fuses FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 8 of 454

Fig. 2: Rear Window Defogger Wiring Diagram (Festiva)

Courtesy of FORD MOTOR CO.

TROUBLE SHOOTING

DEFOGGER DOES NOT OPERATE

Blown fuse(s) or poor contact. Defogger switch defective. Defogger relay defective. Poor connections. Broken wire. Defective grid filament.

INDICATOR LIGHT DOES NOT WORK BUT DEFOGGER DOES WORK

Open circuit from rear defogger switch to instrument panel (Festiva). Defective light bulb. Defective flexible circuit on instrument cluster.

TESTING

SYSTEM TESTING

1. Ensure all in-line fuses or circuit breakers are okay. Turn ignition and control switches to ON position. Glass should feel warm after a

few min u t es.

2. If glass is not warm, use a test light or voltmeter to check for battery voltage at grid feed wire. If voltage is not correct, check wiring

harness, control switch and flexible circuit on instrument cluster. See FILAMENT TESTING.

REAR DEFOGGER SWITCH TESTING

Capri

Remove rear defogger switch. Using an ohmmeter, ensure continuity exists between terminals listed in table at specified switch positions. If

switch does not test as specified, replace rear defogger switch. See REAR DEFOGGER SWITCH CONTINUITY (CAPRI) table.

REAR DEFOGGER SWITCH CONTINUITY (CAPRI)

Festiva

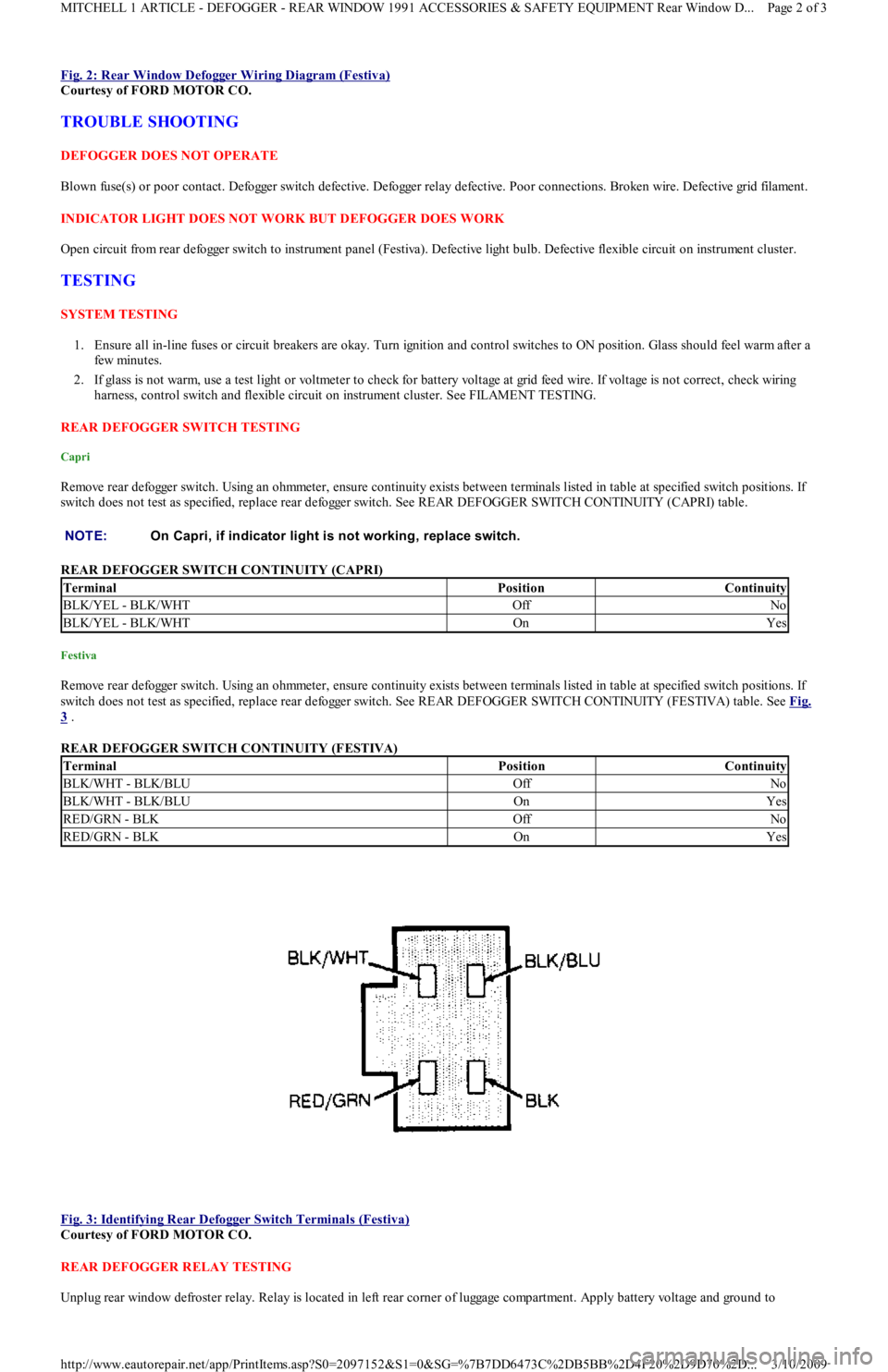

Remove rear defogger switch. Using an ohmmeter, ensure continuity exists between terminals listed in table at specified switch positions. If

switch does not test as specified, replace rear defogger switch. See REAR DEFOGGER SWITCH CONTINUITY (FESTIVA) table. See Fig.

3 .

REAR DEFOGGER SWITCH CONTINUITY (FESTIVA)

Fig. 3: Identifying Rear Defogger Switch Terminals (Festiva)

Courtesy of FORD MOTOR CO.

REAR DEFOGGER RELAY TESTING

Unplug rear window defroster relay. Relay is located in left rear corner of luggage compartment. Apply battery voltage and ground to NOTE:On Capri, if indicator light is not working, replace switch.

TerminalPositionContinuity

BLK/YEL - BLK/WHTOffNo

BLK/YEL - BLK/WHTOnYes

TerminalPositionContinuity

BLK/WHT - BLK/BLUOffNo

BLK/WHT - BLK/BLUOnYes

RED/GRN - BLKOffNo

RED/GRN - BLKOnYes

Page 2 of 3 MITCHELL 1 ARTICLE - DEFOGGER - REAR WINDOW 1991 ACCESSORIES & SAFETY EQUIPMENT Rear Window D

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 18 of 454

Back To Article

ST EERING COLUMN SWIT CHES

1991 ACCESSORIES & SAFET Y EQUIPMENT Ford Motor Co. Steering Colum n Switches

DESCRIPTION & OPERATION

DISABLING AIR BAG SYSTEM

To disable SRS, disconnect battery cable. Unplug back-up power supply 3-way harness connector. System is now disabled. Back-up power

supply is mounted to inside of instrument panel, left of glove box opening. Glove box door must be opened past its stops and lowered toward

floor to access back-up power supply.

ACTIVATING AIR BAG SYSTEM

To activate SRS, reconnect back-up power supply connector and negative battery cable. From passenger's side of vehicle, turn ignition switch

to RUN position. System is now activated. Check AIR BAG light to ensure system is functioning properly.

TESTING

HAZARD WARNING SWITCH & TURN SIGNAL SWITCH

Capri

1. Remove steering column covers to access turn signal/hazard switch connectors. Turn ignition on. Using a 12-volt test light, ensure

battery voltage is present at Green/Red and Green/Yellow wires at turn signal/hazard switch connectors. If battery voltage is not present,

check METER and HAZARD fuses. Also check hazard and turn signal flasher units and replace as necessary.

2. If battery voltage is present at Green/Red and Green/Yellow wires, place turn signal switch in RIGHT position. Check both Green/White

wires at switch connector. Test light should flash on and off in constant cycles.

3. Place turn signal switch in LEFT position. Check both Green/Black wires at switch connector. Test light should flash on and off in

constant cycles. If turn signal/hazard switch does not function as specified, replace switch.

Festiva

1. Remove steering column covers to access turn signal/hazard switch connectors. Turn ignition on. Using a 12-volt test light, ensure

battery voltage is present at White/Black and Black/Yellow wires at hazard and turn signal switch connectors. If battery voltage is not

present, check METER and HAZARD fuses.

2. If battery voltage is present at White/Black and Black/Yellow wires, place turn signal/hazard switch in RIGHT position. Check

Green/Black wire at switch connector. Test light should flash on and off in constant cycles.

3. Place turn signal/hazard switch in LEFT position. Check Green/White wire at switch connector. Test light should flash on and off in

constant cycles. If turn signal/hazard switch does not function as specified, replace switch.

HEADLIGHT SWITCH

Capri

1. Remove instrument panel bezel to access switch connector. See HEADLIGHT SWITCH under REMOVAL & INSTALLATION.

Disconnect switch electrical connector. Measure voltage between Red and Red/White wires of headlight switch vehicle harness and

ground. If battery voltage is present, go to next step. If battery voltage is not present, check HEAD and MAIN fuses and Red and

Red/White wires between switch and fuse block.

2. Press headlight switch to first position. Using a self powered test light or ohmmeter, check continuity between switch terminals which

correspond to Red and Red/Green wires of vehicle harness connector. Continuity should not exist. If continuity exists, replace switch.

3. Press headlight switch to second position. Check continuity between switch terminals which correspond with the Red and Red/Green

wires of vehicle harness connector. Continuity should exist. If switch does not function as described, replace headlight switch. If swit ch

functions as described but headlights do not work, go to next step.

4. Remove steering column covers to access Flash-To-Pass switch connector. Using a 12-volt test light or voltmeter, place switch in

position indicated in table and check voltage between indicated wire terminals and ground. See FLASH-TO-PASS SWITCH TEST

(CAPRI) table. If switch does not function as indicated, replace switch.

FLASH-TO-PASS SWITCH TEST (CAPRI) CAUTION: On Capri m odels with Supplem ental Restraint System (SRS), observe safety precautions. T he air bag

system is powered directly from the battery and back-up power supply. Before any repairs are

perform ed, disconnect and shield battery ground cable. Disconnect the back-up power supply and wait

at least 15 m inutes BEFORE servicing ANY air bag com ponent. Use caution when working near steering

colum n. Air bag could accidentally deploy at any tim e.

NOTE:T he following disabling sequence is ONLY for com ponent replacem ent purposes.

Switch PositionWire ColorVoltage

Off

Headlights OffREDBattery

"All other wires0

Headlights OnRED, RED/GRN,

RED/BLKBattery

"All other wires0

On

Page 1 of 5 MITCHELL 1 ARTICLE - STEERING COLUMN SWITCHES 1991 ACCESSORIES & SAFETY EQUIPMENT Ford Motor C

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 49 of 454

Back To Article

FUSES & CIRCUIT BREAKERS

Fuses & Circuit Breakers 1988-93 Festiva

FUSES & FUSIBLE LINKS

FUSE PANEL & FUSIBLE LINK BLOCK LOCATIONS

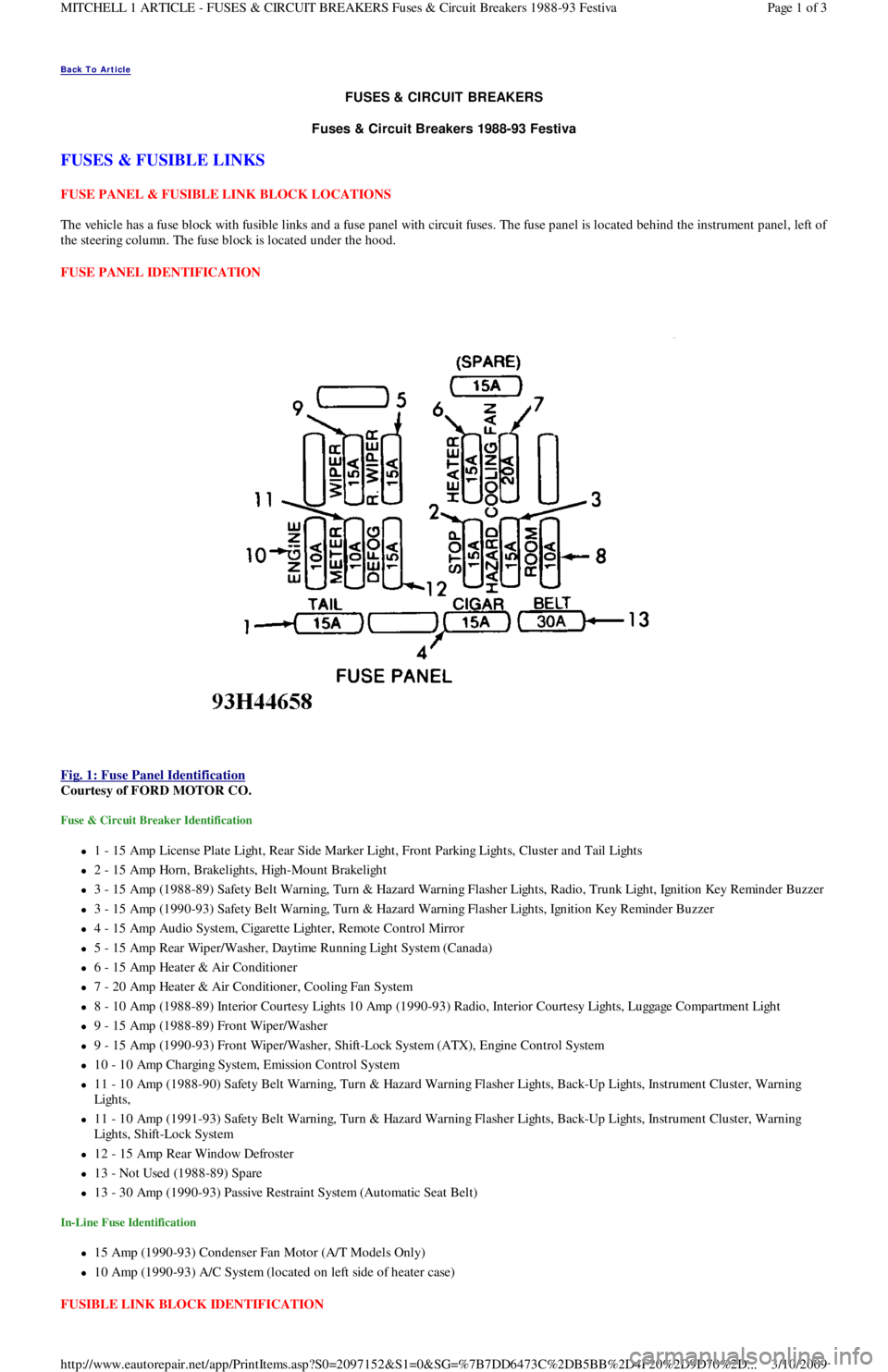

The vehicle has a fuse block with fusible links and a fuse panel with circuit fuses. The fuse panel is located behind the instrument panel, left o

f

the steering column. The fuse block is located under the hood.

FUSE PANEL IDENTIFICATION

Fig. 1: Fuse Panel Identification

Courtesy of FORD MOTOR CO.

Fuse & Circuit Breaker Identification

1 - 15 Amp License Plate Light, Rear Side Marker Ligh t , Fr o n t P a r kin g Ligh t s, C l u st e r a n d Ta il Ligh t s

2 - 15 Amp Horn, Brakelights, High-Mount Brakelight

3 - 15 Amp (1988-89) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Radio, Trunk Light, Ignition Key Reminder Buzzer

3 - 15 Amp (1990-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Ignition Key Reminder Buzzer

4 - 15 Amp Audio System, Cigarette Lighter, Remote Control Mirror

5 - 15 Amp Rear Wiper/Washer, Daytime Running Light System (Canada)

6 - 15 Amp Heater & Air Conditioner

7 - 20 Amp Heater & Air Conditioner, Cooling Fan System

8 - 10 Amp (1988-89) Interior Courtesy Lights 10 Amp (1990-93) Radio, Interior Courtesy Lights, Luggage Compartment Light

9 - 15 Amp (1988-89) Front Wiper/Washer

9 - 15 Amp (1990-93) Front Wiper/Washer, Shift-Lock System (ATX), Engine Control System

10 - 10 Amp Charging System, Emission Control System

11 - 10 Amp (1988-90) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning

Lights,

11 - 10 Amp (1991-93) Safety Belt Warning, Turn & Hazard Warning Flasher Lights, Back-Up Lights, Instrument Cluster, Warning

Lights, Shift-Lock System

12 - 15 Amp Rear Window Defroster

13 - Not Used (1988-89) Spare

13 - 30 Amp (1990-93) Passive Restraint System (Automatic Seat Belt)

In-Line Fuse Identification

15 Amp (1990-93) Condenser Fan Motor (A/T Models Only)

10 Amp (1990-93) A/C System (located on left side of heater case)

FUSIBLE LINK BLOCK IDENTIFICATION

Page 1 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 50 of 454

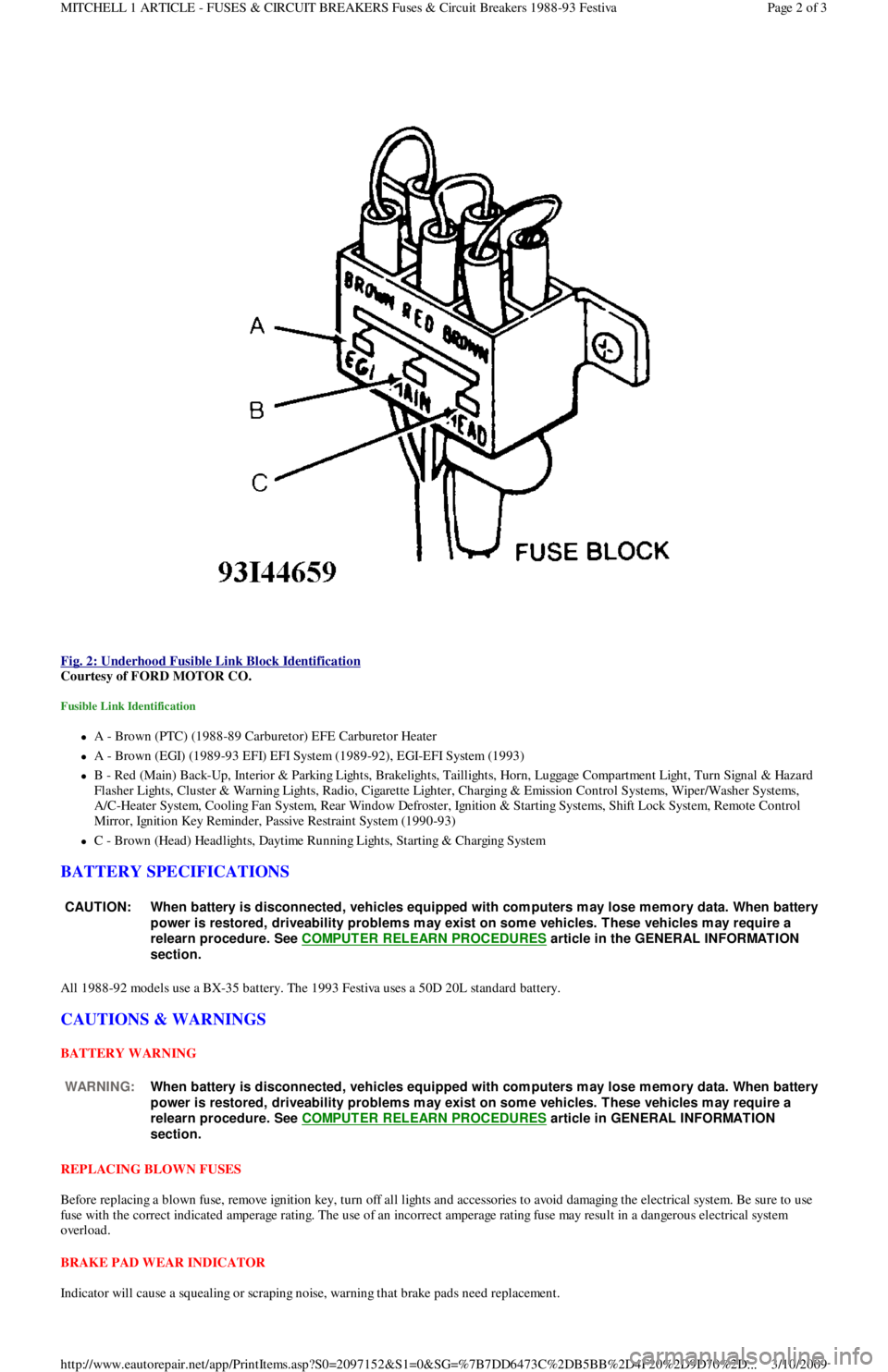

Fig. 2: Underhood Fusible Link Block Identification

Courtesy of FORD MOTOR CO.

Fusible Link Identification

A - Brown (PTC) (1988-89 Carburetor) EFE Carburetor Heater

A - Brown (EGI) (1989-93 EFI) EFI System (1989-92), EGI-EFI System (1993)

B - Red (Main) Back-Up, Interior & Parking Lights, Brakelights, Taillights, Horn, Luggage Compartment Light, Turn Signal & Hazard

F l a sh e r Ligh t s, C l u st e r & Wa r n in g Ligh t s, R a d io , C iga r e t t e Ligh t e r , C h a r gin g & E missio n C o n t r o l S yst e ms, Wip e r / Wa sh e r S yst e ms,

A/C-Heater System, Cooling Fan System, Rear Window Defroster, Ignition & Starting Systems, Shift Lock System, Remote Control

Mirror, Ignition Key Reminder, Passive Restraint System (1990-93)

C - Brown (Head) Headlights, Daytime Running Lights, Starting & Charging System

BATTERY SPECIFICATIONS

All 1988-92 models use a BX-35 battery. The 1993 Festiva uses a 50D 20L standard battery.

CAUTIONS & WARNINGS

BATTERY WARNING

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off all lights and accessories to avoid damaging the electrical system. Be sure to use

fuse with the correct indicated amperage rating. The use of an incorrect amperage rating fuse may result in a dangerous electrical system

overload.

BRAKE PAD WEAR INDICATOR

Indicator will cause a squealing or scraping noise, warning that brake pads need replacement.

CAUT ION: When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUTER RELEARN PROCEDURES

article in the GENERAL INFORMAT ION

section.

WARNING:When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUTER RELEARN PROCEDURES

article in GENERAL INFORMAT ION

section.

Page 2 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 51 of 454

CATALYTIC CONVERTER

Continued operation of vehicle with a severe malfunction could cause converter to overheat, resulting in possible damage to converter and

ve h ic l e .

Any modification to the exhaust system on turbo models, which reduces exhaust backpressure, will lead to lean fuel mixtures and excessive

spark advance. This could cause serious engine damage.

ELECTROSTATIC DISCHARGE SENSITIVE (ESD) PARTS

ENGINE OIL

FUEL PUMP SHUTOFF SWITCH

This switch stops flow of fuel to engine after a collision. The impact does not have to be great for switch to be triggered. Switch must be reset

after collision. Switch is located under left rear speaker in luggage compartment. Press button to reset switch.

FUEL SYSTEM SERVICE

HALOGEN BULBS

PASSIVE RESTRAINTS

RADIATOR CAP

RADIATOR FAN WARNING:Many solid state electrical com ponents can be dam aged by static electricity (ESD). Som e will display a

warning label, but m any will not. Discharge personal static electricity by touching a m etal ground point

on the vehicle prior to servicing any ESD sensitive com ponent.

CAUT ION: Never use non-detergent or straight m ineral oil.

WARNING:Relieve fuel system pressure prior to servicing any fuel system com ponent (fuel injection m odels).

WARNING:Halogen bulbs contain pressurized gas which m ay explode if overheated. DO NOT touch glass portion

of bulb with bare hands. Eye protection should be worn when handling or working around halogen

bulbs.

CAUT ION: Before operating vehicle, securely fasten passive shoulder restraints to the em ergency release buckles.

T he buckle fits in only one way. Ensure to position it properly.

CAUT ION: Always disconnect the fan m otor when working near the radiator fan. T he fan is tem perature controlled

and could start at any tim e even when the ignition key is in the OFF position. DO NOT loosen or rem ove

radiator cap when cooling system is hot.

WARNING:Keep hands away from radiator fan. Fan is controlled by a therm ostatic switch which m ay com e on or

run for up to 15 m inutes even after engine is turned off.

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00058075

Page 3 of 3 MITCHELL 1 ARTICLE - FUSES & CIRCUIT BREAKERS Fuses & Circuit Breakers 1988-93 Festiva

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 214 of 454

Back To Article

GENERAL INFORMATION

T rouble Shooting - Basic Procedures

* PLEASE READ THIS FIRST *

ACCESSORIES & ELECTRICAL

CHARGING SYSTEM TROUBLE SHOOTING

BASIC CHARGING SYSTEM TROUBLE SHOOTING CHART NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Vehicle Will Not Start

Dead batteryCheck battery cells, alternator

belt tension and alternator

output

Loose or corroded battery connectionsCheck all charging system

connections

Ignition circuit or switch malfunctionCheck and replace as necessary

Alternator Light Stays On With Engine Running

Loose or worn alternator drive beltCheck alternator drive tension

and condition, See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Loose alternator wiring connectionsCheck all charging system

connections

Short in alternator light wiringSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Defective alternator stator or diodesSee Bench Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Alternator Light Stays Off With Ignition Switch ON

Blown fuseSee WIRING DIAGRAMS

Defective alternatorSee Testing in ALTERNATOR

article

Defective indicator light bulb or socketSee Indicator Warning Lights in

STANDARD INSTRUMENTS

in the ACCESSORIES &

EQUIPMENT section

Alternator Light Stays OFF With Ignition Switch ON

Short in alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective rectifier bridgeSee Bench Tests in

ALTERNATOR article

Lights or Fuses Burn Out Frequently

Defective alternator wiringSee On-Vehicle Tests in

ALTERNATOR article

Defective regulatorSee Regulator Check in

ALTERNATOR article

Defective batteryCheck and replace as necessary

Ammeter Gauge Shows Discharge

Loose or worn drive beltCheck alternator drive belt

tension and condition. See Belt

Adjustment in TUNE-UP article

in the TUNE-UP section

Defective wiringCheck all wires and wire

Page 1 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 250 of 454

Back To Article

GENERAL INFORMATION

T ROUBLE SHOOT ING

* PLEASE READ THIS FIRST *

ENGINE PERFORMANCE

TUNE-UP TROUBLE SHOOTING NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

NOTE:T his article is generic in nature and all inform ation does not apply to all vehicles. For vehicle specific

inform ation, see the appropriate articles in the ENGINE PERFORMANCE category.

Problem & Possible CauseAction

Carbon Fouled Plugs

C l o gge d Air Fil t e rReplace Air Filter

Incorrect Idle SpeedReset Idle Speed

Faulty Ignition WiringReplace Ignition Wiring

Sticky Valves/Worn Valve SealCheck Valve Train

Fuel Injection OperationCheck Fuel Injection

Wet/Oil Fouled Plugs

Worn Rings/PistonsOverhaul/Replace Engine

Excessive Cylinder WearOverhaul/Replace Engine

Plug Gap Bridged

Combustion Chamber Carbon DepositsClean Combustion

Chamber

Blistered Electrode

Engine OverheatingCheck Cooling System

Loose Spark PlugsClean/Torque Plugs

Over-Advanced TimingReset Timing

Wrong Plug Heat RangeInstall Correct Plug

Melted Electrodes

Incorrect TimingReset Timing

Burned ValvesReplace Valves

Engine OverheatingCheck Cooling System

Wrong Plug Heat RangeInstall Correct Plug

Engine Won't Start

Loose ConnectionsCheck Connections

No PowerCheck Fuses/Battery

Loose/Worn Timing Belt/Chain/GearsCheck Belt/Chain/Gears

Engine Runs Rough

Leaky/Clogged Fuel InjectorsRepair Fuel Injectors

Leaky/Clogged Fuel LinesRepair Fuel Lines

Clogged Fuel FilterReplace Fuel Filter

Incorrect TimingReset Timing/Check

Advance

Faulty Plugs/WiresReplace Plugs/Wires

Uneven CompressionOverhaul/Replace Engine

Poor Acceleration

Incorrect Ignition TimingReset Timing

Leaky ValvesCheck Compression

Component Failure

Spark ArcingReplace Faulty Part

Defective Pick-Up CoilReplace Pick-Up Coil

Defective Ignition CoilReplace Ignition Coil

Defective Control UnitReplace Control Unit

Ignition Diagnosis By Scope Pattern

All Firing Lines Abnormally High

Retarded Ignition TimingReset Ignition Timing

Lean Air/Fuel MixtureAdjust Fuel Mixture

High Secondary ResistanceRepair Secondary

Ign it io n

All Firing Lines Abnormally Low

Rich Air/Fuel MixtureAdjust Air/Fuel Mixture

Arcing Coil WireReplace Coil Wire

Cracked CoilReplace Coil

Low Coil OutputReplace Coil

Low CompressionCheck/Repair Engine

Page 1 of 3 MITCHELL 1 ARTICLE - GENERAL INFORMATION TROUBLE SHOOTING

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 278 of 454

Back To Article

GENERAL INFORMATION

Parasitic Load Explanation & T est Procedures

* PLEASE READ THIS FIRST *

GENERAL INFORMATION

The term Parasitic Load refers to electrical devices that continue to use or draw current after the ignition switch is turned to OFF position. This

small amount of continuous battery draw is expressed in milliamps (mA). On Chrysler vehicles, a typical Parasitic Load should be no more

than 30 milliamps (0.030 amps). On Ford Motor Co. and General Motors vehicles produced after 1980, a typical Parasitic Load should be no

more than 50 milliamps (0.050 amps).

Vehicles produced since 1980 have memory devices that draw current with ignition off for as long as 20 minutes before shutting down the

Parasitic Drain. When Parasitic Load exceeds normal specifications, the vehicle may exhibit dead battery and no-start condition.

Follow test procedure for checking Parasitic Loads to completion. A brief overview of a suggested test procedure is included along with some

typical Parasitic Load specifications. Refer to GENERAL MOTORS PARASITIC LOAD TABLE chart.

TESTING FOR PARASITIC LOAD

The battery circuit must be opened to connect test switch (shunt) and ammeter into the circuit. When a battery cable is removed, timer circuits

within the vehicle computer are interrupted and immediately begin to discharge. If in doubt about the condition of the ammeter fuse, test it

with an ohmmeter prior to beginning test. An open fuse will show the same reading (00.00) as no parasitic drain. Begin test sequence with the

meter installed and on the 10-amp scale. Select lower scale to read parasitic draw.

CHRYSLER IGNITION OFF DRAW (IOD) TEST

To test for excessive IOD, verify that all electrical accessories are OFF. Turn off all lights, remove ignition key, and close all doors and decklid.

If the vehicle is equipped with electronic accessories (illuminated entry, automatic load leveler, body computer, or high line radio), allow the

system to automatically shut off (time out), up to 3 minutes.

1. Raise the hood and disconnect both battery cables, negative first.

2. Reconnect the negative cable and connect a typical 12-volt test light (low wattage bulb) between the positive cable clamp and the

positive battery post. Remove the engine compartment lamp bulb. If the test light does not light, proceed to step 3

. If the test light does

light, proceed to step, 4

. The test light will indicate IOD greater than 3 amps. After higher amperage IOD has been corrected, proceed to

step 3

.

3. ith 12-volt test light still connected (not lit), connect an ammeter (milliampere scale) between the positive cable clamp and the positive

battery post, disconnect test light, refer to instructions provided with ammeter being used. A reading of 30 milliamperes or less indicates

normal electrical draw. If ammeter reads more than 30 milliamperes, excessive IOD must be corrected.

4. Locate the fuse panel and remove fuses or circuit breakers one at a time, and observe ammeter after each fuse or circuit breaker is

removed. If test light goes out and the reading drops below 30 milliamperes when a certain fuse or circuit breaker is removed, that circuit

may have a defect.

5. If IOD is detected after all fuses and circuit breakers have been removed, disconnect the 60-way connector at the Single Module Engine

Control (SMEC), located outboard of the battery.

6. If excessive IOD is detected after all fused circuits and SMEC have been verified, disconnect the B+ terminal from the alternat o r. If

reading drops below 30 milliamperes, reinstall all fuses and circuit breakers, reconnect B+ terminal at alternator, reconnect battery, and

perform alternator diagnostics.

7. Install engine compartment lamp bulb.

TEST PROCEDURE USING TEST SWITCH

1. Turn ignition off. Remove negative battery terminal cable. Install Disconnect Tool (J-38758) test switch male end to negative battery

cable. Turn test switch knob to OFF position (current through meter). Install negative battery cable to the female end of test switch. NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. For m odel-specific inform ation see appropriate articles where

available.

CAUT ION: Always turn ignition off when connecting or disconnecting battery cables, battery chargers or jum per

cables. DO NOT turn test switch to OFF position (which causes current to run through am m eter or

vehicle electrical system ).

NOTE:Mem ory functions of various accessories m ust be reset after the battery is reconnected.

CAUT ION: IOD greater than 3 am ps m ay dam age m illam pm eter.

Page 1 of 4 MITCHELL 1 ARTICLE - GENERAL INFORMATION Parasitic Load Explanation & Test Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 279 of 454

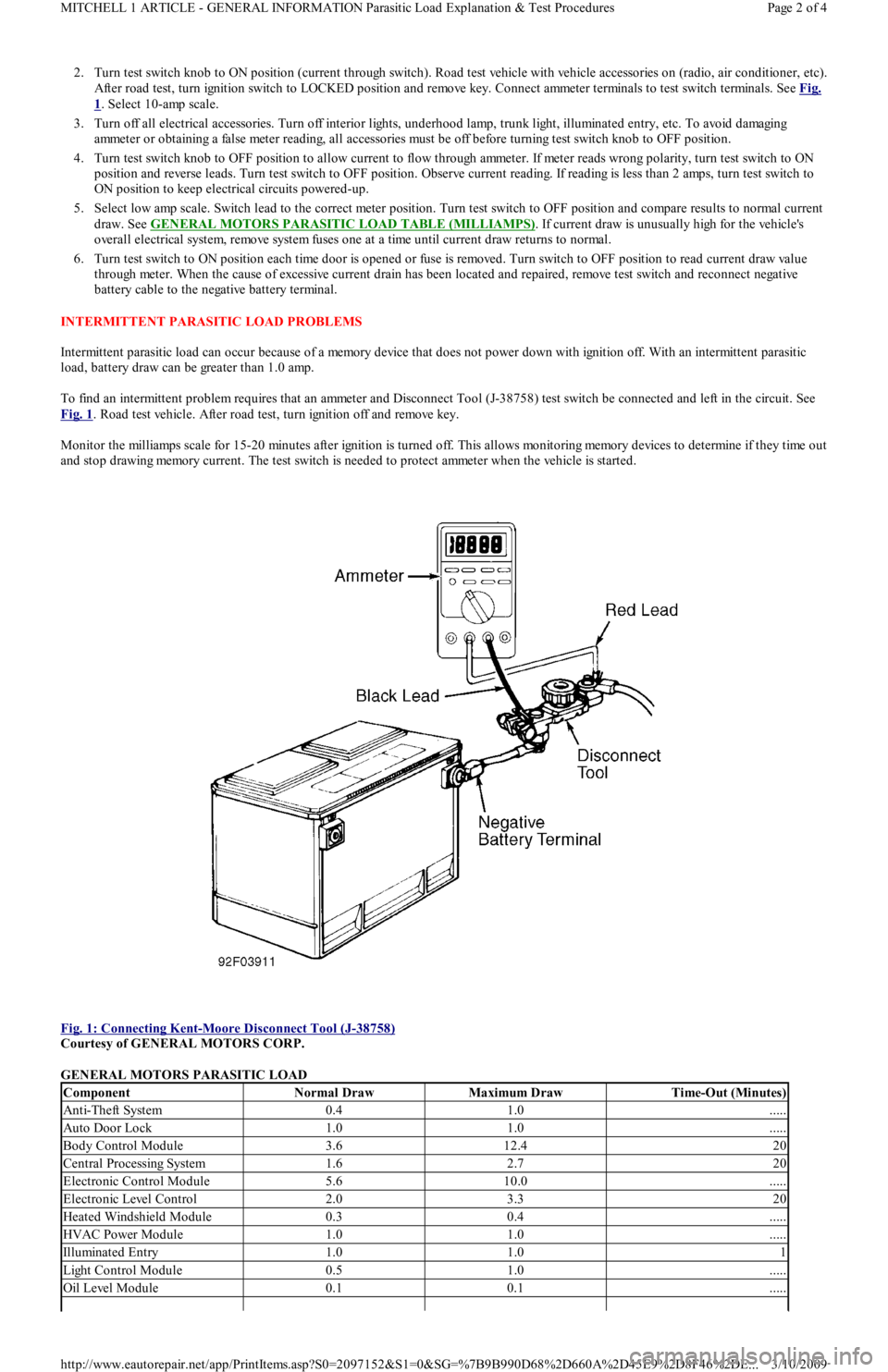

2. Turn test switch knob to ON position (current through switch). Road test vehicle with vehicle accessories on (radio, air conditioner, etc).

After road test, turn ignition switch to LOCKED position and remove key. Connect ammeter terminals to test switch terminals. See Fig.

1. Select 10-amp scale.

3. Turn off all electrical accessories. Turn off interior lights, underhood lamp, trunk light, illuminated entry, etc. To avoid damaging

ammeter or obtaining a false meter reading, all accessories must be off before turning test switch knob to OFF position.

4. Turn test switch knob to OFF position to allow current to flow through ammeter. If meter reads wrong polarity, turn test switch to ON

position and reverse leads. Turn test switch to OFF position. Observe current reading. If reading is less than 2 amps, turn test switch to

ON position to keep electrical circuits powered-up.

5. Select low amp scale. Switch lead to the correct meter position. Turn test switch to OFF position and compare results to normal current

draw. See GENERAL MOTORS PARASITIC LOAD TABLE (MILLIAMPS)

. If current draw is unusually high for the vehicle's

overall electrical system, remove system fuses one at a time until current draw returns to normal.

6. Turn test switch to ON position each time door is opened or fuse is removed. Turn switch to OFF position to read current draw va l u e

through meter. When the cause of excessive current drain has been located and repaired, remove test switch and reconnect negative

battery cable to the negative battery terminal.

INTERMITTENT PARASITIC LOAD PROBLEMS

Intermittent parasitic load can occur because of a memory device that does not power down with ignition off. With an intermittent parasitic

load, battery draw can be greater than 1.0 amp.

To find an intermittent problem requires that an ammeter and Disconnect Tool (J-38758) test switch be connected and left in the circuit. See

Fig. 1

. Road test vehicle. After road test, turn ignition off and remove key.

Monitor the milliamps scale for 15-20 minutes after ignition is turned off. This allows monitoring memory devices to determine if they time out

and stop drawing memory current. The test switch is needed to protect ammeter when the vehicle is started.

Fig. 1: Connecting Kent

-Moore Disconnect Tool (J-38758)

Courtesy of GENERAL MOTORS CORP.

GENERAL MOTORS PARASITIC LOAD

ComponentNormal DrawMaximum DrawTime-Out (Minutes)

Anti-Theft System0.41.0.....

Auto Door Lock1.01.0.....

Body Control Module3.612.420

Central Processing System1.62.720

Electronic Control Module5.610.0.....

Electronic Level Control2.03.320

Heated Windshield Module0.30.4.....

HVAC Power Module1.01.0.....

Illuminated Entry1.01.01

Light Control Module0.51.0.....

Oil Level Module0.10.1.....

Page 2 of 4 MITCHELL 1 ARTICLE - GENERAL INFORMATION Parasitic Load Explanation & Test Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 369 of 454

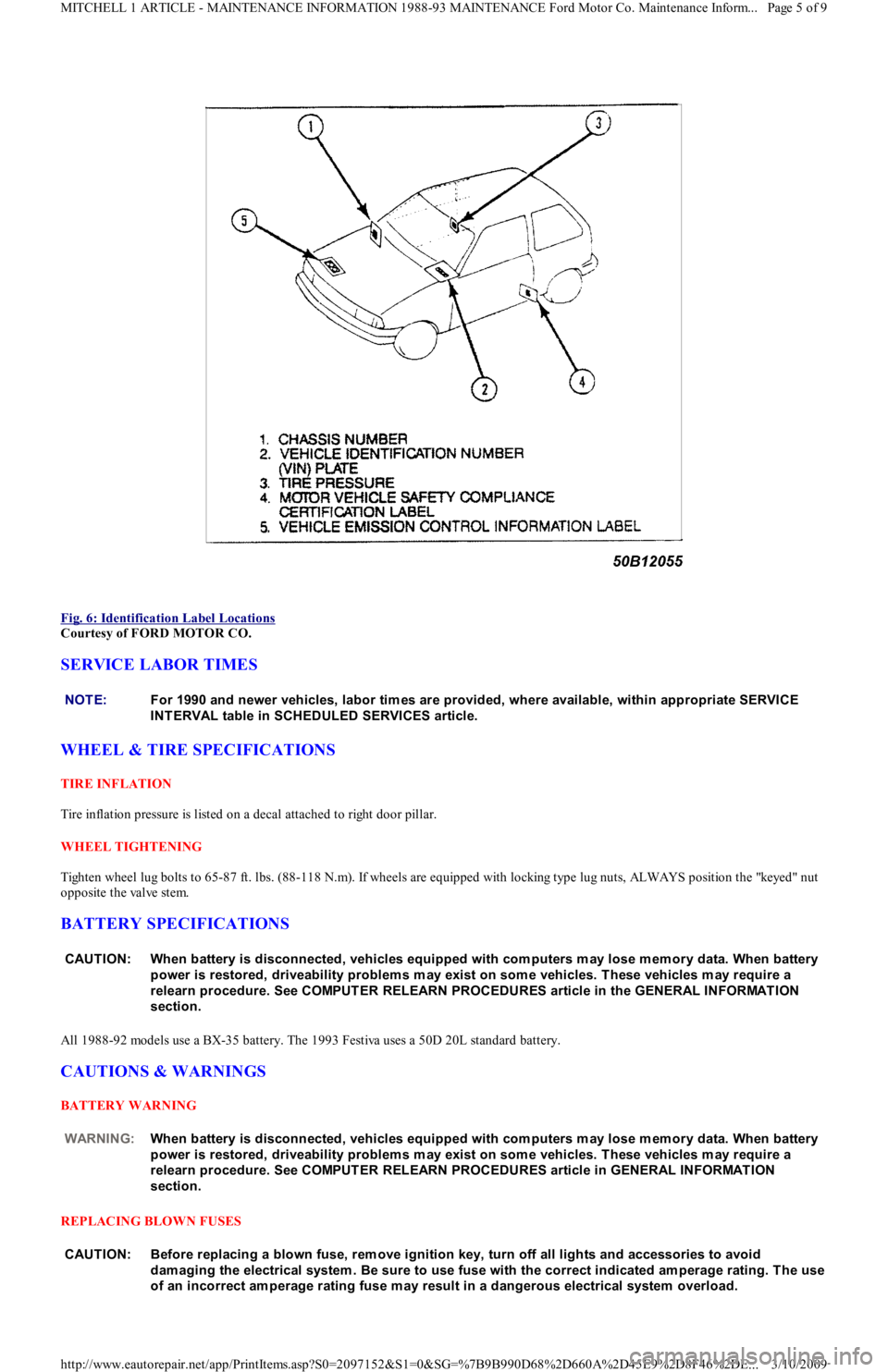

Fig. 6: Identification Label Locations

Courtesy of FORD MOTOR CO.

SERVICE LABOR TIMES

WHEEL & TIRE SPECIFICATIONS

TIRE INFLATION

Tire inflation pressure is listed on a decal attached to right door pillar.

WHEEL TIGHTENING

Tighten wheel lug bolts to 65-87 ft. lbs. (88-118 N.m). If wheels are equipped with locking type lug nuts, ALWAYS position the "keyed" nut

opposite the valve stem.

BATTERY SPECIFICATIONS

All 1988-92 models use a BX-35 battery. The 1993 Festiva uses a 50D 20L standard battery.

CAUTIONS & WARNINGS

BATTERY WARNING

REPLACING BLOWN FUSES

NOTE:For 1990 and newer vehicles, labor tim es are provided, where available, within appropriate SERVICE

INT ERVAL table in SCHEDULED SERVICES article.

CAUT ION: When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUT ER RELEARN PROCEDURES article in the GENERAL INFORMAT ION

section.

WARNING:When battery is disconnected, vehicles equipped with com puters m ay lose m em ory data. When battery

power is restored, driveability problem s m ay exist on som e vehicles. T hese vehicles m ay require a

relearn procedure. See COMPUT ER RELEARN PROCEDURES article in GENERAL INFORMAT ION

section.

CAUT ION: Before replacing a blown fuse, rem ove ignition key, turn off all lights and accessories to avoid

dam aging the electrical system . Be sure to use fuse with the correct indicated am perage rating. T he use

of an incorrect am perage rating fuse m ay result in a dangerous electrical system overload.

Page 5 of 9 MITCHELL 1 ARTICLE - MAINTENANCE INFORMATION 1988-93 MAINTENANCE Ford Motor Co. Maintenance Inform...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...