oil FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 2 of 454

Back To Article

INST RUMENT PANEL

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Switches & Instrum ent Panels - Standard

DESCRIPTION & OPERATION

Instrument panel on Capri contains a speedometer, tachometer, fuel, water temperature, oil pressure and voltmeter gauges. A boost gauge is

incorporated into the tachometer on turbo models. Instrument panel is equipped with indicator/warning lights for charging system, air b ag,

manual shift, seat belt, turn signals, high beam and brakes. A CHECK ENGINE light, located on instrument panel, illuminates if a

computerized engine control fault occurs with engine running.

Instrument panel on Festiva contains a speedometer, fuel and water temperature gauges. Instrument panel is equipped with indicator/warning

lights for charging system, oil pressure, seat belt, rear defogger, turn signals, high beam and brakes. A CHECK ENGINE light, located on

instrument panel, illuminates if a computerized engine control fault occurs with engine running.

TROUBLE SHOOTING

FUEL GAUGE

Fuel Gauge Always Reads Empty

If fuel gauge always reads empty, check these items:

Check fuel gauge for open or damaged wires.

Check for open ground at fuel gauge sending unit.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel instrument panel.

Check for fuel tank float full of fuel (sunk).

Fuel Gauge Always Reads Full

If fuel gauge always reads full, check these items:

Check for fuel gauge Yellow wire shorted to ground.

Check for defective fuel sending unit.

Check for defective fuel gauge.

Check for defective instrument panel voltage regulator (Festiva).

Fuel Gauge Inaccurate

If fuel gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective fuel sending unit.

Check for defective instrument panel voltage regulator (Festiva).

TEMPERATURE GAUGE

Temperature Gauge Always Reads Cold

If temperature gauge always reads cold, check these items:

Check temperature gauge for open wire.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow power feed wire from fuse panel to instrument panel.

Temperature Gauge Always Reads Hot

CAUT ION: On m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag system

is powered directly from the battery and back-up power supply. Before any repairs are perform ed,

disconnect and shield battery ground cable. Disconnect the back-up power supply BEFORE servicing

ANY air bag com ponent. Use caution when working near steering colum n. Air bag could accidentally

deploy at any tim e.

NOTE:Ensure continuity exists between chassis ground and Black wire of instrum ent panel connector,

especially if fault exists in m ultiple gauge circuits. See appropriate chassis wiring diagram in the

WIRING DIAGRAMS Section.

Page 1 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 3 of 454

If temperature gauge always reads hot, check these items:

Check for temperature gauge wire shorted to ground.

Check for defective temperature sender.

Check for defective temperature gauge.

Check for defective instrument panel voltage regulator (Festiva).

Temperature Gauge Inaccurate

If temperature gauge is inaccurate, check these items:

Check for faulty (loose or corroded) wire connections.

Check for defective temperature sender.

Check for defective instrument panel voltage regulator (Festiva).

SPEEDOMETER

Speedometer Does Not Operate

If speedometer does not operate, check these items:

Check for broken speedometer drive cable.

Check for broken drive gear in transmission.

Check for defective speedometer head.

Speedometer Needle Bounces

If speedometer needle bounces, check these items:

Check for binding speedometer drive cable.

Check for missing teeth on drive gear in transmission.

Check for defective speedometer head.

Speedometer Does Not Indicate Correct Vehicle Speed

If speedometer does not indicate correct vehicle speed, check these items:

Check for incorrect size tires.

Check for improper tire inflation.

Check for defective speedometer head.

TACHOMETER (CAPRI)

Tachometer Does Not Work, But All Other Gauges Work Properly

-If tachometer does not work, but all other gauges function properly, check these items:

Check for defective tachometer.

Check for open Yellow/Black tachometer signal wire from ignition coil to instrument panel.

Check for faulty Black ground wire to instrument panel.

Tachometer & All Gauges Do Not Function

If tachometer and all other gauges do not function properly, check these items:

Check for blown 10-amp METER fuse in fuse panel.

Check for open in Black/Yellow wire to fuse panel to instrument panel and Black/White wire from ignition switch to fuse panel

Tachometer Reading Low

If tachometer reading is lower than normal, check these items:

Check for defective tachometer.

Check for faulty Black ground wire at instrument panel.

TURBO BOOST GAUGE (CAPRI)

Turbo Boost Gauge Always Reads Low

If turbo boost gauge always reads low, check these items:

Check boost gauge for open or damaged wires.

Check for defective boost sensing unit.

Check for defective boost gauge.

Check for blown 10-amp METER fuse in fuse panel.

Check for loose or corroded connections.

Page 2 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 4 of 454

Turbo Boost Gauge Always Reads High

If turbo boost gauge always reads high, check these items:

Check for damaged White/Black signal wire.

Check for defective boost sensing unit.

Check for defective boost gauge.

Turbo Boost Gauge Inaccurate

If turbo boost gauge is inaccurate, check these items:

Check for loose or corroded connections.

Check for defective boost sensing unit.

Check for defective boost gauge.

TESTING

FUEL GAUGE SENDING UNIT

Capri

Remove rear seat cushion. Disconnect fuel pump/fuel gauge sending unit electrical connector at access cover. Turn ignition on. Fuel gauge

should read empty. Using a jumper wire, connect Yellow fuel gauge wire of vehicle harness connector to ground. Fuel gauge should read full.

If fuel gauge operates as specified, replace fuel gauge sending unit.

Festiva

Remove fuel gauge sending unit from tank. See FUEL SENDING UNIT under REMOVAL & INSTALLATION. Connect an ohmmeter and

check sending unit resistance as indicated in FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

table. Replace sending unit if

resistance is drastically different than specification.

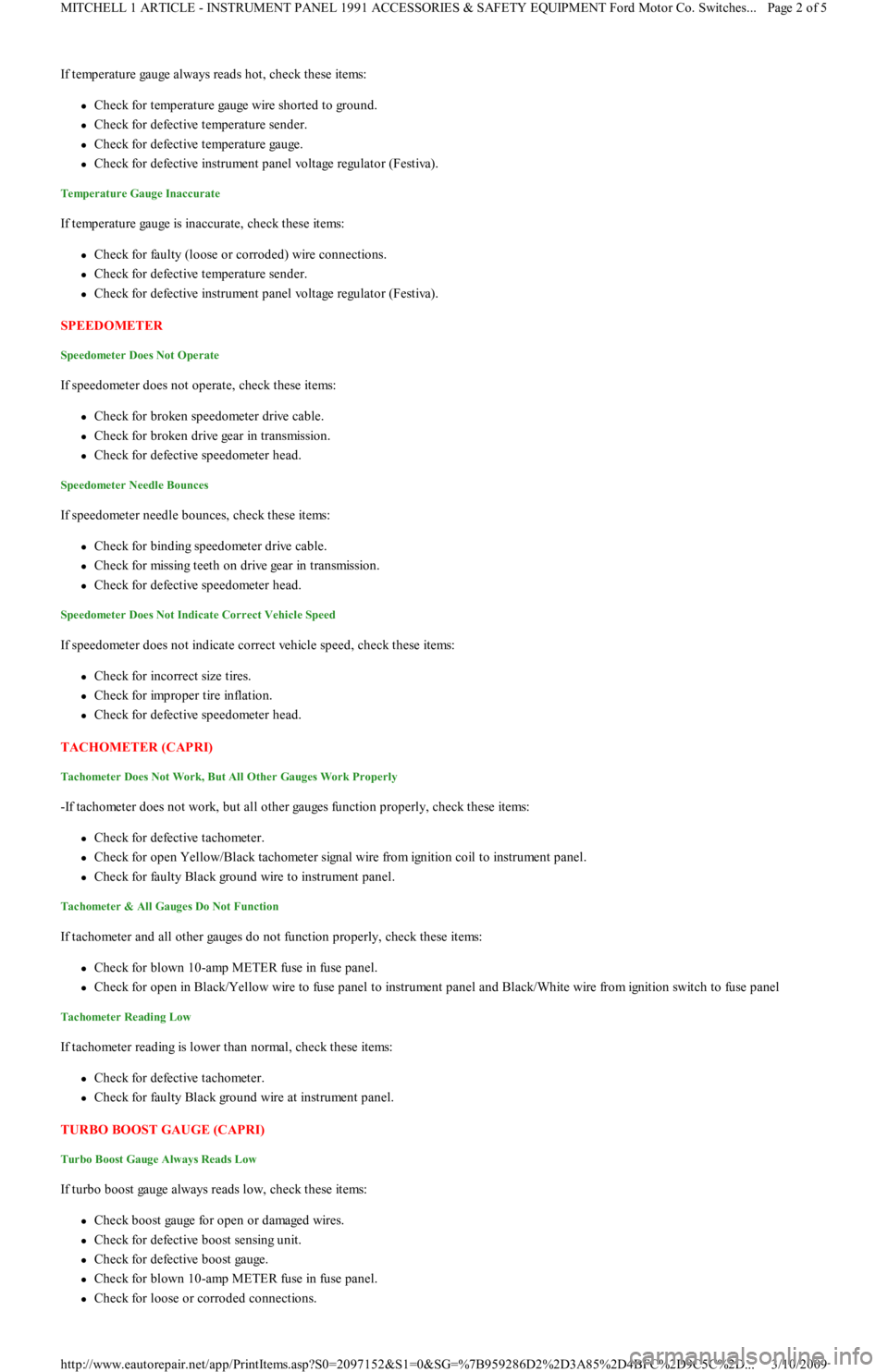

FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

OIL PRESSURE GAUGE (CAPRI)

1. Remove electrical connector from oil pressure sending unit located on right side of engine block. Turn ignition switch on. Oil pressure

gauge should read low. Install a jumper wire between Yellow/Red wire of oil pressure sending unit vehicle harness connector and

ground. Oil pressure gauge should read high.

2. If oil pressure gauge operates as specified, replace sending unit. If gauge does not operate as specified, check instrument panel power

and ground circuits.

OIL PRESSURE WARNING LIGHT (FESTIVA)

Light Stays On With Engine Running

1. Turn ignition on (DO NOT start engine). Disconnect Yellow/Red wire from oil pressure switch connector. Light should go off.

2. If light stays on, repair short in Yellow/Red wire between oil indicator light and oil pressure switch. Reconnect wire to switch. Light

should be on with ignition on. If light does not go off when engine is started, check switch or engine for low oil pressure.

Oil Light Will Not Go On With Ignition On

1. Ground Yellow/Red wire at instrument panel connector. If light goes on, repair Yellow/Red wire between oil pressure switch and

indicator light or replace defective oil pressure switch.

2. If light does not illuminate, check bulb or check instrument panel ground circuit.

TEMPERATURE GAUGE (CAPRI)

1. Remove electrical connector from temperature sending unit located at front of cylinder head. Connect one lead of Gauge System Tester

(021-00055) to connector and other tester lead to ground. Set tester to 18 ohms, turn ignition switch on and observe temperature gauge.

Gauge should read 250°F.

2. Turn tester to 60 ohms. Gauge should read 175°F. Turn tester to 223 ohms. Gauge should read 100°F. If all readings are within twice

the needle width of correct reading, gauge is functioning properly. If readings are not as specified, replace gauge.

TEMPERATURE GAUGE (FESTIVA)

See TROUBLE SHOOTING for possible service areas.

TEMPERATURE SENDING UNIT (CAPRI)

Remove sending unit from engine and place in container of water. Heat water to 176°F (80°C). Measure resistance between sending unit

connector and case. Resistance should be 49.3-57.7 ohms. If resistance is not as specified, replace sending unit. NOTE:Inspect fuel tank for distortion or dam age. If distorted or dam aged, repair or replace tank before testing.

Float PositionOhms

Full Position (Up)Approximately 7

Half-Full Position (Middle)Approximately 33

Empty Position (Down)Approximately 95

Page 3 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 6 of 454

2. Lift access plate and disconnect sending unit wiring. To relieve fuel pressure, start engine and run it until engine stalls. Turn ignition off.

Disconnect and plug fuel lines at sending unit. Remove sending u n it a t t a c h in g sc r e ws. R e mo ve se n d in g u n it . To in st a l l , r e ve r se removal

procedure.

TACHOMETER

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove tachometer.

To install tachometer, reverse removal procedure. On Capri, the tachometer/speedometer/boost gauge assembly must be replaced as an

assembly.

TEMPERATURE GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove temperature

gauge. To install gauge, reverse removal procedure. On Capri, the temperature/oil pressure gauge assembly must be replaced as an assembly.

TEMPERATURE SENDING UNIT

Removal

Disconnect sending unit wire, located on side of block below thermostat housing (Festiva) or cylinder head (Capri). Remove radiator cap to

relieve cooling system pressure. Position drain pan below sending unit. Remove temperature sending unit.

Installation

To install, apply Pipe Sealant With Teflon (D8AZ-19554-A) to threads of sending unit. Reverse removal procedure to complete installation.

Fill cooling system to proper level. Start engine and check for coolant leaks at sending unit.

WIRING DIAGRAMS

CAUT ION: T achom eter is calibrated at factory. Rough handling could disturb calibration.

NOTE:Refer to the appropriate WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028301

Page 5 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 42 of 454

Installation (All)

1. To install axle shaft, reverse removal procedure. Always install a NEW retaining circlip. Check seals at both ends of axle shaft. If

necessary, replace seals prior to installation. Lubricate transaxle seal lip with transaxle oil. See Fig. 1

.

2. After installing axle shaft into transaxle, pull axle shaft outward by hand to ensure proper engagement of retaining circlip and snap ring.

Install axle shaft into wheel hub. Align suspension alignment marks and tighten nuts.

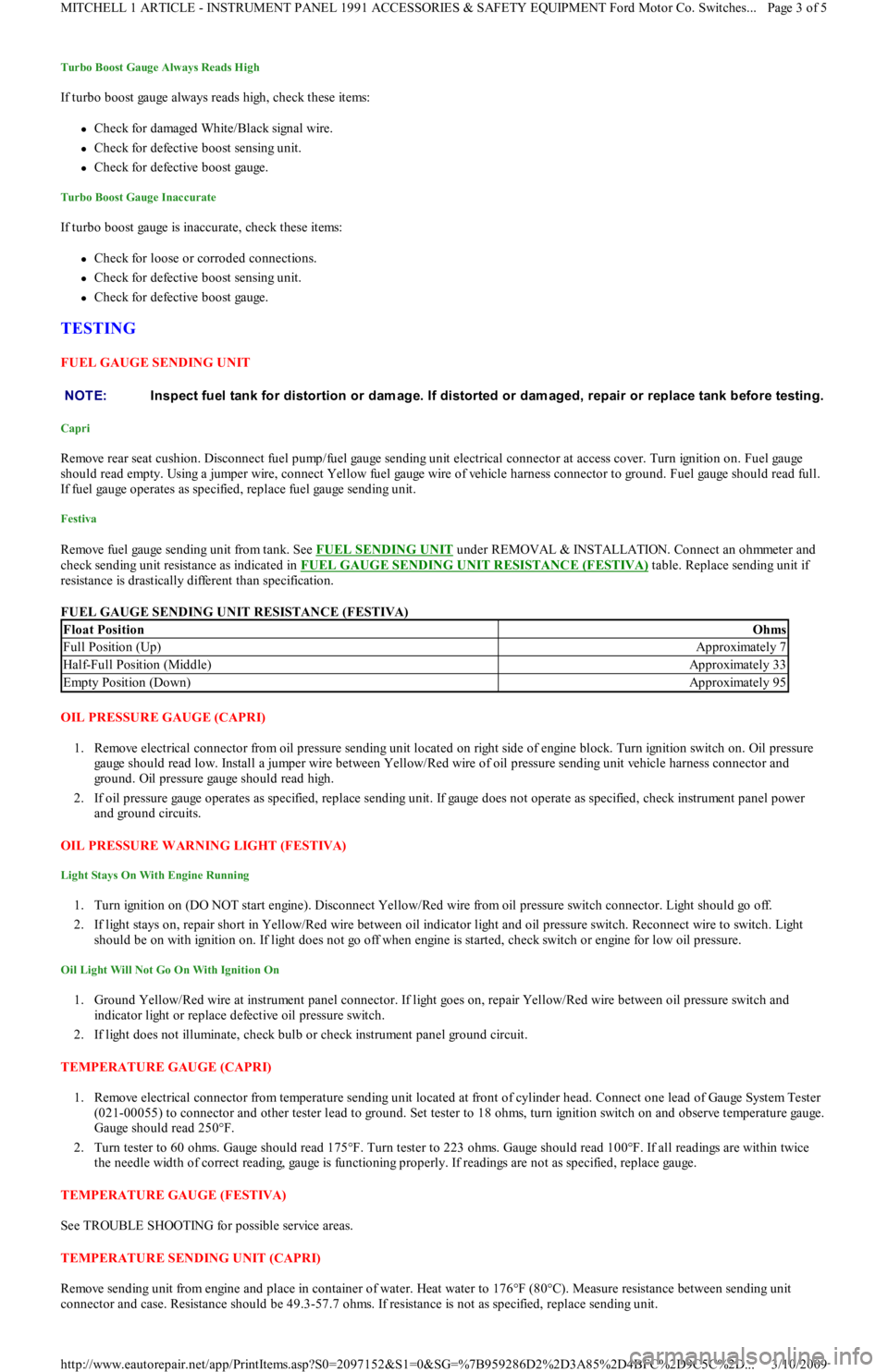

INTERMEDIATE SHAFT

Removal

Intermediate shaft and axle shaft are removed as an assembly. See FWD AXLE SHAFTS under REMOVAL, DISASSEMBLY,

REASSEMBLY & INSTALLATION.

Disassembly

Separate intermediate shaft from axle shaft. Remove circlip from intermediate shaft and press off bearing and bracket assembly. See Fig. 4 .

Press bearing out of bracket. Inspect bracket for damage or wear and replace if necessary.

Reassembly

Press NEW bearing into bracket and install NEW seals. Install bearing and bracket assembly onto intermediate shaft. Install NEW circlip.

Assemble intermediate shaft to axle shaft.

Installation

Intermediate shaft and axle shaft are installed as an assembly. See FWD AXLE SHAFTS under REMOVAL, DISASSEMBLY,

REASSEMBLY & INSTALLATION.

Fig. 4: Exploded View Of Intermediate Shaft

Courtesy of FORD MOTOR CO.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:Always install NEW cotter pin, washer and suspension lock nuts.

ApplicationFt. Lbs. (N.m)

Axle Nut (1) 116-173 (157-235)

Ball Joint Pinch Bolt32-40 (43-54)

Steering Knuckle-To-Strut Bolt69-86 (93-117)

Caliper Retaining Bolt29-36 (39-49)

Stabilizer Bar Bracket Nut40-50 (54-68)

Stabilizer Link Bolt9-13 (12-18)

Tie Rod End Nut21-32 (29-44)

Wheel Lug Nuts66-89 (90-120)

(1)Ensure locking flange on nut is staked into axle slot.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00042994

Page 3 of 3 MITCHELL 1 ARTICLE - AXLE SHAFTS - FRONT 1988-93 Drive Axles - FWD Axle Shafts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 44 of 454

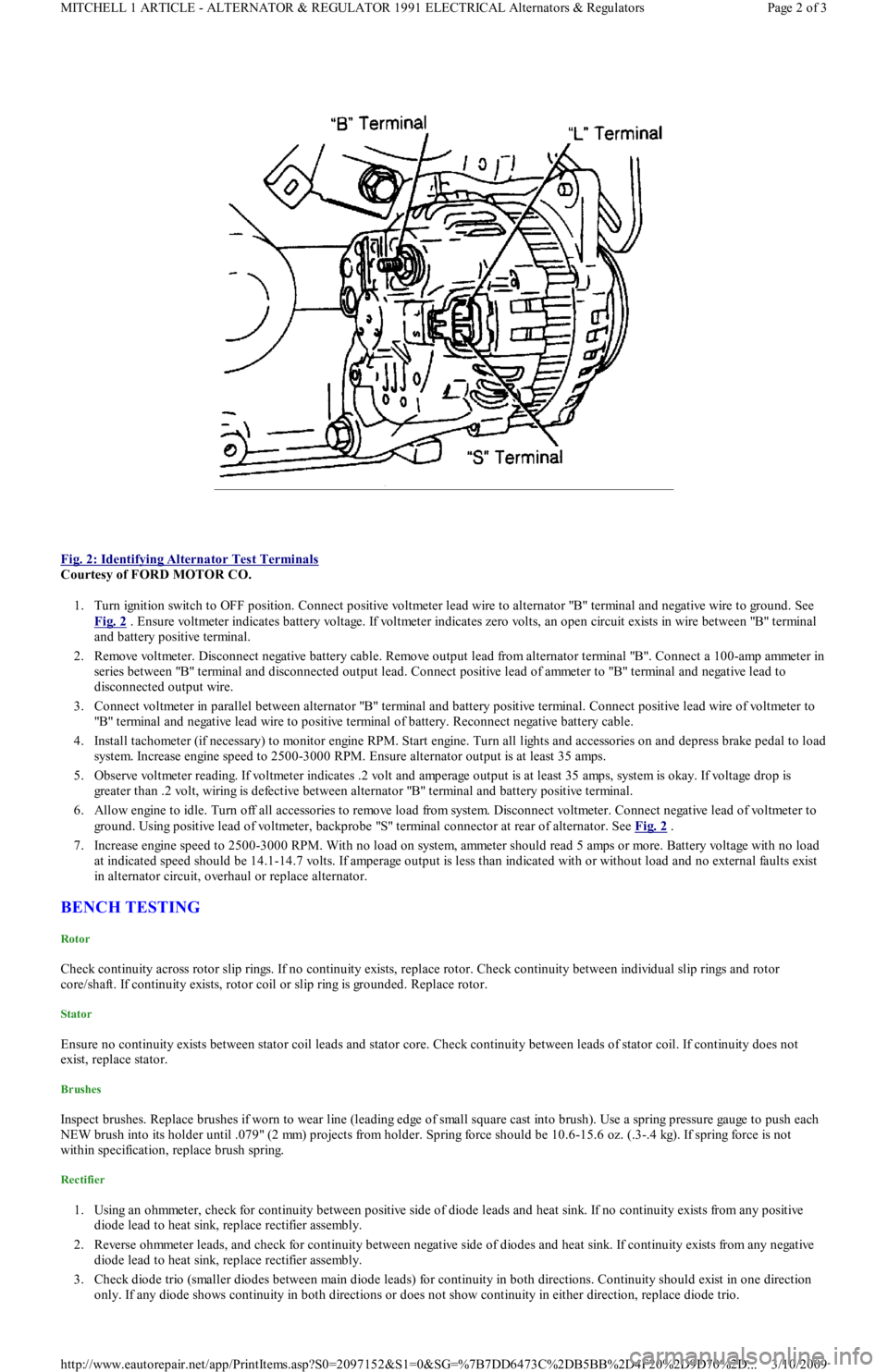

Fig. 2: Identifying Alternator Test Terminals

Courtesy of FORD MOTOR CO.

1. Turn ignition switch to OFF position. Connect positive voltmeter lead wire to alternator "B" terminal and negative wire to ground. See

Fig. 2

. Ensure voltmeter indicates battery voltage. If voltmeter indicates zero volts, an open circuit exists in wire between "B" terminal

and battery positive terminal.

2. Remove voltmeter. Disconnect negative battery cable. Remove output lead from alternator terminal "B". Connect a 100-amp ammeter in

series between "B" terminal and disconnected output lead. Connect positive lead of ammeter to "B" terminal and negative lead to

disconnected output wire.

3. Connect voltmeter in parallel between alternator "B" terminal and battery positive terminal. Connect positive lead wire of voltmeter to

"B" terminal and negative lead wire to positive terminal of battery. Reconnect negative battery cable.

4. Install tachometer (if necessary) to monitor engine RPM. Start engine. Turn all lights and accessories on and depress brake pedal to load

system. Increase engine speed to 2500-3000 RPM. Ensure alternator output is at least 35 amps.

5. Observe voltmeter reading. If voltmeter indicates .2 volt and amperage output is at least 35 amps, system is okay. If voltage drop is

greater than .2 volt, wiring is defective between alternator "B" terminal and battery positive terminal.

6. Allow engine to idle. Turn off all accessories to remove load from system. Disconnect voltmeter. Connect negative lead of voltmeter to

ground. Using positive lead of voltmeter, backprobe "S" terminal connector at rear of alternator. See Fig. 2

.

7. Increase engine speed to 2500-3000 RPM. With no load on system, ammeter should read 5 amps or more. Battery voltage with no load

at indicated speed should be 14.1-14.7 volts. If amperage output is less than indicated with or without load and no external faults exist

in alternator circuit, overhaul or replace alternator.

BENCH TESTING

Rotor

Check continuity across rotor slip rings. If no continuity exists, replace rotor. Check continuity between individual slip rings and rotor

core/shaft. If continuity exists, rotor coil or slip ring is grounded. Replace rotor.

Stator

Ensure no continuity exists between stator coil leads and stator core. Check continuity between leads of stator coil. If continuity does not

exist, replace stator.

Brushes

Inspect brushes. Replace brushes if worn to wear line (leading edge of small square cast into brush). Use a spring pressure gauge to push each

NEW brush into its holder until .079" (2 mm) projects from holder. Spring force should be 10.6-15.6 oz. (.3-.4 kg). If spring force is not

within specification, replace brush spring.

Rectifier

1. Using an ohmmeter, check for continuity between positive side of diode leads and heat sink. If no continuity exists from any positive

diode lead to heat sink, replace rectifier assembly.

2. Reverse ohmmeter leads, and check for continuity between negative side of diodes and heat sink. If continuity exists from any n e ga t ive

diode lead to heat sink, replace rectifier assembly.

3. Check diode trio (smaller diodes between main diode leads) for continuity in both directions. Continuity should exist in one direction

only. If any diode shows continuity in both directions or does not show continuity in either direction, replace diode trio.

Page 2 of 3 MITCHELL 1 ARTICLE - ALTERNATOR & REGULATOR 1991 ELECTRICAL Alternators & Regulators

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 47 of 454

SOLENOIDS & SOLENOID VALVES

SOLENOIDS & SOLENOID VALVES LOCATION

SWITCHES

SWITCHES LOCATION

MISCELLANEOUS

MISCELLANEOUS LOCATION

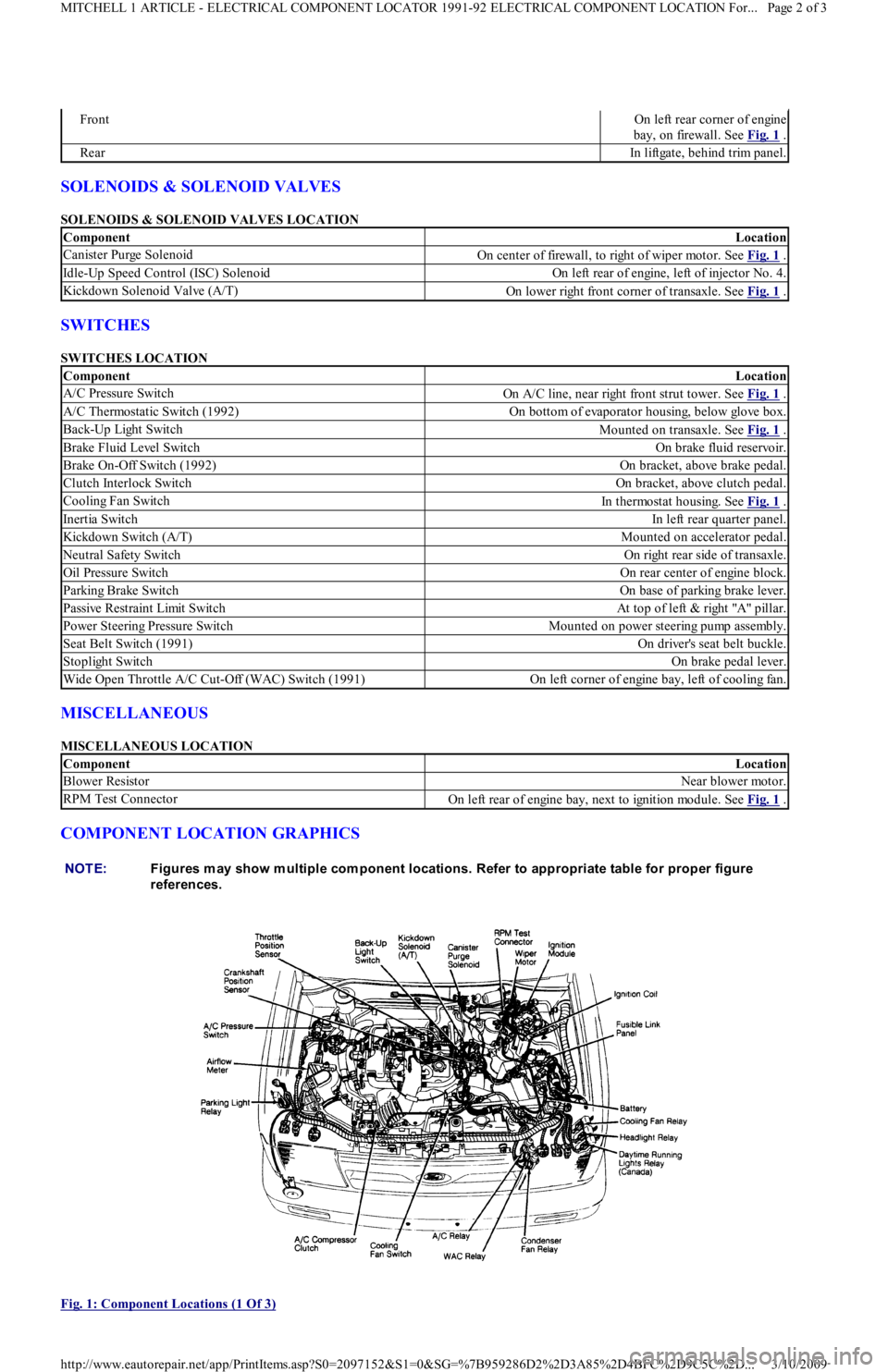

COMPONENT LOCATION GRAPHICS

Fig. 1: Component Locations (1 Of 3)

FrontOn left rear corner of engine

bay, on firewall. See Fig. 1

.

RearIn liftgate, behind trim panel.

ComponentLocation

Canister Purge SolenoidOn center of firewall, to right of wiper motor. See Fig. 1 .

Idle-Up Speed Control (ISC) SolenoidOn left rear of engine, left of injector No. 4.

Kickdown Solenoid Valve (A/T)On lower right front corner of transaxle. See Fig. 1 .

ComponentLocation

A/C Pressure SwitchOn A/C line, near right front strut tower. See Fig. 1 .

A/C Thermostatic Switch (1992)On bottom of evaporator housing, below glove box.

Back-Up Light SwitchMounted on transaxle. See Fig. 1 .

Brake Fluid Level SwitchOn brake fluid reservoir.

Brake On-Off Switch (1992)On bracket, above brake pedal.

Clutch Interlock SwitchOn bracket, above clutch pedal.

Cooling Fan SwitchIn thermostat housing. See Fig. 1 .

Inertia SwitchIn left rear quarter panel.

Kickdown Switch (A/T)Mounted on accelerator pedal.

Neutral Safety SwitchOn right rear side of transaxle.

Oil Pressure SwitchOn rear center of engine block.

Parking Brake SwitchOn base of parking brake lever.

Passive Restraint Limit SwitchAt top of left & right "A" pillar.

Power Steering Pressure SwitchMounted on power steering pump assembly.

Seat Belt Switch (1991)On driver's seat belt buckle.

Stoplight SwitchOn brake pedal lever.

Wide Open Throttle A/C Cut-Off (WAC) Switch (1991)On left corner of engine bay, left of cooling fan.

ComponentLocation

Blower ResistorNear blower motor.

RPM Test ConnectorOn left rear of engine bay, next to ignition module. See Fig. 1 .

NOTE:Figures m ay show m ultiple com ponent locations. Refer to appropriate table for proper figure

references.

Page 2 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 51 of 454

CATALYTIC CONVERTER

Continued operation of vehicle with a severe malfunction could cause converter to overheat, resulting in possible damage to converter and

ve h ic l e .

Any modification to the exhaust system on turbo models, which reduces exhaust backpressure, will lead to lean fuel mixtures and excessive

spark advance. This could cause serious engine damage.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

ENGINE OIL

FUEL PUMP SHUTOFF SWITCH

This switch stops flow of fuel to engine after a collision. The impact does not have to be great for switch to be triggered. Switch must be reset

after collision. Switch is located under left rear speaker in luggage compartment. Press button to reset switch.

FUEL SYSTEM SERVICE

HALOGEN BULBS

PASSIVE RESTRAINTS

RADIATOR CAP

RADIATOR FAN WARNING:Many solid state electrical com ponents can be dam aged by static electricity (ESD). Som e will display a

warning label, but m any will not. Discharge personal static electricity by touching a m etal ground point

on the vehicle prior to servicing any ESD sensitive com ponent.

CAUT ION: Never use non-detergent or straight m ineral oil.

WARNING:Relieve fuel system pressure prior to servicing any fuel system com ponent (fuel injection m odels).

WARNING:Halogen bulbs contain pressurized gas which m ay explode if overheated. DO NOT touch glass portion

of bulb with bare hands. Eye protection should be worn when handling or working around halogen

bulbs.

CAUT ION: Before operating vehicle, securely fasten passive shoulder restraints to the em ergency release buckles.

T he buckle fits in only one way. Ensure to position it properly.

CAUT ION: Always disconnect the fan m otor when working near the radiator fan. T he fan is tem perature controlled

and could start at any tim e even when the ignition key is in the OFF position. DO NOT loosen or rem ove

radiator cap when cooling system is hot.

WARNING:Keep hands away from radiator fan. Fan is controlled by a therm ostatic switch which m ay com e on or

run for up to 15 m inutes even after engine is turned off.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00058075

Page 3 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 53 of 454

3. If voltage is not present or is less than 8 volts at starter solenoid terminal "S", malfunction in circuit to terminal "S" is indicated. Proceed

to the following tests.

IGNITION SWITCH TEST

1. Locate ignition switch connector under dash. Using a 12-volt test light or voltmeter, ensure voltage is present on Black/Yellow wire

when ignition switch is turned to RUN or ON position. This will verify proper operation of ignition switch.

2. If there is no voltage on Black/Yellow wire, the problem is either ignition switch or circuit between battery and ignition switch.

CLUTCH ENGAGE SWITCH (M/T) TEST

Unplug clutch engage switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals. Continuity should

exist when switch plunger is pushed in and should not exist when switch plunger is released. If clutch engage switch does not operate as

specified, replace switch.

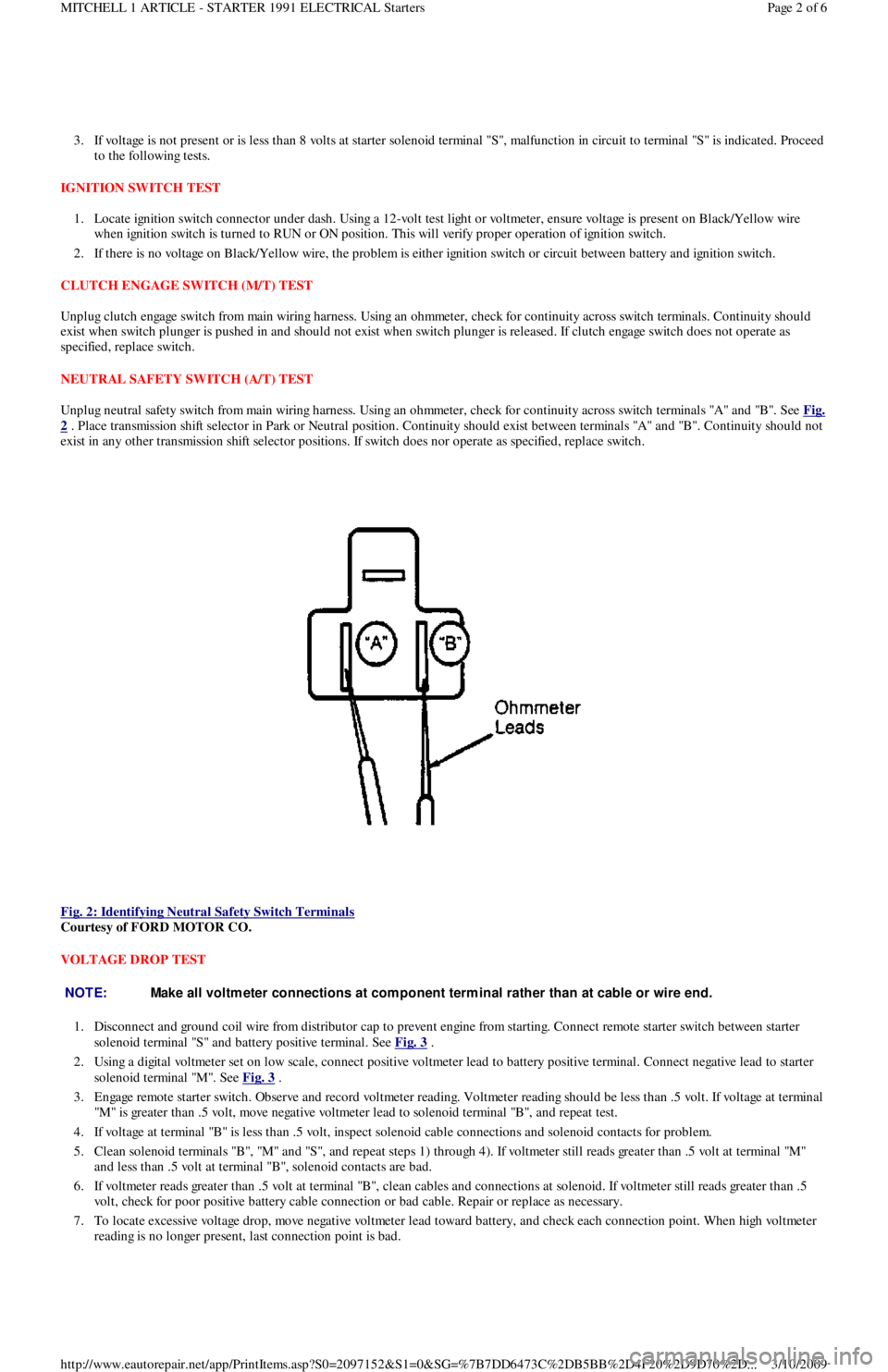

NEUTRAL SAFETY SWITCH (A/T) TEST

Unplug neutral safety switch from main wiring harness. Using an ohmmeter, check for continuity across switch terminals "A" and "B". See Fig.

2 . Place transmission shift selector in Park or Neutral position. Continuity should exist between terminals "A" and "B". Continuity should not

exist in any other transmission shift selector positions. If switch does nor operate as specified, replace switch.

Fig. 2: Identifying Neutral Safety Switch Terminals

Courtesy of FORD MOTOR CO.

VOLTAGE DROP TEST

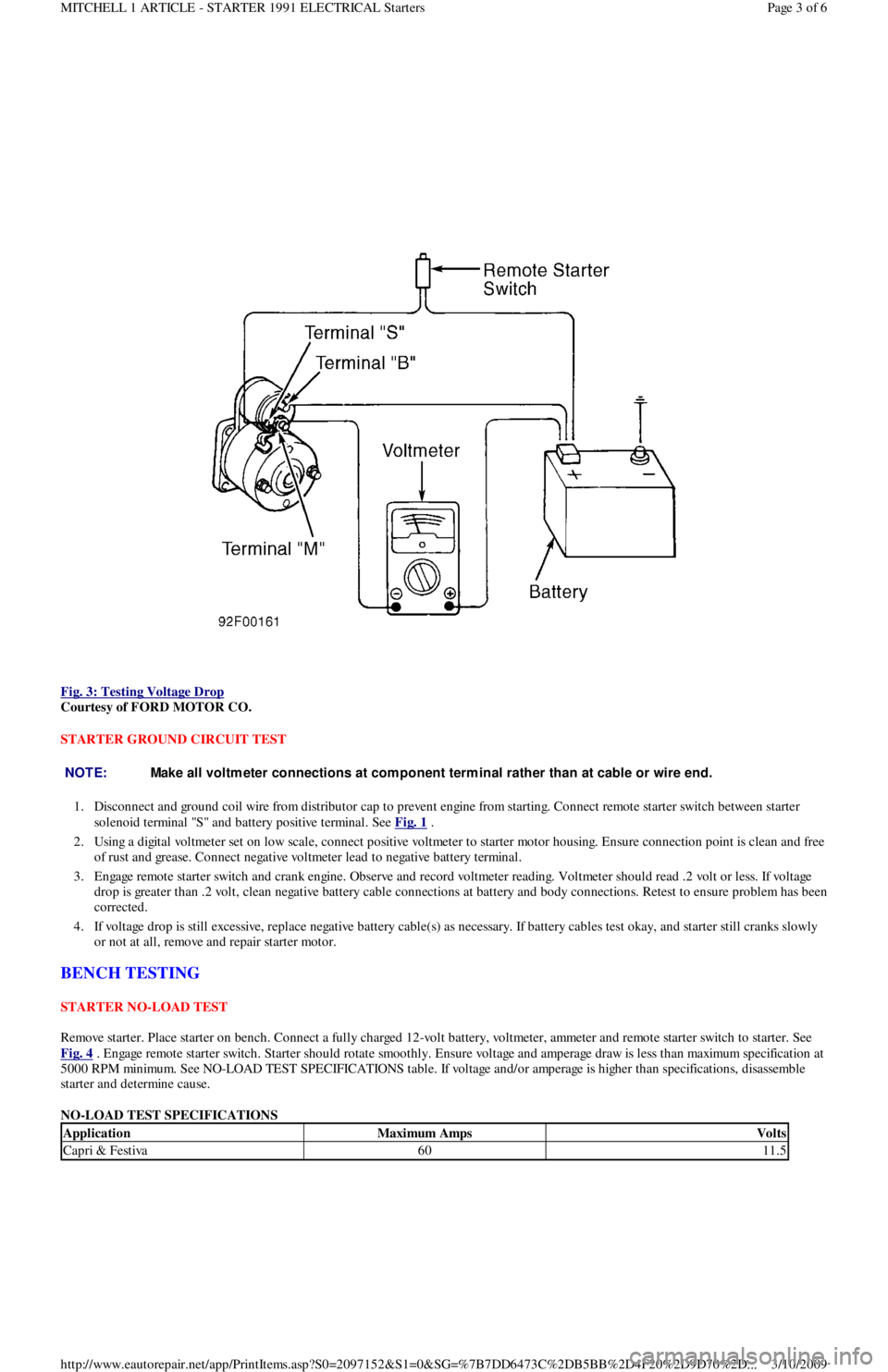

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 3

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter lead to battery positive terminal. Connect negative lead to starter

solenoid terminal "M". See Fig. 3

.

3. Engage remote starter switch. Observe and record voltmeter reading. Voltmeter reading should be less than .5 volt. If voltage at terminal

"M" is greater than .5 volt, move negative voltmeter lead to solenoid terminal "B", and repeat test.

4. If voltage at terminal "B" is less than .5 volt, inspect solenoid cable connections and solenoid contacts for problem.

5 . Cl ean so l en o id t ermin al s "B", "M" an d "S", an d rep eat st ep s 1 ) through 4). If voltmeter still reads greater than .5 volt at termin al "M"

and less than .5 volt at terminal "B", solenoid contacts are bad.

6. If voltmeter reads greater than .5 volt at terminal "B", clean cables and connections at solenoid. If voltmeter still reads greater than .5

volt, check for poor positive battery cable connection or bad cable. Repair or replace as necessary.

7. To locate excessive voltage drop, move negative voltmeter lead toward battery, and check each connection point. When high voltmeter

reading is no longer present, last connection point is bad.

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

Page 2 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 54 of 454

Fig. 3: Testing Voltage Drop

Courtesy of FORD MOTOR CO.

STARTER GROUND CIRCUIT TEST

1. Disconnect and ground coil wire from distributor cap to prevent engine from starting. Connect remote starter switch between starter

solenoid terminal "S" and battery positive terminal. See Fig. 1

.

2. Using a digital voltmeter set on low scale, connect positive voltmeter to starter motor housing. Ensure connection point is clean and free

of rust and grease. Connect negative voltmeter lead to negative battery terminal.

3. Engage remote starter switch and crank engine. Observe and record voltmeter reading. Voltmeter should read .2 volt or less. If voltage

drop is greater than .2 volt, clean negative battery cable connections at battery and body connections. Retest to ensure problem has been

corrected.

4. If voltage drop is still excessive, replace negative battery cable(s) as necessary. If battery cables test okay, and starter still cranks slowly

or not at all, remove and repair starter motor.

BENCH TESTING

STARTER NO-LOAD TEST

Remove starter. Place starter on bench. Connect a fully charged 12-volt battery, voltmeter, ammeter and remote starter switch to starter. See

Fig. 4

. Engage remote starter switch. Starter should rotate smoothly. Ensure voltage and amperage draw is less than maximum specification at

5000 RPM minimum. See NO-LOAD TEST SPECIFICATIONS table. If voltage and/or amperage is higher than specifications, disassemble

starter and determine cause.

NO-LOAD TEST SPECIFICATIONS

NOTE:Make all voltm eter connections at com ponent term inal rather than at cable or wire end.

ApplicationMaximum AmpsVolts

Capri & Festiva6011.5

Page 3 of 6 MITCHELL 1 ARTICLE - STARTER 1991 ELECTRICAL Starters

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...