air filter FORD FESTIVA 1991 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 250 of 454

Back To Article

GENERAL INFORMATION

T ROUBLE SHOOT ING

* PLEASE READ THIS FIRST *

ENGINE PERFORMANCE

TUNE-UP TROUBLE SHOOTING NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Carbon Fouled Plugs

C l o gge d Air Fil t e rReplace Air Filter

Incorrect Idle SpeedReset Idle Speed

Faulty Ignition WiringReplace Ignition Wiring

Sticky Valves/Worn Valve SealCheck Valve Train

Fuel Injection OperationCheck Fuel Injection

Wet/Oil Fouled Plugs

Worn Rings/PistonsOverhaul/Replace Engine

Excessive Cylinder WearOverhaul/Replace Engine

Plug Gap Bridged

Combustion Chamber Carbon DepositsClean Combustion

Chamber

Blistered Electrode

Engine OverheatingCheck Cooling System

Loose Spark PlugsClean/Torque Plugs

Over-Advanced TimingReset Timing

Wrong Plug Heat RangeInstall Correct Plug

Melted Electrodes

Incorrect TimingReset Timing

Burned ValvesReplace Valves

Engine OverheatingCheck Cooling System

Wrong Plug Heat RangeInstall Correct Plug

Engine Won't Start

Loose ConnectionsCheck Connections

No PowerCheck Fuses/Battery

Loose/Worn Timing Belt/Chain/GearsCheck Belt/Chain/Gears

Engine Runs Rough

Leaky/Clogged Fuel InjectorsRepair Fuel Injectors

Leaky/Clogged Fuel LinesRepair Fuel Lines

Clogged Fuel FilterReplace Fuel Filter

Incorrect TimingReset Timing/Check

Advance

Faulty Plugs/WiresReplace Plugs/Wires

Uneven CompressionOverhaul/Replace Engine

Poor Acceleration

Incorrect Ignition TimingReset Timing

Leaky ValvesCheck Compression

Component Failure

Spark ArcingReplace Faulty Part

Defective Pick-Up CoilReplace Pick-Up Coil

Defective Ignition CoilReplace Ignition Coil

Defective Control UnitReplace Control Unit

Ignition Diagnosis By Scope Pattern

All Firing Lines Abnormally High

Retarded Ignition TimingReset Ignition Timing

Lean Air/Fuel MixtureAdjust Fuel Mixture

High Secondary ResistanceRepair Secondary

Ign it io n

All Firing Lines Abnormally Low

Rich Air/Fuel MixtureAdjust Air/Fuel Mixture

Arcing Coil WireReplace Coil Wire

Cracked CoilReplace Coil

Low Coil OutputReplace Coil

Low CompressionCheck/Repair Engine

Page 1 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 251 of 454

FUEL INJECTION TROUBLE SHOOTING

Se ve r a l High F ir in g Lin e s

Fuel Mixture UnbalancedCheck Fuel System

EGR Valve Stuck OpenClean/Replace EGR

Valve

High Plug Wire ResistanceReplace Plug Wire

Cracked/Broken PlugsReplace Plugs

Intake Vacuum LeakRepair Leak

Several Low Firing Lines

Fuel Mixture UnbalancedAdjust Fuel Mixture

Plug Wires ArcingReplace Plug Wires

Cracked Coil ArcingReplace Coil

Uneven CompressionCheck/Repair Engine

Faulty Spark PlugsReplace Plugs

Cylinders Not Firing

Cracked Distributor CapReplace Cap

Shorted Plug WiresReplace Plug Wires

Mechanical Engine FaultCheck/Repair Engine

Spark Plugs FouledReplace Plugs

Carbon Track in Distributor CapReplace Cap

Hard Starting

Defective Ignition Coil(s)Replace Coil(s)

Fouled Spark PlugsReplace Plugs

Incorrect TimingReset Ignition Timing

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Cold Start Valve InoperativeTest Cold Start Valve

Poor Vacuum/Electrical ConnectionRepair Connections

Contaminated FuelTest Fuel for Water/Alcohol

Bad Fuel Pump Relay/CircuitTest Relay/Wiring

Battery Voltage LowCharge/Test Battery

Low Fuel PressureTest Press. Regulator/Pump

No Distributor Reference PulseRepair Ignition System

Coolant Temp. Sensor DefectiveTest Temp. Sensor/Circuit

No Power To InjectorsCheck Injector Fuse/Relay

Hard Starting

Defective Idle Air Control (IAC)Test IAC and Circuit

EGR Valve OpenTest EGR Valve/Control

Circuit

Restricted Fuel LinesInspect/Replace Fuel Lines

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Engine Stalls During Parking ManeuverCheck P.S. Press. Switch

Rough Idle

Dirty Fuel InjectorsClean/Replace Injectors

Poor MAP Sensor SignalTest MAP Sensor/Circuit

Intermittent Fuel Injector OperationCheck Harness Connectors

Erratic Vehicle Speed Sensor InputsHarness Too Close to Plug

Wires

Poor O2 Sensor SignalTest O2 Sensor/Circuit

Faulty PCV SystemCheck PCV Valve and

Hoses

Poor Acceleration

Weak Fuel PumpReplace Fuel Pump

Dirty Fuel InjectorsClean/Replace Injectors

Excessive Intake Valve DepositsClean Intake System

Poor High Speed Operation

Low Fuel Pump VolumeFaulty Fuel Pump/Filter

Poor MAP Sensor SignalTest Speed Sensor/Circuit

Acceleration Ping/Knock

Faulty EGR SystemCheck EGR Valve and

Hoses

Poor Knock Sensor SignalTest Knock Sensor/Circuit

Poor Baro Sensor SignalTest Baro Sensor/Circuit

Improper Ignition TimingAdjust Timing

Engine OverheatingCheck Cooling System

Poor Quality FuelUse Different Fuel

Carbon Build-UpDecarbon Engine

Page 2 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 263 of 454

Fig. 5: Identifying Vehicle Calibration Label (1989

-93 Ford Models)

Courtesy of FORD MOTOR CO.

EMISSION CONTROL VISUAL INSPECTION

A visual inspection is made to determine if any required emission control devices are missing, modified or disconnected. Missing, mo d ifie d o r

disconnected systems must be made fully operational before a vehicle can be certified.

POSITIVE CRANKCASE VENTILATION (PCV)

PCV controls the flow of crankcase fumes into the intake manifold while preventing gases and flames from traveling in the opposite direction.

PCV is either an open or closed system. See Fig. 4

.

Ensure PCV system is installed as required. Verify valve, required hoses, connections, flame arresters, etc., are present, routed properly and in

serviceable condition.

Fig. 6: Typical Open & Closed Type PCV System

THERMOSTATIC AIR CLEANER (TAC)

The TAC supplies warm air to air intake during cold engine operation. This system is active during cold engine warm-up only. Under all other

operating conditions, air cleaner function is the same as any non-thermostatic unit.

Ensure required exhaust shroud, hot air duct, vacuum hoses and air cleaner components are present and installed properly. See Fig. 7

. Ensure

any required thermostatic vacuum switches are in place and vacuum hoses are installed and in serviceable condition. Also ensure air cleaner

lid is installed right side up. Check for oversized air filter elements and for additional holes in the air cleaner housing.

NOTE:T he following em ission control visual inspection procedures should be used as a guide only. When

perform ing a visual inspection, always follow your state's recom m ended inspection procedures.

Page 3 of 12 MITCHELL 1 ARTICLE - EMISSION CONTROL VISUAL INSPECTION PROCEDURES 1983-93 GENERAL INFORMATI

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 270 of 454

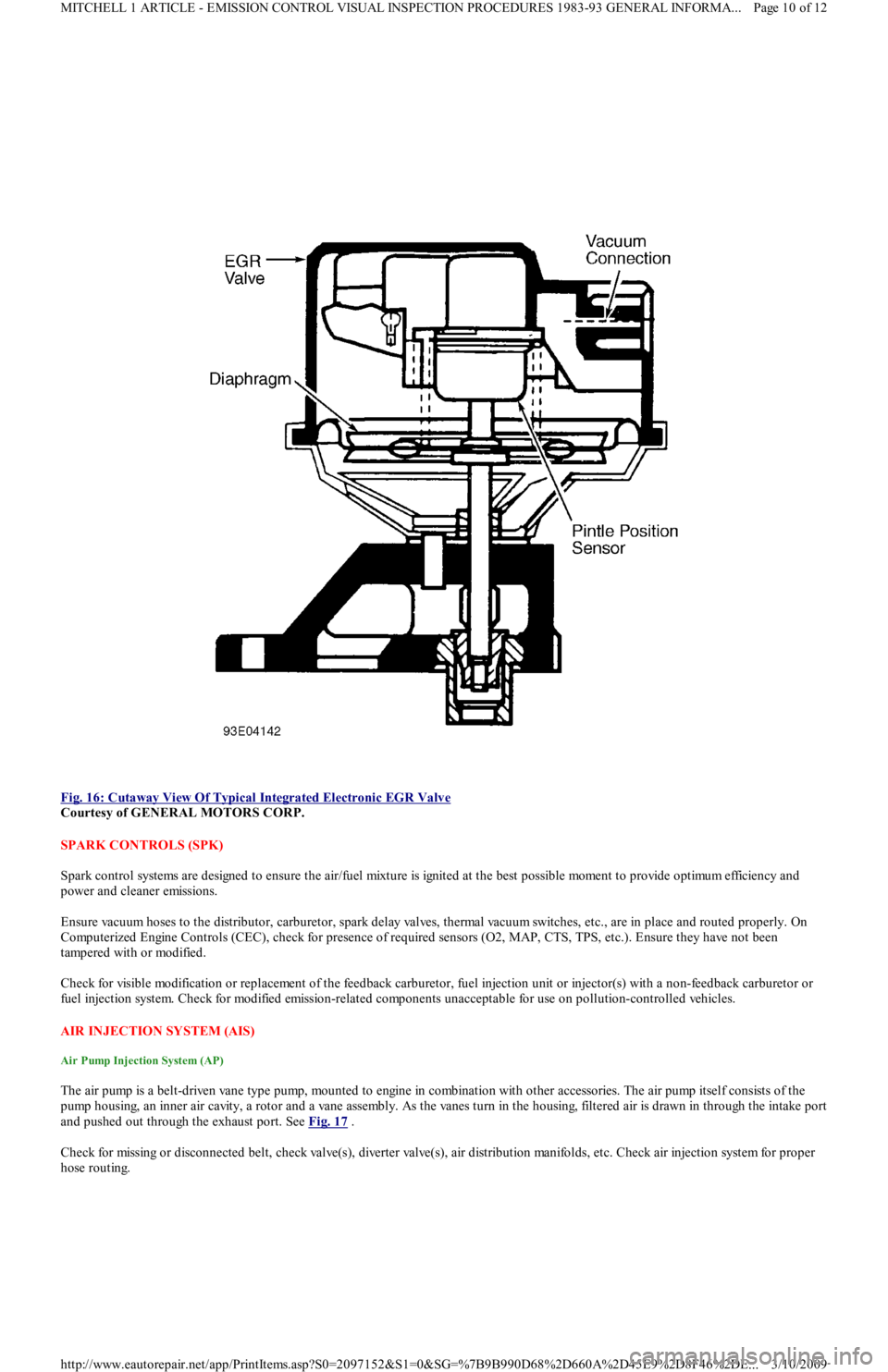

Fig. 16: Cutaway View Of Typical Integrated Electronic EGR Valve

Courtesy of GENERAL MOTORS CORP.

SPARK CONTROLS (SPK)

Spark control systems are designed to ensure the air/fuel mixture is ignited at the best possible moment to provide optimum efficiency and

power and cleaner emissions.

Ensure vacuum hoses to the distributor, carburetor, spark delay valves, thermal vacuum switches, etc., are in place and routed properly. On

Computerized Engine Controls (CEC), check for presence of required sensors (O2, MAP, CTS, TPS, etc.). Ensure they have not been

tampered with or modified.

Check for visible modification or replacement of the feedback carburetor, fuel injection unit or injector(s) with a non-feedback carburetor or

fuel injection system. Check for modified emission-related components unacceptable for use on pollution-controlled vehicles.

AIR INJECTION SYSTEM (AIS)

Air Pump Injection System (AP)

The air pump is a belt-driven vane type pump, mounted to engine in combination with other accessories. The air pump itself consists of the

pump housing, an inner air cavity, a rotor and a vane assembly. As the vanes turn in the housing, filtered air is drawn in through the intake port

and pushed out through the exhaust port. See Fig. 17

.

Check for missing or disconnected belt, check valve(s), diverter valve(s), air distribution manifolds, etc. Check air injection system for proper

hose routing.

Page 10 of 12 MITCHELL 1 ARTICLE - EMISSION CONTROL VISUAL INSPECTION PROCEDURES 1983-93 GENERAL INFORMA...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 339 of 454

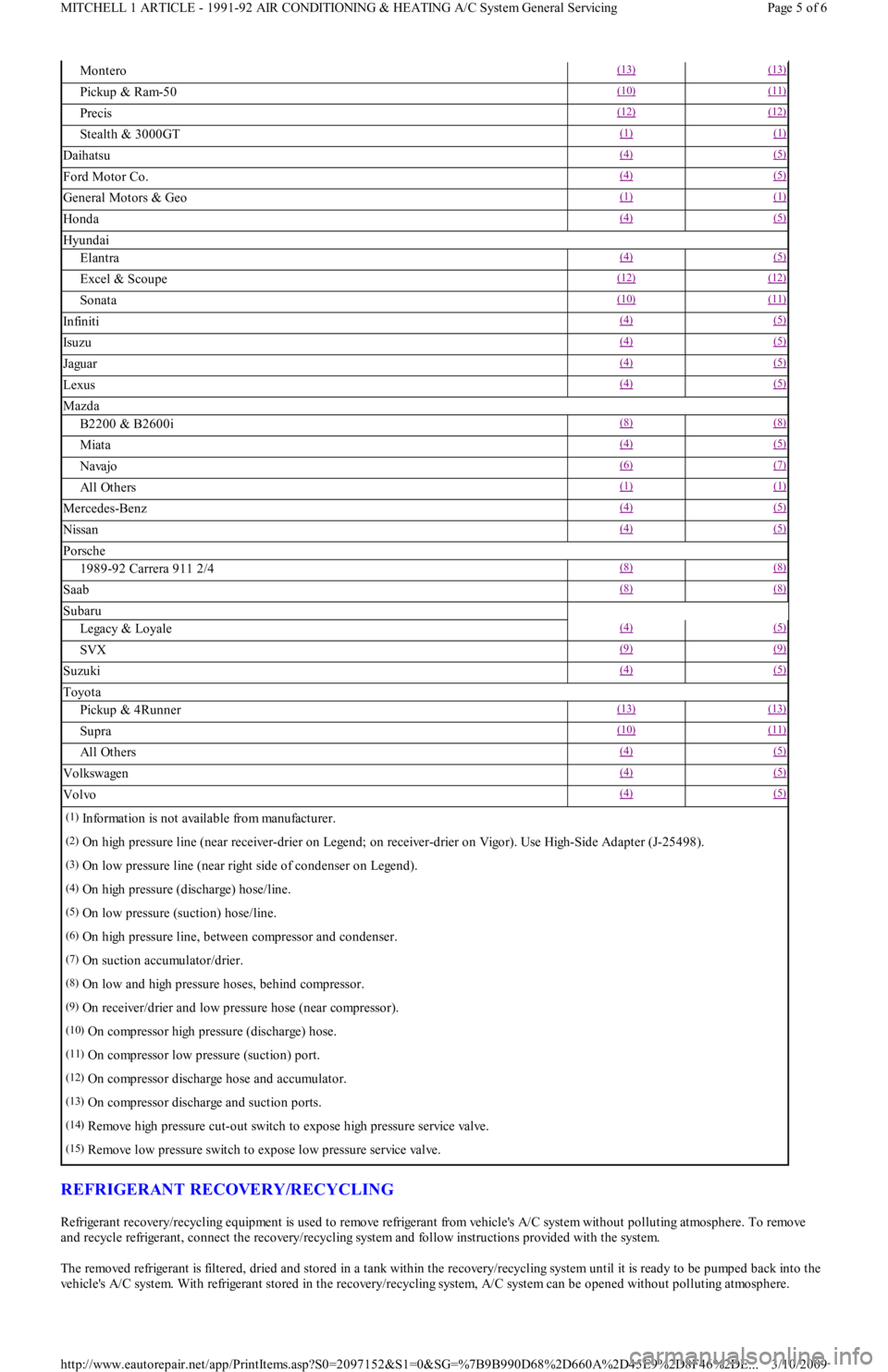

REFRIGERANT RECOVERY/RECYCLING

Refrigerant recovery/recycling equipment is used to remove refrigerant from vehicle's A/C system without polluting atmosphere. To remove

and recycle refrigerant, connect the recovery/recycling system and follow instructions provided with the system.

The removed refrigerant is filtered, dried and stored in a tank within the recovery/recycling system until it is ready to be pumped back into the

vehicle's A/C system. With refrigerant stored in the recovery/recycling system, A/C system can be opened without polluting atmosphere.

Montero(13) (13)

Pickup & Ram-50(10) (11)

Precis(12) (12)

Stealth & 3000GT(1) (1)

Daihatsu(4) (5)

Ford Motor Co.(4) (5)

General Motors & Geo(1) (1)

Honda(4) (5)

Hyundai

Elantra(4) (5)

Excel & Scoupe(12) (12)

Sonata(10) (11)

In fin it i(4) (5)

Isu zu(4) (5)

Jaguar(4) (5)

Lexus(4) (5)

Mazda

B2200 & B2600i(8) (8)

Miata(4) (5)

Navajo(6) (7)

All Others(1) (1)

Mercedes-Benz(4) (5)

Nissan(4) (5)

Porsche

1989-92 Carrera 911 2/4(8) (8)

Saab(8) (8)

Subaru

Legacy & Loyale(4) (5)

SVX(9) (9)

Suzuki(4) (5)

Toyota

Pickup & 4Runner(13) (13)

Supra(10) (11)

All Others(4) (5)

Volkswagen(4) (5)

Volvo(4) (5)

(1)Information is not available from manufacturer.

(2)On high pressure line (near receiver-drier on Legend; on receiver-drier on Vigor). Use High-Side Adapter (J-25498).

(3)On low pressure line (near right side of condenser on Legend).

(4)On high pressure (discharge) hose/line.

(5)On low pressure (suction) hose/line.

(6)On high pressure line, between compressor and condenser.

(7)On suction accumulator/drier.

(8)On low and high pressure hoses, behind compressor.

(9)On receiver/drier and low pressure hose (near compressor).

(10)On compressor high pressure (discharge) hose.

(11)On compressor low pressure (suction) port.

(12)On compressor discharge hose and accumulator.

(13)On compressor discharge and suction ports.

(14)Remove high pressure cut-out switch to expose high pressure service valve.

(15)Remove low pressure switch to expose low pressure service valve.

Page 5 of 6 MITCHELL 1 ARTICLE - 1991-92 AIR CONDITIONING & HEATING A/C System General Servicing

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 436 of 454

Back To Article

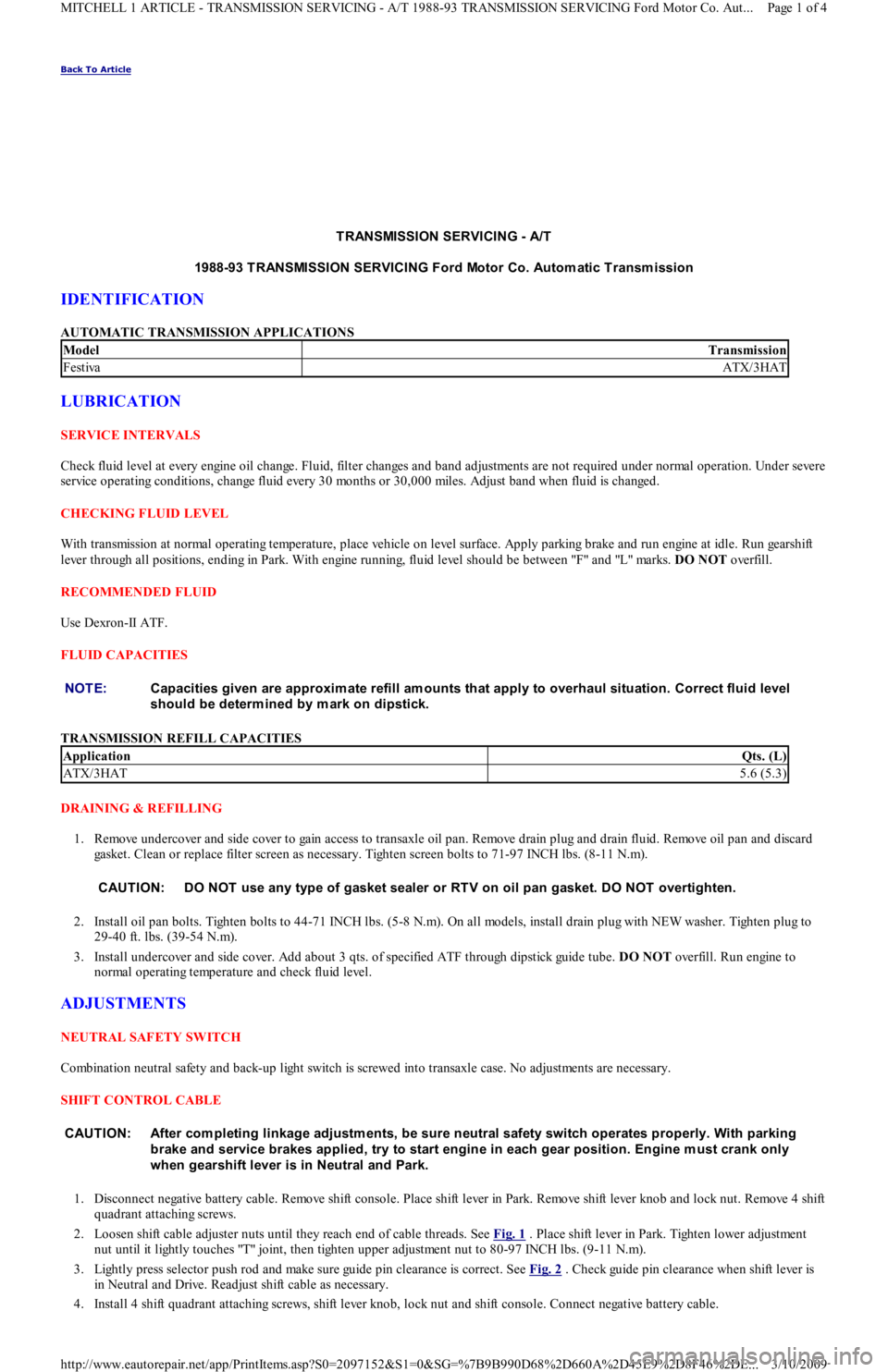

T RANSMISSION SERVICING - A/T

1988-93 T RANSMISSION SERVICING Ford Motor Co. Autom atic T ransm ission

IDENTIFICATION

AUTOMATIC TRANSMISSION APPLICATIONS

LUBRICATION

SERVICE INTERVALS

Check fluid level at every engine oil change. Fluid, filter changes and band adjustments are not required under normal operation. Under severe

service operating conditions, change fluid every 30 months or 30,000 miles. Adjust band when fluid is changed.

CHECKING FLUID LEVEL

With transmission at normal operating temperature, place vehicle on level surface. Apply parking brake and run engine at idle. Run gearshift

lever through all positions, ending in Park. With engine running, fluid level should be between "F" and "L" marks. DO NOT overfill.

RECOMMENDED FLUID

Use Dexron-II ATF.

FLUID CAPACITIES

TRANSMISSION REFILL CAPACITIES

DRAINING & REFILLING

1. Remove undercover and side cover to gain access to transaxle oil pan. Remove drain plug and drain fluid. Remove oil pan and discard

gasket. Clean or replace filter screen as necessary. Tighten screen bolts to 71-97 INCH lbs. (8-11 N.m).

2. Install oil pan bolts. Tighten bolts to 44-71 INCH lbs. (5-8 N.m). On all models, install drain plug with NEW washer. Tighten plug to

29-40 ft. lbs. (39-54 N.m).

3. Install undercover and side cover. Add about 3 qts. of specified ATF through dipstick guide tube. DO NOT overfill. Run engine to

normal operating temperature and check fluid level.

ADJUSTMENTS

NEUTRAL SAFETY SWITCH

Combination neutral safety and back-up light switch is screwed into transaxle case. No adjustments are necessary.

SHIFT CONTROL CABLE

1. Disconnect negative battery cable. Remove shift console. Place shift lever in Park. Remove shift lever knob and lock nut. Remove 4 shift

quadrant attaching screws.

2. Loosen shift cable adjuster nuts until they reach end of cable threads. See Fig. 1

. Place shift lever in Park. Tighten lower adjustment

nut until it lightly touches "T" joint, then tighten upper adjustment nut to 80-97 INCH lbs. (9-11 N.m).

3. Lightly press selector push rod and make sure guide pin clearance is correct. See Fig. 2

. Check guide pin clearance when shift lever is

in Neutral and Drive. Readjust shift cable as necessary.

4. Install 4 shift quadrant attaching screws, shift lever knob, lock nut and shift console. Connect negative battery cable.

ModelTransmission

FestivaATX/3HAT

NOTE:Capacities given are approxim ate refill am ounts that apply to overhaul situation. Correct fluid level

should be determ ined by m ark on dipstick.

ApplicationQts. (L)

ATX/3HAT5.6 (5.3)

CAUT ION: DO NOT use any type of gasket sealer or RT V on oil pan gasket. DO NOT overtighten.

CAUT ION: After com pleting linkage adjustm ents, be sure neutral safety switch operates properly. With parking

brake and service brakes applied, try to start engine in each gear position. Engine m ust crank only

when gearshift lever is in Neutral and Park.

Page 1 of 4 MITCHELL 1 ARTICLE - TRANSMISSION SERVICING - A/T 1988-93 TRANSMISSION SERVICING Ford Motor Co. Aut

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...