tire type FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 13 of 296

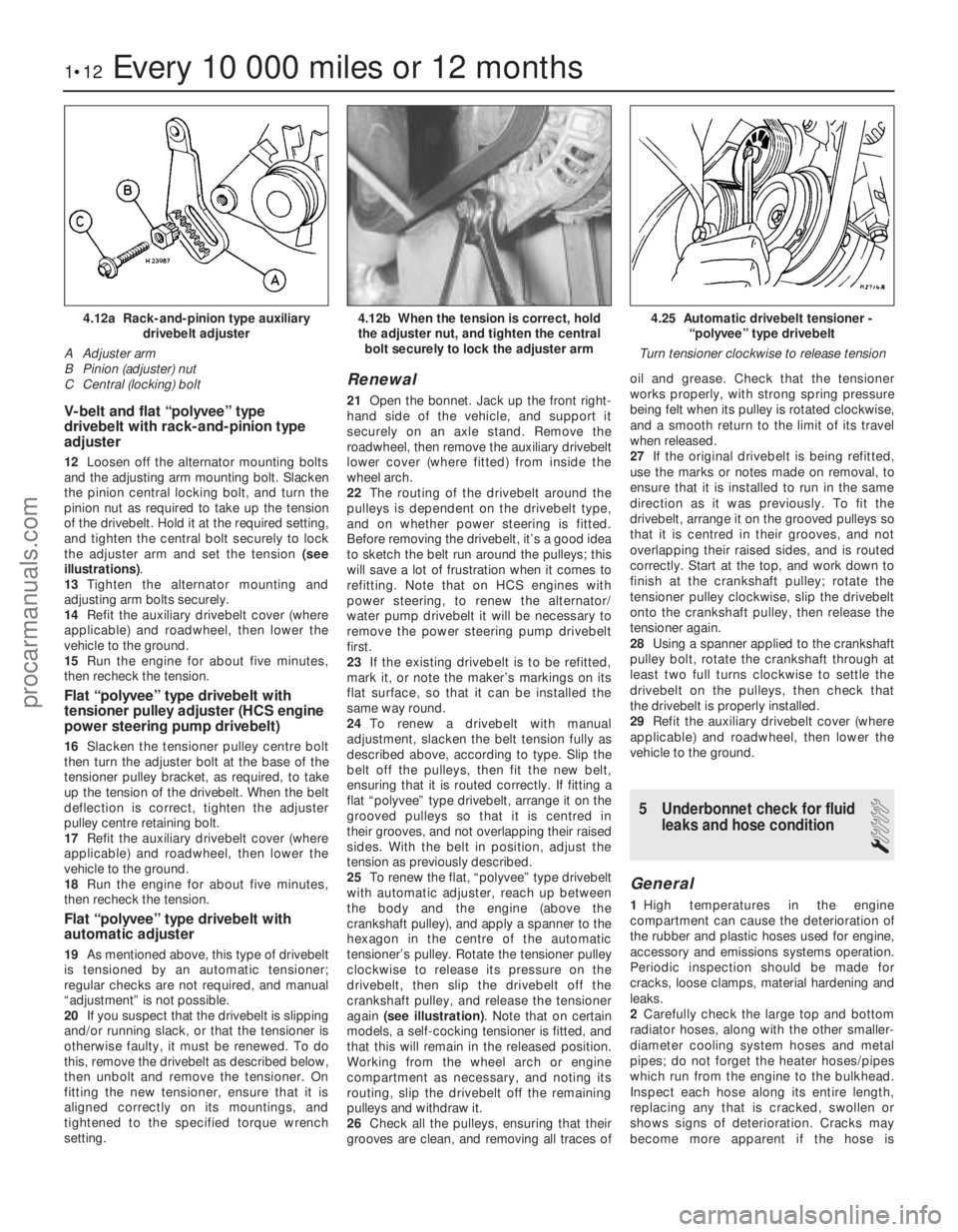

V-belt and flat “polyvee” type

drivebelt with rack-and-pinion type

adjuster

12Loosen off the alternator mounting bolts

and the adjusting arm mounting bolt. Slacken

the pinion central locking bolt, and turn the

pinion nut as required to take up the tension

of the drivebelt. Hold it at the required setting,

and tighten the central bolt securely to lock

the adjuster arm and set the tension (see

illustrations) .

13 Tighten the alternator mounting and

adjusting arm bolts securely.

14 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

15 Run the engine for about five minutes,

then recheck the tension.

Flat “polyvee” type drivebelt with

tensioner pulley adjuster (HCS engine

power steering pump drivebelt)

16 Slacken the tensioner pulley centre bolt

then turn the adjuster bolt at the base of the

tensioner pulley bracket, as required, to take

up the tension of the drivebelt. When the belt

deflection is correct, tighten the adjuster

pulley centre retaining bolt.

17 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

18 Run the engine for about five minutes,

then recheck the tension.

Flat “polyvee” type drivebelt with

automatic adjuster

19 As mentioned above, this type of drivebelt

is tensioned by an automatic tensioner;

regular checks are not required, and manual

“adjustment” is not possible.

20 If you suspect that the drivebelt is slipping

and/or running slack, or that the tensioner is

otherwise faulty, it must be renewed. To do

this, remove the drivebelt as described below,

then unbolt and remove the tensioner. On

fitting the new tensioner, ensure that it is

aligned correctly on its mountings, and

tightened to the specified torque wrench

setting.

Renewal

21 Open the bonnet. Jack up the front right-

hand side of the vehicle, and support it

securely on an axle stand. Remove the

roadwheel, then remove the auxiliary drivebelt

lower cover (where fitted) from inside the

wheel arch.

22 The routing of the drivebelt around the

pulleys is dependent on the drivebelt type,

and on whether power steering is fitted.

Before removing the drivebelt, it’s a good idea

to sketch the belt run around the pulleys; this

will save a lot of frustration when it comes to

refitting. Note that on HCS engines with

power steering, to renew the alternator/

water pump drivebelt it will be necessary to

remove the power steering pump drivebelt

first.

23 If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed the

same way round.

24 To renew a drivebelt with manual

adjustment, slacken the belt tension fully as

described above, according to type. Slip the

belt off the pulleys, then fit the new belt,

ensuring that it is routed correctly. If fitting a

flat “polyvee” type drivebelt, arrange it on the

grooved pulleys so that it is centred in

their grooves, and not overlapping their raised

sides. With the belt in position, adjust the

tension as previously described.

25 To renew the flat, “polyvee” type drivebelt

with automatic adjuster, reach up between

the body and the engine (above the

crankshaft pulley), and apply a spanner to the

hexagon in the centre of the automatic

tensioner’s pulley. Rotate the tensioner pulley

clockwise to release its pressure on the

drivebelt, then slip the drivebelt off the

crankshaft pulley, and release the tensioner

again (see illustration) . Note that on certain

models, a self-cocking tensioner is fitted, and

that this will remain in the released position.

Working from the wheel arch or engine

compartment as necessary, and noting its

routing, slip the drivebelt off the remaining

pulleys and withdraw it.

26 Check all the pulleys, ensuring that their

grooves are clean, and removing all traces of oil and grease. Check that the tensioner

works properly, with strong spring pressure

being felt when its pulley is rotated clockwise,

and a smooth return to the limit of its travel

when released.

27

If the original drivebelt is being refitted,

use the marks or notes made on removal, to

ensure that it is installed to run in the same

direction as it was previously. To fit the

drivebelt, arrange it on the grooved pulleys so

that it is centred in their grooves, and not

overlapping their raised sides, and is routed

correctly. Start at the top, and work down to

finish at the crankshaft pulley; rotate the

tensioner pulley clockwise, slip the drivebelt

onto the crankshaft pulley, then release the

tensioner again.

28 Using a spanner applied to the crankshaft

pulley bolt, rotate the crankshaft through at

least two full turns clockwise to settle the

drivebelt on the pulleys, then check that

the drivebelt is properly installed.

29 Refit the auxiliary drivebelt cover (where

applicable) and roadwheel, then lower the

vehicle to the ground.

5 Underbonnet check for fluid leaks and hose condition

1

General

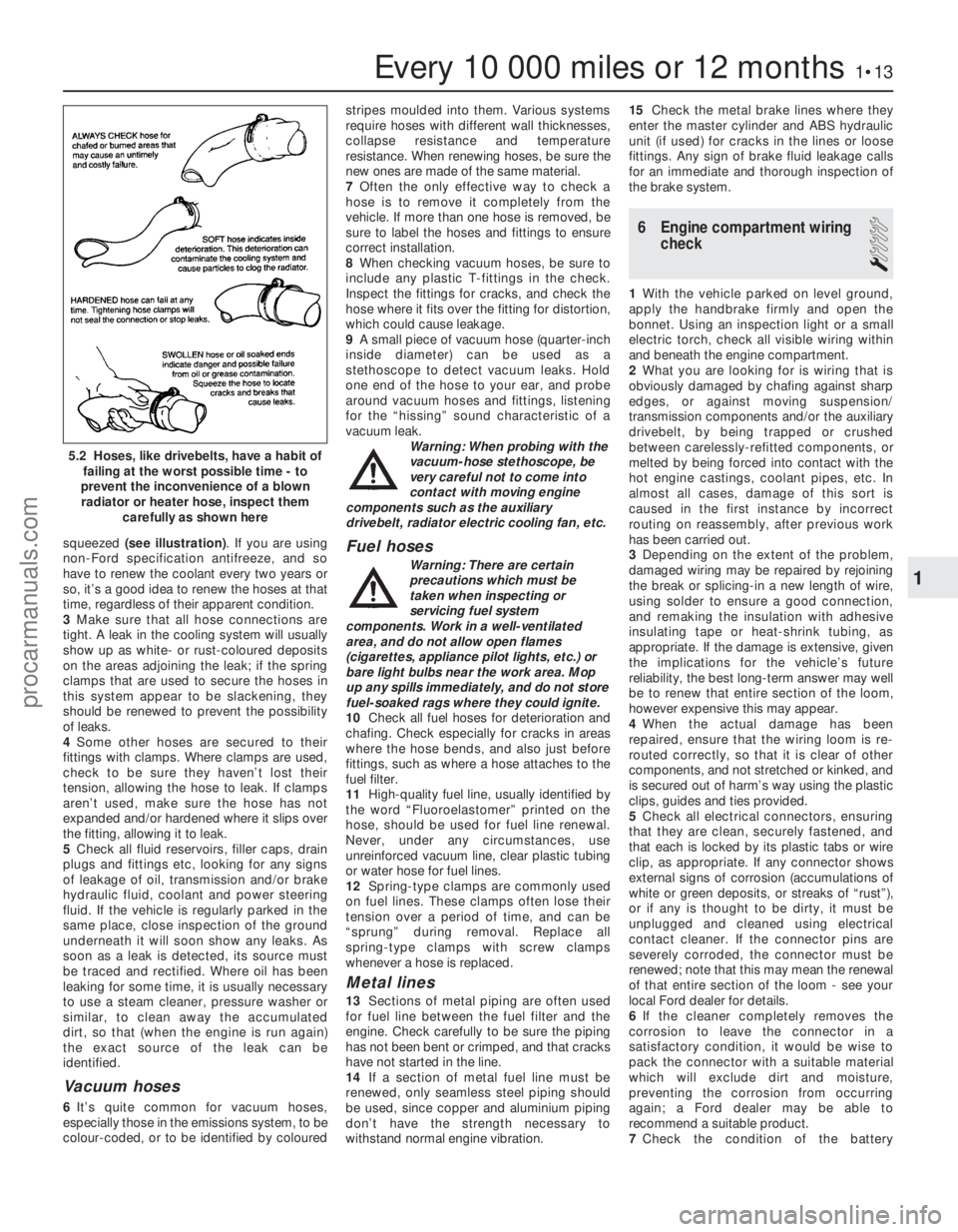

1High temperatures in the engine

compartment can cause the deterioration of

the rubber and plastic hoses used for engine,

accessory and emissions systems operation.

Periodic inspection should be made for

cracks, loose clamps, material hardening and

leaks.

2 Carefully check the large top and bottom

radiator hoses, along with the other smaller-

diameter cooling system hoses and metal

pipes; do not forget the heater hoses/pipes

which run from the engine to the bulkhead.

Inspect each hose along its entire length,

replacing any that is cracked, swollen or

shows signs of deterioration. Cracks may

become more apparent if the hose is

1•12Every 10 000 miles or 12 months

4.25 Automatic drivebelt tensioner - “polyvee” type drivebelt

Turn tensioner clockwise to release tension4.12b When the tension is correct, hold

the adjuster nut, and tighten the central bolt securely to lock the adjuster arm4.12a Rack-and-pinion type auxiliary drivebelt adjuster

A Adjuster arm

B Pinion (adjuster) nut

C Central (locking) bolt

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 14 of 296

squeezed (see illustration) . If you are using

non-Ford specification antifreeze, and so

have to renew the coolant every two years or

so, it’s a good idea to renew the hoses at that

time, regardless of their apparent condition.

3 Make sure that all hose connections are

tight. A leak in the cooling system will usually

show up as white- or rust-coloured deposits

on the areas adjoining the leak; if the spring

clamps that are used to secure the hoses in

this system appear to be slackening, they

should be renewed to prevent the possibility

of leaks.

4 Some other hoses are secured to their

fittings with clamps. Where clamps are used,

check to be sure they haven’t lost their

tension, allowing the hose to leak. If clamps

aren’t used, make sure the hose has not

expanded and/or hardened where it slips over

the fitting, allowing it to leak.

5 Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs

of leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

fluid. If the vehicle is regularly parked in the

same place, close inspection of the ground

underneath it will soon show any leaks. As

soon as a leak is detected, its source must

be traced and rectified. Where oil has been

leaking for some time, it is usually necessary

to use a steam cleaner, pressure washer or

similar, to clean away the accumulated

dirt, so that (when the engine is run again)

the exact source of the leak can be

identified.

Vacuum hoses

6 It’s quite common for vacuum hoses,

especially those in the emissions system, to be

colour-coded, or to be identified by coloured stripes moulded into them. Various systems

require hoses with different wall thicknesses,

collapse resistance and temperature

resistance. When renewing hoses, be sure the

new ones are made of the same material.

7

Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8 When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9 A small piece of vacuum hose (quarter-inch

inside diameter) can be used as a

stethoscope to detect vacuum leaks. Hold

one end of the hose to your ear, and probe

around vacuum hoses and fittings, listening

for the “hissing” sound characteristic of a

vacuum leak. Warning: When probing with the

vacuum-hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the auxiliary

drivebelt, radiator electric cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be

taken when inspecting or

servicing fuel system

components. Work in a well-ventilated

area, and do not allow open flames

(cigarettes, appliance pilot lights, etc.) or

bare light bulbs near the work area. Mop

up any spills immediately, and do not store

fuel-soaked rags where they could ignite.

10 Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

fuel filter.

11 High-quality fuel line, usually identified by

the word “Fluoroelastomer” printed on the

hose, should be used for fuel line renewal.

Never, under any circumstances, use

unreinforced vacuum line, clear plastic tubing

or water hose for fuel lines.

12 Spring- type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all

spring- type clamps with screw clamps

whenever a hose is replaced.

Metal lines

13 Sections of metal piping are often used

for fuel line between the fuel filter and the

engine. Check carefully to be sure the piping

has not been bent or crimped, and that cracks

have not started in the line.

14 If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration. 15

Check the metal brake lines where they

enter the master cylinder and ABS hydraulic

unit (if used) for cracks in the lines or loose

fittings. Any sign of brake fluid leakage calls

for an immediate and thorough inspection of

the brake system.

6 Engine compartment wiring check

1

1With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2 What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelt, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly, after previous work

has been carried out.

3 Depending on the extent of the problem,

damaged wiring may be repaired by rejoining

the break or splicing-in a new length of wire,

using solder to ensure a good connection,

and remaking the insulation with adhesive

insulating tape or heat-shrink tubing, as

appropriate. If the damage is extensive, given

the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4 When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5 Check all electrical connectors, ensuring

that they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Ford dealer for details.

6 If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a suitable material

which will exclude dirt and moisture,

preventing the corrosion from occurring

again; a Ford dealer may be able to

recommend a suitable product.

7 Check the condition of the battery

Every 10 000 miles or 12 months1•13

5.2 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown radiator or heater hose, inspect them

carefully as shown here

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 15 of 296

connections - remake the connections or

renew the leads if a fault is found. Use the

same techniques to ensure that all earth

points in the engine compartment provide

good electrical contact through clean, metal-

to-metal joints, and that all are securely

fastened. (In addition to the earth connection

at the engine lifting eye, and that from the

transmission to the body/battery, there are

others in various places, so check carefully).

8Refer to Section 21 for details of spark plug

(HT) lead checks.

7 Valve clearance adjustment

2

Refer to Chapter 2, Part A.

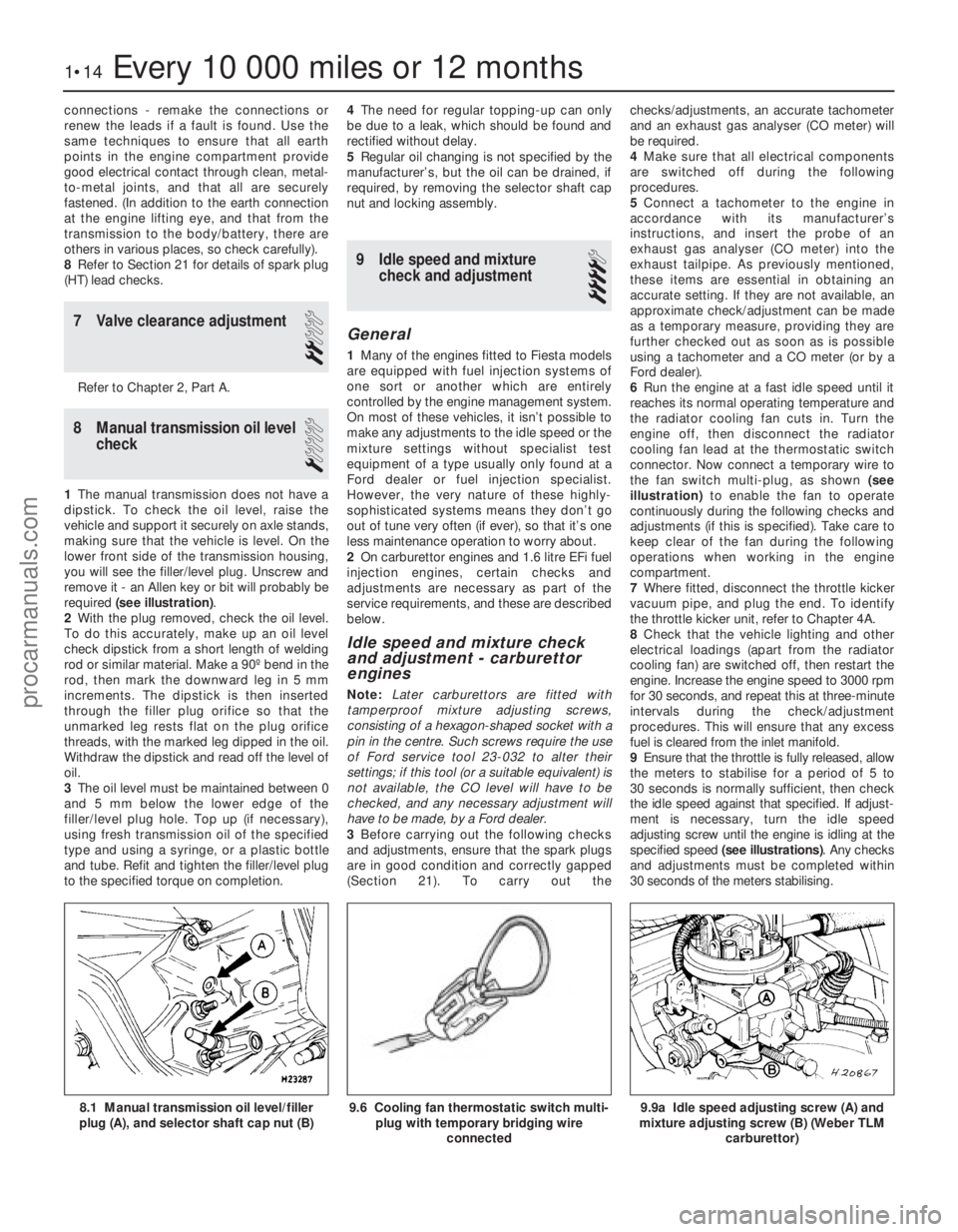

8 Manual transmission oil level check

1

1The manual transmission does not have a

dipstick. To check the oil level, raise the

vehicle and support it securely on axle stands,

making sure that the vehicle is level. On the

lower front side of the transmission housing,

you will see the filler/level plug. Unscrew and

remove it - an Allen key or bit will probably be

required (see illustration) .

2 With the plug removed, check the oil level.

To do this accurately, make up an oil level

check dipstick from a short length of welding

rod or similar material. Make a 90º bend in the

rod, then mark the downward leg in 5 mm

increments. The dipstick is then inserted

through the filler plug orifice so that the

unmarked leg rests flat on the plug orifice

threads, with the marked leg dipped in the oil.

Withdraw the dipstick and read off the level of

oil.

3 The oil level must be maintained between 0

and 5 mm below the lower edge of the

filler/level plug hole. Top up (if necessary),

using fresh transmission oil of the specified

type and using a syringe, or a plastic bottle

and tube. Refit and tighten the filler/level plug

to the specified torque on completion. 4

The need for regular topping-up can only

be due to a leak, which should be found and

rectified without delay.

5 Regular oil changing is not specified by the

manufacturer’s, but the oil can be drained, if

required, by removing the selector shaft cap

nut and locking assembly.

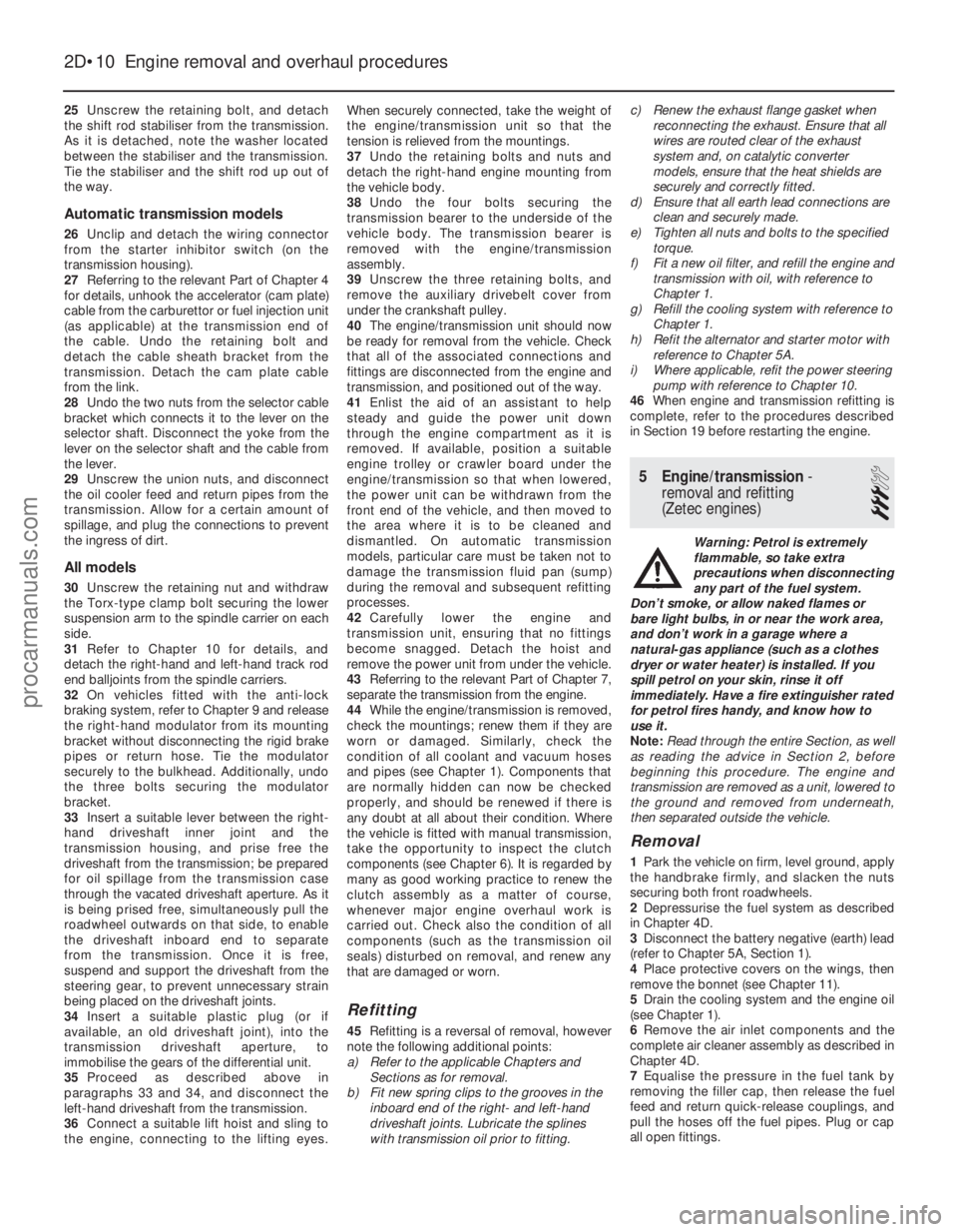

9 Idle speed and mixture check and adjustment

4

General

1Many of the engines fitted to Fiesta models

are equipped with fuel injection systems of

one sort or another which are entirely

controlled by the engine management system.

On most of these vehicles, it isn’t possible to

make any adjustments to the idle speed or the

mixture settings without specialist test

equipment of a type usually only found at a

Ford dealer or fuel injection specialist.

However, the very nature of these highly-

sophisticated systems means they don’t go

out of tune very often (if ever), so that it’s one

less maintenance operation to worry about.

2 On carburettor engines and 1.6 litre EFi fuel

injection engines, certain checks and

adjustments are necessary as part of the

service requirements, and these are described

below.

Idle speed and mixture check

and adjustment - carburettor

engines

Note: Later carburettors are fitted with

tamperproof mixture adjusting screws,

consisting of a hexagon-shaped socket with a

pin in the centre. Such screws require the use

of Ford service tool 23-032 to alter their

settings; if this tool (or a suitable equivalent) is

not available, the CO level will have to be

checked, and any necessary adjustment will

have to be made, by a Ford dealer.

3 Before carrying out the following checks

and adjustments, ensure that the spark plugs

are in good condition and correctly gapped

(Section 21). To carry out the checks/adjustments, an accurate tachometer

and an exhaust gas analyser (CO meter) will

be required.

4

Make sure that all electrical components

are switched off during the following

procedures.

5 Connect a tachometer to the engine in

accordance with its manufacturer’s

instructions, and insert the probe of an

exhaust gas analyser (CO meter) into the

exhaust tailpipe. As previously mentioned,

these items are essential in obtaining an

accurate setting. If they are not available, an

approximate check/adjustment can be made

as a temporary measure, providing they are

further checked out as soon as is possible

using a tachometer and a CO meter (or by a

Ford dealer).

6 Run the engine at a fast idle speed until it

reaches its normal operating temperature and

the radiator cooling fan cuts in. Turn the

engine off, then disconnect the radiator

cooling fan lead at the thermostatic switch

connector. Now connect a temporary wire to

the fan switch multi-plug, as shown (see

illustration) to enable the fan to operate

continuously during the following checks and

adjustments (if this is specified). Take care to

keep clear of the fan during the following

operations when working in the engine

compartment.

7 Where fitted, disconnect the throttle kicker

vacuum pipe, and plug the end. To identify

the throttle kicker unit, refer to Chapter 4A.

8 Check that the vehicle lighting and other

electrical loadings (apart from the radiator

cooling fan) are switched off, then restart the

engine. Increase the engine speed to 3000 rpm

for 30 seconds, and repeat this at three-minute

intervals during the check/adjustment

procedures. This will ensure that any excess

fuel is cleared from the inlet manifold.

9 Ensure that the throttle is fully released, allow

the meters to stabilise for a period of 5 to

30 seconds is normally sufficient, then check

the idle speed against that specified. If adjust-

ment is necessary, turn the idle speed

adjusting screw until the engine is idling at the

specified speed (see illustrations) . Any checks

and adjustments must be completed within

30 seconds of the meters stabilising.

1•14Every 10 000 miles or 12 months

9.9a Idle speed adjusting screw (A) and

mixture adjusting screw (B) (Weber TLM

carburettor)9.6 Cooling fan thermostatic switch multi-plug with temporary bridging wire

connected8.1 Manual transmission oil level/filler

plug (A), and selector shaft cap nut (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 23 of 296

the corrosion which would otherwise occur

as the corrosion inhibitors become progress-

ively less effective. Always use an ethylene

glycol-based antifreeze which is suitable for

use in mixed-metal cooling systems.

20If the antifreeze used is to Ford’s

specification, the levels of protection it affords

are indicated in the Specifications Section of

this Chapter. To give the recommended

standard mixture ratio for this antifreeze, 40%

(by volume) of antifreeze must be mixed with

60% of clean, soft water; if you are using any

other type of antifreeze, follow its

manufacturer’s instructions to achieve the

correct ratio. It is best to make up slightly

more than the system’s specified capacity, so

that a supply is available for subsequent

topping-up.

21 Before adding antifreeze, the cooling

system should be completely drained,

preferably flushed, and all hoses checked for

condition and security. As noted earlier, fresh

antifreeze will rapidly find any weaknesses in

the system.

22 After filling with antifreeze, a label should

be attached to the expansion tank, stating the

type and concentration of antifreeze used,

and the date installed. Any subsequent

topping-up should be made with the same

type and concentration of antifreeze. If

topping-up using antifreeze to Ford’s

specification, note that a 50/50 mixture is

permissible, purely for convenience.

23 Do not use engine antifreeze in the

windscreen/tailgate washer system, as it will

damage the vehicle’s paintwork. A

screenwash additive should be added to the

washer system in its maker’s recommended

quantities.

Antifreeze - notes on renewal

24 Ford state that, where antifreeze to Ford

specification ESD-M97B-49-A is used, it will

last the lifetime of the vehicle. This is subject

to it being used in the recommended

concentration, unmixed with any other type of

antifreeze or additive, and topped-up when

necessary using only that antifreeze mixed 50/50 with clean water. If any other type of

antifreeze is added, the lifetime guarantee no

longer applies; to restore the lifetime

protection, the system must be drained and

thoroughly reverse-flushed before fresh

coolant mixture is poured in.

25

If the vehicle’s history (and therefore the

quality of the antifreeze in it) is unknown,

owners who wish to follow Ford’s

recommendations are advised to drain and

thoroughly reverse-flush the system before

refilling with fresh coolant mixture. If the

appropriate quality of antifreeze is used, the

coolant can then be left for the life of the

vehicle.

26 If any antifreeze other than Ford’s is to be

used, the coolant must be renewed at regular

intervals to provide an equivalent degree of

protection; the conventional recommendation

is to renew the coolant every two or three

years.

27 The above assumes the use of a mixture

(in exactly the specified concentration) of

clean, soft water and of antifreeze to Ford’s

specification or equivalent. It is also assumed

that the cooling system is maintained in a

scrupulously-clean condition, by ensuring that

only clean coolant is added on topping-up,

and by thorough reverse-flushing whenever

the coolant is drained.

General cooling system checks

28 The engine should be cold for the cooling

system checks, so perform the following

procedure before driving the vehicle, or

after it has been shut off for at least three

hours.

29 Remove the expansion tank filler cap, and

clean it thoroughly inside and out with a rag.

Also clean the filler neck on the expansion

tank. The presence of rust or corrosion in the

filler neck indicates that the coolant should be

changed. The coolant inside the expansion

tank should be relatively clean and

transparent. If it is rust-coloured, drain and

flush the system, and refill with a fresh coolant

mixture.

30 Carefully check the radiator hoses and heater hoses along their entire length; renew

any hose which is cracked, swollen or

deteriorated (see Section 5).

31

Inspect all other cooling system

components (joint faces, etc.) for leaks. A leak

in the cooling system will usually show up as

white- or rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

32 Clean the front of the radiator with a soft

brush to remove all insects, leaves, etc,

embedded in the radiator fins. Be careful not

to damage the radiator fins, or cut your fingers

on them.

24 Air cleaner element renewal

1

1 The air cleaner filter element is located in

the air cleaner assembly mounted either on

top of the carburettor or CFi unit, or on the

left-hand or right-hand side of the engine

compartment at the front. Remove the air

cleaner lid as follows according to type.

Carburettor and CFi fuel

injection models

2 Undo the two or three retaining screws on

the top of the air cleaner lid (see illustration).

3 Release the clips, and lift off the air cleaner

cover (see illustration) .

EFi fuel injection models

4If the idle speed control valve is

mounted on the air cleaner, disconnect the

multi-plug and the air bypass hose from the

valve.

5 Disconnect the flexible hose between the

air cleaner lid and the air inlet duct or

turbocharger air intake.

6 Release the retaining clips and lift off the air

cleaner lid (see illustration) .

1•22Every 30 000 miles or three years

24.6 On EFi fuel injection engines, release

the retaining clips and lift off the air

cleaner lid24.3 . . . then spring back the clips and lift of the lid24.2 On carburettor and CFi fuel injectionengines, undo the air cleaner lid retaining

screws . . .

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 79 of 296

25Unscrew the retaining bolt, and detach

the shift rod stabiliser from the transmission.

As it is detached, note the washer located

between the stabiliser and the transmission.

Tie the stabiliser and the shift rod up out of

the way.

Automatic transmission models

26 Unclip and detach the wiring connector

from the starter inhibitor switch (on the

transmission housing).

27 Referring to the relevant Part of Chapter 4

for details, unhook the accelerator (cam plate)

cable from the carburettor or fuel injection unit

(as applicable) at the transmission end of

the cable. Undo the retaining bolt and

detach the cable sheath bracket from the

transmission. Detach the cam plate cable

from the link.

28 Undo the two nuts from the selector cable

bracket which connects it to the lever on the

selector shaft. Disconnect the yoke from the

lever on the selector shaft and the cable from

the lever.

29 Unscrew the union nuts, and disconnect

the oil cooler feed and return pipes from the

transmission. Allow for a certain amount of

spillage, and plug the connections to prevent

the ingress of dirt.

All models

30 Unscrew the retaining nut and withdraw

the Torx-type clamp bolt securing the lower

suspension arm to the spindle carrier on each

side.

31 Refer to Chapter 10 for details, and

detach the right-hand and left-hand track rod

end balljoints from the spindle carriers.

32 On vehicles fitted with the anti-lock

braking system, refer to Chapter 9 and release

the right-hand modulator from its mounting

bracket without disconnecting the rigid brake

pipes or return hose. Tie the modulator

securely to the bulkhead. Additionally, undo

the three bolts securing the modulator

bracket.

33 Insert a suitable lever between the right-

hand driveshaft inner joint and the

transmission housing, and prise free the

driveshaft from the transmission; be prepared

for oil spillage from the transmission case

through the vacated driveshaft aperture. As it

is being prised free, simultaneously pull the

roadwheel outwards on that side, to enable

the driveshaft inboard end to separate

from the transmission. Once it is free,

suspend and support the driveshaft from the

steering gear, to prevent unnecessary strain

being placed on the driveshaft joints.

34 Insert a suitable plastic plug (or if

available, an old driveshaft joint), into the

transmission driveshaft aperture, to

immobilise the gears of the differential unit.

35 Proceed as described above in

paragraphs 33 and 34, and disconnect the

left-hand driveshaft from the transmission.

36 Connect a suitable lift hoist and sling to

the engine, connecting to the lifting eyes. When securely connected, take the weight of

the engine/transmission unit so that the

tension is relieved from the mountings.

37

Undo the retaining bolts and nuts and

detach the right-hand engine mounting from

the vehicle body.

38 Undo the four bolts securing the

transmission bearer to the underside of the

vehicle body. The transmission bearer is

removed with the engine/transmission

assembly.

39 Unscrew the three retaining bolts, and

remove the auxiliary drivebelt cover from

under the crankshaft pulley.

40 The engine/transmission unit should now

be ready for removal from the vehicle. Check

that all of the associated connections and

fittings are disconnected from the engine and

transmission, and positioned out of the way.

41 Enlist the aid of an assistant to help

steady and guide the power unit down

through the engine compartment as it is

removed. If available, position a suitable

engine trolley or crawler board under the

engine/transmission so that when lowered,

the power unit can be withdrawn from the

front end of the vehicle, and then moved to

the area where it is to be cleaned and

dismantled. On automatic transmission

models, particular care must be taken not to

damage the transmission fluid pan (sump)

during the removal and subsequent refitting

processes.

42 Carefully lower the engine and

transmission unit, ensuring that no fittings

become snagged. Detach the hoist and

remove the power unit from under the vehicle.

43 Referring to the relevant Part of Chapter 7,

separate the transmission from the engine.

44 While the engine/transmission is removed,

check the mountings; renew them if they are

worn or damaged. Similarly, check the

condition of all coolant and vacuum hoses

and pipes (see Chapter 1). Components that

are normally hidden can now be checked

properly, and should be renewed if there is

any doubt at all about their condition. Where

the vehicle is fitted with manual transmission,

take the opportunity to inspect the clutch

components (see Chapter 6). It is regarded by

many as good working practice to renew the

clutch assembly as a matter of course,

whenever major engine overhaul work is

carried out. Check also the condition of all

components (such as the transmission oil

seals) disturbed on removal, and renew any

that are damaged or worn.

Refitting

45 Refitting is a reversal of removal, however

note the following additional points:

a) Refer to the applicable Chapters and Sections as for removal.

b) Fit new spring clips to the grooves in the

inboard end of the right- and left-hand

driveshaft joints. Lubricate the splines

with transmission oil prior to fitting. c) Renew the exhaust flange gasket when

reconnecting the exhaust. Ensure that all

wires are routed clear of the exhaust

system and, on catalytic converter

models, ensure that the heat shields are

securely and correctly fitted.

d) Ensure that all earth lead connections are

clean and securely made.

e) Tighten all nuts and bolts to the specified torque.

f) Fit a new oil filter, and refill the engine and transmission with oil, with reference to

Chapter 1.

g) Refill the cooling system with reference to Chapter 1.

h) Refit the alternator and starter motor with reference to Chapter 5A.

i) Where applicable, refit the power steering pump with reference to Chapter 10.

46 When engine and transmission refitting is

complete, refer to the procedures described

in Section 19 before restarting the engine.

5 Engine/transmission -

removal and refitting

(Zetec engines)

3

Warning: Petrol is extremely

flammable, so take extra

precautions when disconnecting

any part of the fuel system.

Don’t smoke, or allow naked flames or

bare light bulbs, in or near the work area,

and don’t work in a garage where a

natural-gas appliance (such as a clothes

dryer or water heater) is installed. If you

spill petrol on your skin, rinse it off

immediately. Have a fire extinguisher rated

for petrol fires handy, and know how to

use it.

Note: Read through the entire Section, as well

as reading the advice in Section 2, before

beginning this procedure. The engine and

transmission are removed as a unit, lowered to

the ground and removed from underneath,

then separated outside the vehicle.

Removal

1 Park the vehicle on firm, level ground, apply

the handbrake firmly, and slacken the nuts

securing both front roadwheels.

2 Depressurise the fuel system as described

in Chapter 4D.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

4 Place protective covers on the wings, then

remove the bonnet (see Chapter 11).

5 Drain the cooling system and the engine oil

(see Chapter 1).

6 Remove the air inlet components and the

complete air cleaner assembly as described in

Chapter 4D.

7 Equalise the pressure in the fuel tank by

removing the filler cap, then release the fuel

feed and return quick-release couplings, and

pull the hoses off the fuel pipes. Plug or cap

all open fittings.

2D•10 Engine removal and overhaul procedures

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 93 of 296

careful not to scratch the bearing - use your

fingernail or the edge of a credit card.

Final crankshaft refitting

18Carefully lift the crankshaft out of the

engine. Clean the bearing surfaces of the

shells in the block, then apply a thin, uniform

layer of clean molybdenum disulphide- based

grease, engine assembly lubricant, or clean

engine oil to each surface. Coat the

thrustwasher surfaces as well.

19 Lubricate the crankshaft oil seal journals

with molybdenum disulphide-based grease,

engine assembly lubricant, or clean engine oil.

20 Make sure the crankshaft journals are

clean, then lay the crankshaft back in place in

the block (see illustration) . Clean the bearing

surfaces of the shells in the caps, then

lubricate them. Install the caps in their

respective positions, with the arrows pointing

to the timing belt/chain end of the engine.

21 Working on one cap at a time, from the

centre main bearing outwards (and ensuring

that each cap is tightened down squarely and

evenly onto the block), tighten the main

bearing cap bolts to the specified torque

wrench setting.

22 Rotate the crankshaft a number of times

by hand, to check for any obvious binding.

23 Check the crankshaft endfloat (see Sec-

tion 12). It should be correct if the crankshaft

thrust faces aren’t worn or damaged.

24 Refit the crankshaft left-hand oil seal

carrier, and install a new seal (see Part A, B

or C of this Chapter according to engine type).

18 Piston/connecting rod

assemblies - refitting and big-end

bearing running clearance check

4

Note: On HCS engines, new big-end bearing

cap retaining bolts will be required for

reassembly.

1 Before refitting the piston/connecting rod

assemblies, the cylinder bores must be

perfectly clean, the top edge of each cylinder

must be chamfered, and the crankshaft must

be in place.

2 Remove the big-end bearing cap from No 1

cylinder connecting rod (refer to the marks

noted or made on removal). Remove the

original bearing shells, and wipe the bearing

recesses of the connecting rod and cap with a

clean, lint-free cloth. They must be kept

spotlessly-clean!

Big-end bearing running

clearance check

3 Clean the back of the new upper bearing

shell, fit it to the connecting rod, then fit the

other shell of the bearing set to the big-end

bearing cap. Make sure that the tab on each

shell fits into the notch in the rod or cap

recess (see illustration) .

Caution: Don’t hammer the shells into

place, and don’t nick or gouge the bearing

face. Don’t lubricate the bearing at this

time.

4 It’s critically important that all mating

surfaces of the bearing components are

perfectly clean and oil-free when they’re

assembled.

5 Position the piston ring gaps as described

in Section 16, lubricate the piston and rings

with clean engine oil, and attach a piston ring

compressor to the piston. Leave the skirt

protruding about a quarter-inch, to guide the

piston into the cylinder bore. The rings must

be compressed until they’re flush with the

piston.

6 Rotate the crankshaft until No 1 crankpin

(big-end) journal is at BDC (Bottom Dead

Centre), and apply a coat of engine oil to the

cylinder walls.

7 Arrange the No 1 piston/connecting rod

assembly so that the arrow on the piston crown points to the timing belt/chain end of

the engine. Gently insert the assembly into the

No 1 cylinder bore, and rest the bottom edge

of the ring compressor on the engine block.

8

Tap the top edge of the ring compressor to

make sure it’s contacting the block around its

entire circumference.

9 Gently tap on the top of the piston with the

end of a wooden hammer handle (see

illustration) , while guiding the connecting

rod’s big-end onto the crankpin. The piston

rings may try to pop out of the ring

compressor just before entering the cylinder

bore, so keep some pressure on the ring

compressor. Work slowly, and if any

resistance is felt as the piston enters the

cylinder, stop immediately. Find out what’s

binding, and fix it before proceeding. Do not,

for any reason, force the piston into the

cylinder - you might break a ring and/or the

piston.

10 To check the big-end bearing running

clearance, cut a piece of the appropriate-size

Plastigauge slightly shorter than the width of

the connecting rod bearing, and lay it in place

on the No 1 crankpin (big-end) journal, parallel

with the crankshaft centre-line (see

illustration 17.11).

11 Clean the connecting rod-to-cap mating

surfaces, and refit the big-end bearing cap.

Tighten the cap bolts evenly - on the HCS and

Zetec engines, first use a torque wrench to

tighten the bolts to the Stage 1 torque setting,

then use an ordinary socket extension bar and

an angle gauge to tighten the bolts further

through the Stage 2 angle (see illustration).

On the CVH and PTE engines, tighten the

bolts progressively to the specified torque;

further angle-tightening is not required on

these engines. Use a thin-wall socket, to

avoid erroneous torque readings that can

result if the socket is wedged between the

cap and nut. If the socket tends to wedge

itself between the nut and the cap, lift up on it

slightly until it no longer contacts the cap.

Don’t rotate the crankshaft at any time during

this operation!

12 Unscrew the bolts and detach the cap,

being very careful not to disturb the

Plastigauge.

13 Compare the width of the crushed

2D•24 Engine removal and overhaul procedures

18.11 Angle-tightening the big-end bolts

using the correct tool18.9 The piston can be driven gently into

the cylinder bore with the end of a wooden

or plastic hammer handle18.3 Tab on each big-end bearing shell

must engage with notch in connecting rod

or cap

17.20 Refit the crankshaft after checkingbearing clearances

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 191 of 296

39With the drivebelt tensioned correctly,

tighten the pivot and adjuster bolts to the

specified torque. Re-check the tension of the

drivebelt after tightening the bolts.

40 Reconnect the rigid brake pipes to the

modulator, tightening the unions to seal the

system.

41 Refit the modulator drivebelt cover and

secure with its two retaining bolts. Take care

not to damage the driveshaft CV joint gaiter as

the cover is eased into position.

42 Refit the belt-break switch to the

modulator drivebelt cover, taking care not to

damage the belt contact arm as it passes

through the cover.

43 Reconnect the modulator return hose by

pushing the hose firmly into its brake fluid

reservoir location, then lever out the collar to

retain it.

44 Refit the front suspension crossmember

and the one-piece undertray, as applicable.

45 Refit the roadwheels, then remove the

axle stands and lower the vehicle to the

ground. Tighten the wheel nuts to the

specified torque.

46 Top-up the brake fluid reservoir using

fresh fluid of the specified type (see “ Weekly

checks ”), then bleed the brake hydraulic

system in accordance with Section 14. Refit

the reservoir filler cap and the warning

indicator wiring multi-plug on completion.

47 Reconnect the battery negative lead.

Modulator drivebelt

48Disconnect the battery negative (earth)

lead (refer to Chapter 5A, Section 1).

49 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the relevant front roadwheel.

50 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front

suspension crossmember (see Chapter 10).

51 Remove the belt-break switch from the

relevant drivebelt cover, then remove the

drivebelt cover, as described in the previous

sub-Section.

52 Slacken the modulator pivot and adjuster

bolts to release drivebelt tension, then slip the

drivebelt from the modulator.

53 Remove the track rod end balljoint from

the steering arm on the spindle carrier (see

Chapter 10).

54 Disconnect the anti-roll bar connecting

link (where applicable) and release the brake

hose from their locations on the suspension

strut.

55 Remove the pinch bolt and nut securing

the lower suspension arm balljoint to the

spindle carrier, and separate the balljoint from

the spindle carrier assembly.

56 To release the driveshaft inner CV joint

from the differential, have an assistant pull the

spindle carrier away from the centre of the

vehicle whilst you insert a lever between the

inner CV joint and the transmission casing,

then firmly strike the lever with the flat of the hand, but be careful not to damage adjacent

components. Make provision for escaping

transmission oil, if possible plugging the

opening to prevent excessive loss. Do not

allow the CV joints to bend more than 20°

from the horizontal or internal damage may

occur. If both driveshafts are to be removed,

immobilise the differential by inserting an old

joint or suitable shaft, before the other

driveshaft is removed.

57

Slide the drivebelt off the driveshaft.

58 Remove the snap-ring from the groove in

the splines of the inner CV joint. This snap-

ring must be renewed every time the

driveshaft is withdrawn from the differential.

59 With the drivebelt removed, closely

examine the condition of the belt over its

entire length. Renew the belt if any cracks are

noticed in the fabric at the roots of the teeth, if

there is any abrasion of the fabric facing

material, or if there are any tears starting from

the edge of the belt.

60 If, since the drivebelts were last renewed,

a vehicle has covered more than 30 000 miles

(48 000 km) or a period of more than two

years has elapsed, the drivebelts should be

renewed as a matter of course.

61 Prior to refitting the drivebelt, thoroughly

clean its CV joint pulley location.

62 Fit the drivebelt over the driveshaft then,

with a new snap-ring fitted to the inner CV

joint splines, lubricate the splines with

transmission oil. Remove the temporary plug

and insert the inner CV joint to its

transmission casing location. Press against

the spindle carrier so that the snap-ring

engages fully to hold the CV joint splines in

the differential.

63 Refitting is now a reversal of the removal

procedure, tensioning the drivebelt as

described in the previous sub-Section. Ensure

that the pinch-bolt securing the lower

suspension arm balljoint to the spindle carrier

locates in the annular groove on the balljoint

spindle. Secure the track rod and balljoint,

using a new split pin. Tighten the suspension

components to their specified torque (see

Chapter 10).

64 Check the level of the transmission oil,

and top-up as required (see Chapter 1).

Modulator belt-break switch

65 Modulator belt-break switches are fitted

to each of the two drivebelt covers, and clip

into position. To remove, gently squeeze the

protruding lever on the switch towards the

main switch body and lift out, ensuring that

the belt contact arm does not catch on the

drivebelt cover.

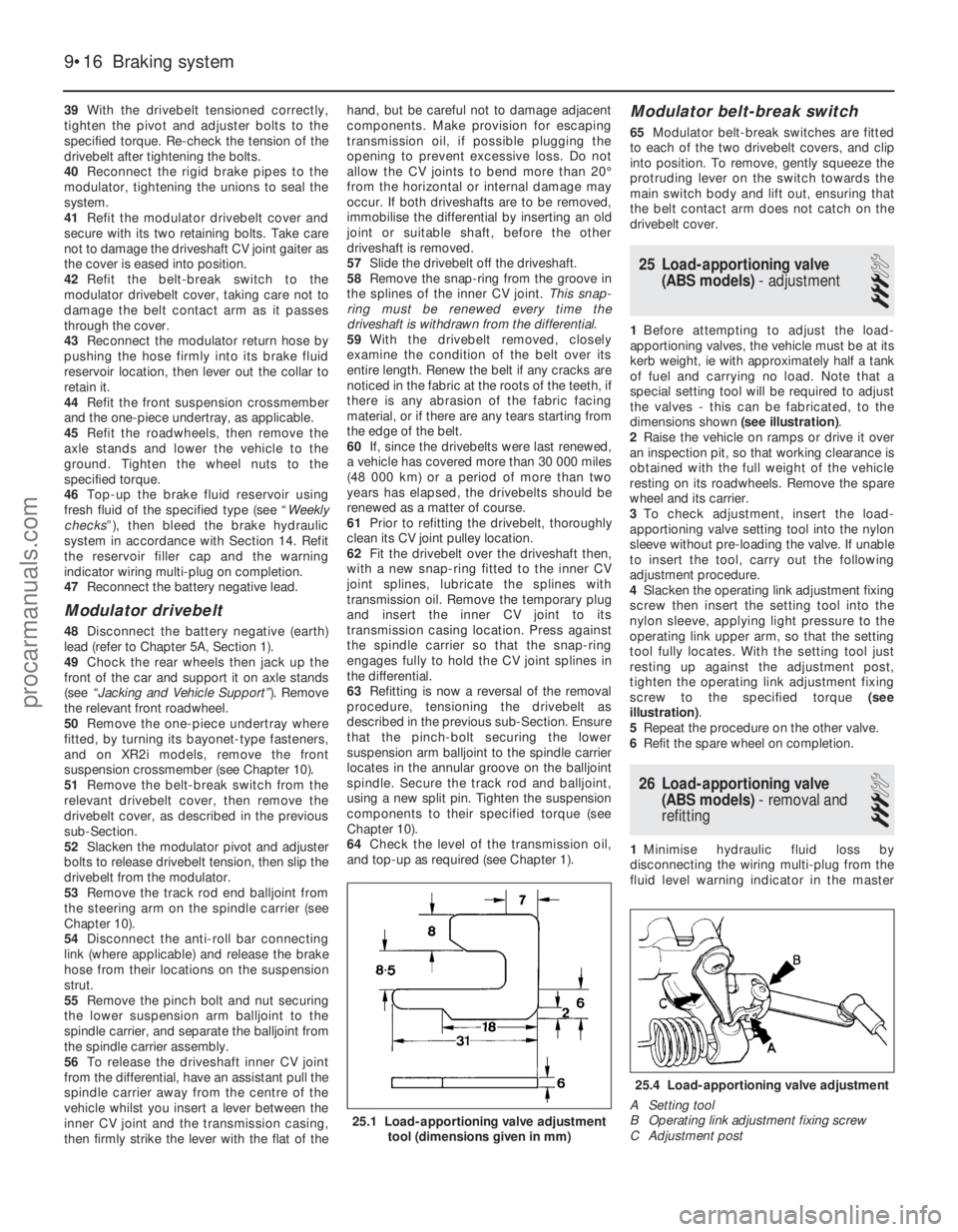

25 Load-apportioning valve (ABS models) - adjustment

3

1Before attempting to adjust the load-

apportioning valves, the vehicle must be at its

kerb weight, ie with approximately half a tank

of fuel and carrying no load. Note that a

special setting tool will be required to adjust

the valves - this can be fabricated, to the

dimensions shown (see illustration).

2 Raise the vehicle on ramps or drive it over

an inspection pit, so that working clearance is

obtained with the full weight of the vehicle

resting on its roadwheels. Remove the spare

wheel and its carrier.

3 To check adjustment, insert the load-

apportioning valve setting tool into the nylon

sleeve without pre-loading the valve. If unable

to insert the tool, carry out the following

adjustment procedure.

4 Slacken the operating link adjustment fixing

screw then insert the setting tool into the

nylon sleeve, applying light pressure to the

operating link upper arm, so that the setting

tool fully locates. With the setting tool just

resting up against the adjustment post,

tighten the operating link adjustment fixing

screw to the specified torque (see

illustration) .

5 Repeat the procedure on the other valve.

6 Refit the spare wheel on completion.

26 Load-apportioning valve

(ABS models) - removal and

refitting

3

1 Minimise hydraulic fluid loss by

disconnecting the wiring multi-plug from the

fluid level warning indicator in the master

9•16 Braking system

25.4 Load-apportioning valve adjustment

A Setting tool

B Operating link adjustment fixing screw

C Adjustment post

25.1 Load-apportioning valve adjustment tool (dimensions given in mm)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 200 of 296

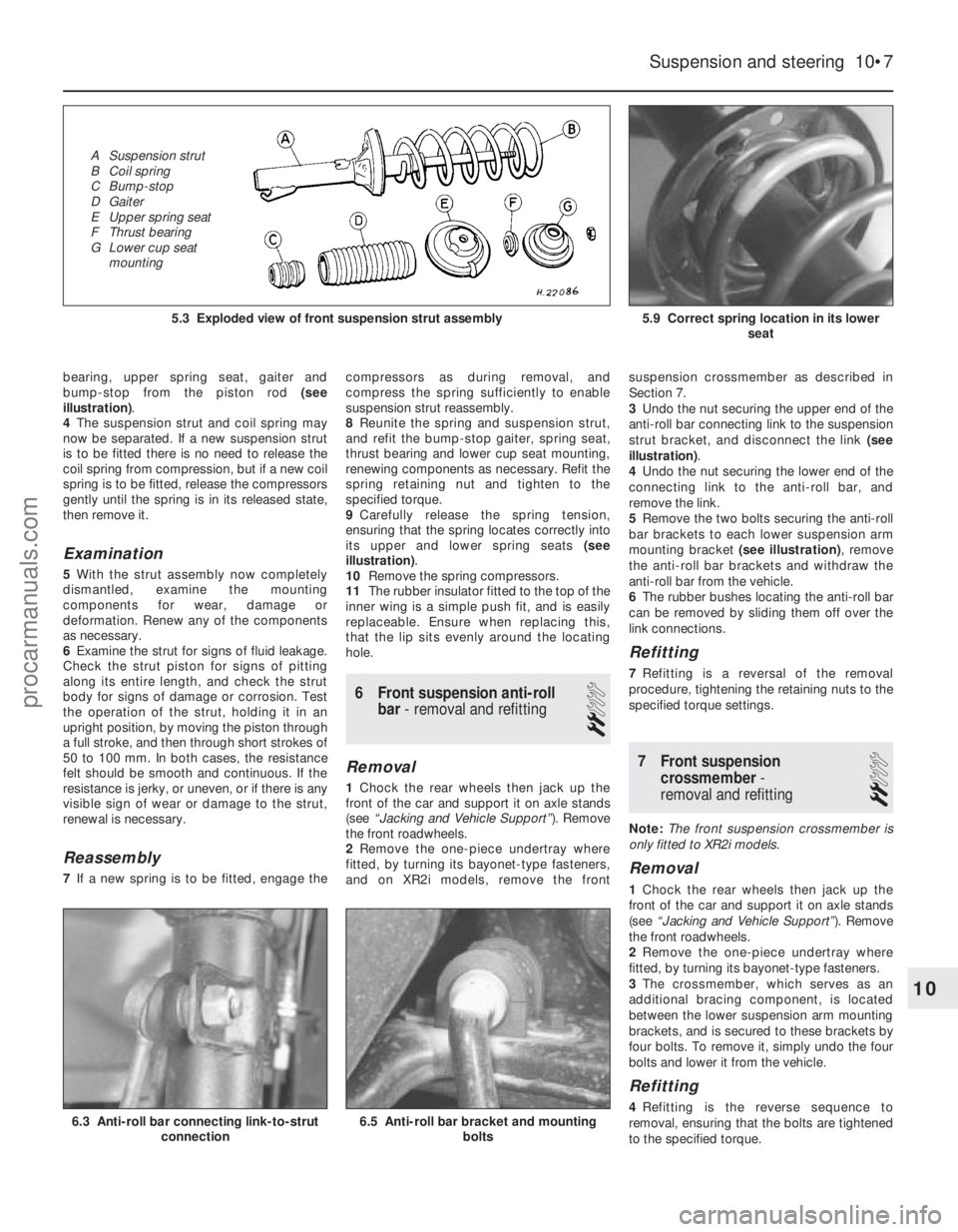

bearing, upper spring seat, gaiter and

bump-stop from the piston rod (see

illustration) .

4 The suspension strut and coil spring may

now be separated. If a new suspension strut

is to be fitted there is no need to release the

coil spring from compression, but if a new coil

spring is to be fitted, release the compressors

gently until the spring is in its released state,

then remove it.

Examination

5 With the strut assembly now completely

dismantled, examine the mounting

components for wear, damage or

deformation. Renew any of the components

as necessary.

6 Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage or corrosion. Test

the operation of the strut, holding it in an

upright position, by moving the piston through

a full stroke, and then through short strokes of

50 to 100 mm. In both cases, the resistance

felt should be smooth and continuous. If the

resistance is jerky, or uneven, or if there is any

visible sign of wear or damage to the strut,

renewal is necessary.

Reassembly

7 If a new spring is to be fitted, engage the compressors as during removal, and

compress the spring sufficiently to enable

suspension strut reassembly.

8

Reunite the spring and suspension strut,

and refit the bump-stop gaiter, spring seat,

thrust bearing and lower cup seat mounting,

renewing components as necessary. Refit the

spring retaining nut and tighten to the

specified torque.

9 Carefully release the spring tension,

ensuring that the spring locates correctly into

its upper and lower spring seats (see

illustration) .

10 Remove the spring compressors.

11 The rubber insulator fitted to the top of the

inner wing is a simple push fit, and is easily

replaceable. Ensure when replacing this,

that the lip sits evenly around the locating

hole.

6 Front suspension anti-roll

bar - removal and refitting

2

Removal

1Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheels.

2 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners,

and on XR2i models, remove the front suspension crossmember as described in

Section 7.

3

Undo the nut securing the upper end of the

anti-roll bar connecting link to the suspension

strut bracket, and disconnect the link (see

illustration) .

4 Undo the nut securing the lower end of the

connecting link to the anti-roll bar, and

remove the link.

5 Remove the two bolts securing the anti-roll

bar brackets to each lower suspension arm

mounting bracket (see illustration), remove

the anti-roll bar brackets and withdraw the

anti-roll bar from the vehicle.

6 The rubber bushes locating the anti-roll bar

can be removed by sliding them off over the

link connections.

Refitting

7 Refitting is a reversal of the removal

procedure, tightening the retaining nuts to the

specified torque settings.

7 Front suspension crossmember -

removal and refitting

2

Note: The front suspension crossmember is

only fitted to XR2i models.

Removal

1 Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the front roadwheels.

2 Remove the one-piece undertray where

fitted, by turning its bayonet-type fasteners.

3 The crossmember, which serves as an

additional bracing component, is located

between the lower suspension arm mounting

brackets, and is secured to these brackets by

four bolts. To remove it, simply undo the four

bolts and lower it from the vehicle.

Refitting

4 Refitting is the reverse sequence to

removal, ensuring that the bolts are tightened

to the specified torque.

Suspension and steering 10•7

5.9 Correct spring location in its lower seat5.3 Exploded view of front suspension strut assembly

6.5 Anti-roll bar bracket and mountingbolts6.3 Anti-roll bar connecting link-to-strutconnection

10

1595Ford Fiesta Remake

A Suspension strut

B Coil spring

C Bump-stop

D Gaiter

E Upper spring seat

F Thrust bearing

G Lower cup seat

mountingprocarmanuals.com

http://vnx.su

Page 203 of 296

3Unscrew and remove the upper mounting

through-bolt and nut.

4 Withdraw the upper mounting cup and the

spring seat.

5 The suspension strut and coil spring can now

be separated. If the coil spring or strut is to be

renewed, the original coil spring must be

released from the compressor. If it is to be re-

used, the coil spring can be left in compression.

Examination

6 With the strut assembly now completely

dismantled, examine the mounting

components for wear, damage or deformation.

Renew any of the components as necessary.

7 Examine the strut for signs of fluid leakage.

Check the strut piston for signs of pitting

along its entire length, and check the strut

body for signs of damage or deterioration of

the mountings. Test the operation of the strut,

holding it in an upright position, by moving the

piston through a full stroke, and then through

short strokes of 50 to 100 mm. In both cases,

the resistance felt should be smooth and

continuous. If the resistance is jerky, or

uneven, or if there is any visible sign of wear

or damage to the strut, renewal is necessary.

Reassembly

8 Reassembly is a reversal of the dismantling

procedure but note the following points: a) When the spring is located over the

suspension strut, the spring seat, cup and

through-bolt fitted, tighten the retaining

bolt to the specified torque.

b) When reassembled, check that the upper

and lower spring tails are correctly

engaged with their spring seats before

removing the spring compressor.

12 Rear axle (all models except

Courier) -

removal and refitting

3

Removal

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Remove

the rear roadwheels.

2 Refer to Chapter 9 for details, and disconnect

the handbrake cable equaliser from the primary

cable. Remove the handbrake rear cable from

its adjuster and its fixed body locations.

3 Disconnect the rear brake flexible hydraulic

brake hoses from their rigid line connections.

Clamp the hoses before disconnecting them,

to minimise the fluid loss and air entry into the

hydraulic system (see Chapter 9 for details).

4 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

5 Locate suitable jacks or axle stands under

the axle beam to support its weight (not to lift

it), then unscrew the four mounting bracket

bolts each side. 6

Unscrew and remove the strut-to-axle

mounting bolt each side.

7 Check that all associated fittings are clear,

then lower the axle and remove it from under

the vehicle.

8 If the twist beam axle has been damaged, it

must be renewed. Refer to Chapter 9 for

details on removing the rear brakes from the

axle. To remove the front mounting/pivot

brackets from the axle, unscrew the pivot bolt.

Refitting

9 Refitting is a reversal of the removal

procedure, but note the following: a) Reconnect the axle at the front floor mountings first, and tighten the retaining

bolts to the specified torque.

b) Reconnect the axle to the suspension struts, but do not fully retighten the securing

bolts until after the vehicle is lowered to the

ground and is standing on its wheels.

c) Ensure that all brake fluid line connections are clean before reconnecting them. Refer

to the appropriate Sections in Chapter 9

for specific details on reconnecting the

brake lines, bleeding the brake hydraulic

system, and for reconnecting the

handbrake cable and its adjustment.

d) When the vehicle is lowered and is standing

on its wheels, tighten the suspension

fastenings to their specified torque settings.

13 Rear axle pivot bushes (all

models except Courier) -

renewal

3

Note: Two different types of pivot bushes

have been fitted during the course of Fiesta

production. It is understood that once stocks

of the early type are exhausted, only the latter

type will be supplied by Ford parts dealers. If

renewing pivot bushes on a pre-April 1990

model, and only the later type bushes are

available, fit the new bushes as described

from paragraph 15 onward.

Pre-April 1990 models

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).2

Position a suitable support (preferably

adjustable) under the axle twist beam so that

it is capable of carrying the weight of the axle

(not the weight of the vehicle).

3 On ABS-equipped models, undo the

retaining nuts and detach the ABS load-

apportioning valve operating links from the

axle beam. Do not remove the load-

apportioning valve (see Chapter 9).

4 Unscrew the nuts, withdraw the pivot bolts,

then lower the rear axle so that the bushes are

clear of their mounting brackets (see

illustration) . Take care not to allow the brake

pipes to become distorted and stretched - if

necessary, disconnect the hydraulic lines (see

Chapter 9 for details).

5 Undo the four body mounting bracket bolts

and remove the brackets.

6 Using a soft-faced hammer and a suitable

punch or drift, drive the bushes from their

locations, taking care not to raise any burrs on

the trailing arm eyes.

7 To fit the new bushes, obtain a steel tube of

a diameter slightly less than that of the bush

location in the axle, various flat washers and a

long bolt and nut.

8 Place the new bush in position in its axle

location with the bush collar nearest to the

outer edge of the vehicle. The bush must be

installed with its voids positioned as shown

(see illustration) . Using the steel tube,

washers, long bolt and nut, draw the bush

inwards towards the centre of the vehicle (see

illustration) . Care should be taken to avoid

damage to the bush and to obtain correct

10•10 Suspension and steering

13.8b Fitting pivot bush with its collar

(arrowed) towards the outer edge of the vehicle13.8a Correct pivot bush positioning intrailing arm

A Left-hand side B Right-hand side

13.4 Pivot bush bolt (A) and body mounting bracket bolts (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 279 of 296

1595 Ford Fiesta Remake

MOT test checksREF•13

REF

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

M It is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

M Inspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free fr om

leaks.

M Examine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

M Examine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound and pr

operly seated, and that the wheel is not

distorted or damaged.

M Check that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressur es

ar e correct.

M Check the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

fr ont wheel alignment.

Body corrosion

M Check the condition of the entire vehicle

structur e for signs of corrosion in load-bearing

ar eas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

pr ofessional repairs are likely to be needed.

M Damage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

M Have the engine at normal operating

temperatur e, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

M Befor e any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allow the engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unbur nt fuel (dirty air cleaner element, or other

carbur ettor or fuel system fault).

M An exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydr ocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

M At the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

Fr om January 1996 a much tighter limit

(ar ound 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

pr oblem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsM With the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

M Excessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

M The only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density . The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

procarmanuals.com

http://vnx.su