wiper fluid FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 23 of 454

Back To Article

WIPER/WASHER SYST EM

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Wiper/Washer System s

DESCRIPTION & OPERATION

Capri and Festiva vehicles are equipped with a 2-speed wiper motor with an optional intermittent system. The Festiva rear wiper uses a single

speed wiper motor. Washer systems for both front and rear washers use pumps mounted near fluid reservoirs.

ADJUSTMENTS

W IPER ARM ADJUSTMENT

Remove wiper arm and blade assemblies from pivot shafts. Turn wiper switch on and allow wiper motor to cycle 2 to 3 times. Turn wiper

switch off to place pivot shafts in park position. Reinstall wiper arm and blade assemblies with tips of wiper blades at specified distance from

lower edge of windshield. See WIPER BLADE ADJUSTMENT SPECIFICATIONS

table. Tighten wiper arm retaining nut to 89-124

INCH Lbs. (10-14 N.m).

WIPER BLADE ADJUSTMENT SPECIFICATIONS

TESTING

FRONT WIPER MOTOR TEST

Capri

1. Check WIPER fuse in interior fuse block and replace if necessary. Perform FRONT INTERVAL WIPE MODULE TEST . If

wiper/washer switch and interval module are operating properly, disconnect wiper motor connector. Turn ignition on and place

wiper/washer switch in HIGH position. Measure voltage at Blue/Red and Blue wires at wiper motor vehicle harness connector.

2. If battery voltage is not present, check Blue/Red or Blue wire for open circuit. If battery voltage is present at Blue/Red and Blue wires,

check Black ground wire at wiper motor vehicle harness connector for an open circuit and repair as necessary. If Black ground wire is

okay, replace wiper motor.

Festiva

1. Place wiper in any position other than park. Remove WIPER fuse. Disconnect wiper motor electrical connector. Using an ohmmeter,

check for continuity to ground at motor case. Continuity should exist. If continuity does not exist, replace or repair wiper motor ground

strap or wire.

2. Check for continuity to ground at Blue/Black terminal of wiper motor. Continuity should exist. If continuity does not exist, replace

wiper motor.

FRONT INTERVAL WIPE MODULE TEST

Capri

1. Check WIPER fuse in interior fuse block and replace if necessary. Perform FRONT WIPER/WASHER SWITCH TEST . Access

interval wipe module connector. Interval wipe module is located below instrument panel near console. Ensure wiper switch is in OFF

position. Turn ignition on and measure voltage at Blue/White and Blue/Black wires of module connector. Battery voltage should not be

present. Turn wiper switch to LOW position. Measure voltage at Blue/White and Blue/Black wires of module connector. Battery voltage

should be present.

2. Turn wiper switch to HIGH position. Measure voltage at Blue/White, Blue/Black and Blue/Red wires of module connector. Battery

voltage should be present. Turn wiper switch to INT position. Measure voltage at Blue/White and Blue/Black wires of module

connector. Battery voltage should be present during each cycle. If module does not perform as specified, replace module.

Festiva

Information is not available from manufacturer.

FRONT WIPER/WASHER SWITCH TEST

Capri

Remove lower steering column cover to gain access to wiper switch electrical connector. Using an ohmmeter, ensure continuity exists between

terminals listed in table at specified switch positions. If switch does not test as specified, replace wiper/washer switch. See FRONT

WIPER/WASHER SWITCH CONTINUITY (CAPRI) table. See Fig. 1 .

FRONT WIPER/WASHER SWITCH CONTINUITY (CAPRI)

ApplicationIn. (mm)

Capri

Driver Side1.0 (25)

Passenger Side1.26 (32)

Festiva

Both Sides1.0 (25)

Rear(1) 3.15 (80)

(1)From left edge of liftgate window.

TerminalPositionContinuity

Page 1 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 25 of 454

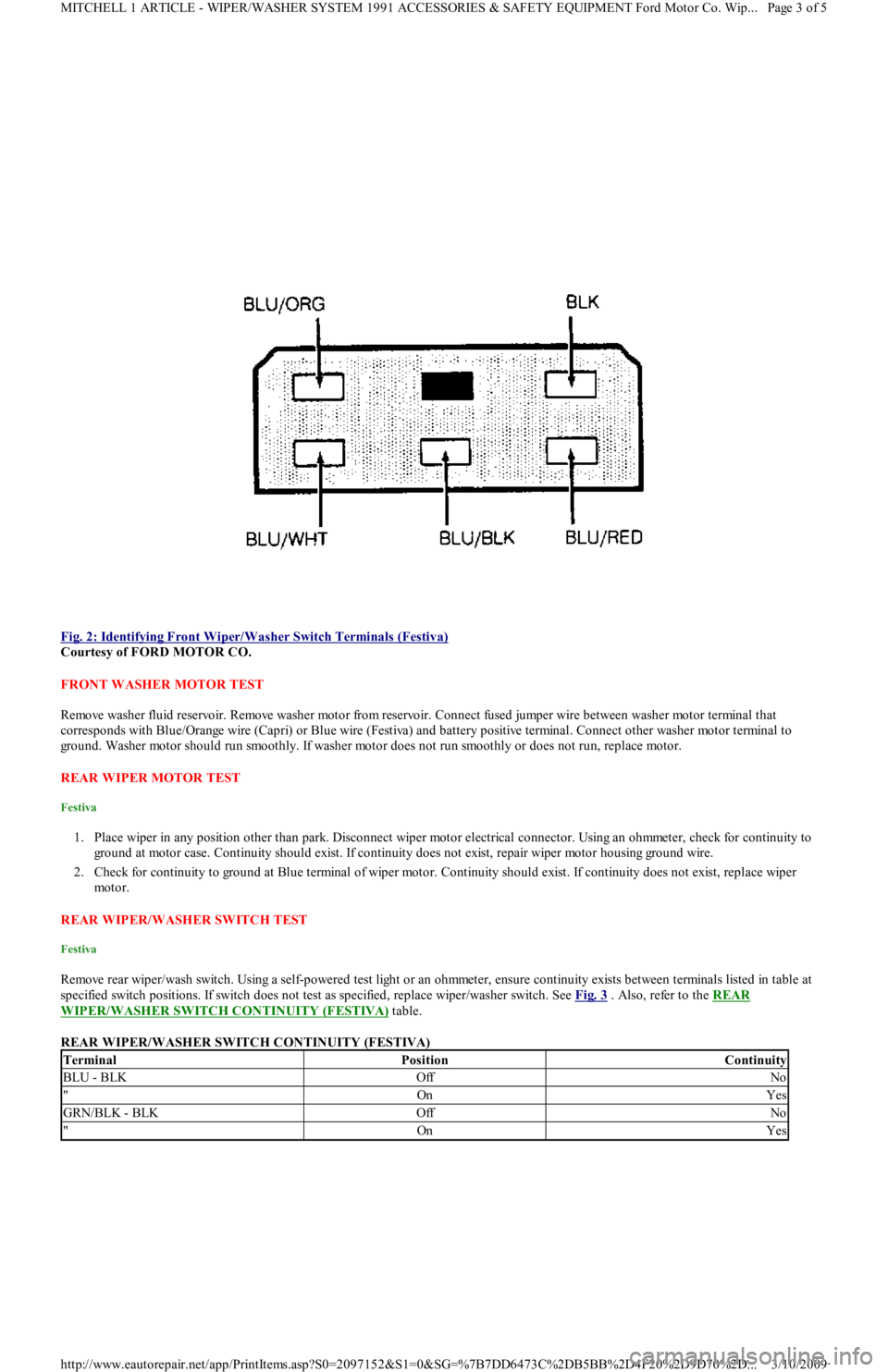

Fig. 2: Identifying Front Wiper/Washer Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

FRONT WASHER MOTOR TEST

Remove washer fluid reservoir. Remove washer motor from reservoir. Connect fused jumper wire between washer motor terminal that

corresponds with Blue/Orange wire (Capri) or Blue wire (Festiva) and battery positive terminal. Connect other washer motor terminal to

ground. Washer motor should run smoothly. If washer motor does not run smoothly or does not run, replace motor.

REAR WIPER MOTOR TEST

Festiva

1. Place wiper in any position other than park. Disconnect wiper motor electrical connector. Using an ohmmeter, check for continuity to

ground at motor case. Continuity should exist. If continuity does not exist, repair wiper motor housing ground wire.

2. Check for continuity to ground at Blue terminal of wiper motor. Continuity should exist. If continuity does not exist, replace wiper

mo t o r.

REAR WIPER/WASHER SWITCH TEST

Festiva

Remove rear wiper/wash switch. Using a self-powered test light or an ohmmeter, ensure continuity exists between terminals listed in table at

specified switch positions. If switch does not test as specified, replace wiper/washer switch. See Fig. 3

. Also, refer to the REAR

WIPER/WASHER SWITCH CONTINUITY (FESTIVA) table.

REAR WIPER/WASHER SWITCH CONTINUITY (FESTIVA)

TerminalPositionContinuity

BLU - BLKOffNo

"OnYes

GRN/BLK - BLKOffNo

"OnYes

Page 3 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 27 of 454

Disconnect fluid lines and remove reservoir. To install, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove washer reservoir filler neck attaching bolt. Remove coolant expansion reservoir. Disconnect

washer pump electrical connector. Remove left front splash shield.

2. Disconnect washer pump fluid lines and detach lines from reservoir clips. Remove reservoir attaching nuts and bolt. Detach washer

reservoir from filler neck and remove reservoir. To install, reverse removal procedure.

REAR WIPER MOTOR

Removal & Installation (Festiva)

Remove rear wiper arm and blade assembly. Remove boot from outer bushing attaching nut. Remove outer bushing attaching nut and remove

outer bushing. Remove liftgate trim panel. Disconnect wiper motor electrical connector. Remove 4 wiper motor mounting bolts and remove

motor. To install, reverse removal procedure.

REAR WIPER/WASHER SWITCH

Removal & Installation (Festiva)

Disconnect negative battery cable. Remove steering column covers. Remove screws securing instrument panel bezel to instrument panel. Pull

instrument bezel away from instrument panel. Disconnect electrical connectors from switches in bezel. Compress wiper/washer switch lock

tabs and remove switch from bezel. To install, reverse removal procedure.

REAR WASHER MOTOR & RESERVOIR

Removal & Installation (Festiva)

Open liftgate and detach reservoir cap. Remove rear quarter trim panel. Remove reservoir mounting bolts. Disconnect electrical connector

from washer pump. Disconnect fluid lines. Remove reservoir. To install, reverse removal procedure.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See appropriate chassis wiring diagram in the WIRING DIAGRAMS Section.

ApplicationINCH Lbs. (N.m)

Front Wiper Arm Retaining Nut89-124 (10-14)

Front Wiper Motor Mounting Bolts62-89 (7-10)

Rear Outer Bushing Retaining Nut27-44 (3-5)

Rear Wiper Arm Nut53-62 (6-7)

Rear Wiper Motor Mounting Bolts71-97 (8-11)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028304

Page 5 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 47 of 454

SOLENOIDS & SOLENOID VALVES

SOLENOIDS & SOLENOID VALVES LOCATION

SWITCHES

SWITCHES LOCATION

MISCELLANEOUS

MISCELLANEOUS LOCATION

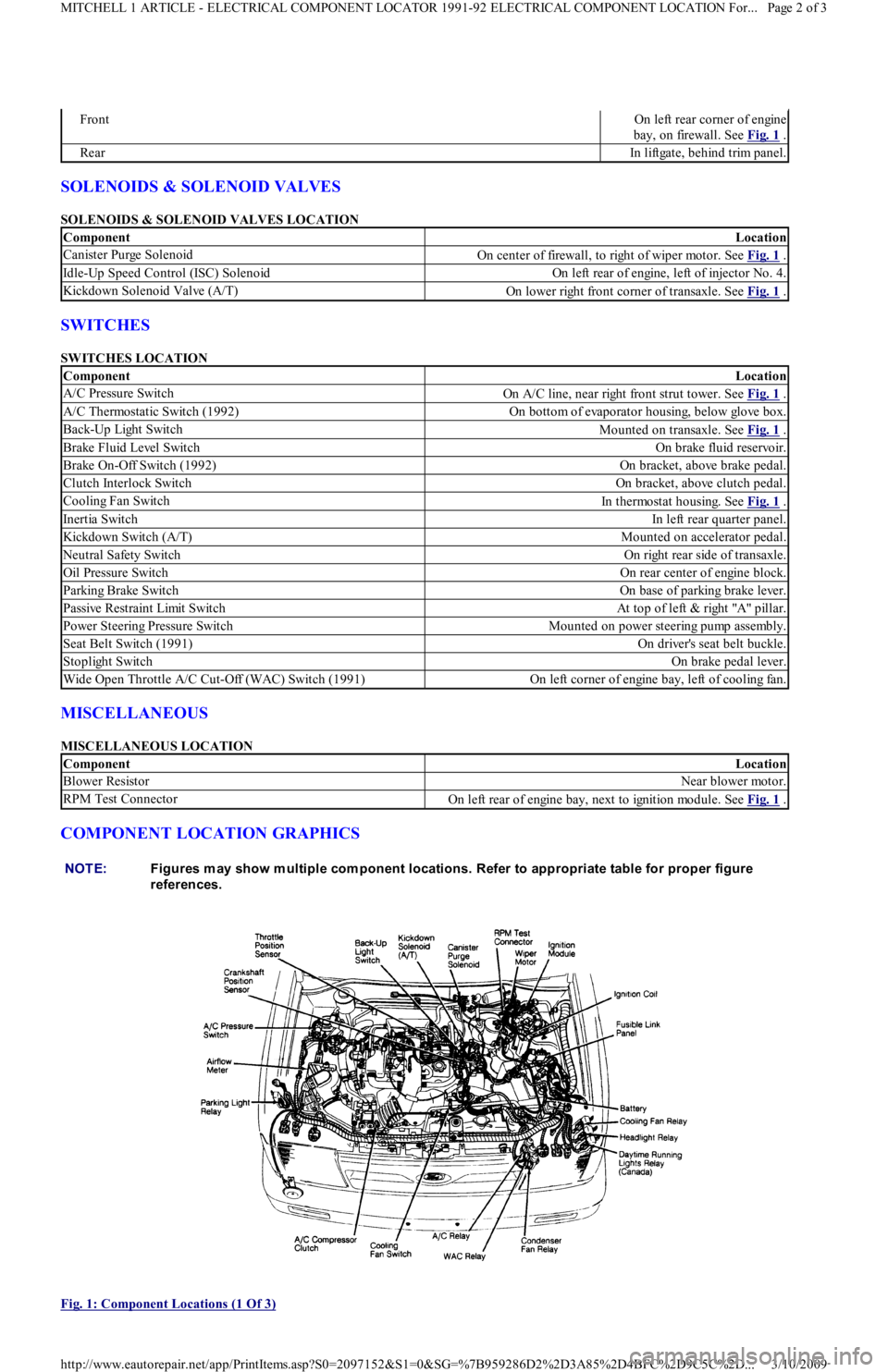

COMPONENT LOCATION GRAPHICS

Fig. 1: Component Locations (1 Of 3)

FrontOn left rear corner of engine

bay, on firewall. See Fig. 1

.

RearIn liftgate, behind trim panel.

ComponentLocation

Canister Purge SolenoidOn center of firewall, to right of wiper motor. See Fig. 1 .

Idle-Up Speed Control (ISC) SolenoidOn left rear of engine, left of injector No. 4.

Kickdown Solenoid Valve (A/T)On lower right front corner of transaxle. See Fig. 1 .

ComponentLocation

A/C Pressure SwitchOn A/C line, near right front strut tower. See Fig. 1 .

A/C Thermostatic Switch (1992)On bottom of evaporator housing, below glove box.

Back-Up Light SwitchMounted on transaxle. See Fig. 1 .

Brake Fluid Level SwitchOn brake fluid reservoir.

Brake On-Off Switch (1992)On bracket, above brake pedal.

Clutch Interlock SwitchOn bracket, above clutch pedal.

Cooling Fan SwitchIn thermostat housing. See Fig. 1 .

Inertia SwitchIn left rear quarter panel.

Kickdown Switch (A/T)Mounted on accelerator pedal.

Neutral Safety SwitchOn right rear side of transaxle.

Oil Pressure SwitchOn rear center of engine block.

Parking Brake SwitchOn base of parking brake lever.

Passive Restraint Limit SwitchAt top of left & right "A" pillar.

Power Steering Pressure SwitchMounted on power steering pump assembly.

Seat Belt Switch (1991)On driver's seat belt buckle.

Stoplight SwitchOn brake pedal lever.

Wide Open Throttle A/C Cut-Off (WAC) Switch (1991)On left corner of engine bay, left of cooling fan.

ComponentLocation

Blower ResistorNear blower motor.

RPM Test ConnectorOn left rear of engine bay, next to ignition module. See Fig. 1 .

NOTE:Figures m ay show m ultiple com ponent locations. Refer to appropriate table for proper figure

references.

Page 2 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...