Ignition lock FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 4 of 454

Turbo Boost Gauge Always Reads High

If turbo boost gauge always reads high, check these items:

Check for damaged White/Black signal wire.

Check for defective boost sensing unit.

Check for defective boost gauge.

Turbo Boost Gauge Inaccurate

If turbo boost gauge is inaccurate, check these items:

Check for loose or corroded connections.

Check for defective boost sensing unit.

Check for defective boost gauge.

TESTING

FUEL GAUGE SENDING UNIT

Capri

Remove rear seat cushion. Disconnect fuel pump/fuel gauge sending unit electrical connector at access cover. Turn ignition on. Fuel gauge

should read empty. Using a jumper wire, connect Yellow fuel gauge wire of vehicle harness connector to ground. Fuel gauge should read full.

If fuel gauge operates as specified, replace fuel gauge sending unit.

Festiva

Remove fuel gauge sending unit from tank. See FUEL SENDING UNIT under REMOVAL & INSTALLATION. Connect an ohmmeter and

check sending unit resistance as indicated in FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

table. Replace sending unit if

resistance is drastically different than specification.

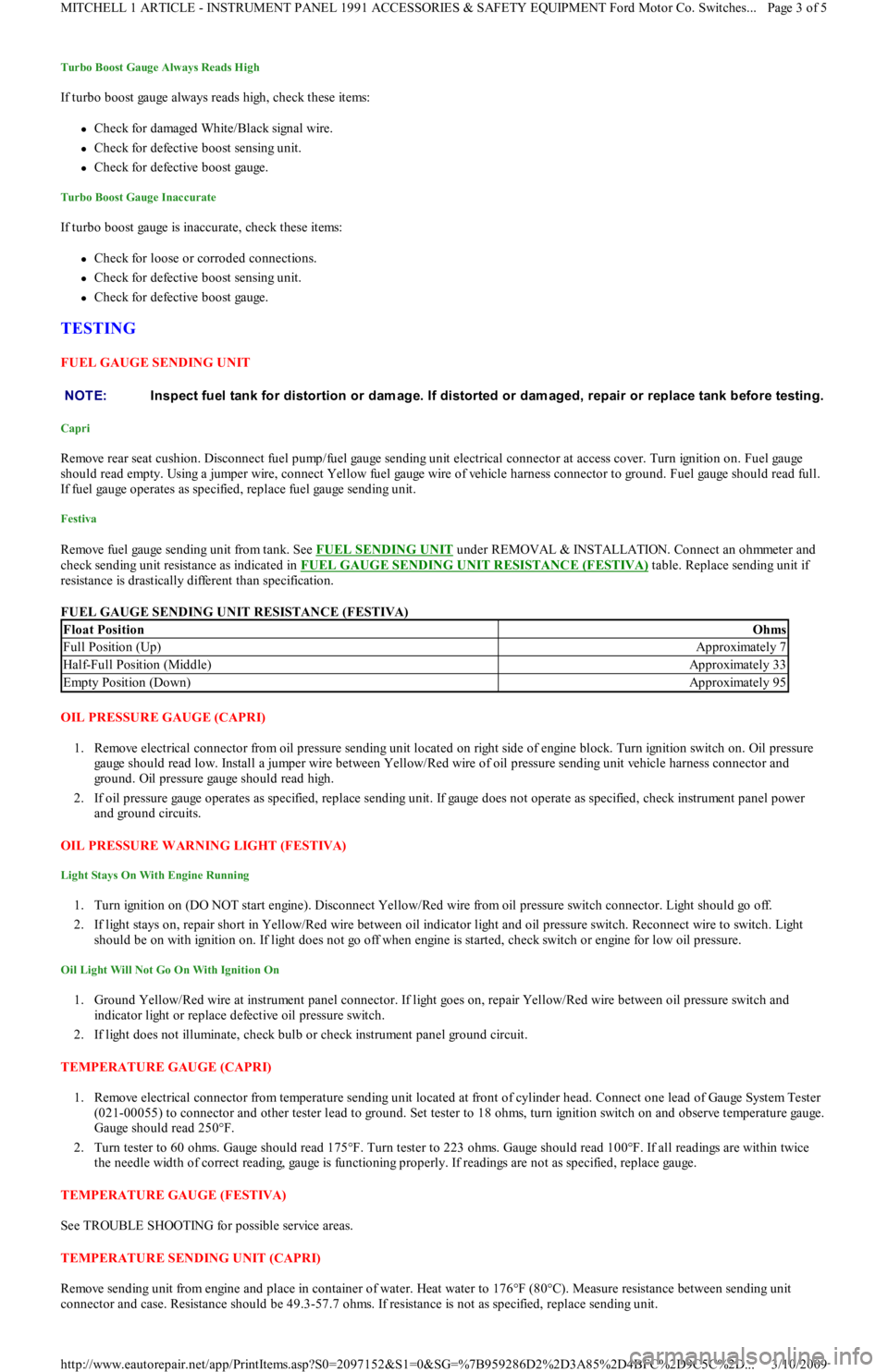

FUEL GAUGE SENDING UNIT RESISTANCE (FESTIVA)

OIL PRESSURE GAUGE (CAPRI)

1. Remove electrical connector from oil pressure sending unit located on right side of engine block. Turn ignition switch on. Oil pressure

gauge should read low. Install a jumper wire between Yellow/Red wire of oil pressure sending unit vehicle harness connector and

ground. Oil pressure gauge should read high.

2. If oil pressure gauge operates as specified, replace sending unit. If gauge does not operate as specified, check instrument panel power

and ground circuits.

OIL PRESSURE WARNING LIGHT (FESTIVA)

Light Stays On With Engine Running

1. Turn ignition on (DO NOT start engine). Disconnect Yellow/Red wire from oil pressure switch connector. Light should go off.

2. If light stays on, repair short in Yellow/Red wire between oil indicator light and oil pressure switch. Reconnect wire to switch. Light

should be on with ignition on. If light does not go off when engine is started, check switch or engine for low oil pressure.

Oil Light Will Not Go On With Ignition On

1. Ground Yellow/Red wire at instrument panel connector. If light goes on, repair Yellow/Red wire between oil pressure switch and

indicator light or replace defective oil pressure switch.

2. If light does not illuminate, check bulb or check instrument panel ground circuit.

TEMPERATURE GAUGE (CAPRI)

1. Remove electrical connector from temperature sending unit located at front of cylinder head. Connect one lead of Gauge System Tester

(021-00055) to connector and other tester lead to ground. Set tester to 18 ohms, turn ignition switch on and observe temperature gauge.

Gauge should read 250°F.

2. Turn tester to 60 ohms. Gauge should read 175°F. Turn tester to 223 ohms. Gauge should read 100°F. If all readings are within twice

the needle width of correct reading, gauge is functioning properly. If readings are not as specified, replace gauge.

TEMPERATURE GAUGE (FESTIVA)

See TROUBLE SHOOTING for possible service areas.

TEMPERATURE SENDING UNIT (CAPRI)

Remove sending unit from engine and place in container of water. Heat water to 176°F (80°C). Measure resistance between sending unit

connector and case. Resistance should be 49.3-57.7 ohms. If resistance is not as specified, replace sending unit. NOTE:Inspect fuel tank for distortion or dam age. If distorted or dam aged, repair or replace tank before testing.

Float PositionOhms

Full Position (Up)Approximately 7

Half-Full Position (Middle)Approximately 33

Empty Position (Down)Approximately 95

Page 3 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 5 of 454

TURBO BOOST GAUGE & SENSOR (CAPRI)

1. Disconnect 3-pin boost sensor electrical connected located on right side of firewall. Turn ignition on. Measure voltage between

Yellow/Green and Black wires. Voltage should be greater than 10 volts. Turn ignition off. If voltage is greater than 10 volts, go t o n e xt

step. If voltage is 10 volts or less, repair Yellow/Green or Black wires as necessary.

2. Remove instrument panel. See INSTRUMENT PANEL

under REMOVAL & INSTALLATION. Disconnect instrument panel 8-pin

connector. With boost sensor disconnected, measure resistance through White/Black between instrument panel and boost sensor harness

connector. If resistance is less than 5 ohms, go to next step. If resistance is 5 ohms or more, repair or replace White/Black wire.

3. With 8-pin instrument panel connector disconnected, ground White/Black at boost gauge. Boost gauge should read low. Apply 12 vo l t s

to White/Black wire at boost gauge. Boost gauge should read high. If boost gauge operates as specified, go to next step. If boost gauge

does not operate as specified, replace boost gauge.

4. Reconnect instrument panel connectors (if removed). With ignition on and boost sensor disconnected, install jumper wire between

Yellow/Green and White/Black wires of boost sensor vehicle harness connector. Boost gauge should read high. If boost gauge reads

high, replace boost sensor. If boost gauge does not read high, go to TROUBLE SHOOTING

for other possible causes.

REMOVAL & INSTALLATION

INSTRUMENT PANEL

Removal & Installation (Capri)

1. Disconnect negative battery cable. Pull storage compartment from heater/radio bezel. Pull outward and remove trim covers located on

both sides of steering column. Remove retaining screws and carefully pull instrument panel bezel partially away from dash. Disconnect

electrical connectors from clock and switches in bezel. Remove instrument panel bezel.

2. Disconnect speedometer cable from transaxle. Remove instrument panel retaining screws and slide instrument panel outward. Press lock

tab and release speedometer cable from instrument panel. Remove electrical connectors from rear of instrument panel. Remove

instrument panel. To install instrument panel, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove upper and lower steering column covers. Remove screws from panel bezel and remove bezel.

Disconnect rear wiper switch and rear defogger switch wiring harness connectors (if equipped).

2. Remove instrument panel-to-dash screws. Pull panel from dash. Reach behind panel and release speedometer drive cable lock tab. Lift

lock tabs and disconnect 2 electrical connectors from rear of panel. Remove panel. To install instrument panel, reverse removal

procedure.

INDICATOR LIGHTS

Removal & Installation

Remove instrument panel for access to indicator light bulbs. See INSTRUMENT PANEL under REMOVAL & INSTALLATION. To remove

bulb, rotate bulb counterclockwise to disengage locking tabs. When tabs release, pull bulb from printed circuit board. To install bulb, reverse

removal procedure. Install instrument panel and test lights.

SPEEDOMETER R & I

Removal & Installation (Capri)

R e mo ve n e ga t ive b a t t e r y c a b l e . R e mo ve in st r u me n t p a n e l . S e e INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble

instrument panel and remove speedometer/tachometer/boost gauge assembly from instrument panel. To install, apply a 3/16" (4.6 mm) b al l o f

Silicone Damping Grease (D7AZ-19A331-A) into drive hole of speedometer head. Reverse removal procedure to complete installation.

Removal & Installation (Festiva)

R e mo ve n e ga t ive b a t t e r y c a b l e . R e mo ve in st r u me n t p a n e l . S e e INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble

instrument panel and remove speedometer head assembly from instrument panel. Speedometer is a separate module and can be removed

independently from gauges. To install, reverse removal procedure.

SPEED SENSOR

On vehicles equipped with speed control, a speed sensor is mounted in speedometer head assembly. If replacement is necessary, speedometer

head assembly must be replaced. See SPEEDOMETER R & I

under REMOVAL & INSTALLATION.

FUEL GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove fuel gauge.

To install gauge, reverse removal procedure. On Capri, the fuel/volt gauge must be replaced as an assembly.

FUEL SENDING UNIT

Removal & Installation

1. For Festiva, remove rear seat. For Capri, remove rear seat cushion. On Festiva, remove carpet hold-down pins and lift carpet for access

to sending unit access plate. On all models, remove access plate screws. NOTE:Federal law requires that a label stating the odom eter has been repaired or replaced be affixed to any

vehicle that has its odom eter repaired, replaced or set to zero.

Page 4 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 6 of 454

2. Lift access plate and disconnect sending unit wiring. To relieve fuel pressure, start engine and run it until engine stalls. Turn ignition off.

Disconnect and plug fuel lines at sending unit. Remove sending u n it a t t a c h in g sc r e ws. R e mo ve se n d in g u n it . To in st a l l , r e ve r se removal

procedure.

TACHOMETER

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove tachometer.

To install tachometer, reverse removal procedure. On Capri, the tachometer/speedometer/boost gauge assembly must be replaced as an

assembly.

TEMPERATURE GAUGE

Removal & Installation

Remo ve in st ru men t p an el . See INSTRUMENT PANEL under REMOVAL & INSTALLATION. Disassemble panel and remove temperature

gauge. To install gauge, reverse removal procedure. On Capri, the temperature/oil pressure gauge assembly must be replaced as an assembly.

TEMPERATURE SENDING UNIT

Removal

Disconnect sending unit wire, located on side of block below thermostat housing (Festiva) or cylinder head (Capri). Remove radiator cap to

relieve cooling system pressure. Position drain pan below sending unit. Remove temperature sending unit.

Installation

To install, apply Pipe Sealant With Teflon (D8AZ-19554-A) to threads of sending unit. Reverse removal procedure to complete installation.

Fill cooling system to proper level. Start engine and check for coolant leaks at sending unit.

WIRING DIAGRAMS

CAUT ION: T achom eter is calibrated at factory. Rough handling could disturb calibration.

NOTE:Refer to the appropriate WIRING DIAGRAMS article in the WIRING DIAGRAMS section.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028301

Page 5 of 5 MITCHELL 1 ARTICLE - INSTRUMENT PANEL 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Switches

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 18 of 454

Back To Article

ST EERING COLUMN SWIT CHES

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Steering Colum n Switches

DESCRIPTION & OPERATION

DISABLING AIR BAG SYSTEM

To disable SRS, disconnect battery cable. Unplug back-up power supply 3-way harness connector. System is now disabled. Back-up power

supply is mounted to inside of instrument panel, left of glove box opening. Glove box door must be opened past its stops and lowered toward

floor to access back-up power supply.

ACTIVATING AIR BAG SYSTEM

To activate SRS, reconnect back-up power supply connector and negative battery cable. From passenger's side of vehicle, turn ignition switch

to RUN position. System is now activated. Check AIR BAG light to ensure system is functioning properly.

TESTING

HAZARD WARNING SWITCH & TURN SIGNAL SWITCH

Capri

1. Remove steering column covers to access turn signal/hazard switch connectors. Turn ignition on. Using a 12-volt test light, ensure

battery voltage is present at Green/Red and Green/Yellow wires at turn signal/hazard switch connectors. If battery voltage is not present,

check METER and HAZARD fuses. Also check hazard and turn signal flasher units and replace as necessary.

2. If battery voltage is present at Green/Red and Green/Yellow wires, place turn signal switch in RIGHT position. Check both Green/White

wires at switch connector. Test light should flash on and off in constant cycles.

3. Place turn signal switch in LEFT position. Check both Green/Black wires at switch connector. Test light should flash on and off in

constant cycles. If turn signal/hazard switch does not function as specified, replace switch.

Festiva

1. Remove steering column covers to access turn signal/hazard switch connectors. Turn ignition on. Using a 12-volt test light, ensure

battery voltage is present at White/Black and Black/Yellow wires at hazard and turn signal switch connectors. If battery voltage is not

present, check METER and HAZARD fuses.

2. If battery voltage is present at White/Black and Black/Yellow wires, place turn signal/hazard switch in RIGHT position. Check

Green/Black wire at switch connector. Test light should flash on and off in constant cycles.

3. Place turn signal/hazard switch in LEFT position. Check Green/White wire at switch connector. Test light should flash on and off in

constant cycles. If turn signal/hazard switch does not function as specified, replace switch.

HEADLIGHT SWITCH

Capri

1. Remove instrument panel bezel to access switch connector. See HEADLIGHT SWITCH under REMOVAL & INSTALLATION.

Disconnect switch electrical connector. Measure voltage between Red and Red/White wires of headlight switch vehicle harness and

ground. If battery voltage is present, go to next step. If battery voltage is not present, check HEAD and MAIN fuses and Red and

Red/White wires between switch and fuse block.

2. Press headlight switch to first position. Using a self powered test light or ohmmeter, check continuity between switch terminals which

correspond to Red and Red/Green wires of vehicle harness connector. Continuity should not exist. If continuity exists, replace switch.

3. Press headlight switch to second position. Check continuity between switch terminals which correspond with the Red and Red/Green

wires of vehicle harness connector. Continuity should exist. If switch does not function as described, replace headlight switch. If swit ch

functions as described but headlights do not work, go to next step.

4. Remove steering column covers to access Flash-To-Pass switch connector. Using a 12-volt test light or voltmeter, place switch in

position indicated in table and check voltage between indicated wire terminals and ground. See FLASH-TO-PASS SWITCH TEST

(CAPRI) table. If switch does not function as indicated, replace switch.

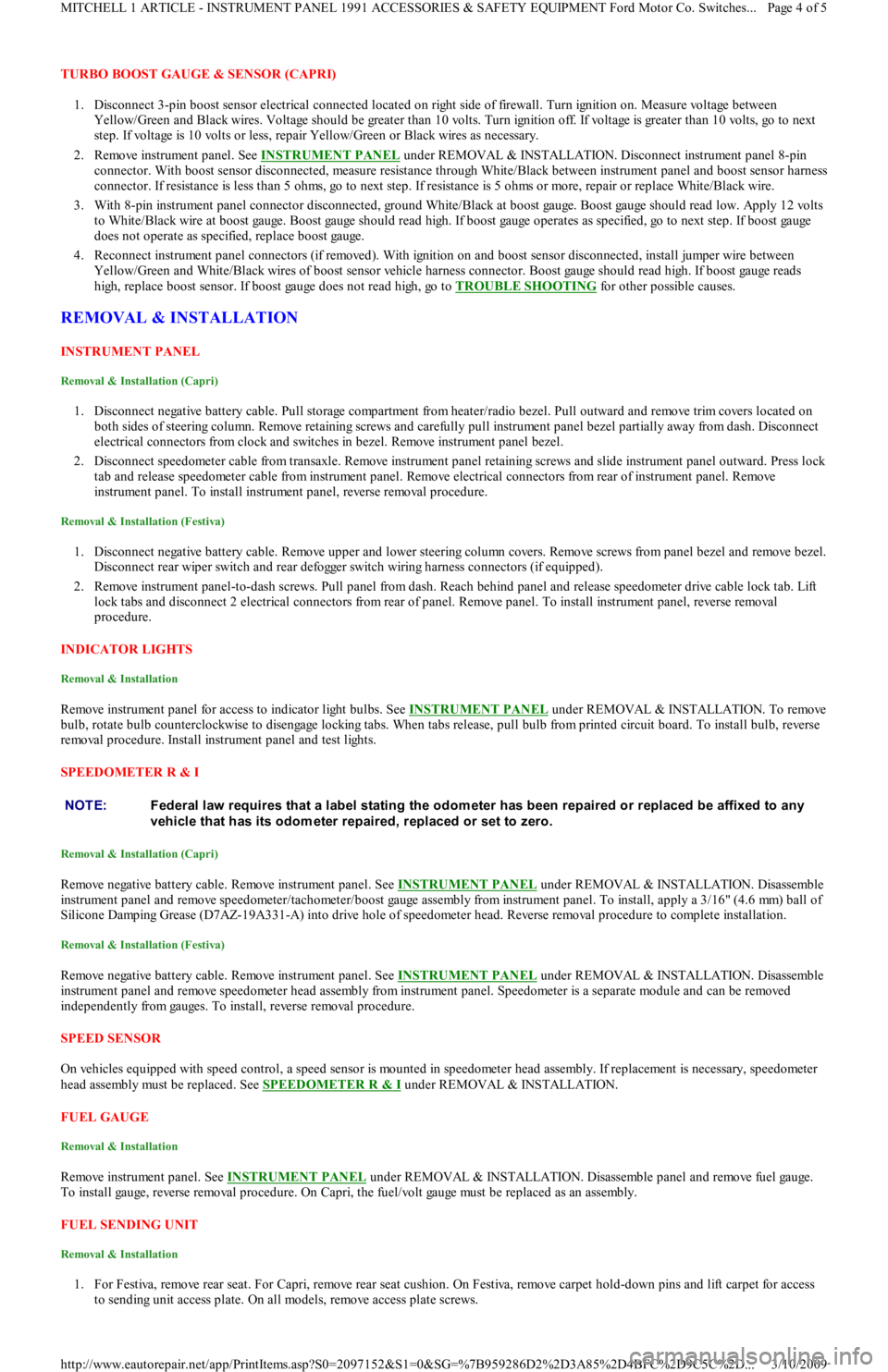

FLASH-TO-PASS SWITCH TEST (CAPRI) CAUTION: On Capri m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag

system is powered directly from the battery and back-up power supply. Before any repairs are

perform ed, disconnect and shield battery ground cable. Disconnect the back-up power supply and wait

at least 15 m inutes BEFORE servicing ANY air bag com ponent. Use caution when working near steering

colum n. Air bag could accidentally deploy at any tim e.

NOTE:T he following disabling sequence is ONLY for com ponent replacem ent purposes.

Switch PositionWire ColorVoltage

Off

Headlights OffREDBattery

"All other wires0

Headlights OnRED, RED/GRN,

RED/BLKBattery

"All other wires0

On

Page 1 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 19 of 454

Festiva

Disconnect headlight switch. Using an ohmmeter, place switch in position indicated in table and check continuity between switch terminals

that correspond to wire colors listed. See HEADLIGHT SWITCH CONTINUITY TEST (FESTIVA) table. If switch does not function

indicated, replace switch.

HEADLIGHT SWITCH CONTINUITY TEST (FESTIVA)

IGNITION SWITCH

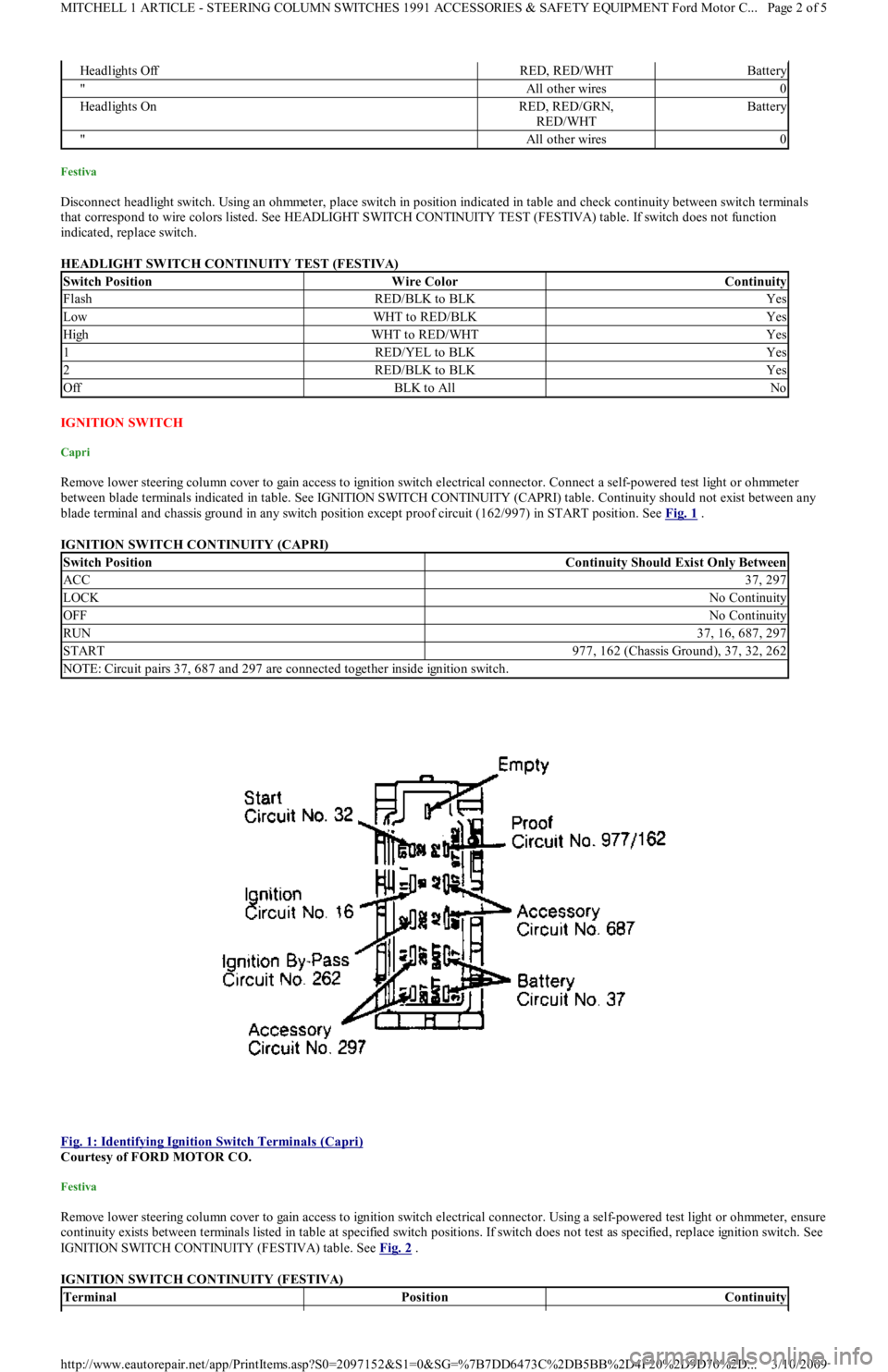

Capri

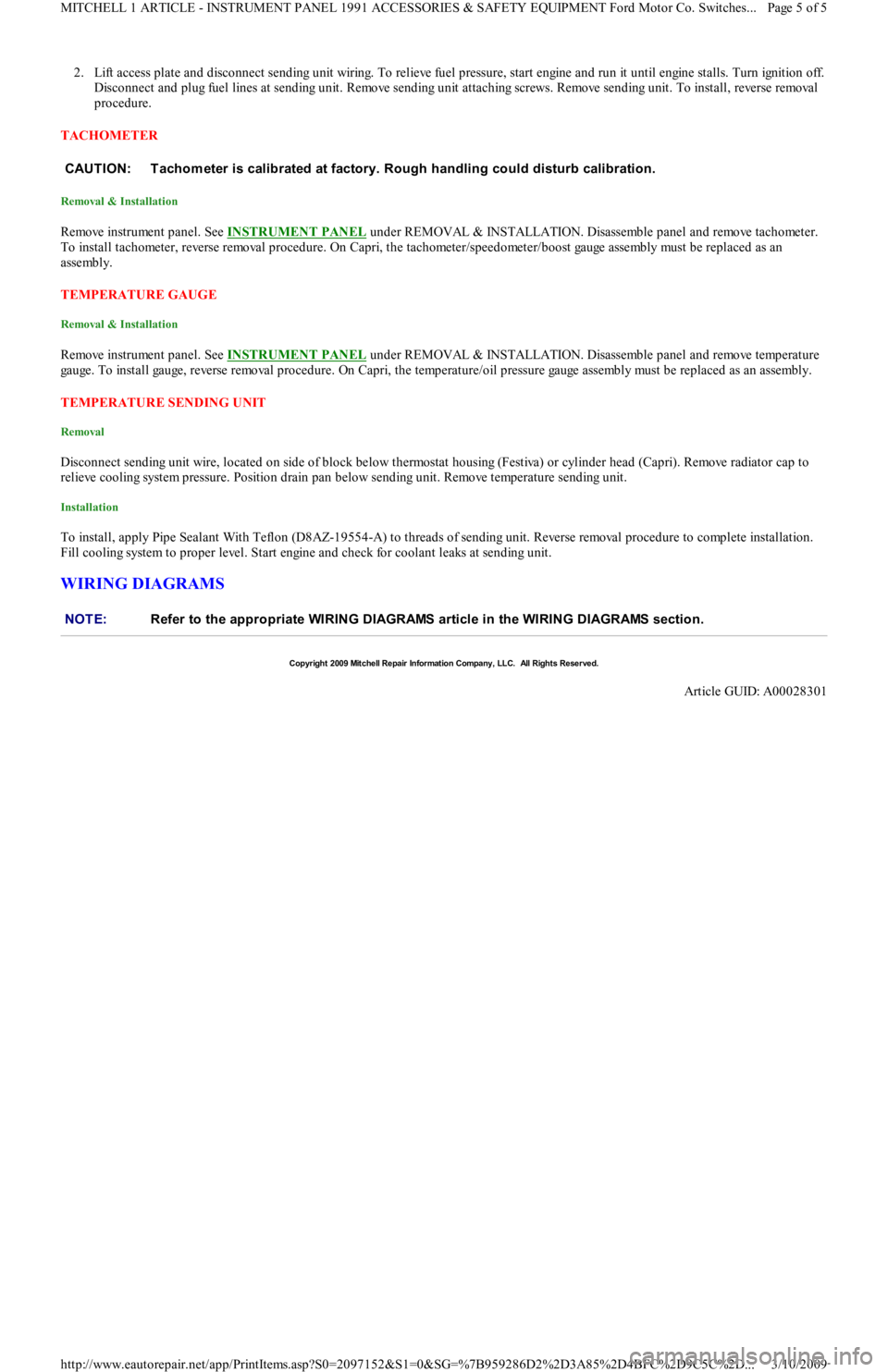

Remove lower steering column cover to gain access to ignition switch electrical connector. Connect a self-powered test light or ohmmeter

between blade terminals indicated in table. See IGNITION SWITCH CONTINUITY (CAPRI) table. Continuity should not exist between any

blade terminal and chassis ground in any switch position except proof circuit (162/997) in START position. See Fig. 1

.

IGNITION SWITCH CONTINUITY (CAPRI)

Fig. 1: Identifying Ignition Switch Terminals (Capri)

Courtesy of FORD MOTOR CO.

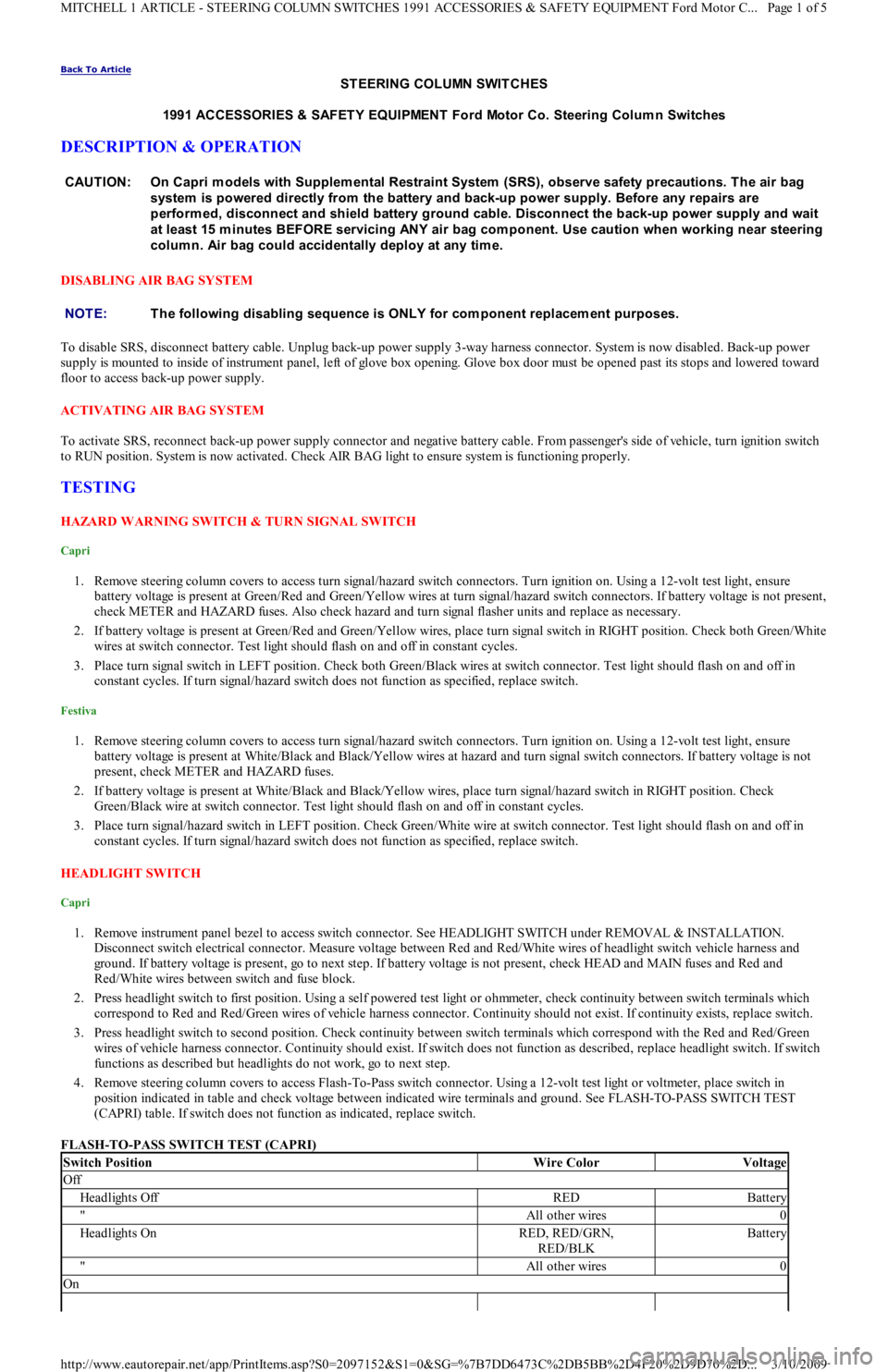

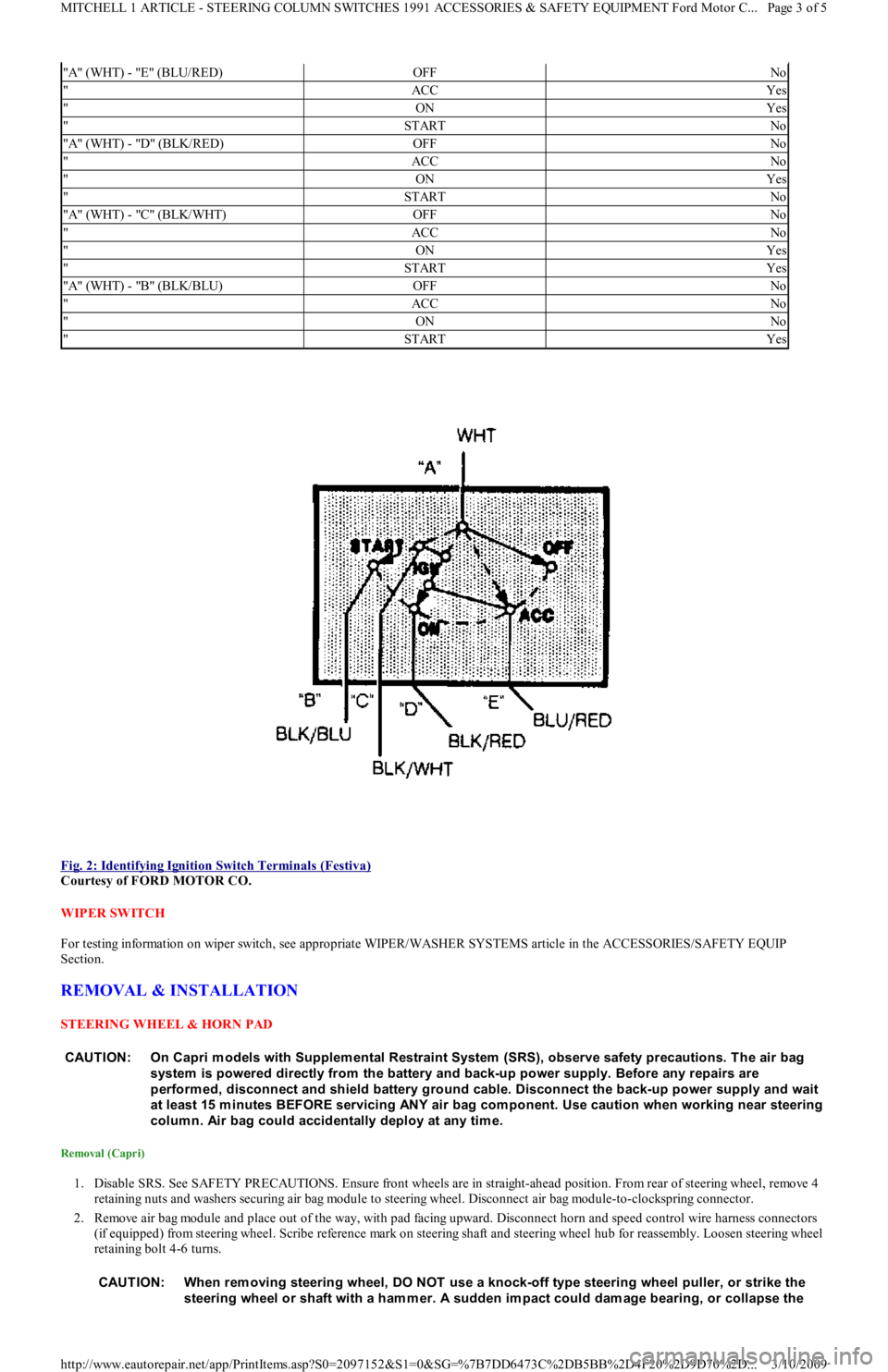

Festiva

Remove lower steering column cover to gain access to ignition switch electrical connector. Using a self-powered test light or ohmmeter, ensure

continuity exists between terminals listed in table at specified switch positions. If switch does not test as specified, replace ignition switch. See

IGNITION SWITCH CONTINUITY (FESTIVA) table. See Fig. 2

.

IGNITION SWITCH CONTINUITY (FESTIVA)

Headlights OffRED, RED/WHTBattery

"All other wires0

Headlights OnRED, RED/GRN,

RED/WHTBattery

"All other wires0

Switch PositionWire ColorContinuity

FlashRED/BLK to BLKYes

LowWHT to RED/BLKYes

HighWHT to RED/WHTYes

1RED/YEL to BLKYes

2RED/BLK to BLKYes

OffBLK to AllNo

Switch PositionContinuity Should Exist Only Between

ACC37, 297

LOCKNo Continuity

OFFNo Continuity

RUN37, 16, 687, 297

START977, 162 (Chassis Ground), 37, 32, 262

NOTE: Circuit pairs 37, 687 and 297 are connected together inside ignition switch.

TerminalPositionContinuity

Page 2 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 20 of 454

Fig. 2: Identifying Ignition Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

WIPER SWITCH

For testing information on wiper switch, see appropriate WIPER/WASHER SYSTEMS article in the ACCESSORIES/SAFETY EQUIP

Section.

REMOVAL & INSTALLATION

STEERING WHEEL & HORN PAD

Removal (Capri)

1. Disable SRS. See SAFETY PRECAUTIONS. Ensure front wheels are in straight-ahead position. From rear of steering wheel, remove 4

retaining nuts and washers securing air bag module to steering wheel. Disconnect air bag module-to-clockspring connector.

2. Remove air bag module and place out of the way, with pad facing upward. Disconnect horn and speed control wire harness connectors

(if equipped) from steering wheel. Scribe reference mark on steering shaft and steering wheel hub for reassembly. Loosen steering wheel

retaining bolt 4-6 turns.

"A" (WHT) - "E" (BLU/RED)OFFNo

"ACCYes

"ONYes

"STARTNo

"A" (WHT) - "D" (BLK/RED)OFFNo

"ACCNo

"ONYes

"STARTNo

"A" (WHT) - "C" (BLK/WHT)OFFNo

"ACCNo

"ONYes

"STARTYes

"A" (WHT) - "B" (BLK/BLU)OFFNo

"ACCNo

"ONNo

"STARTYes

CAUTION: On Capri m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag

system is powered directly from the battery and back-up power supply. Before any repairs are

perform ed, disconnect and shield battery ground cable. Disconnect the back-up power supply and wait

at least 15 m inutes BEFORE servicing ANY air bag com ponent. Use caution when working near steering

colum n. Air bag could accidentally deploy at any tim e.

CAUT ION: When rem oving steering wheel, DO NOT use a knock-off type steering wheel puller, or strike the

steering wheel or shaft with a ham m er. A sudden im pact could dam age bearing, or collapse the

Page 3 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 21 of 454

3. Position Steering Wheel Remover (T67L-3600-A) on steering wheel. Tighten bolt on remover until steering wheel is loose. Remove

steering wheel puller, steering wheel retaining bolt, and steering wheel.

Installation

1. Ensure front wheels are in straight-ahead position. Route clockspring wiring harness through steering wheel opening. Position steering

wheel on steering shaft and align reference marks.

2. Ensure clockspring wire is not pinched when positioning steering wheel. Install new steering wheel retaining bolt and tighten to

specification. See TORQUE SPECIFICATIONS table at end of article. Connect horn and speed control wiring connectors (if equipped)

to steering wheel.

3. Connect air bag module-to-clockspring connector. Install air bag module. Tighten air bag module retaining nuts to specification.

Activate SRS. See SAFETY PRECAUTIONS. Check AIR BAG light to ensure system is functioning properly.

Removal (Festiva)

From back of steering wheel, remove 2 screws securing horn pad. Disconnect horn wire from horn pad and remove pad. Remove steering

wheel nut. Scribe reference mark on steering shaft and steering wheel hub for reassembly. Using Steering Wheel Puller (T67L-3600-A),

remove steering wheel.

Installation

Position steering wheel on steering shaft and align reference marks. Be sure cutouts in rear cover engage turn signal canceling cam. To

complete installation, reverse removal procedure.

COMBINATION SW ITCH

Removal (Capri)

1. Disconnect negative battery cable. Remove lower steering column cover. Remove center access panel and trim cover under steering

column. Remove left side defroster connector tube. Remove steering column upper retaining bolts. Column will pivot downward and

rest on instrument panel brace.

2. Remove 2 switch retaining screws and remove switch. Grasp switch and lever and pull lever out of switch. Disconnect switch electrical

connectors and remove switch.

Installation

Align key with slot and install lever in switch assembly. Position switch on steering column and install retaining screws. To complete

installation, reverse removal procedure.

Removal (Festiva)

1. Disconnect negative battery cable. Remove steering wheel. See STEERING WHEEL & HORN PAD under REMOVAL &

INSTALLATION. Remove 4 screws from upper half of lower steering column cover and remove cover. Remove upper steering column

cover. Remove 5 clips from lower half of lower steering column cover and remove cover.

2. Release wiring harness clip and unplug 4 harness connectors from back of combination switch. From below steering column, loosen

band clamp securing switch hub to steering column jacket. Pull switch assembly from steering column.

Installation

Slide combination switch assembly onto steering column. Make sure switch assembly is seated and level against end of column jacket. To

complete installation, reverse removal procedure.

HEADLIGHT SWITCH

Removal & Installation (Capri)

1. Headlight off/on switch is located on left side of instrument panel bezel. Disconnect negative battery cable. Pull out center storage

compartment. Remove 2 upper screws, 2 lower screws and heater/radio bezel. Pull outward and remove trim covers located on both

sides of steering column.

2. Remove retaining screws and carefully pull instrument panel bezel partially away from dash. Disconnect electrical connector from

headlight switch. Depress tangs on both sides of switch and remove switch from bezel. To install, reverse removal procedure.

IGNITION SWITCH & LOCK CYLINDER

Removal (Capri)

1. Disconnect negative battery cable. Remove lower steering column cover. Remove center access panel and trim cover under steering

column. Remove left side defroster connector tube. Remove steering column upper retaining bolts. Column will pivot downward and

rest on instrument panel brace. steering colum n.

CAUT ION: Rem ove steering wheel carefully to avoid dam aging clockspring wiring, air bag m odule connector, or

accidentally turning clockspring. After steering wheel rem oval, tape clockspring in position to prevent

dam age and keep it from being turned accidentally.

CAUTION: Ensure that no wiring is pinched beneath steering colum n when lowered.

Page 4 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 22 of 454

2. With ignition key inserted in lock assembly, rotate tumbler while pushing release pin with a .125" (3.17 mm) drift punch. Pull tumbler

assembly out of housing. Remove upper column cover. Remove column lock shield. Disconnect ignition switch electrical connector.

Remove switch retaining screws and remove switch.

Installation

Position ignition switch on column lock assembly. Make sure actuator pin of lock assembly fits into slot in ignition switch. To complete

installation, reverse removal procedure.

Removal & Installation (Festiva)

1. Disconnect negative battery cable. Remove 4 screws from upper half of lower steering column cover and remove cover. Remove upper

steering column cover. Remove 5 clips from lower half of lower steering column cover and remove cover.

2. Remove 4 steering column shield nuts and remove shield. Remove 2 shield bracket bolts and remove bracket. Remove air discharge duct

from below steering column. Remove steering column attaching nuts then lower steering column mounting bracket.

3. Remove tie strap securing key warning buzzer switch wires. Remove ignition switch attaching screw. Pull switch loose from switch

housing. Remove switch harness from routing clip and disconnect electrical connectors. Remove switch. To install, reverse removal

procedure.

TURN SIGNAL SWITCH

See COMBINATION SWITCH under REMOVAL & INSTALLATION.

WIPER SWITCH

Removal & Installation (Capri)

Remove center trim panel and lower steering column cover. Disconnect wiper switch electrical connector and pull wiring from routing clip.

Firmly grasp switch and lever and pull out to remove. To install, reverse removal procedure.

Removal & installation (Festiva)

See COMBINATION SWITCH under REMOVAL & INSTALLATION.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS CAUTION: Ensure that no wiring is pinched beneath steering colum n when it is lowered.

ApplicationFt. Lbs. (N.m)

Capri

Column Lock Shield Screw & Nut11-14 (15-19)

Ignition Lock Housing Bolt12-13 (16-18)

Steering Wheel Bolt23-33 (31-45)

Upper Column Retaining Bolts17-23 (23-31)

Festiva

Steering Wheel Nut29-36 (39-49)

Upper Column Retaining Bolts23-34 (31-46)

INCH Lbs. (N.m)

Capri

Ign it io n Swit ch Screw50-70 (5.6-7.9)

Capri & Festiva

Air Bag Module-To-Steering Wheel Nuts35-53 (4-6)

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00028303

Page 5 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 23 of 454

Back To Article

WIPER/WASHER SYST EM

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Wiper/Washer System s

DESCRIPTION & OPERATION

Capri and Festiva vehicles are equipped with a 2-speed wiper motor with an optional intermittent system. The Festiva rear wiper uses a single

speed wiper motor. Washer systems for both front and rear washers use pumps mounted near fluid reservoirs.

ADJUSTMENTS

W IPER ARM ADJUSTMENT

Remove wiper arm and blade assemblies from pivot shafts. Turn wiper switch on and allow wiper motor to cycle 2 to 3 times. Turn wiper

switch off to place pivot shafts in park position. Reinstall wiper arm and blade assemblies with tips of wiper blades at specified distance from

lower edge of windshield. See WIPER BLADE ADJUSTMENT SPECIFICATIONS

table. Tighten wiper arm retaining nut to 89-124

INCH Lbs. (10-14 N.m).

WIPER BLADE ADJUSTMENT SPECIFICATIONS

TESTING

FRONT WIPER MOTOR TEST

Capri

1. Check WIPER fuse in interior fuse block and replace if necessary. Perform FRONT INTERVAL WIPE MODULE TEST . If

wiper/washer switch and interval module are operating properly, disconnect wiper motor connector. Turn ignition on and place

wiper/washer switch in HIGH position. Measure voltage at Blue/Red and Blue wires at wiper motor vehicle harness connector.

2. If battery voltage is not present, check Blue/Red or Blue wire for open circuit. If battery voltage is present at Blue/Red and Blue wires,

check Black ground wire at wiper motor vehicle harness connector for an open circuit and repair as necessary. If Black ground wire is

okay, replace wiper motor.

Festiva

1. Place wiper in any position other than park. Remove WIPER fuse. Disconnect wiper motor electrical connector. Using an ohmmeter,

check for continuity to ground at motor case. Continuity should exist. If continuity does not exist, replace or repair wiper motor ground

strap or wire.

2. Check for continuity to ground at Blue/Black terminal of wiper motor. Continuity should exist. If continuity does not exist, replace

wiper motor.

FRONT INTERVAL WIPE MODULE TEST

Capri

1. Check WIPER fuse in interior fuse block and replace if necessary. Perform FRONT WIPER/WASHER SWITCH TEST . Access

interval wipe module connector. Interval wipe module is located below instrument panel near console. Ensure wiper switch is in OFF

position. Turn ignition on and measure voltage at Blue/White and Blue/Black wires of module connector. Battery voltage should not be

present. Turn wiper switch to LOW position. Measure voltage at Blue/White and Blue/Black wires of module connector. Battery voltage

should be present.

2. Turn wiper switch to HIGH position. Measure voltage at Blue/White, Blue/Black and Blue/Red wires of module connector. Battery

voltage should be present. Turn wiper switch to INT position. Measure voltage at Blue/White and Blue/Black wires of module

connector. Battery voltage should be present during each cycle. If module does not perform as specified, replace module.

Festiva

Information is not available from manufacturer.

FRONT WIPER/WASHER SWITCH TEST

Capri

Remove lower steering column cover to gain access to wiper switch electrical connector. Using an ohmmeter, ensure continuity exists between

terminals listed in table at specified switch positions. If switch does not test as specified, replace wiper/washer switch. See FRONT

WIPER/WASHER SWITCH CONTINUITY (CAPRI) table. See Fig. 1 .

FRONT WIPER/WASHER SWITCH CONTINUITY (CAPRI)

ApplicationIn. (mm)

Capri

Driver Side1.0 (25)

Passenger Side1.26 (32)

Festiva

Both Sides1.0 (25)

Rear(1) 3.15 (80)

(1)From left edge of liftgate window.

TerminalPositionContinuity

Page 1 of 5 MITCHELL 1 ARTICLE - WIPER/WASHER SYSTEM 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor Co. Wip

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 30 of 454

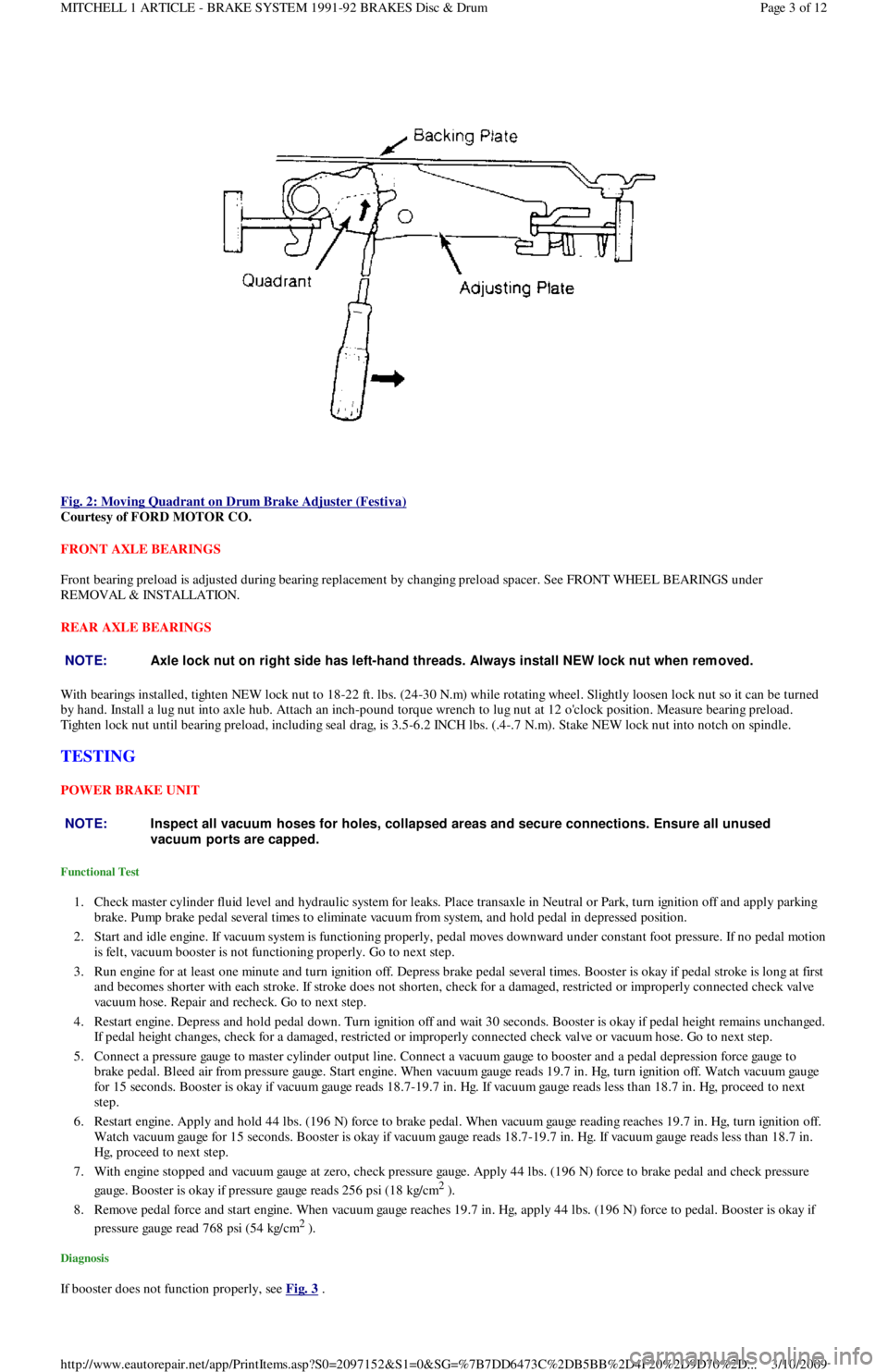

Fig. 2: Moving Quadrant on Drum Brake Adjuster (Festiva)

Courtesy of FORD MOTOR CO.

FRONT AXLE BEARINGS

Front bearing preload is adjusted during bearing replacement by changing preload spacer. See FRONT WHEEL BEARINGS under

REMOVAL & INSTALLATION.

REAR AXLE BEARINGS

With bearings installed, tighten NEW lock nut to 18-22 ft. lbs. (24-30 N.m) while rotating wheel. Slightly loosen lock nut so it can be turned

by hand. Install a lug nut into axle hub. Attach an inch-pound torque wrench to lug nut at 12 o'clock position. Measure bearing preload.

Tighten lock nut until bearing preload, including seal drag, is 3.5-6.2 INCH lbs. (.4-.7 N.m). Stake NEW lock nut into notch on spindle.

TESTING

POWER BRAKE UNIT

Functional Test

1. Check master cylinder fluid level and hydraulic system for leaks. Place transaxle in Neutral or Park, turn ignition off and apply parking

brake. Pump brake pedal several times to eliminate vacuum from system, and hold pedal in depressed position.

2. Start and idle engine. If vacuum system is functioning properly, pedal moves downward under constant foot pressure. If no pedal motion

is felt, vacuum booster is not functioning properly. Go to next step.

3. Run engine for at least one minute and turn ignition off. Depress brake pedal several times. Booster is okay if pedal stroke is long at first

and becomes shorter with each stroke. If stroke does not shorten, check for a damaged, restricted or improperly connected check va l ve

vacuum hose. Repair and recheck. Go to next step.

4. Restart engine. Depress and hold pedal down. Turn ignition off and wait 30 seconds. Booster is okay if pedal height remains unchanged.

If pedal height changes, check for a damaged, restricted or improperly connected check valve or vacuum hose. Go to next step.

5. Connect a pressure gauge to master cylinder output line. Connect a vacuum gauge to booster and a pedal depression force gauge to

brake pedal. Bleed air from pressure gauge. Start engine. When vacuum gauge reads 19.7 in. Hg, turn ignition off. Watch vacuum ga u ge

for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in. Hg, proceed to next

step.

6. Restart engine. Apply and hold 44 lbs. (196 N) force to brake pedal. When vacuum gauge reading reaches 19.7 in. Hg, turn ignition off.

Watch vacuum gauge for 15 seconds. Booster is okay if vacuum gauge reads 18.7-19.7 in. Hg. If vacuum gauge reads less than 18.7 in.

Hg, proceed to next step.

7. With engine stopped and vacuum gauge at zero, check pressure gauge. Apply 44 lbs. (196 N) force to brake pedal and check pressure

gauge. Booster is okay if pressure gauge reads 256 psi (18 kg/cm

2 ).

8. Remove pedal force and start engine. When vacuum gauge reaches 19.7 in. Hg, apply 44 lbs. (196 N) force to pedal. Booster is okay if

pressure gauge read 768 psi (54 kg/cm

2 ).

Diagnosis

If booster does not function properly, see Fig. 3 .

NOTE:Axle lock nut on right side has left-hand threads. Always install NEW lock nut when rem oved.

NOTE:Inspect all vacuum hoses for holes, collapsed areas and secure connections. Ensure all unused

vacuum ports are capped.

Page 3 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...