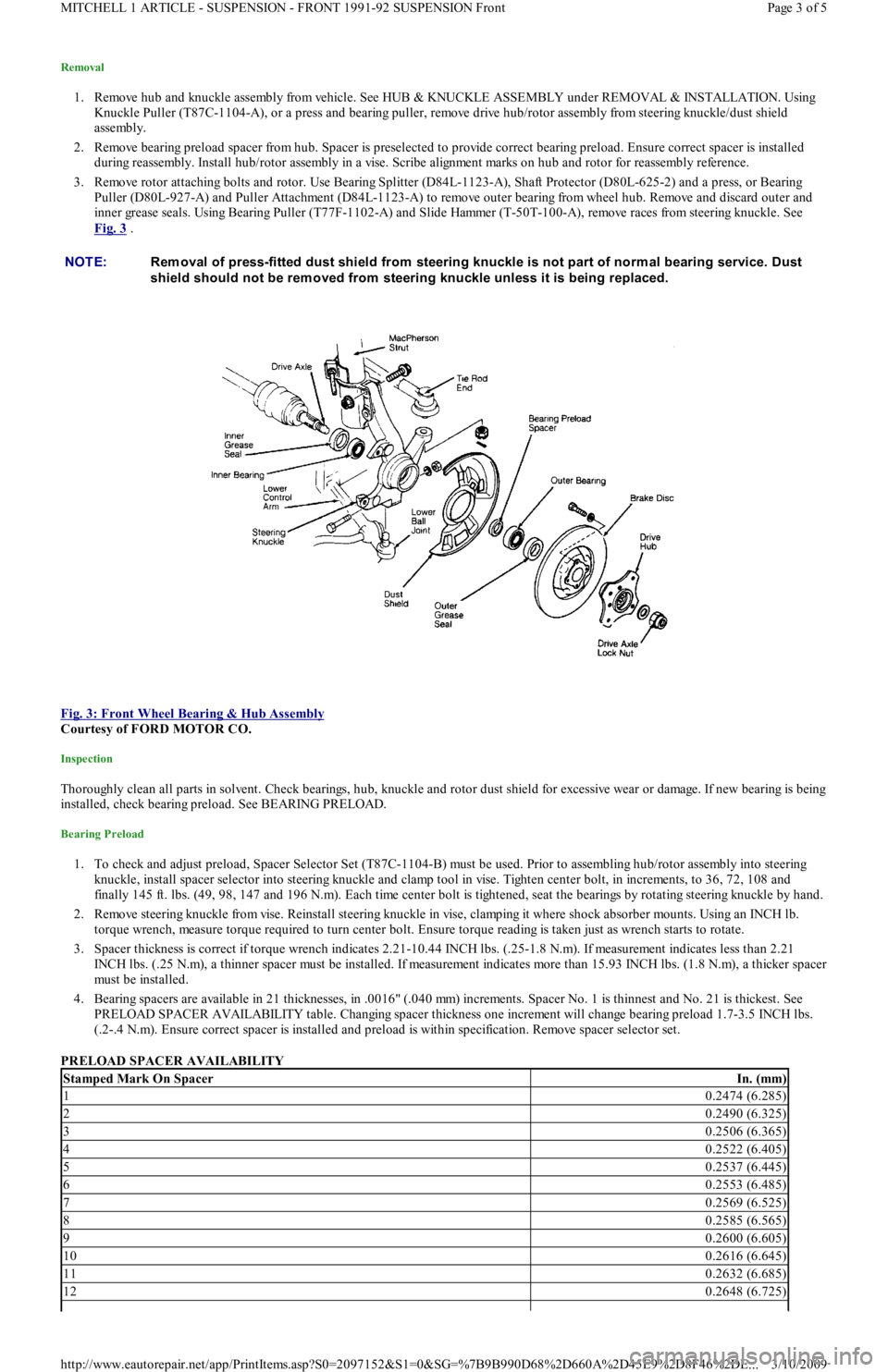

Removal

1. Remove hub and knuckle assembly from vehicle. See HUB & KNUCKLE ASSEMBLY under REMOVAL & INSTALLATION. Using

Knuckle Puller (T87C-1104-A), or a press and bearing puller, remove drive hub/rotor assembly from steering knuckle/dust shield

assembly.

2. Remove bearing preload spacer from hub. Spacer is preselected to provide correct bearing preload. Ensure correct spacer is installed

during reassembly. Install hub/rotor assembly in a vise. Scribe alignment marks on hub and rotor for reassembly reference.

3. Remove rotor attaching bolts and rotor. Use Bearing Splitter (D84L-1123-A), Shaft Protector (D80L-625-2) and a press, or Bearing

Puller (D80L-927-A) and Puller Attachment (D84L-1123-A) to remove outer bearing from wheel hub. Remove and discard outer and

inner grease seals. Using Bearing Puller (T77F-1102-A) and Slide Hammer (T-50T-100-A), remove races from steering knuckle. See

Fig. 3

.

Fig. 3: Front Wheel Bearing & Hub Assembly

Courtesy of FORD MOTOR CO.

Inspection

Thoroughly clean all parts in solvent. Check bearings, hub, knuckle and rotor dust shield for excessive wear or damage. If new bearing is being

installed, check bearing preload. See BEARING PRELOAD.

Bearing Preload

1. To check and adjust preload, Spacer Selector Set (T87C-1104-B) must be used. Prior to assembling hub/rotor assembly into steering

knuckle, install spacer selector into steering knuckle and clamp tool in vise. Tighten center bolt, in increments, to 36, 72, 108 and

finally 145 ft. lbs. (49, 98, 147 and 196 N.m). Each time center bolt is tightened, seat the bearings by rotating steering knuckle by hand.

2. Remove steering knuckle from vise. Reinstall steering knuckle in vise, clamping it where shock absorber mounts. Using an INCH lb.

torque wrench, measure torque required to turn center bolt. Ensure torque reading is taken just as wrench starts to rotate.

3. Spacer thickness is correct if torque wrench indicates 2.21-10.44 INCH lbs. (.25-1.8 N.m). If measurement indicates less than 2.21

INCH lbs. (.25 N.m), a thinner spacer must be installed. If measurement indicates more than 15.93 INCH lbs. (1.8 N.m), a thicker spacer

must be installed.

4. Bearing spacers are available in 21 thicknesses, in .0016" (.040 mm) increments. Spacer No. 1 is thinnest and No. 21 is thickest. See

PRELOAD SPACER AVAILABILITY table. Changing spacer thickness one increment will change bearing preload 1.7-3.5 INCH lbs.

(.2-.4 N.m). Ensure correct spacer is installed and preload is within specification. Remove spacer selector set.

PRELOAD SPACER AVAILABILITY NOTE:Rem oval of press-fitted dust shield from steering knuckle is not part of norm al bearing service. Dust

shield should not be rem oved from steering knuckle unless it is being replaced.

Stamped Mark On SpacerIn. (mm)

10.2474 (6.285)

20.2490 (6.325)

30.2506 (6.365)

40.2522 (6.405)

50.2537 (6.445)

60.2553 (6.485)

70.2569 (6.525)

80.2585 (6.565)

90.2600 (6.605)

100.2616 (6.645)

110.2632 (6.685)

120.2648 (6.725)

Page 3 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 394 of 454

Installation

1. Using Bearing Cup Replacer (D79P-1202-A) and Universal Driver Handle (T80T-4000-W), install bearing races in steering knuckle.

Lubricate bearing races and bearing. Install inner bearing into steering knuckle. Lubricate seal lips and install inner bearing seal into

knuckle. Install original bearing preload spacer in steering knuckle (or spacer selected during bearing preload check). Position outer

bearing in knuckle. Install outer seal. Install hub onto rotor, using reference marks made during removal. Install rotor to hub attaching

bolts.

2. Using a press and adapter from Spacer Selector Set (T87C-1104-B), install knuckle assembly onto hub. To complete installation,

reverse removal procedure.

LOWER CONTROL ARM & BALL JOINT (FESTIVA)

Removal

Remove lower control arm pivot bolt at frame bracket. Remove ball joint clamp bolt and nut from steering knuckle assembly. Remove

stabilizer bushing retaining nut from rear of control arm. Remove rear bushing washer and bushing. Lower the control arm and pry ball joint

stud out of steering knuckle. Disconnect control arm from stabilizer end and remove.

Inspection

Check control arm and bushings for excessive wear or damage. Ensure ball joint stud moves freely but is not loose. Use Ball Joint Rotating

Adapter (T87C-5493-C) to check ball joint rotating torque. Rotating torque should be 16-27 INCH lbs. (1.8-3.1 N.m).

Installation

1. Install front bushing washer with dished side forward. Position bushing stabilizer end and engage control arm with stabilizer. Raise

control arm inner end into pivot bracket on frame. Install pivot bolt to hold it in position.

2. Engage control arm ball joint stud with clamp bore in steering knuckle. Install clamp bolt and nut. Install stabilizer rear bushing and

washer with dished side forward on stabilizer end. Tighten all bolts and nuts to specification.

LOWER CONTROL ARM (CAPRI)

Removal & Installation

Raise and support vehicle. Remove wheel and disconnect stabilizer bar from control arm, if equipped. Remove ball joint clamp bolt. Remove

control arm front mount bolt. Remove control arm rear bracket and mount bolts. Remove control arm. To install, reverse removal procedure.

BALL JOINT (CAPRI)

Removal & Installation

1. Raise and support vehicle. Remove wheel. Remove ball joint clamp bolt from steering knuckle. Use small pry bar to pull down on lower

control arm to separate it from steering knuckle. Remove 2 ball joint retaining bolts and pry ball joint off control arm. To install, reverse

removal procedure.

LOWER CONTROL ARM BUSHING

Removal & Installation (Capri)

1. Remove control arm from vehicle. See LOWER CONTROL ARM. Use Bushing Receiver Cup (T87C-5493-B1), Bushing Driver (T87C-

5493-B2) and vise to remove control arm bushing.

2. To install, press bushing into control arm using same tools used for removal. Refit control arm to chassis.

Removal & Installation (Festiva)

1. Remove control arm from vehicle. See LOWER CONTROL ARM & BALL JOINT. Use Bushing Receiver Cup (T88C-5493-E), Bushing

Pilot (T81P-5493-B2) and "C" Clamp Assembly (T74P-3044-A1) to remove control arm bushing.

2. To install, press bushing into control arm using same tools used for removal. Refit control arm to chassis.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

130.2663 (6.765)

140.2679 (6.805)

150.2695 (6.845)

160.2711 (6.885)

170.2726 (6.925)

180.2742 (6.965)

190.2758 (7.005)

200.2774 (7.045)

210.2789 (7.085)

NOTE:Insert bushing quickly and sm oothly. Bushing should only be distorted for a short tim e.

ApplicationFt. Lbs. (N.m)

Capri

Ball Joint Pinch Bolt32-40 (43-54)

Brake Rotor-To-Hub33-40 (44-54)

Page 4 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 395 of 454

Caliper Attaching Bolts29-36 (39-49)

Control Arm Bolt-To-Ball Joint69-86 (93-117)

Control Arm Bracket Bolt44-54 (59-74)

Control Arm Front Bolt69-86 (93-117)

Control Arm Rear Bolt55-69 (75-93)

Drive Axle Nut116-174 (157-236)

Shock Absorber Bolt-To-Knuckle69-72 (93-97)

Stabilizer Bracket Nuts40-50 (54-68)

Steering Knuckle-To-Strut69-86 (93-117)

Steering Knuckle-To-Tie Rod22-33 (29-44)

Strut Assembly-To-Strut Tower17-22 (23-29)

Strut Rod Nut22-27 (29-36)

Wheel Lug Nut65-88 (90-120)

Festiva

Ball Joint Pinch Bolt32-40 (43-54)

Brake Rotor-To-Hub33-40 (44-54)

Caliper Attaching Bolts29-36 (39-49)

Control Arm Bushing Nuts47-57 (64-77)

Control Arm Pivot Bolt32-40 (43-54)

Stabilizer Bar Nuts-To-Control Arm47-57 (64-77)

Stabilizer Mounting Bracket Nuts40-50 (54-68)

Steering Knuckle-To-Strut69-86 (93-117)

Steering Knuckle-To-Tie Rod22-33 (29-44)

Strut Assembly-To-Strut Tower22-27 (29-36)

Wheel Lug Nut65-88 (90-120)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00121554

Page 5 of 5 MITCHELL 1 ARTICLE - SUSPENSION - FRONT 1991-92 SUSPENSION Front

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 396 of 454

Back To Article

SUSPENSION - REAR

1991-92 SUSPENSION Rear

DESCRIPTION

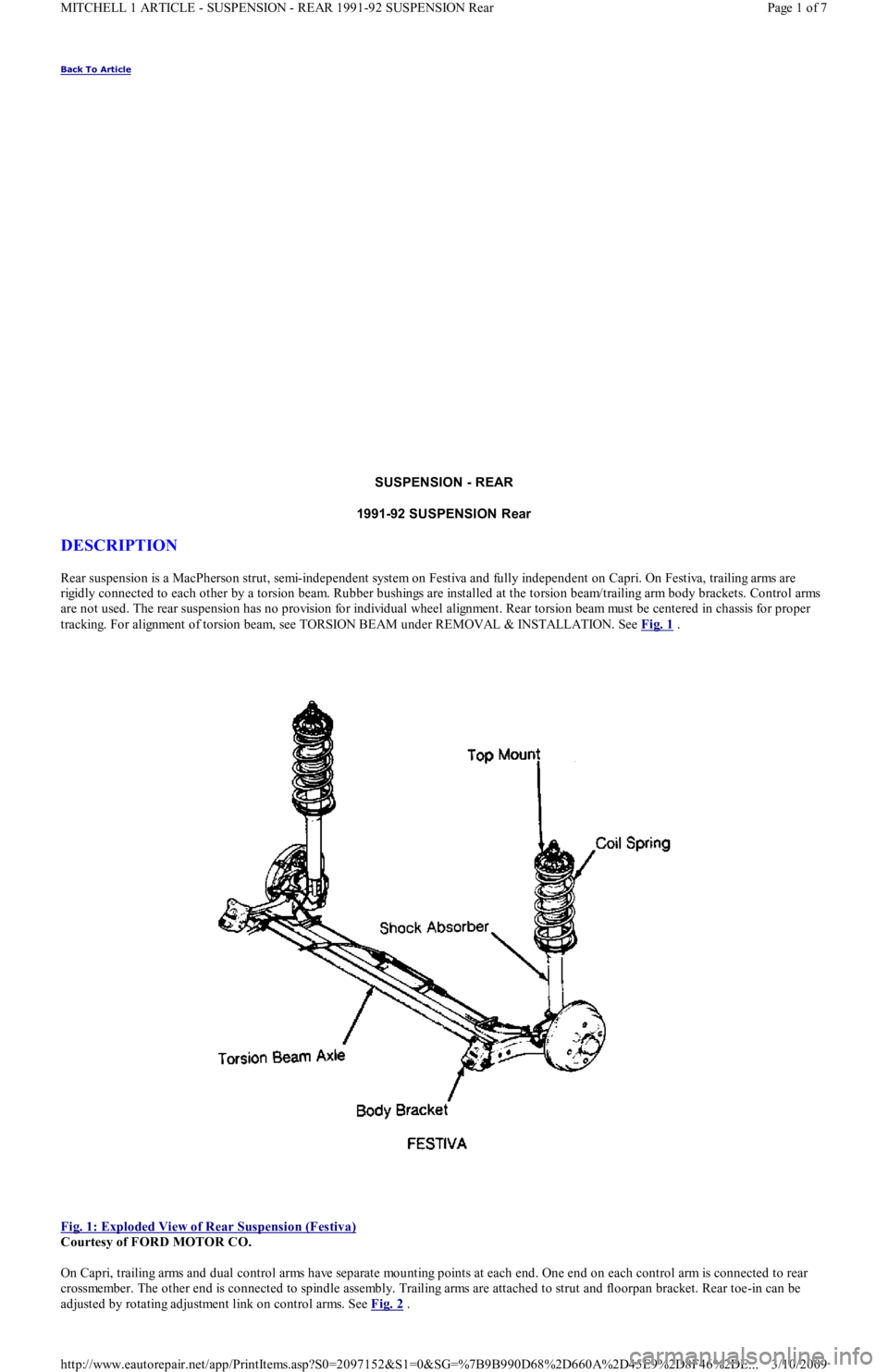

Rear suspension is a MacPherson strut, semi-independent system on Festiva and fully independent on Capri. On Festiva, trailing arms are

rigidly connected to each other by a torsion beam. Rubber bushings are installed at the torsion beam/trailing arm body brackets. Control arms

are not used. The rear suspension has no provision for individual wheel alignment. Rear torsion beam must be centered in chassis for proper

tracking. For alignment of torsion beam, see TORSION BEAM under REMOVAL & INSTALLATION. See Fig. 1

.

Fig. 1: Exploded View of Rear Suspension (Festiva)

Courtesy of FORD MOTOR CO.

On Capri, trailing arms and dual control arms have separate mounting points at each end. One end on each control arm is connected to rear

crossmember. The other end is connected to spindle assembly. Trailing arms are attached to strut and floorpan bracket. Rear toe-in can be

adjusted by rotating adjustment link on control arms. See Fig. 2

.

Page 1 of 7 MITCHELL 1 ARTICLE - SUSPENSION - REAR 1991-92 SUSPENSION Rear

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...