strut FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 32 of 454

lock nut. Discard axle lock nut. Separate tie rod end from knuckle.

2. Disconnect brake hose from strut (if necessary). Remove brake caliper assembly from knuckle and wire out of way. Remove nuts and

bolts holding ball joint and strut to knuckle assembly.

3. Remove knuckle assembly from ball joint and drive shaft. If binding occurs, use a dual-jawed puller to force knuckle/hub/rotor assembly

off drive axle shaft.

4. Using a puller, separate knuckle from wheel hub. Retain original outer bearing preload spacer to maintain bearing preload setting. If

replacing bearing, change spacer to maintain proper bearing preload (if necessary). See FRONT WHEEL BEARINGS under REMOVAL

& INSTALLATION. Scribe match marks between hub and rotor assembly. Remove rotor-to-hub bolts. Separate hub from rotor.

Installation

Align marks and install rotor on hub. Press knuckle and preload spacer into wheel hub assembly. To complete installation, reverse removal

procedure. Tighten axle shaft lock nut to 117-175 ft. lbs. (159-237 N.m).

REAR BRAKE CALIPER & PADS

Removal (Capri)

1. Raise and support vehicle. Remove tire and wheel assembly. Using needle-nose pliers, remove parking brake return spring. Loosen

parking brake cable housing adjusting nut. Remove cable housing from bracket on lower control arm. Loosen parking brake cable

bracket-to-caliper attaching bolt. Remove parking brake cable from caliper.

2. Remove lower caliper retaining bolt. Pivot caliper upward on upper caliper guide pin. Remove brake pad retaining spring, pads and

shims. If replacing rear brake pads only, reverse removal procedure to install. If removing caliper, proceed to next step.

3. Remove attaching clip from brake flex hose. Remove flex hose banjo bolt from caliper and discard copper washers. Remove lower

caliper retaining bolt. Using a cold chisel, remove upper caliper guide pin dust cap. Using an Allen wrench, remove upper caliper guide

pin. Lift caliper off rotor.

Installation

1. To install, fit brake pads and shims into caliper anchor plate. Remove upper guide pin and lower guide pin bushing from caliper.

Remove guide pin and guide pin bushing dust boots. Lubricate upper guide pin and lower guide pin bushing with Disc Brake Caliper

Slide Grease (D7AZ-19590-A).

2. To complete installation, reverse removal procedure. To fit caliper over new brake pads, it may be necessary to rotate caliper piston into

caliper bore. Use NEW copper washers on flex hose. Bleed brakes, and then pump brake pedal several times to seat pads.

REAR BRAKE ROTOR

Removal & Installation (Capri)

See REAR WHEEL BEARINGS under REMOVAL & INSTALLATION.

REAR BRAKE SHOES

Removal & Installation (Festiva)

Remove brake drum. Remove hold-down springs. Remove return springs. Remove self adjuster. See Fig. 8 . To install, reverse removal

procedure. Apply brake grease to all shoe contact points. See REAR BRAKE SHOES under ADJUSTMENTS.

REAR WHEEL CYLINDER

Removal & Installation (Festiva)

Remove rear brake shoes. Disconnect brake line from wheel cylinder. Remove wheel cylinder. To install, reverse removal procedure. Bleed

brake system.

MASTER BRAKE CYLINDER

Removal

Disconnect low fluid level sensor wiring (if equipped). Drain some brake fluid from reservoir. Disconnect brake lines from master cylinder.

Cap lines and master cylinder ports. Remove attaching nuts and master cylinder.

Installation

To install, reverse removal procedure. Fill master cylinder to proper level and bleed hydraulic system (if necessary).

POWER BRAKE UNIT

Removal & Installation

Remove master cylinder. Disconnect vacuum line. Remove clevis pin at brake pedal. Remove power brake unit. To install, reverse removal

procedure.

FRONT WHEEL BEARINGS NOTE:Hub and rotor are a m atched and balanced assem bly. Before rem oving rotor, locate paint or etch

m ark indicating proper hub-to-rotor alignm ent. If m arks are not present, m ark hub and rotor for

assem bly alignm ent. Failure to properly align hub and rotor can result in an im balance condition.

Page 5 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 38 of 454

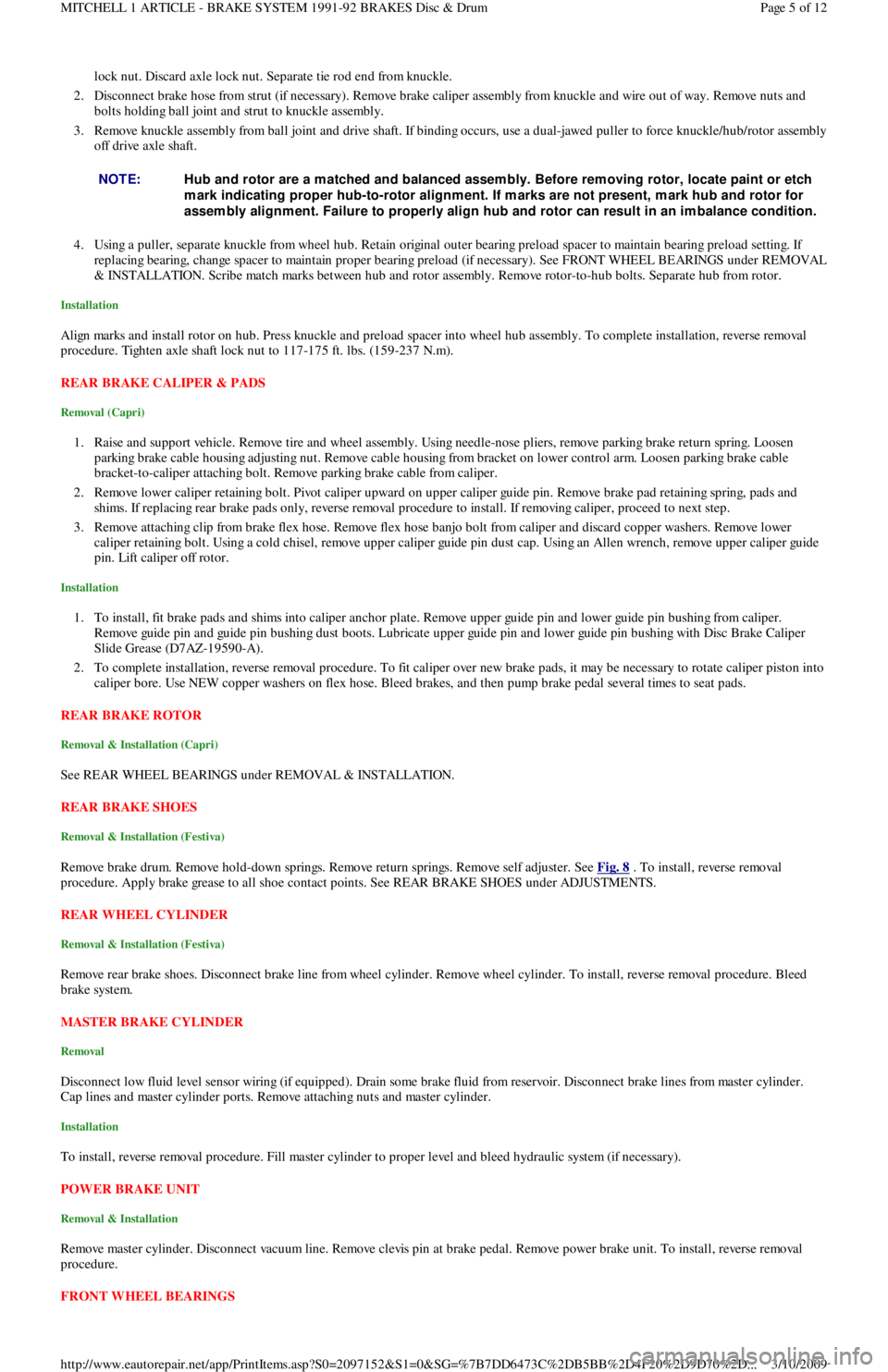

Fig. 12: Exploded View of Master Cylinder (Festiva)

Courtesy of FORD MOTOR CO.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

DISC BRAKE SPECIFICATIONS

DISC BRAKE SPECIFICATIONS

ApplicationFt. Lbs. (N.m)

Backing Plate/Spindle Bolts (Rear)32-45 (43-61)

Brake Hose to Caliper16-22 (22-30)

Caliper Guide/Mounting Bolt29-36 (39-49)

Caliper Banjo Bolt16-21 (22-29)

Front Drive Axle Nut117-175 (159-237)

Hub-To-Rotor Bolt33-40 (45-54)

Power Booster Mounting Nuts

Capri14-19 (19-26)

Festiva12-17 (16-23)

Rear Axle Nut(1)

Rear Strut/Spindle (Capri-Rear)69-86 (93-117)

Rotor-To-Hub Bolts33-40 (44-54)

Steering Knuckle-To-Control Arm32-40 (43-54)

Steering Knuckle-To-Strut69-86 (93-117)

Steering Knuckle-To-Tie Rod21-33 (29-44)

Wheel Lug Nut65-87 (88-118)

INCH Lbs. (N.m)

Master Cylinder-To-Booster Nut89-142 (10-16)

Wheel Cylinder Mounting Bolt89-106 (10-12)

(1)See REAR AXLE BEARINGS under ADJUSTMENTS.

ApplicationIn. (mm)

Capri

Lateral Runout.004 (.1)

Parallelism.004 (.1)

Original Thickness

Front.71 (18)

Rear.39 (10)

Min imu m Refin ish Th ickn ess

Front.660 (16.762)

Rear.384 (9.762)

Discard Thickness

Front.63 (16)

Rear.35 (9)

Page 11 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 42 of 454

Installation (All)

1. To install axle shaft, reverse removal procedure. Always install a NEW retaining circlip. Check seals at both ends of axle shaft. If

necessary, replace seals prior to installation. Lubricate transaxle seal lip with transaxle oil. See Fig. 1

.

2. After installing axle shaft into transaxle, pull axle shaft outward by hand to ensure proper engagement of retaining circlip and snap ring.

Install axle shaft into wheel hub. Align suspension alignment marks and tighten nuts.

INTERMEDIATE SHAFT

Removal

Intermediate shaft and axle shaft are removed as an assembly. See FWD AXLE SHAFTS under REMOVAL, DISASSEMBLY,

REASSEMBLY & INSTALLATION.

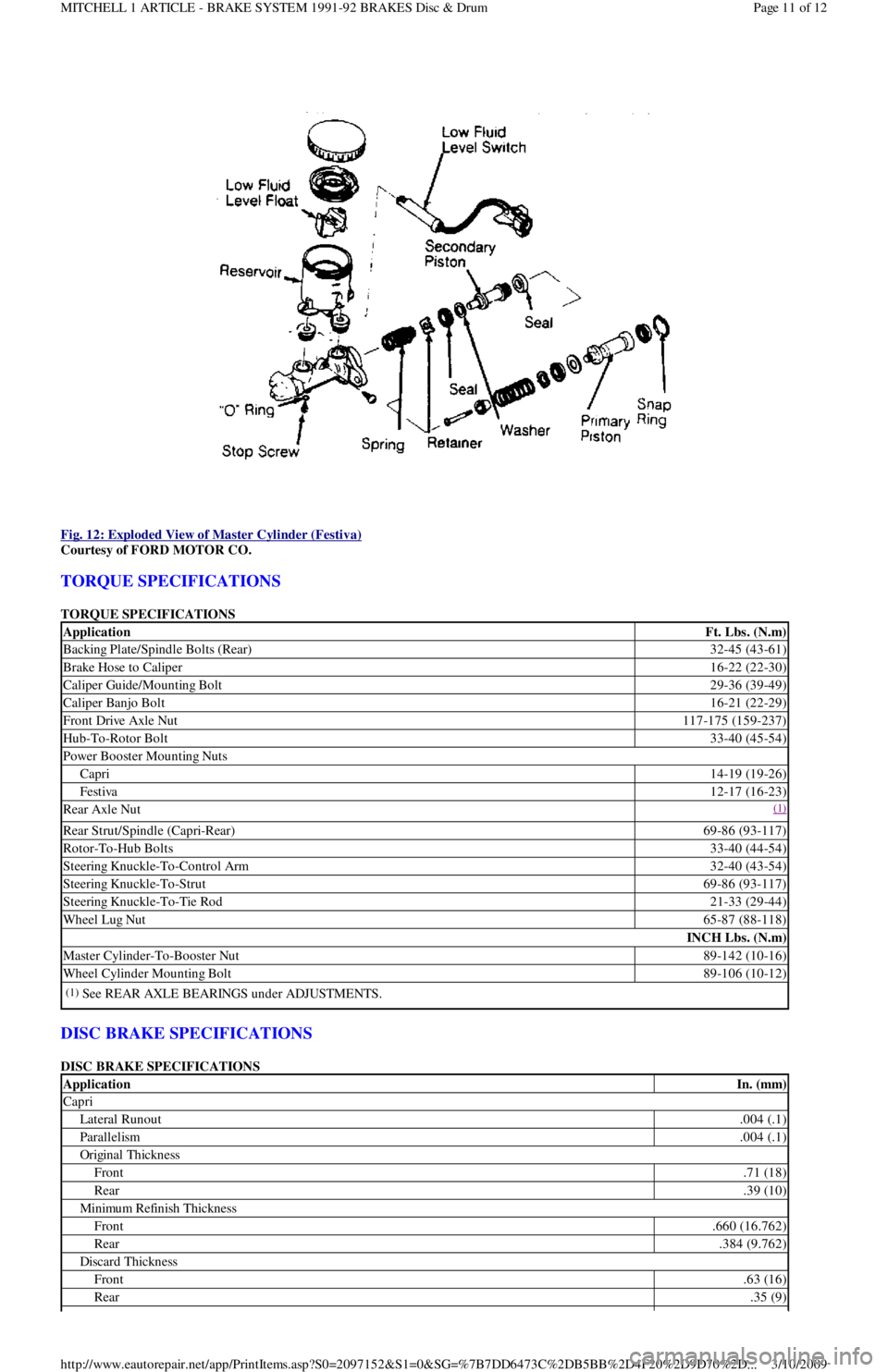

Disassembly

Separate intermediate shaft from axle shaft. Remove circlip from intermediate shaft and press off bearing and bracket assembly. See Fig. 4 .

Press bearing out of bracket. Inspect bracket for damage or wear and replace if necessary.

Reassembly

Press NEW bearing into bracket and install NEW seals. Install bearing and bracket assembly onto intermediate shaft. Install NEW circlip.

Assemble intermediate shaft to axle shaft.

Installation

Intermediate shaft and axle shaft are installed as an assembly. See FWD AXLE SHAFTS under REMOVAL, DISASSEMBLY,

REASSEMBLY & INSTALLATION.

Fig. 4: Exploded View Of Intermediate Shaft

Courtesy of FORD MOTOR CO.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE:Always install NEW cotter pin, washer and suspension lock nuts.

ApplicationFt. Lbs. (N.m)

Axle Nut (1) 116-173 (157-235)

Ball Joint Pinch Bolt32-40 (43-54)

Steering Knuckle-To-Strut Bolt69-86 (93-117)

Caliper Retaining Bolt29-36 (39-49)

Stabilizer Bar Bracket Nut40-50 (54-68)

Stabilizer Link Bolt9-13 (12-18)

Tie Rod End Nut21-32 (29-44)

Wheel Lug Nuts66-89 (90-120)

(1)Ensure locking flange on nut is staked into axle slot.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00042994

Page 3 of 3 MITCHELL 1 ARTICLE - AXLE SHAFTS - FRONT 1988-93 Drive Axles - FWD Axle Shafts

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 46 of 454

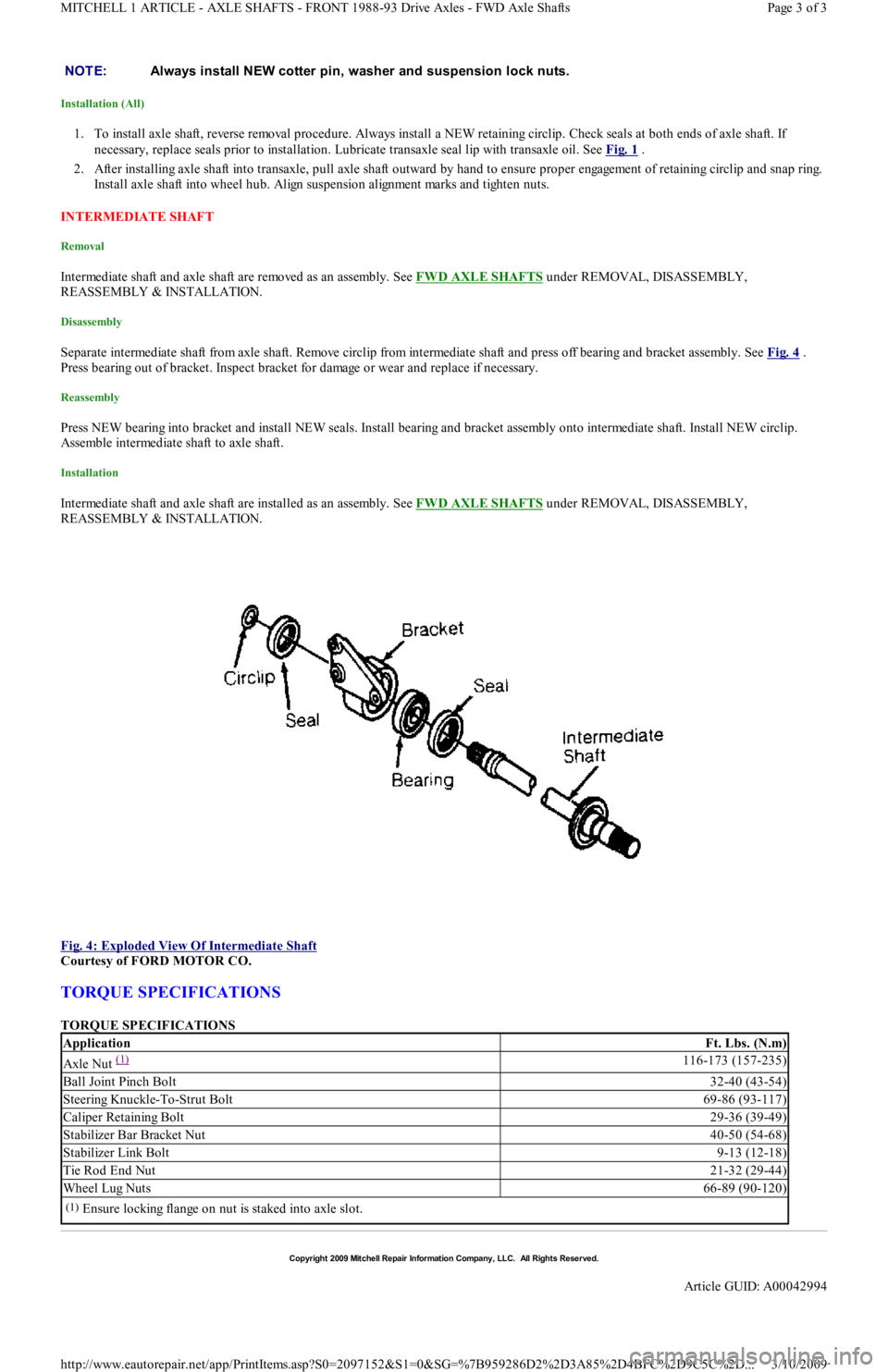

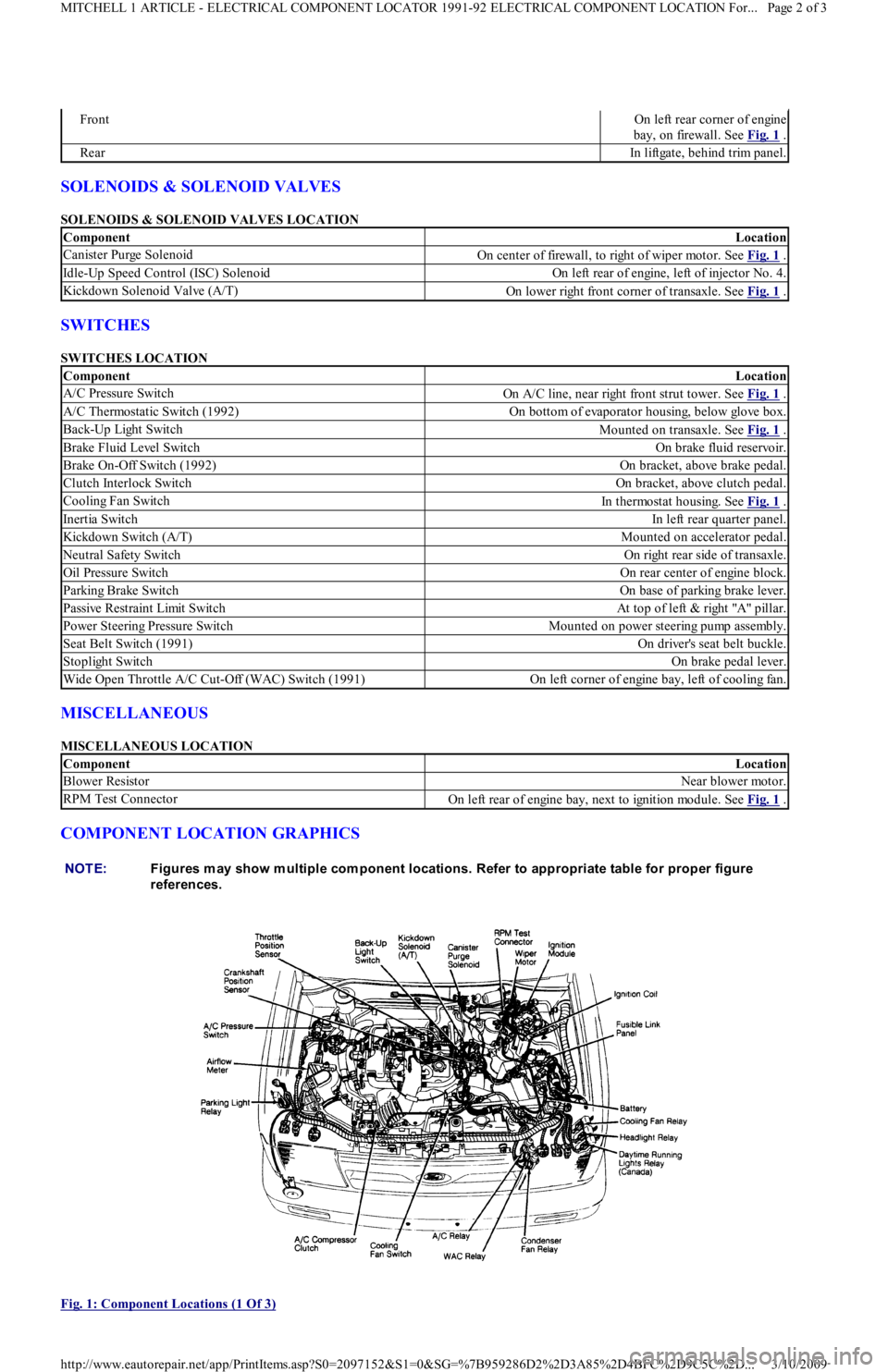

Back To Article

ELECT RICAL COMPONENT LOCAT OR

1991-92 ELECT RICAL COMPONENT LOCAT ION Ford Motor Co. Electrical Com ponents

BUZZERS, RELAYS & TIMERS

BUZZERS, RELAYS & TIMERS LOCATION

CIRCUIT PROTECTION DEVICES

CIRCUIT PROTECTION DEVICES LOCATION

CONTROL UNITS

CONTROL UNITS LOCATION

SENDING UNITS & SENSORS

SENDING UNITS & SENSORS LOCATION

MOTORS

MOTORS LOCATION

ComponentLocation

A/C Clutch Relay (1991)On right front of engine bay, near power

steering pump.

A/C RelayOn left front corner of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2

A/C Wide Open Throttle (WAC) RelayOn left front corner of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2 .

Cooling Fan RelayOn left front fender panel, near

headlight. See Fig. 1

& Fig. 2 .

Condenser Fan RelayOn left front of engine bay, left of

cooling fan. See Fig. 1

& Fig. 2 .

Daytime Running Light (DRL) Relay (Canada) (1992)On left front corner of engine bay, near

headlight. See Fig. 1

.

Fuel Pump RelayBehind left side of dash, near ECA.

Headlight RelayBehind left headlight. See Fig. 1 .

Horn RelayUnder left side of dash. See Fig. 3 .

Main RelayIn left front corner of engine bay, near

battery.

P a r kin g Ligh t R e l a yOn right front corner of engine bay. See

Fig. 1

.

Turn Signal/Flasher RelayUnder left side of dash, behind ECA.

See Fig. 3

.

ComponentLocation

A/C In-Line FuseOn left side of heater case.

Condenser Fan In-Line FuseOn right side of steering column.

Fuse PanelBehind access panel, to left of steering column.

Fusible LinksOn left front strut tower. See Fig. 1 .

ComponentLocation

Electronic Control Assembly (ECA)Behind left side of dash, left of steering column.

Passive Restraint ModuleUnder driver's seat.

ComponentLocation

Airflow MeterOn right front corner of engine bay. See Fig. 1 .

Coolant Temperature Sending UnitBelow thermostat housing.

Crankshaft Position SensorInside distributor. See Fig. 1 .

EGR Temperature Sensor (1991)In exhaust manifold, near EGR valve.

Engine Coolant Temperature (ECT) SensorOn top of engine, near injector No. 1.

Fuel Gauge Sending Unit (1992)In fu el t an k.

Throttle Position Sensor (TPS)On left side of throttle body. See Fig. 1 .

ComponentLocation

Blower MotorUnder center of dash, behind

radio.

Windshield Washer Motors:

Front (1991)On right front fender panel,

bottom of washer reservoir.

Front (1992)On left front corner of engine

bay, in front of battery.

RearOn body panel, behind right

rear quarter panel.

Windshield Wiper Motor

Page 1 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 47 of 454

SOLENOIDS & SOLENOID VALVES

SOLENOIDS & SOLENOID VALVES LOCATION

SWITCHES

SWITCHES LOCATION

MISCELLANEOUS

MISCELLANEOUS LOCATION

COMPONENT LOCATION GRAPHICS

Fig. 1: Component Locations (1 Of 3)

FrontOn left rear corner of engine

bay, on firewall. See Fig. 1

.

RearIn liftgate, behind trim panel.

ComponentLocation

Canister Purge SolenoidOn center of firewall, to right of wiper motor. See Fig. 1 .

Idle-Up Speed Control (ISC) SolenoidOn left rear of engine, left of injector No. 4.

Kickdown Solenoid Valve (A/T)On lower right front corner of transaxle. See Fig. 1 .

ComponentLocation

A/C Pressure SwitchOn A/C line, near right front strut tower. See Fig. 1 .

A/C Thermostatic Switch (1992)On bottom of evaporator housing, below glove box.

Back-Up Light SwitchMounted on transaxle. See Fig. 1 .

Brake Fluid Level SwitchOn brake fluid reservoir.

Brake On-Off Switch (1992)On bracket, above brake pedal.

Clutch Interlock SwitchOn bracket, above clutch pedal.

Cooling Fan SwitchIn thermostat housing. See Fig. 1 .

Inertia SwitchIn left rear quarter panel.

Kickdown Switch (A/T)Mounted on accelerator pedal.

Neutral Safety SwitchOn right rear side of transaxle.

Oil Pressure SwitchOn rear center of engine block.

Parking Brake SwitchOn base of parking brake lever.

Passive Restraint Limit SwitchAt top of left & right "A" pillar.

Power Steering Pressure SwitchMounted on power steering pump assembly.

Seat Belt Switch (1991)On driver's seat belt buckle.

Stoplight SwitchOn brake pedal lever.

Wide Open Throttle A/C Cut-Off (WAC) Switch (1991)On left corner of engine bay, left of cooling fan.

ComponentLocation

Blower ResistorNear blower motor.

RPM Test ConnectorOn left rear of engine bay, next to ignition module. See Fig. 1 .

NOTE:Figures m ay show m ultiple com ponent locations. Refer to appropriate table for proper figure

references.

Page 2 of 3 MITCHELL 1 ARTICLE - ELECTRICAL COMPONENT LOCATOR 1991-92 ELECTRICAL COMPONENT LOCATION For...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 156 of 454

Back To Article

F - BASIC TESTING

1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Procedures

INTRODUCTION

The following diagnostic steps help prevent overlooking simple problems and begin diagnosis for a no-start condition.

The first step in diagnosing any driveability problem is to verify the complaint. Test drive the vehicle under the conditions in which the

problem reportedly occurred.

Before entering self-diagnostics, perform a careful and complete visual inspection. Most engine control problems result from mechanical

breakdowns, poor electrical connections or damaged/misrouted vacuum hoses. Before condemning the computerized system, perform each test

listed in this article.

PRELIMINARY INSPECTION & ADJUSTMENTS

VISUAL INSPECTION

Perform a visual inspection of all electrical wiring. Look for chafed, stretched, cut or pinched wiring. Ensure electrical connections fit tightly

and are not corroded. Ensure vacuum hoses are properly routed and are not cut or pinched. If necessary, see VACUUM DIAGRAMS article in

the ENGINE PERFORMANCE Section to verify routing and connections. Inspect air induction system for possible vacuum leaks.

MECHANICAL INSPECTION

Compression

Engine mechanical condition can be checked using a compression gauge, vacuum gauge or engine analyzer. See engine analyzer instruction

manual for specific instructions. Lowest compression reading must be not less than 75 percent of highest reading.

Exhaust System Backpressure

Exhaust system can be checked with a vacuum gauge or a 0-5 psi pressure gauge. If a pressure gauge is used, remove O2 sensor. Connect gauge

to O2 sensor port. Start engine, and run at 2500 RPM. If exhaust system backpressure is more than 2 psi, exhaust system or catalytic converter

is plugged.

If a vacuum gauge is used, connect it to intake manifold vacuum. Start engine. Observe vacuum gauge. Open throttle part way and hold steady.

If vacuum gauge drops slowly after stabilizing, check exhaust system for a restriction.

FUEL PRESSURE

Fuel Pressure Release

Start engine (if possible), and unplug VAF meter connector. When engine stalls, turn ignition off and reconnect VAF meter wiring. Usin g sh o p

towel, cover fitting to absorb leakage when opening fuel system.

Fuel Pressure Check

1. Connect fuel pressure gauge between fuel filter and fuel rail. Open main valve, and close drain valve. Locate fuel pump check connector

in engine compartment, near left strut. Connect jumper wire between fuel pump test terminals (Black and Green/White wires on Capri

or Black and Green/Red wires on Festiva).

2. Turn ignition on to activate fuel pump. If pump does not run, check fuel pump circuit. If possible, start engine. Measure and record fuel

pressure. For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS

article. Disconnect vacuum from pressure

regulator. Turn engine off. Wait 5 minutes and ensure residual pressure is at least 21 psi (1.5 kg/cm

2 ).

3. Operate fuel pump by reconnecting jumper wire at fuel pump check connector. Check fuel pump performance. Pinch hose between

pressure gauge and fuel filter. Do not hold longer than necessary to check pressure.For fuel pressure specifications, see FUEL

PRESSURE SPECIFICATIONS article. If pump does not meet specifications, check fuel pump circuit, fuel pump, fuel tank and fuel

filter or replace fuel pump.

FUEL PUMP PERFORMANCE NOTE:Unless stated otherwise in test procedure, perform all voltage tests with a Digital Volt-Ohm m eter

(DVOM) with a m inim um 10-m egohm input im pedance.

CAUT ION: DO NOT use ignition switch during com pression tests on fuel injected vehicles. Fuel injectors are

triggered by ignition switch during cranking m ode. Use a rem ote starter to crank engine to prevent fire

hazard and catalytic converter and engine oiling system contam ination.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection system com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

NOTE:For 1991 fuel pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article. For 1992 fuel

pressure specifications, see FUEL PRESSURE SPECIFICAT IONS

article.

ApplicationPressure psi (kg/cm2 )Min. Vol. in 10 sec. Ozs. (cc)

Capri(1) 5.5 (167)

Festiva(1) 7.4 (220)

Page 1 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 243 of 454

POWER STEERING TROUBLE SHOOTING

BASIC POWER STEERING TROUBLE SHOOTING CHART

Steering gear adjustment too looseSee MANUAL STEERING

GEAR article

Steering arms loose on knucklesTighten and check steering

linkage

Rack and pinion mounting looseTighten all mounting bolts

Rack and pinion out of adjustmentSee adjustment in STEERING

article

Tie rod end looseTighten and check steering

linkage

Excessive Pitman shaft-to-ball nut lashRepair as necessary

Poor Returnability

Lack of lubricant in ball joint or linkageLubricate and service systems

Binding in linkage or ball jointsSee STEERING LINKAGE

and SUSPENSION article

Improper front end alignmentSee WHEEL ALIGNMENT

article

Improper tire pressureInflate to proper pressure

Tie rod bindingInflate to proper pressure

Shaft seal rubbing shaftSee STEERING COLUMN

article

Excessive Vertical Motion

Improper tire pressureInflate to proper pressure

Tires, wheels or rotors out of balanceBalance tires then check

wheels and rotors

Worn or faulty shock absorbersCheck and replace if necessary

Loose tie rod ends or steeringTighten or replace if necessary

Loose or worn wheel bearingsSee SUSPENSION article

Steering Pulls to One Side

Improper tire pressureInflate to proper pressure

Front tires are different sizesRotate or replace if necessary

Wheel bearings not adjusted properlySee FRONT SUSPENSION

article

Bent or broken suspension componentsSee FRONT SUSPENSION

article

Improper wheel alignmentSee WHEEL ALIGNMENT

article

Brakes draggingSee BRAKES article

Instability

Low or uneven tire pressureInflate to proper pressure

Loose or worn wheel bearingsSee FRONT SUSPENSION

article

Loose or worn idler arm bushingSee FRONT SUSPENSION

article

Loose or worn strut bushingsSee FRONT SUSPENSION

article

Incorrect front wheel alignmentSee WHEEL ALIGNMENT

article

Steering gear not centeredSee MANUAL STEERING

GEARS article

Springs or shockCheck and replace if necessary

Improper cross shaftSee MANUAL STEERING

GEARS article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Rattle or Chucking Noise

Pressure hoses touching engine partsAdjust to proper clearance

Loose Pitman shaftAdjust or replace if necessary

Tie rods ends or Pitman arm looseTighten and check system

Rack and pinion mounts looseTighten all mounting bolts

Free play in worm gearSee POWER STEERING

GEAR article

Loose sector shaft or thrust bearing adjustmentSee POWER STEERING

GEAR

Free play in pot couplingSee STEERING COLUMN

article

Page 30 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 247 of 454

SUSPENSION TROUBLE SHOOTING

BASIC SUSPENSION TROUBLE SHOOTING CHART

article

Shroud or housing looseTighten holding screws

Lock plate retaining ring not seatedSee STEERING COLUMN

article

Loose sight shieldTighten holding screws

High Steering Shaft Effort

Co l u mn assemb l y misal ign edSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Tight steering universal jointSee STEERING COLUMN

article

High Shift Effort

Column is out of alignmentSee STEERING COLUMN

article

Improperly installed dust shieldAdjust or replace

Seals or bearings not lubricatedSee STEERING COLUMNS

article

Mounting bracket screws too longReplace with new shorter

screws

Burrs on shift tubeRemove burrs or replace tube

Lower bowl bearing assembled wrongSee STEERING COLUMN

article

Shift tube bent or brokenReplace as necessary

Improper adjustment of shift leversSee STEERING COLUMN

article

Improper Trans. Shifting

Sheared shift tube jointReplace as necessary

Sheared lower shaft leverReplace as necessary

Improper shift lever adjustmentSee STEERING COLUMN

article

Improper gate plate adjustmentSee STEERING COLUMN

article

Excess Play in Column

Instrument panel bracket bolts looseTighten bolts and check

bracket

Broken weld nut on jacketSee STEERING COLUMN

article

Instrument bracket capsule shearedSee STEERING COLUMN

article

Column bracket/jacket bolts looseTighten bolts and check

bracket

Steering Locks in Gear

Release lever mechanismSee STEERING COLUMN

article

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Front End Noise

Loose or worn wheelSee Wheel Bearing

Adjustment in SUSPENSION

Worn shocks or shock mountingsReplace struts or strut

mo u n t in gs

Worn struts or strut mountingsReplace struts or strut

mo u n t in gs

Loose or worn lower control armSee SUSPENSION

Loose steering gear-to-frame boltsSee STEERING

Worn control arm bushingsSee SUSPENSION

Ball joints not lubricatedLubricate ball joints & see

Ball Joint Checking in

SUSPENSION

Front Wheel Shake, Shimmy, or Vibration

Tires or wheels out of balanceCheck tire balance

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Drive shaft unbalancedCheck drive shaft balance

Loose or worn wheel bearingsSee WHEEL ALIGNMENT

Loose or worn tie rod endsSee SUSPENSION

Page 34 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 248 of 454

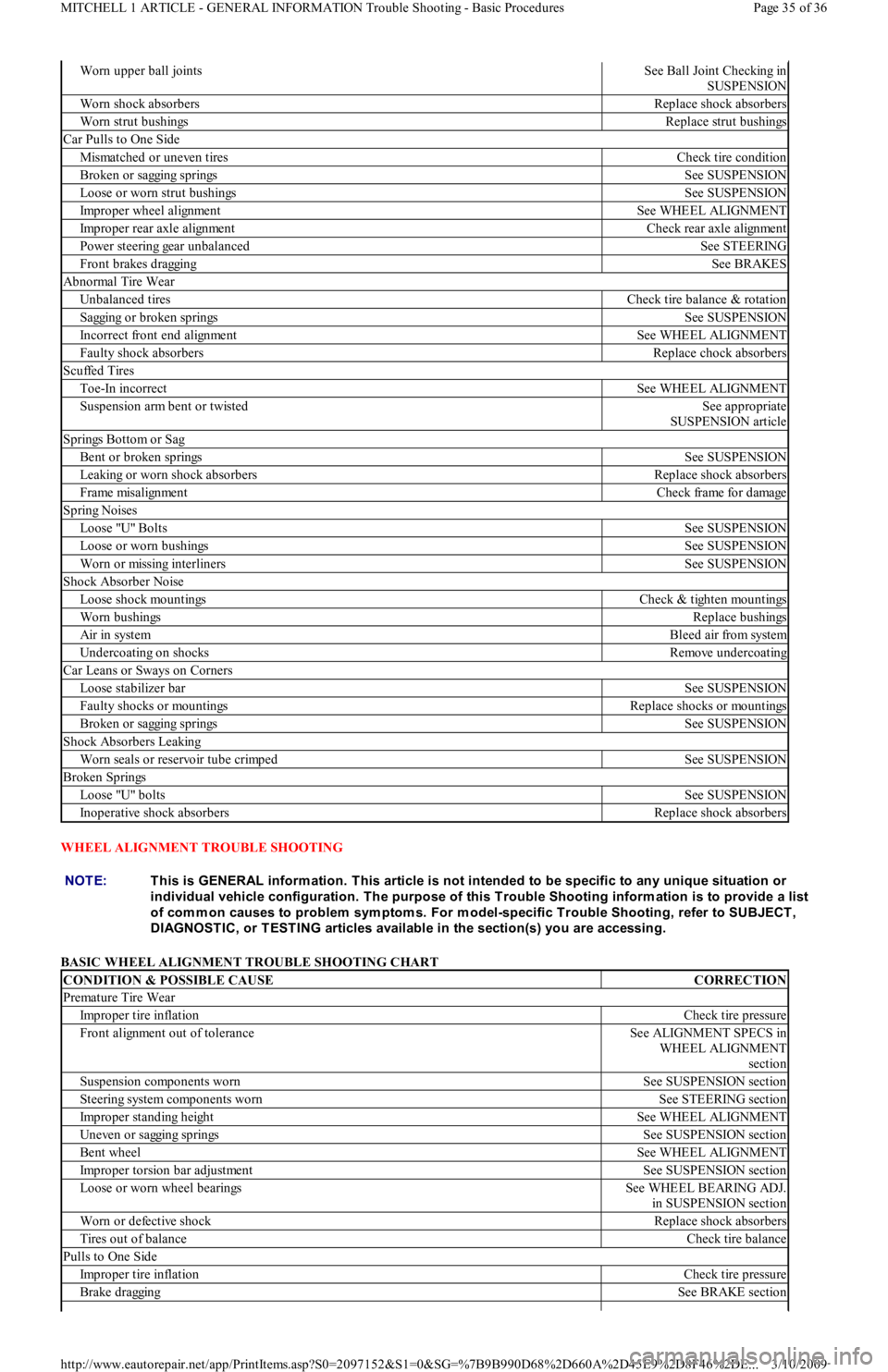

WHEEL ALIGNMENT TROUBLE SHOOTING

BASIC WHEEL ALIGNMENT TROUBLE SHOOTING CHART

Worn upper ball jointsSee Ball Joint Checking in

SUSPENSION

Worn shock absorbersReplace shock absorbers

Worn strut bushingsReplace strut bushings

Car Pulls to One Side

Mismatched or uneven tiresCheck tire condition

Broken or sagging springsSee SUSPENSION

Loose or worn strut bushingsSee SUSPENSION

Improper wheel alignmentSee WHEEL ALIGNMENT

Improper rear axle alignmentCheck rear axle alignment

Power steering gear unbalancedSee STEERING

Front brakes draggingSee BRAKES

Abnormal Tire Wear

Unbalanced tiresCheck tire balance & rotation

Sagging or broken springsSee SUSPENSION

Incorrect front end alignmentSee WHEEL ALIGNMENT

Faulty shock absorbersReplace chock absorbers

Scuffed Tires

Toe-In incorrectSee WHEEL ALIGNMENT

Suspension arm bent or twistedSee appropriate

SUSPENSION article

Springs Bottom or Sag

Bent or broken springsSee SUSPENSION

Leaking or worn shock absorbersReplace shock absorbers

Frame misalignmentCheck frame for damage

Spring Noises

Lo o se "U" Bo l t sSee SUSPENSION

Loose or worn bushingsSee SUSPENSION

Worn or missing interlinersSee SUSPENSION

Shock Absorber Noise

Loose shock mountingsCheck & tighten mountings

Worn bushingsReplace bushings

Air in systemBleed air from system

Undercoating on shocksRemove undercoating

Car Leans or Sways on Corners

Loose stabilizer barSee SUSPENSION

Faulty shocks or mountingsReplace shocks or mountings

Broken or sagging springsSee SUSPENSION

Shock Absorbers Leaking

Worn seals or reservoir tube crimpedSee SUSPENSION

Broken Springs

Lo o se "U" b o l t sSee SUSPENSION

Inoperative shock absorbersReplace shock absorbers

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Premature Tire Wear

Improper tire inflationCheck tire pressure

Front alignment out of toleranceSee ALIGNMENT SPECS in

WHEEL ALIGNMENT

section

Suspension components wornSee SUSPENSION section

Steering system components wornSee STEERING section

Improper standing heightSee WHEEL ALIGNMENT

Uneven or sagging springsSee SUSPENSION section

Bent wheelSee WHEEL ALIGNMENT

Improper torsion bar adjustmentSee SUSPENSION section

Loose or worn wheel bearingsSee WHEEL BEARING ADJ.

in SUSPENSION section

Worn or defective shockReplace shock absorbers

Tires out of balanceCheck tire balance

Pulls to One Side

Improper tire inflationCheck tire pressure

Brake draggingSee BRAKE section

Page 35 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

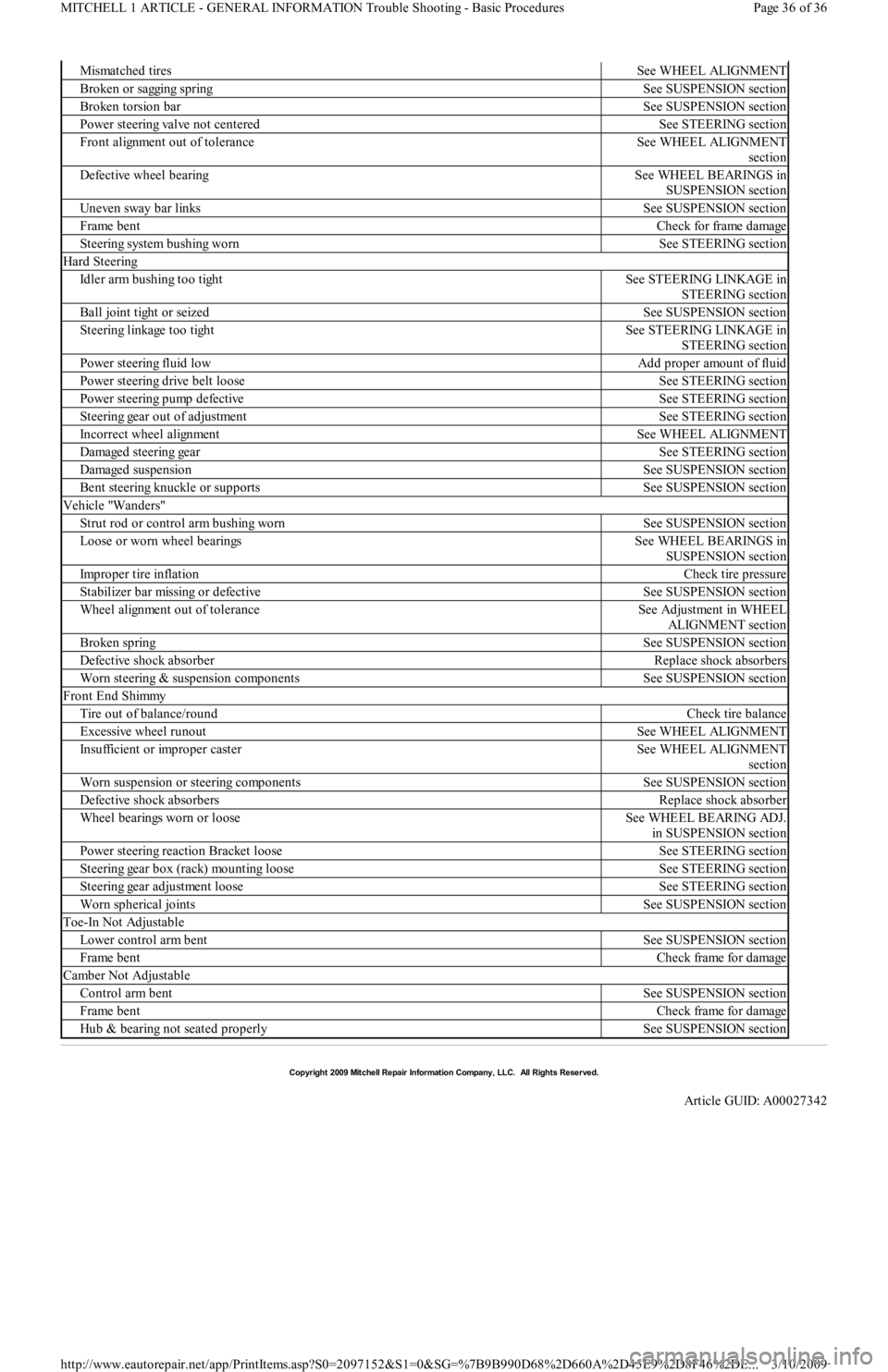

Page 249 of 454

Mismatched tiresSee WHEEL ALIGNMENT

Broken or sagging springSee SUSPENSION section

Broken torsion barSee SUSPENSION section

Power steering valve not centeredSee STEERING section

Front alignment out of toleranceSee WHEEL ALIGNMENT

section

Defective wheel bearingSee WHEEL BEARINGS in

SUSPENSION section

Uneven sway bar linksSee SUSPENSION section

Frame bentCheck for frame damage

Steering system bushing wornSee STEERING section

Hard Steering

Idler arm bushing too tightSee STEERING LINKAGE in

STEERING section

Ball joint tight or seizedSee SUSPENSION section

Steering linkage too tightSee STEERING LINKAGE in

STEERING section

Power steering fluid lowAdd proper amount of fluid

Power steering drive belt looseSee STEERING section

Power steering pump defectiveSee STEERING section

Steering gear out of adjustmentSee STEERING section

Incorrect wheel alignmentSee WHEEL ALIGNMENT

Damaged steering gearSee STEERING section

Damaged suspensionSee SUSPENSION section

Bent steering knuckle or supportsSee SUSPENSION section

Vehicle "Wanders"

Strut rod or control arm bushing wornSee SUSPENSION section

Loose or worn wheel bearingsSee WHEEL BEARINGS in

SUSPENSION section

Improper tire inflationCheck tire pressure

Stabilizer bar missing or defectiveSee SUSPENSION section

Wheel alignment out of toleranceSee Adjustment in WHEEL

ALIGNMENT section

Broken springSee SUSPENSION section

Defective shock absorberReplace shock absorbers

Worn steering & suspension componentsSee SUSPENSION section

Front End Shimmy

Tire out of balance/roundCheck tire balance

Excessive wheel runoutSee WHEEL ALIGNMENT

Insufficient or improper casterSee WHEEL ALIGNMENT

section

Worn suspension or steering componentsSee SUSPENSION section

Defective shock absorbersReplace shock absorber

Wheel bearings worn or looseSee WHEEL BEARING ADJ.

in SUSPENSION section

Power steering reaction Bracket looseSee STEERING section

Steering gear box (rack) mounting looseSee STEERING section

Steering gear adjustment looseSee STEERING section

Worn spherical jointsSee SUSPENSION section

Toe-In Not Adjustable

Lower control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Camber Not Adjustable

Control arm bentSee SUSPENSION section

Frame bentCheck frame for damage

Hub & bearing not seated properlySee SUSPENSION section

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00027342

Page 36 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...