fuel tank removal FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 48 of 296

23Refer to the procedure in Section 9 when

refitting the camshaft sprocket.

24 Refit and tension the timing belt as

described in Section 8.

25 Lubricate the hydraulic tappets with

hypoid oil before refitting them into their

original locations in the cylinder head.

26 Lubricate and refit the rocker arms and

guides in their original sequence, use new

nuts and tighten them to the specified torque

setting. It is essential, before each rocker arm

is installed and its nut tightened, that the

respective cam follower is positioned at its

lowest point (in contact with the cam base

circle). Turn the cam (using the crankshaft

pulley bolt) as necessary to achieve this.

27 Refit the rocker cover as described in

Section 4.

28 Refit the remaining components with

reference to the relevant Sections in this

Chapter or elsewhere in the manual.

29 On completion, reconnect the battery

negative lead.

12 Cylinder head -

removal and refitting

4

Removal

Note: The following procedure describes

removal and refitting of the cylinder head

complete with inlet and exhaust manifolds. If

wished, the manifolds may be removed first,

as described in the relevant Part of Chapter 4,

and the cylinder head then removed on its

own.

1 On fuel-injected engines, depressurise the

fuel system as described in Chapter 4B or 4C.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Refer to Chapter 1 and drain the cooling

system. 4

Remove the rocker cover as described in

Section 4.

5 Disconnect the accelerator and choke

cables as applicable (refer to the relevant Part

of Chapter 4).

6 Loosen off the retaining clips and

disconnect the upper coolant hose, the

expansion tank hose and the heater hose

from the thermostat housing. Also disconnect

the heater hose from the inlet manifold.

7 On CFi models, disconnect the heated

coolant hose from the injector unit.

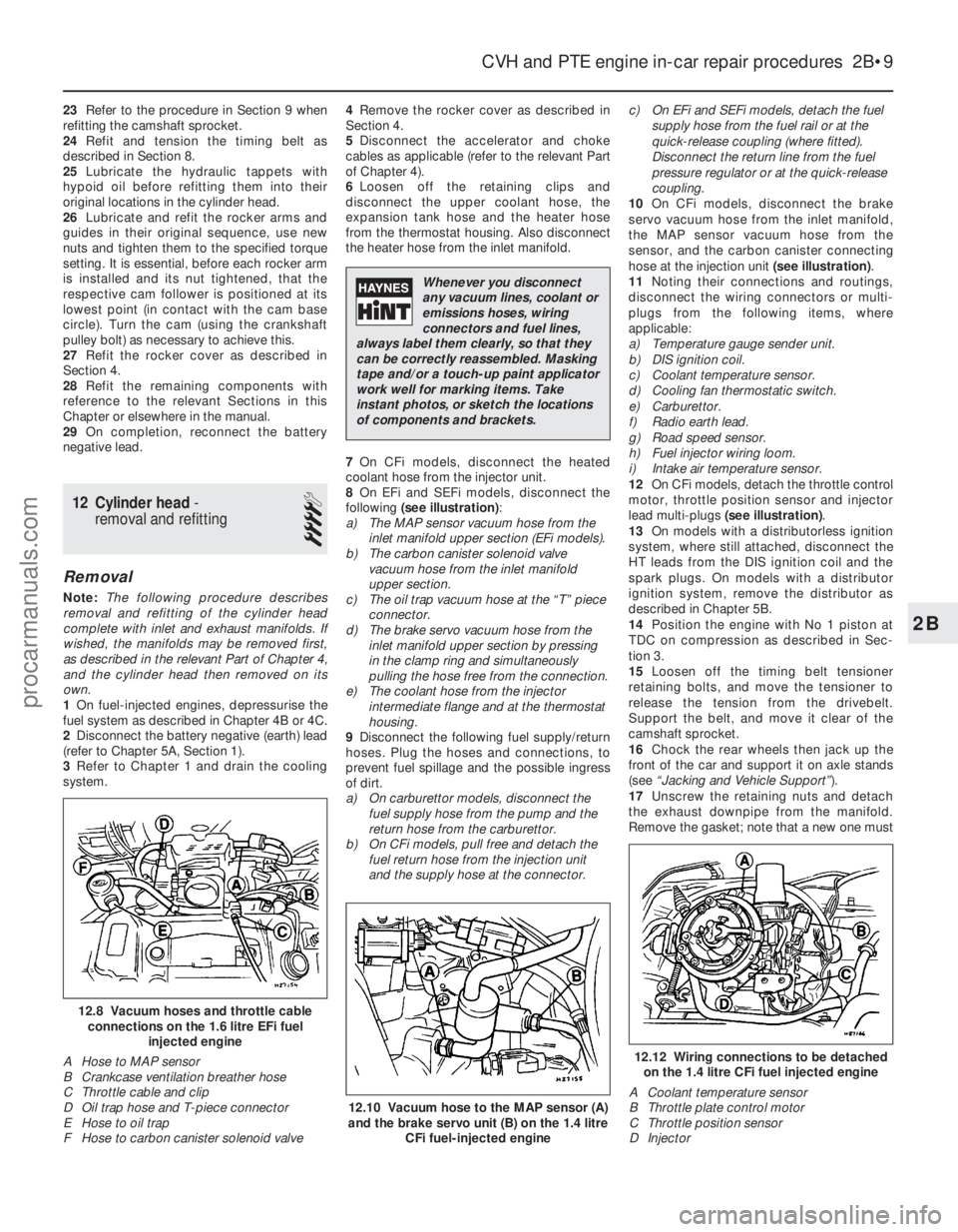

8 On EFi and SEFi models, disconnect the

following (see illustration) :

a) The MAP sensor vacuum hose from the inlet manifold upper section (EFi models).

b) The carbon canister solenoid valve

vacuum hose from the inlet manifold

upper section.

c) The oil trap vacuum hose at the “T” piece

connector.

d) The brake servo vacuum hose from the

inlet manifold upper section by pressing

in the clamp ring and simultaneously

pulling the hose free from the connection.

e) The coolant hose from the injector

intermediate flange and at the thermostat

housing.

9 Disconnect the following fuel supply/return

hoses. Plug the hoses and connections, to

prevent fuel spillage and the possible ingress

of dirt.

a) On carburettor models, disconnect the fuel supply hose from the pump and the

return hose from the carburettor.

b) On CFi models, pull free and detach the

fuel return hose from the injection unit

and the supply hose at the connector. c) On EFi and SEFi models, detach the fuel

supply hose from the fuel rail or at the

quick-release coupling (where fitted).

Disconnect the return line from the fuel

pressure regulator or at the quick-release

coupling.

10 On CFi models, disconnect the brake

servo vacuum hose from the inlet manifold,

the MAP sensor vacuum hose from the

sensor, and the carbon canister connecting

hose at the injection unit (see illustration).

11 Noting their connections and routings,

disconnect the wiring connectors or multi-

plugs from the following items, where

applicable:

a) Temperature gauge sender unit.

b) DIS ignition coil.

c) Coolant temperature sensor.

d) Cooling fan thermostatic switch.

e) Carburettor.

f) Radio earth lead.

g) Road speed sensor.

h) Fuel injector wiring loom.

i) Intake air temperature sensor.

12 On CFi models, detach the throttle control

motor, throttle position sensor and injector

lead multi-plugs (see illustration) .

13 On models with a distributorless ignition

system, where still attached, disconnect the

HT leads from the DIS ignition coil and the

spark plugs. On models with a distributor

ignition system, remove the distributor as

described in Chapter 5B.

14 Position the engine with No 1 piston at

TDC on compression as described in Sec-

tion 3.

15 Loosen off the timing belt tensioner

retaining bolts, and move the tensioner to

release the tension from the drivebelt.

Support the belt, and move it clear of the

camshaft sprocket.

16 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

17 Unscrew the retaining nuts and detach

the exhaust downpipe from the manifold.

Remove the gasket; note that a new one must

CVH and PTE engine in-car repair procedures 2B•9

12.12 Wiring connections to be detached on the 1.4 litre CFi fuel injected engine

A Coolant temperature sensor

B Throttle plate control motor

C Throttle position sensor

D Injector

12.10 Vacuum hose to the MAP sensor (A)

and the brake servo unit (B) on the 1.4 litre

CFi fuel-injected engine

12.8 Vacuum hoses and throttle cableconnections on the 1.6 litre EFi fuel injected engine

A Hose to MAP sensor

B Crankcase ventilation breather hose

C Throttle cable and clip

D Oil trap hose and T-piece connector

E Hose to oil trap

F Hose to carbon canister solenoid valve

2B

1595Ford Fiesta Remake

Whenever you disconnect

any vacuum lines, coolant or

emissions hoses, wiring

connectors and fuel lines,

always label them clearly, so that they

can be correctly reassembled. Masking

tape and/or a touch-up paint applicator

work well for marking items. Take

instant photos, or sketch the locations

of components and brackets.

procarmanuals.com

http://vnx.su

Page 63 of 296

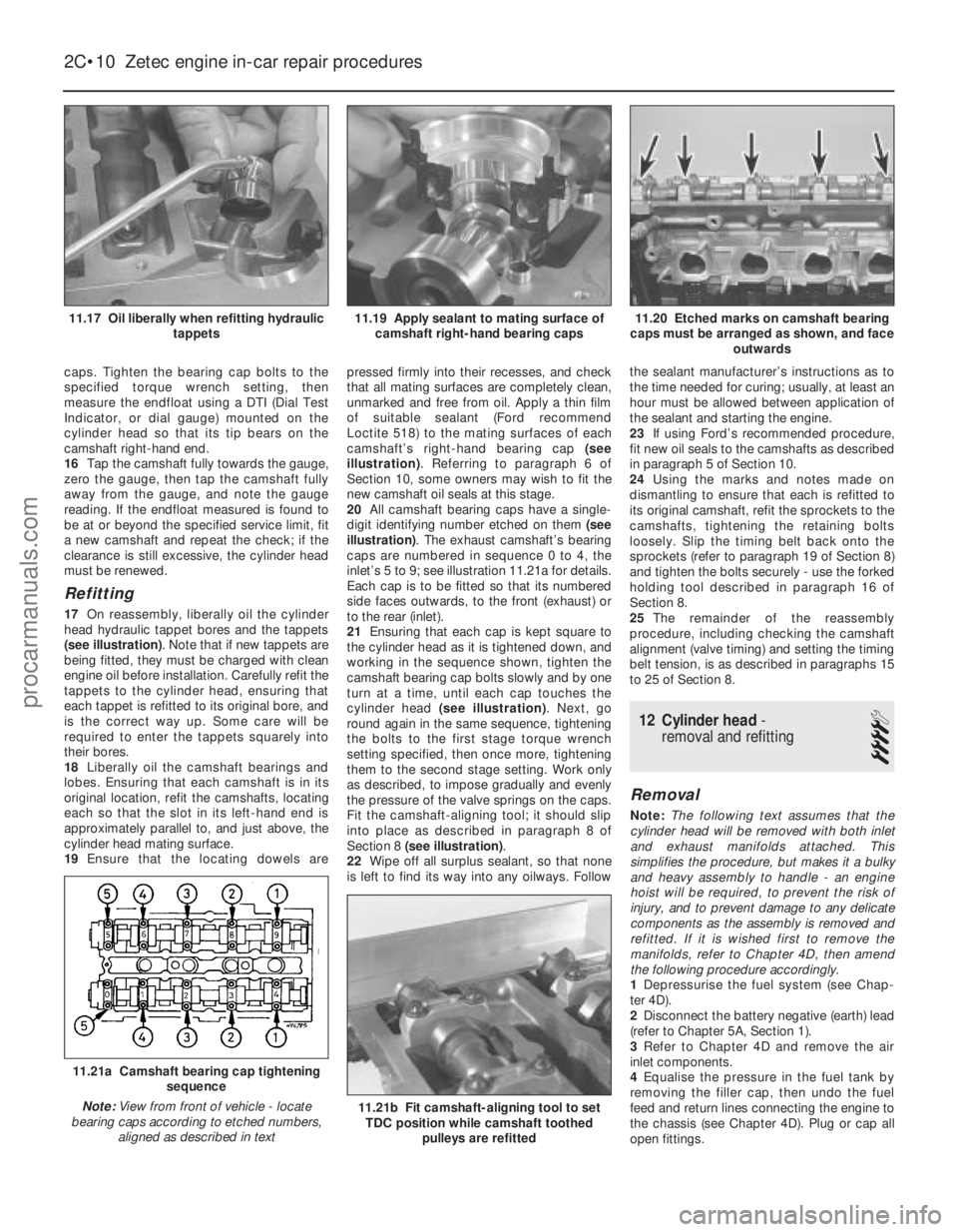

caps. Tighten the bearing cap bolts to the

specified torque wrench setting, then

measure the endfloat using a DTI (Dial Test

Indicator, or dial gauge) mounted on the

cylinder head so that its tip bears on the

camshaft right-hand end.

16Tap the camshaft fully towards the gauge,

zero the gauge, then tap the camshaft fully

away from the gauge, and note the gauge

reading. If the endfloat measured is found to

be at or beyond the specified service limit, fit

a new camshaft and repeat the check; if the

clearance is still excessive, the cylinder head

must be renewed.

Refitting

17 On reassembly, liberally oil the cylinder

head hydraulic tappet bores and the tappets

(see illustration) . Note that if new tappets are

being fitted, they must be charged with clean

engine oil before installation. Carefully refit the

tappets to the cylinder head, ensuring that

each tappet is refitted to its original bore, and

is the correct way up. Some care will be

required to enter the tappets squarely into

their bores.

18 Liberally oil the camshaft bearings and

lobes. Ensuring that each camshaft is in its

original location, refit the camshafts, locating

each so that the slot in its left-hand end is

approximately parallel to, and just above, the

cylinder head mating surface.

19 Ensure that the locating dowels are pressed firmly into their recesses, and check

that all mating surfaces are completely clean,

unmarked and free from oil. Apply a thin film

of suitable sealant (Ford recommend

Loctite 518) to the mating surfaces of each

camshaft’s right-hand bearing cap

(see

illustration) . Referring to paragraph 6 of

Section 10, some owners may wish to fit the

new camshaft oil seals at this stage.

20 All camshaft bearing caps have a single-

digit identifying number etched on them (see

illustration) . The exhaust camshaft’s bearing

caps are numbered in sequence 0 to 4, the

inlet’s 5 to 9; see illustration 11.21a for details.

Each cap is to be fitted so that its numbered

side faces outwards, to the front (exhaust) or

to the rear (inlet).

21 Ensuring that each cap is kept square to

the cylinder head as it is tightened down, and

working in the sequence shown, tighten the

camshaft bearing cap bolts slowly and by one

turn at a time, until each cap touches the

cylinder head (see illustration) . Next, go

round again in the same sequence, tightening

the bolts to the first stage torque wrench

setting specified, then once more, tightening

them to the second stage setting. Work only

as described, to impose gradually and evenly

the pressure of the valve springs on the caps.

Fit the camshaft-aligning tool; it should slip

into place as described in paragraph 8 of

Section 8 (see illustration) .

22 Wipe off all surplus sealant, so that none

is left to find its way into any oilways. Follow the sealant manufacturer’s instructions as to

the time needed for curing; usually, at least an

hour must be allowed between application of

the sealant and starting the engine.

23

If using Ford’s recommended procedure,

fit new oil seals to the camshafts as described

in paragraph 5 of Section 10.

24 Using the marks and notes made on

dismantling to ensure that each is refitted to

its original camshaft, refit the sprockets to the

camshafts, tightening the retaining bolts

loosely. Slip the timing belt back onto the

sprockets (refer to paragraph 19 of Section 8)

and tighten the bolts securely - use the forked

holding tool described in paragraph 16 of

Section 8.

25 The remainder of the reassembly

procedure, including checking the camshaft

alignment (valve timing) and setting the timing

belt tension, is as described in paragraphs 15

to 25 of Section 8.

12 Cylinder head -

removal and refitting

4

Removal

Note: The following text assumes that the

cylinder head will be removed with both inlet

and exhaust manifolds attached. This

simplifies the procedure, but makes it a bulky

and heavy assembly to handle - an engine

hoist will be required, to prevent the risk of

injury, and to prevent damage to any delicate

components as the assembly is removed and

refitted. If it is wished first to remove the

manifolds, refer to Chapter 4D, then amend

the following procedure accordingly.

1 Depressurise the fuel system (see Chap-

ter 4D).

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Refer to Chapter 4D and remove the air

inlet components.

4 Equalise the pressure in the fuel tank by

removing the filler cap, then undo the fuel

feed and return lines connecting the engine to

the chassis (see Chapter 4D). Plug or cap all

open fittings.

2C•10 Zetec engine in-car repair procedures

11.21b Fit camshaft-aligning tool to set TDC position while camshaft toothed

pulleys are refitted

11.21a Camshaft bearing cap tightening sequence

Note: View from front of vehicle - locate

bearing caps according to etched numbers, aligned as described in text

11.20 Etched marks on camshaft bearing

caps must be arranged as shown, and face outwards11.19 Apply sealant to mating surface ofcamshaft right-hand bearing caps11.17 Oil liberally when refitting hydraulic tappets

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 79 of 296

25Unscrew the retaining bolt, and detach

the shift rod stabiliser from the transmission.

As it is detached, note the washer located

between the stabiliser and the transmission.

Tie the stabiliser and the shift rod up out of

the way.

Automatic transmission models

26 Unclip and detach the wiring connector

from the starter inhibitor switch (on the

transmission housing).

27 Referring to the relevant Part of Chapter 4

for details, unhook the accelerator (cam plate)

cable from the carburettor or fuel injection unit

(as applicable) at the transmission end of

the cable. Undo the retaining bolt and

detach the cable sheath bracket from the

transmission. Detach the cam plate cable

from the link.

28 Undo the two nuts from the selector cable

bracket which connects it to the lever on the

selector shaft. Disconnect the yoke from the

lever on the selector shaft and the cable from

the lever.

29 Unscrew the union nuts, and disconnect

the oil cooler feed and return pipes from the

transmission. Allow for a certain amount of

spillage, and plug the connections to prevent

the ingress of dirt.

All models

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Refer to Chapter 10 for details, and

detach the right-hand and left-hand track rod

end balljoints from the spindle carriers.

32 On vehicles fitted with the anti-lock

braking system, refer to Chapter 9 and release

the right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator

bracket.

33 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side, to enable

the driveshaft inboard end to separate

from the transmission. Once it is free,

suspend and support the driveshaft from the

steering gear, to prevent unnecessary strain

being placed on the driveshaft joints.

34 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

35 Proceed as described above in

paragraphs 33 and 34, and disconnect the

left-hand driveshaft from the transmission.

36 Connect a suitable lift hoist and sling to

the engine, connecting to the lifting eyes. When securely connected, take the weight of

the engine/transmission unit so that the

tension is relieved from the mountings.

37

Undo the retaining bolts and nuts and

detach the right-hand engine mounting from

the vehicle body.

38 Undo the four bolts securing the

transmission bearer to the underside of the

vehicle body. The transmission bearer is

removed with the engine/transmission

assembly.

39 Unscrew the three retaining bolts, and

remove the auxiliary drivebelt cover from

under the crankshaft pulley.

40 The engine/transmission unit should now

be ready for removal from the vehicle. Check

that all of the associated connections and

fittings are disconnected from the engine and

transmission, and positioned out of the way.

41 Enlist the aid of an assistant to help

steady and guide the power unit down

through the engine compartment as it is

removed. If available, position a suitable

engine trolley or crawler board under the

engine/transmission so that when lowered,

the power unit can be withdrawn from the

front end of the vehicle, and then moved to

the area where it is to be cleaned and

dismantled. On automatic transmission

models, particular care must be taken not to

damage the transmission fluid pan (sump)

during the removal and subsequent refitting

processes.

42 Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

remove the power unit from under the vehicle.

43 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

44 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1). Components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to inspect the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

45 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting. c) Renew the exhaust flange gasket when

reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system and, on catalytic converter

models, ensure that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to Chapter 1.

h) Refit the alternator and starter motor with reference to Chapter 5A.

i) Where applicable, refit the power steering pump with reference to Chapter 10.

46 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

5 Engine/transmission -

removal and refitting

(Zetec engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs, in or near the work area,

and don’t work in a garage where a

natural-gas appliance (such as a clothes

dryer or water heater) is installed. If you

spill petrol on your skin, rinse it off

immediately. Have a fire extinguisher rated

for petrol fires handy, and know how to

use it.

Note: Read through the entire Section, as well

as reading the advice in Section 2, before

beginning this procedure. The engine and

transmission are removed as a unit, lowered to

the ground and removed from underneath,

then separated outside the vehicle.

Removal

1 Park the vehicle on firm, level ground, apply

the handbrake firmly, and slacken the nuts

securing both front roadwheels.

2 Depressurise the fuel system as described

in Chapter 4D.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

4 Place protective covers on the wings, then

remove the bonnet (see Chapter 11).

5 Drain the cooling system and the engine oil

(see Chapter 1).

6 Remove the air inlet components and the

complete air cleaner assembly as described in

Chapter 4D.

7 Equalise the pressure in the fuel tank by

removing the filler cap, then release the fuel

feed and return quick-release couplings, and

pull the hoses off the fuel pipes. Plug or cap

all open fittings.

2D•10 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 106 of 296

4A

1595Ford Fiesta Remake

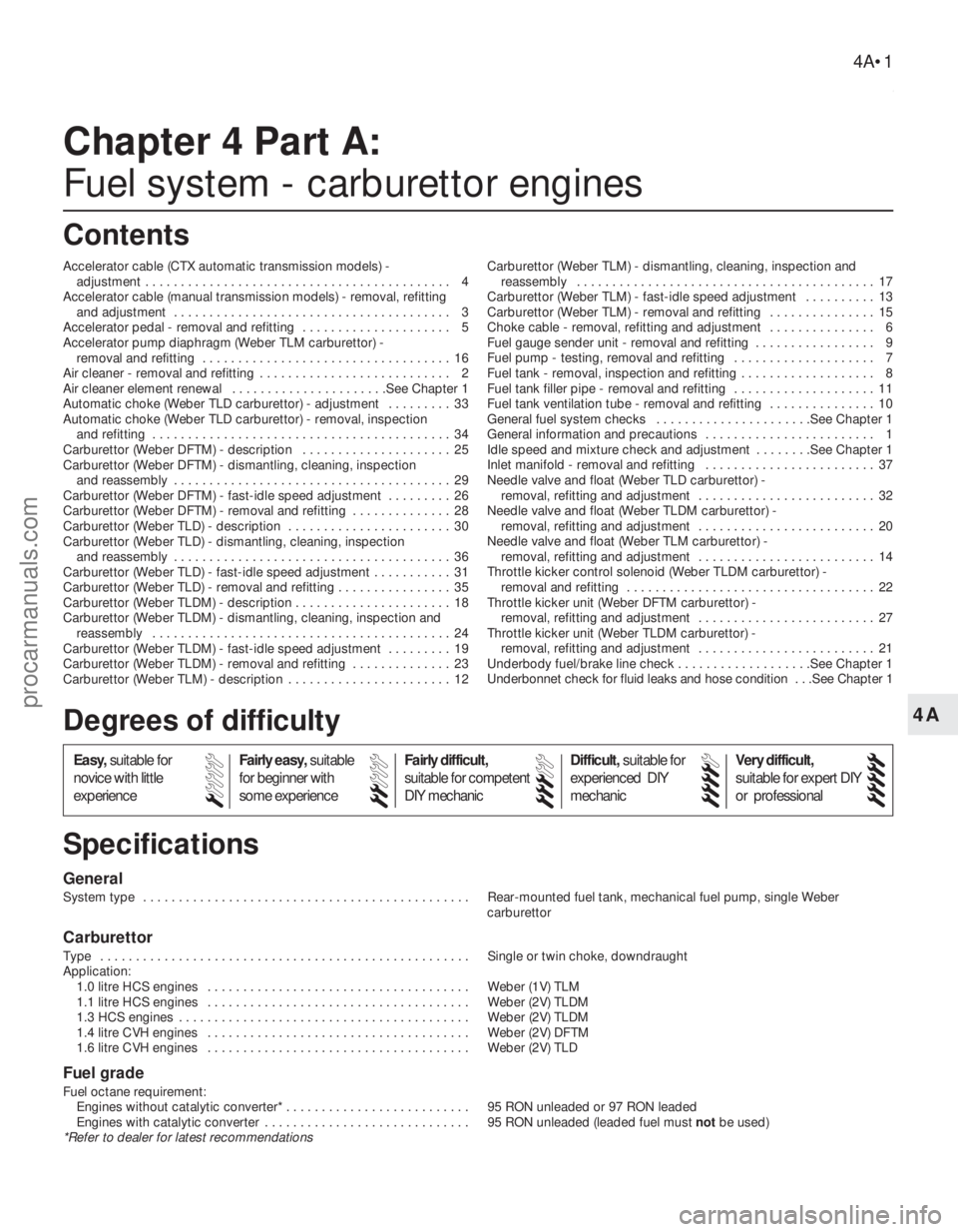

General

System type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . Rear-mounted fuel tank, mechanical fuel pump, single Webercarburettor

Carburettor

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . Single or twin choke, downdraught

Application:1.0 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. Weber (1V) TLM

1.1 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. Weber (2V) TLDM

1.3 HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . Weber (2V) TLDM

1.4 litre CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. Weber (2V) DFTM

1.6 litre CVH engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. Weber (2V) TLD

Fuel grade

Fuel octane requirement:Engines without catalytic converter* . . . . . . . . . . . . . . . . . . . . . . . . . . 95 RON unleaded or 97 RON leaded

Engines with catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 RON unleaded (leaded fuel must notbe used)

*Refer to dealer for latest recommendations

Chapter 4 Part A:

Fuel system - carburettor engines

Accelerator cable (CTX automatic transmission models) -

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 4

Accelerator cable (manual transmission models) - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 3

Accelerator pedal - removal and refitting . . . . . . . . . . . . . . . . . . . . . 5

Accelerator pump diaphragm (Weber TLM carburettor) - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air cleaner - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Air cleaner element renewal . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

Automatic choke (Weber TLD carburettor) - adjustment . . . . . . . . . 33

Automatic choke (Weber TLD carburettor) - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 34

Carburettor (Weber DFTM) - description . . . . . . . . . . . . . . . . . . . . . 25

Carburettor (Weber DFTM) - dismantling, cleaning, inspection and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 29

Carburettor (Weber DFTM) - fast-idle speed adjustment . . . . . . . . . 26

Carburettor (Weber DFTM) - removal and refitting . . . . . . . . . . . . . . 28

Carburettor (Weber TLD) - description . . . . . . . . . . . . . . . . . . . . . . . 30

Carburettor (Weber TLD) - dismantling, cleaning, inspection and reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . 36

Carburettor (Weber TLD) - fast-idle speed adjustment . . . . . . . . . . . 31

Carburettor (Weber TLD) - removal and refitting . . . . . . . . . . . . . . . . 35

Carburettor (Weber TLDM) - description . . . . . . . . . . . . . . . .\

. . . . . . 18

Carburettor (Weber TLDM) - dismantling, cleaning, inspection and

reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 24

Carburettor (Weber TLDM) - fast-idle speed adjustment . . . . . . . . . 19

Carburettor (Weber TLDM) - removal and refitting . . . . . . . . . . . . . . 23

Carburettor (Weber TLM) - description . . . . . . . . . . . . . . . . . . . . . . . 12 Carburettor (Weber TLM) - dismantling, cleaning, inspection and

reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . 17

Carburettor (Weber TLM) - fast-idle speed adjustment . . . . . . . . . . 13

Carburettor (Weber TLM) - removal and refitting . . . . . . . . . . . . . . . 15

Choke cable - removal, refitting and adjustment . . . . . . . . . . . . . . . 6

Fuel gauge sender unit - removal and refitting . . . . . . . . . . . . . . . . . 9

Fuel pump - testing, removal and refitting . . . . . . . . . . . . . . . . . . . . 7

Fuel tank - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 8

Fuel tank filler pipe - removal and refitting . . . . . . . . . . . . . . . . . . . . 11

Fuel tank ventilation tube - removal and refitting . . . . . . . . . . . . . . . 10

General fuel system checks . . . . . . . . . . . . . . . . . . . . . .See Chapter 1

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Idle speed and mixture check and adjustment . . . . . . . .See Chapter 1

Inlet manifold - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 37

Needle valve and float (Weber TLD carburettor) -

removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 32

Needle valve and float (Weber TLDM carburettor) - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 20

Needle valve and float (Weber TLM carburettor) - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 14

Throttle kicker control solenoid (Weber TLDM carburettor) -

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Throttle kicker unit (Weber DFTM carburettor) - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 27

Throttle kicker unit (Weber TLDM carburettor) - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 21

Underbody fuel/brake line check . . . . . . . . . . . . . . . . . . .See\

Chapter 1

Underbonnet check for fluid leaks and hose condition . . .See Chapter 1

4A•1

Specifications Contents

Easy, suitable for

novice with little

experience Fairly easy,

suitable

for beginner with

some experience Fairly difficult,

suitable for competent

DIY mechanic

Difficult,

suitable for

experienced DIY

mechanic Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

procarmanuals.com

http://vnx.su

Page 108 of 296

1 General information andprecautions

General information

The fuel system on all models with

carburettor induction comprises a rear-

mounted fuel tank, a mechanical diaphragm

fuel pump, a carburettor and an air cleaner. The fuel tank is mounted at the rear, under

the floorpan behind the rear seats. The tank

has a “ventilation-to-atmosphere system”

through a combined roll-over/anti-trickle fill

valve assembly, located in the left-hand rear

wheel arch. A filler neck sensing pipe, integral

with the fuel tank filler pipe, will shut off the

petrol pump filler gun when the predetermined

maximum level of fuel is reached in the tank,

so preventing spillage and wastage. A

conventional fuel level sender unit is mounted

in the top face of the fuel tank. One of two fuel pump types will be fitted,

depending on the engine type. On HCS

engines, the fuel pump is operated by a

pivoting rocker arm; one end rests on an

eccentric lobe on the engine camshaft, and

the other end is attached to the fuel pump

diaphragm. The pump fitted to the CVH

engine is operated by a separate pushrod,

one end rests on an eccentric lobe on the

engine camshaft, and the other rests on the

pump actuating rod which operates the

diaphragm. Both types of mechanical pump

incorporate a nylon mesh filter, and are of

sealed type (they cannot be serviced or

overhauled). Four different types of Weber carburettor

are featured in the range, further details being

given in later Sections of this Chapter. The air cleaner incorporates a “waxstat”

controlled air inlet, supplying either hot air

from a shroud mounted around the exhaust

manifold, or cool air from a duct in the front of

the vehicle.

Precautions

Warning: Petrol is extremely

flammable - great care must be

taken when working on any part of the fuel system. Do not smoke or allow

any naked flames or uncovered light bulbs

near the work area. Note that gas powered

domestic appliances with pilot flames,

such as heaters, boilers and tumble

dryers, also present a fire hazard - bear

this in mind if you are working in an area

where such appliances are present.

Always keep a suitable fire extinguisher

close to the work area and familiarise

yourself with its operation before starting

work. Wear eye protection when working

on fuel systems and wash off any fuel spilt

on bare skin immediately with soap and

water. Note that fuel vapour is just as

dangerous as liquid fuel; a vessel that has

just been emptied of liquid fuel will still

contain vapour and can be potentially

explosive. Petrol is a highly dangerous and

volatile liquid, and the precautions

necessary when handling it cannot be

overstressed.

Many of the operations described in this

Chapter involve the disconnection of fuel

lines, which may cause an amount of fuel

spillage. Before commencing work, refer

to the above Warning and the information

in “Safety first” at the beginning of this

manual.

When working with fuel system

components, pay particular attention to

cleanliness - dirt entering the fuel system

may cause blockages which will lead to

poor running.

Certain adjustment points in the fuel system

are protected by tamperproof caps, plugs or

seals. In some territories, it is an offence to

drive a vehicle with broken or missing

tamperproof seals. Before disturbing a

tamperproof seal, first check that no local or

national laws will be broken by doing so, and

fit a new tamperproof seal after adjustment is

complete, where required by law. Do not

break tamperproof seals on any vehicle whilst

it is still under warranty. Carburettors are delicate instruments, and

care must be taken not to disturb any

components unnecessarily. Before attempting

work on a carburettor, ensure that the relevant

spares are available; it should be noted that a complete strip down of a carburettor is

unlikely to cure a fault which is not

immediately obvious, without introducing new

problems. If persistent problems occur, it is

recommended that the services of a Ford

dealer or a carburettor specialist are sought.

Most dealers will be able to provide

carburettor rejetting and servicing facilities.

Where necessary, it may be possible to

purchase a reconditioned carburettor.

2 Air cleaner

-

removal and refitting

1

Note: Air cleaner element renewal and air

cleaner temperature control system checks

are described in Chapter 1.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 On CVH engine models, pull free and

release the accelerator cable from the locating

clip on the side of the air cleaner.

3 Undo the two (HCS engine) or three (CVH

engine) retaining screws, and partially lift the

air cleaner from the carburettor so that the

hose and wiring connections to the underside

of the air cleaner body are accessible (see

illustration) .

4 Note their connections and routings, then

detach the wiring multi-plug and hoses from

the underside of the air cleaner (see

illustrations) . On CVH engines, also

disconnect the vacuum hose from the inlet

manifold.

5 Lift the air cleaner from the carburettor.

6 If required, the inlet air temperature sensor

can be unscrewed and removed from the

base of the air cleaner (where fitted).

Refitting

7 Refit in the reverse order of removal. Renew

any hoses that are perished or cracked, and

ensure that all fittings are securely and

correctly reconnected.

Fuel system – carburettor engines 4A•3

2.4b Disconnecting the intake air temperature sensor multi-plug

(CVH engine shown)2.4a Disconnecting the oil separator/

crankcase ventilation hose from the air

cleaner (CVH engine shown)2.3 Undoing the air cleaner retainingscrews (HCS engine shown)

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 110 of 296

position at the carburettor, then secure the

outer cable with its retaining clip.

Adjustment

12To check that the choke cable is correctly

adjusted, the control knob must be pulled out

to the full-on position and the choke lever

must be in contact with its stop. Adjust as

required if necessary.

13 Press the choke knob fully in (to the off

position), then check that the choke linkage at

the carburettor has fully returned to its off

position and the choke valve plate in the

carburettor is at a right angle (90º) to the

venturi.

14 Refit the air cleaner.

15 Reconnect the battery, turn the ignition

on, operate the choke and check that the

choke warning light operates correctly.

7 Fuel pump -

testing, removal and refitting

2

Note: Refer to the warning note in Section 1

before proceeding.

Testing

1 Access to the fuel pump on HCS engine models is best gained from underneath the

vehicle

(see illustrations) . Apply the

handbrake, then raise and support it on axle

stands at the front end (see “Jacking and

vehicle support” ).

2 The fuel pump may be tested by

disconnecting the fuel feed pipe from the

carburettor, and placing the pipe’s open end

in a suitable container.

3 Detach the multi-plug from the DIS ignition

coil, or the LT lead from the negative terminal

of the ignition coil, to prevent the engine from

firing.

4 Actuate the starter motor. If the fuel pump

is in good working order, regular well-defined

spurts of fuel should eject from the open end

of the disconnected fuel pipe.

5 If this does not occur, and there is fuel in

the tank, the pump is defective and must be

renewed. The fuel pump is a sealed unit, and

cannot be repaired.

Removal

6 Two types of mechanical fuel pump are

fitted, the application depending on the

engine type. Some models may also be fitted

with a fuel vapour separator (see illustration) ;

if this is removed, its hoses should be labelled

to avoid the possibility of confusion and

incorrect attachment on refitting. 7

To remove the fuel pump, first disconnect

the battery negative (earth) lead (refer to

Chapter 5A, Section 1).

8 Where applicable, remove the air cleaner to

improve access to the fuel pump (see Sec-

tion 2).

9 Disconnect the fuel hoses from the fuel

pump, noting their respective connections for

refitting. Where quick-release couplings are

used on the fuel hoses, release the protruding

locking lugs on each union, by squeezing

them together and carefully pulling the

coupling apart. Use rag to soak up any spilt

fuel. Where the unions are colour-coded, the

pipes cannot be confused. Where both unions

are the same colour, note carefully which pipe

is connected to which, and ensure that they

are correctly reconnected on refitting. Plug

the hoses to prevent fuel spillage and the

ingress of dirt.

10 Unscrew and remove the retaining bolts

or nuts (as applicable) and remove the fuel

pump.

11 Recover the gasket/spacer (see

illustration) and if required, withdraw the

pump operating pushrod (CVH engines only).

12 Thoroughly clean the mating faces on the

pump and engine.

Refitting

13 Refit in the reverse order of removal. Be

sure to use a new gasket, and tighten the

securing bolts/nuts securely. Ensure that the

hoses are correctly and securely reconnected.

If they were originally secured with crimped

type hose clips, discard them and fit

screw type clips. Where quick-release

couplings are fitted, press them together until

the locking lugs snap into their groove.

14 When the engine is restarted, check

the pump connections for any signs of fuel

leaks.

8 Fuel tank - removal,

inspection and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Run the fuel level as low as possible prior to

removing the tank.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Remove the fuel filler cap, then syphon or

pump out the remaining fuel from the fuel tank

(there is no drain plug). The fuel must be

emptied into a suitable container for storage.

4 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support” ). Remove

the rear roadwheels.

5 Unclip and disconnect the fuel feed and

return hoses located in front of the fuel tank,

and allow any residual fuel to drain into a

Fuel system – carburettor engines 4A•5

7.6 Fuel pump and fuel vapour separator

arrangement on HCS engine (shown from

below)

7.1b Fuel pump assembly fitted to CVHengines (securing nuts arrowed)

A Fuel feed from tank

B Fuel return to tank

C Fuel feed to carburettor7.1a Fuel pump location on HCS engine (shown from below)

A Fuel inlet hose

B Fuel return hose to tank

C Fuel outlet hose to carburettor

D Pump securing bolts

7.11 Gasket/spacer fitment on HCS

engine. Note position of the lug (arrowed)

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 111 of 296

container which can be sealed (see

illustration) . Where quick-release couplings

are used on the fuel hoses, release the

protruding locking lugs on each union, by

squeezing them together and carefully pulling

the coupling apart. Note that the fuel supply

hose couplings are identified by a white

colour band and the return hose couplings by

a yellow colour band.

6 Disconnect the filler neck sensing pipe

connection from the rear of the tank (see

illustration) .

7 Support beneath the tank to hold it in

position and remove its four securing bolts

(see illustration) .

8 Partially lower the fuel tank and disconnect

the ventilation tube from the tank top surface

and also disconnect the sender unit multi-

plug. The filler pipe should release from its

fuel tank seal location as the tank is

withdrawn.

Inspection

9 Whilst removed, the fuel tank can be

inspected for damage or deterioration.

Removal of the sender unit (see Section 9) will

allow a partial inspection of the interior. If the

tank is contaminated with sediment or water,

swill it out with clean petrol. Do not under any

circumstances undertake any repairs on a

leaking or damaged fuel tank; this work must

be carried out by a professional who has

experience in this critical and potentially-

dangerous work.

10 Whilst the fuel tank is removed from the

vehicle, it should not be placed in an area

where sparks or open flames could ignite the

fumes coming out of the tank. Be especially

careful inside garages where a natural-gas

type appliance is located, because the pilot

light could cause an explosion.

11 Check the condition of the filler pipe seal

in the fuel tank, and renew it if necessary.

Refitting

All models

12 Refitting is a reversal of the removal

procedure. Apply a light smear of grease to the

filler pipe seal, to ease fitting. Ensure that all

connections are securely fitted. Where quick-

release fuel couplings are fitted, press them together until the locking lugs snap into their

groove. If evidence of contamination was

found, do not return any previously-drained

fuel to the tank unless it is carefully filtered first.

9

Fuel gauge sender unit -

removal and refitting

3

Note: Ford specify the use of their service tool

23-014 (a large box spanner with projecting

teeth to engage the fuel gauge sender unit

retaining ring’s slots) for this task. While

alternatives are possible, in view of the difficulty

experienced in removing and refitting the

sender unit, owners are strongly advised to

obtain the correct tool before starting work. The

help of an assistant will be required. Refer to the

warning note in Section 1 before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

2 Engage the special tool into the sender unit

then carefully turn the sender unit and release

it from the top of the tank.

Refitting

3 Refit the sender unit in the reverse order of

removal. Be sure to fit a new seal, and

lubricate it with a smear of grease to prevent it

from distorting when fitting the sender unit.

10 Fuel tank ventilation tube -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 The fuel tank ventilation tube runs from the

top surface of the fuel tank to the combined roll-

over/anti-trickle-fill valve assembly mounted in

the left-hand rear wheelarch (see illustration).

Its purpose is to eliminate any possibility of

vacuum or pressure build-up in the fuel tank.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and vehicle support” ). Remove

the left-hand rear roadwheel.

4 Support the fuel tank from underneath on a

suitable jack, using a large thick sheet of

board to spread the weight, then undo and

remove the four fuel tank securing bolts.

5 Lower the fuel tank slightly in such a manner

so as to allow access to disconnect the

ventilation tube from the tank top surface.

Ensure that the fuel tank does not foul or strain

any adjacent components as it is lowered;

take appropriate action, as necessary.

6 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve, release

the tube from its retaining clips and remove.

Refitting

7 Refitting is a reversal of the removal

procedure, ensuring that the fuel tank filler

pipe is located correctly with the tank.

11 Fuel tank filler pipe -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Remove the fuel tank as described in

Section 8.

4A•6 Fuel system – carburettor engines

10.1 Combined roll-over anti-trickle-fill valve assembly

A Tube ventilating to atmosphere

B Ventilation tube from fuel tank

8.7 Fuel tank securing bolts (arrowed)8.6 Filler neck sensing pipe connection at the rear of the fuel tank

1595Ford Fiesta Remake

8.5 Fuel feed and return pipe connections

(arrowed)procarmanuals.com

http://vnx.su

Page 112 of 296

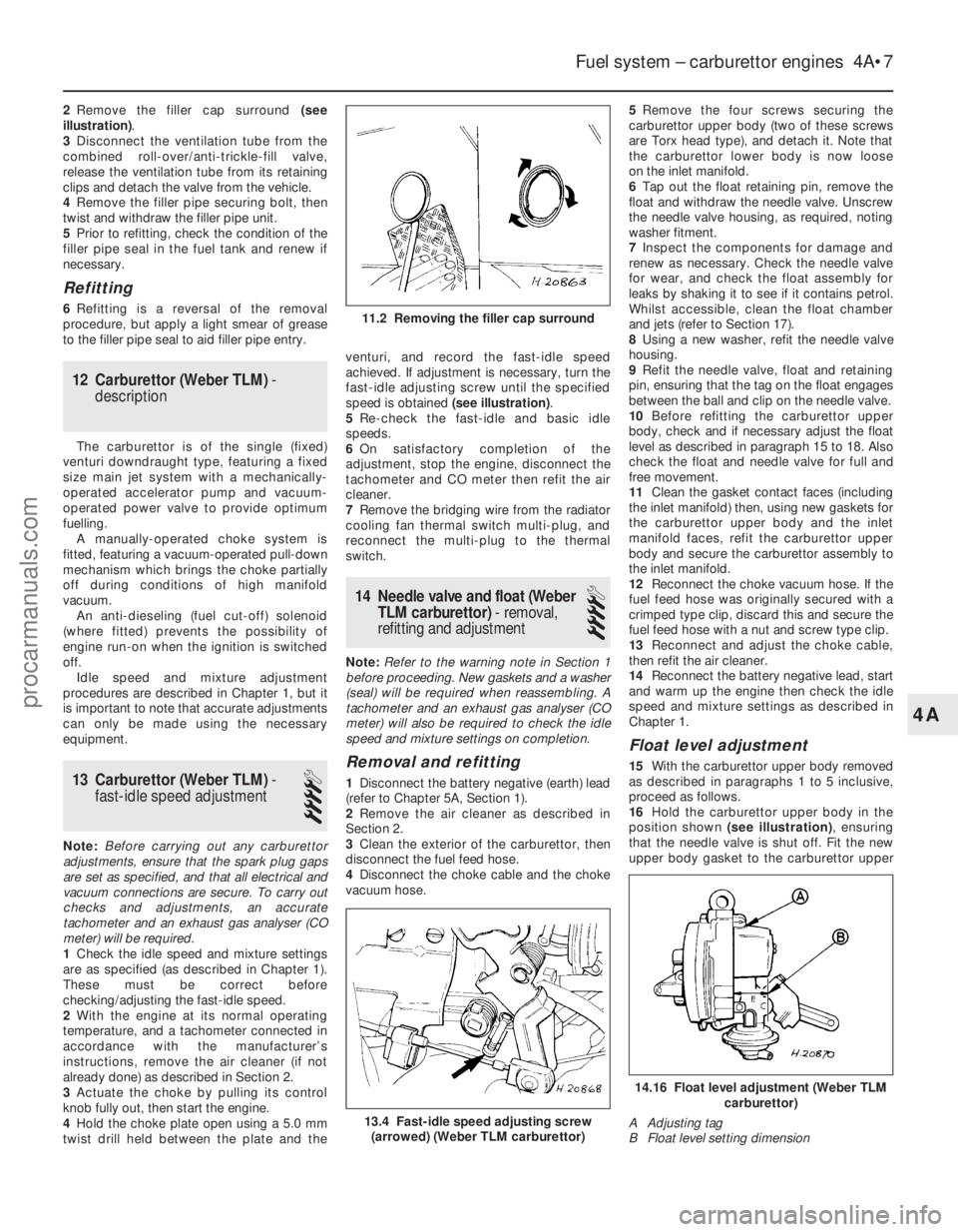

2Remove the filler cap surround (see

illustration) .

3 Disconnect the ventilation tube from the

combined roll-over/anti-trickle-fill valve,

release the ventilation tube from its retaining

clips and detach the valve from the vehicle.

4 Remove the filler pipe securing bolt, then

twist and withdraw the filler pipe unit.

5 Prior to refitting, check the condition of the

filler pipe seal in the fuel tank and renew if

necessary.

Refitting

6 Refitting is a reversal of the removal

procedure, but apply a light smear of grease

to the filler pipe seal to aid filler pipe entry.

12 Carburettor (Weber TLM) -

description

The carburettor is of the single (fixed)

venturi downdraught type, featuring a fixed

size main jet system with a mechanically-

operated accelerator pump and vacuum-

operated power valve to provide optimum

fuelling. A manually-operated choke system is

fitted, featuring a vacuum-operated pull-down

mechanism which brings the choke partially

off during conditions of high manifold

vacuum. An anti-dieseling (fuel cut-off) solenoid

(where fitted) prevents the possibility of

engine run-on when the ignition is switched

off. Idle speed and mixture adjustment

procedures are described in Chapter 1, but it

is important to note that accurate adjustments

can only be made using the necessary

equipment.

13 Carburettor (Weber TLM) -

fast-idle speed adjustment

4

Note: Before carrying out any carburettor

adjustments, ensure that the spark plug gaps

are set as specified, and that all electrical and

vacuum connections are secure. To carry out

checks and adjustments, an accurate

tachometer and an exhaust gas analyser (CO

meter) will be required.

1 Check the idle speed and mixture settings

are as specified (as described in Chapter 1).

These must be correct before

checking/adjusting the fast-idle speed.

2 With the engine at its normal operating

temperature, and a tachometer connected in

accordance with the manufacturer’s

instructions, remove the air cleaner (if not

already done) as described in Section 2.

3 Actuate the choke by pulling its control

knob fully out, then start the engine.

4 Hold the choke plate open using a 5.0 mm

twist drill held between the plate and the venturi, and record the fast-idle speed

achieved. If adjustment is necessary, turn the

fast-idle adjusting screw until the specified

speed is obtained

(see illustration).

5 Re-check the fast-idle and basic idle

speeds.

6 On satisfactory completion of the

adjustment, stop the engine, disconnect the

tachometer and CO meter then refit the air

cleaner.

7 Remove the bridging wire from the radiator

cooling fan thermal switch multi-plug, and

reconnect the multi-plug to the thermal

switch.

14 Needle valve and float (Weber

TLM carburettor) - removal,

refitting and adjustment

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets and a washer

(seal) will be required when reassembling. A

tachometer and an exhaust gas analyser (CO

meter) will also be required to check the idle

speed and mixture settings on completion.

Removal and refitting

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Clean the exterior of the carburettor, then

disconnect the fuel feed hose.

4 Disconnect the choke cable and the choke

vacuum hose. 5

Remove the four screws securing the

carburettor upper body (two of these screws

are Torx head type), and detach it. Note that

the carburettor lower body is now loose

on the inlet manifold.

6 Tap out the float retaining pin, remove the

float and withdraw the needle valve. Unscrew

the needle valve housing, as required, noting

washer fitment.

7 Inspect the components for damage and

renew as necessary. Check the needle valve

for wear, and check the float assembly for

leaks by shaking it to see if it contains petrol.

Whilst accessible, clean the float chamber

and jets (refer to Section 17).

8 Using a new washer, refit the needle valve

housing.

9 Refit the needle valve, float and retaining

pin, ensuring that the tag on the float engages

between the ball and clip on the needle valve.

10 Before refitting the carburettor upper

body, check and if necessary adjust the float

level as described in paragraph 15 to 18. Also

check the float and needle valve for full and

free movement.

11 Clean the gasket contact faces (including

the inlet manifold) then, using new gaskets for

the carburettor upper body and the inlet

manifold faces, refit the carburettor upper

body and secure the carburettor assembly to

the inlet manifold.

12 Reconnect the choke vacuum hose. If the

fuel feed hose was originally secured with a

crimped type clip, discard this and secure the

fuel feed hose with a nut and screw type clip.

13 Reconnect and adjust the choke cable,

then refit the air cleaner.

14 Reconnect the battery negative lead, start

and warm up the engine then check the idle

speed and mixture settings as described in

Chapter 1.

Float level adjustment

15 With the carburettor upper body removed

as described in paragraphs 1 to 5 inclusive,

proceed as follows.

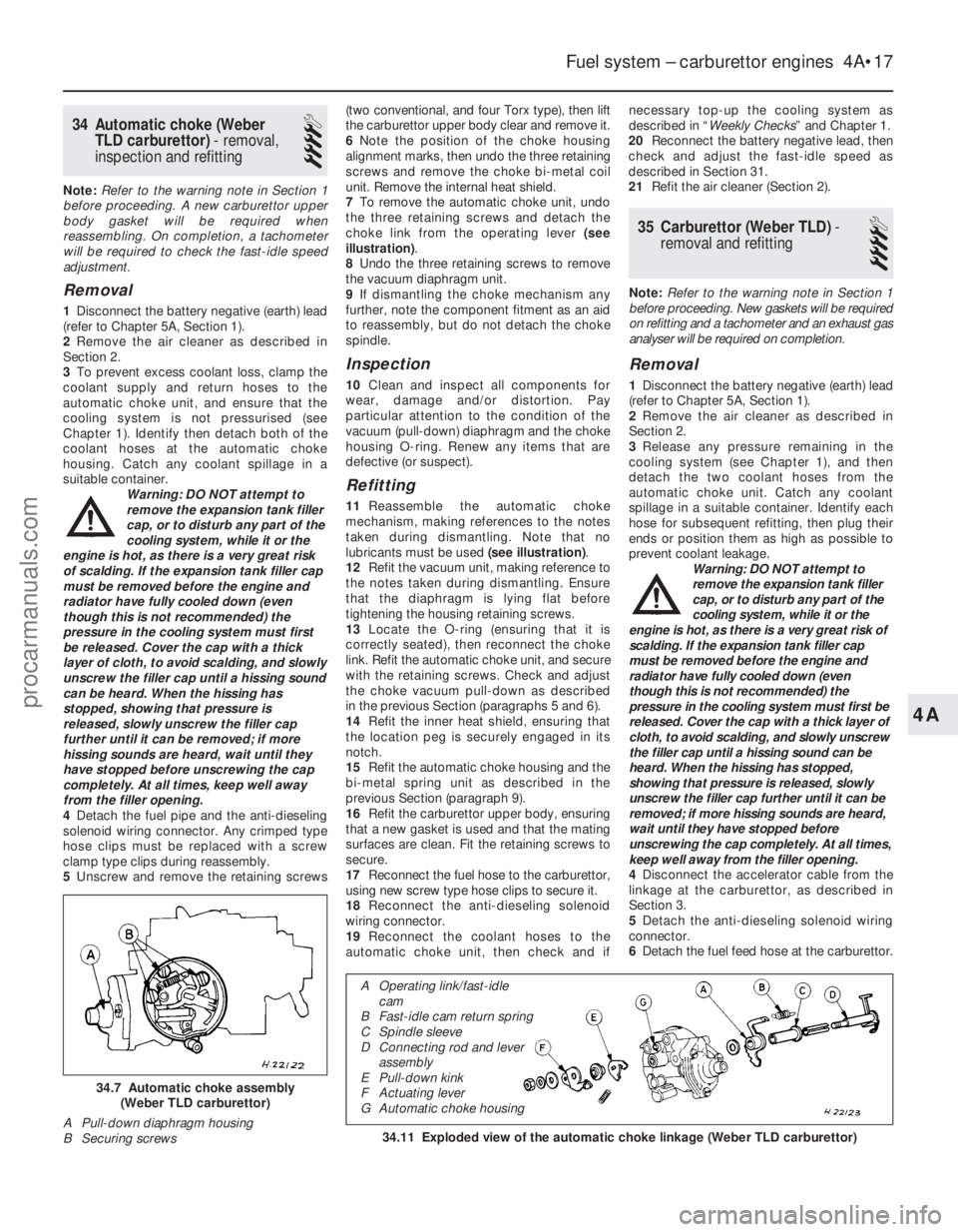

16 Hold the carburettor upper body in the

position shown (see illustration) , ensuring

that the needle valve is shut off. Fit the new

upper body gasket to the carburettor upper

Fuel system – carburettor engines 4A•7

13.4 Fast-idle speed adjusting screw (arrowed) (Weber TLM carburettor)

11.2 Removing the filler cap surround

14.16 Float level adjustment (Weber TLM carburettor)

A Adjusting tag

B Float level setting dimension

4A

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 121 of 296

tachometer and an exhaust gas analyser (CO

meter) will be required.

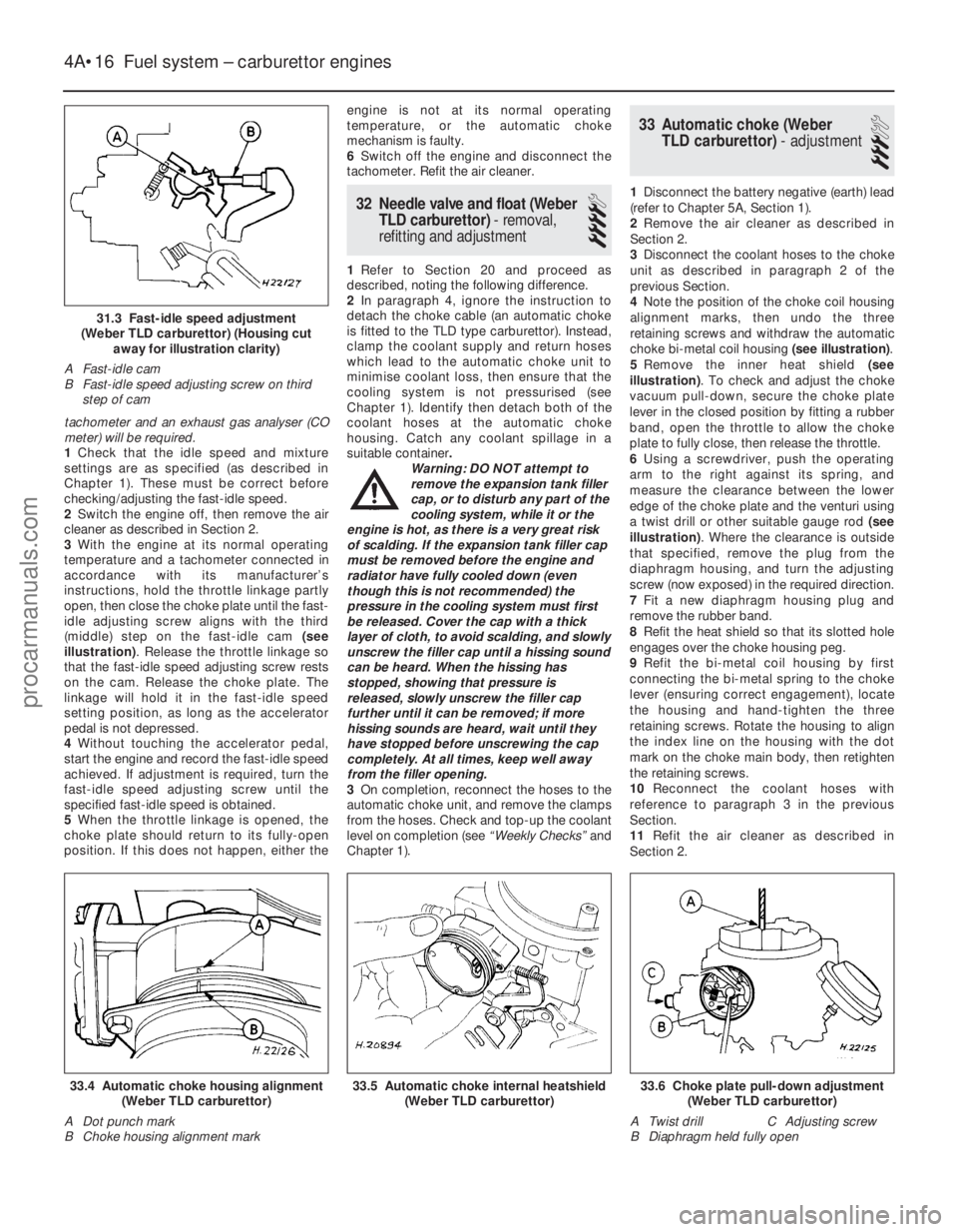

1Check that the idle speed and mixture

settings are as specified (as described in

Chapter 1). These must be correct before

checking/adjusting the fast-idle speed.

2 Switch the engine off, then remove the air

cleaner as described in Section 2.

3 With the engine at its normal operating

temperature and a tachometer connected in

accordance with its manufacturer’s

instructions, hold the throttle linkage partly

open, then close the choke plate until the fast-

idle adjusting screw aligns with the third

(middle) step on the fast-idle cam (see

illustration) . Release the throttle linkage so

that the fast-idle speed adjusting screw rests

on the cam. Release the choke plate. The

linkage will hold it in the fast-idle speed

setting position, as long as the accelerator

pedal is not depressed.

4 Without touching the accelerator pedal,

start the engine and record the fast-idle speed

achieved. If adjustment is required, turn the

fast-idle speed adjusting screw until the

specified fast-idle speed is obtained.

5 When the throttle linkage is opened, the

choke plate should return to its fully-open

position. If this does not happen, either the engine is not at its normal operating

temperature, or the automatic choke

mechanism is faulty.

6

Switch off the engine and disconnect the

tachometer. Refit the air cleaner.

32 Needle valve and float (Weber

TLD carburettor) - removal,

refitting and adjustment

4

1 Refer to Section 20 and proceed as

described, noting the following difference.

2 In paragraph 4, ignore the instruction to

detach the choke cable (an automatic choke

is fitted to the TLD type carburettor). Instead,

clamp the coolant supply and return hoses

which lead to the automatic choke unit to

minimise coolant loss, then ensure that the

cooling system is not pressurised (see

Chapter 1). Identify then detach both of the

coolant hoses at the automatic choke

housing. Catch any coolant spillage in a

suitable container .

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first

be released. Cover the cap with a thick

layer of cloth, to avoid scalding, and slowly

unscrew the filler cap until a hissing sound

can be heard. When the hissing has

stopped, showing that pressure is

released, slowly unscrew the filler cap

further until it can be removed; if more

hissing sounds are heard, wait until they

have stopped before unscrewing the cap

completely. At all times, keep well away

from the filler opening.

3 On completion, reconnect the hoses to the

automatic choke unit, and remove the clamps

from the hoses. Check and top-up the coolant

level on completion (see “Weekly Checks”and

Chapter 1).

33 Automatic choke (Weber TLD carburettor) - adjustment

3

1Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Disconnect the coolant hoses to the choke

unit as described in paragraph 2 of the

previous Section.

4 Note the position of the choke coil housing

alignment marks, then undo the three

retaining screws and withdraw the automatic

choke bi-metal coil housing (see illustration).

5 Remove the inner heat shield (see

illustration) . To check and adjust the choke

vacuum pull-down, secure the choke plate

lever in the closed position by fitting a rubber

band, open the throttle to allow the choke

plate to fully close, then release the throttle.

6 Using a screwdriver, push the operating

arm to the right against its spring, and

measure the clearance between the lower

edge of the choke plate and the venturi using

a twist drill or other suitable gauge rod (see

illustration) . Where the clearance is outside

that specified, remove the plug from the

diaphragm housing, and turn the adjusting

screw (now exposed) in the required direction.

7 Fit a new diaphragm housing plug and

remove the rubber band.

8 Refit the heat shield so that its slotted hole

engages over the choke housing peg.

9 Refit the bi-metal coil housing by first

connecting the bi-metal spring to the choke

lever (ensuring correct engagement), locate

the housing and hand-tighten the three

retaining screws. Rotate the housing to align

the index line on the housing with the dot

mark on the choke main body, then retighten

the retaining screws.

10 Reconnect the coolant hoses with

reference to paragraph 3 in the previous

Section.

11 Refit the air cleaner as described in

Section 2.

4A•16 Fuel system – carburettor engines

33.6 Choke plate pull-down adjustment (Weber TLD carburettor)

A Twist drill C Adjusting screw

B Diaphragm held fully open33.5 Automatic choke internal heatshield (Weber TLD carburettor)33.4 Automatic choke housing alignment(Weber TLD carburettor)

A Dot punch mark

B Choke housing alignment mark

1595Ford Fiesta Remake

31.3 Fast-idle speed adjustment

(Weber TLD carburettor) (Housing cut away for illustration clarity)

A Fast-idle cam

B Fast-idle speed adjusting screw on third step of cam

procarmanuals.com

http://vnx.su

Page 122 of 296

34 Automatic choke (WeberTLD carburettor) - removal,

inspection and refitting

4

Note: Refer to the warning note in Section 1

before proceeding. A new carburettor upper

body gasket will be required when

reassembling. On completion, a tachometer

will be required to check the fast-idle speed

adjustment.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 To prevent excess coolant loss, clamp the

coolant supply and return hoses to the

automatic choke unit, and ensure that the

cooling system is not pressurised (see

Chapter 1). Identify then detach both of the

coolant hoses at the automatic choke

housing. Catch any coolant spillage in a

suitable container.

Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk

of scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first

be released. Cover the cap with a thick

layer of cloth, to avoid scalding, and slowly

unscrew the filler cap until a hissing sound

can be heard. When the hissing has

stopped, showing that pressure is

released, slowly unscrew the filler cap

further until it can be removed; if more

hissing sounds are heard, wait until they

have stopped before unscrewing the cap

completely. At all times, keep well away

from the filler opening.

4 Detach the fuel pipe and the anti-dieseling

solenoid wiring connector. Any crimped type

hose clips must be replaced with a screw

clamp type clips during reassembly.

5 Unscrew and remove the retaining screws (two conventional, and four Torx type), then lift

the carburettor upper body clear and remove it.

6

Note the position of the choke housing

alignment marks, then undo the three retaining

screws and remove the choke bi-metal coil

unit. Remove the internal heat shield.

7 To remove the automatic choke unit, undo

the three retaining screws and detach the

choke link from the operating lever (see

illustration) .

8 Undo the three retaining screws to remove

the vacuum diaphragm unit.

9 If dismantling the choke mechanism any

further, note the component fitment as an aid

to reassembly, but do not detach the choke

spindle.

Inspection

10 Clean and inspect all components for

wear, damage and/or distortion. Pay

particular attention to the condition of the

vacuum (pull-down) diaphragm and the choke

housing O-ring. Renew any items that are

defective (or suspect).

Refitting

11 Reassemble the automatic choke

mechanism, making references to the notes

taken during dismantling. Note that no

lubricants must be used (see illustration).

12 Refit the vacuum unit, making reference to

the notes taken during dismantling. Ensure

that the diaphragm is lying flat before

tightening the housing retaining screws.

13 Locate the O-ring (ensuring that it is

correctly seated), then reconnect the choke

link. Refit the automatic choke unit, and secure

with the retaining screws. Check and adjust

the choke vacuum pull-down as described

in the previous Section (paragraphs 5 and 6).

14 Refit the inner heat shield, ensuring that

the location peg is securely engaged in its

notch.

15 Refit the automatic choke housing and the

bi-metal spring unit as described in the

previous Section (paragraph 9).

16 Refit the carburettor upper body, ensuring

that a new gasket is used and that the mating

surfaces are clean. Fit the retaining screws to

secure.

17 Reconnect the fuel hose to the carburettor,

using new screw type hose clips to secure it.

18 Reconnect the anti-dieseling solenoid

wiring connector.

19 Reconnect the coolant hoses to the

automatic choke unit, then check and if necessary top-up the cooling system as

described in “

Weekly Checks ” and Chapter 1.

20 Reconnect the battery negative lead, then

check and adjust the fast-idle speed as

described in Section 31.

21 Refit the air cleaner (Section 2).

35 Carburettor (Weber TLD) -

removal and refitting

4

Note: Refer to the warning note in Section 1

before proceeding. New gaskets will be required

on refitting and a tachometer and an exhaust gas

analyser will be required on completion.

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the air cleaner as described in

Section 2.

3 Release any pressure remaining in the

cooling system (see Chapter 1), and then

detach the two coolant hoses from the

automatic choke unit. Catch any coolant

spillage in a suitable container. Identify each

hose for subsequent refitting, then plug their

ends or position them as high as possible to

prevent coolant leakage. Warning: DO NOT attempt to

remove the expansion tank filler

cap, or to disturb any part of the

cooling system, while it or the

engine is hot, as there is a very great risk of

scalding. If the expansion tank filler cap

must be removed before the engine and

radiator have fully cooled down (even

though this is not recommended) the

pressure in the cooling system must first be

released. Cover the cap with a thick layer of

cloth, to avoid scalding, and slowly unscrew

the filler cap until a hissing sound can be

heard. When the hissing has stopped,

showing that pressure is released, slowly

unscrew the filler cap further until it can be

removed; if more hissing sounds are heard,

wait until they have stopped before

unscrewing the cap completely. At all times,

keep well away from the filler opening.

4 Disconnect the accelerator cable from the

linkage at the carburettor, as described in

Section 3.

5 Detach the anti-dieseling solenoid wiring

connector.

6 Detach the fuel feed hose at the carburettor.

Fuel system – carburettor engines 4A•17

34.11 Exploded view of the automatic choke linkage (Weber TLD carburet\

tor)

34.7 Automatic choke assembly

(Weber TLD carburettor)

A Pull-down diaphragm housing

B Securing screws

4A

1595Ford Fiesta Remake

A Operating link/fast-idle cam

B Fast-idle cam return spring

C Spindle sleeve

D Connecting rod and lever assembly

E Pull-down kink

F Actuating lever

G Automatic choke housing

procarmanuals.com

http://vnx.su